Multi-phase numeric controlled borer with automatic tool changer

A technology of automatic tool change and drilling machine, which is applied in positioning devices, boring/drilling, drilling/drilling equipment, etc. The effect of speeding up processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

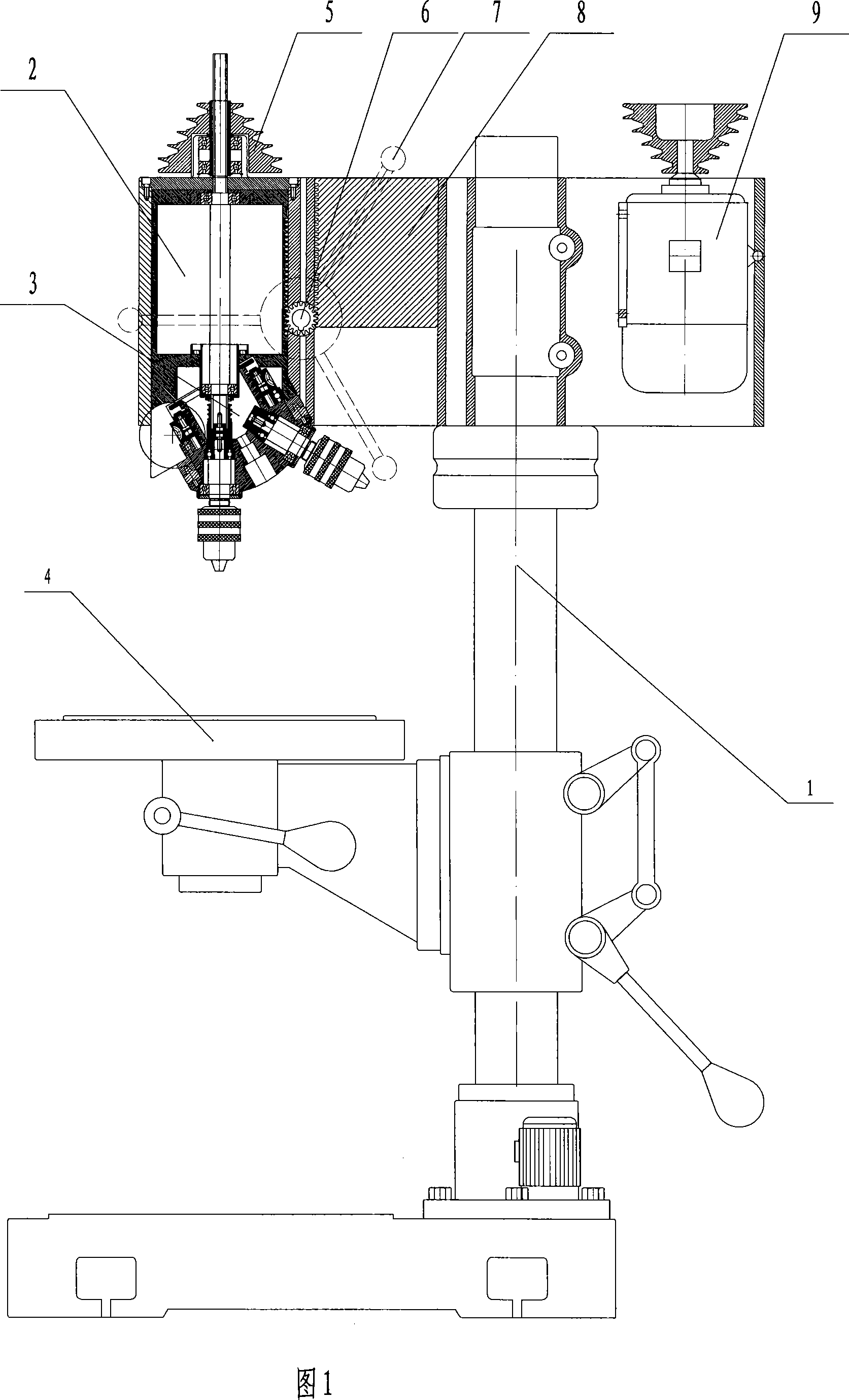

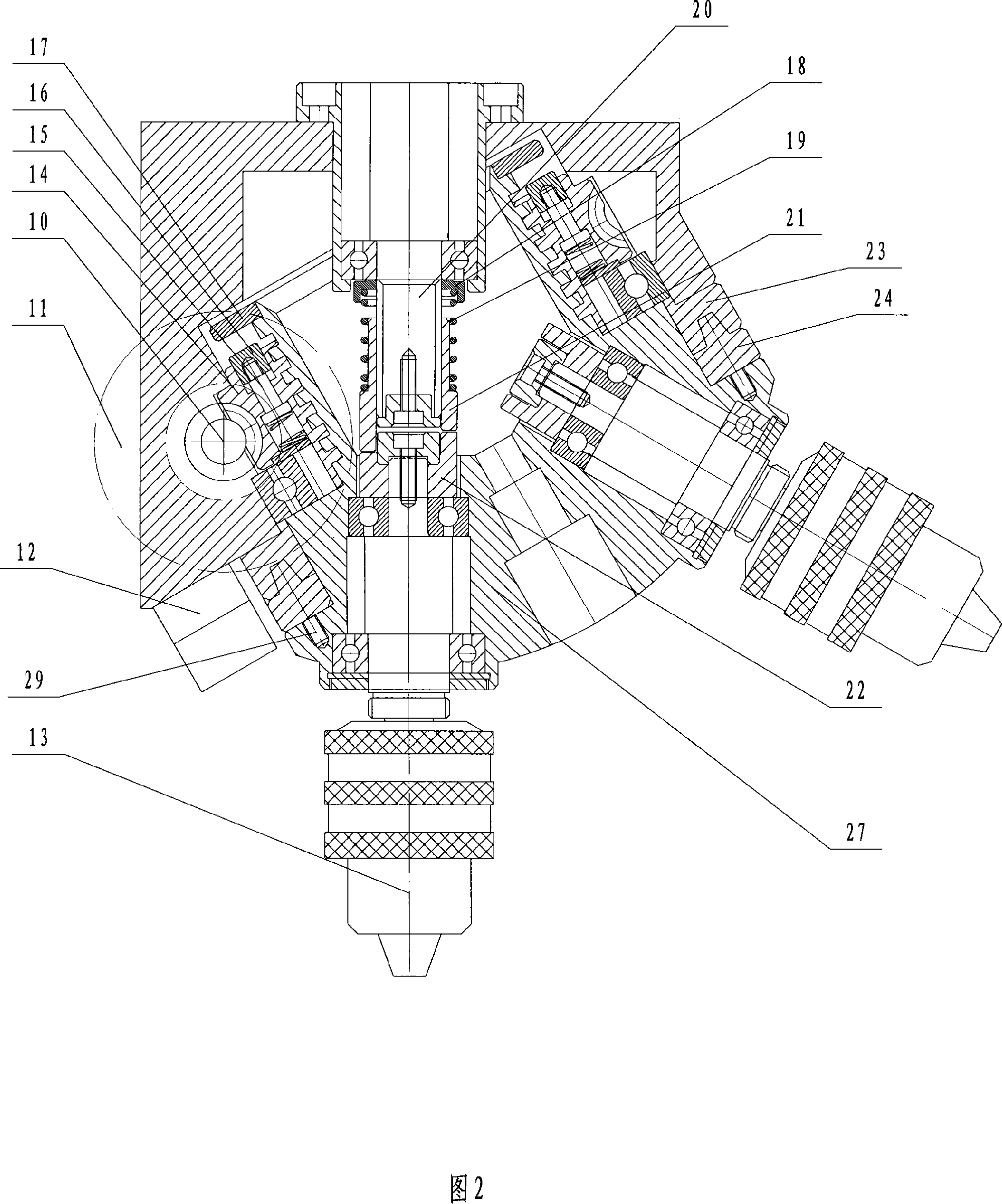

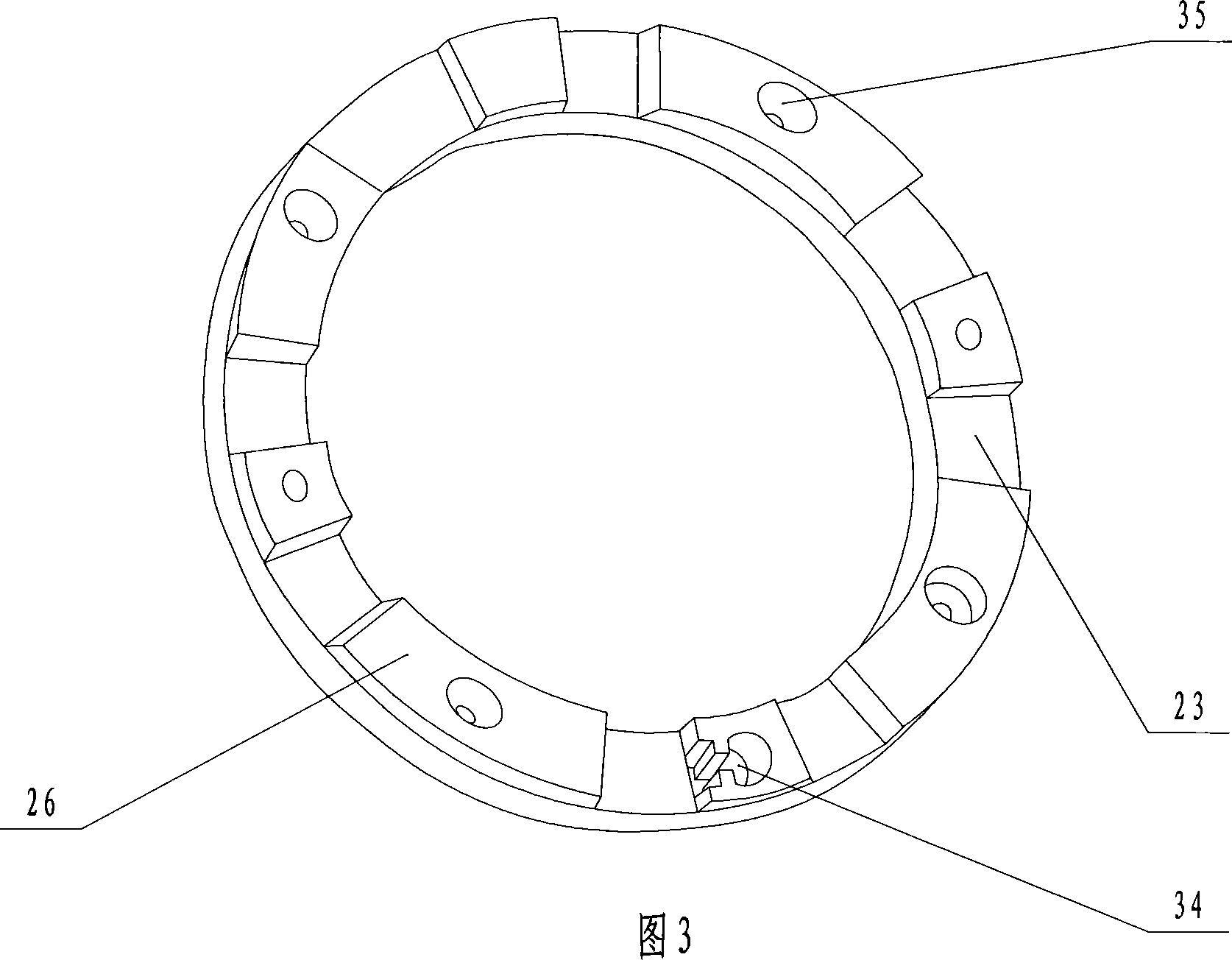

[0032]Embodiment: A numerically controlled multi-position automatic tool-changing drilling machine, including a machine base 1 with a lifting system 2 on the machine base, the lifting system is driven by a feed gear 6 with an operating handle 7, and a balance weight 8 is also provided on the machine base. One side of the feed gear meshes with the lifting system, and the other side meshes with the balance weight. A working platform 4 is provided under the lifting system on the machine base. The working platform can be lifted on the machine base. The end of the lifting system is equipped with a tool changer. Bit system 3 (see accompanying drawing 2), afterbody is provided with belt pulley 5, is provided with motor 9 (seeing accompanying drawing 1) on the side opposite to lift system on the support, pulley is connected with motor by belt, and cutter transposition system consists of The tool changing motor 11 drives the worm 10, the worm meshes with the worm gear 14, the worm gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com