Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

161results about How to "No need to move" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

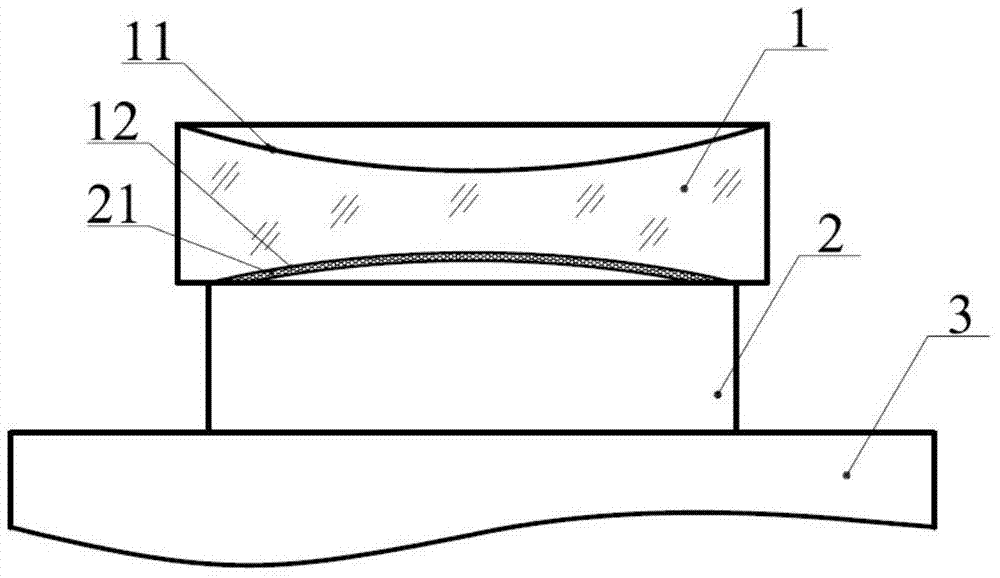

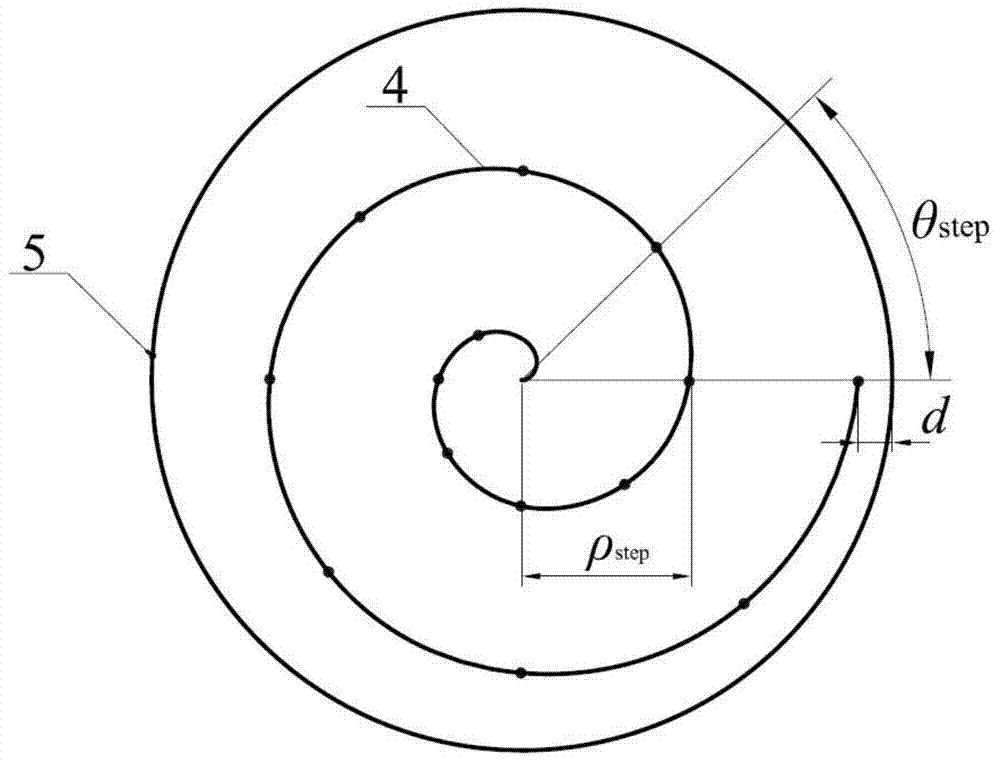

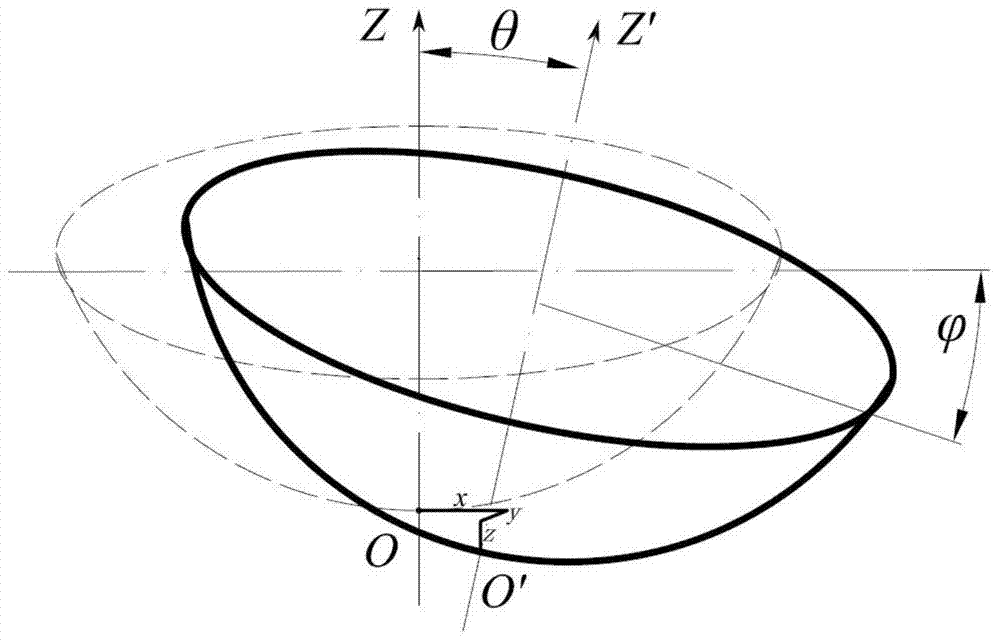

Method for automatically compensating pose errors in machining process of optical element

InactiveCN103592893ANo need to moveQuick and easy compensation processProgramme controlComputer controlMeasurement pointMathematical model

The invention discloses a method for automatically compensating pose errors in the machining process of an optical element, relates to the machining field of optical elements, and aims to provide a method for automatically eliminating installation errors without adjusting a workpiece. The method adopts the following steps that the optical element is firstly clamped on a working table of a machine tool, and the surface of the optical element is measured; actual position measuring points are then transformed to be theoretical position measuring points according to a pose error vector construction transformation matrix; an objective function for solving pose error vectors and a solving mathematic model are built, and the pose errors are solved; a transformation matrix is built according to solutions of the pose errors, and position vectors and direction vectors of resident points on machining paths are transformed respectively; finally, the transformed resident points are subjected to post-processing to obtain a machining program after pose error compensating. The method can accurately and rapidly compensate the pose errors of the optical element and is suitable for being applied to the field of optical machining controlled by a computer.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

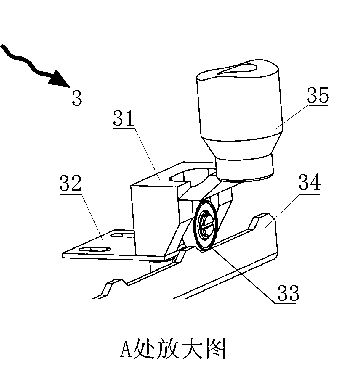

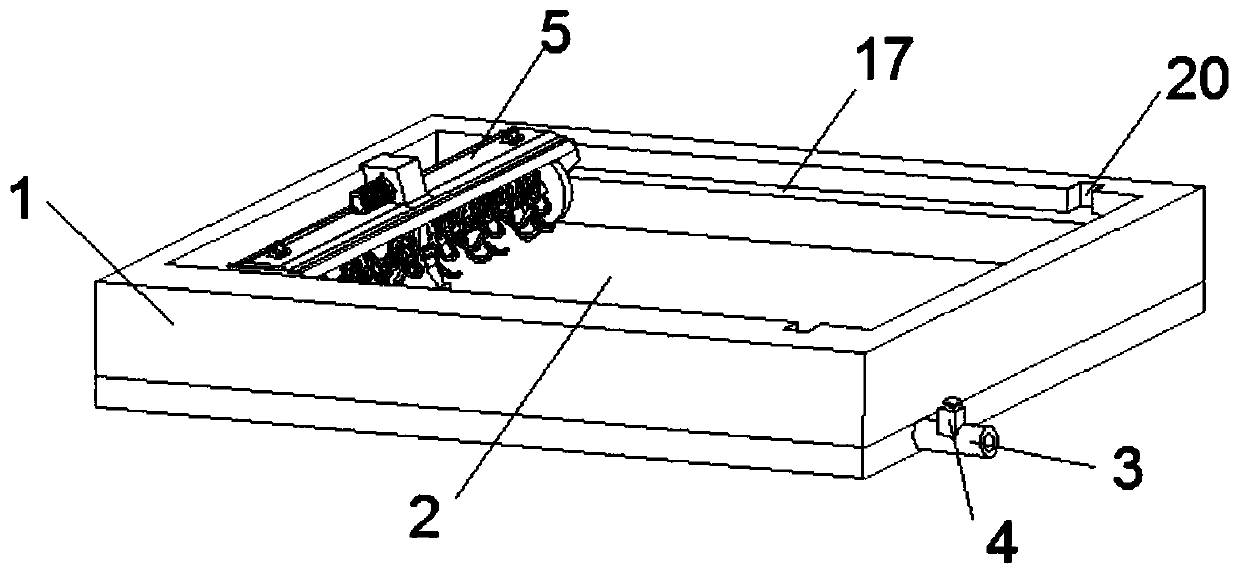

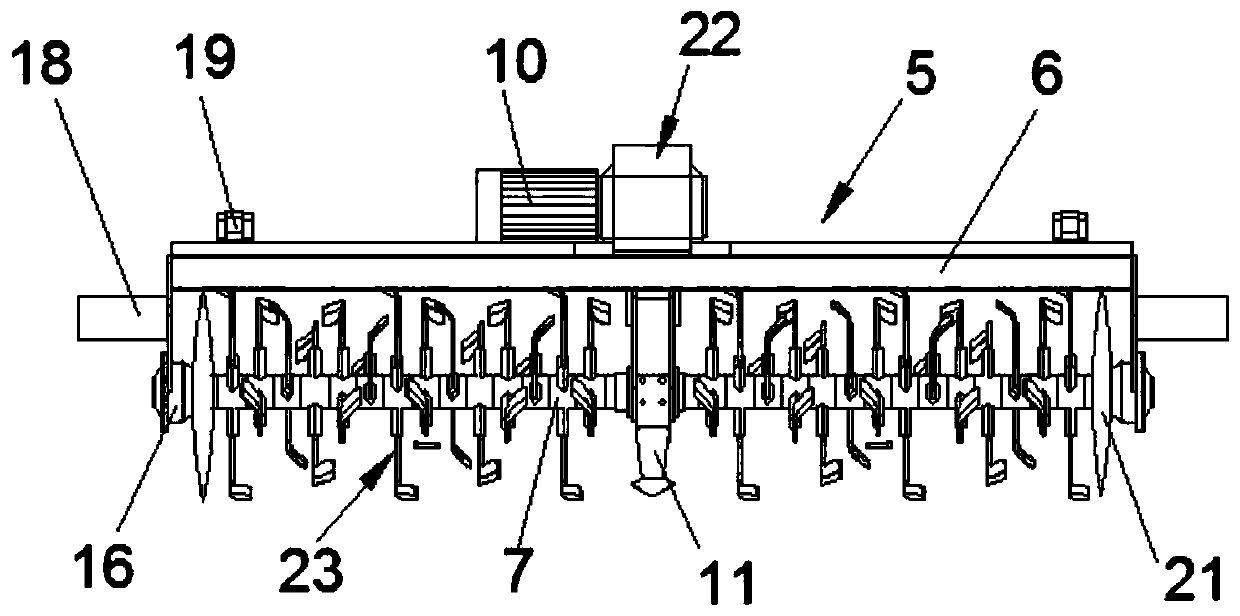

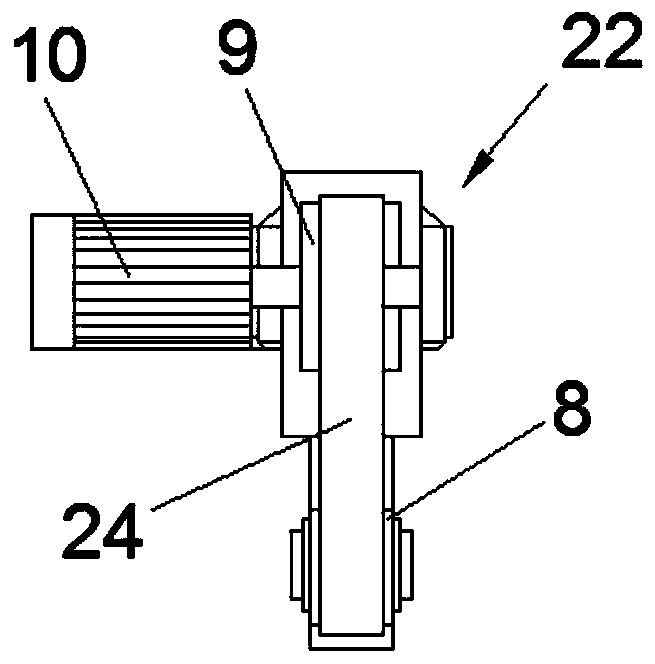

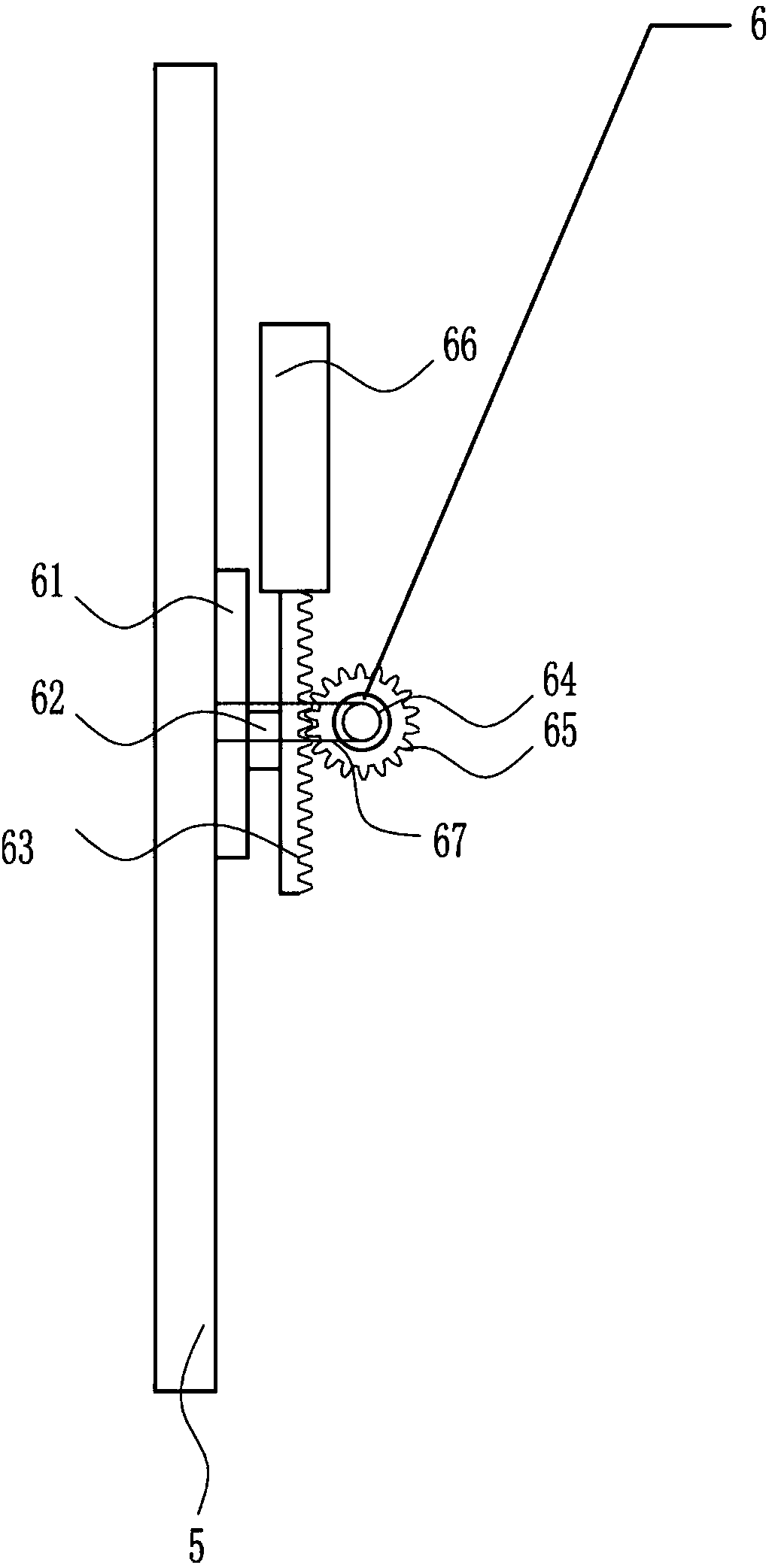

Automatic doffing trolley of spinning machine

The invention relates to an automatic doffing trolley of a spinning machine. The automatic doffing trolley comprises a doffing trolley body and an automatic doffing device. The automatic doffing device is arranged on a bottom plate located on the upper portion of the doffing trolley body. A pre-loosening mechanism of the automatic doffing device is arranged on the bottom plate of the doffing trolley body through a spring steel plate. A pre-loosening block is fixed on the spring steel plate. When the trolley moves forwards, the pre-loosening block moves forwards along with the trolley, is inserted into the lower end of a bobbin, and enables the lower end of the bobbin to ascend along an oblique plane of the pre-loosening block. Then, under the action of a plane cam, the pre-loosening block abuts against the lower end of the bobbin, moves upwards in the direction parallel to the axis of a spindle blade and enables the full bobbin to break away from the spindle blade under the blocking action of a spindle hook. The bobbin bounced upwards enters a manipulator device. The upper ends of claws of the manipulator device clamp the upper end, without yarn, of the full bobbin and then pull the full bobbin out. The pre-loosening force of the pre-loosening mechanism is parallel to the axis of the spindle blade and has little influence on a spindle bearing. The manipulator device clamps the upper end, without the yarn, of the bobbin, and the quality index of the yarn can not be influenced.

Owner:SHANXI JINXIN CARD CLOTHING

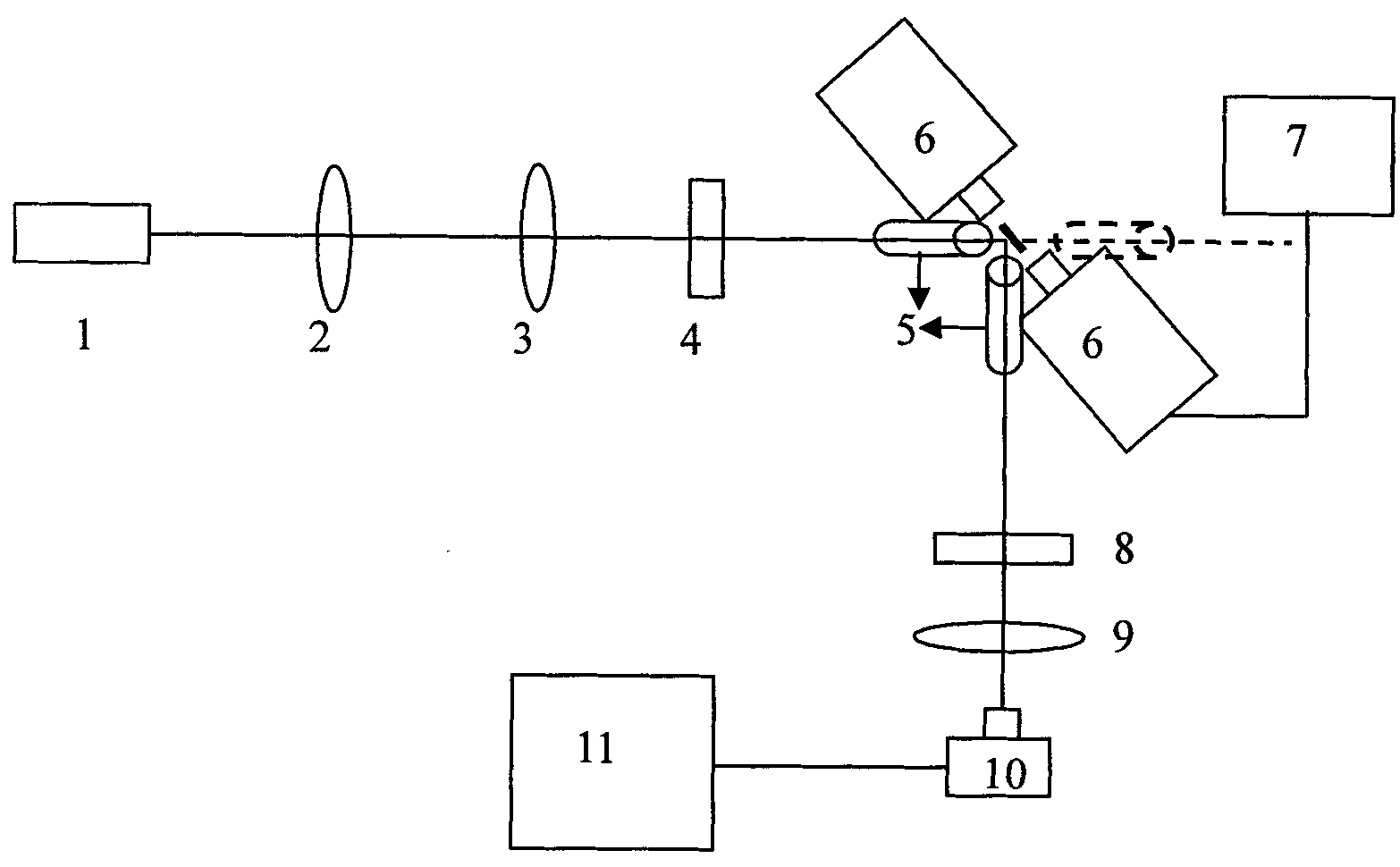

Magnetooptic ellipsometry measurement device and measurement method

InactiveCN101865827AAvoid the hassle of moving electromagnetsAccurate measurementPolarisation-affecting propertiesPhase-affecting property measurementsOptical pathPhysics

The invention relates to a magnetooptic ellipsometry measurement device and a measurement method, which belong to the technical field of magnetooptic measurement on magnetic materials. The device comprises a power source, a laser source, a light path system, electromagnets and a personal computer, and can be used for carrying out magnetooptic ellipsometry measurement. The invention is characterized in that: (1) spectrometers added in the light path can accurately measure the angle of incidence, and because the resolution of the angle measurement of the spectrometer can reach 0.01 degrees, the measurement precision is high; (2) by modifying the spectrometer, a collimator of the spectrometer can be dismounted, the electromagnets do not need to be moved during angle measurement, and thereby measurement is more accurate and convenient; (3) the light path is simple and practical, and the optical elements needed by the light path are universal optical elements, so the cost is low; (4) operation is convenient, and longitudinal and polar magnetooptic ellipsometry measurements can be carried out on material without moving the electromagnets.

Owner:SHANDONG UNIV

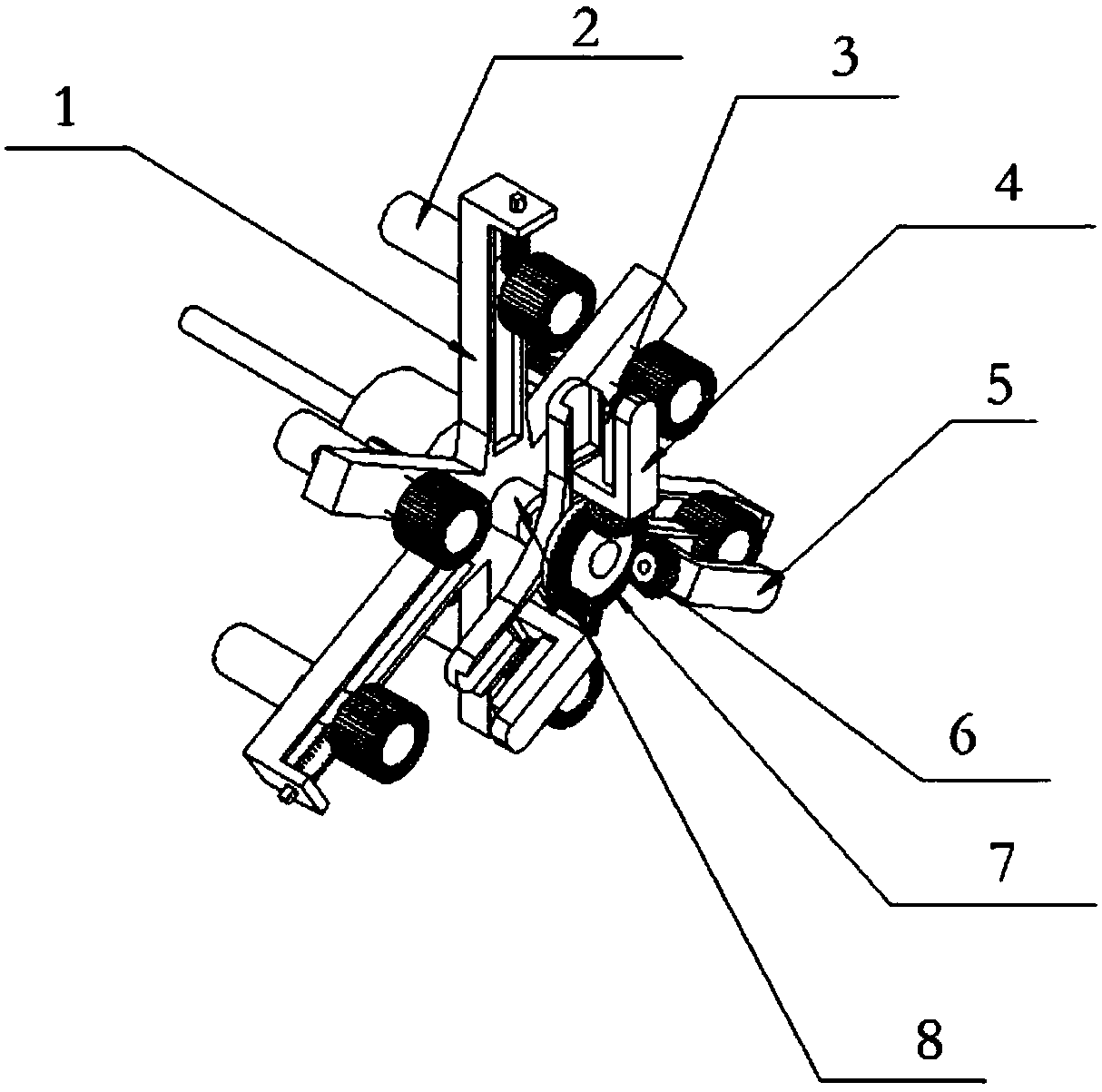

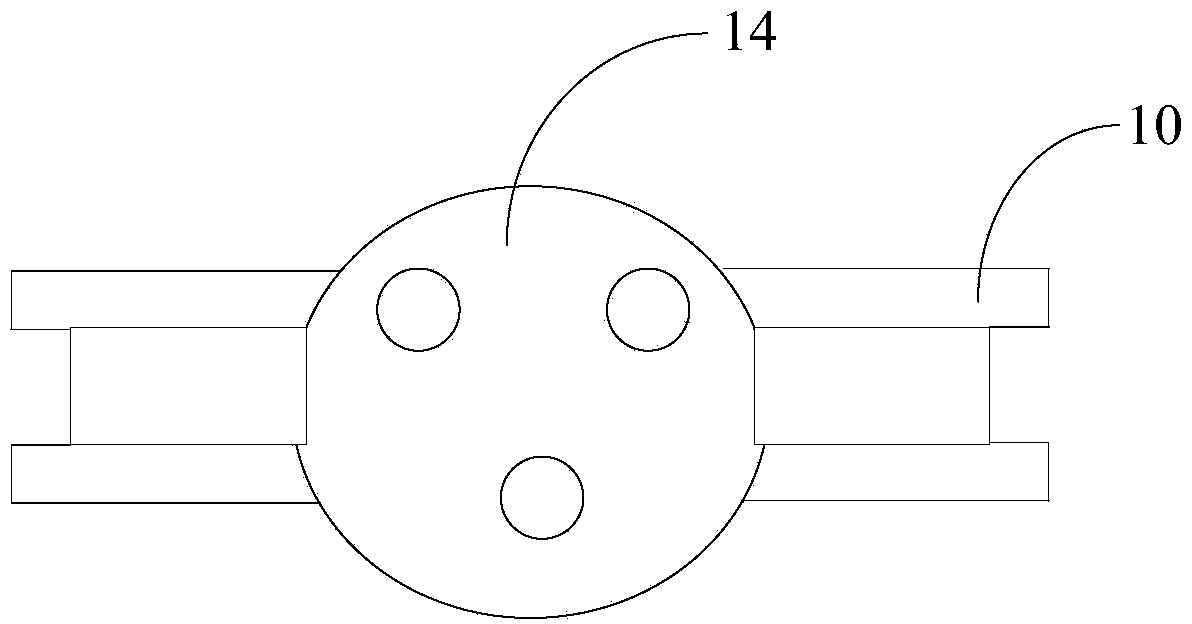

Device and method for machining end part of pipe fitting, and application

InactiveCN107900806ASimple structureEasy clampingRevolution surface grinding machinesCleaning using toolsPipe fittingInsertion stent

The invention discloses a device and a method for machining the end part of a pipe fitting, and an application. The device comprises a self-centering component and an internal adjustment component or / and an external adjustment component which are distributed separately along the same axis, wherein each of the internal adjustment component and the external adjustment component comprises a pluralityof adjustable supports which are uniformly distributed along the axis and rotary elements arranged on the supports; and with the automatic alignment of the self-centering component in the pipe fitting, the rotary elements of the internal adjustment component are outwards extensible in the radial direction of the adjustable supports, and the rotary elements of the external adjustment component areinwards extensible in the radial direction of the adjustable supports until the inner pipe wall or / and the outer pipe wall of the pipe fitting are clamped separately. The device disclosed by the invention is simple in structure and convenient to clamp, and the pipe fitting does not need to be moved during machining.

Owner:山东豪迈重工有限公司

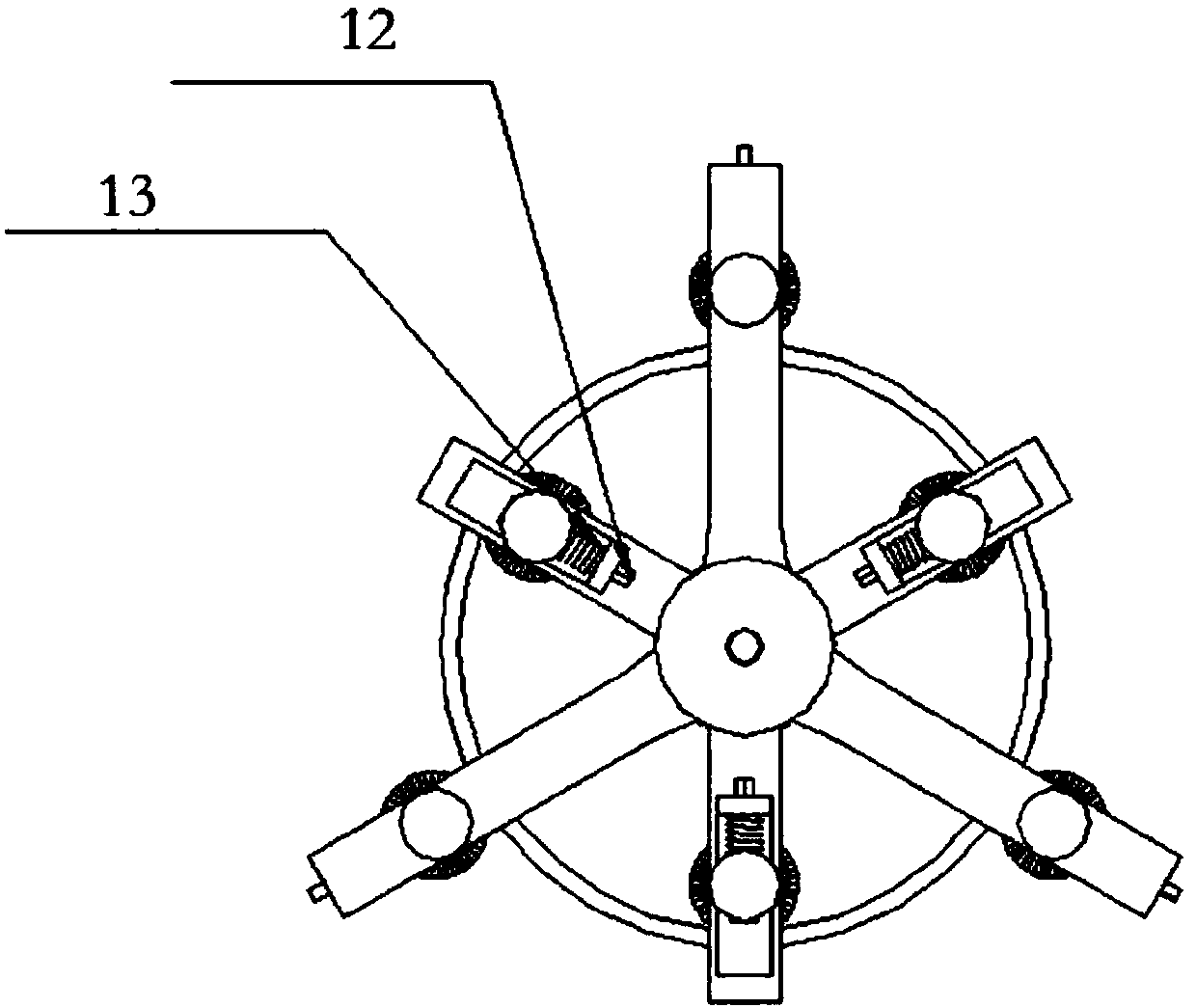

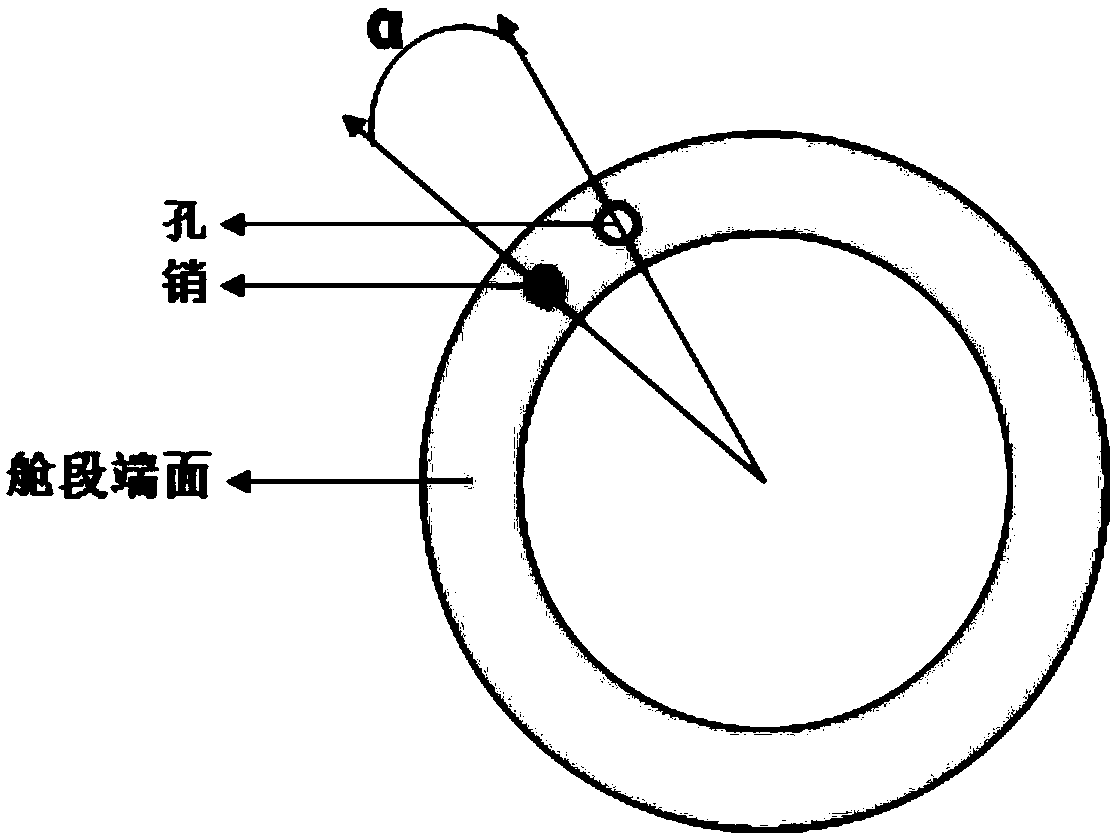

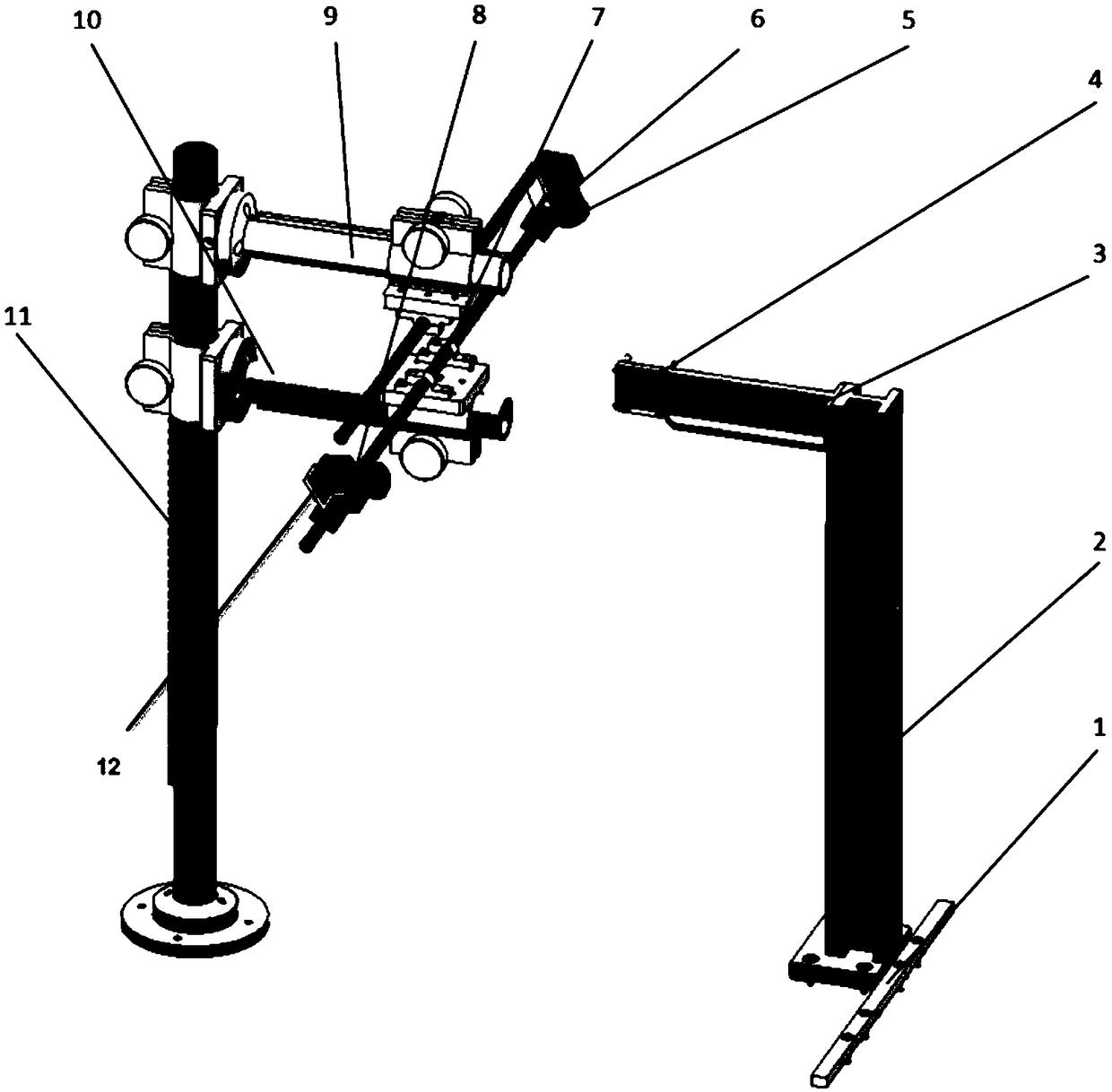

Double-camera measurement device and measurement method for cabin pin hole abutting corner

ActiveCN109029299ANo need to moveAchieve regulationUsing optical meansMeasurement deviceClassical mechanics

The invention discloses a double-camera measurement device and measurement method for a cabin pin hole abutting corner and mainly solves a problem of inconvenience in measurement on the cabin pin holeabutting corner due to the space limitation in the prior art. The double-camera measurement device comprises a camera supporting part and a calibration frame; the camera supporting part comprises a camera beam (10) and a camera upright (11); the camera beam (10) is vertically connected with the camera upright (11); a camera jack stay is mounted on the camera beam; two sliding supporting blocks (5) which can rotate around the camera jack stay are symmetrically mounted at both sides of the camera jack stay and are used for mounting two industrial cameras (6, 12); the calibration frame is positioned opposite to the camera upright and comprises a positioning strip (1), a calibration frame upright (2), a calibration frame beam (3) and calibration plates (4); the calibration frame upright is vertically mounted next to the positioning strip; the calibration frame beam and the calibration frame upright are mounted in a mutually vertical mode; and the calibration plates are mounted at the front side and the reverse side of the calibration frame beam. The double-camera measurement device and measurement method are high in measurement accuracy, can implement non-target measurement and can beused for assembling of airplanes and guided missiles.

Owner:XIDIAN UNIV

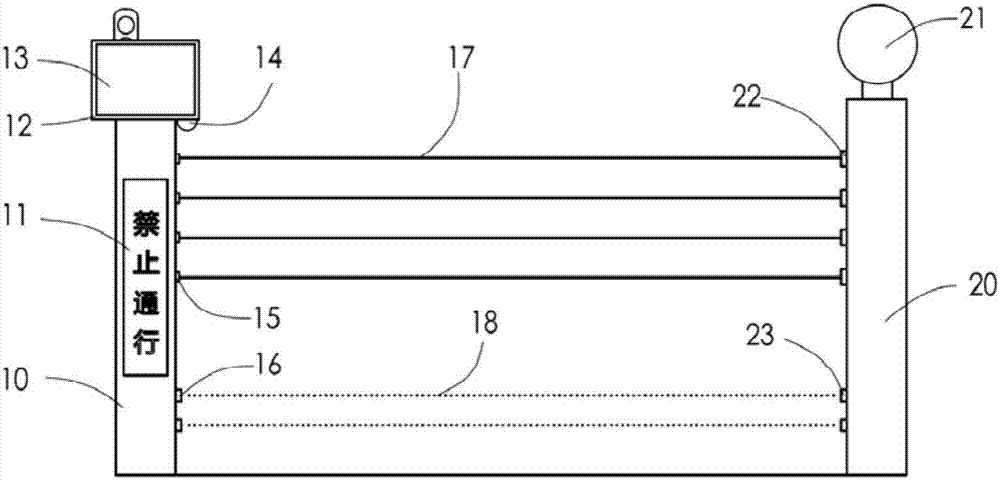

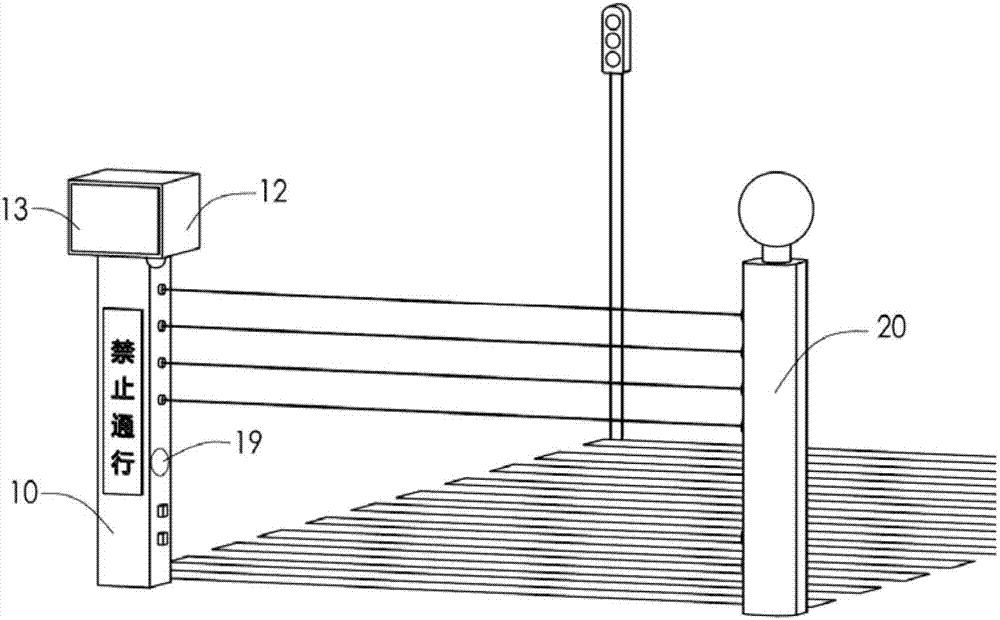

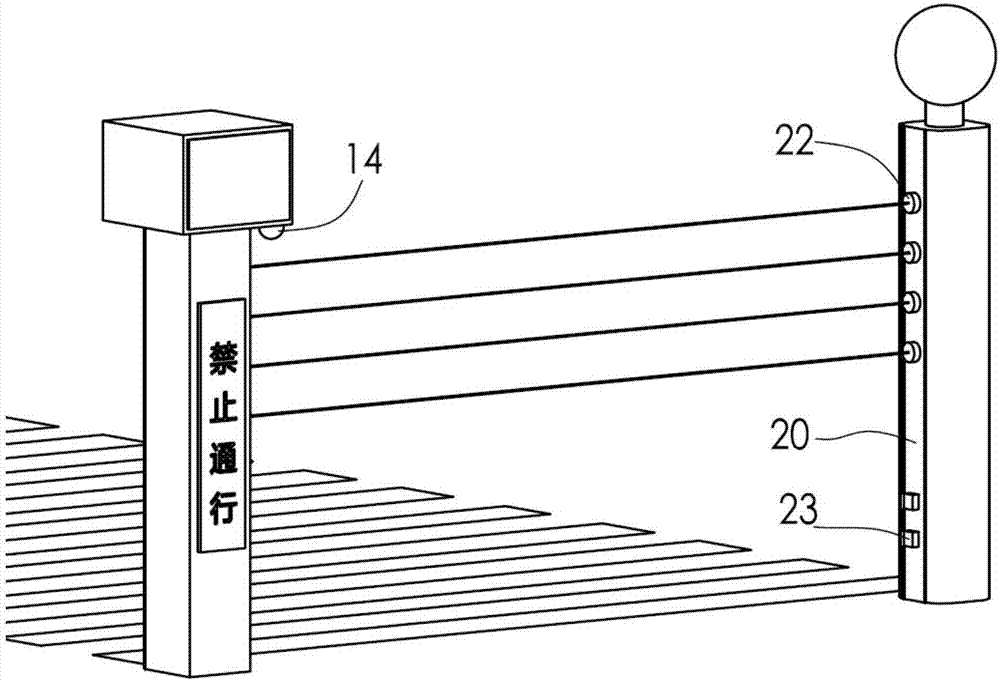

Light-screen line-crossing warning device

PendingCN107230347ANo harm to peopleCause some damagesArrangements for variable traffic instructionsControl with pedestrian guidance indicatorEngineeringLaser beams

The invention belongs to the technical field of intelligent traffic equipment and specifically relates to a light-screen line-crossing warning device. The warning device comprises a generation device and a receiving device cooperated with the generation device. The generation device or the receiving device is equipped with a caution display screen; the surface of the generation device or the receiving device is equipped with a plurality of laser generators and infrared emitters; and the surface of the receiving device or the generation device is equipped with a plurality of laser receivers corresponding to the plurality of laser generators, and a plurality of laser receivers corresponding to the infrared emitters, wherein the laser generators are used for generating visible laser beams.

Owner:陈少君

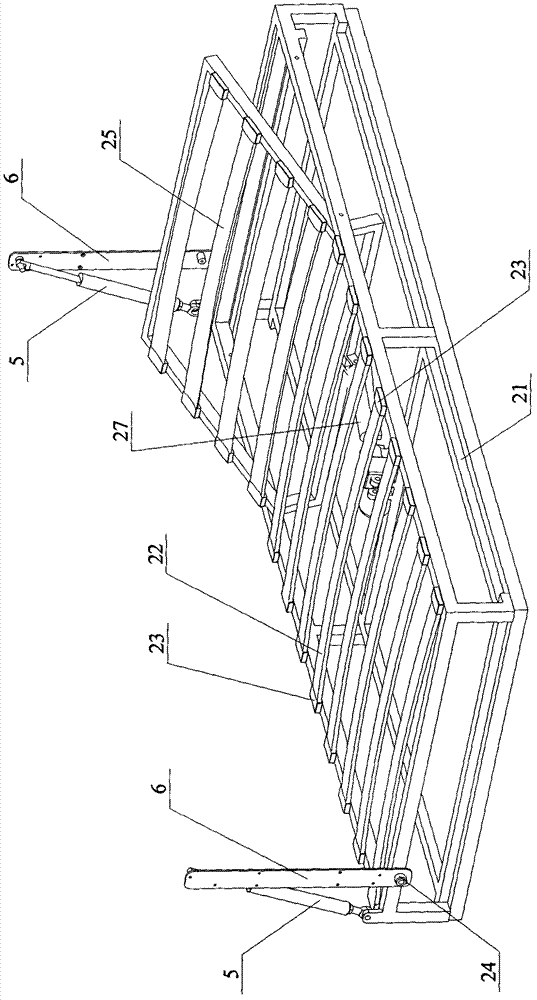

Double-layer cabinet bed

The present invention discloses a double-layer cabinet bed, which comprises a cabinet and two bed bodies arranged inside the cabinet, wherein the two bed bodies are respectively arranged on the upper portion and the lower portion. The bed body comprises a frame type bedframe and a bed plate arranged on the upper surface of the bedframe, wherein the bed plate comprises a plurality of plate strips. Inner surfaces of a left side wall and a right side wall of the cabinet are respectively fixed with an installation plate for installing the bedframe. Rear portions of a left side edge and a right side edge of the bedframe respectively form a pivotal connection with lower ends of the installation plates. Both ends of two bedframe assistance gas spring respectively form a hinge connection with upper ends of the installation plates and rear end portions of the left side edge and the right side edge of the bedframe. The bed body arranged on the lower portion is provided with bed legs for providing support effects during putting down of the bed body and use. The bed body arranged on the upper portion is provided with a staircase for providing a support effect during putting down of the bed body and use. The double-layer cabinet bed of the present invention is a combination body of the bed and the cabinet, and has the following advantages that: space is rationally used, operation is convenient, labor is saved, a safety characteristics is provided, moving is not required after folding, and purposes of convenient sleep and convenient leisure are achieved.

Owner:张阿华

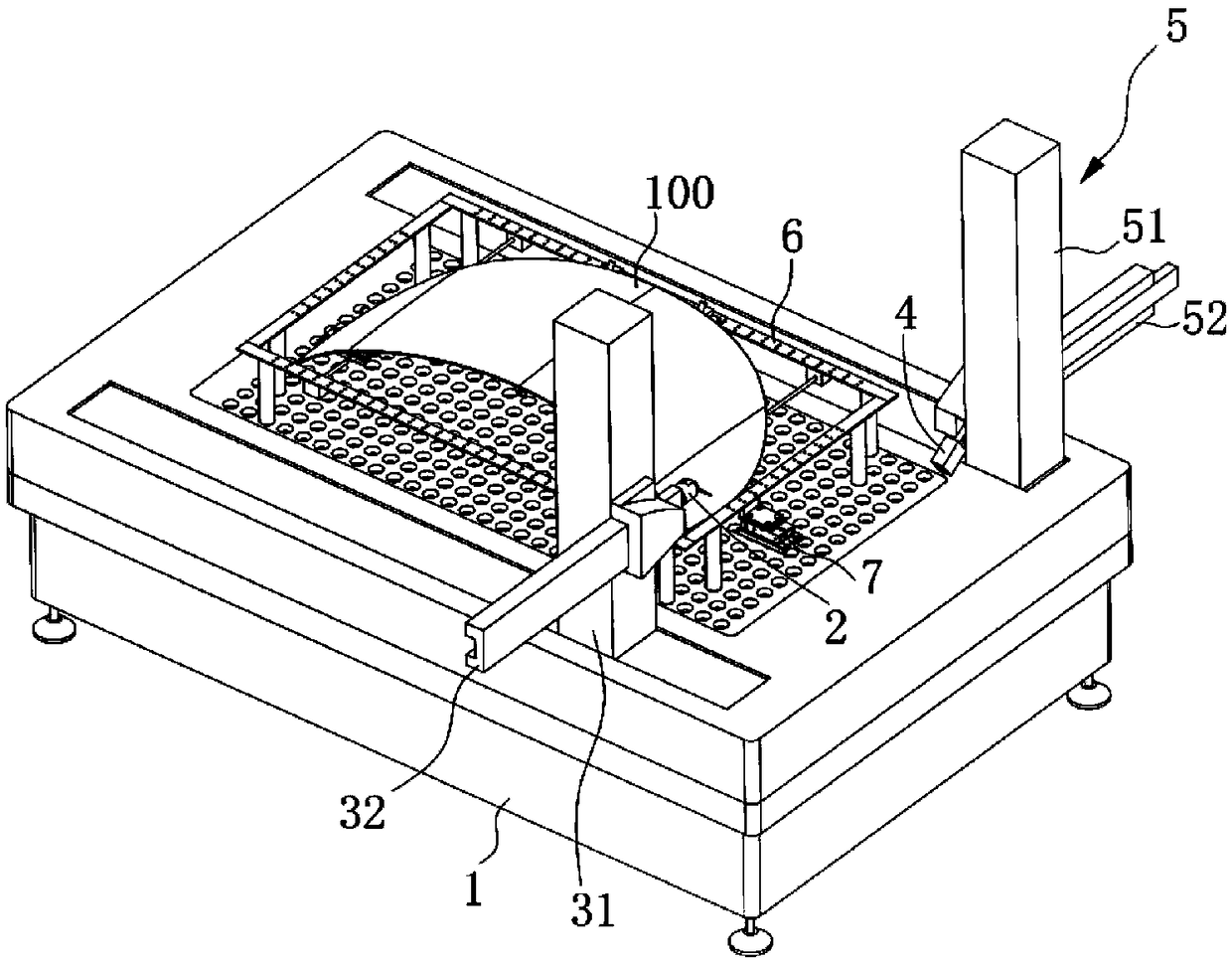

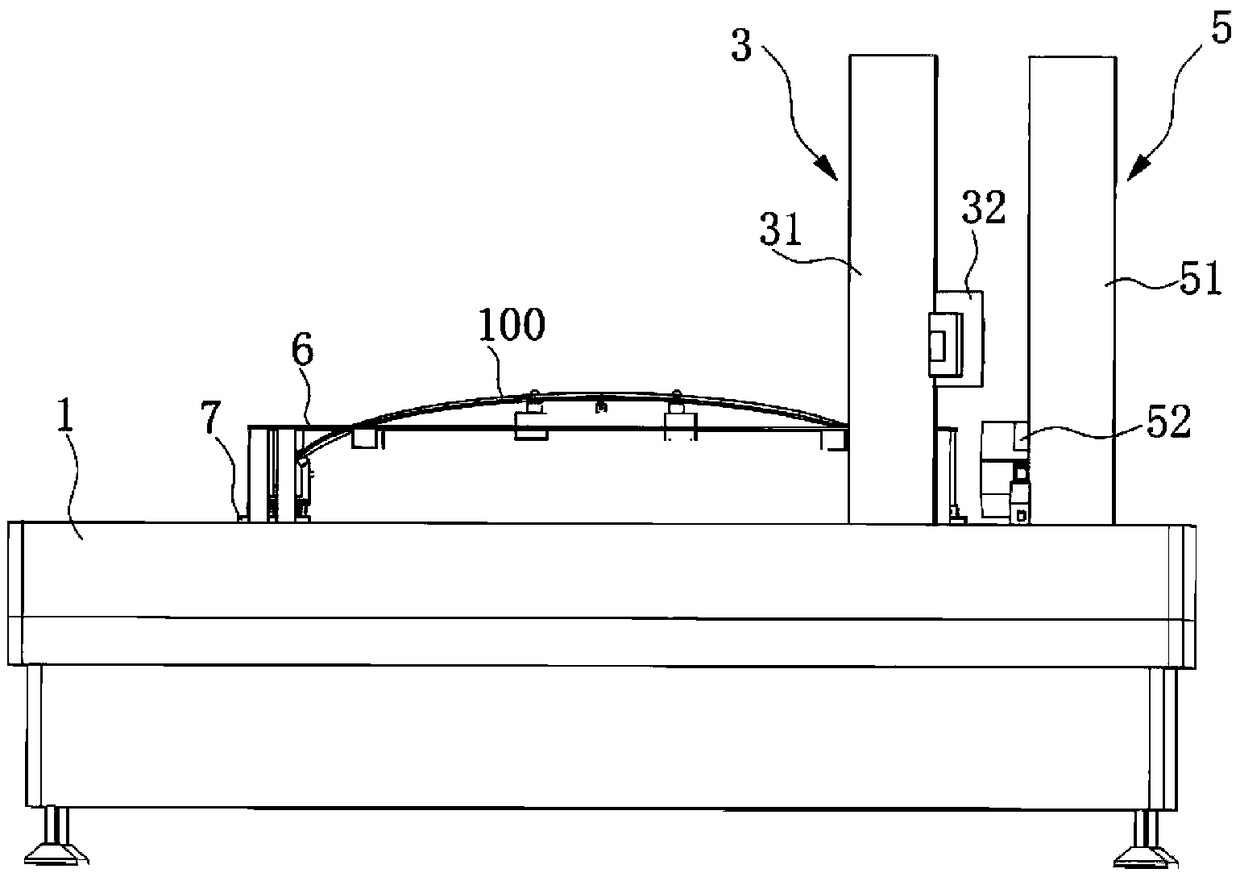

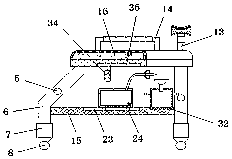

Automatic automobile glass detecting device and method

PendingCN109084682ASmall footprintTo achieve the purpose of detectionUsing optical meansLaser probeEngineering

The invention relates to the technical field of glass detecting, in particular to an automatic automobile glass detecting device and method. The automatic automobile glass detecting device comprises ameasuring table, a fixed clamp, a first measuring assembly and / or a second measuring assembly and a controller. The fixed clamp is used for clamping automobile glass, and the fixed clamp is arrangedon the measuring table. The first measuring assembly comprises a point laser probe, and the point laser probe is capable of scanning to obtain coordinates of a specified point on the outer surface ofthe automobile glass. The second measuring assembly comprises a line laser probe capable of scanning to obtain coordinates of points of a black edge of the automobile glass. The controller receives the coordinates of the specified point obtained by the first measuring assembly and / or the coordinates of the points of the black edge of the glass obtained by the second measuring assembly, and compares the difference of the coordinates. The automatic automobile glass detecting device can save a large number of electronic inspection tools and save the space occupied by the inspection tools, and canfurther realize the purpose of detecting without moving the automobile glass under the action of the fixed clamp, thereby improving the detecting precision.

Owner:FUYAO GRP SHANGHAI AUTOMOBILE GLASS CO LTD

Box body welding production line and production method

The invention discloses a box body welding production line and a production method. The production line comprises a plate discharge hole forming equipment line, a rolling forming line, a punching device, a bending device and a welding device; the plate discharge hole forming equipment line is used for leveling steel and punching the surface of the steel, and a material plate is manufactured; the rolling forming line is used for rolling a bending edge on the material plate; the punching device is used for cutting off the material plate into a plurality of groups, each group of material plates comprises four continuous sections, and the four sections are corresponding to four side wall plates of the box body; the bending device is used for bending the cut material plate into a side wall frame of the box body; and the welding device is used for welding the frame into a whole box body. The full-automatic production line and process of punching, rolling, cutting, bending and welding are adopted, so that full-automatic forming from the steel plate to the box body is realized, the processing of hole forming and three-dimensional features on the side wall of the box body is completed once,the production efficiency is high, the labor cost is low, and the processing quality is high.

Owner:LAIZHOU KASIKAITE IND & TRADE CO LTD

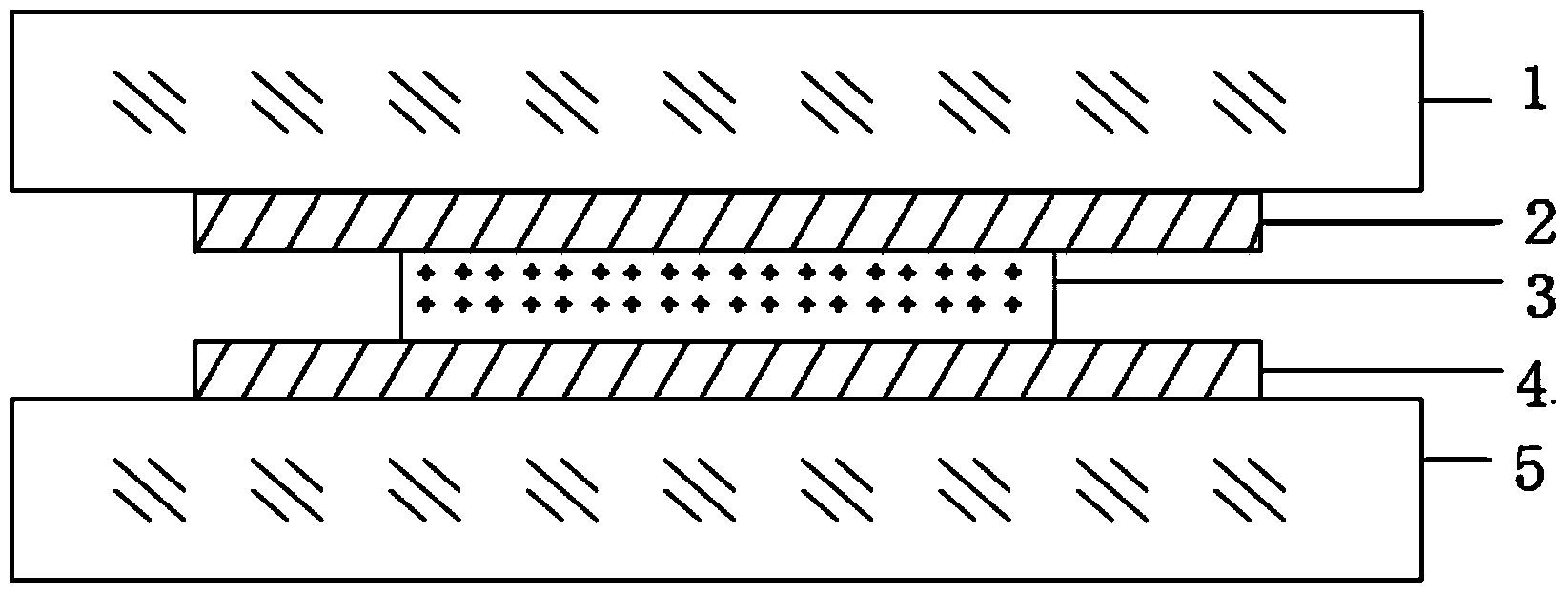

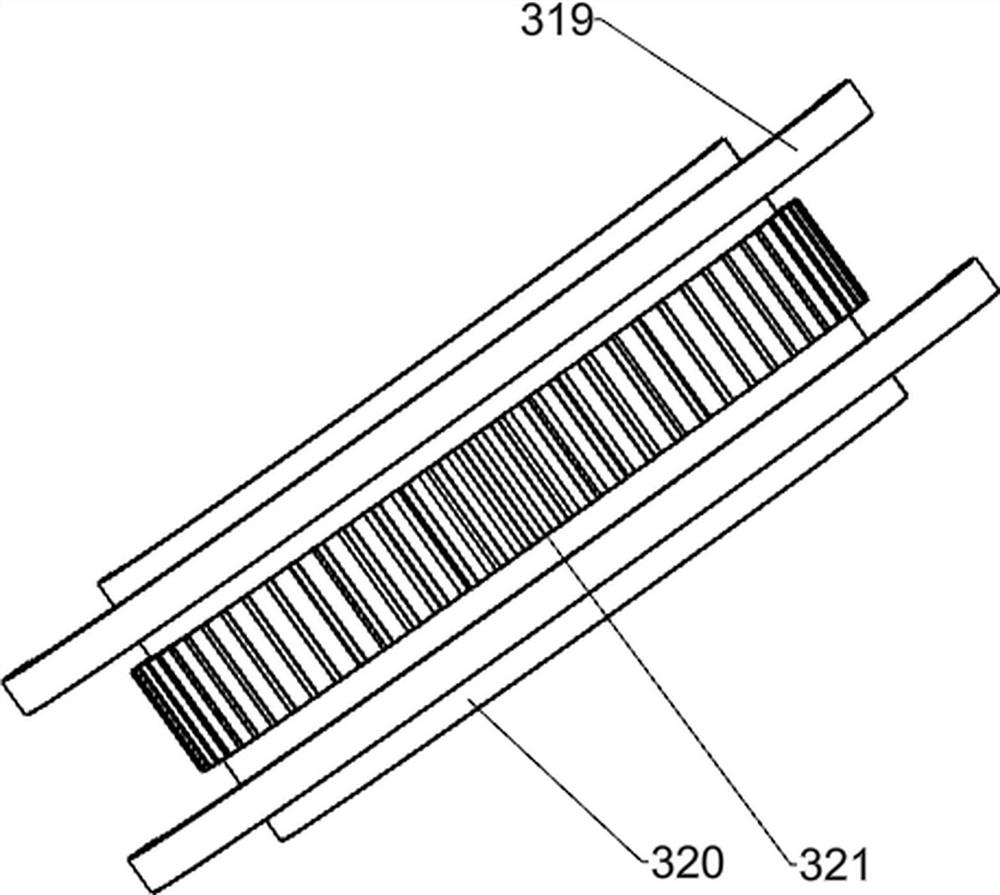

Preparation method for infrared heat-light modulator adopting sandwich composite structure

InactiveCN103820764AEnabling thermo-optic modulationLower working temperatureVacuum evaporation coatingSputtering coatingVanadium dioxideLight modulation

An infrared heat-light modulator adopting a sandwich composite structure consists of two substrates, FTO transparent conductive film layers and a vanadium dioxide film layer. A preparation method of the infrared heat-light modulator comprises the following steps: adopting a sol-gel method, precipitating an FTO transparent conductive film layer on each substrate, then sputtering metal vanadium on one FTO transparent conductive film through direct current magnetic control, obtaining the nano vanadium dioxide film layer through medium temperature annealing, and finally encapsulating the nano vanadium dioxide film layer with the other substrate with precipitated FTO transparent conductive film so as to form the infrared heat-light modulator adopting the sandwich composite structure. The infrared heat-light modulator can realize infrared band heat-light modulation, is low in insertion loss, achieves femtosecond level in phase change speed, has the advantages of low power consumption, simple structure, high reliability, easiness in manufacture and the like, and can be applied to the technical field of photoelectrons.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Holographic imaging system and imaging method for taking photos to collect three-dimensional information

InactiveCN105404127AImprove acquisitionSave human effortStereoscopic photographyHolographic imagingImaging data

The invention discloses a holographic imaging system and imaging method for taking photos to collect three-dimensional information. The holographic imaging system comprises an image data collection device, a data processing device and a holographic image projector, wherein the image data collection device, the data processing device and the holographic image projector are sequentially connected with one another; the image data collection device is used for collecting image data of a target object, and transmitting the image data to the data processing device; the data processing device is used for receiving the image data and reconstructing three-dimensional holographic data according to the image data; and the holographic image projector is used for receiving the three-dimensional holographic data, and projecting and displaying the three-dimensional holographic data through the holographic image projector. According to the holographic imaging system, the three-dimensional information of a viewing angle of the target object is collected through one-time taking photos and scanning, and is displayed through the holographic image projector. The holographic imaging system is simple to operate and convenient to use; complicate three-dimensional data can be processed; and a three-dimensional model can be quickly built.

Owner:王志向

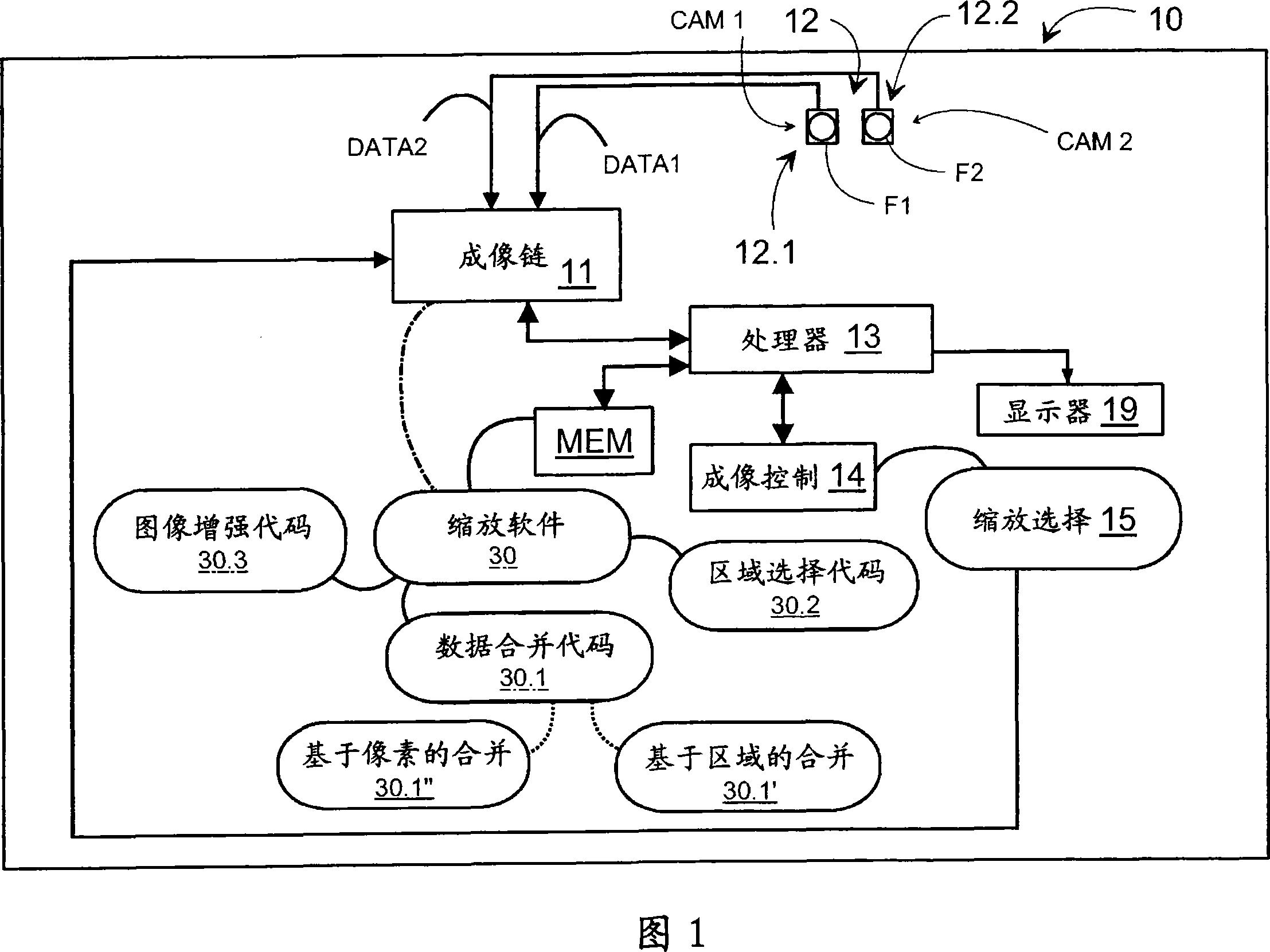

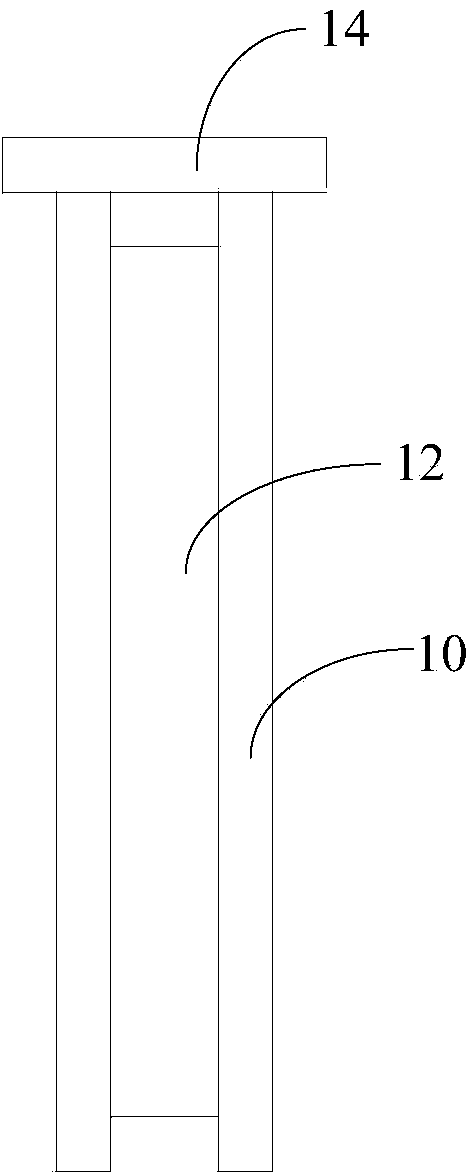

Electronic device and a method in an electronic device for forming image information, and a corresponding program product

InactiveCN1993981ACreate a zoom functionNo need to moveTelevision system detailsColor television detailsComputer visionImaging data

The invention relates to an electronic device (10), which includes - camera means (12), including at least one camera element (CAMl) for forming image data (DATAl) from an imaging subject (17),- a first lens arrangement (Fl) according to a set focal length, arranged in connection with the camera means (12), and means (11) for processing the image data (DATAl) into image information (IMAGE), the processing including, for example, zooming othe imaging subject (17).The said camera means (12) additionally include at least a second camera element (CAM2) equipped with a second lens arrangement (F2), the focal length of which differs from the focal length of the said first lens arrangement (Fl) in an established manner and from the sets of image data (DATAl, DATA2) formed by the first and second camera elements (CAMl, CAM2) is arranged to be processed by using the data- processing means (11) the image information (IMAGE) with the desired zooming of the imaging subject (17). In addition, the invention also relates to a method and program product.

Owner:NOKIA CORP

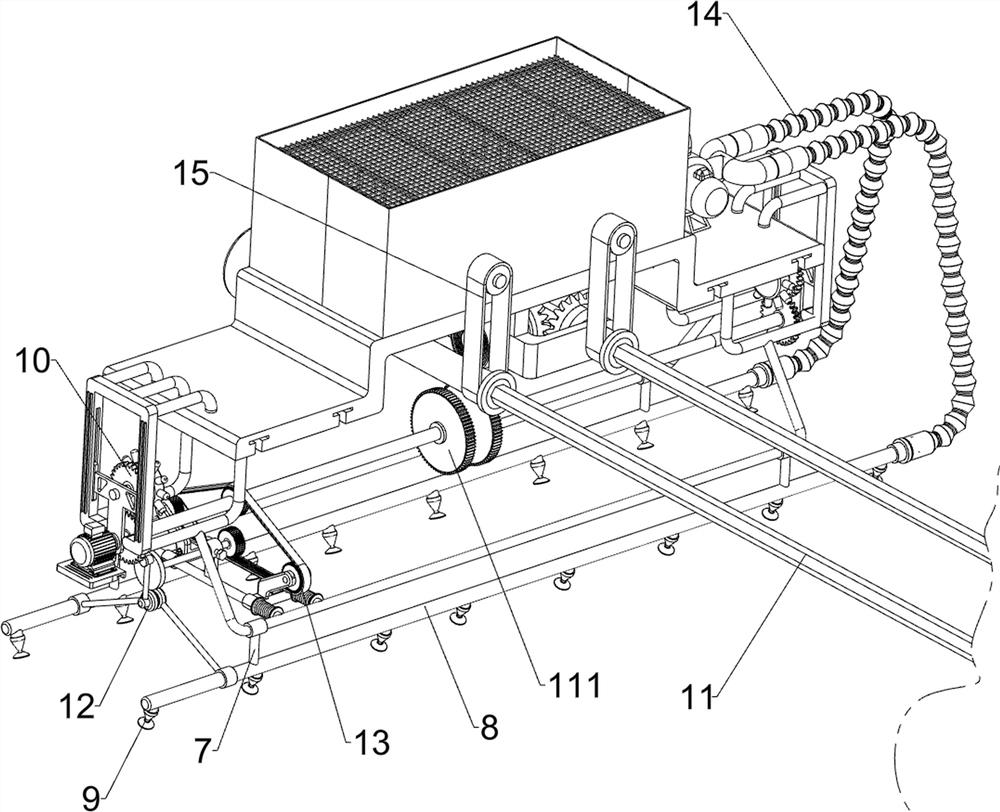

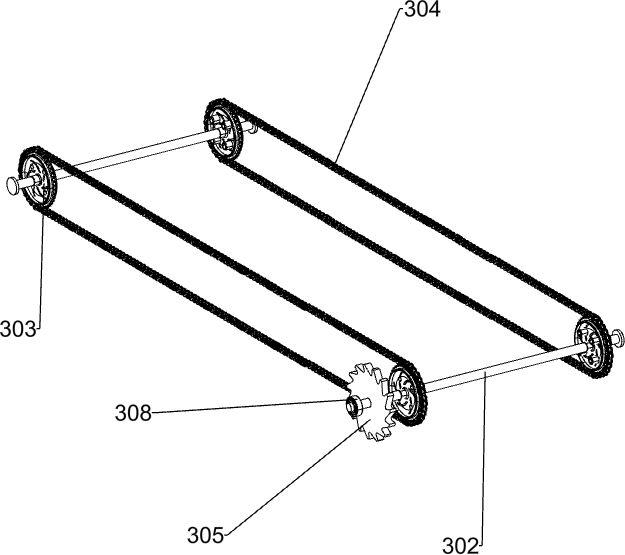

Reciprocating type automatic tomato irrigation device for agricultural Internet of Things

InactiveCN113396755AFully wateredImprove irrigation effectManure treatmentClimate change adaptationAgricultural scienceSprayer

The invention discloses a reciprocating type automatic tomato irrigation device for agricultural Internet of Things. The reciprocating type automatic tomato irrigation device comprises two guide rails, a sliding plate, swing rods and a reciprocating mechanism, wherein a sliding rack is placed between the guide rails, the two sides of the sliding rack are connected with a plurality of limiting wheels, and the limiting wheels are in contact fit with the guide rails; the sliding plate is connected to the sliding rack in a sliding mode, the sliding frames are connected to the two sides of the top of the sliding plate, and a connecting frame is connected between the inner side faces of the sliding frames and connected with the sliding plate; the lower portion of the connecting frame is rotationally connected with the multiple swing rods, a liquid spraying pipe is connected between the swing rods on the same side, and the liquid spraying pipe is connected with the multiple sprayers; and the reciprocating mechanism is arranged between the sliding frames and the sliding rack. Through the reciprocating mechanism, the sprayers can reciprocate, so that tomatoes can be comprehensively watered, and the irrigation effect can be improved.

Owner:林建丹

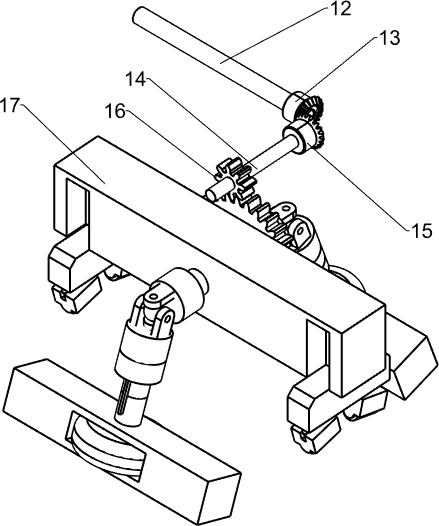

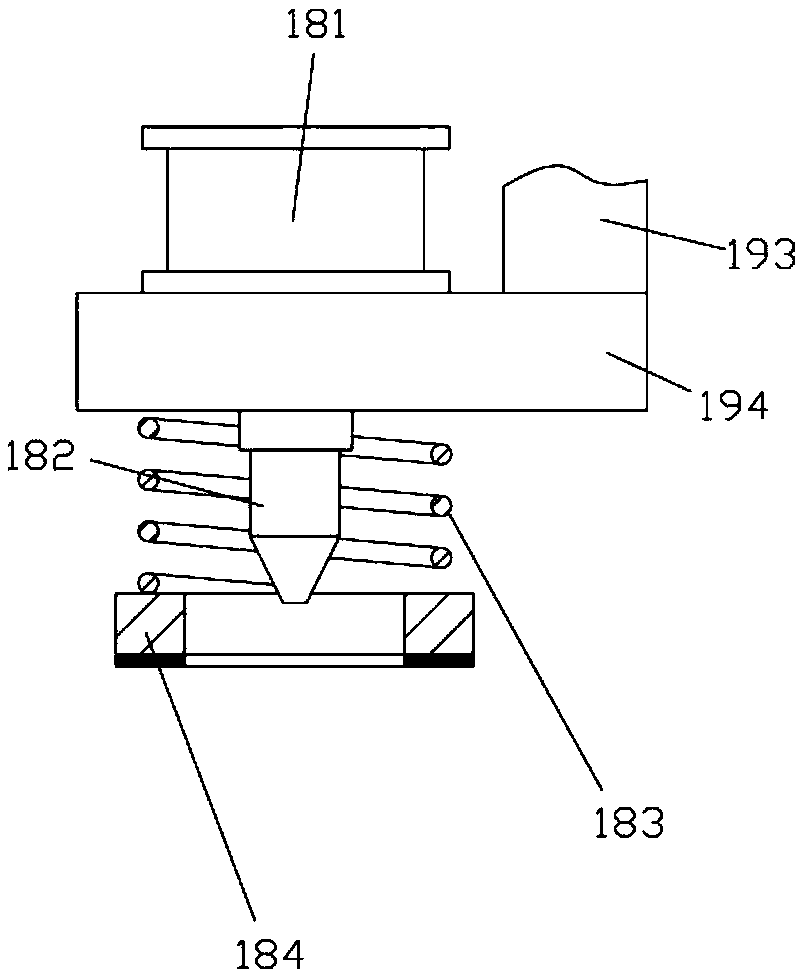

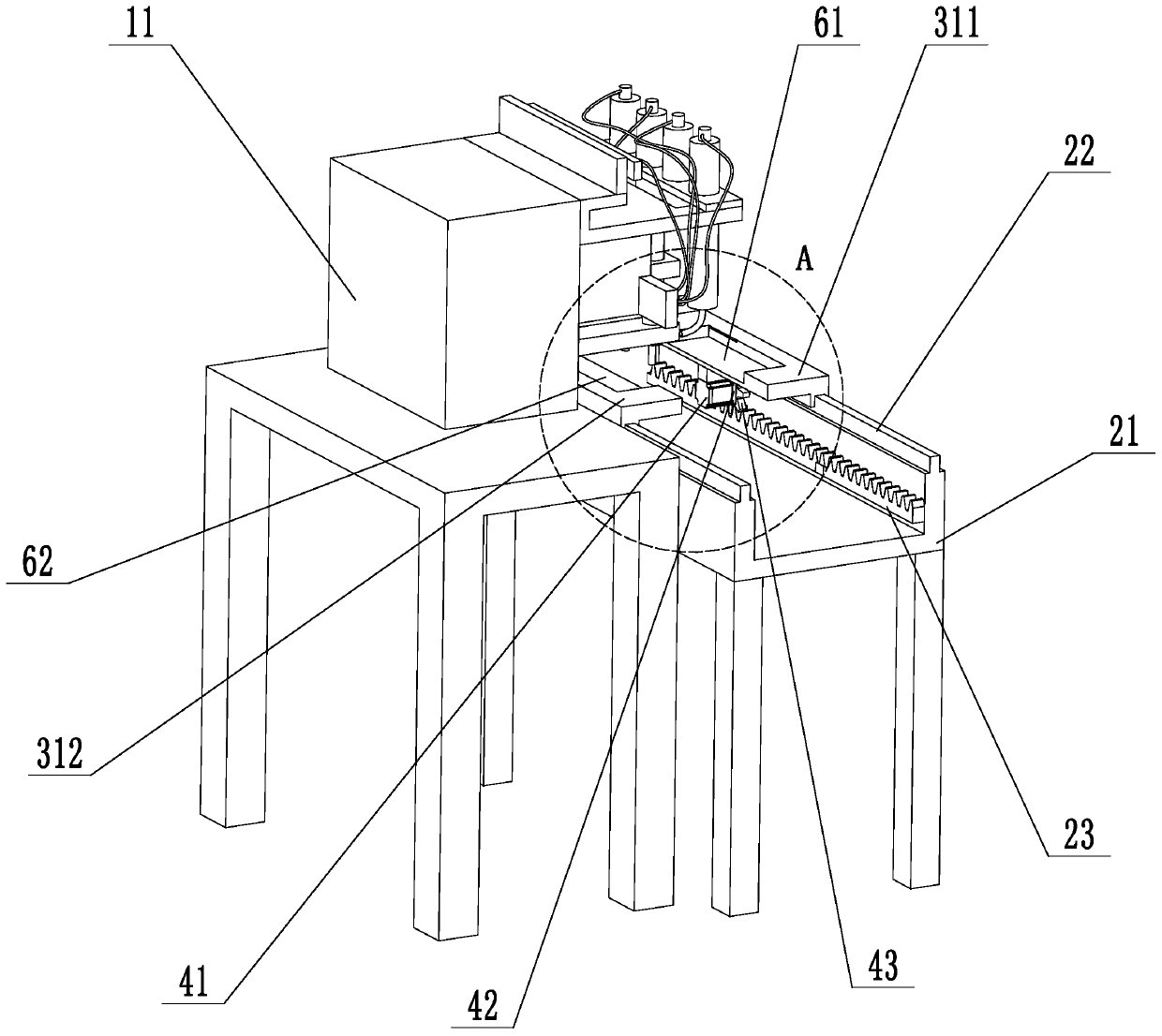

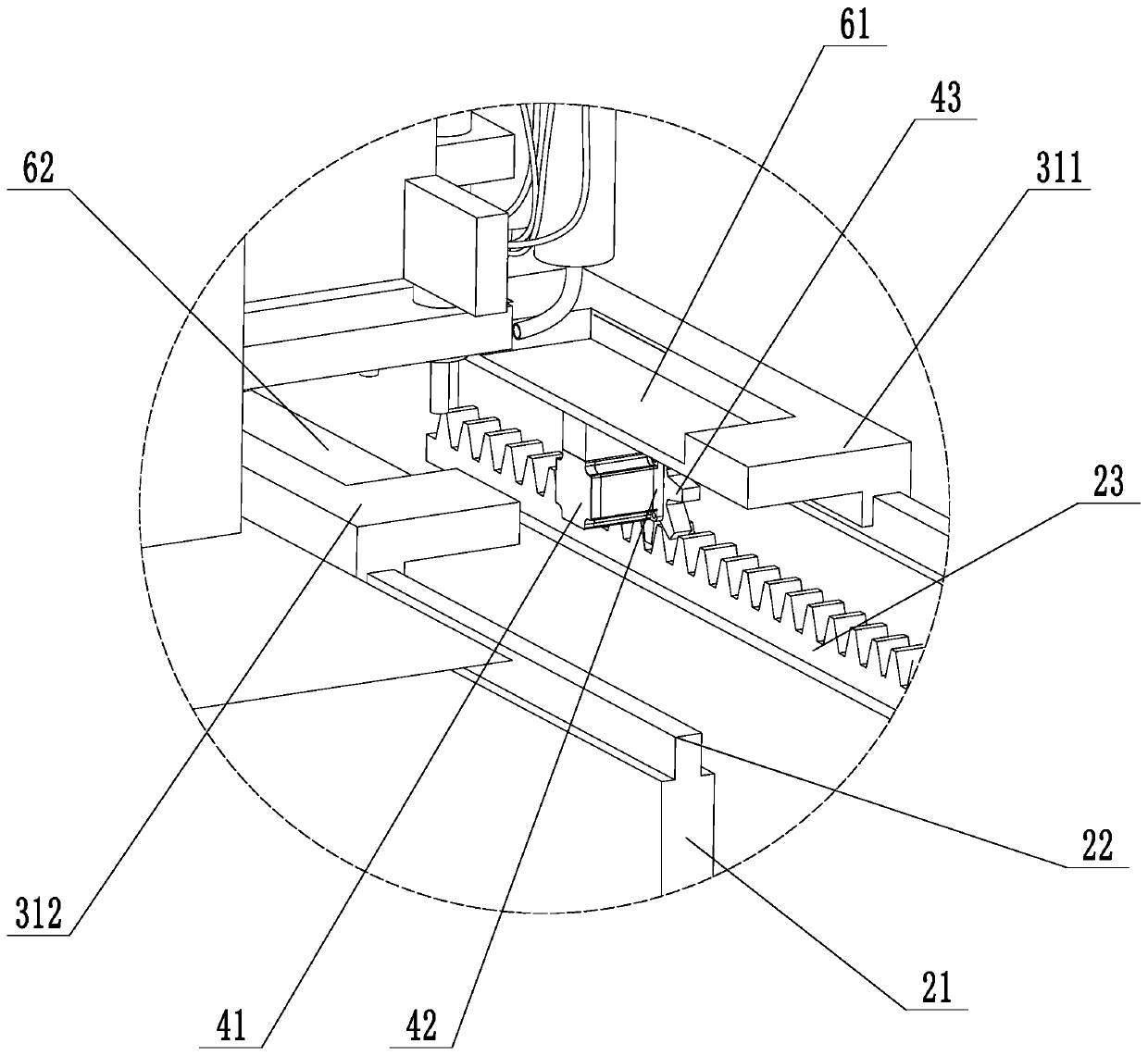

Woodsword handle slotting machine

ActiveCN111775219ANo need to movePrevent fallingProfiling/shaping machinesWood mortising machinesMechanical engineeringIndustrial engineering

The invention relates to a slotting machine, in particular to a woodsword handle slotting machine. The invention aims to solve the technical problem so as to provide the woodsword handle slotting machine capable of automatically pressing a hole opener, enabling a woodsword handle to move intermittently and reducing the manual operation. The invention provides the technical scheme that the woodsword handle slotting machine comprises support legs and a slotting mechanism, wherein a bottom plate is arranged on the top parts of the support legs; a rotary placement mechanism is arranged on the front side of the middle part of the bottom plate; the slotting mechanism is arranged on the side part of the bottom plate; an intermittent pressing mechanism is arranged on the rear part of the bottom plate; a part of the intermittent pressing mechanism contacts a part of the rotary placement mechanism; and the part of the intermittent pressing mechanism is matched with a part of the slotting mechanism. According to the woodsword handle slotting machine provided by the invention, through the rotary placement mechanism, the woodsword handle can be moved intermittently without the need of being directly moved by manpower; the woodsword handle can be slotted through the slotting mechanism; and through the intermittent pressing mechanism, the hole opener is automatically moved downwards intermittently without the need of being pressed by manpower.

Owner:邱锦芳

Bed with folding desk

The invention discloses a bed with a folding desk. The bed with the folding desk comprises a bed, a slideway, a support rod, a desk board and desk legs; the slideway is provided with an inverted 'C'-shaped slide groove; the support rod is movably connected with the slideway through a protuberance with the bottom which is fit with the slide groove in shape; the desk board is movably connected with the support rod through a connecting element; the back surface of the desk board is provided with two desk leg grooves in symmetrical distribution; two walls at one end of each desk leg groove are respectively provided with a round desk leg fixing hole; the desk legs and the desk leg grooves are same in size, and one end of each desk leg is provided with a protruding round rotating rod which is adaptive to the size of the desk leg fixing hole; the support rod and the desk legs are all formed by the serial connecting and embedding of a plurality of pull rods; the desk board can rotate by taking a shaft of the connecting element as the center, and an included angle between the desk board and the support rod is within a range of 0 degree-180 degrees; and the slideway and the desk board can be installed at any side of the bed, and also can be installed at two sides of the bed. The bed with the folding desk, provided by the invention, has the advantages of being simple in structure, convenient to use, and small in occupied space.

Owner:朱华平

Method for grafting old trees

The invention relates to a method for grafting old trees, in particular to a method for grafting century-long old trees with part of the trunk being withered to death. In order to overcome the major defect that the century-long old trees are difficult to be conserved continuously in a grafting manner in the prior art, the invention provides a method for grafting century-long old trees with part of the trunk being withered to death for survival. The method comprises the following steps: determining the viable part in the old tree, wherein, if the size of the viable part is larger than 50% that of the trunk of the old tree, the method is feasible; implanting a conspecific grafting seedling provided with a root system into the lower end of the viable part of the old tree; and grafting a conspecific grafting seedling provided with branches and leaves onto the upper end of the viable part of the old tree, wherein, the root system of the conspecific grafting seedling is imbedded in the soil; and one end of the conspecific grafting seedling with the braches and leaves is grafted onto the viable part of the old tree, and the rest thereof is fixed onto the old tree.

Owner:夏万新

Orthopedic nursing massage rehabilitation device

InactiveCN112754815AEasy to useImprove convenienceDiagnosticsVibration massagePhysical medicine and rehabilitationOrthopedic department

The invention relates to the technical field of massage rehabilitation devices, and particularly relates to an orthopedic nursing massage rehabilitation device. The device comprises a protective shell and a motor, wherein the motor is fixedly connected to the bottom end of the interior of the protective shell, and vibration mechanisms are arranged on the left and right sides of the bottom end of the interior of the protective shell respectively; each vibration mechanism comprises a first fixing block, the first fixing blocks are fixed to the front and rear sides of the interior of the protective shell, and first rotating shafts are movably connected to the interiors of the two first fixing blocks through bearings respectively; and cams are fixed to the ends, close to each other, of the two first rotating shafts, height adjusting mechanisms are arranged on the sides, away from each other, of the two vibration mechanisms respectively, and an angle adjusting mechanism is arranged at the bottom end of the protective shell. According to the orthopedic nursing massage rehabilitation device, the situation is avoided that an existing nursing massage rehabilitation device cannot be directly placed on a sickbed for use, the whole device is small, the whole device is convenient to move, the device is more convenient and faster to use, and the practicability and convenience of the device are improved.

Owner:ZHEJIANG PROVINCIAL HOSPITAL OF TRADITIONAL CHINESE MEDICINE

Multi-functional examination bed convenient to adjust for proctology department

PendingCN108175630ASuitable temperatureEasy to adjust the tilt angleDiagnosticsOperating tablesThermal insulationEngineering

The invention belongs to the technical field of examination, and particularly relates to a multi-functional examination bed convenient to adjust for a proctology department. For the problem of a single function and convenient adjustment of the examination bed for the proctology department, the following scheme is proposed that the examination bed comprises a cushion plate, the four corners of thebottom of the cushion plate are connected with supporting legs through fastening bolts, the middle portion of the opposite sides of the supporting legs at the two sides located on the same side of thecushion plate is connected with a same cross brace through fastening bolts, and the middle portions of the tops of the two cross braces are both connected with adjusting hydrocylinders through hinges. According to the examination bed, a first heating resistance plate, a temperature sensor and thermal insulation sponge are arranged, heating and thermal insulating can be carried out on a back plate, the cushion plate and a movable plate to provide a suitable temperature for patients, so that the patients are more comfortable and relaxed, the adjustment is convenient, the examination bed is suitable for the requirements of different patients, the use is convenient and quick, the multifunctionality of the examination bed is achieved, and the examination bed is more convenient and healthful, and the patients do not need to move.

Owner:王志国

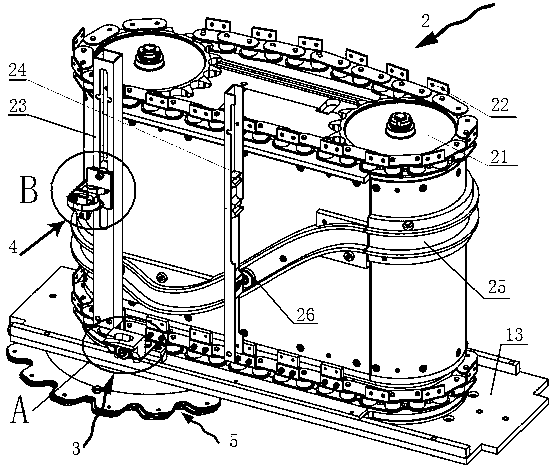

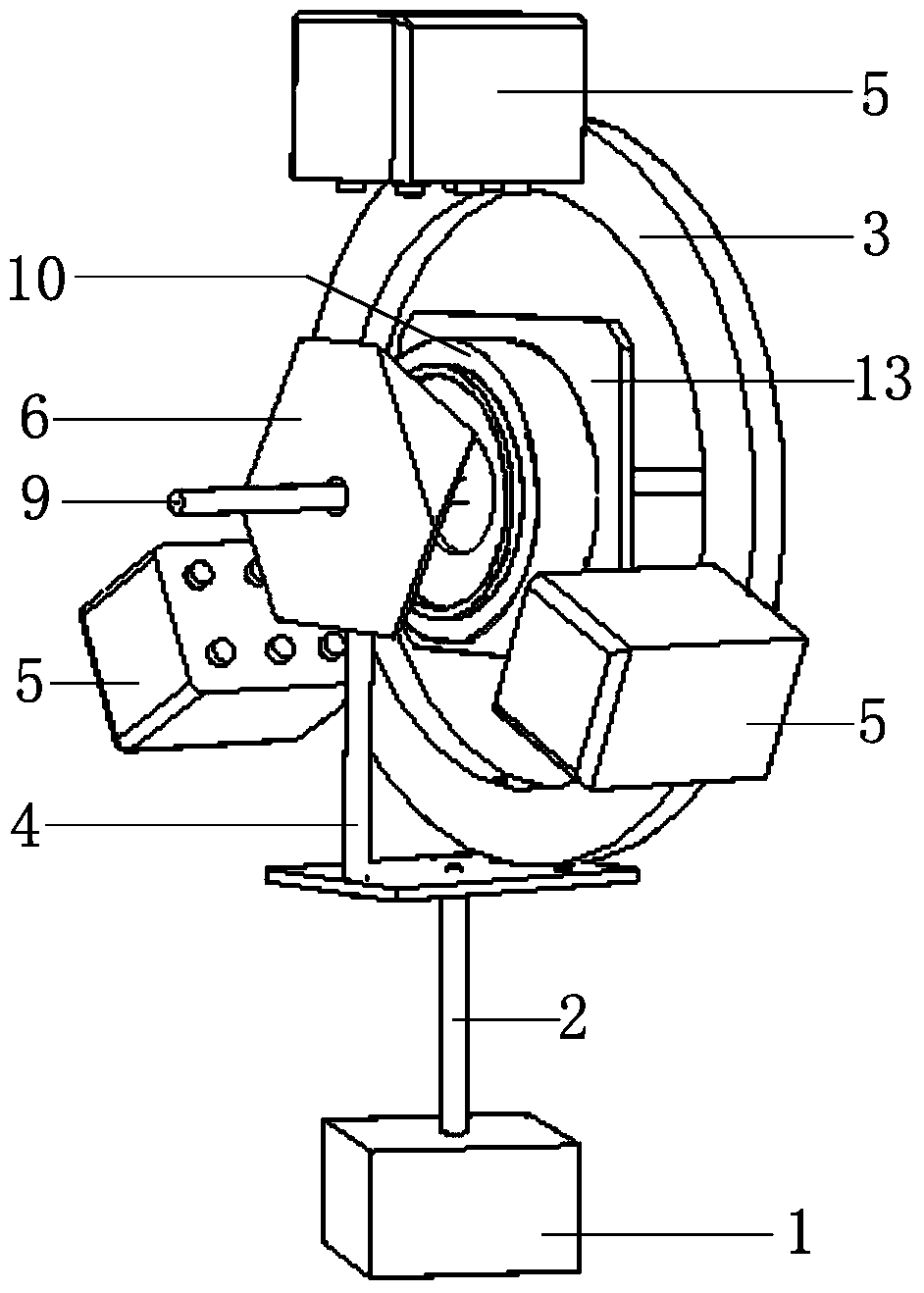

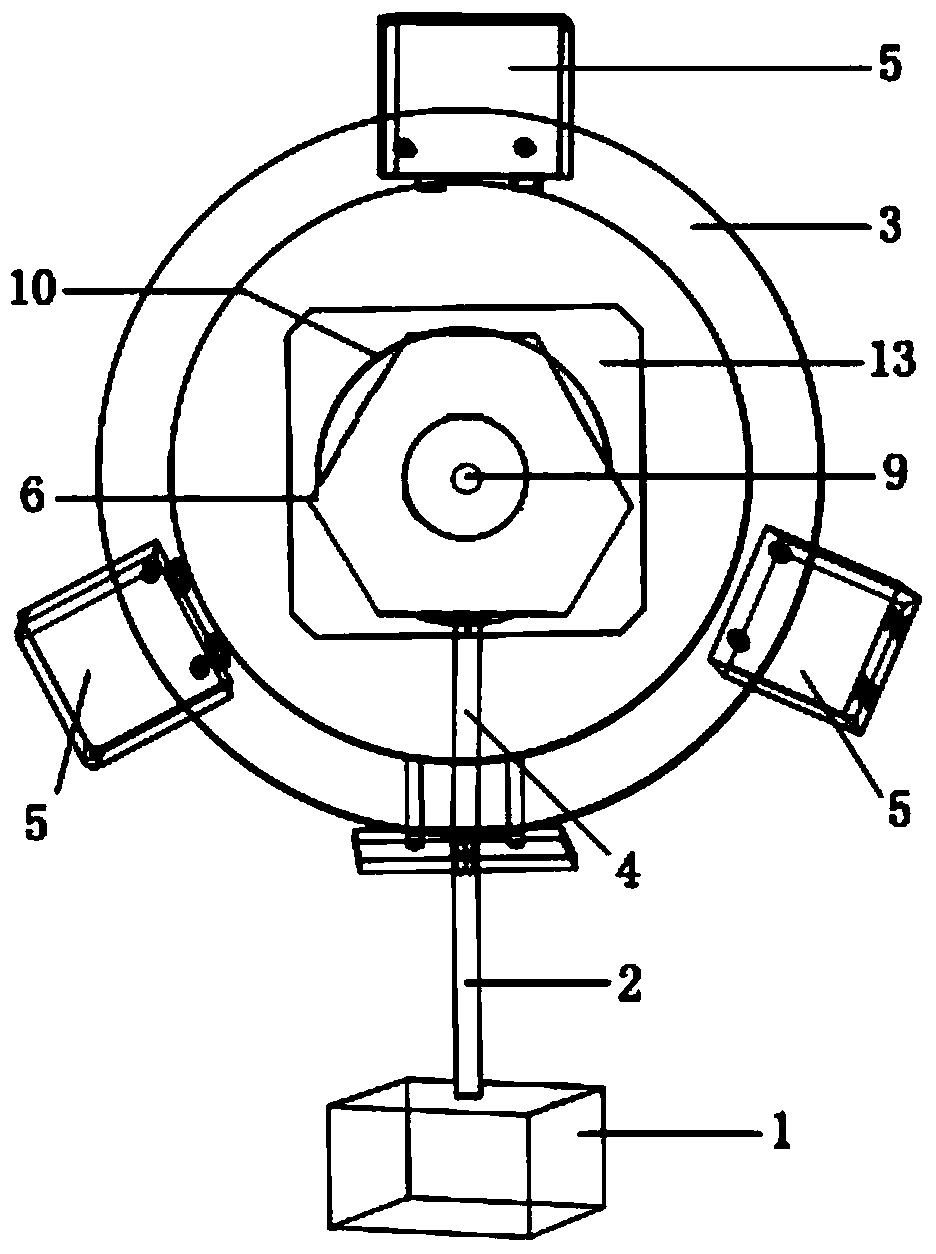

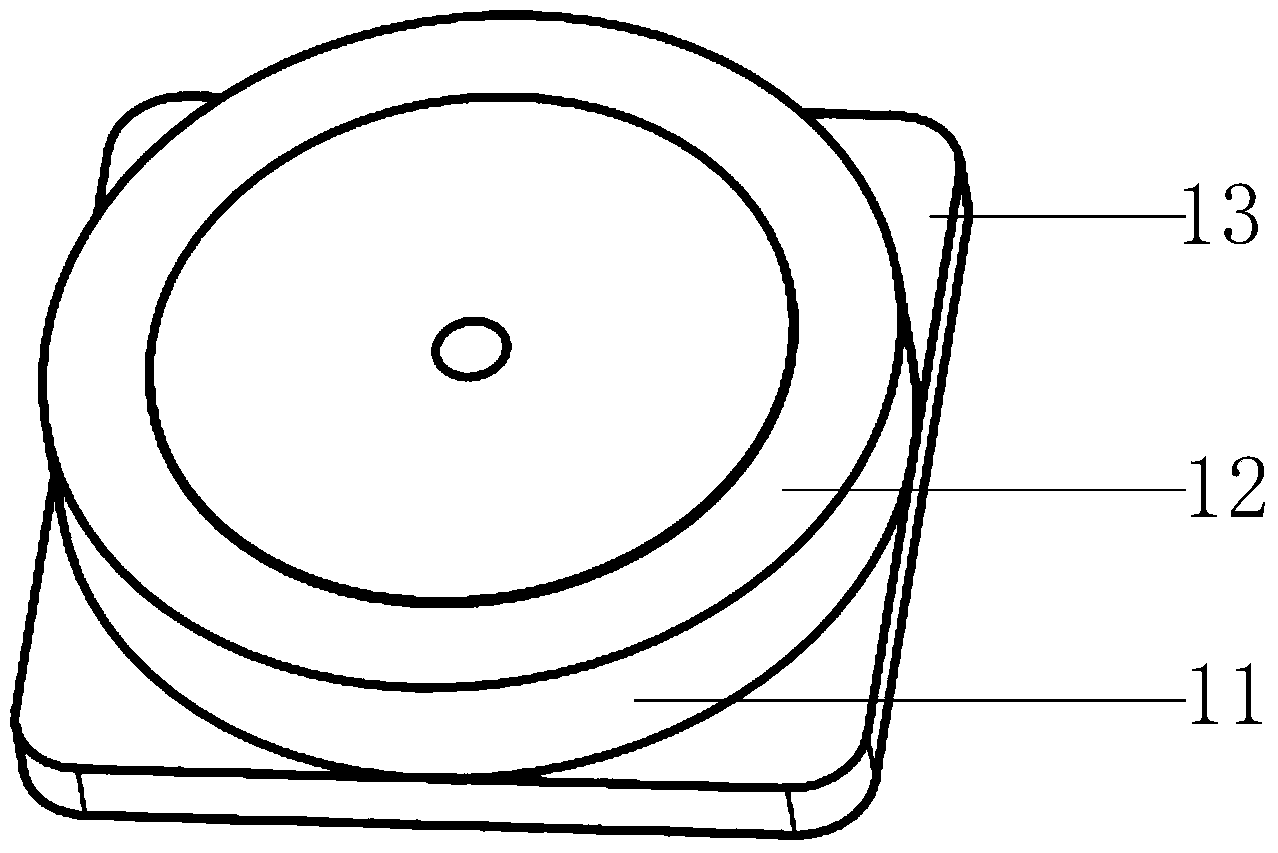

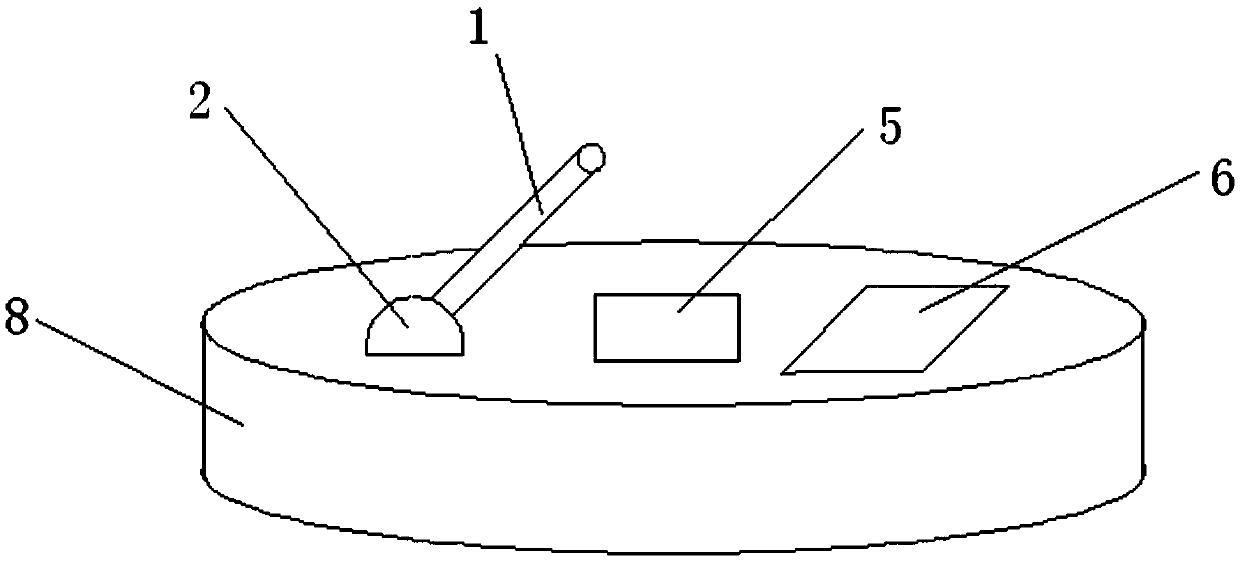

Cold light integrated curing device and method for optical fiber gyroscope sensitive optical fiber ring

The invention relates to a cold light integrated curing device and method for an optical fiber gyroscope sensitive optical fiber ring. The device comprises a fixing part, a light source part and a rotating shaft control part, wherein the fixing part is used for fixing a light source; the light source part is used for radiating the optical fiber gyroscope sensitive optical fiber ring to be cured; the rotating shaft control part is used for rotating the optical fiber gyroscope sensitive optical fiber ring to be cured; the light source part comprises an LED (Light Emitting Diode) ultraviolet lamp and a polyhedron reflection mirror. The device is a low-stress integrated curing system, the sensitive optical fiber ring is driven to rotate through a mechanical structure, and the polyhedron mirror in the mechanical structure is utilized to split the ultraviolet light to the end surface and the annular surface of the optical fiber ring, so that the purpose of integrally curing the optical fiber ring is achieved, the stress inside the optical fiber ring is reduced, and the production efficiency of the optical fiber ring is improved.

Owner:中航捷锐(西安)光电技术有限公司

Remediation tank for heavy metal contaminated soil

The invention discloses a remediation tank for heavy metal contaminated soil. The remediation tank comprises a tank body, the bottom of the tank body is obliquely arranged, the inclination angle is 5-10 DEG, a waterproof layer is laid on the bottom of the tank body, the inclined lower end of the tank body communicates with a water discharge pipe, the water discharge tube is provided with a water discharge valve, and a soil turning device is arranged in the tank body. The remediation tank can conveniently remediate soil, can turn the soil easily by arranging the soil turning device, and avoidsanother soil turning devices from being manually operated for soil turning remediation; and a method for remediating soil by adopting a chemical leaching agent makes the contaminated soil transferredinto the remediation tank and remediated, so the chemical leaching agent is prevented from being added to affect other soils.

Owner:耿言华

Ophthalmologic surgery assist device

ActiveCN107693293AOptimize locationNo need to moveOperating chairsDental chairsMobile deviceOphthalmic surgery

The invention relates to an assist device, in particular to an ophthalmologic surgery assist device. The technical problem of the invention is to provide an ophthalmologic surgery assist device whichcan adjust a distance between a tool and a doctor and can allow the doctor to easily take the tool without allowing the doctor to move. To solve the technical problem, the ophthalmologic surgery assist device includes a bottom plate, a first supporting rod, a second supporting rod, a seat, a vertical plate, a lifting device, and a mobile device; the first supporting rod is arranged on the right side of the top of the bottom plate, and the second supporting rod is arranged on the right side of the top of the bottom plate; the second supporting rod is positioned on the right side of the first supporting rod; the seat is arranged between top ends of the second supporting rod and the first supporting rod; and the vertical plate is arranged on the left side of the top of the bottom plate. The ophthalmologic surgery assist device can adjust a distance between a tool and a doctor and can allow the doctor to easily take the tool without allowing the doctor to move.

Owner:长沙湘江爱尔眼科医院有限责任公司

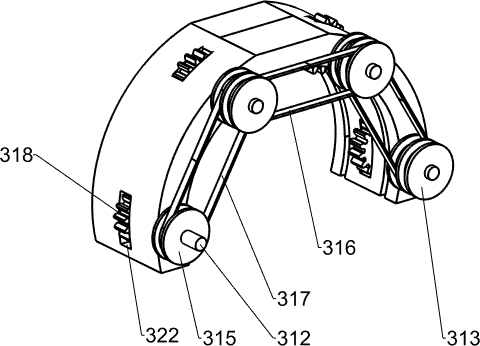

Petroleum pipeline outer wall paint brushing device capable of walking along pipeline

ActiveCN112452655AEasy to paintImprove painting efficiencyLiquid surface applicatorsCoatingsBrush deviceMechanical engineering

The invention relates to a petroleum pipeline outer wall paint brushing device, in particular to a petroleum pipeline outer wall paint brushing device capable of walking along a pipeline, and aims tosolve the technical problem about how to research and develop the petroleum pipeline outer wall paint brushing device which can walk along the pipeline, reduce the workload and improve the brushing efficiency. According to the technical implementation scheme, the petroleum pipeline outer wall paint brushing device capable of walking along the pipeline comprises a support and a brushing mechanism;a discharging mechanism is installed on the support; the brushing mechanism is arranged on the side, close to the discharging mechanism, of the support; and the brushing mechanism is matched with thedischarging mechanism. Through cooperation of the discharging mechanism and the brushing mechanism, paint brushing can be conveniently conducted on the petroleum pipeline, so that the workload can bereduced, and the paint brushing efficiency of the petroleum pipeline can be improved; and a first contact roller rotates anticlockwise, and a first guide wheel is matched with a second guide wheel, sothat the device can conveniently move on the petroleum pipeline, and a user is not required to move the device.

Owner:江苏金鼎建设集团有限公司

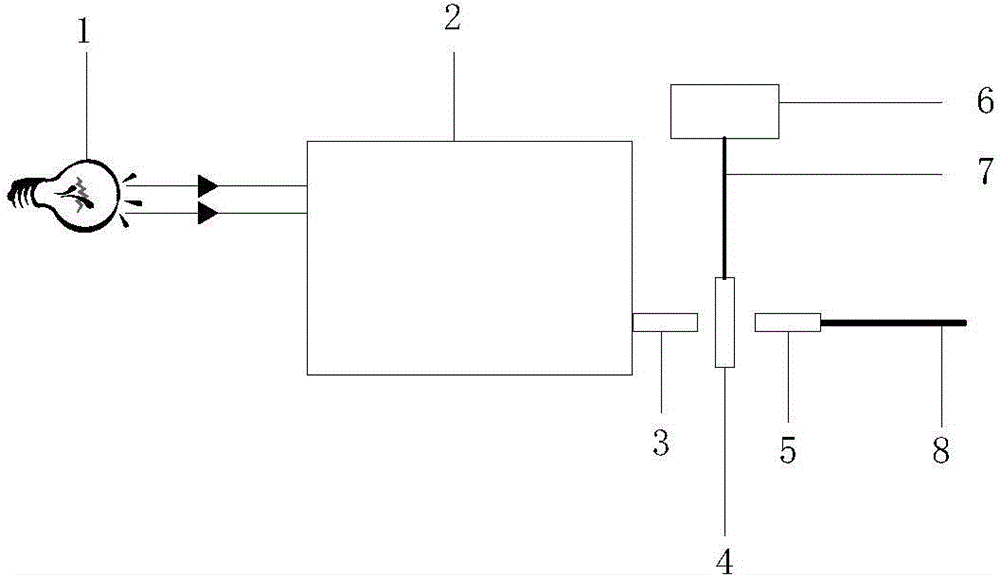

Optical fiber radiation source with adjustable radiation energy and wavelength

ActiveCN103822709AAdjustable wavelengthAdjustable Radiant EnergySpectrum investigationSpectrum generation using diffraction elementsUltrasound attenuationPhotovoltaic detectors

The invention provides an optical fiber radiation source with adjustable radiation energy and wavelength. The optical fiber radiation source comprises a light emitting source, a monochromator, an input collimator, an attenuation slice, an output collimator, a stepper motor, a stepper motor screw and an optical fiber. The light emitting source is directed at an incidence slit of the monochromator. The input collimator is arranged in an emergence slit of the monochromator. The attenuation slice is located between the input collimator and the output collimator. The stepper motor is connected with the attenuation slice through the stepper motor screw, so as to control the movement of the attenuation slice. The input port of the optical fiber and the emergence port of the output collimator are connected. According to the scheme, by adjusting the monochromator and the attenuation ratio of the attenuation slice, the radiation source with adjustable radiation energy and wavelength is realized; the optical fiber is used to output a beam, thus the propagation direction of the beam can be conveniently changed; and the requirements of adjustable radiation energy and wavelength of the radiation source and flexible change of the beam direction are satisfied when calibration is carried out on a spectrometer, a photoelectric detector and the like.

Owner:CHINA ELECTRONIS TECH INSTR CO LTD

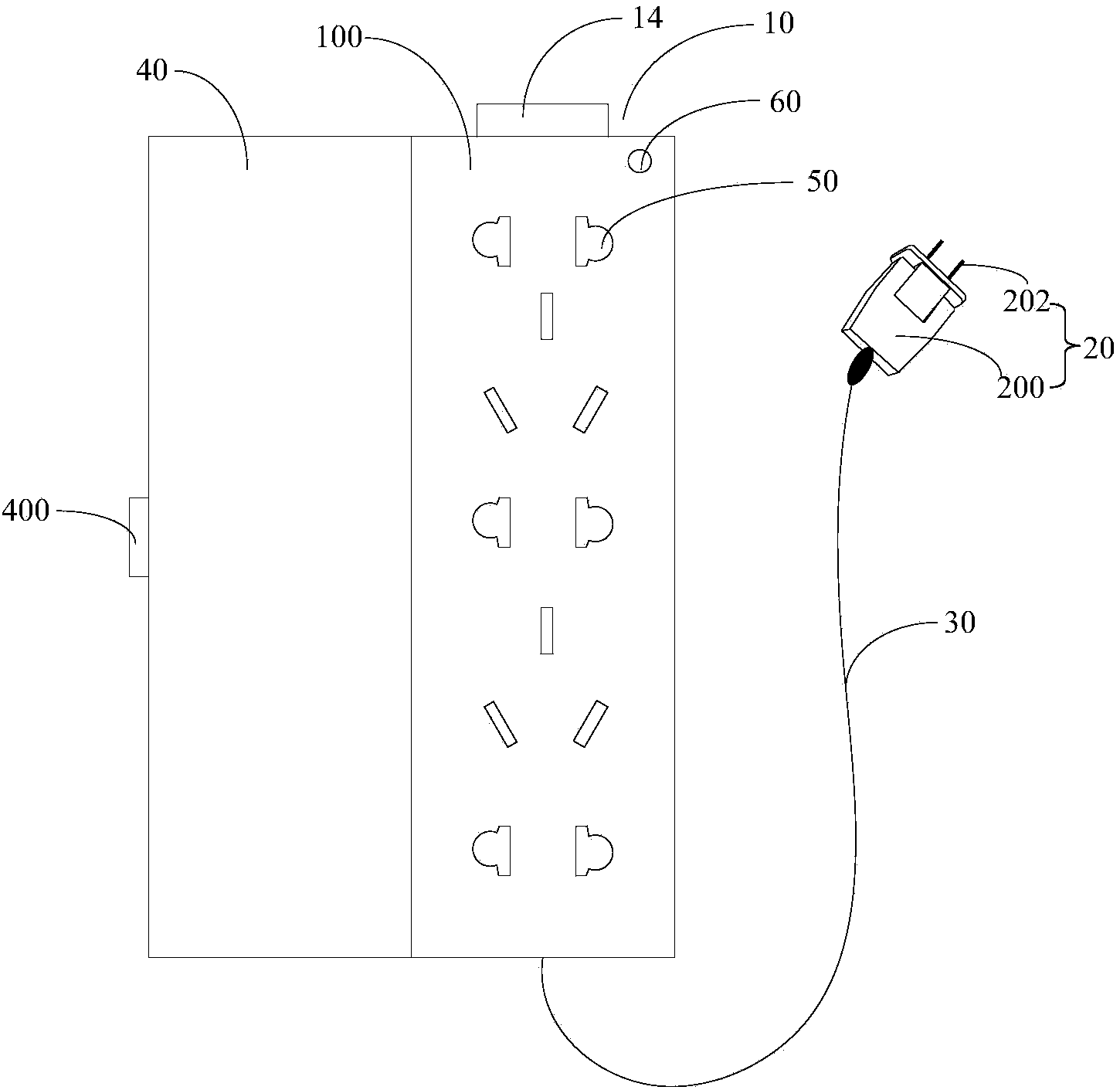

Socket

InactiveCN103682740ASocket moveNo need to moveSecuring/insulating coupling contact membersEngineeringElectric wire

A socket comprises a socket body, a plug, a power cord and a panel. The plug is connected with the socket body through the power cord. The socket body comprises a first surface and a second surface opposite to the same. The first surface is provided with jacks. The panel which is movable covers the first surface. The side of the socket body is provided with a cord groove capable of accommodating the power cord and a plug recess which matches with the plug. The plug comprises a plug body and pins. The pins are movably connected with the plug body. When the socket is in use, the pins are movably connected with the plug body; the included angle between the pins and the plug body is variable, and when the distance between the socket on a wall and furniture is small, the plug can be inserted into the socket on the wall in small space by adjusting the socket body and the plug, with no need of moving the furniture; the socket is convenient to use.

Owner:HUIZHOU KELIN ELECTRICAL APPLIANCE

Control cabinet body rib strip punching machine

The invention discloses a control cabinet body rib strip punching machine which comprises a rack. An installation groove is formed in the middle of the top face of a top plate of the rack, an inner installation die is inserted in the installation groove in a sleeving mode, a plurality of permanent magnetic iron blocks are formed at the edge portion of the bottom face of the inner installation die,the permanent magnetic iron blocks are inserted in positioning concaved holes formed on the edge portion of the bottom face of the installation groove in a sleeving mode and adsorbed with the top plate of the rack. Side supporting columns are fixed to the side wall of the top plate of the rack, an upper top plate is fixed to the top faces of all the side supporting columns, a lifting oil cylinderis fixed to the middle of the top face of the upper top plate, a pushing rod of the lifting oil cylinder passes through the bottom face of the upper top plate and is connected with a lifting plate ina screwed mode, side supporting plates are fixed to the left and right sides of the bottom face of the lifting plate, the two ends of a transverse moving screw rod are hinged to the two side supporting plates, and a moving motor is fixed to the outer side wall of one of the side supporting plates. According to the control cabinet body rib strip punching machine, to-be-machined rib strips can be punched continuously, the to-be-machined rib strips are not required to be moved, safety is achieved, the efficiency is high, and the effect is good.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

Building height automatic measuring device

InactiveCN109931908AGuaranteed accuracyReduce laborOptical rangefindersAutomatic Data ProcessingLaser transmitter

The invention discloses a building height automatic measuring device, which comprises a bearing frame, an angle measuring device, a display device, a laser transmitter and a microprocessor. The bearing frame comprises three legs and a support; the support is provided a cavity; two DC motors, a power supply, a horizontal automatic adjusting device and a lifting device are arranged in the cavity; alifting rod is vertically disposed on the support; a rotating table is rotarily arranged on the lifting rod; the upper end of the rotating table is provided with the laser transmitter; the laser transmitter can rotate for 180 DEG around a hinge shaft; the angle measuring device obtains an angle value to be inputted to the microprocessor; the microprocessor simultaneously receives parameters for acquiring a height; after a needed parameter is received, the microprocessor automatically runs, and the height of the building is obtained through processing and is displayed on the display device. Themicroprocessor with automatic data processing is equipped, and after corresponding needed initial data are acquired, the microprocessor can perform automatic processing to obtain the height of the building.

Owner:王文明

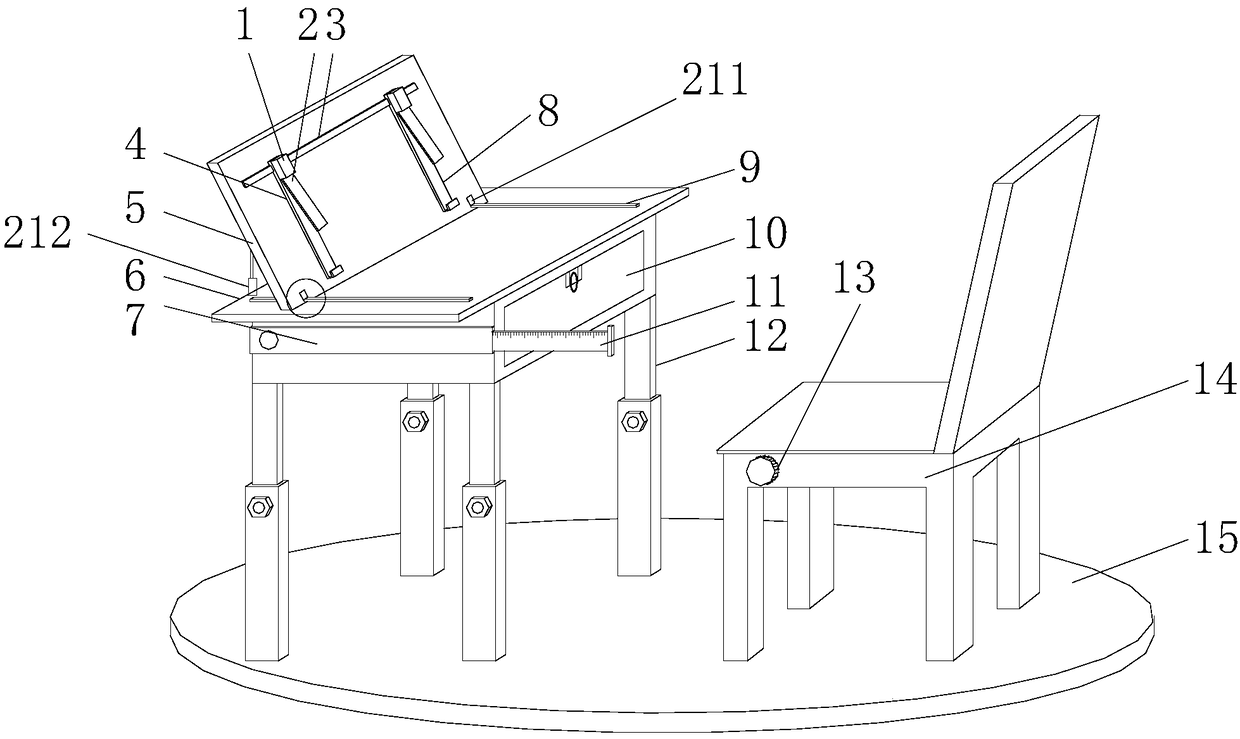

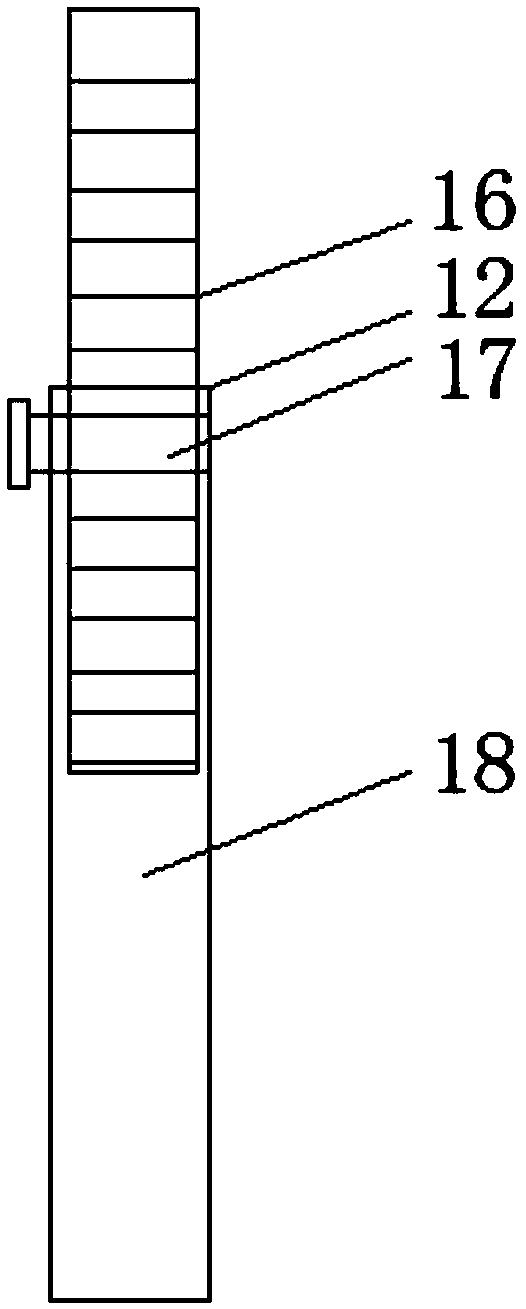

Lifting anti-myopia table and chair

The invention discloses a lifting anti-myopia table and chair. The lifting anti-myopia table and chair comprises a baffle, a table top and a bottom plate; a table drawer is mounted on the bottom of the table top; supporting legs are mounted on the bottom of the table drawer; each supporting leg includes a telescopic section and a fixing section; second guiding rails are mounted on a top surface ofthe table top; the baffle is slidingly mounted on the second guiding rails; a first guiding rail is mounted on one side wall of the baffle; a first moving bookrack and a second moving bookrack are slidingly mounted on the first guiding rail; mounting blocks are mounted on the first moving bookrack and the second moving bookrack; and a connection rod is mounted on a front outer wall of the table drawer through a connection shaft. The bookracks and a scale are arranged; when people are studying, people can fix a book on the bookracks, and adjusts a distance between a chest and the table throughthe scale, and in this way, the sitting posture can be effectively corrected, eyes can be effectively protected during studying to prevent people from getting myopia.

Owner:叶菁

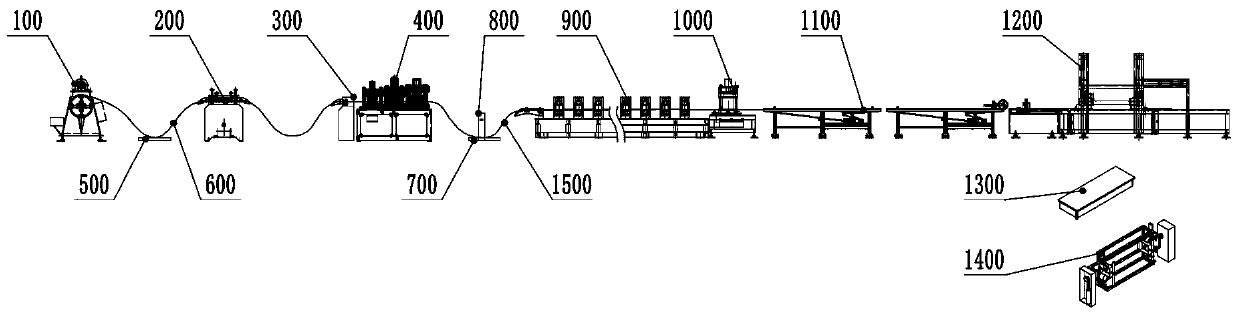

Integrated inductor production line

ActiveCN110534327AImprove work efficiencyTight production cycleCoils manufactureMechanical conveyorsInductorWinding machine

The invention relates to an integrated inductor production line. The integrated inductor production line comprises a winding machine used for manufacturing a winding body, a laser stripping machine used for stripping enameled wires at two ends of the winding body, and a welding machine used for welding the winding body in a seat body. The integrated inductor production line further comprises a conveying table, a guide rail arranged on the conveying table and at least three conveying devices arranged on the guide rail and used for conveying jigs on the winding machine, the laser stripping machine and the welding machine, wherein the winding machine, the laser stripping machine and the welding machine are sequentially arranged along the conveying table. The conveying device comprises a sliding table slidably connected with the guide rail and a driving device arranged on the sliding table and used for driving the sliding table to move on the guide rail. The driving device comprises a servo motor arranged on the sliding table, a precision servo speed reducer connected with the output end of the servo motor and a gear arranged on an output shaft of the precision servo speed reducer. Theintegrated inductor production line is used for automatic production of the integrated inductor, and has the characteristics of high production efficiency and compact production takt.

Owner:深圳感通科技有限公司

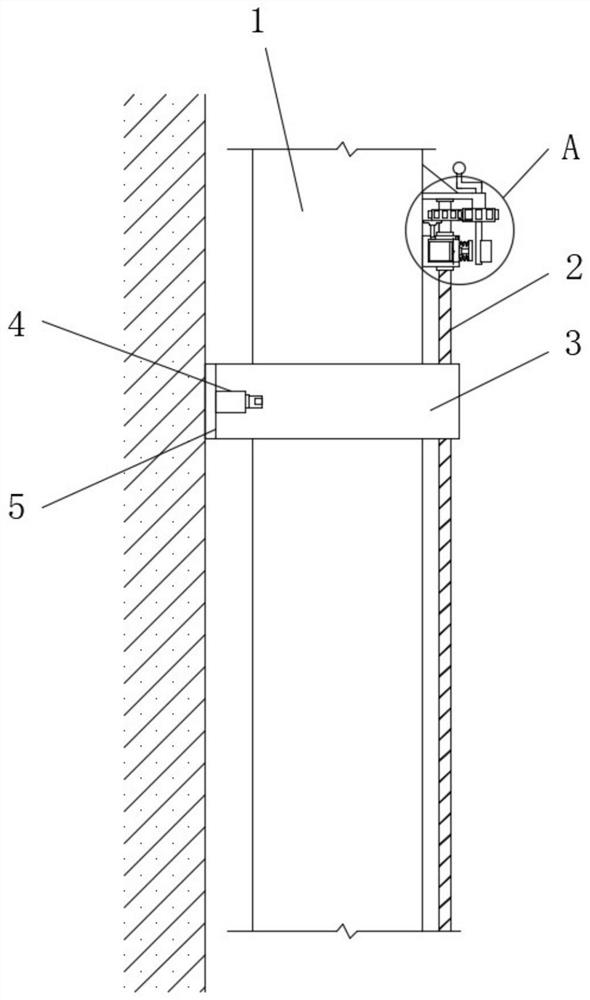

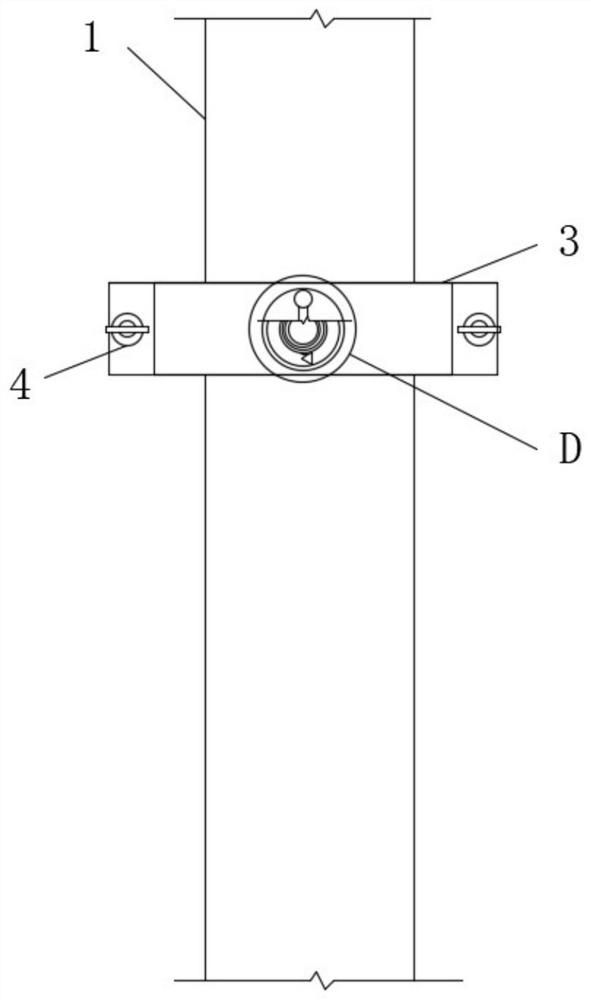

Heating and ventilation pipeline fixed installing structure realizing tight attachment

InactiveCN112503260AEasy to adjustGuaranteed smoothness and lubricationPipe supportsGear lubrication/coolingEngineeringThermodynamics

Owner:温州港臣信息科技有限公司

System and method for producing and culturing liquid spawns of edible fungus

The invention discloses a system and a method for producing and culturing liquid spawns of an edible fungus. The system comprises a nutrient solution sterilized tank, a heat exchanger, a cooling-water machine set and a plurality of liquid spawn culture tanks, and further comprises a nutrient solution circulation pipeline, a nutrient solution sterilization and cooling pipeline, a nutrient solution conveying pipeline, a germ-free compressed air inlet pipeline, a blow-off pipeline and a liquid spawn conveying pipeline. The invention further discloses a method for producing and culturing the liquid spawns of the edible fungus by using the system. According to the system and the method provided by the invention, residue spawns in the liquid spawn culture tanks can be used as stock cultures for again culture, so that the infection risks due to successive vaccination can be avoided; the sterilization, the cooling, the conveying and the germ-free air supply of the spawns are completed in inclosed vessels and pipelines, so that the infection probability is zero; the movement of the liquid spawn culture tanks is avoided, so that the investment is reduced, safety and reliability are realized, the amount of used labor is reduced, and the labor intensity is reduced.

Owner:LIANYUNGANG GUOXIN EDIBLE FUNGUS OF COMPLETE SETSOF EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com