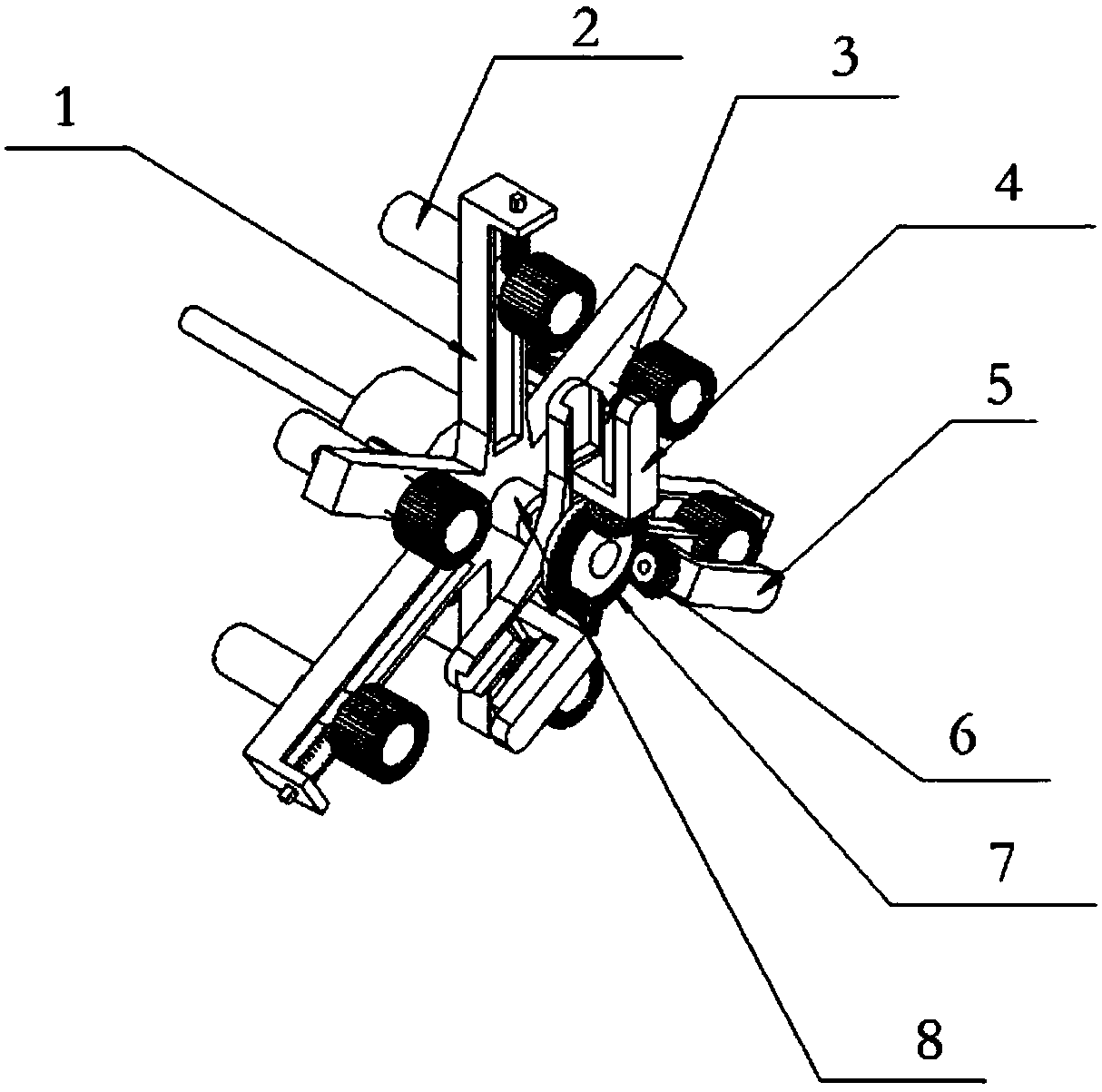

Device and method for machining end part of pipe fitting, and application

A technology for processing devices and pipe fittings, which is applied in the field of pipe fitting end processing devices, can solve the problems of high professional ability requirements, waste of manpower, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0074] The sixth typical implementation of the present invention differs from the fifth typical implementation in that the rotating wheel is replaced by a cylindrical soft brush to clean the pipe to be tested for surface inspection of the pipe.

[0075] The present invention can also be used for milling and centering of irregular pipe fittings. The following two examples can be described.

[0076] The seventh typical implementation of the present invention is different from the third typical implementation in that the flap wheel is replaced by a milling cutter, so that the pipe to be tested can be milled.

[0077] The eighth typical implementation of the present invention differs from the seventh typical implementation in that the milling cutter is replaced by a ratchet with a toothed structure on the surface, so that the pipe to be tested can be milled, and the irregular pipe can be milled. just.

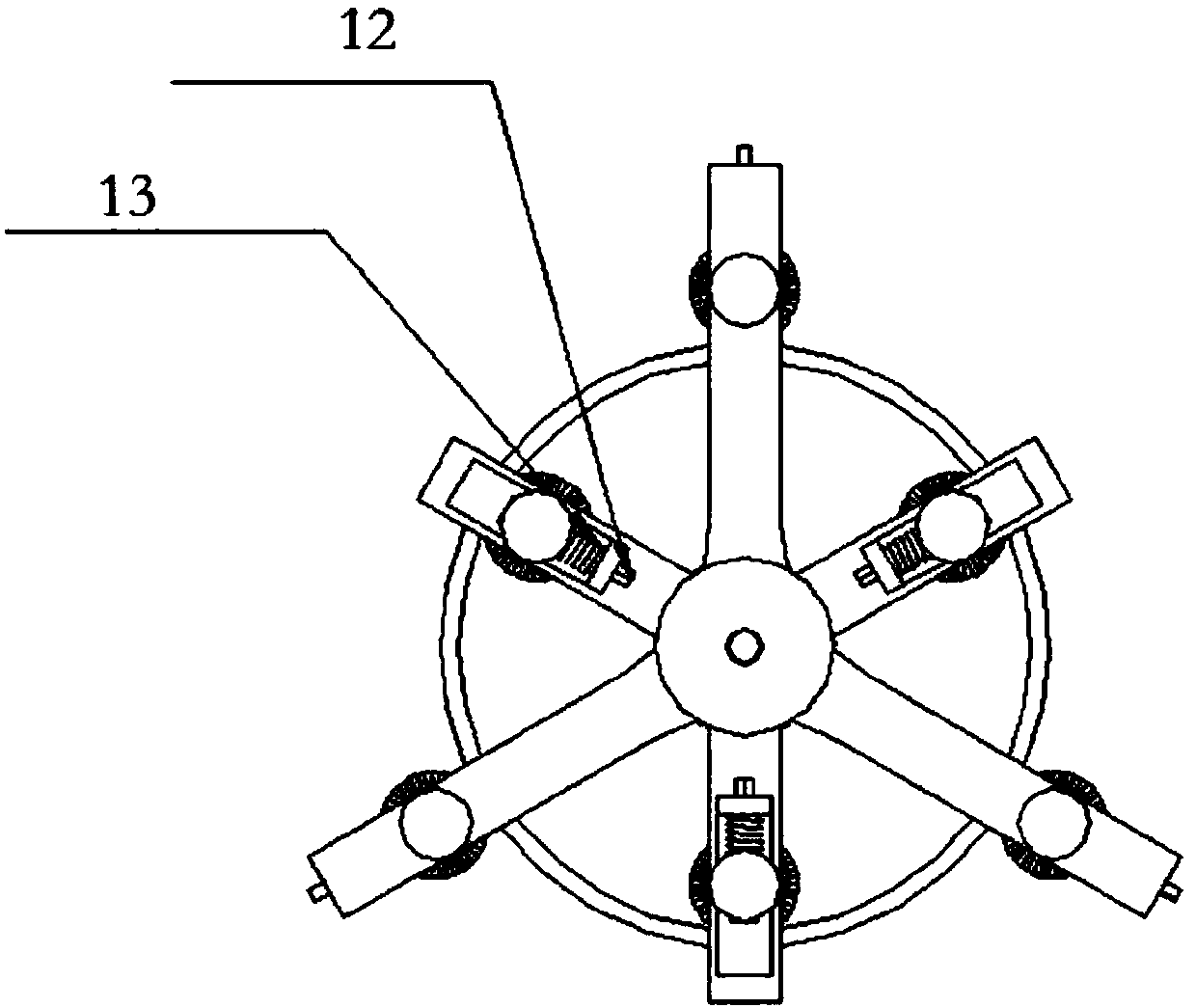

[0078] Of course, the number of jaws of the self-centering chuck is not nece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com