Cold light integrated curing device and method for optical fiber gyroscope sensitive optical fiber ring

A fiber optic gyroscope and curing device technology, applied in measuring devices, instruments, etc., can solve the problems of uneven curing intensity, low production efficiency, and large production energy consumption of a single bulb irradiating an optical fiber ring, and achieve feasibility and operability performance, improve curing efficiency, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The structure and working principle of the present invention will be described below in conjunction with the drawings and embodiments, and the examples given are only used to explain the present invention, but not to limit the protection scope of the present invention.

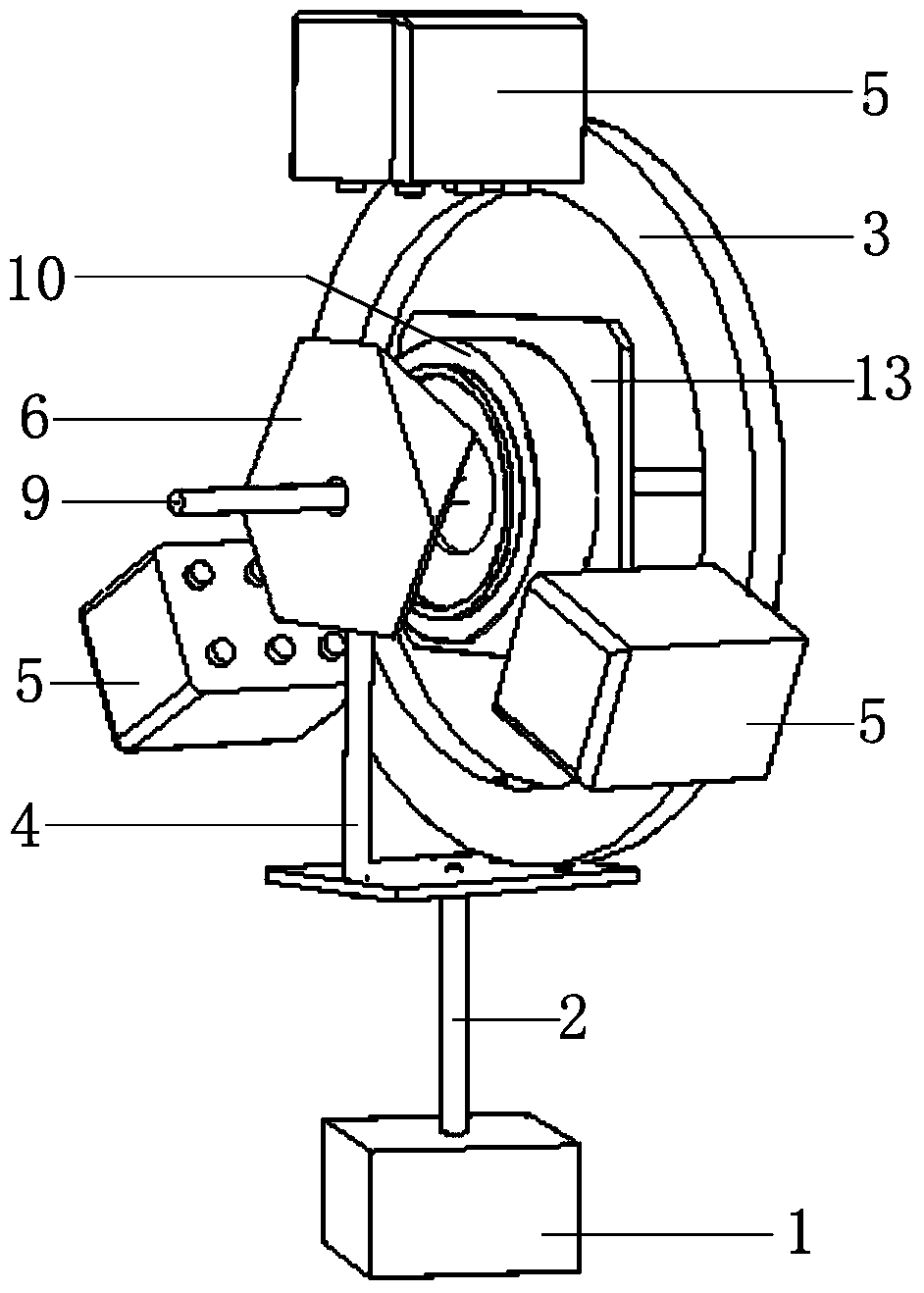

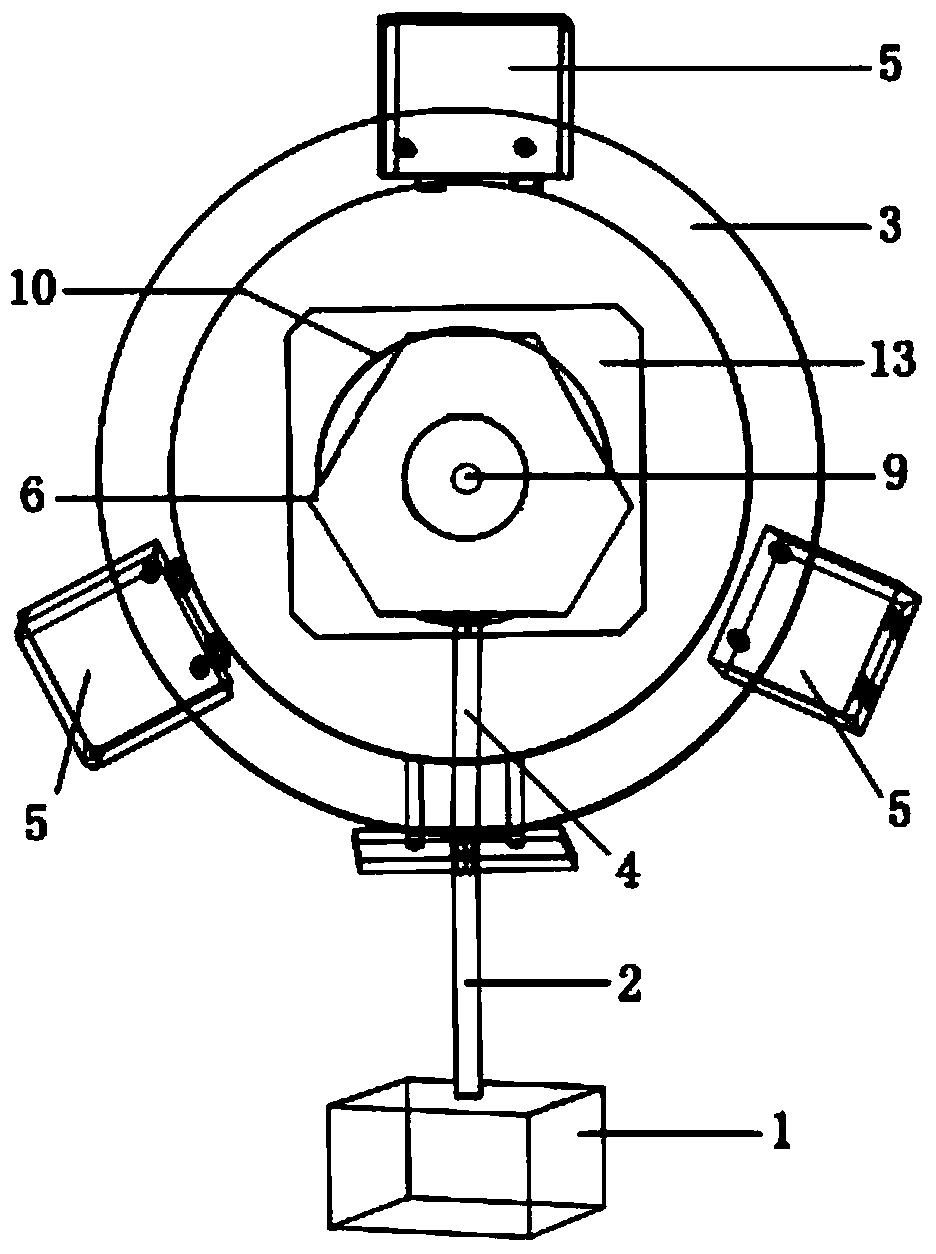

[0031] Such as figure 1 , 2 As shown, the device is generally divided into three parts: a fixed part, a light source part and a rotating shaft control part.

[0032] Wherein, the fixed part includes a stable base 1, on which a support 2 is fixed, the support 2 supports a fixed frame 3 on the one hand, and supports a threaded post 4 with a threaded end on the other hand. . The base 1, the support 2, the fixed frame 3, and the threaded column 4 constitute the fixed part.

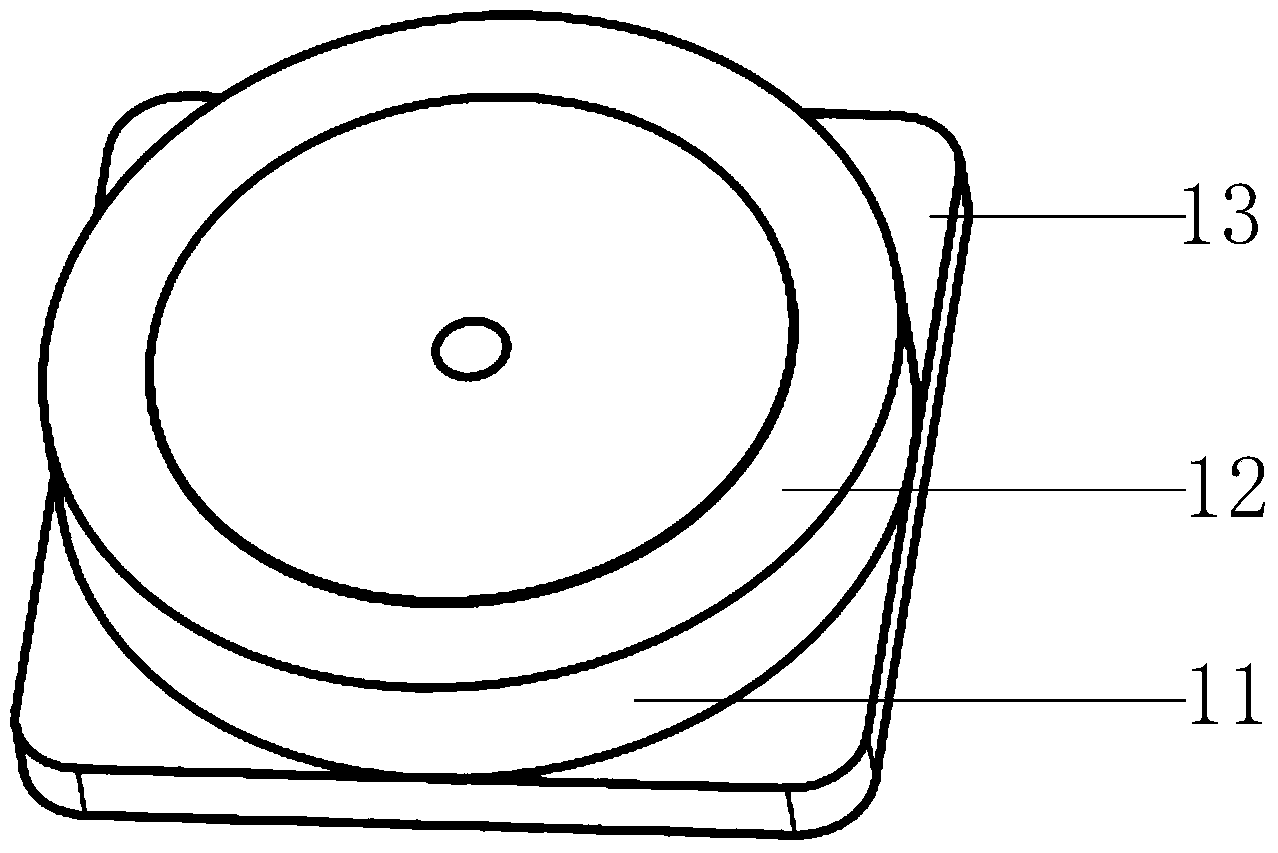

[0033] On the fixed frame 3, several LED ultraviolet lamps 5 are uniformly fixed; a polyhedral reflector 6 is connected to the threaded end of the threaded column 4, and the polyhedral reflector 6 is positioned at the front of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com