Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "No bad situation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

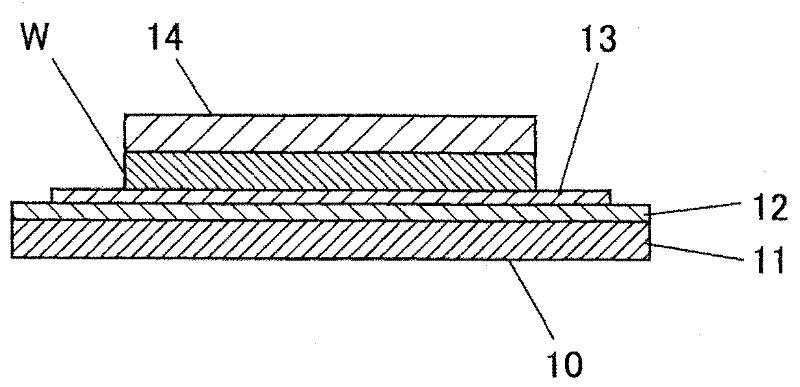

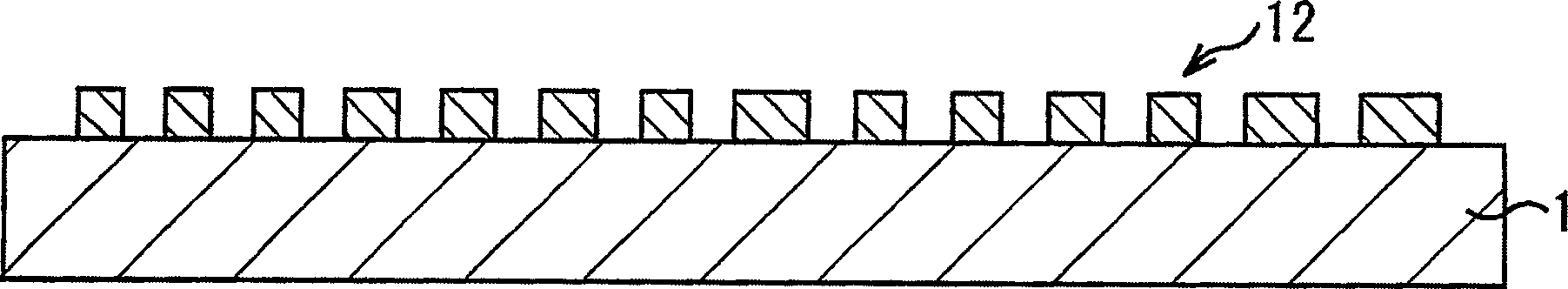

Adhesive tape for wafer processing

ActiveCN102206469ANo bad situationUniform expansionFilm/foil adhesivesSemiconductor/solid-state device manufacturingSoftening pointCement

The invention provides adhesive tape for wafer processing, which has uniform expansion suitable for application for truncating cement layers through expansion and sufficient shrinkage shown in a heating contraction process and results in no unfavorable conditions due to relaxation after the heating contraction process. The expansive adhesive tape 10 which is suitably applied for truncating a cement layer (13) along the wafer through expansion has a base material film 11 which is made of thermoplastic crosslinking resin provided with a Vickers softening point more than 50 DEG but less than 90 DEG as specified in JIS K7206 and having a stress increased over 9 MPa due to heating contraction.

Owner:FURUKAWA ELECTRIC CO LTD

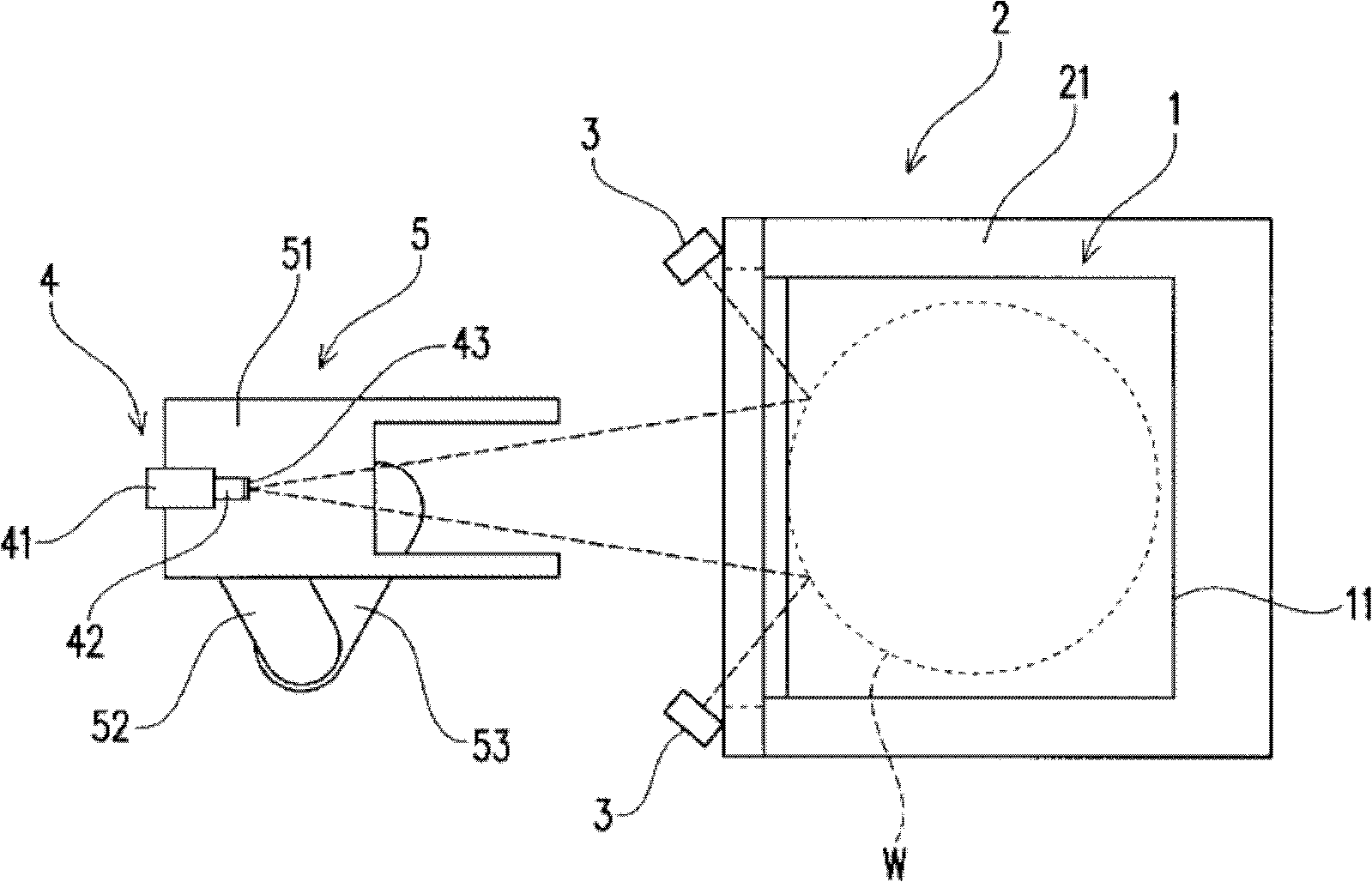

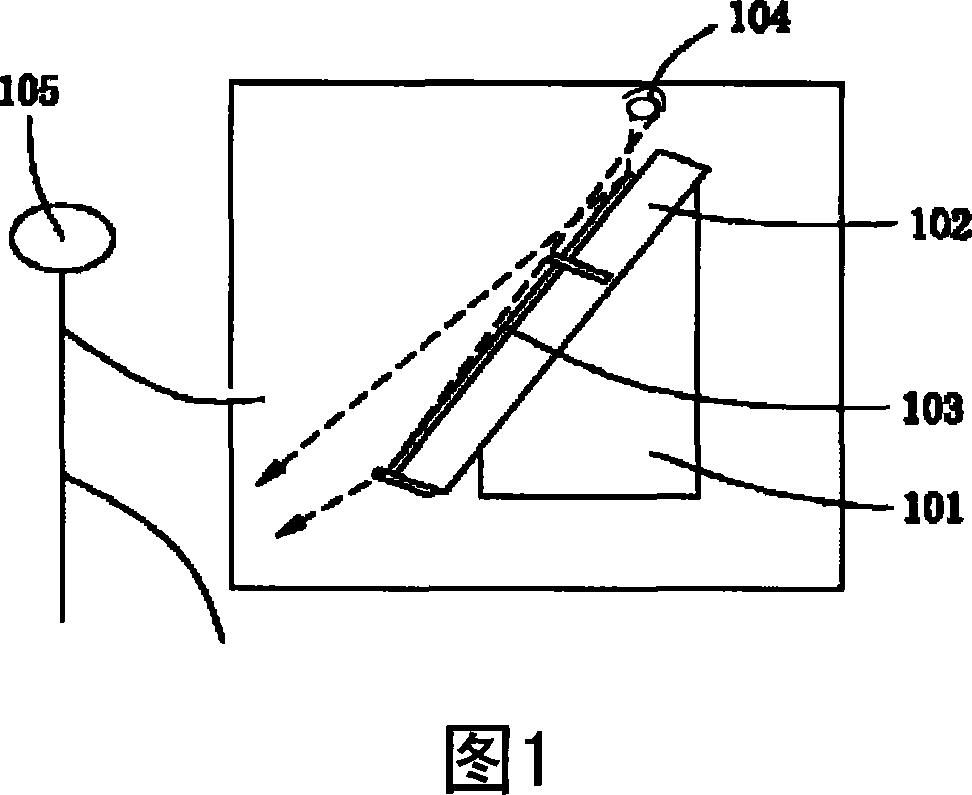

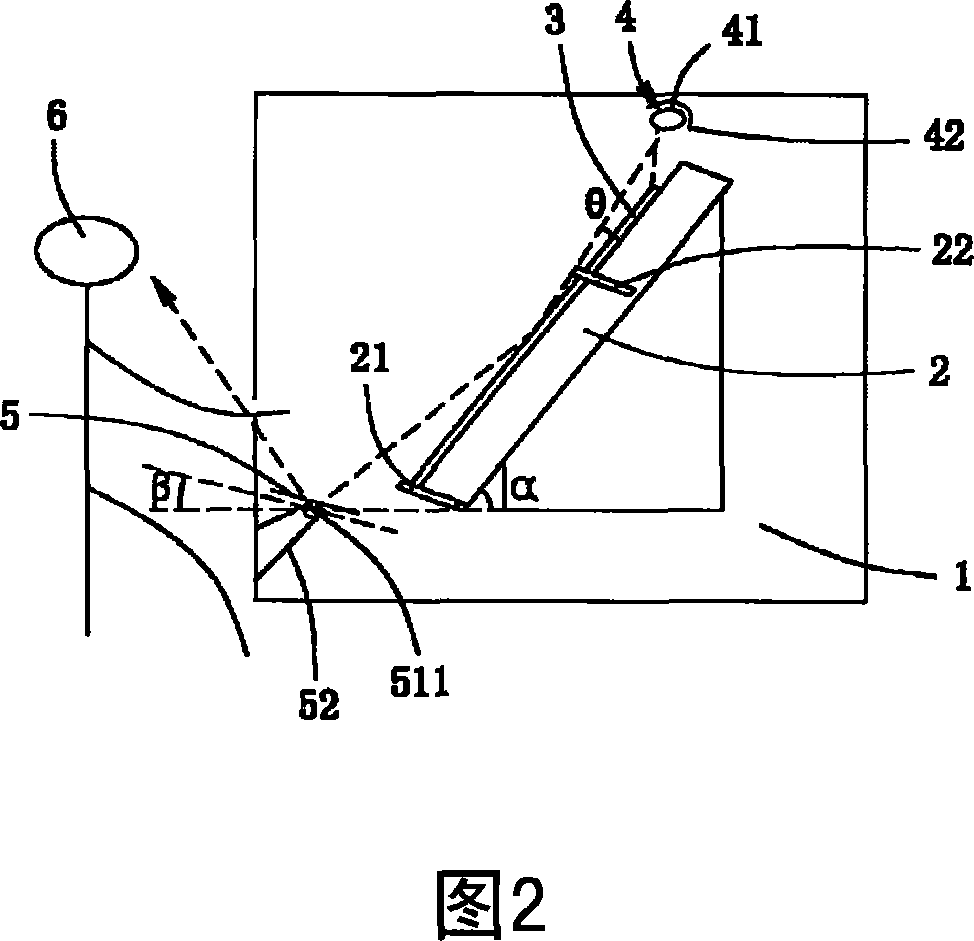

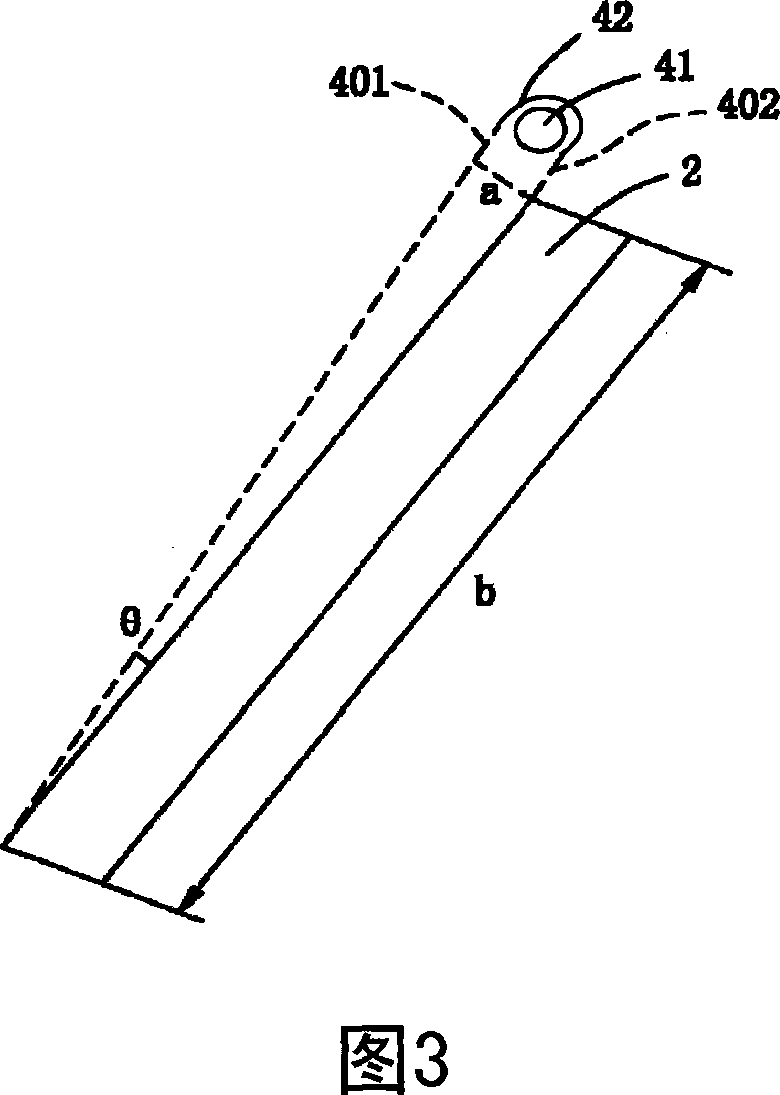

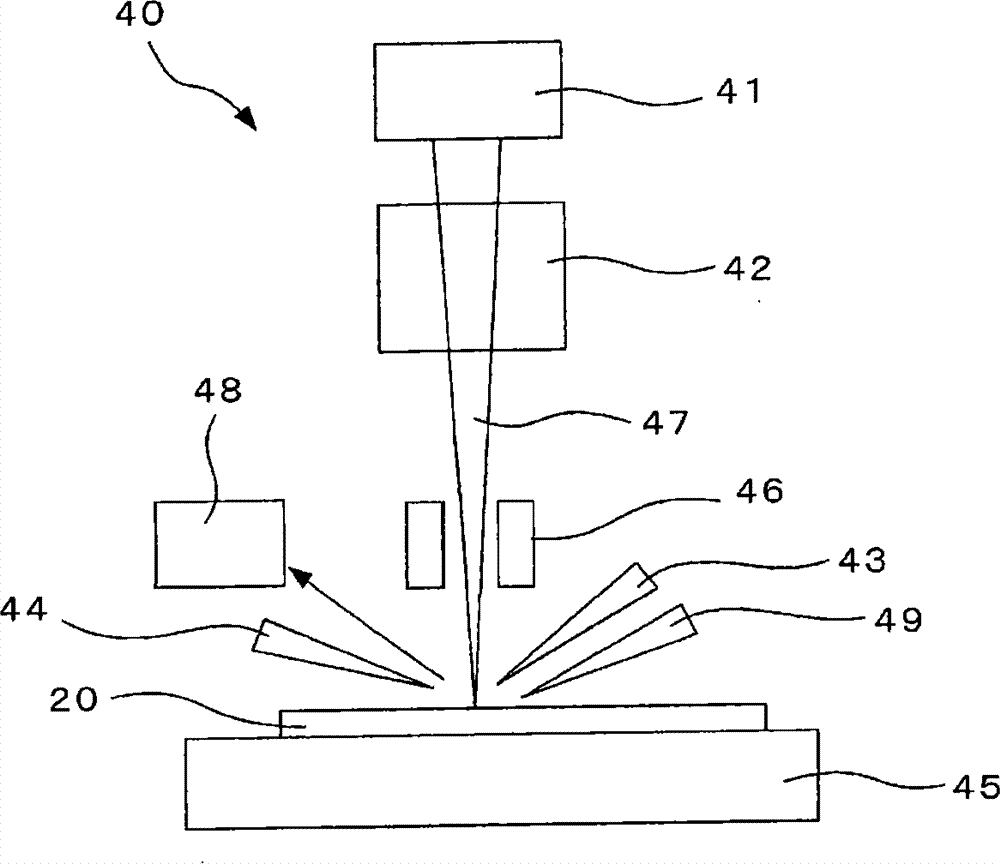

Wafer detecting apparatus

ActiveCN102576687ANo bad situationAccurate detectionSemiconductor/solid-state device manufacturingUsing optical meansEngineering

Disclosed is a wafer detecting apparatus which can accurately detect a wafer storage state. The wafer detecting apparatus detects the storage state of a plurality of wafers (W) in a wafer storing container (1), which is capable of storing the wafers by stacking the wafers in the vertical direction and is capable of having the wafers carried in and out from the front. The wafer detecting apparatus is provided with: a long illuminating apparatus (3), which irradiates the wafers in the wafer container (1) with light, and which is long in the vertical direction; and an image pickup apparatus (4) having reflected light inputted thereto, said reflected light being the light emitted from the illuminating apparatus (3), applied to the wafers (W) and reflected. The image pickup apparatus (4) is disposed on the front side of the wafer storing container (1), and the illuminating apparatus (3) is disposed on the left and / or the right side of the image pickup apparatus (4).

Owner:SHINKO ELECTRIC CO LTD

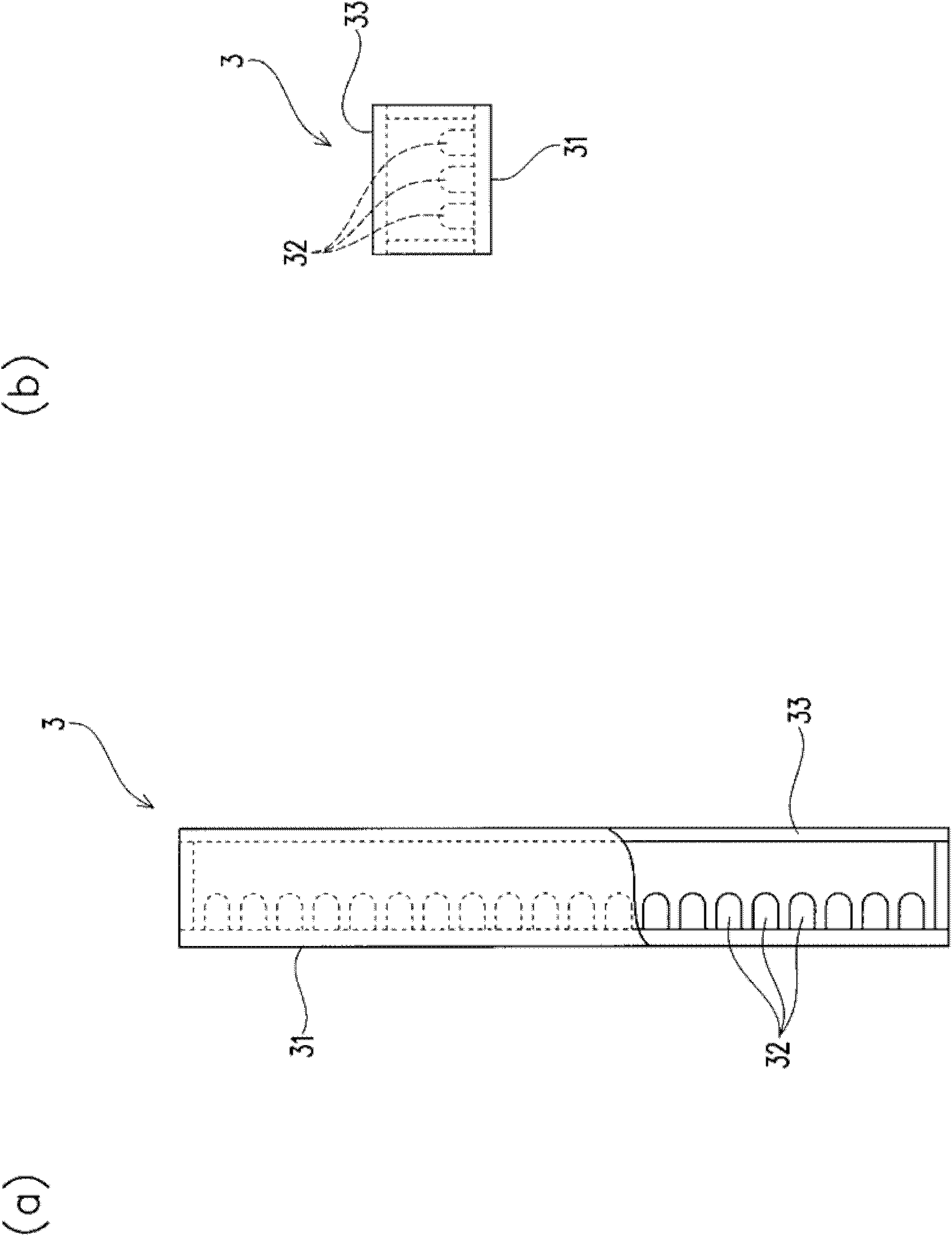

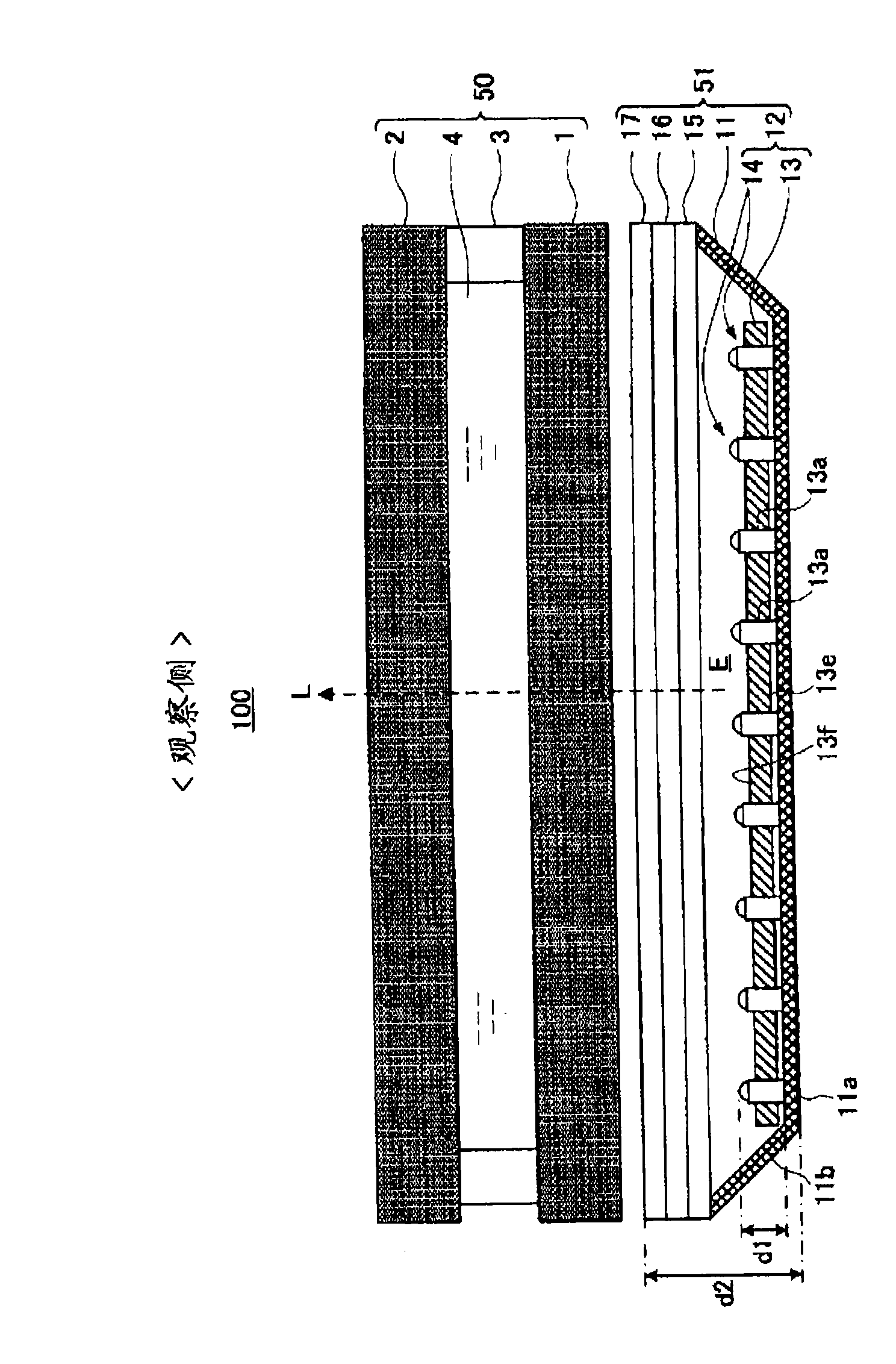

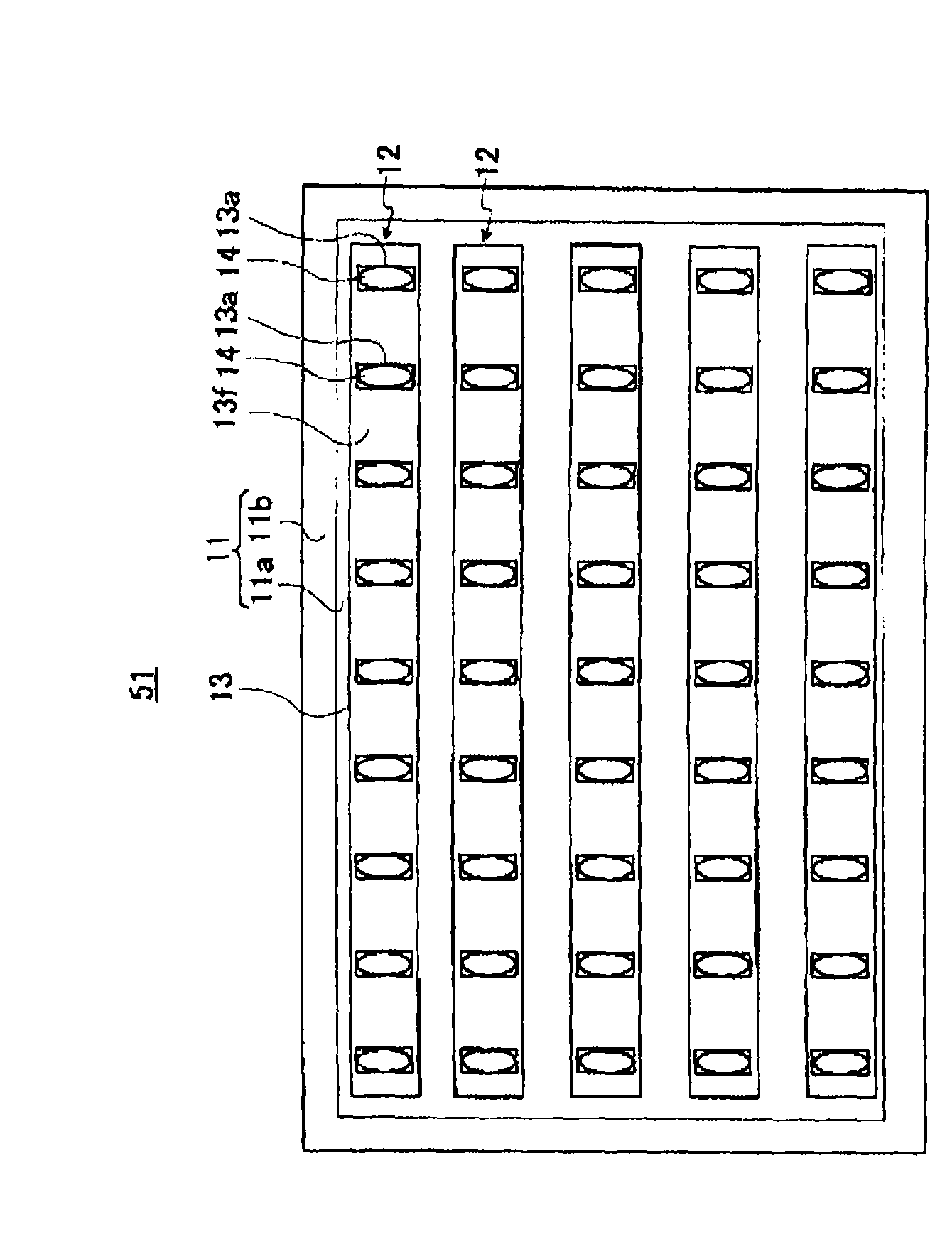

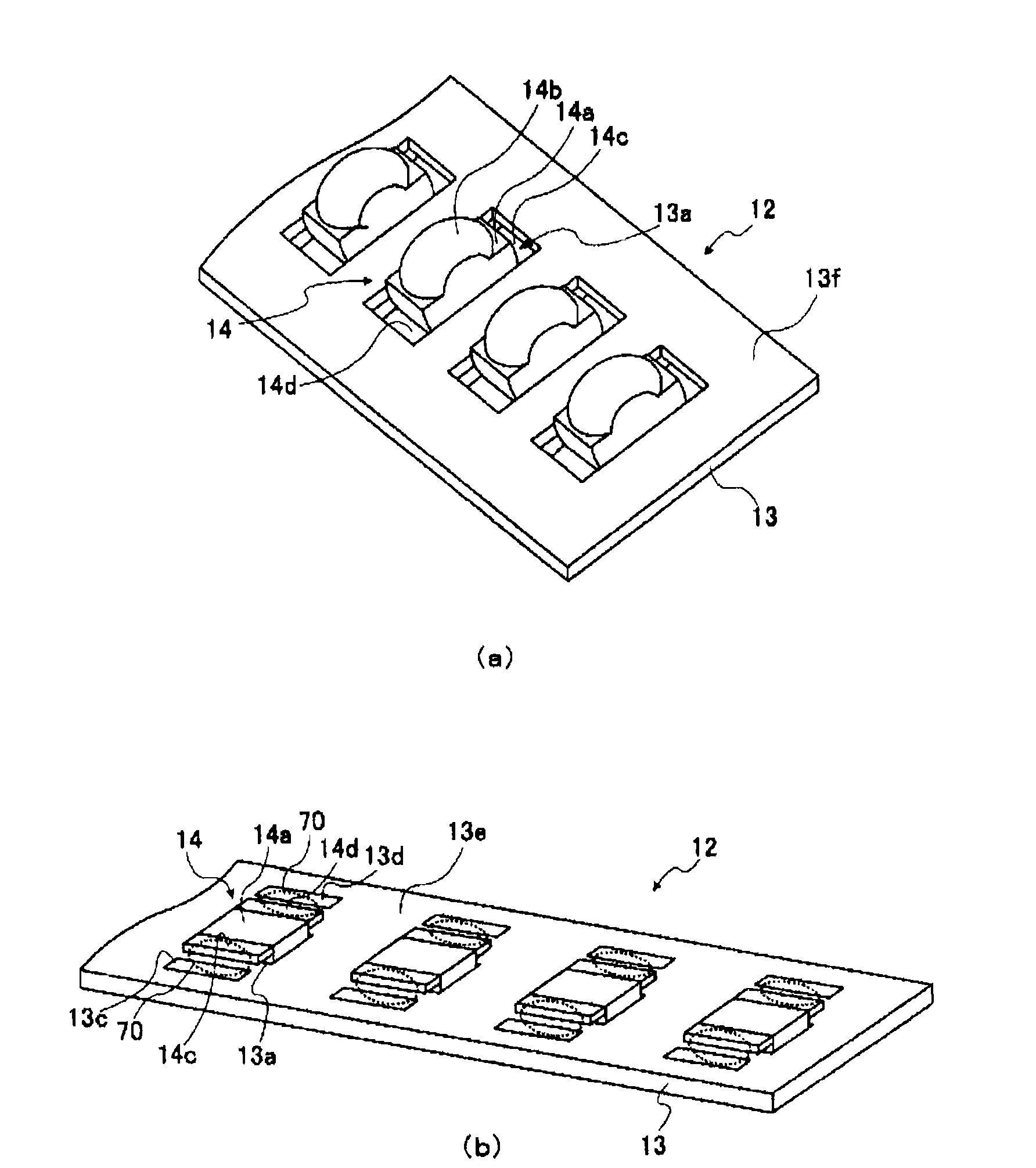

Lighting device, electro-optic device, and electronic device

InactiveCN101566290AThe overall thickness is thinAchieve thinningPoint-like light sourceNon-linear opticsElectricityLiquid-crystal display

The invention relates to a lighting device, a liquid crystal display device and an electronic device; miniaturization and thin type of a light source unit can be realized in a vertical typed lighting device. The lighting device is a so-called vertical type lighting device, and comprises a circuit board and light source units of a plurality of light sources connected with the circuit board. Particularly in the light source unit, each light source is allocated on the circuit board in a manner that at least part of the light source is positioned on the width direction of the circuit board or the internal part of the circuit board. Concretely, each light source is allocated on the circuit board in a state that at least a part of base material composing each light source enters run-through holes arranged on the circuit board. Therefore, at least a part of each light source is partially overlapped with the width direction part of the circuit board or the internal part of the circuit board. Thus, the width of the light source unit can become thinner compared with the light source unit formed by allocating light source on the circuit board.

Owner:EPSON IMAGING DEVICES CORP

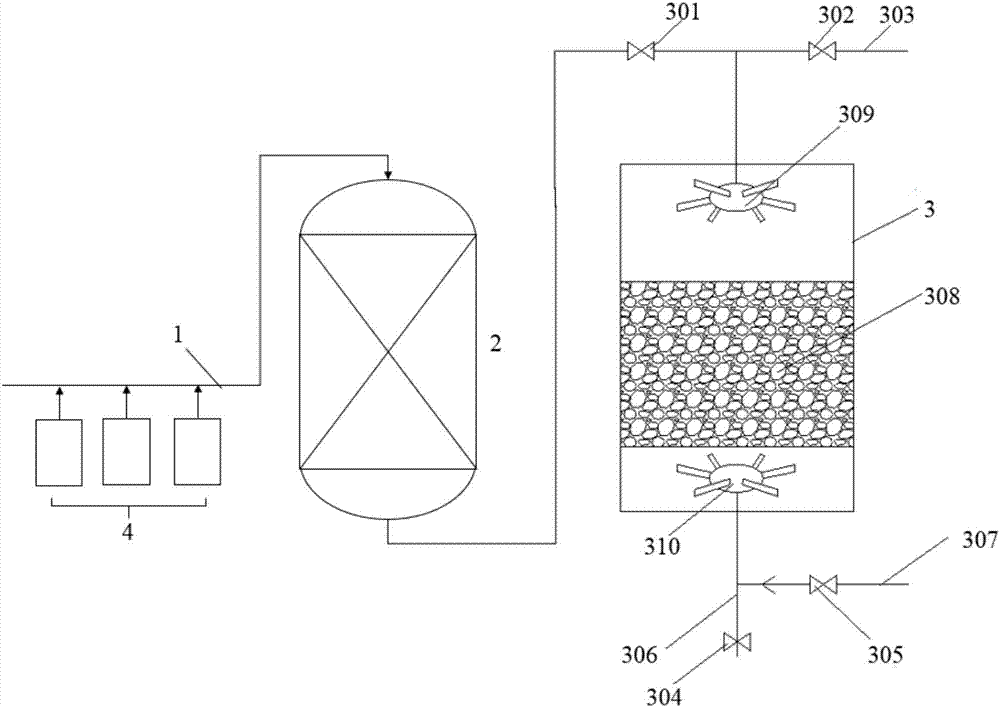

Method for treating coking biochemical effluent by microwave-oxidation-coagulation technology

ActiveCN101767912AReduce usageImprove processing efficiencyWater/sewage treatment by magnetic/electric fieldsMultistage water/sewage treatmentSludge cakeMicrowave oven

The invention provides a method for treating coking biochemical effluent by microwave-oxidation-coagulation technology, which comprises the following steps of: A, adding a mixed reagent consisting of H2O2 and Fe2+ into the coking biochemical effluent until the mass concentration of hydrogen peroxide in water is between 0.01 and 1 percent, and controlling the pH to between 2.0 to 6.0; B, delivering the mixed liquid into an industrial microwave oven for processing for 5 to 60s; C, regulating the pH value of the mixed liquid to between 6.0 and 6.5 or 7.5 and 8.5, and carrying out oxidation treatment for 1 to 4 hours under an aeration condition that the aeration rate is 10 to 40m<3> / h; D, adding a coagulant into the liquid until the mass concentration of the coagulant in the liquid is betweenone millionth and one hundred thousandth; E, precipitating and separating; F, filtrating the liquid to obtain process effluent for recycling; and G, collecting sludge, separating the liquid from the sludge; and returning the liquid to the step D, and filter-pressing the sludge to obtain sludge cakes. The method realizes recycling, does not discharge sewage, and effectively solves the problem thatpresent coking sewage is difficult to treat and to recycle.

Owner:云南天朗环境科技有限公司

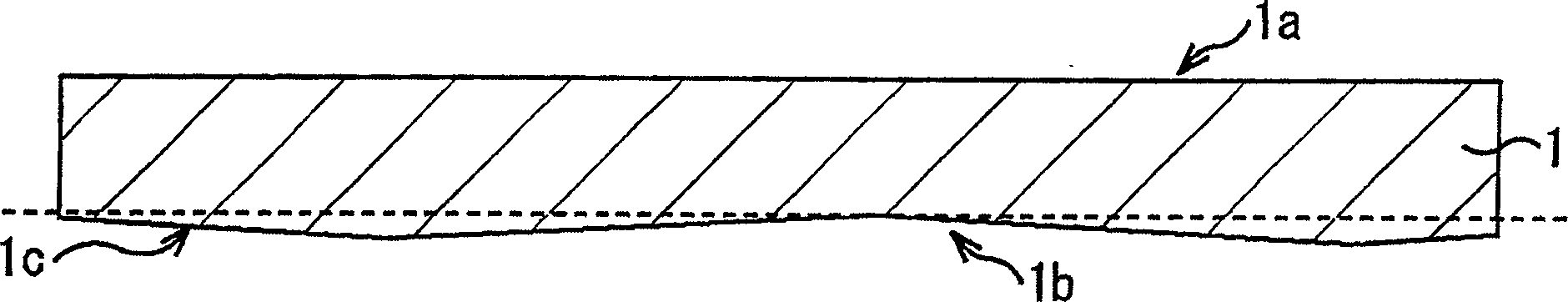

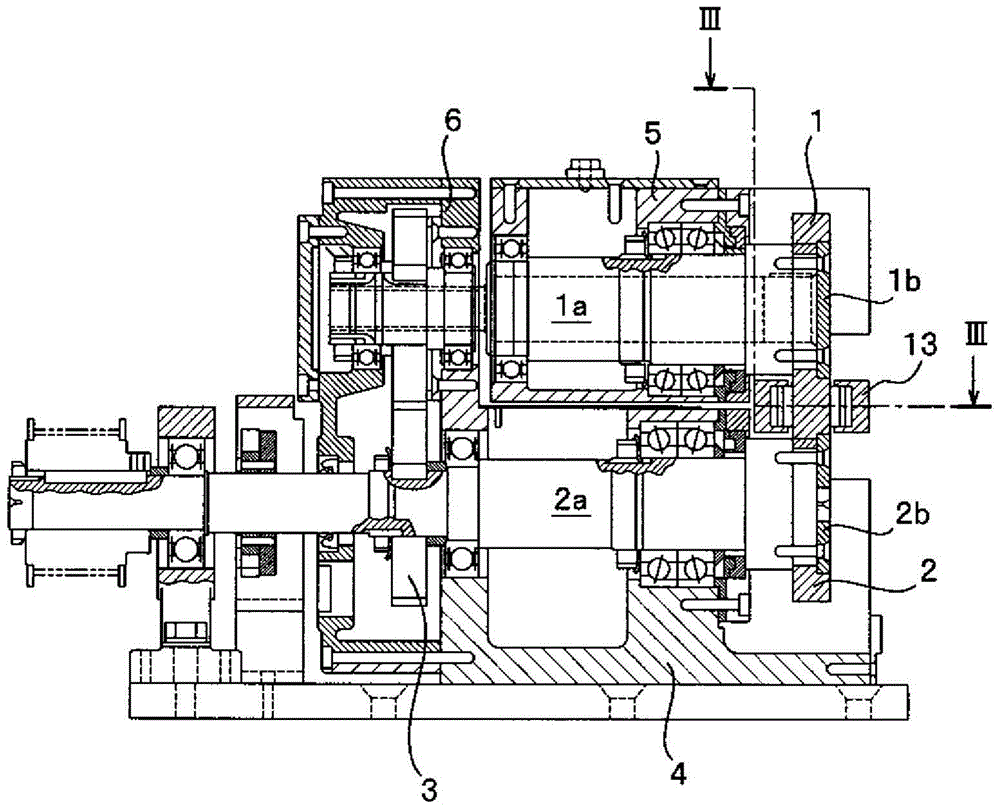

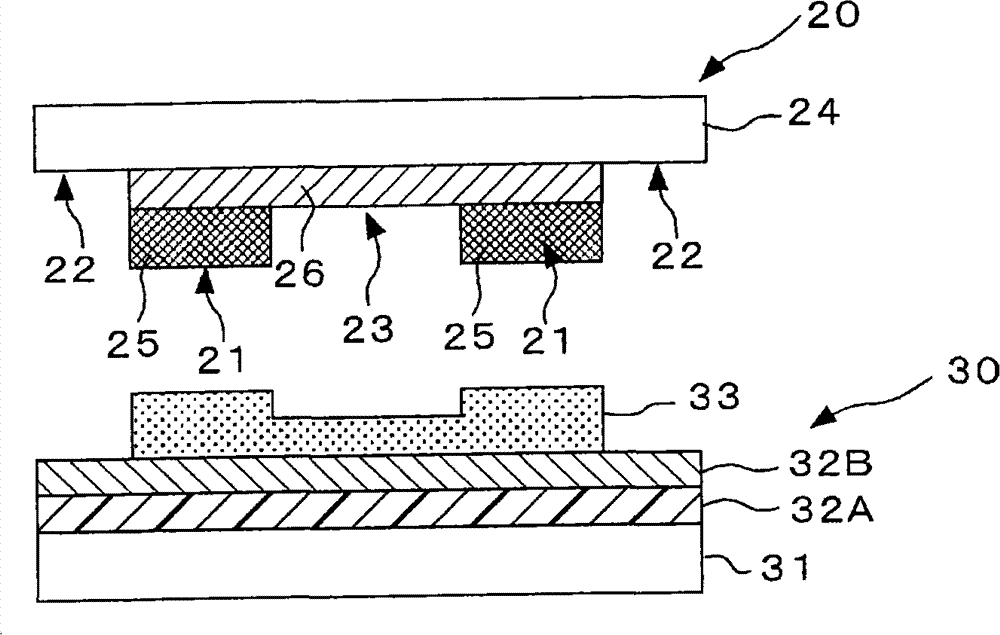

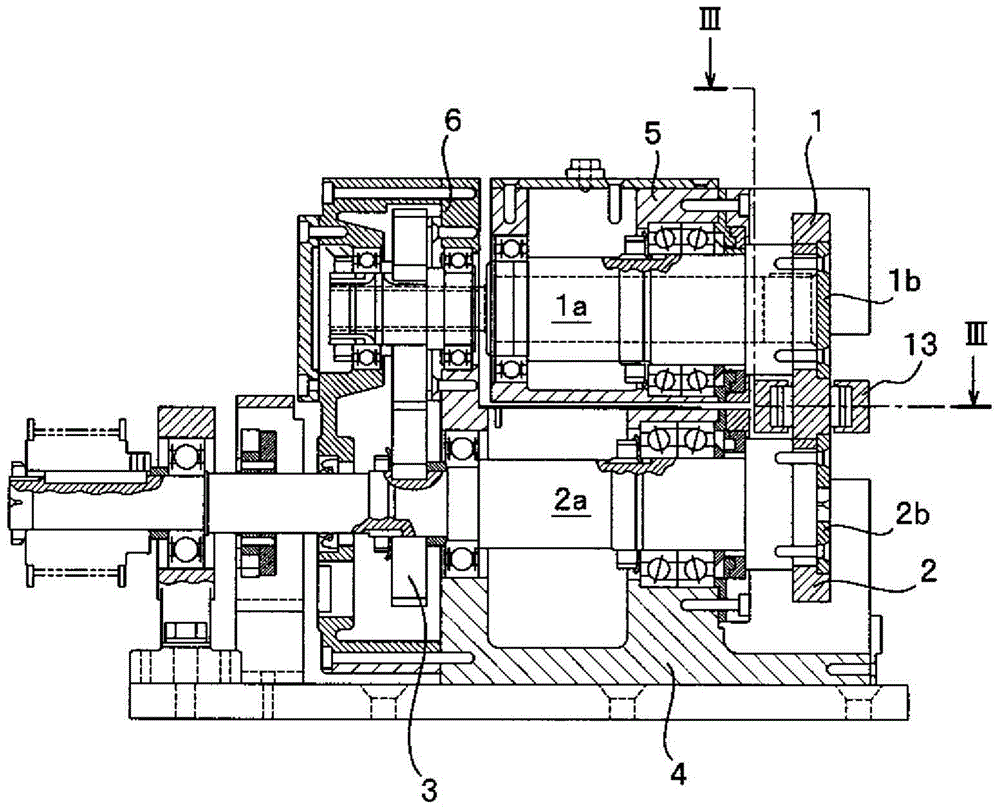

Method for forming bumps, semiconductor device and method for manufacturing same, substrate processing apparatus, and semiconductor manufacturing apparatus

InactiveCN1685489AImprove reliabilityInexpensive and high-speed planarizationSolid-state devicesSemiconductor/solid-state device manufacturingResistSingle point

The rear (1b) of a semiconductor substrate (1) is fixed to the support face (11a) of a substrate support base (11) by vacuum clamping. The thickness of the semiconductor substrate (1) is uniform by planarizing the rear (1b), and the rear (1b) is forcedly free of waviness caused by the vacuum clamping to the support face (11a), so that the rear (1b) functions as the reference face of the planarization of the front (1a). In this state, Au projections (2) on the front (1a) and the surface layer of a resist mask (12) is cut with a single point tool (10) to planarize the surface of Au projections (2) and that of the resist mask (12) so as to be flat continuously. Thus, instead of CMP, the surface of a fine bump formed on a substrate is planarized at low cost low costly and speedily.

Owner:FUJITSU LTD

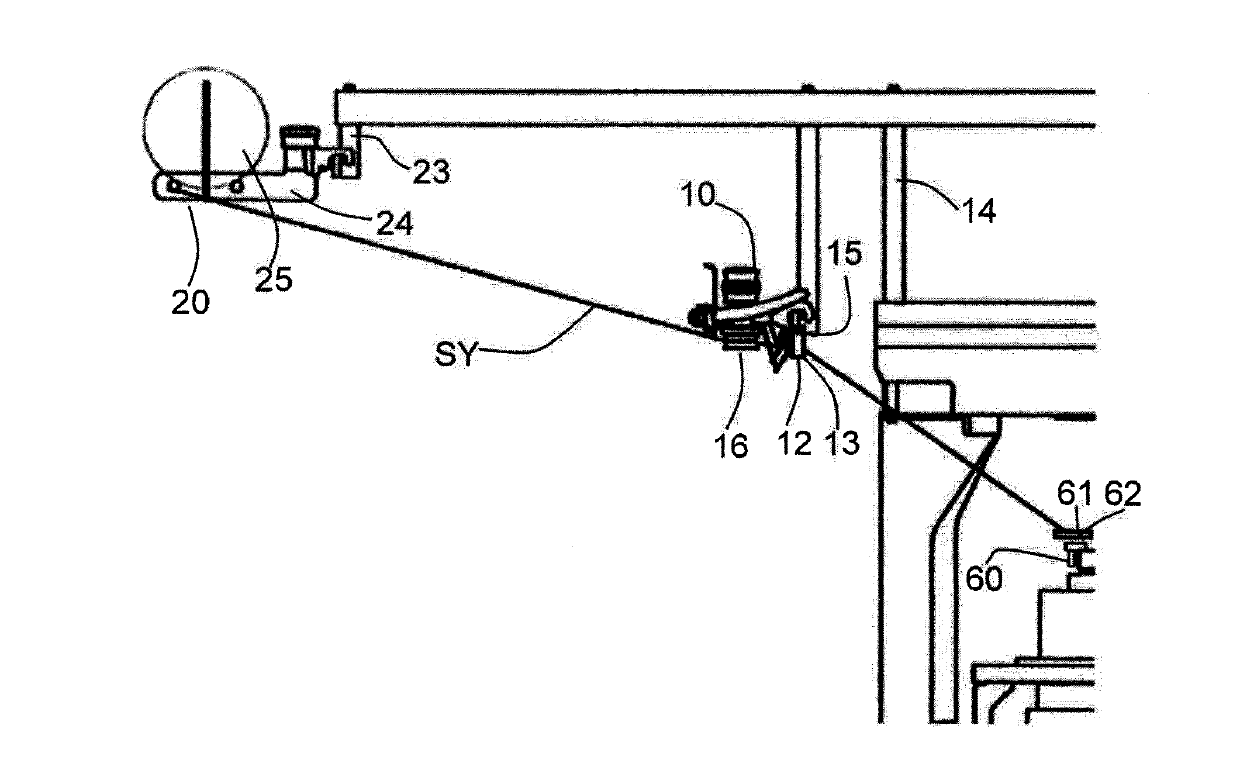

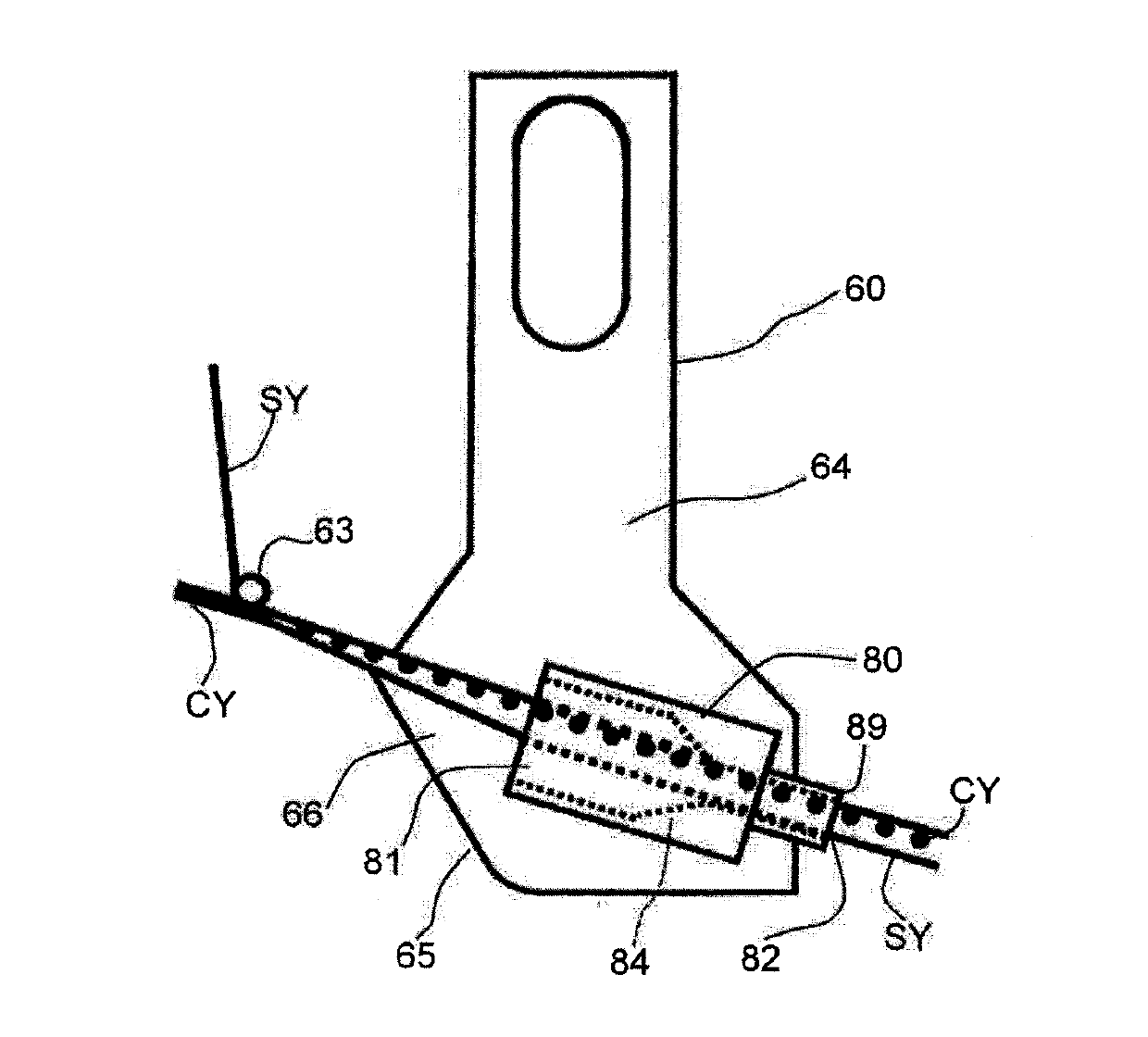

Slit yarn knitting method in circular knitting machine, apparatus therefor and knit fabric

InactiveCN103306036AReduce manufacturing costNo bad situationOrnamental textile articlesCircular knitting machinesYarnEngineering

A method for knitting a slit yarn made of a sheet-like raw material and having a width of several millimeters by a knitting machine while covering a core yarn with the slit yarn, an apparatus used therefor and a knit fabric obtained thereby are provided. A slit yarn feeding device is provided for feeding a slit yarn (SY), separately from a yarn feeding device for feeding a core yarn (CY). A covering means (80) for wrapping the core yarn (CY) in the slit yarn (SY) is provided between the slit yarn feeding device and a knitting portion (50). Also provided is a guide means (12, 61, 63) for guiding the slit yarn (SY) from the slit yarn feeding device to the covering means (80) such that the slit yarn (SY) will not be twisted and will not crease, and a front and back thereof will not be inverted.

Owner:PRECISION FUKUHARA WORKS

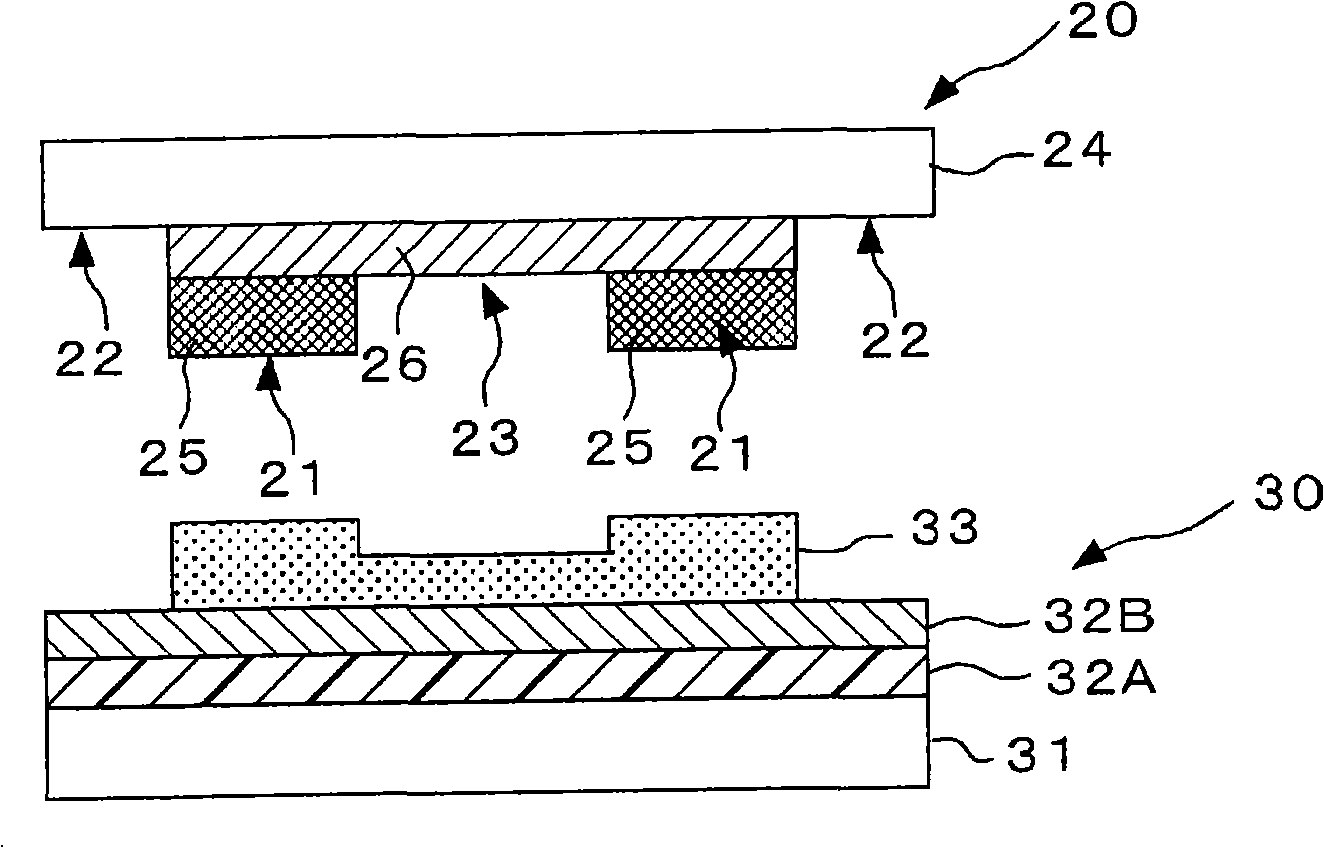

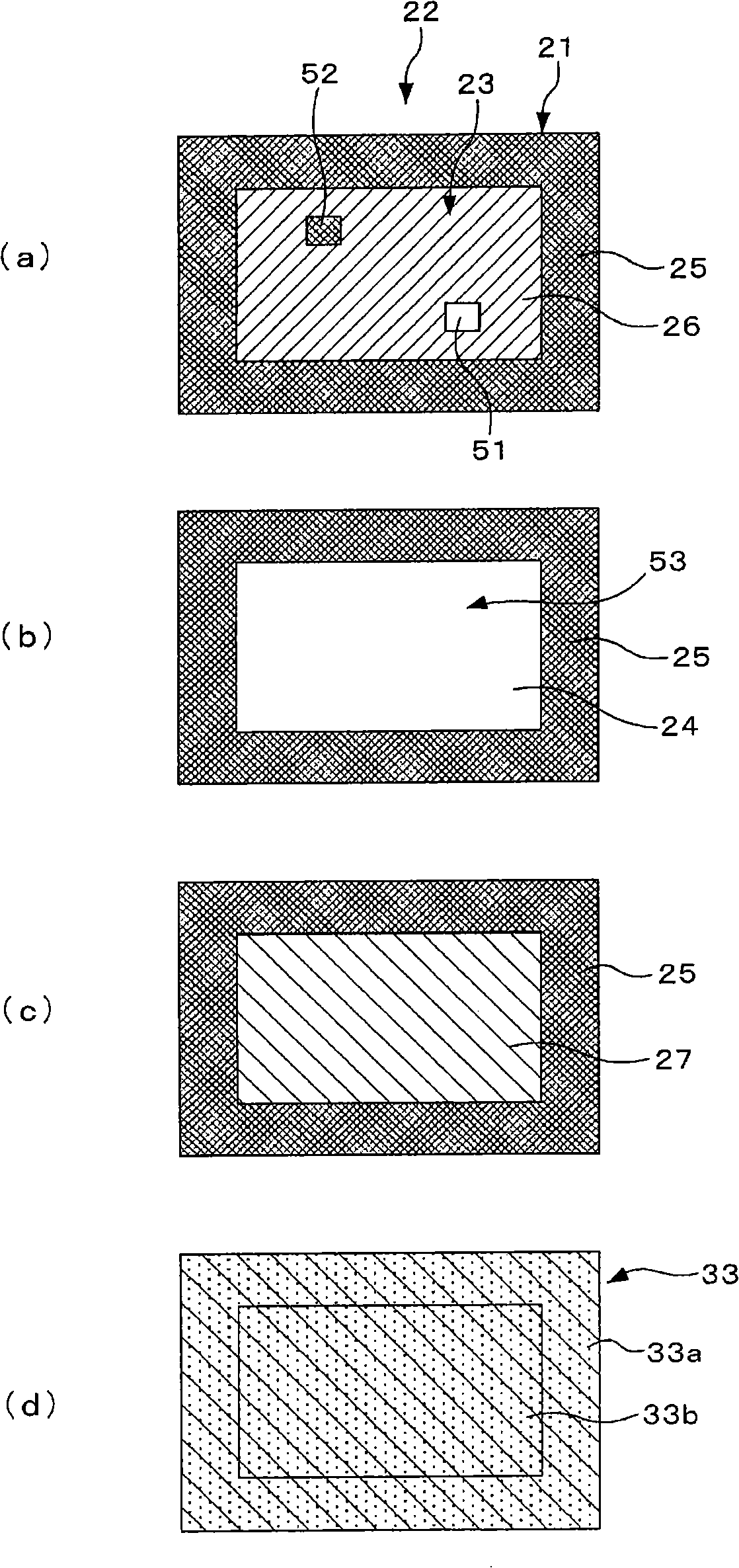

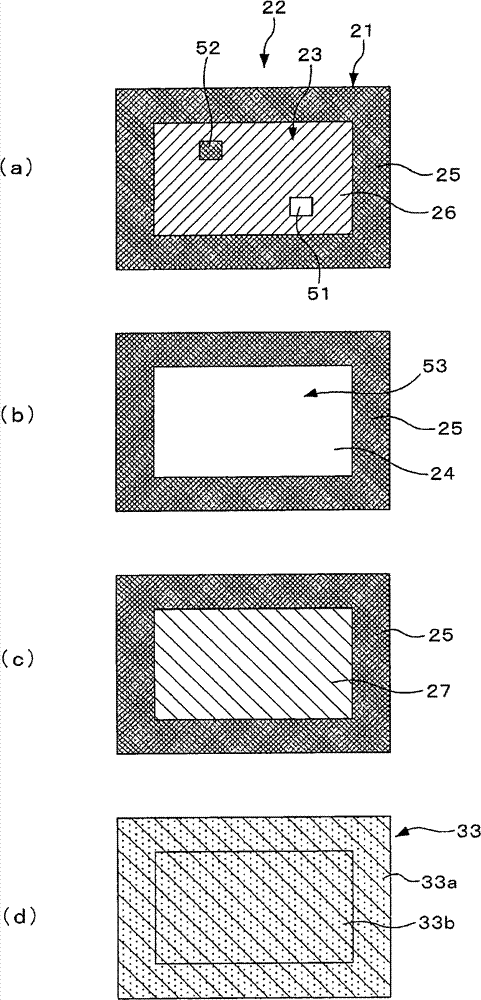

Fault correcting method for gray tone mask, gray tone mask and manufacturing method thereof

InactiveCN101339362ACorrection is appropriateReduced efficiency of evasion checksPhotomechanical apparatusOriginals for photomechanical treatmentGray levelComputer science

The invention provides a gray level mask defection correcting method, that is a gray level mask defection correcting method for a semi-translucent section (23) having a shading section (21), a translucent section (22) and reducing translucent amount of exposal light to specified amount. The semi-translucent section (23) formed by semi-translucent film (26), and has a working procedure for determining the defection parts (51), (52) when generating defection in the semi-translucent section (23); a working procedure all semi-translucent film (26) of the semi-translucent section including the defections (51), (52), that is an area surrounded by at least on of the shading section and the translucent section; and a working procedure forming semi-translucent correcting film (27) different from raw material or composition of the semi-translucent film (26) at the semi-translucent film (26) removed area (53).

Owner:HOYA CORP +1

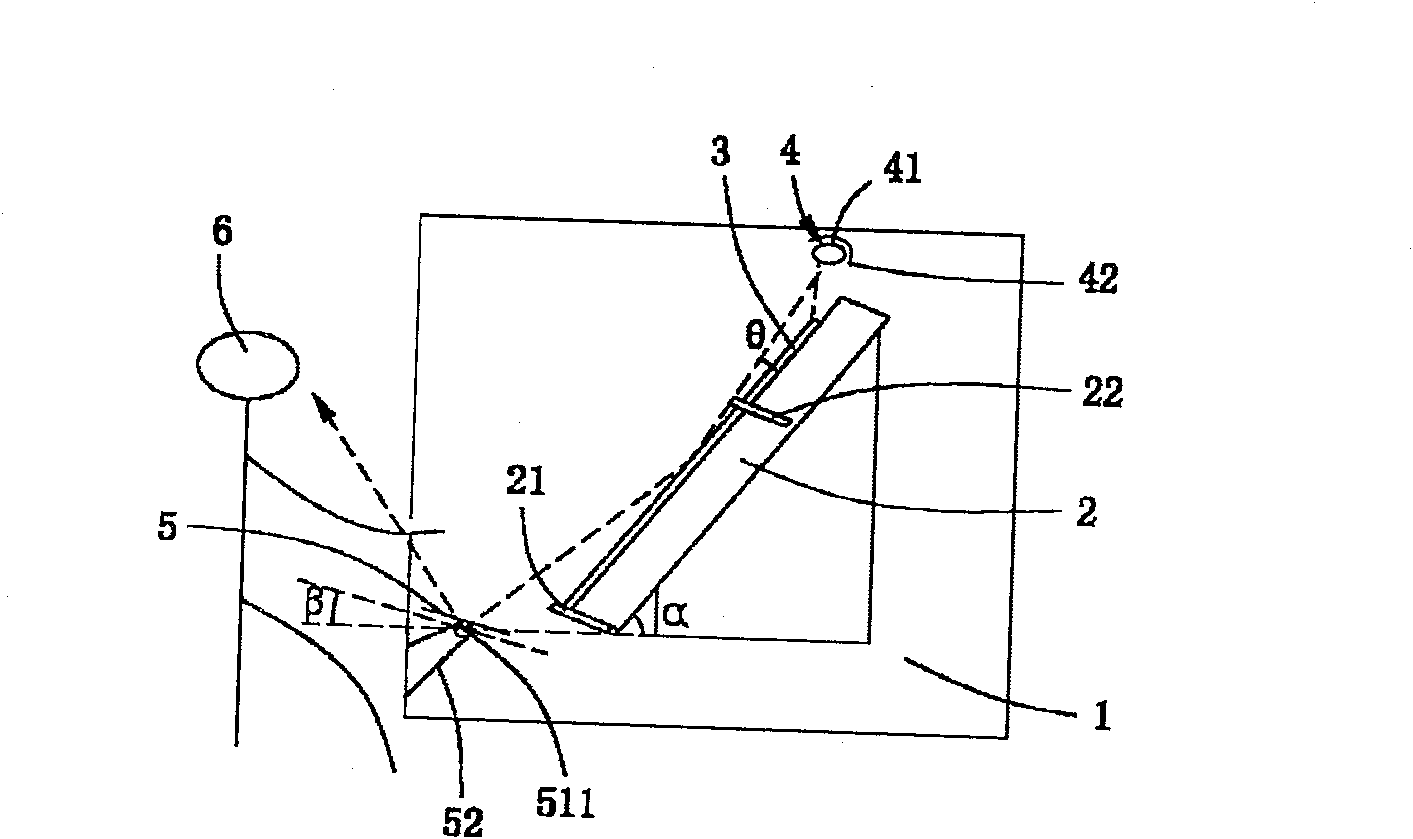

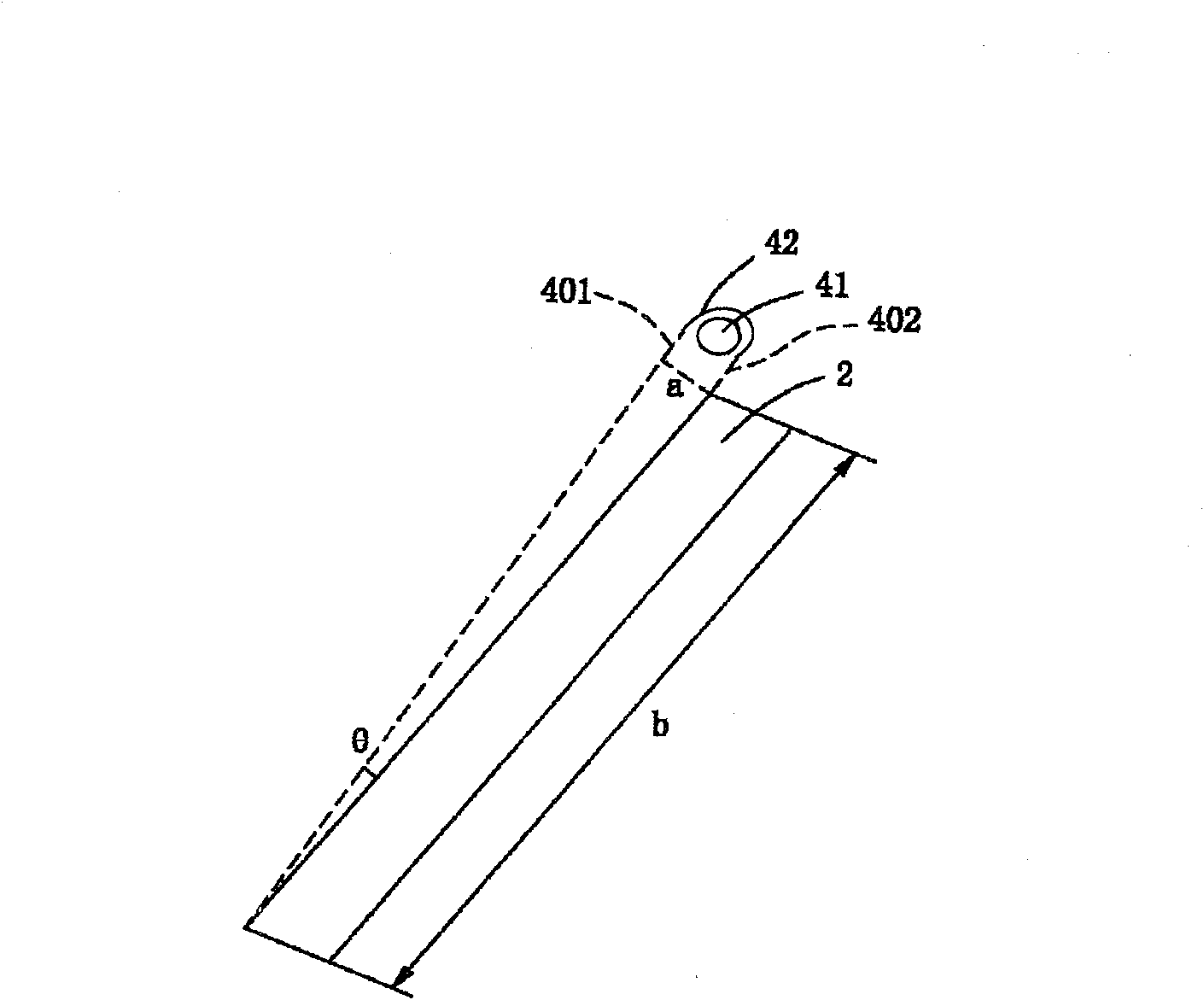

Plate processing apparatus

A plate processor comprises a carrier platform for supporting a plate product as the glass baseboard of liquid crystal display device, a light source at one end of the platform for lighting the baseboard on the platform, and a mirror at another end opposite the light source on the platform, to reflect the light reflected from the baseboard on the platform secondary, into eye of operator. Therefore, operator can clearly watch the processing state on the surface of the baseboard on the platform, as clearness or the like.

Owner:AU OPTRONICS CORP

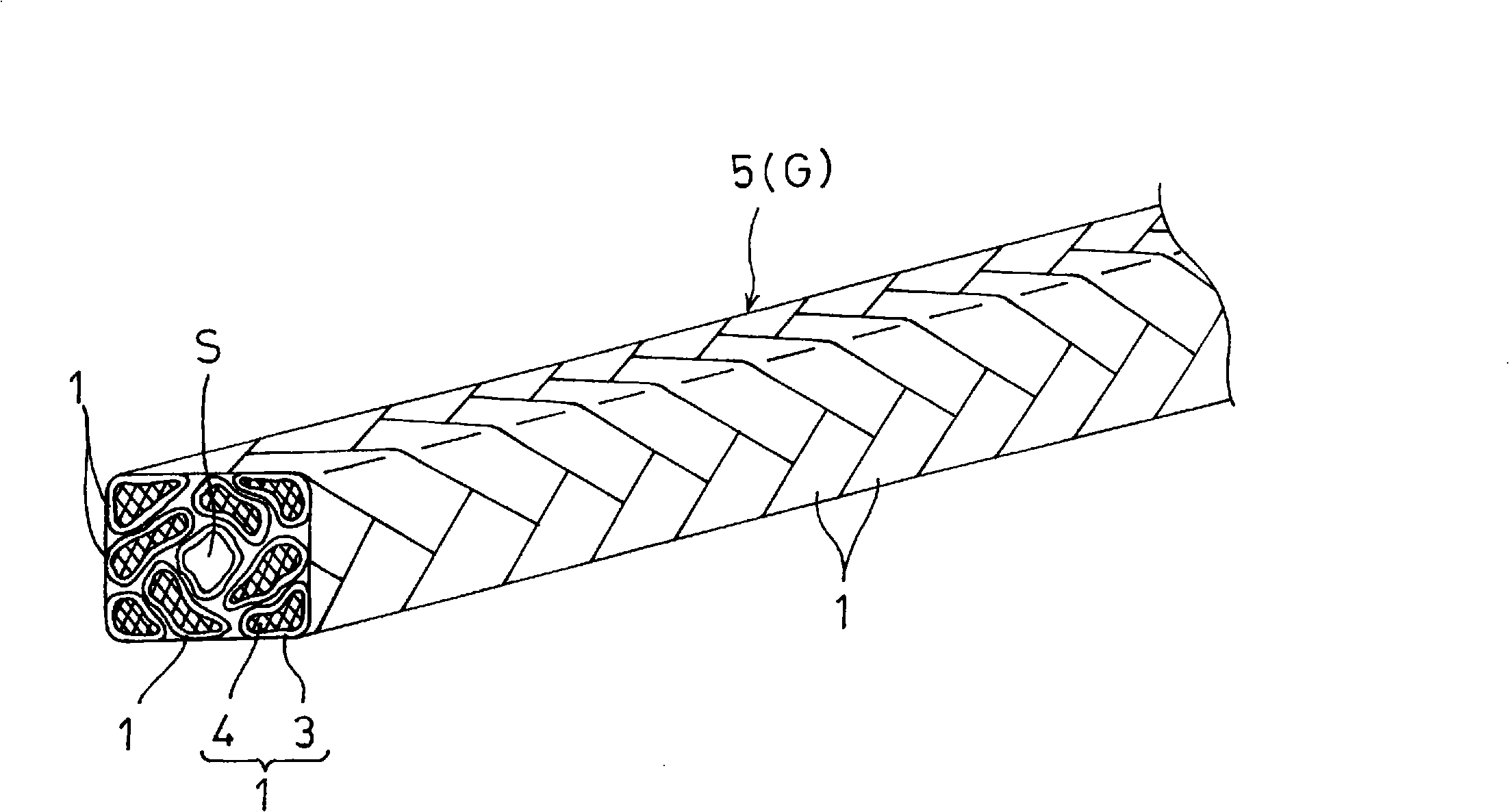

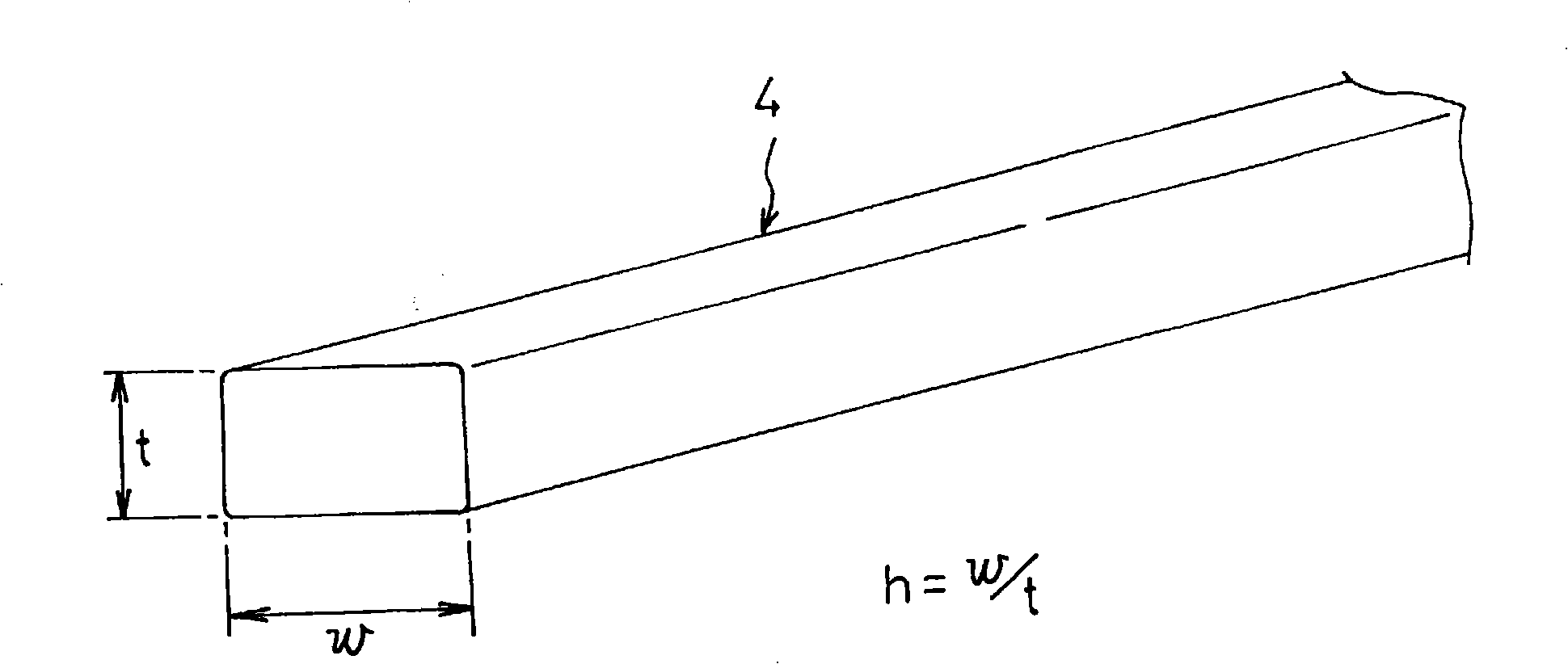

Yarn and gland packing

ActiveCN101300381ANo bad situationAvoid loss of tightnessEngine sealsWeft knittingAspect ratioPartial loss

A yarn of exfoliated graphite as a base material that is improved so as to have enriched flexibility free from any stick-out of exfoliated graphite at ordinary bending processing, thereby avoiding any partial loss of exfoliated graphite at twisting or braiding operation for preparing of a gland packing. Yarn (1) for gland packing is produced by filling the interior of tubular member (3) obtained by knitting or folding Inconel wire (2) of 0.1 mm diameter with fibrous exfoliated graphite (4) in the form of a fiber with a cross section set so as to exhibit an aspect ratio, being a quotient of width (h=w / t) divided by thickness (t), of 1 to 5.

Owner:NIPPON PILLAR PACKING CO LTD

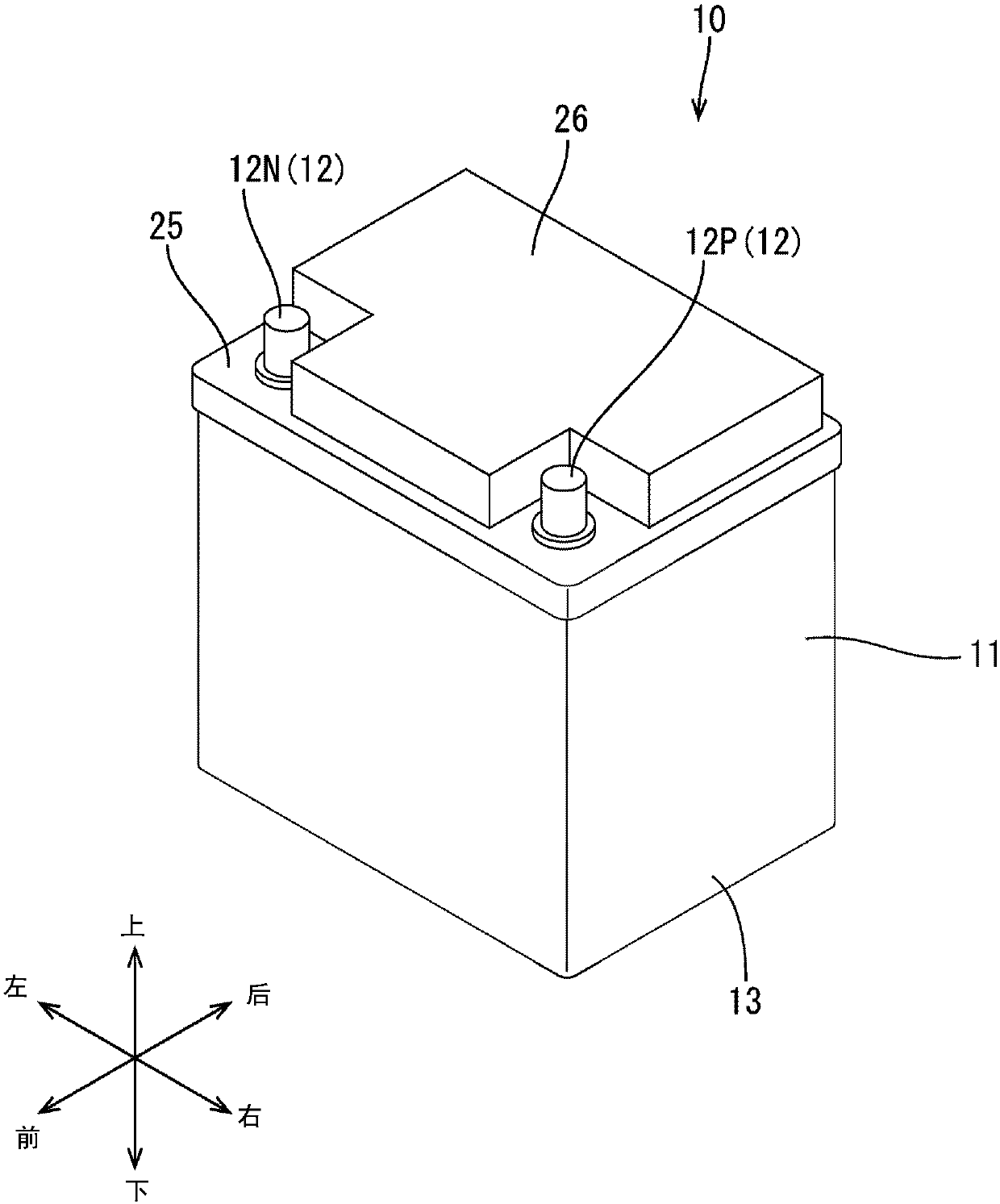

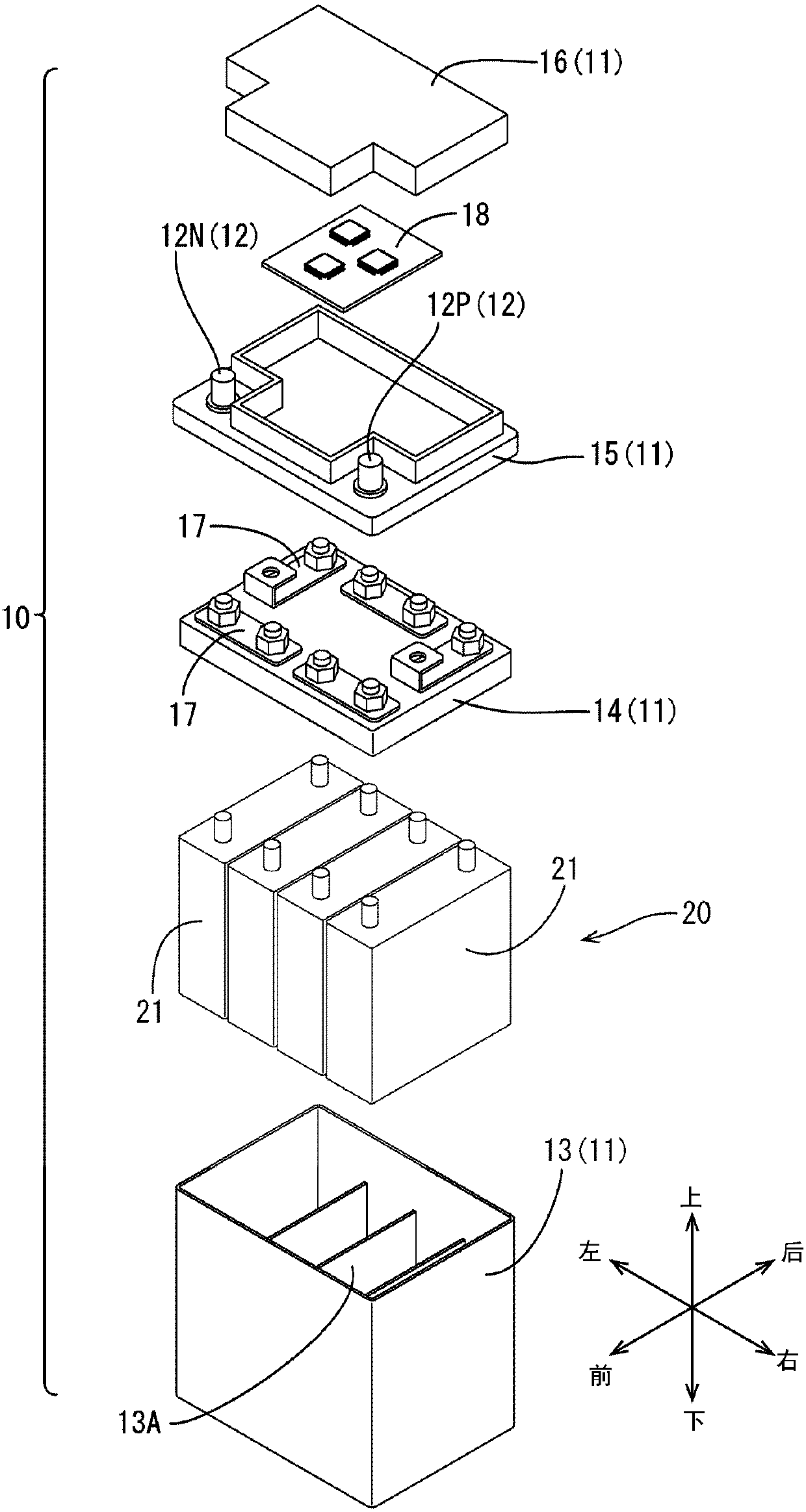

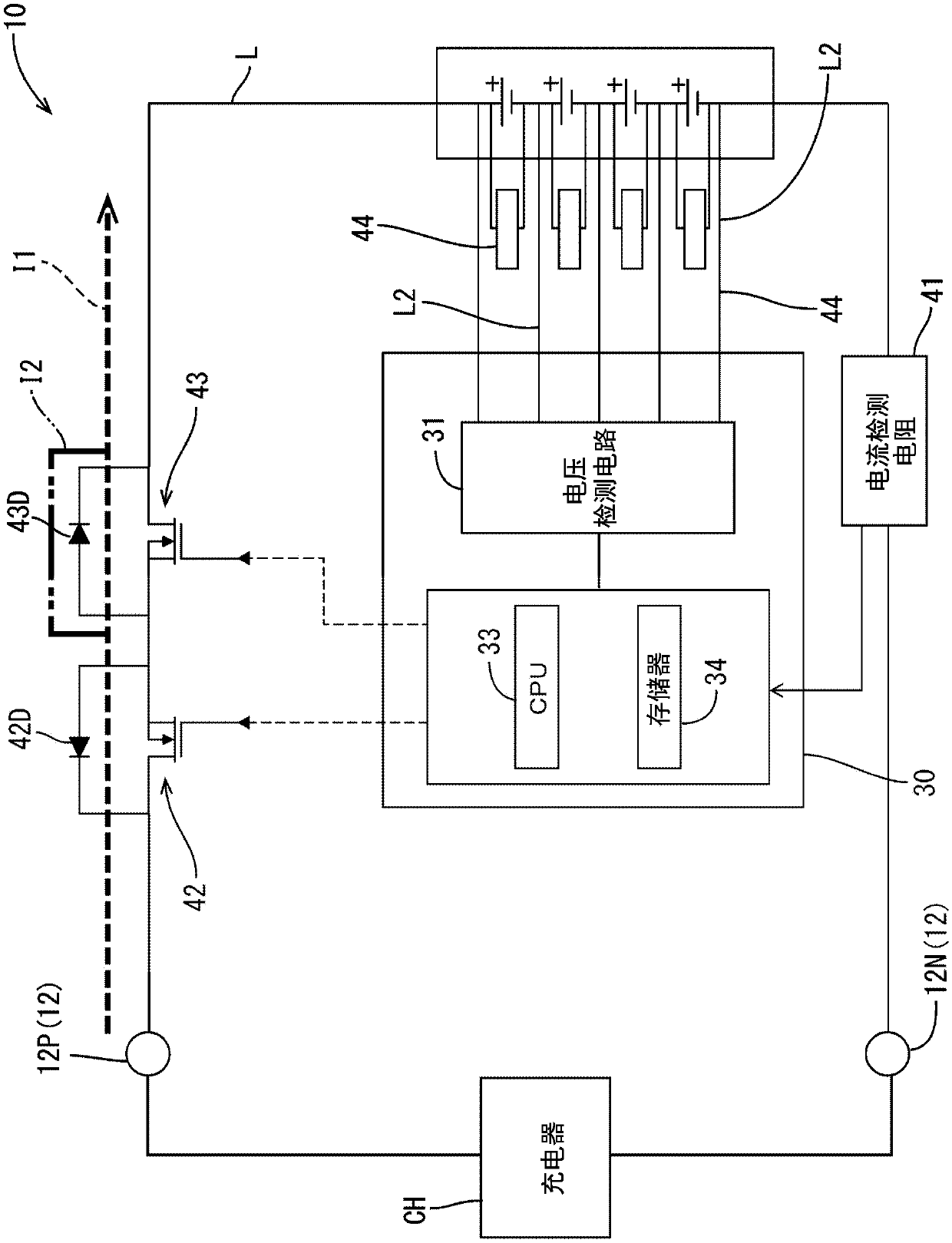

Energy storage apparatus and charge control method for the same

PendingCN107706958APrevent high voltageHigh voltageCharge equalisation circuitCells structural combinationCharge voltageOvercharge

The present invention provides a power storage apparatus and a charge control method for the same. Even if the charging is performed at a charging voltage higher than the assumed charging voltage, itis possible to continue charging without causing an inconvenience. The energy storage apparatus (10) includes an assembled battery (20) including a plurality of energy storage devices (21), a discharge shutoff device (43) incorporating a parasitic diode (43D), configured to switch a path of a charge to the assembled battery to a path through the parasitic diode, a voltage detection circuit (31) configured to detect a cell voltage of the energy storage device (21) and a battery voltage of the assembled battery (20), and a battery management unit (30). When the cell voltage in at least one energy storage device among the plurality of energy storage devices (21) is higher than a full charge voltage and equal to or more than an equalization start threshold value lower than an overcharge voltage, a CPU (33) of the battery management unit (30) switches a path of the charge to the assembled battery (20) to a path through the parasitic diode (43D) with the discharge shutoff device (43).

Owner:GS YUASA INT LTD

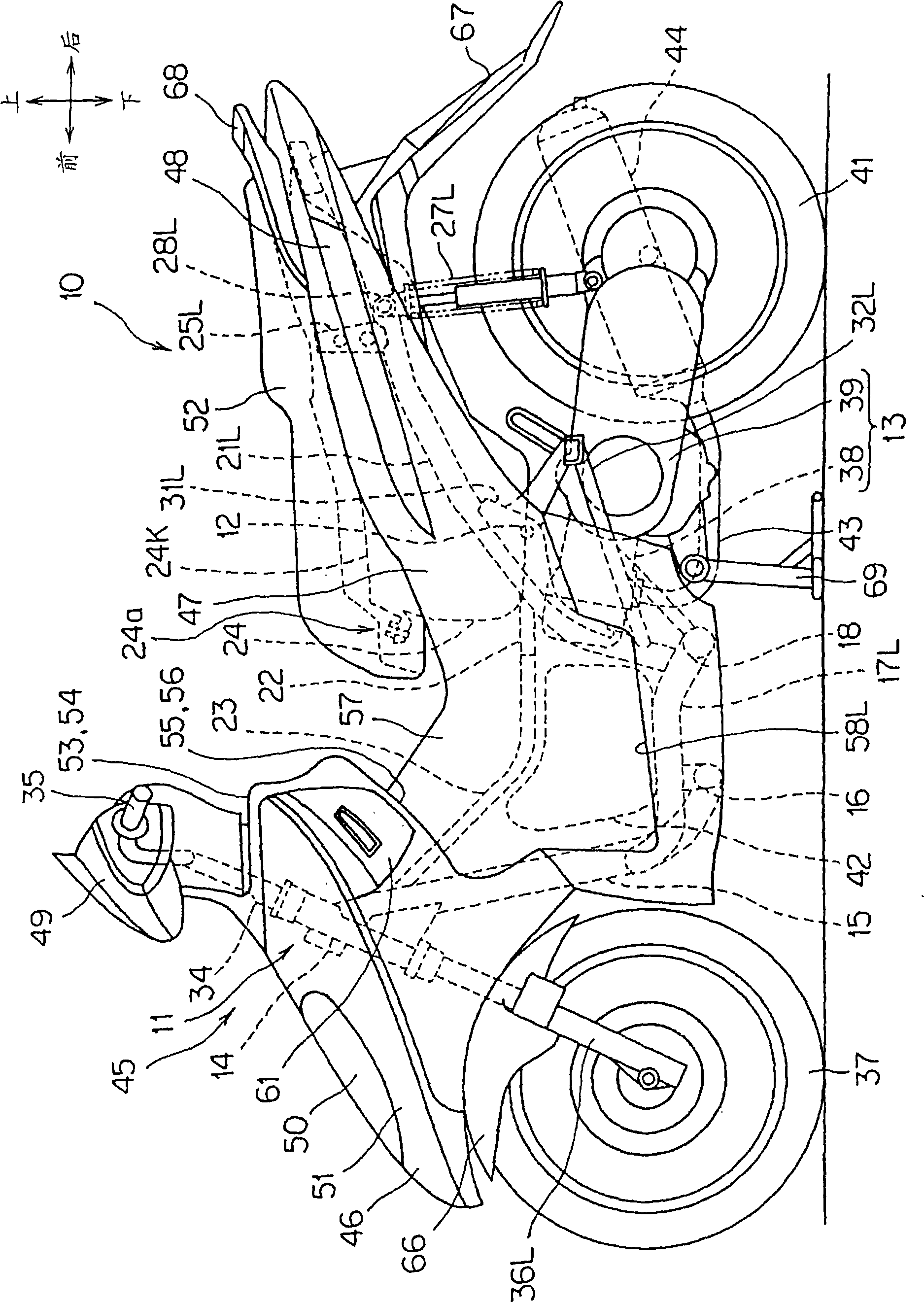

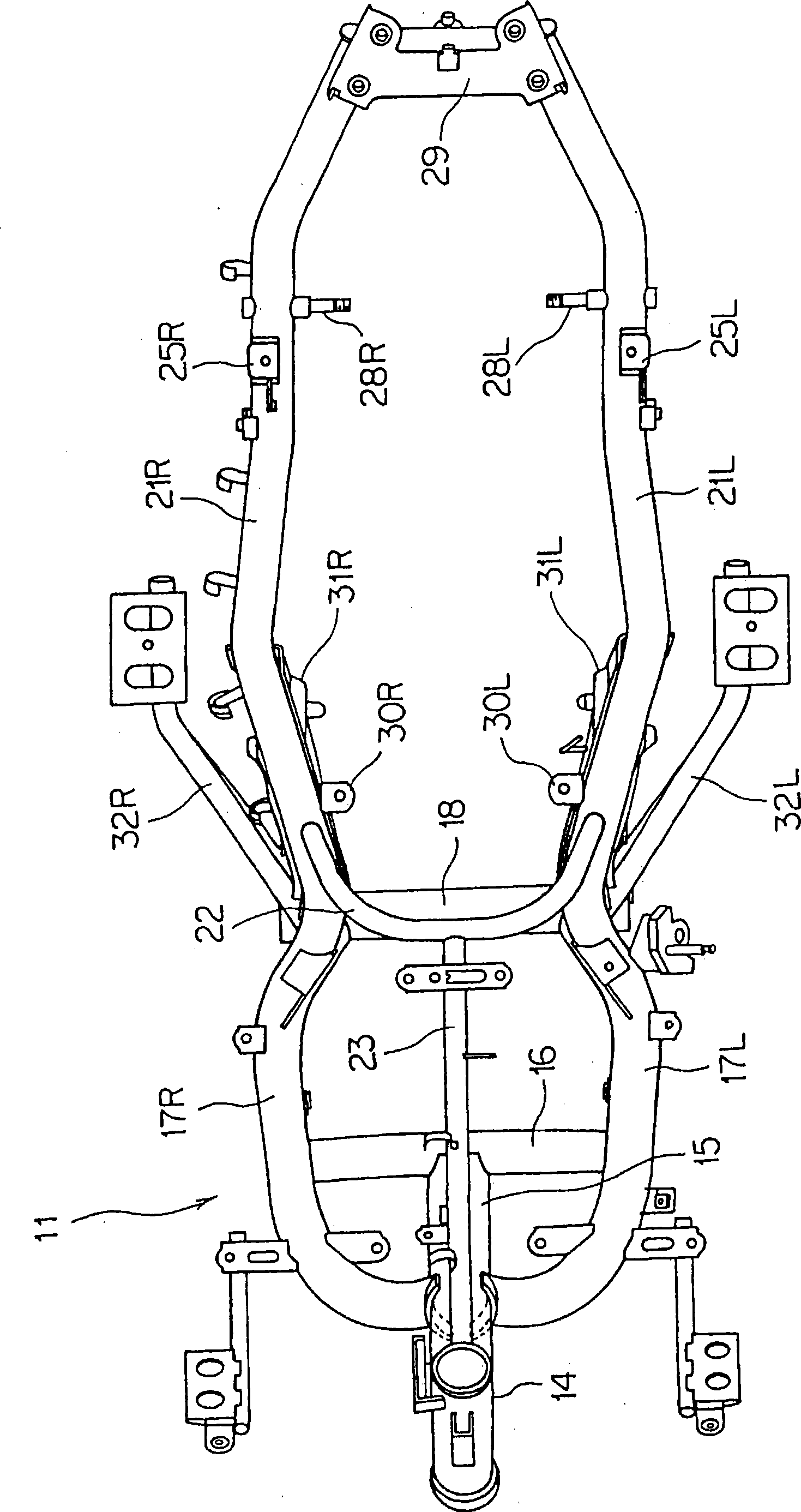

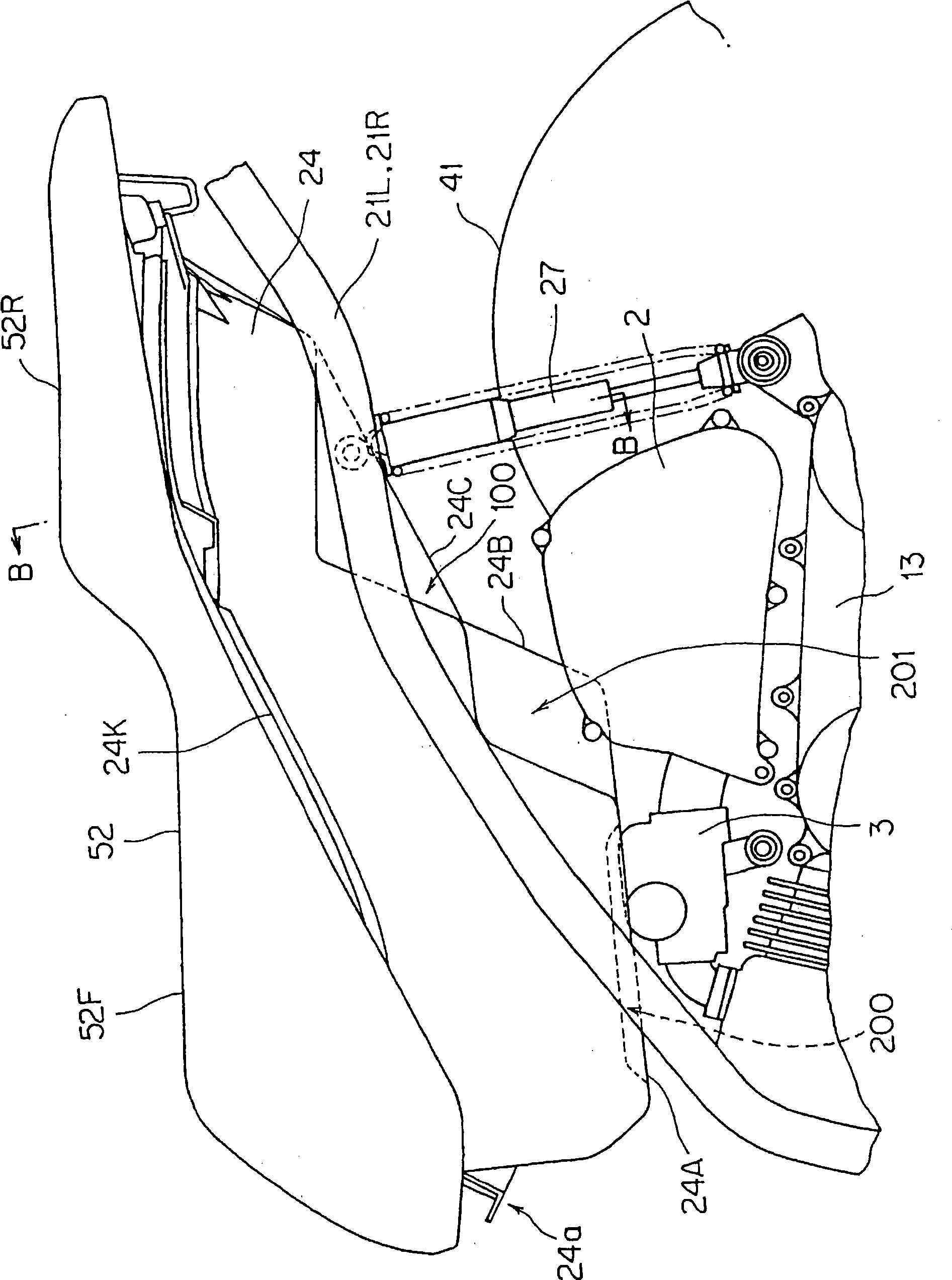

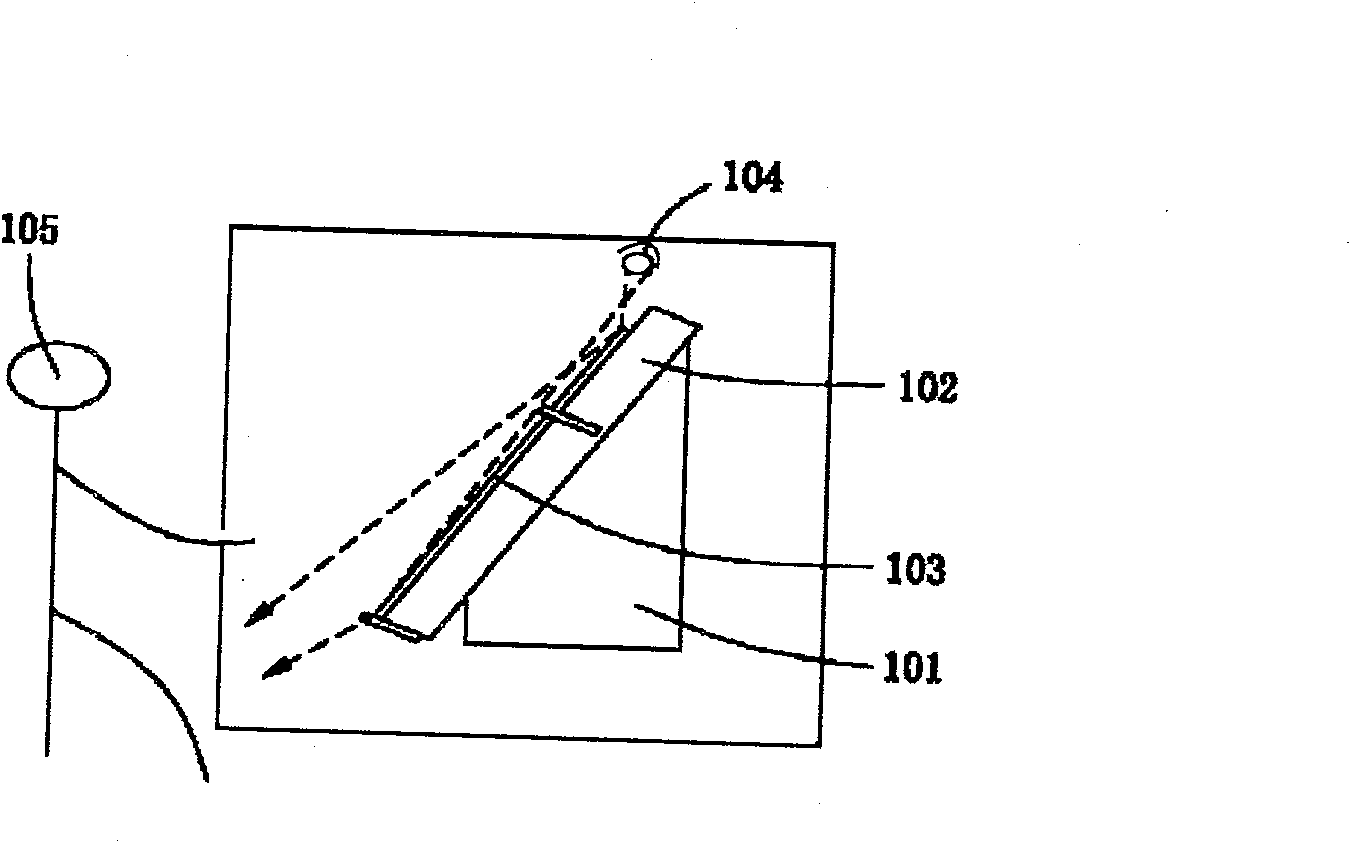

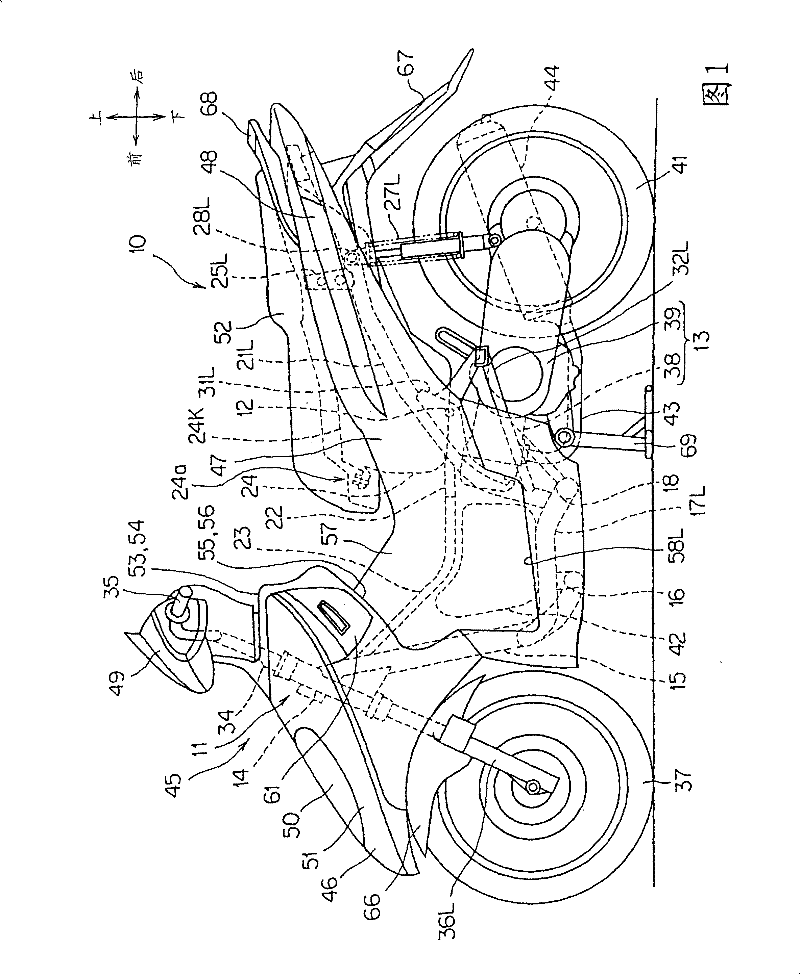

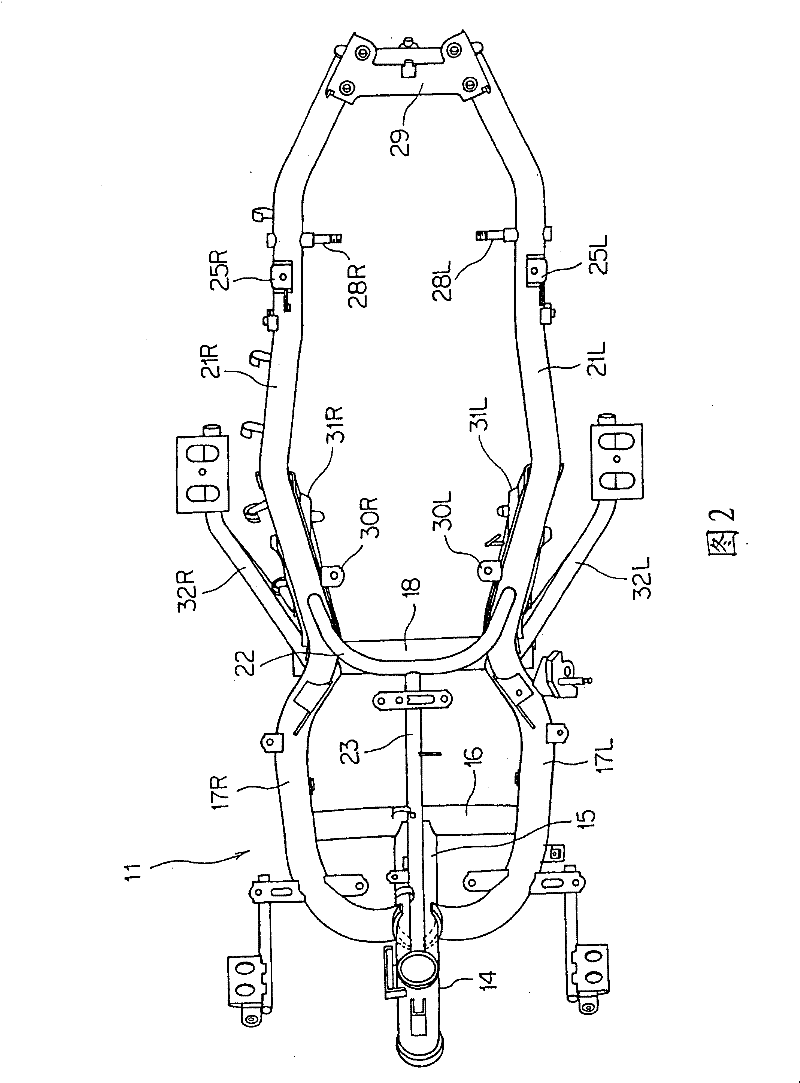

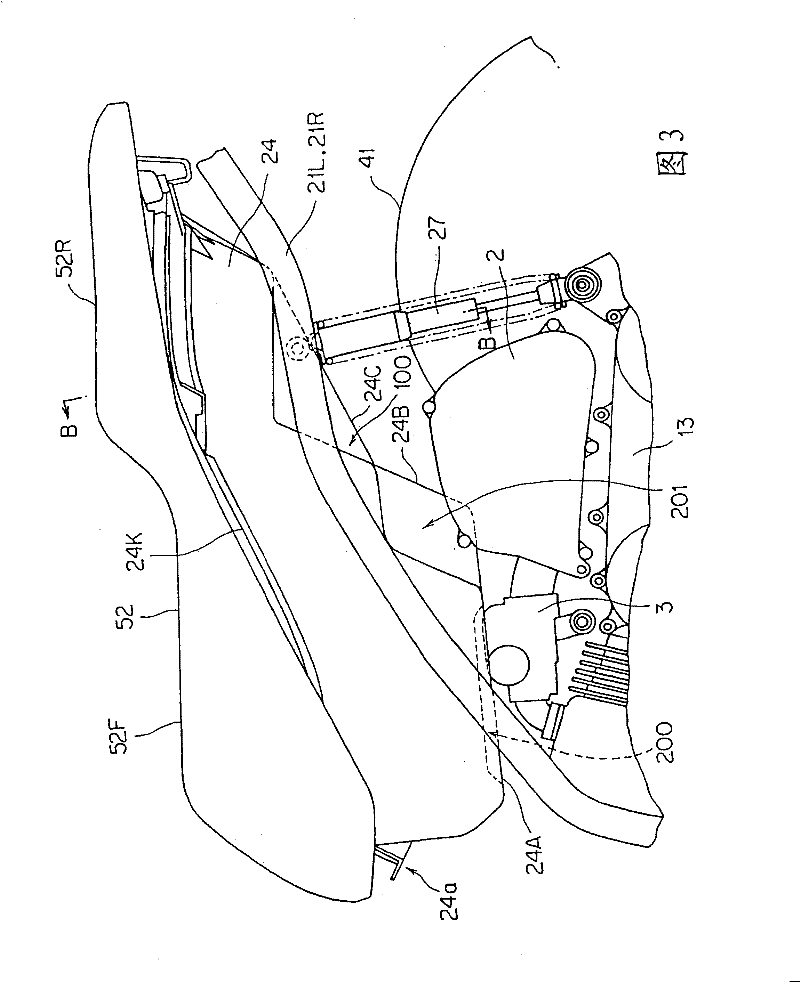

Storage box structure of motor two-wheeler

ActiveCN101468679ASave storage spaceUse effectivelyCycle saddlesCycle containersVehicle frameAerospace engineering

The present invention provides a containing box structure of motor two-wheel vehicle which can ensure a large containing space even the upper part of back buffer is fixed at the inner side of vehicle frame. The motor two-wheel vehicle is provided with one pair of vehicle frames (21L, 21R) in left-and-right direction. The containing box (24) is configured below the seat and between the pair of vehicle frames. Simultaneously the upper part of buffer (27) which is used for suspending the back wheel (41) is installed on one surface or two surfaces of the opposite inner side surfaces of vehicle frame. Two outer sides of containing box are respectively installed with a dent (100L, 100R) for preventing the interference to the upper part of buffer (27). The flat surfaces (102L, 102R) which are flat in the left-and-right direction of vehicle are formed in the inner part of containing box and at the dents thereby forming a first containing space (S1). Furthermore a slant surface (104) is formed between the left dent and the right dent thereby forming a second containing space (S2).

Owner:HONDA MOTOR CO LTD

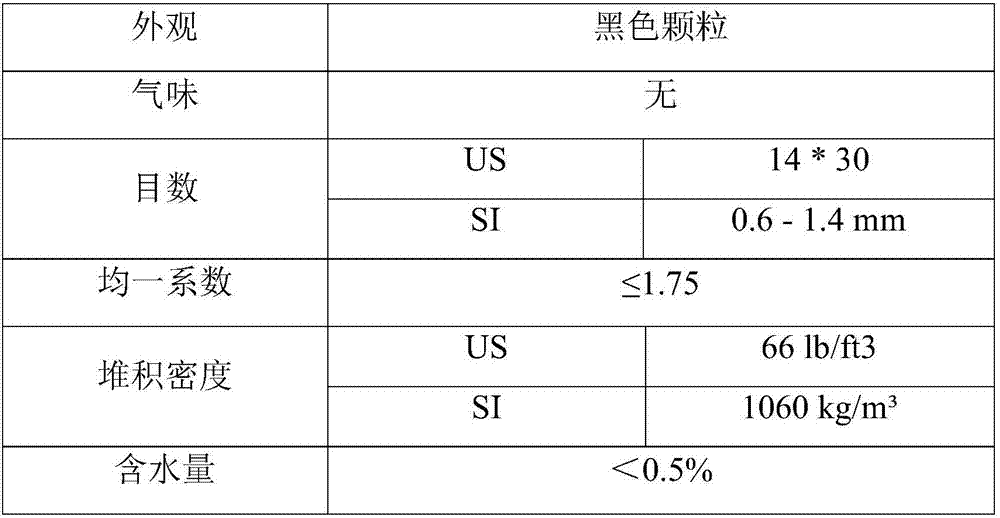

System and method for treating heavy metal pollution of soil

ActiveCN107282618AGood removal effectReduce processing difficultyContaminated soil reclamationSoil heavy metalsSoil washing

The invention relates to a system and method for treating heavy metal pollution of soil. The system comprises soil washing equipment, a mixing pipe, a contact reactor and a catalyst tank which are sequentially connected; a first circulating hole and a second circulating hole are respectively formed in the upper and lower parts of the catalyst tank; the first circulating hole is respectively connected with an outlet of the contact reactor and a backwash liquid outlet pipe by a first valve and a second valve; the second circulating hole is respectively connected with a water outlet pipe and a backwash water inlet pipe by a third valve and a fourth valve; and a packing layer is arranged inside the catalyst tank and is filled with spherical particles with manganese dioxide coatings. The system and method are capable of comprehensively treating heavy metal pollution, parts of VOCs and other soil pollution at one step, greatly lowering the treatment difficulty, greatly shortening the process flow and greatly reducing the floor area, simpler in operation, extremely wide in pollutant removal range and extremely good in removal effect.

Owner:科海思(北京)科技有限公司

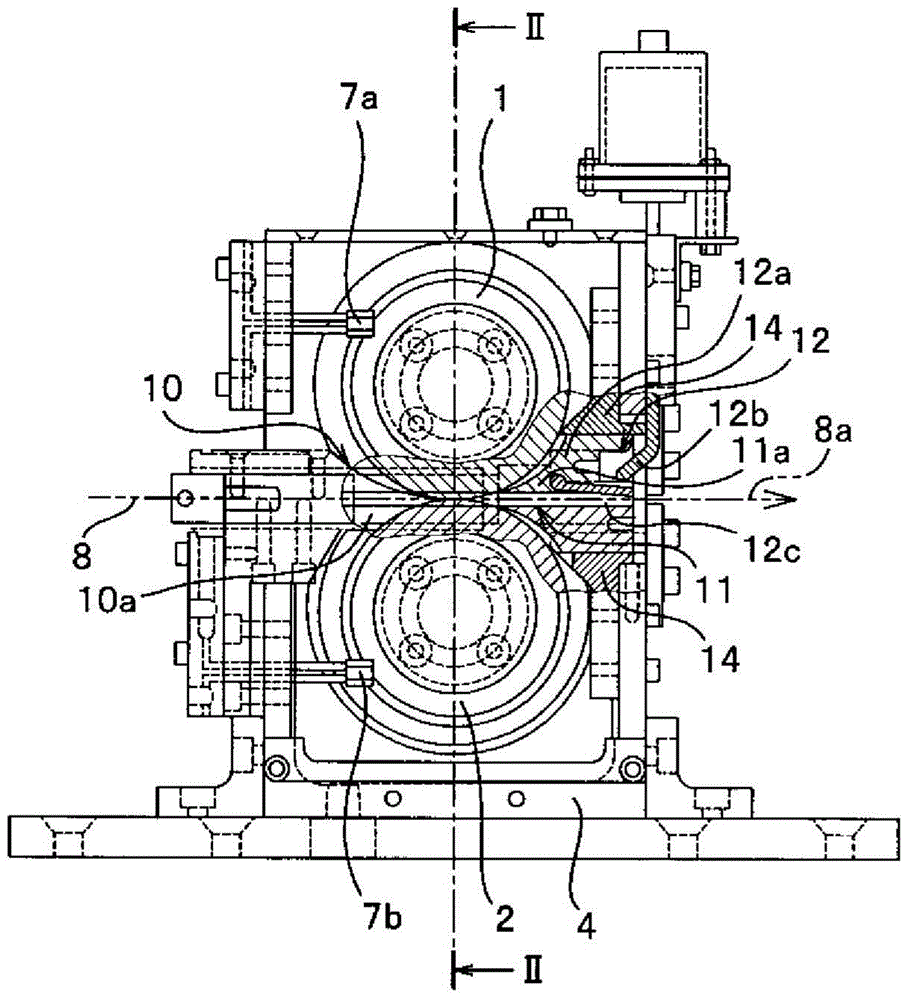

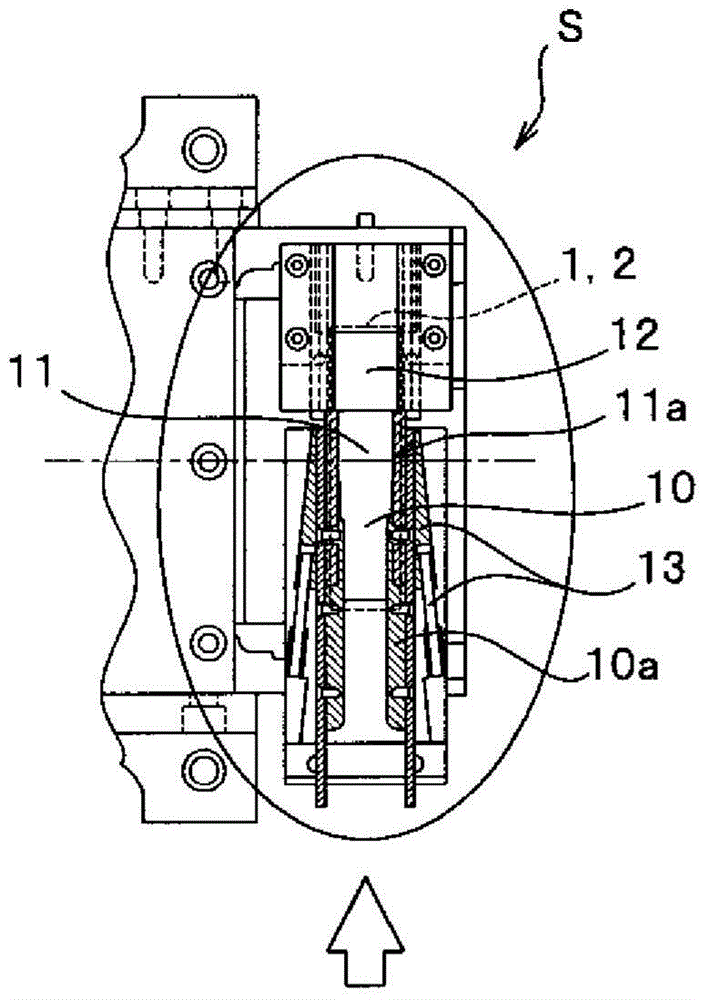

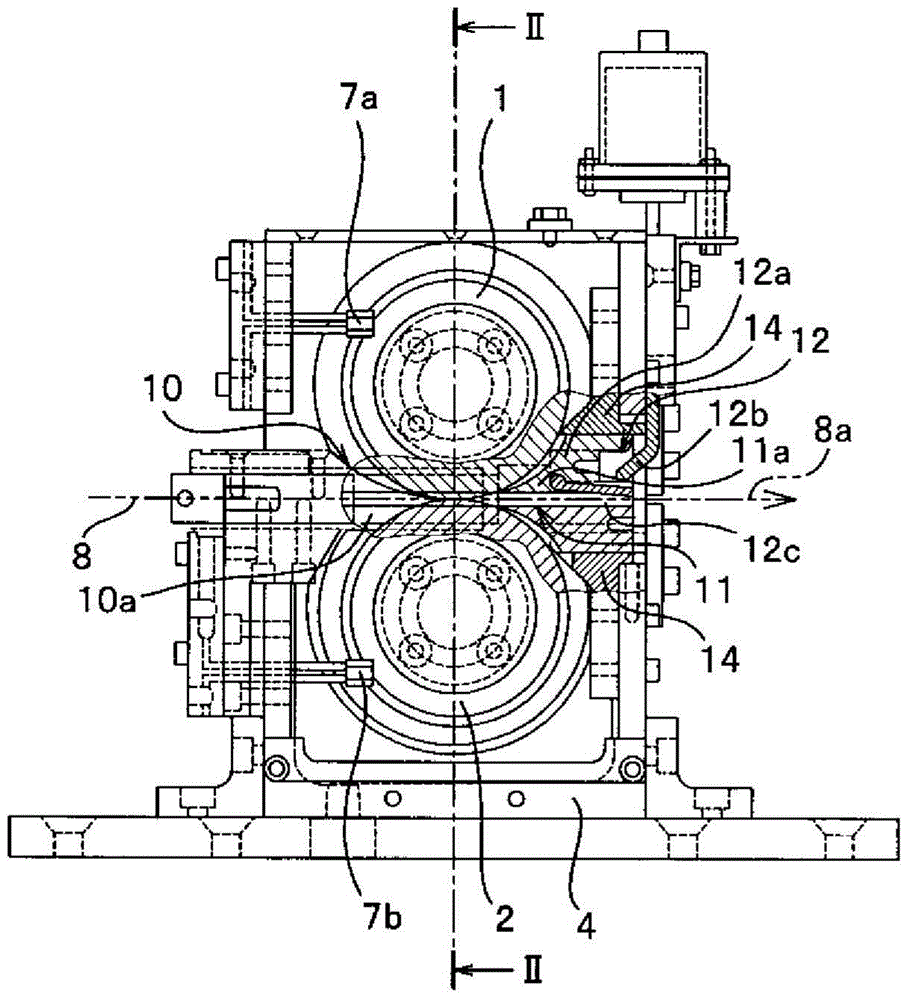

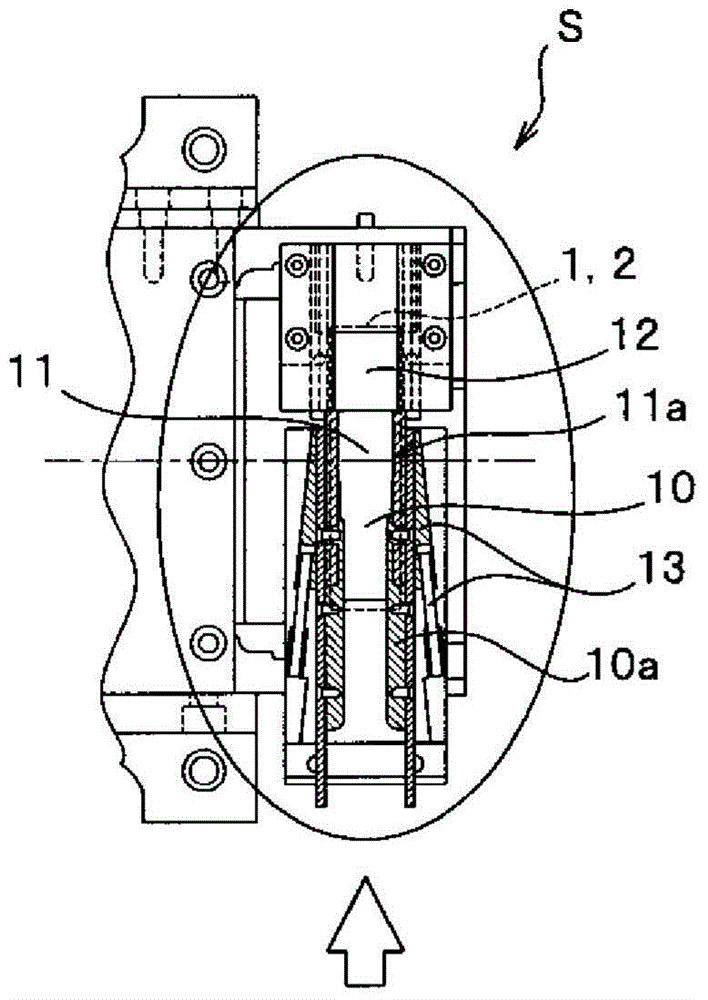

Fiber tow crimping device and method for manufacturing crimped fiber tow

According to the present invention, a tow-width restrictor (10a), constructed from a plate material shaped substantially as an isosceles triangle having an acute angle at the front tip with respect to the direction of travel, is disposed in the tow introduction part (10) of a pair of fiber-tow push-in rolls further upstream from the nip point (9) of push-in rolls (1, 2). A tow protrusion preventer (11a) for preventing fiber protrusion in the fiber tow (8) is disposed subsequent to the tow-width restrictor (10a) in a roll side surface that includes the nip point (9) of the pair of the push-in rolls (1, 2). The difference between the push-in roll width (A) and the distance (B) between the inner wall surfaces of a pair of protrusion prevention holding plates (15) is 0.2-12 mm. The distance (C) between the tip of the tow-width restrictor (10a) and the nip point (9) of the push-in rolls (1, 2) is 0-22 mm.

Owner:TOYAMA FILTER TOW

Fault correcting method for gray tone mask, gray tone mask and manufacturing method thereof

InactiveCN101339362BCorrection is appropriateReduced efficiency of evasion checksPhotomechanical apparatusOriginals for photomechanical treatmentGray levelComputer science

Owner:HOYA CORP +1

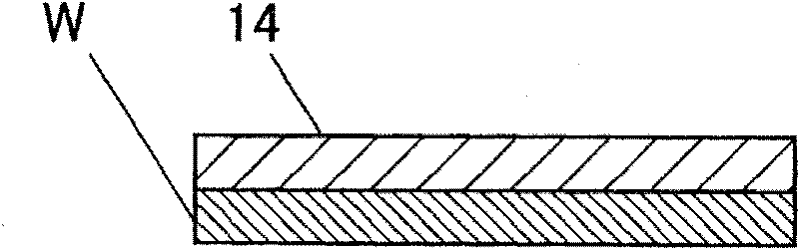

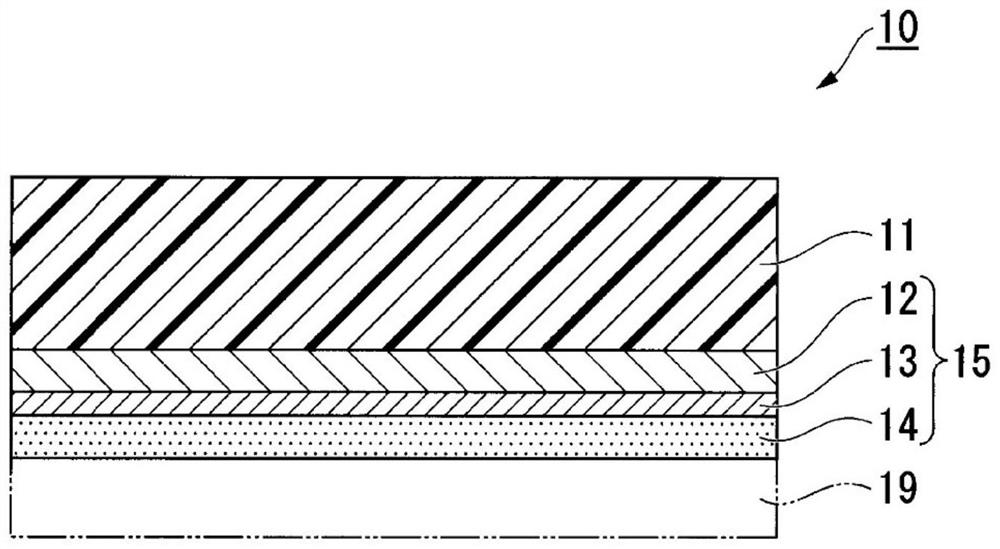

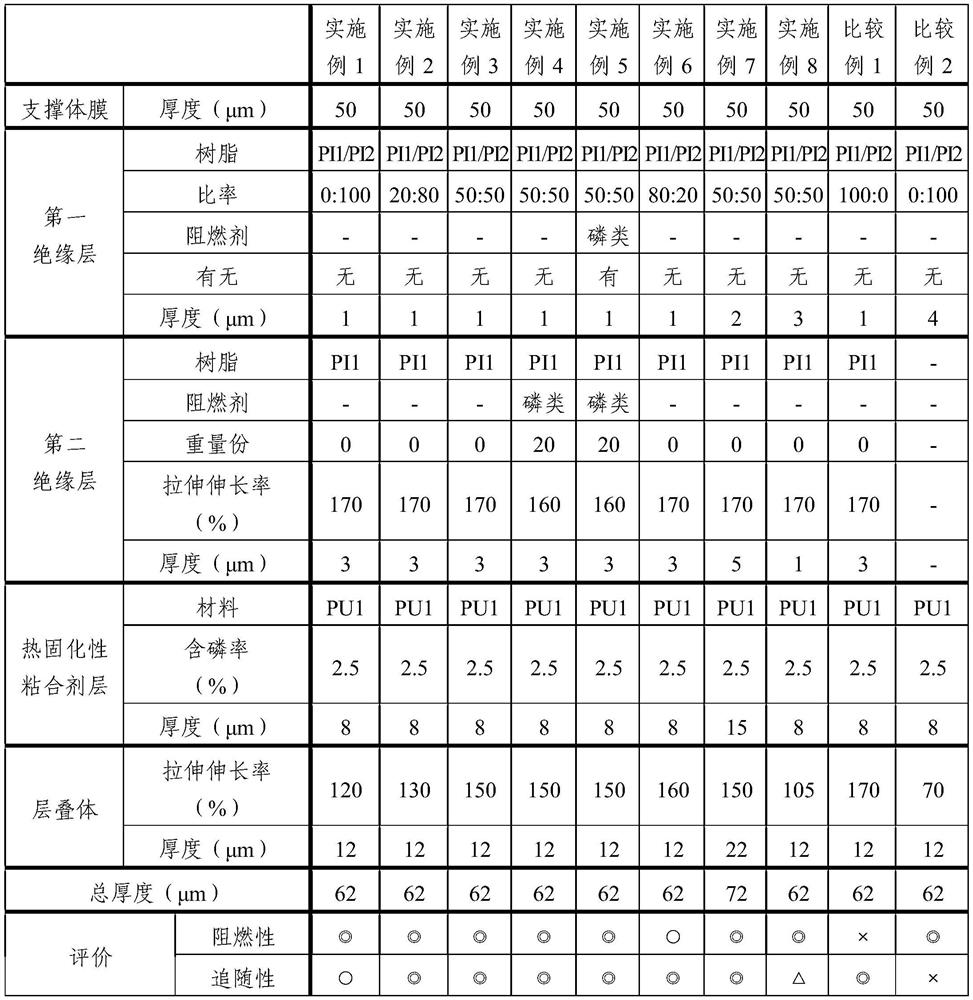

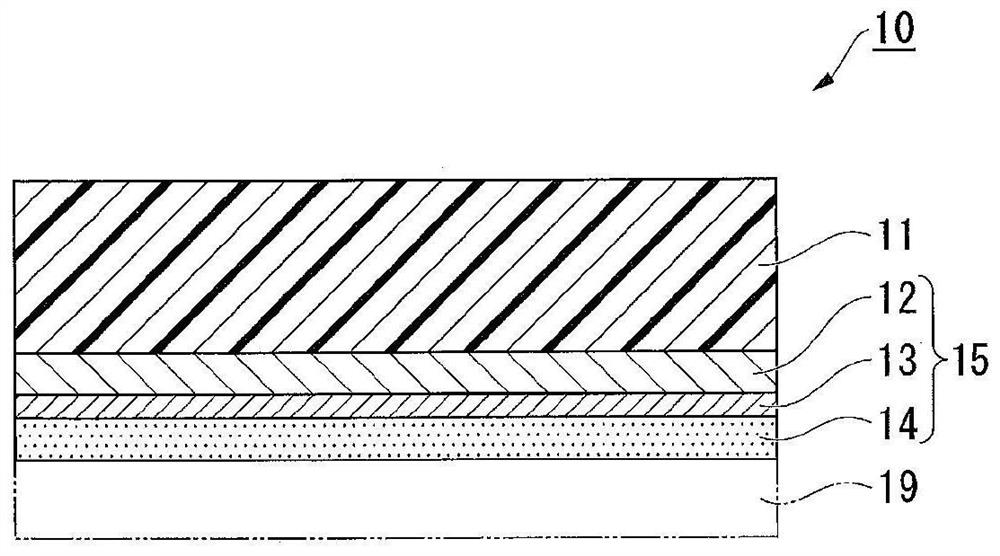

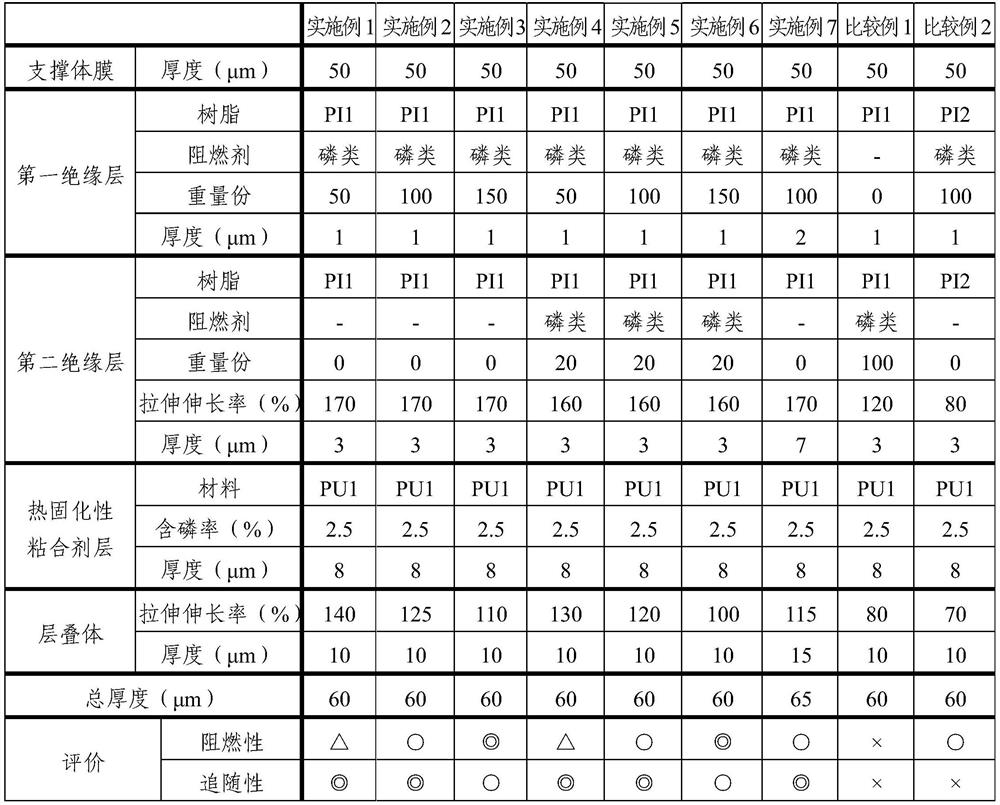

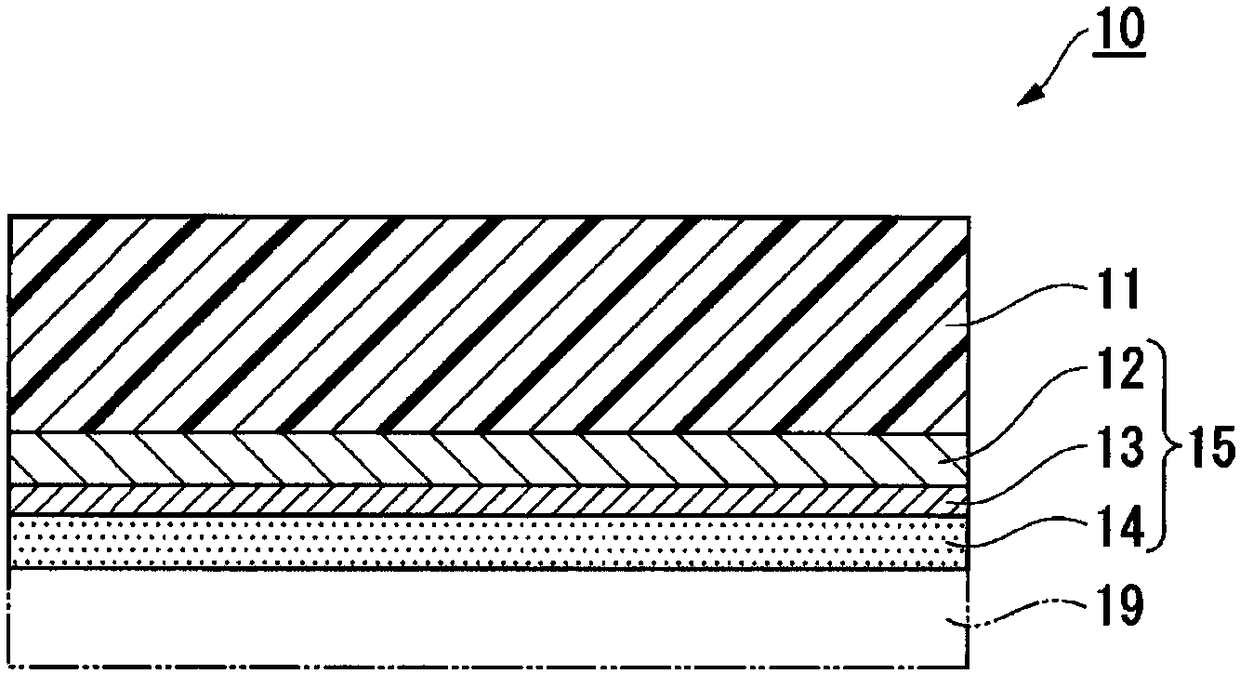

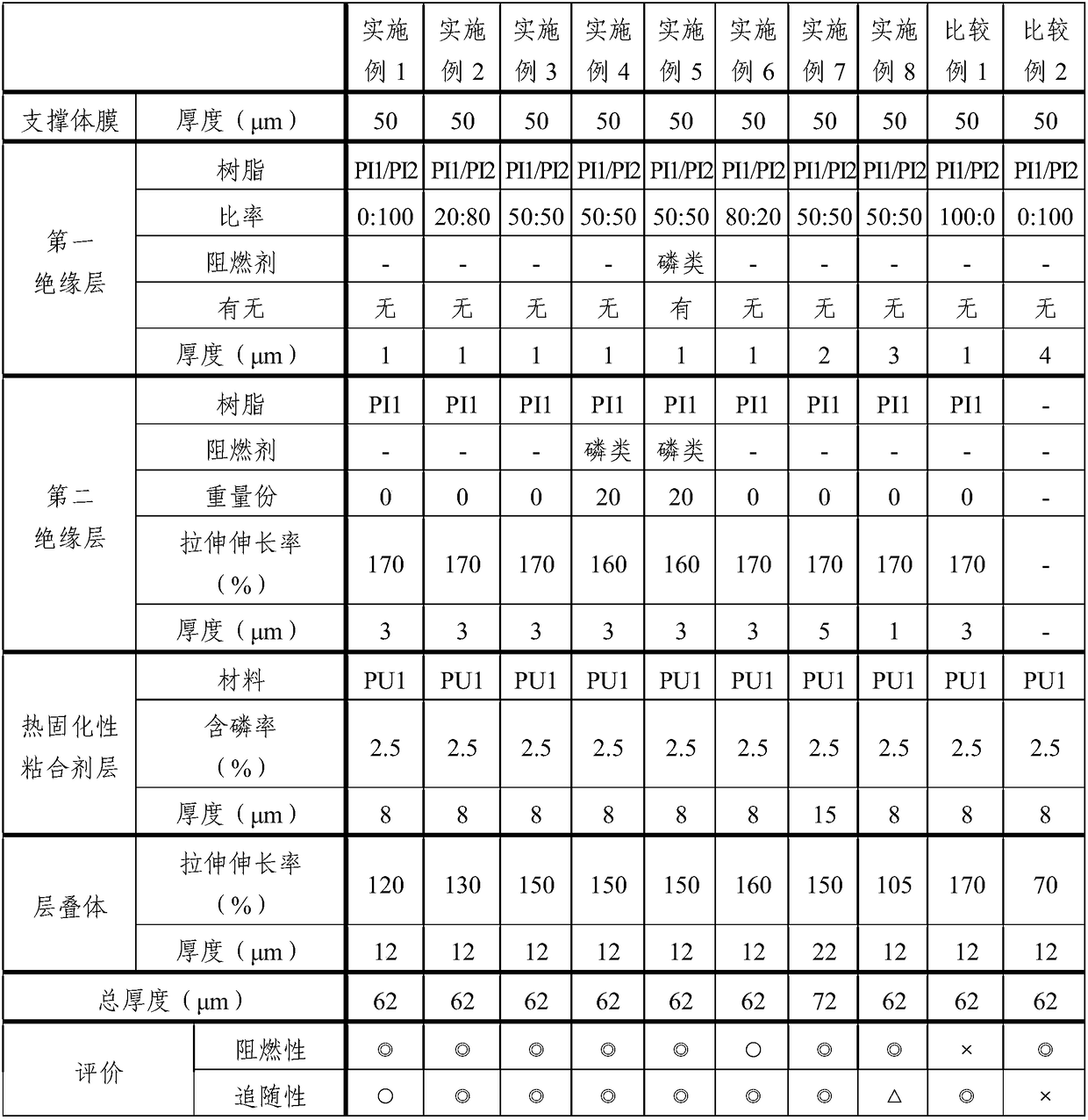

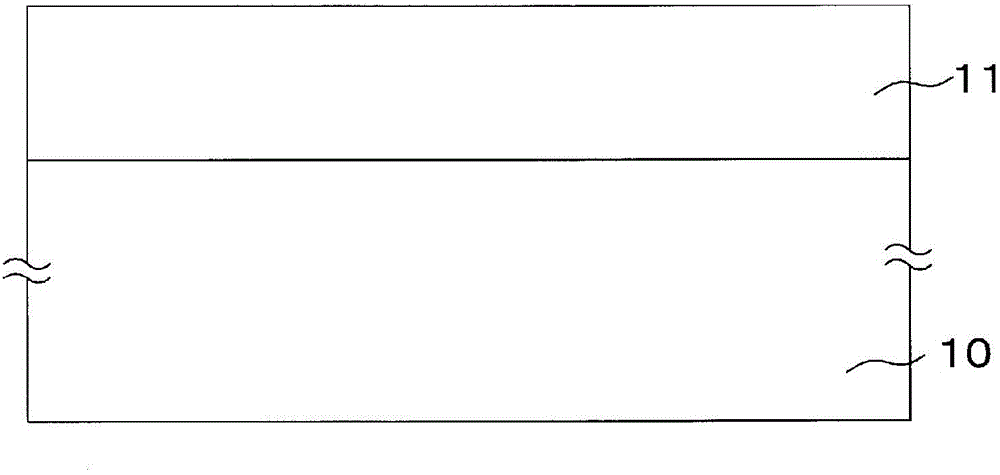

cover film

ActiveCN108624244BNo bad situationImprove protectionFilm/foil adhesive primer layersPolyureas/polyurethane adhesivesPolymer scienceThin membrane

The present invention provides a cover film that has good processability and handleability and is excellent in followability to FPC even if it is a thin film. The cover film (10) is characterized in that a first insulating layer (12), a second insulating layer (13), and a thermosetting adhesive layer (14) are sequentially laminated on one surface of a support film (11). The first insulating layer (12) contains a flame-retardant resin, and the support film (11) is removed from the first insulating layer (12), the second insulating layer (13), the thermosetting adhesive layer (14 ) The tensile elongation of the formed laminate (15) is 100% or more.

Owner:FUJIMORI KOGYO CO LTD

Method for treating coking biochemical effluent by microwave-oxidation-coagulation technology

ActiveCN101767912BReduce usageImprove processing efficiencyWater/sewage treatment by magnetic/electric fieldsMultistage water/sewage treatmentSludge cakeMicrowave oven

The invention provides a method for treating coking biochemical effluent by microwave-oxidation-coagulation technology, which comprises the following steps of: A, adding a mixed reagent consisting of H2O2 and Fe2+ into the coking biochemical effluent until the mass concentration of hydrogen peroxide in water is between 0.01 and 1 percent, and controlling the pH to between 2.0 to 6.0; B, delivering the mixed liquid into an industrial microwave oven for processing for 5 to 60s; C, regulating the pH value of the mixed liquid to between 6.0 and 6.5 or 7.5 and 8.5, and carrying out oxidation treatment for 1 to 4 hours under an aeration condition that the aeration rate is 10 to 40m<3> / h; D, adding a coagulant into the liquid until the mass concentration of the coagulant in the liquid is betweenone millionth and one hundred thousandth; E, precipitating and separating; F, filtrating the liquid to obtain process effluent for recycling; and G, collecting sludge, separating the liquid from the sludge; and returning the liquid to the step D, and filter-pressing the sludge to obtain sludge cakes. The method realizes recycling, does not discharge sewage, and effectively solves the problem thatpresent coking sewage is difficult to treat and to recycle.

Owner:云南天朗环境科技有限公司

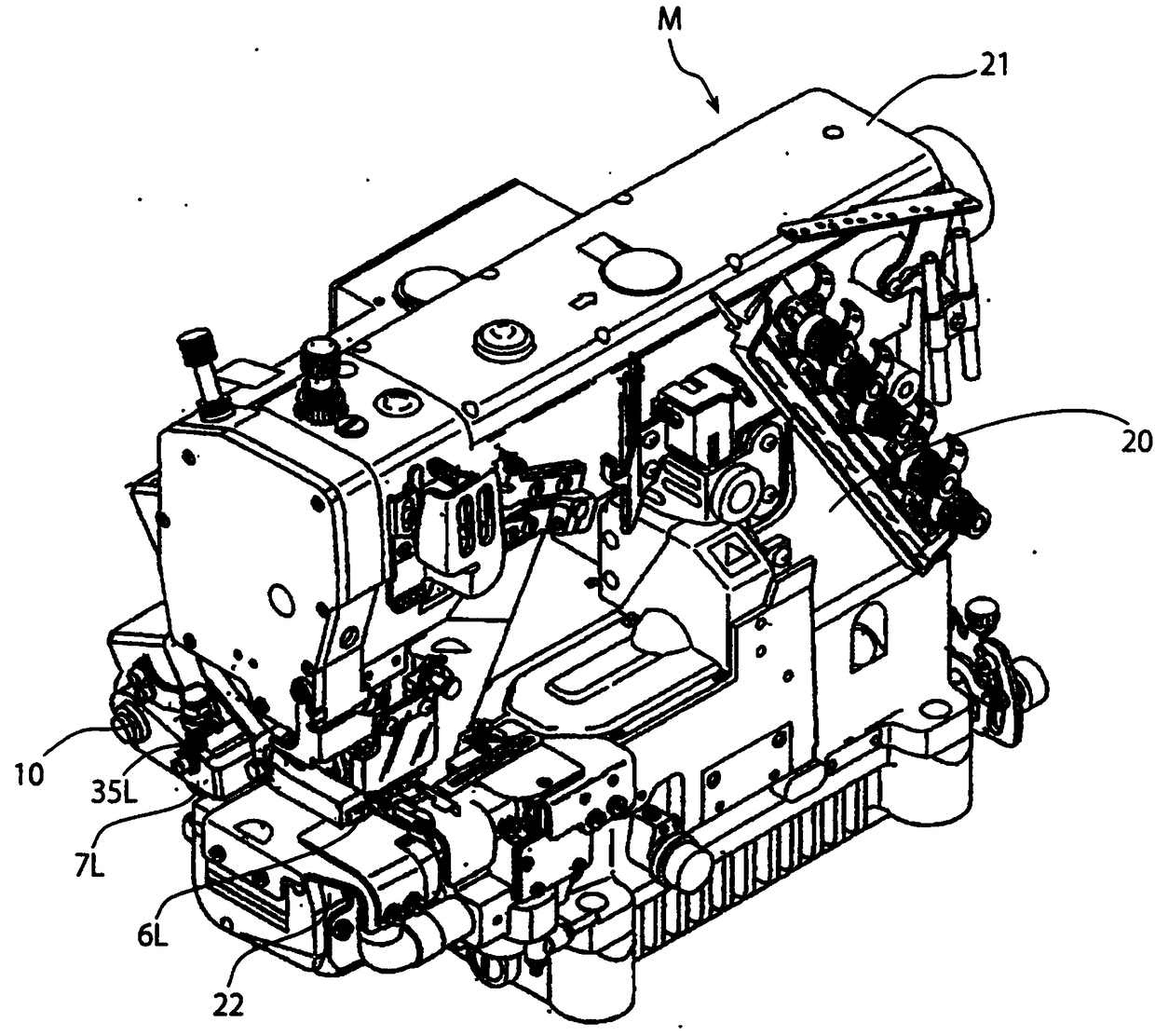

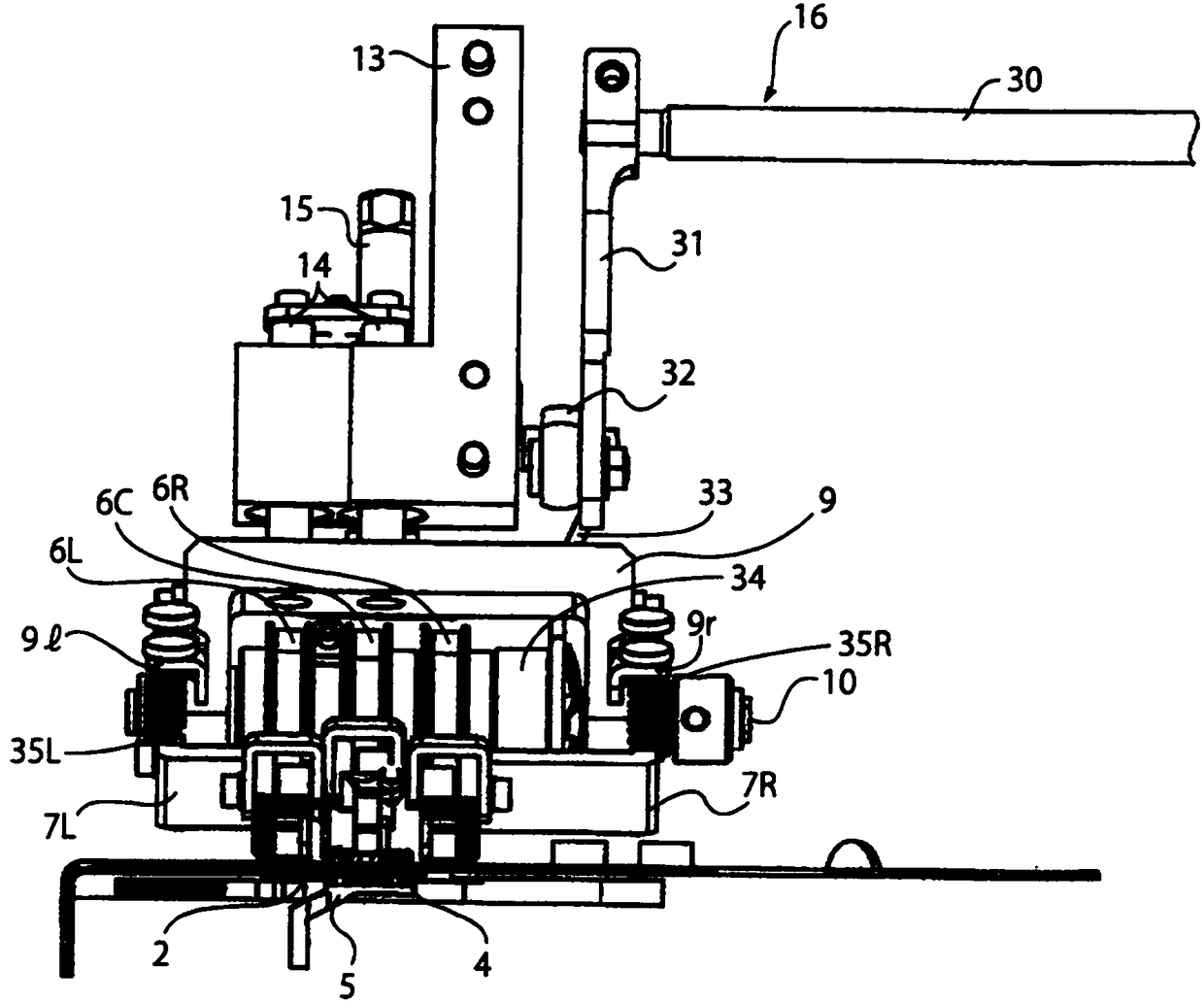

Fabric transferring device of sewing machine

The present invention provides a fabric transferring device of a sewing machine. The device comprises a fabric feeding tooth for feeding of fabrics and a pressure leg. A pair of left and right fabricfeeding belts are arranged at the external portions of left and right sides of the pressure leg in a direction approximately orthorhombic to a sewing traveling direction and is acted at the upper surface of the fabric, the fabrics are forcedly transferred in a length range being in contact with a needle plate in a sewing traveling direction at the surface of the pressure leg. The device further comprises a transmission belt drive mechanism configured to allow the fabric feeding belts to perform synchronization connection with the fabric feeding tooth to cause intermittent drive and a belt up-and-down movement drive mechanism configured to perform drive and connection and up-and-down movement of the fabric feeding belts and the pressure leg. The cost is low compared to the addition of partsof the sewing machine, and in a condition that part and all of fabrics pasting rubber and the like are taken as sewing objects, if even the fabric sewing portions are subjected to transferring resistance caused by friction, and transferring is reliably and smoothly performed to complete a good sewing product.

Owner:YAMATO SEWING MASCH MFG CO LTD

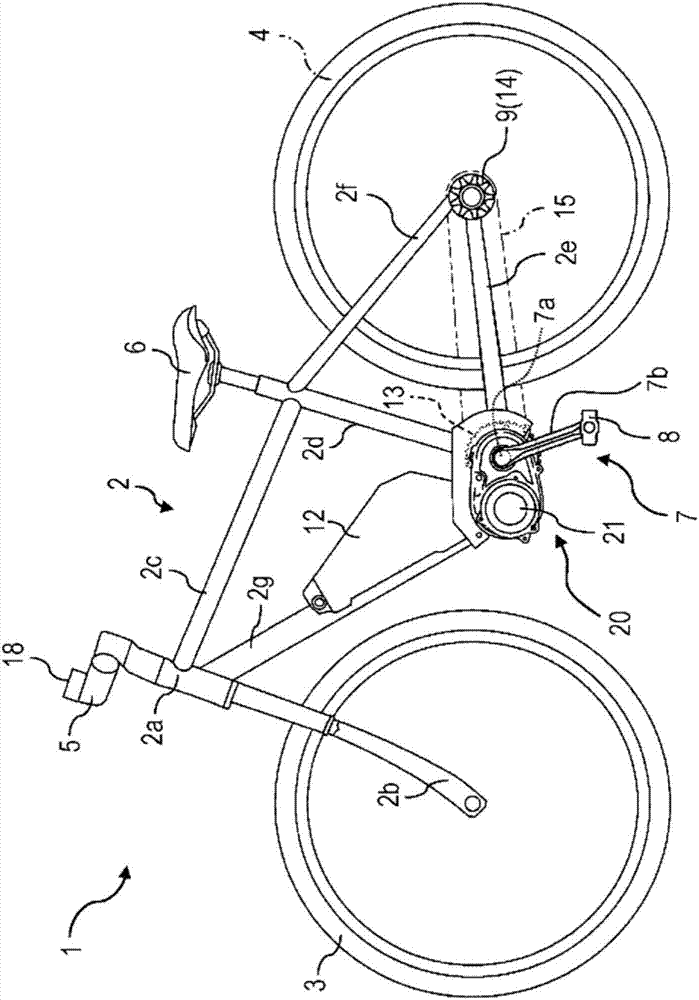

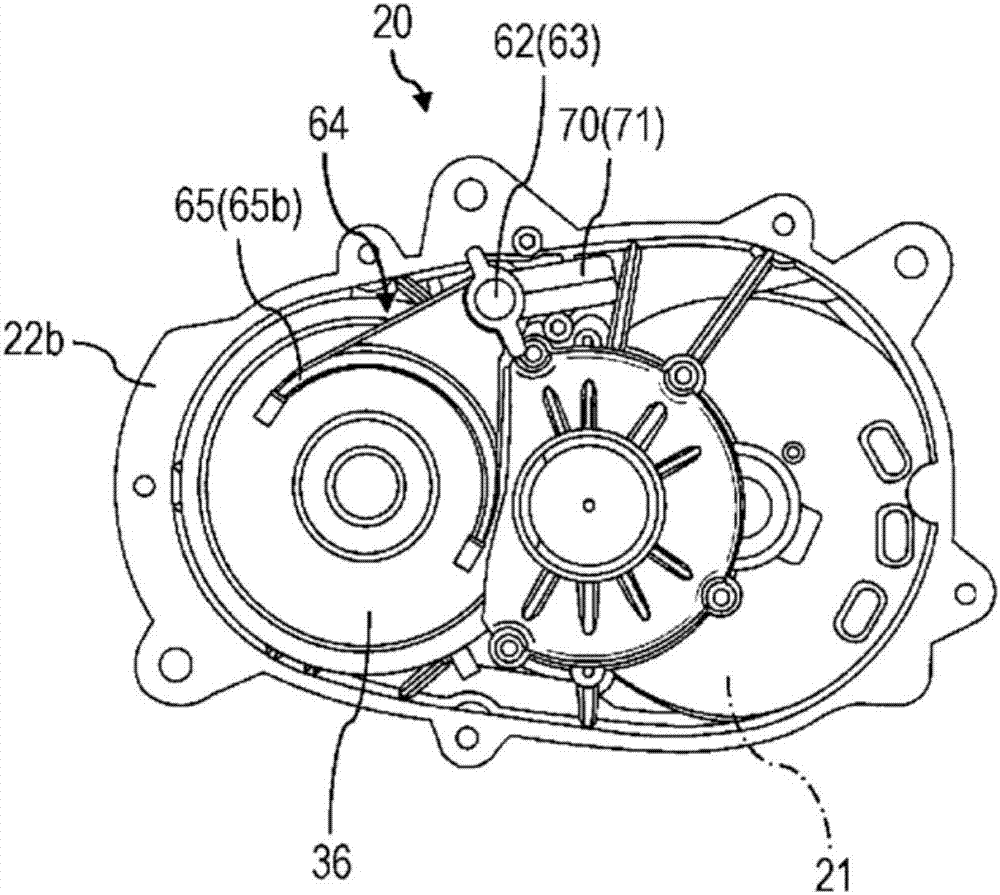

Electric-assist bicycle

InactiveCN107428391AReduce loadNo bad situationWheel based transmissionGearing controlGear wheelSprocket

A drive unit (20) positioned in an intermediate location between a front wheel and a rear wheel is provided with: a resultant force vehicle (29) capable of rotating as a result of the resultant force obtained by synthesizing a human-powered drive force and an auxiliary drive force; a drive sprocket (13) to which the rotations of the resultant force vehicle (29) are transmitted; and a shifting mechanism that transmits drive force to the resultant force vehicle and has a plurality of selectable gears, the gear ratio of which differs. The shifting mechanism has a plurality of gears and a switch movement unit (62) that moves according to the selected gear. In addition, the drive unit (20) is provided with an electric-power switching device that has a gear-switching motor that functions as a gear-switching drive source for producing drive force that moves the switch movement unit (62).

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

cover film

ActiveCN107896417BNo bad situationImprove protectionCircuit bendability/stretchabilityFilm/foil adhesivesPolymer scienceThin membrane

The present invention provides a cover film that has good processability and handleability and is excellent in followability to FPC even if it is a thin film. The cover film (10) provided by the present invention is characterized in that the cover film (10) is formed by sequentially laminating a first insulating layer (12), a second insulating layer (13) on one surface of a support film (11), thermosetting Formed from a permanent adhesive layer (14), the first insulating layer (12) contains a flame retardant, and the support film (11) is removed, the first insulating layer (12), the second insulating layer (13 ), a laminate (15) composed of a thermosetting adhesive layer (14) has a tensile elongation of 100% or more.

Owner:FUJIMORI KOGYO CO LTD

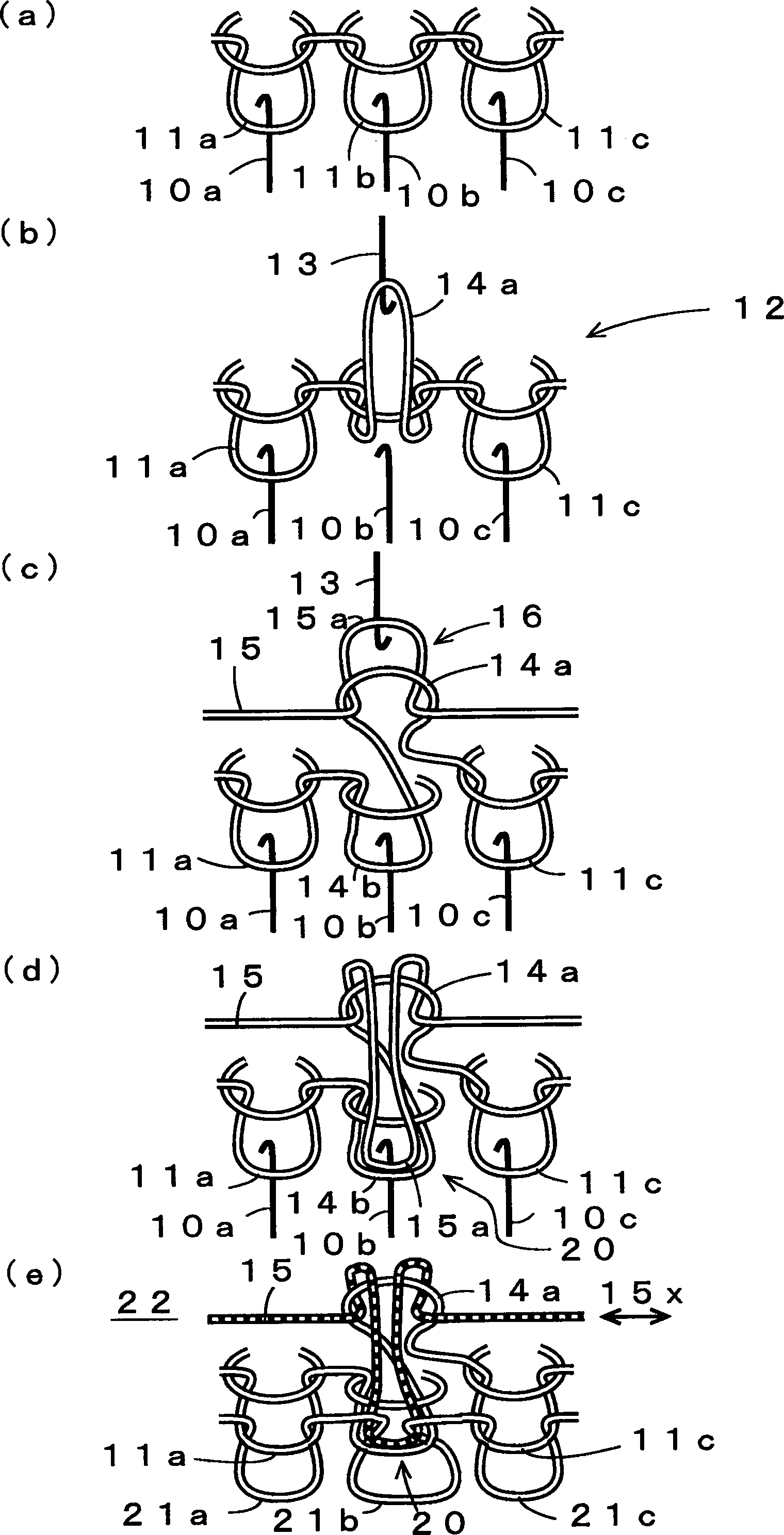

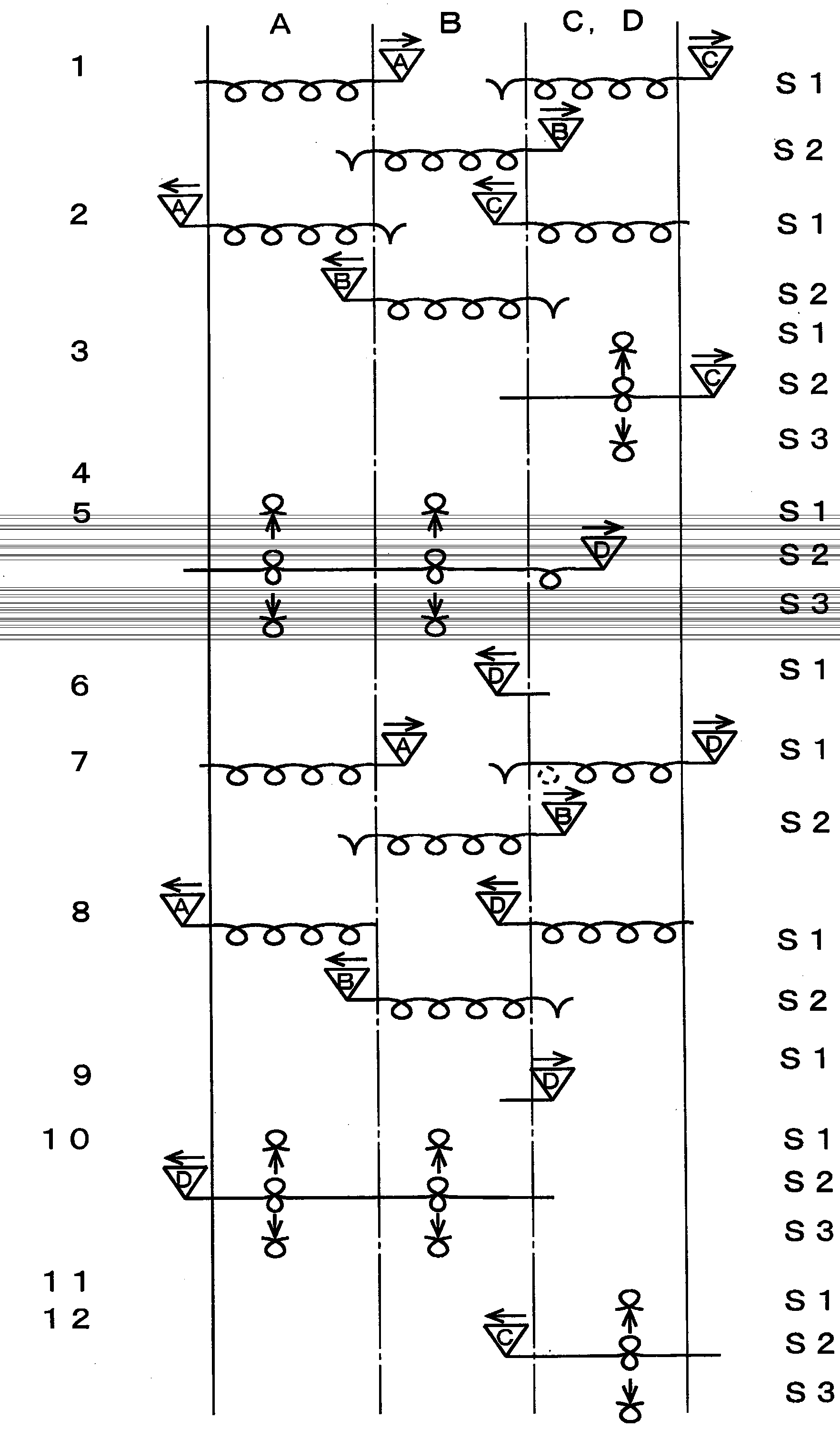

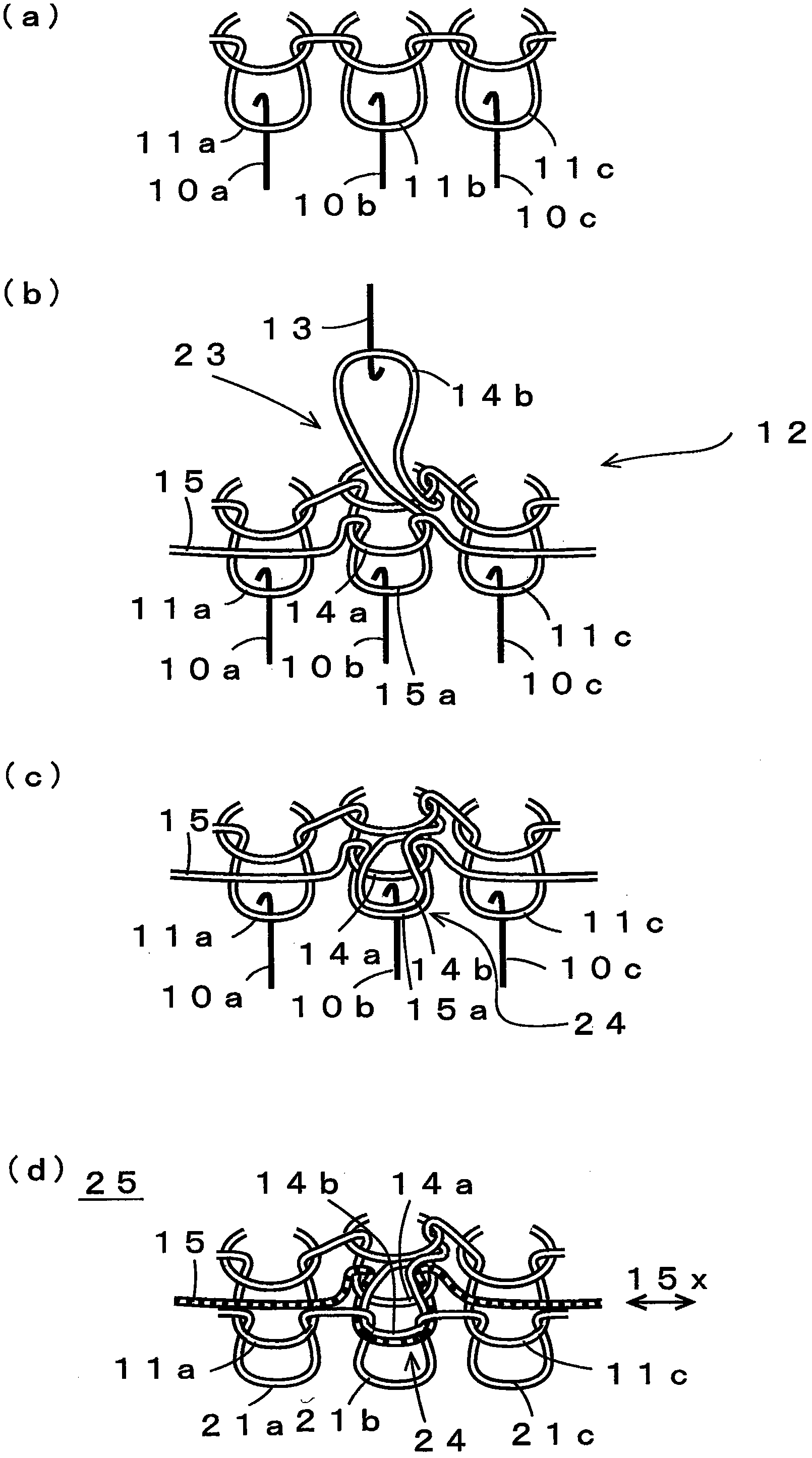

Knitted fabric and knitting method thereof, and designing apparatus

ActiveCN102191614BPrevent bad situationsReliable captureFlat-bed knitting machinesYarnBiomedical engineering

[Problem to be solved] The present invention provides a knitted fabric, a knitting method thereof and a designing apparatus, wherein the knitted fabric is knitted in such a manner that even when the cross - over yarn is reliably captured through the use of the split knit, the knitting yarn, after captured, can be prevented from being slackened to provide problem in knitting. [Solution] A stitch 11b held by a latch needle 10b as a holding needle is transferred to an opposite latch needle 13, as shown in (b), from a state that one course of stitches 11a, 11b, 11c are formed with latch needles 10a, 10b, 10c, as shown in (a). When a cross-over yarn is yarned in, a split knit 16 is carried out to facilitate a capture of the cross-over yarn, as shown in (c). A stitch 15a formed by a latch needle 13 is transferred to the latch needle 10b to form double stitches 20, as shown in (d). After knitting of a knitted fabric 22 is ended, the cross - over yarn 15 shown in dashed line can be drawn out to a lateral direction 15x of the drawing and can be removed from the knitted fabric, as shown in (e).

Owner:SHIMA SEIKI MFG LTD

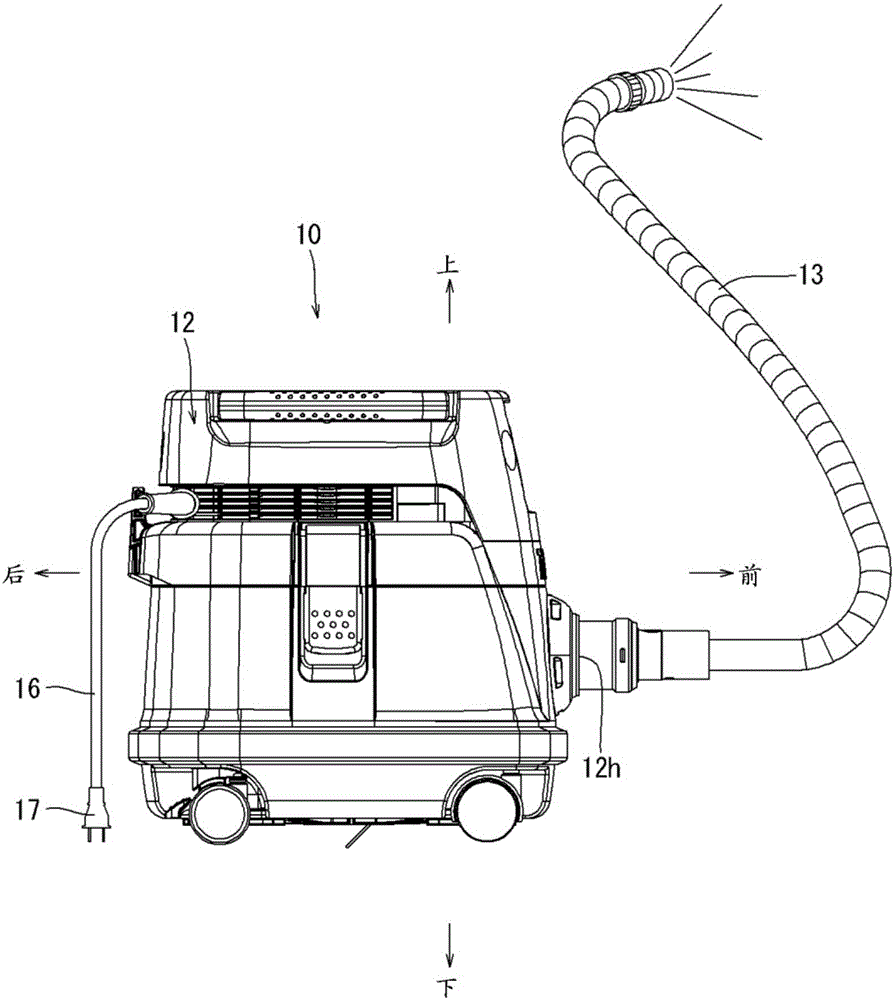

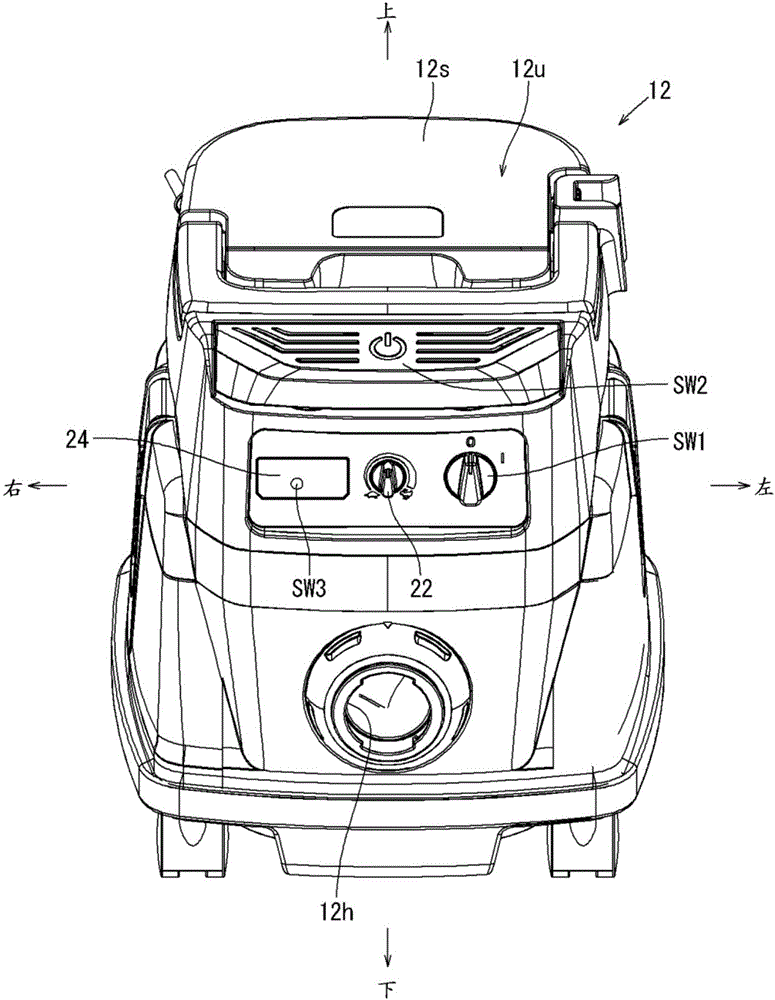

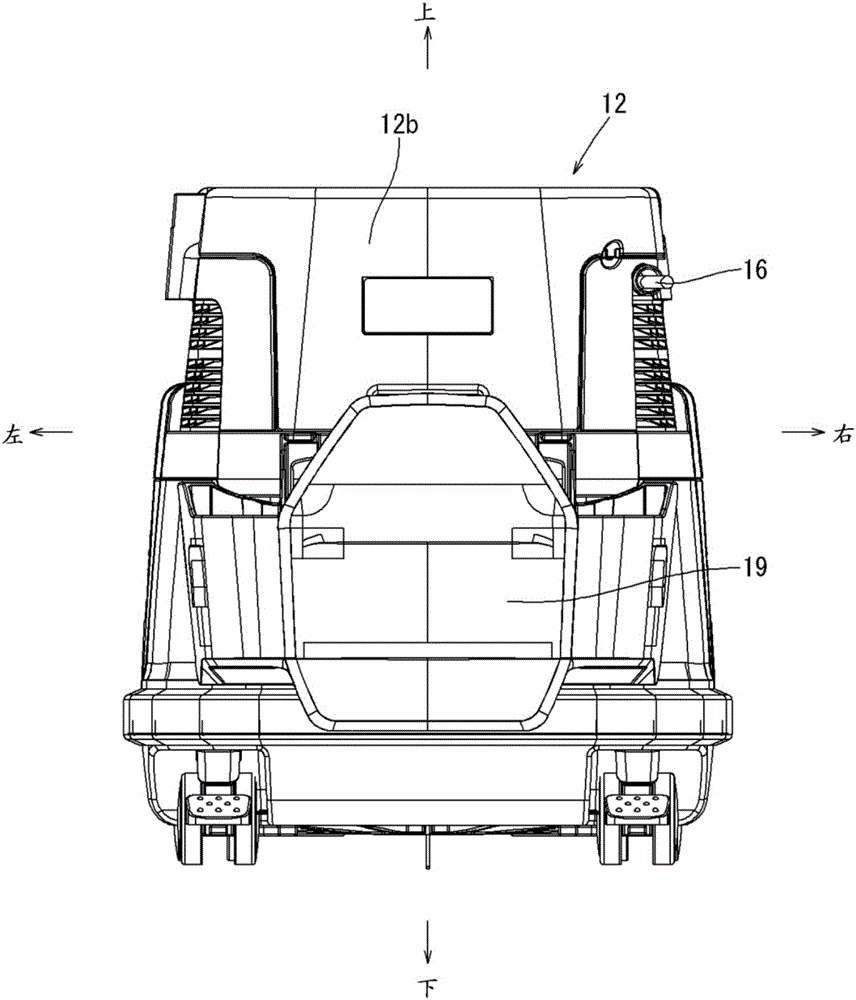

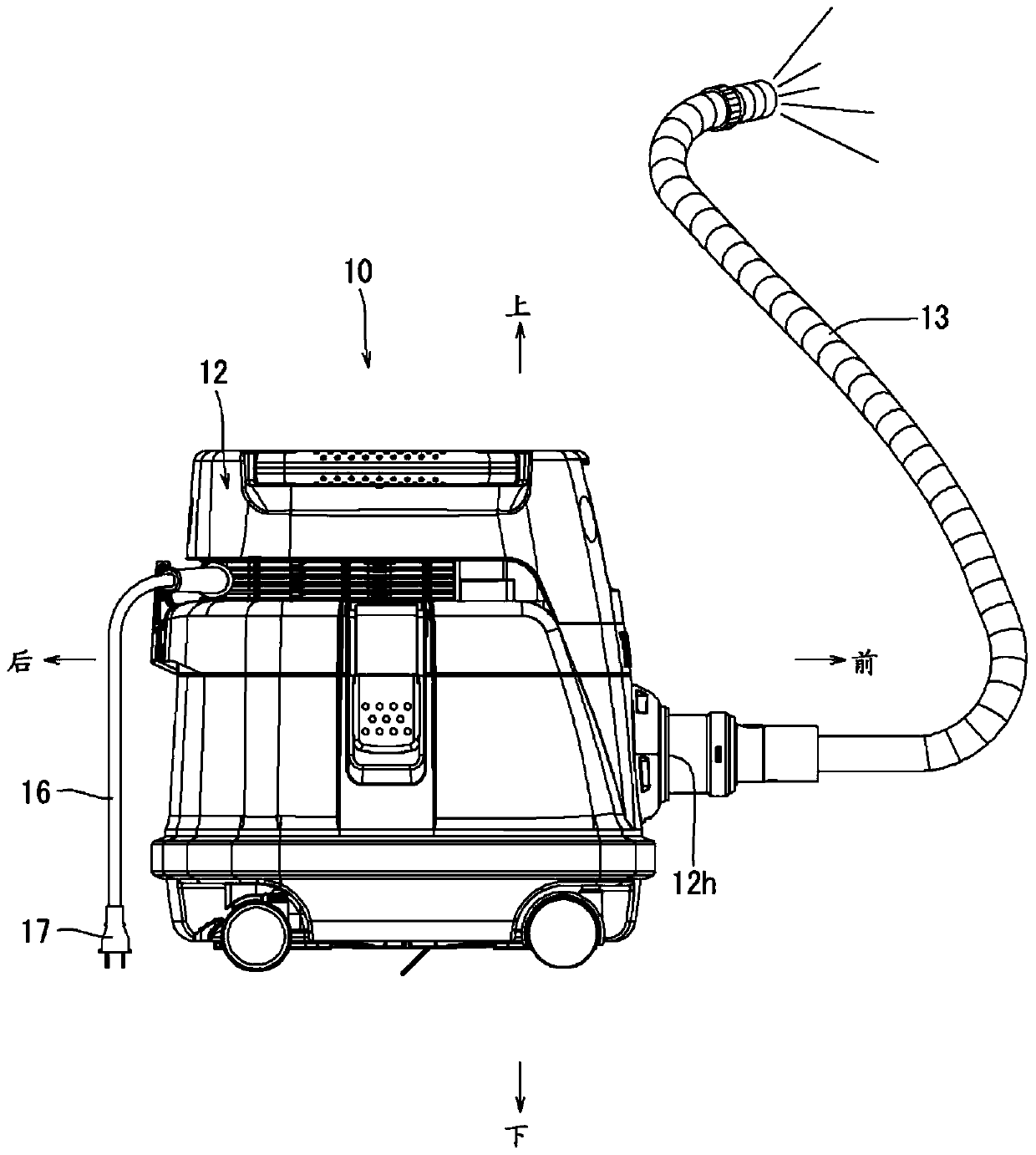

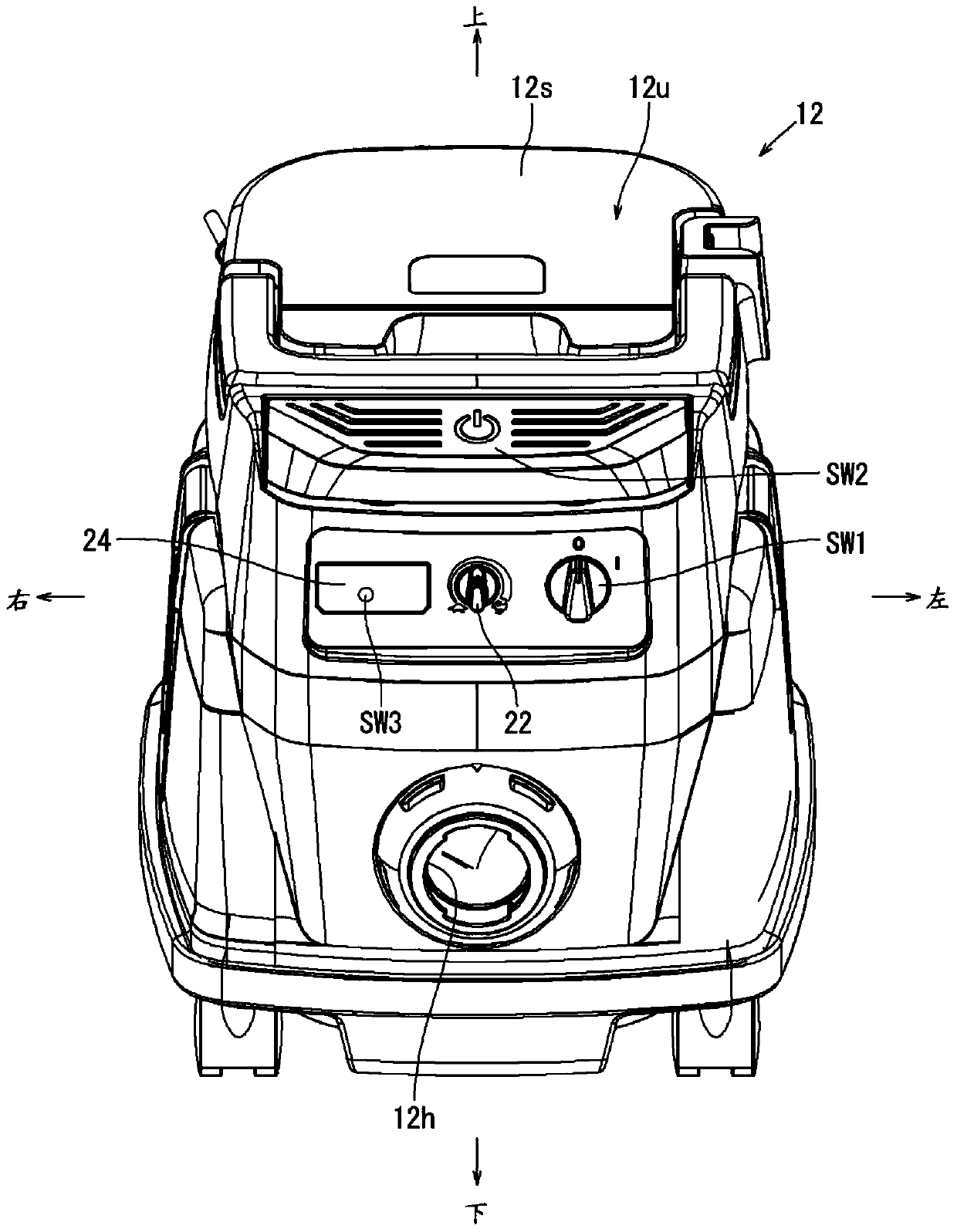

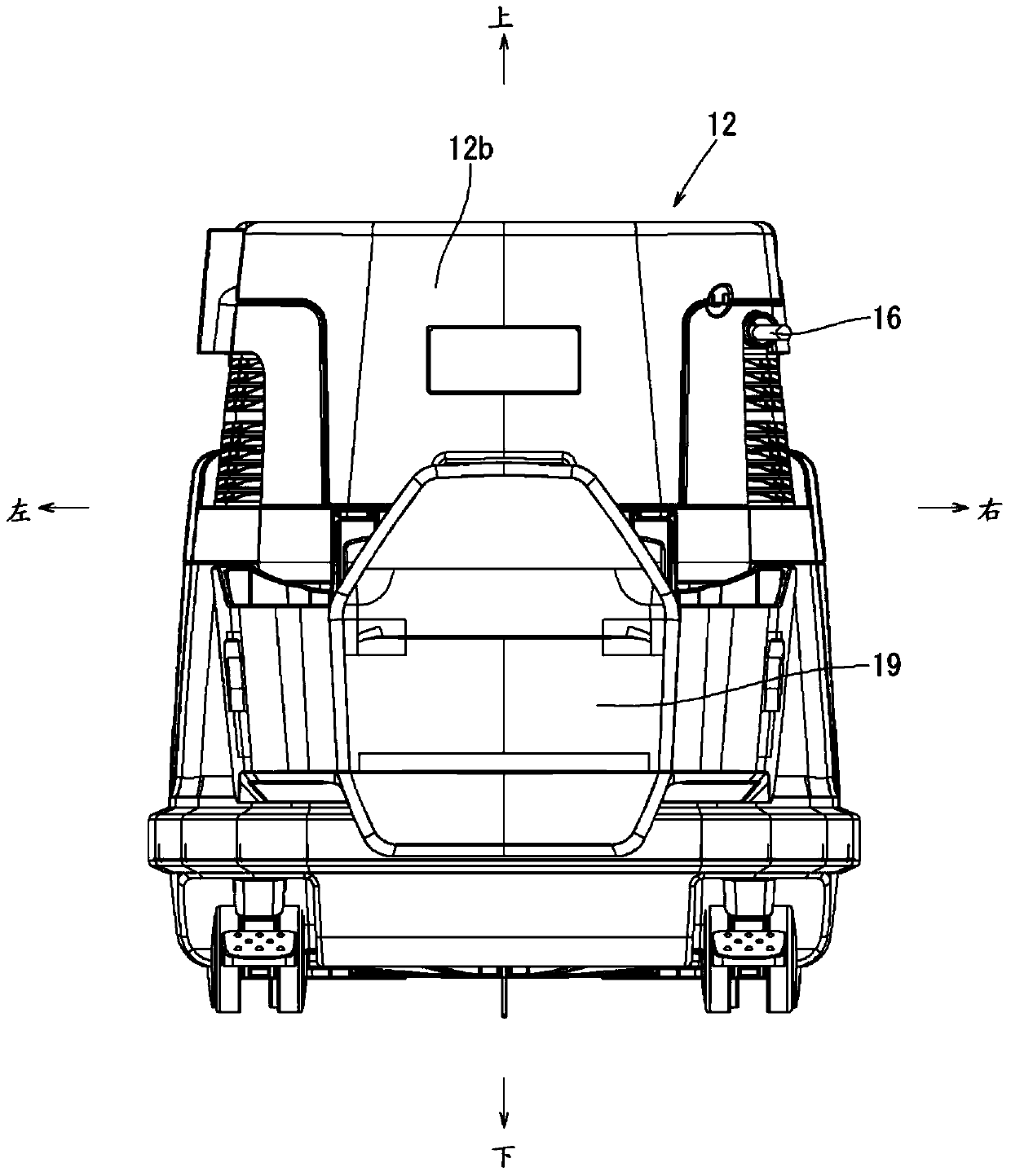

Electronic power equipment

ActiveCN106419730ACompact formGuaranteed insulation performanceAssociation with control/drive circuitsBatteries circuit arrangementsElectricityMotor drive

The objective of the invention is to produce an electronic power equipment which can be driven by AC and DC power sources. An electronic power equipment, which is configured to be connected to both an AC power source and a DC power source, has a motor 14 configured to be driven by both AC power and DC power, an motor driving AC circuit 30 for supplying AC electric power to the motor 14, a motor driving DC circuit 40 for supplying DC electric power to the motor 14, switching parts RL1-RL12 for switching between the motor driving AC circuit 30 and the motor driving DC circuit 40 wherein the AC and DC circuits are insulated relative to each other, and a controller A1 configured to control the switching parts RL1-RL12, the motor driving AC circuit 30, and the motor driving DC circuit 40.

Owner:MAKITA CORP

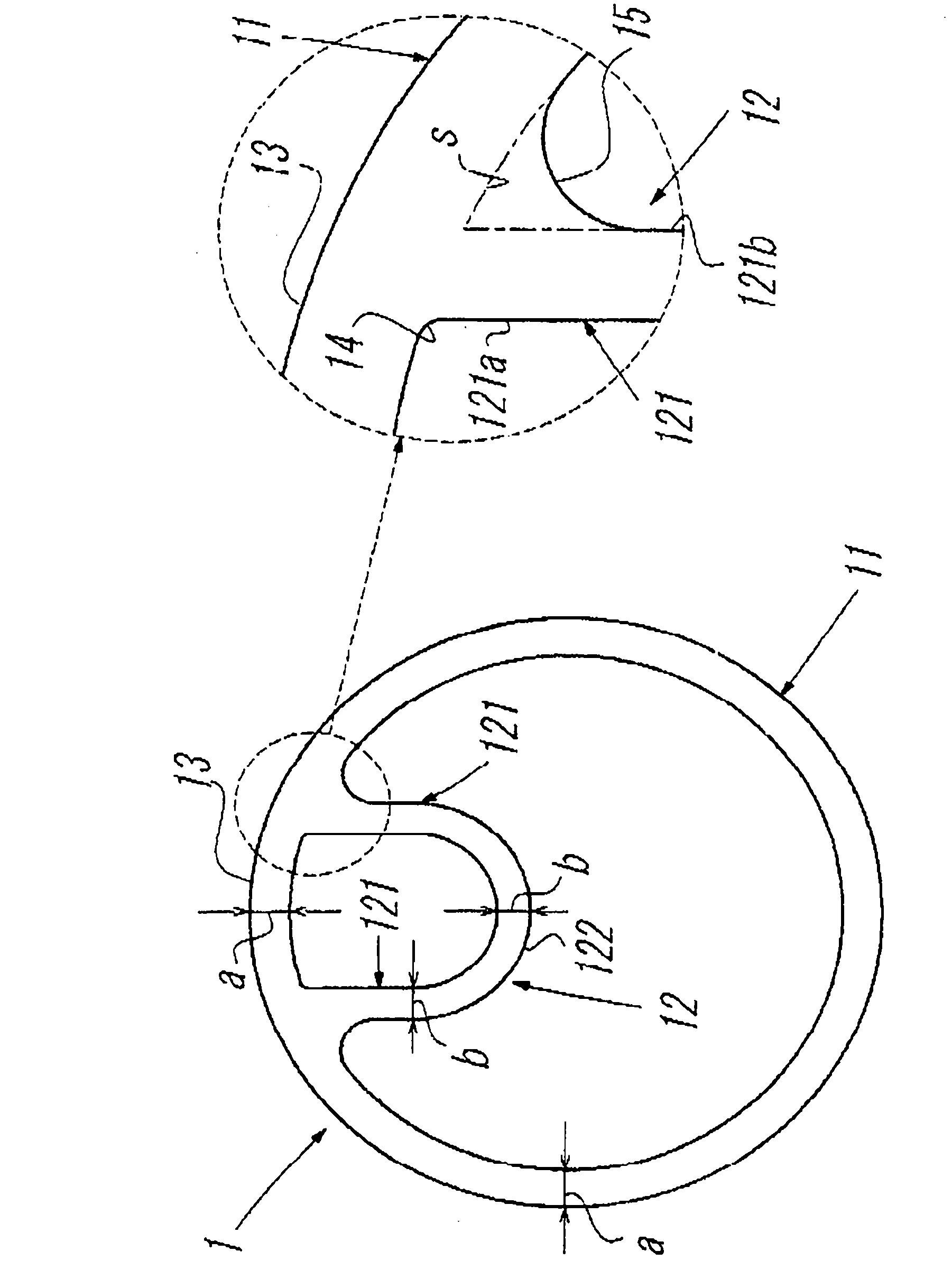

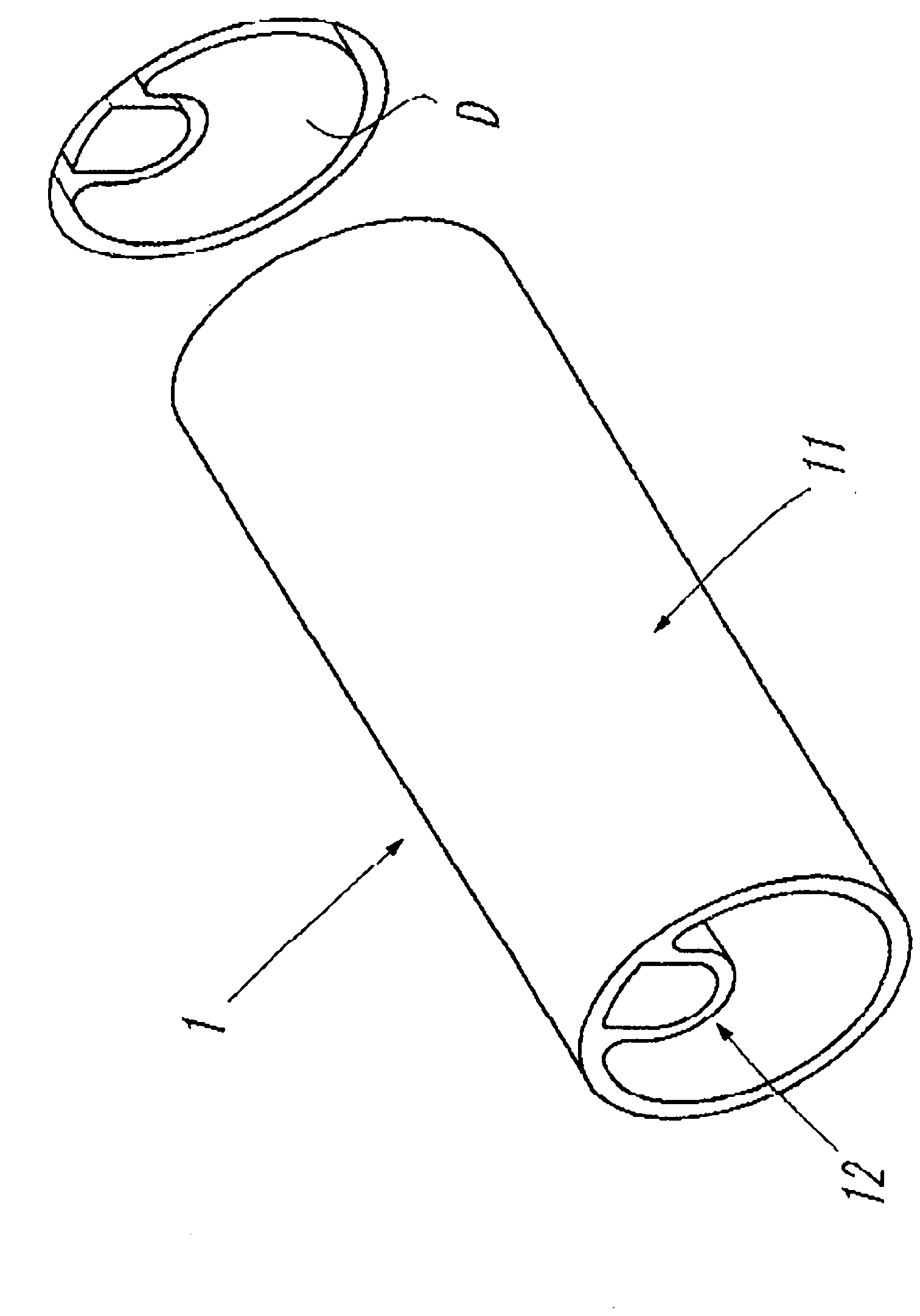

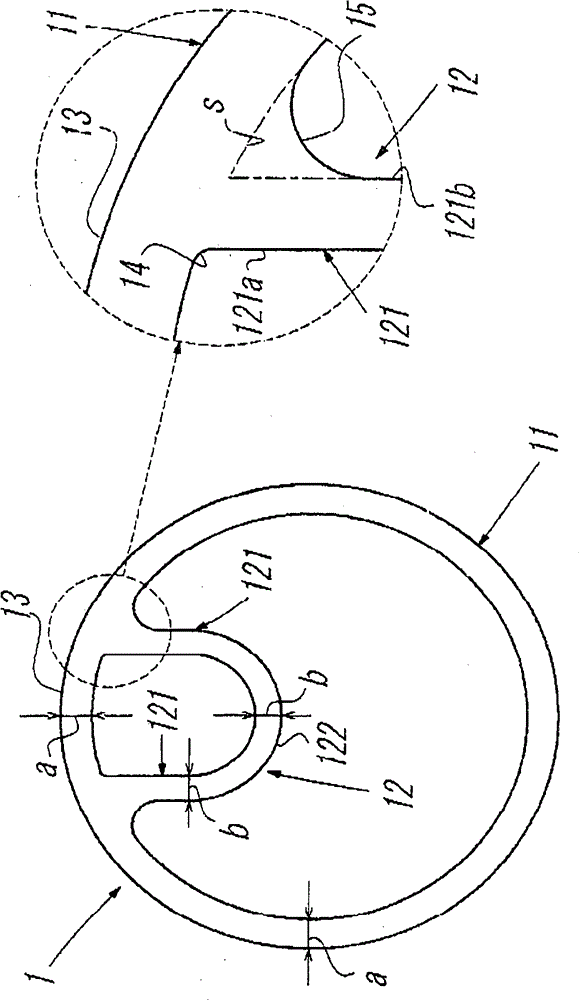

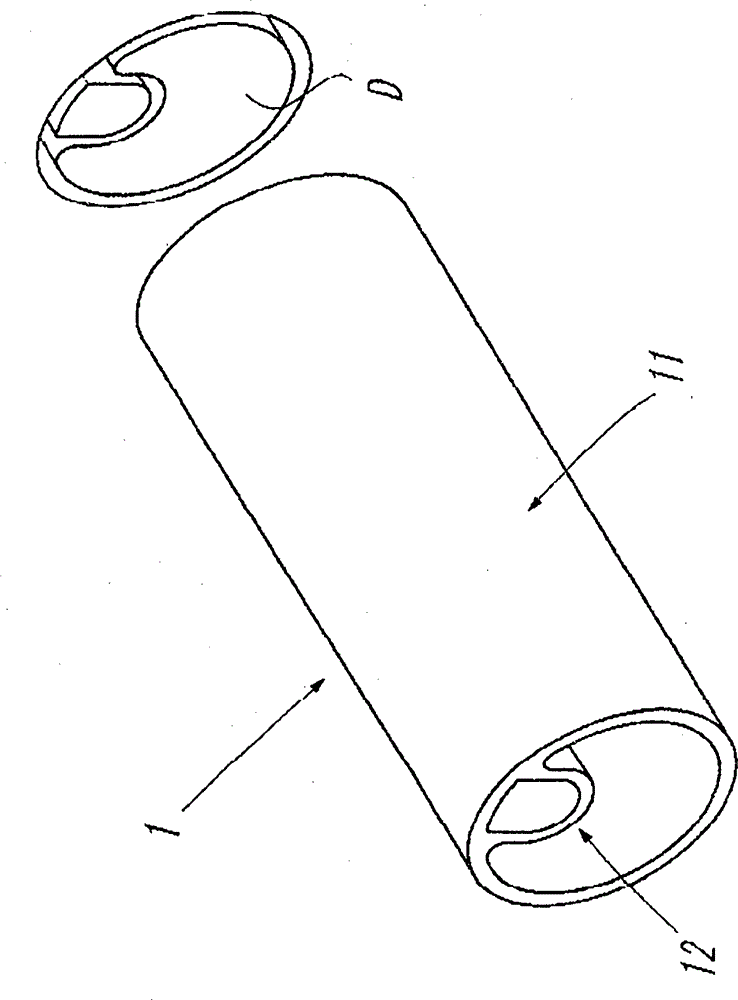

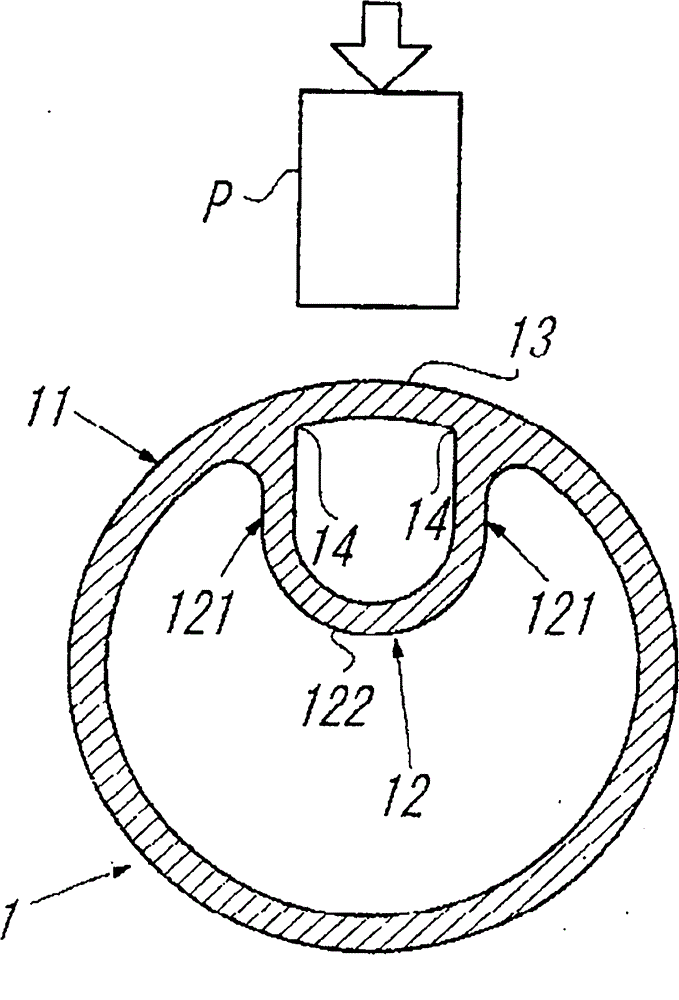

Dual tube and connecting structure thereof

ActiveCN103216687AWith pressure resistanceAvoid hidingPipe elementsRigid pipesEngineeringMaterial Perforation

The invention provides a dual tube and a connecting structure thereof. When a common part of an outer tube and an inner tube undergoes stamping perforation processing for connecting the inner tube, defective conditions caused by stamping of waste materials are avoided. An inner tube (12) is arranged inside an outer tube (11); parts of the outer tube (11) and the inner tube (12) are unified into a whole; the inner tube (12) is provided with side walls (121) extending oppositely in parallel from a common part (13) of the outer tube (11) and the inner tube (12) with the diameter direction of the outer tube (11) between the side walls; and the depth end of the side wall (121) and opposite depth walls (122) of the common part (12) of the outer tube (11) and the inner tube (12) are not expanded to a degree exceeding the space between the side walls (121).

Owner:WATANABE KK

Electric working machine

ActiveCN106419730BCompact formGuaranteed insulation performanceAssociation with control/drive circuitsBatteries circuit arrangementsEngineeringDrive motor

Owner:MAKITA CORP

Plate processing apparatus

Owner:AU OPTRONICS CORP

Storage box structure of motor two-wheeler

ActiveCN101468679BSave storage spaceUse effectivelyCycle saddlesCycle containersVehicle frameAir cleaners

The present invention provides a containing box structure of motor two-wheel vehicle which can ensure a large containing space even the upper part of back buffer is fixed at the inner side of vehicle frame. The motor two-wheel vehicle is provided with one pair of vehicle frames (21L, 21R) in left-and-right direction. The containing box (24) is configured below the seat and between the pair of vehicle frames. Simultaneously the upper part of buffer (27) which is used for suspending the back wheel (41) is installed on one surface or two surfaces of the opposite inner side surfaces of vehicle frame. Two outer sides of containing box are respectively installed with a dent (100L, 100R) for preventing the interference to the upper part of buffer (27). The flat surfaces (102L, 102R) which are flat in the left-and-right direction of vehicle are formed in the inner part of containing box and at the dents thereby forming a first containing space (S1). Furthermore a slant surface (104) is formed between the left dent and the right dent thereby forming a second containing space (S2). An air cleaner (2) is arranged at the front of the buffer, thus the containing box is provided with a yield section (201) of the shell of the air cleaner.

Owner:HONDA MOTOR CO LTD

Coverlay film

ActiveCN108624244ANo bad situationImprove protectionFilm/foil adhesive primer layersPolyureas/polyurethane adhesivesOperabilityMaterials science

The present invention provides a coverlay film which is excellent in processing suitability, operability and adherence to FPC even if the coverylay film is a thin film. The coverlay film is characterized in that, a first insulating layer (12), a second insulating layer (13) and a thermosetting adhesive layer (14) are sequentially laminated on one surface of a support film (11),, wherein the firstinsulating layer (12) contains a flame retardant resin. The tensile elongation of a laminate (15) formed by the first insulating layer (12), the second insulating layer (13) and the thermosetting adhesive layer (14) without the support film (11) is over 100%.

Owner:FUJIMORI KOGYO CO LTD

Dual tube and connecting structure thereof

Owner:WATANABE SEISAKUSHO KK

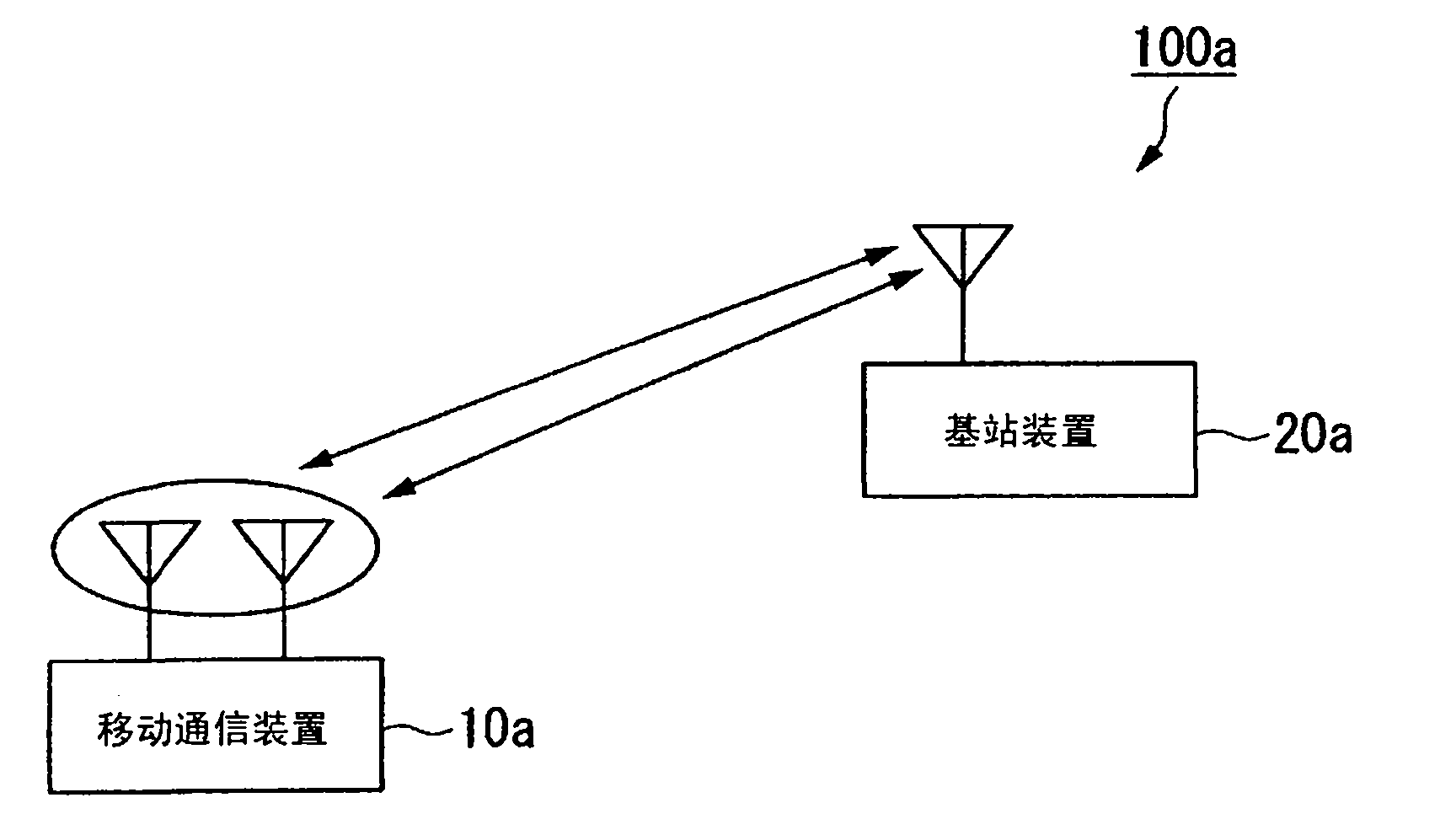

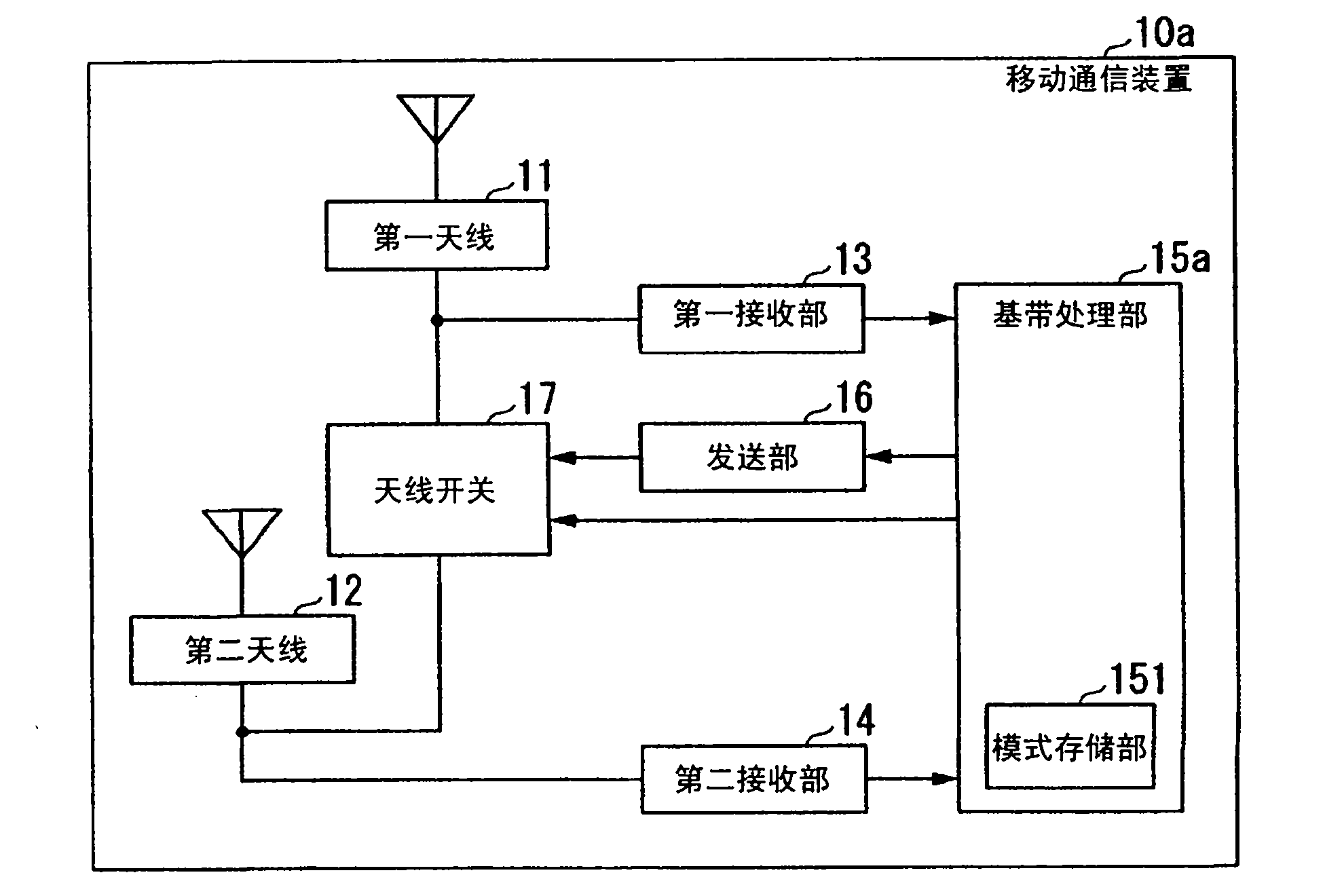

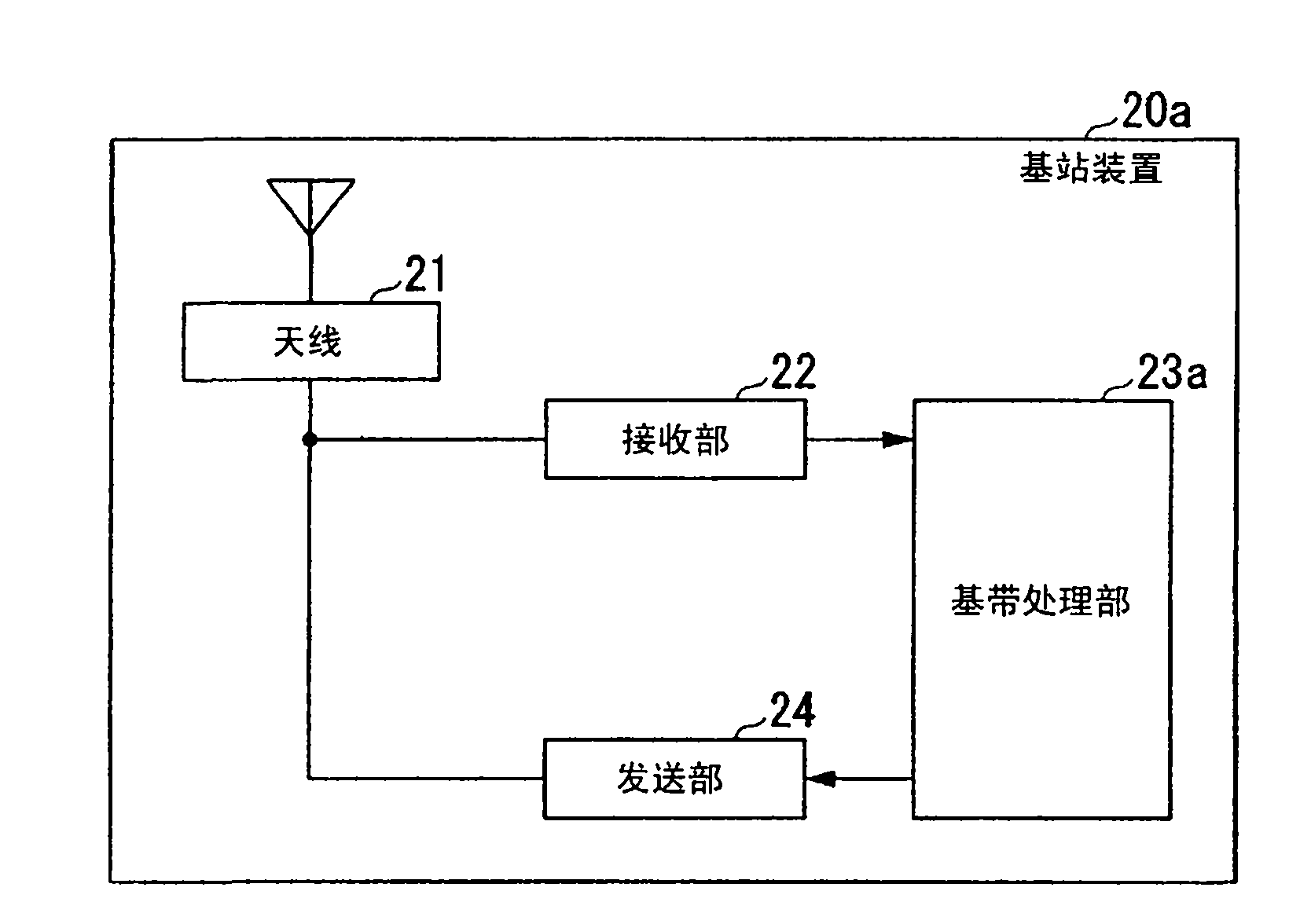

Mobile communication device, base station device, wireless control method, and mobile communication system

ActiveCN101933356AIncrease frequencyNo bad situationSpatial transmit diversityAllocation timingBase station identity codeWireless control

Owner:SHARP KK

Fiber bundle crimping device and method for producing crimped fiber bundle

According to the present invention, a tow-width restrictor (10a), constructed from a plate material shaped substantially as an isosceles triangle having an acute angle at the front tip with respect to the direction of travel, is disposed in the tow introduction part (10) of a pair of fiber-tow push-in rolls further upstream from the nip point (9) of push-in rolls (1, 2). A tow protrusion preventer (11a) for preventing fiber protrusion in the fiber tow (8) is disposed subsequent to the tow-width restrictor (10a) in a roll side surface that includes the nip point (9) of the pair of the push-in rolls (1, 2). The difference between the push-in roll width (A) and the distance (B) between the inner wall surfaces of a pair of protrusion prevention holding plates (15) is 0.2-12 mm. The distance (C) between the tip of the tow-width restrictor (10a) and the nip point (9) of the push-in rolls (1, 2) is 0-22 mm.

Owner:TOYAMA FILTER TOW

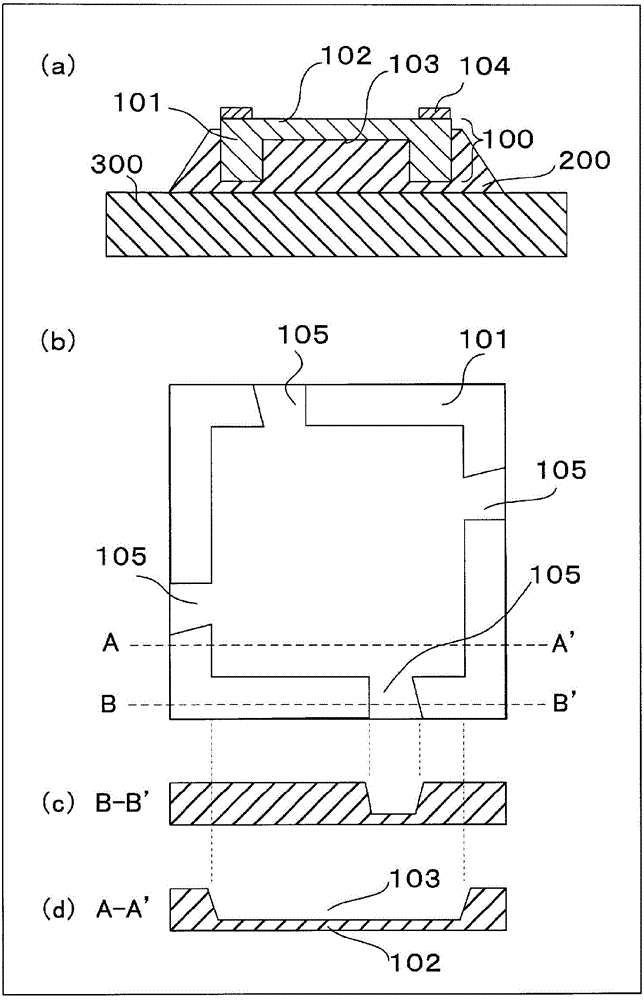

Semiconductor device

InactiveCN104380470AReliable weldingNo bad situationSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor chipEngineering

A groove for air ventilation is formed in a rib with a substantially rectangular ring shape which is provided so as to surround a concave portion provided in a rear surface of a semiconductor chip. The groove is provided in each side or at each corner of the rib so as to traverse the rib from the inner circumference to the outer circumference of the rib. The depth of the groove is equal to or less than the depth of the concave portion provided in the rear surface of the chip. In this way, it is possible to reliably solder a semiconductor device, in which the concave portion is provided in the rear surface of the semiconductor chip and the rib is provided in the outer circumference of the concave portion, to a base substrate, without generating a void in a drain electrode provided in the concave portion.

Owner:FUJI ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com