Electric working machine

A working machine and electric technology, applied in the direction of AC motor control, motor speed or torque control, cleaning machinery, etc., to achieve the effect of ensuring insulation distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

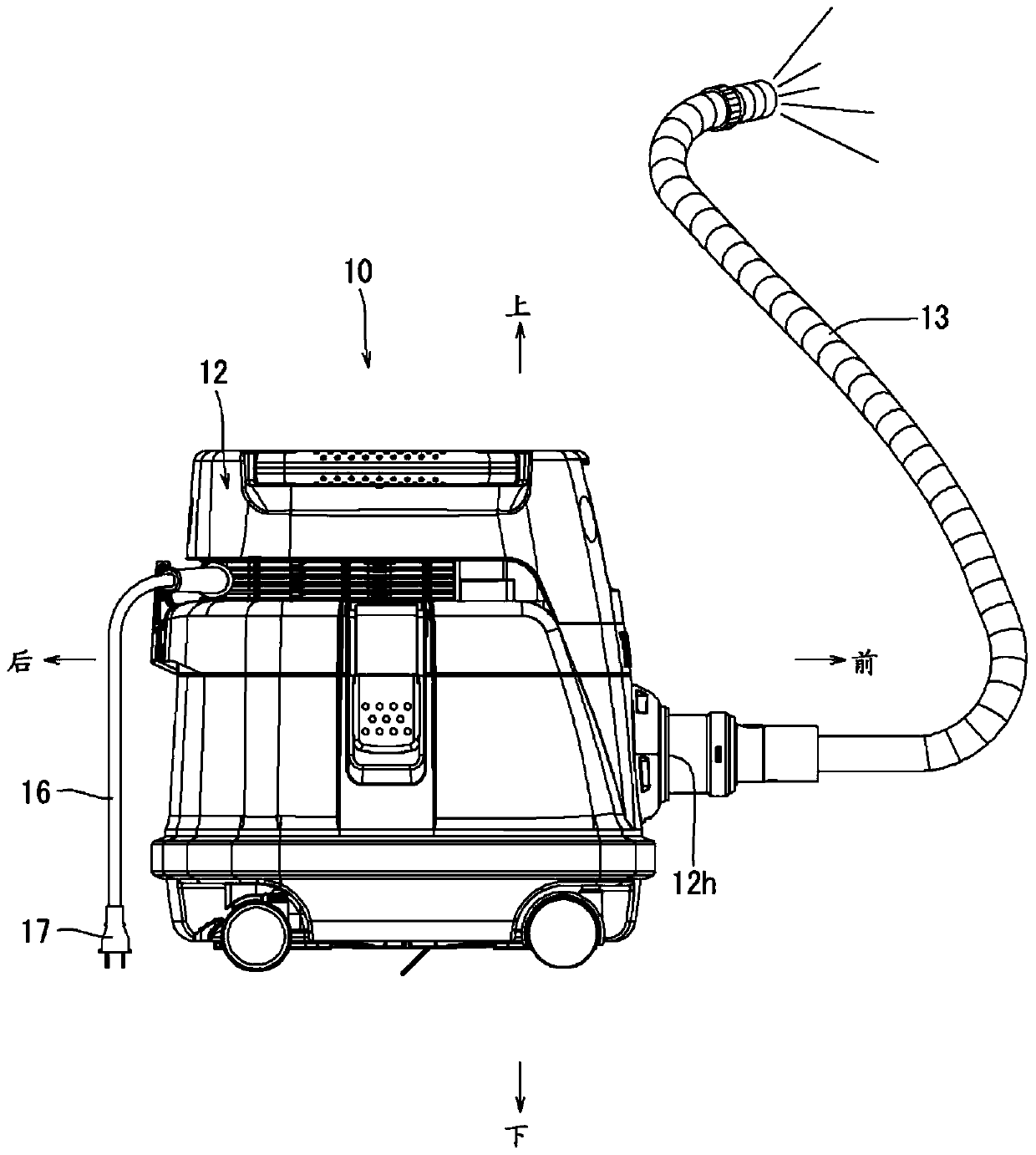

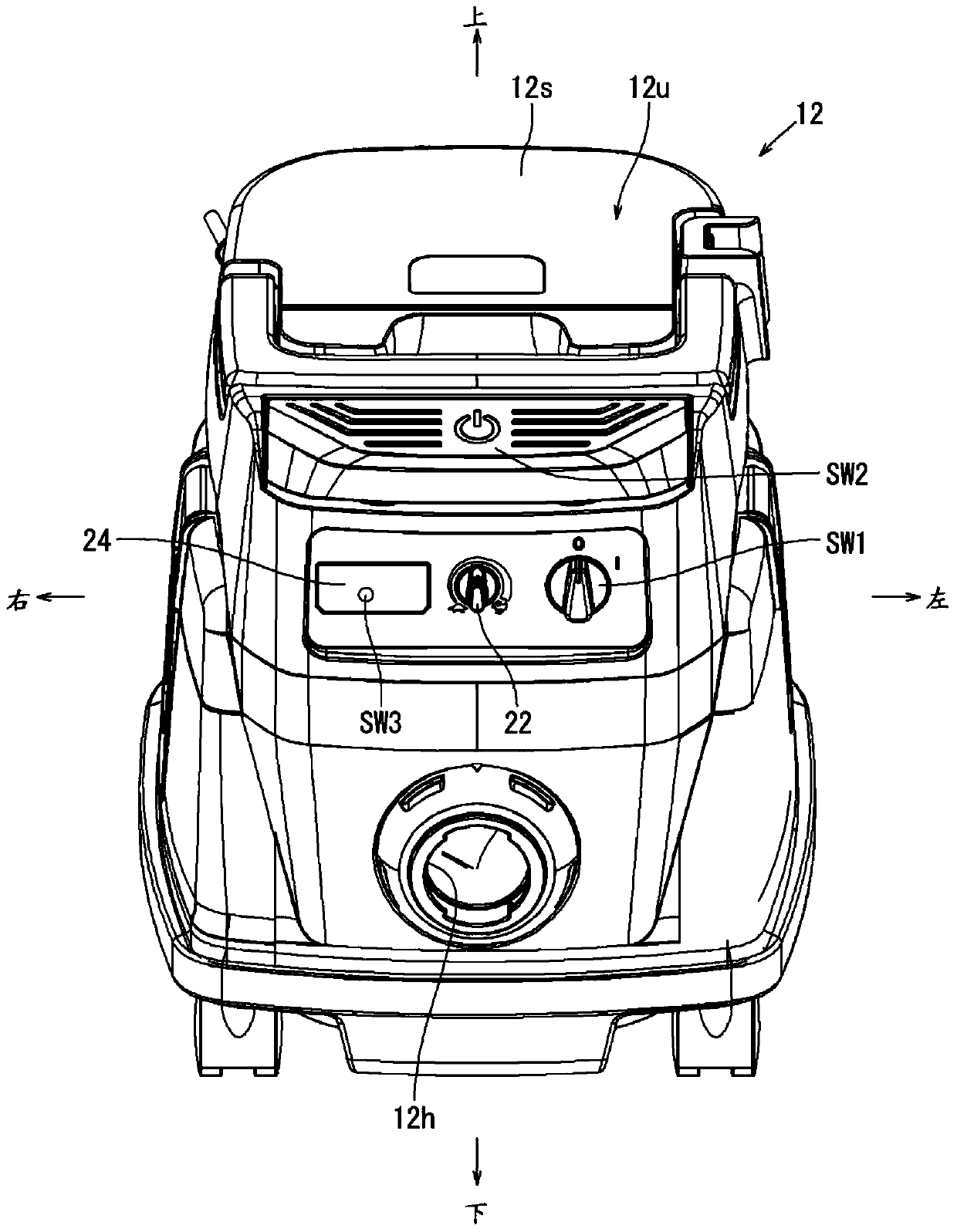

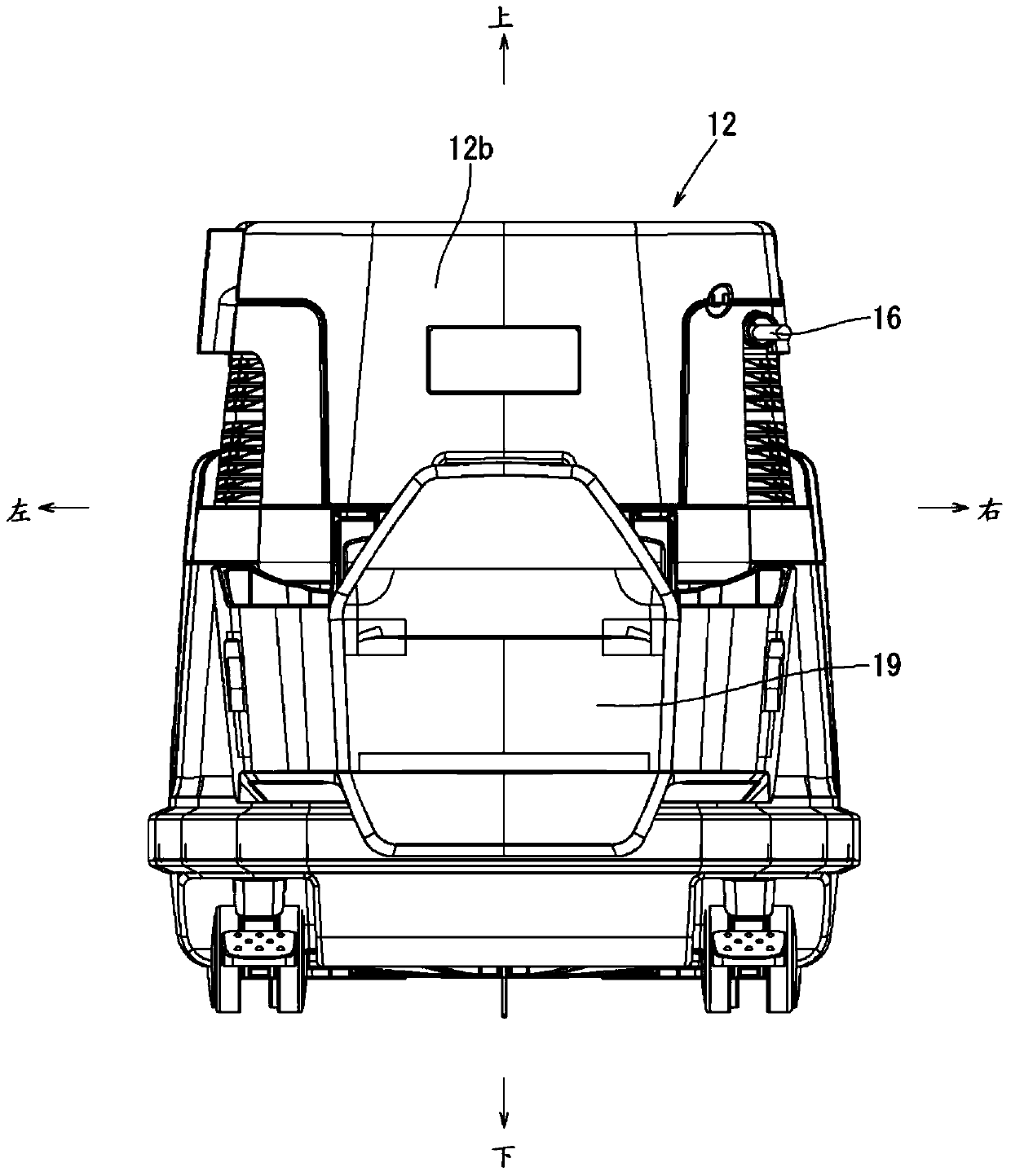

[0033] Below, according to Figure 1 to Figure 10 , the electric working machine according to Embodiment 1 of the present invention will be described. The electric working machine according to the present embodiment is a dust collector 10 that sucks machining chips and the like generated when an object is machined using a tool. Here, the front, rear, left, right, and up and down shown in the drawings correspond to the front, back, left, and right, and up and down of the dust collector 10 .

[0034]

[0035] Such as figure 1 As shown, the dust collector 10 is composed of a dust collector main body 12 and a suction hose 13 connected to a dust collection port 12h of the dust collector main body 12 . The dust collector main body 12 is constituted as a motor 14 (refer to Image 6 The circuit diagram of ) rotates a fan (not shown in the figure) to generate an air flow, whereby outside air can be sucked from the dust collection port 12h via the suction hose 13 . And the dust co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com