Fiber bundle crimping device and method for producing crimped fiber bundle

A technology of crimping device and manufacturing method, which is applied in textiles and papermaking, and can solve the problems of reduced production efficiency of crimped fiber bundles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

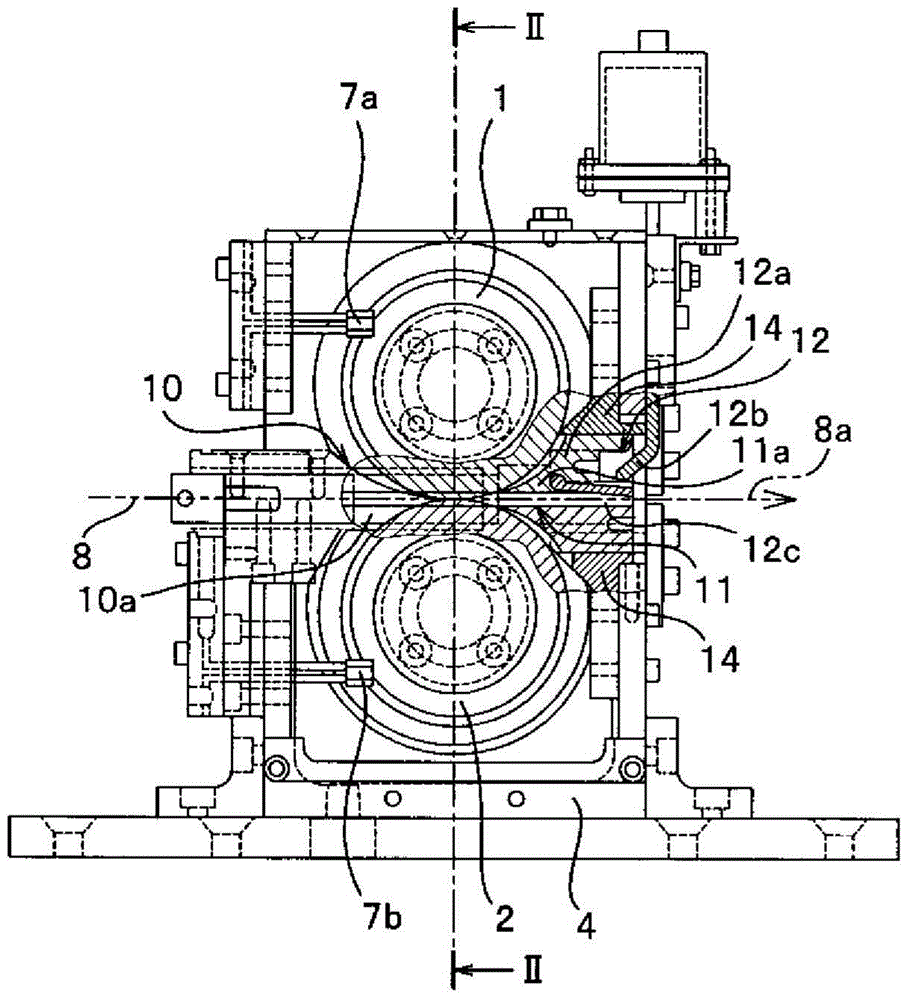

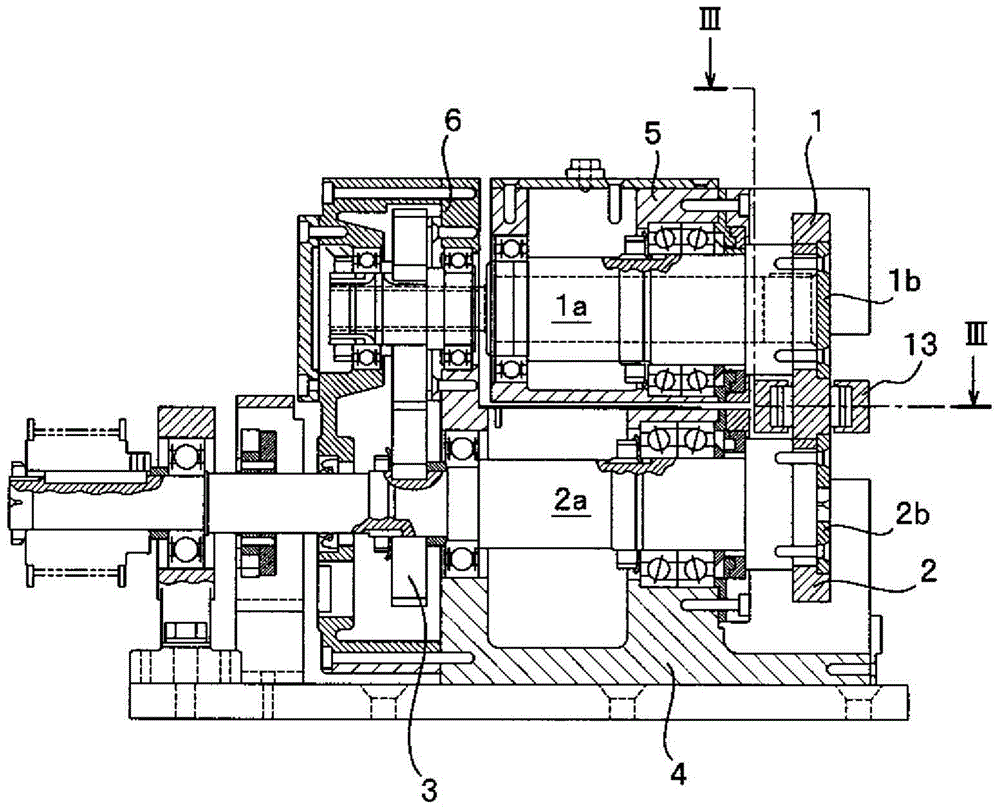

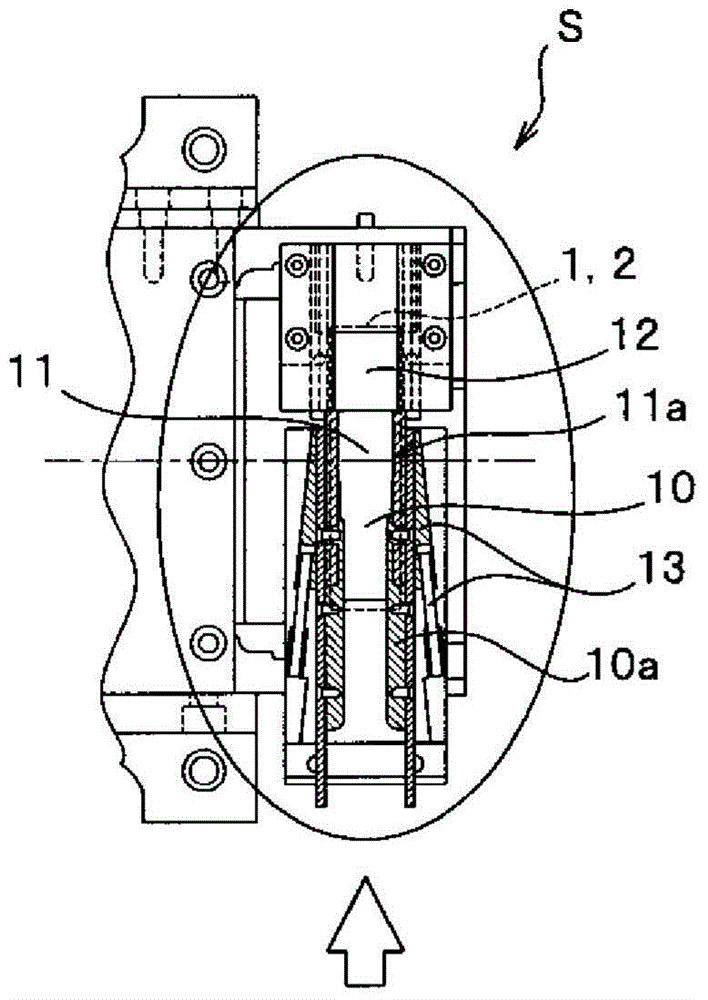

[0084] Prepare figure 1 , figure 2 The shown is a pressing and crimping device for acetate fiber bundles for cigarette filters. In the pressing and crimping device for fiber bundles, the width of the pressing roller is 19mm, and the material of the tow width limiting part is chrome sprayed on the surface. Finished SUS440C stainless steel, tow protruding prevention plate is made of alumina ceramics. As shown in Table 1, the distance B between the width A of the first and second press-in rollers and the wall surface of the left and right pair of tow sticking prevention platens having the tow width restricting portion and the tow sticking out preventing portion The difference (A-B) is set to 5 types of 0.4mm, 1mm, 5mm, 10mm, and 15mm, and the distance C between the front end of the tow width restricting part and the nip of the press-in roller is calculated for each tow width restricting part and the yarn The difference in distance B (A-B) between the walls of the pressure plat...

experiment example 2

[0091] Prepare figure 1 , figure 2 The press-fitting and crimping device for acetate fiber bundles for cigarette filters is shown. In the press-fitting and crimping device for fiber bundles, the width of the press-fitting roller is 19mm, and the material of the tow width limiting part is chrome sprayed on the surface. Finished SUS440C stainless steel, and the material of the pressure plate for preventing the tow from sticking out is alumina ceramics. As shown in Table 2, the distance B between the width A of the first and second press-in rollers and the wall surface of the left and right pair of tow sticking prevention platens having the tow width restricting portion and the tow sticking out preventing portion The difference (A-B) is set to 1.6 mm, and the distance C between the front end of the tow width restricting part and the nip of the press-in roller is set to three types of tow width restricting parts (there are tow width restricting parts) ), the operation was conti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com