Plate processing apparatus

A technology for processing equipment and flat panels, applied to lighting and heating equipment, installation, lighting devices, etc., can solve the problem of not being able to see the surface of the substrate 103, and achieve the effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

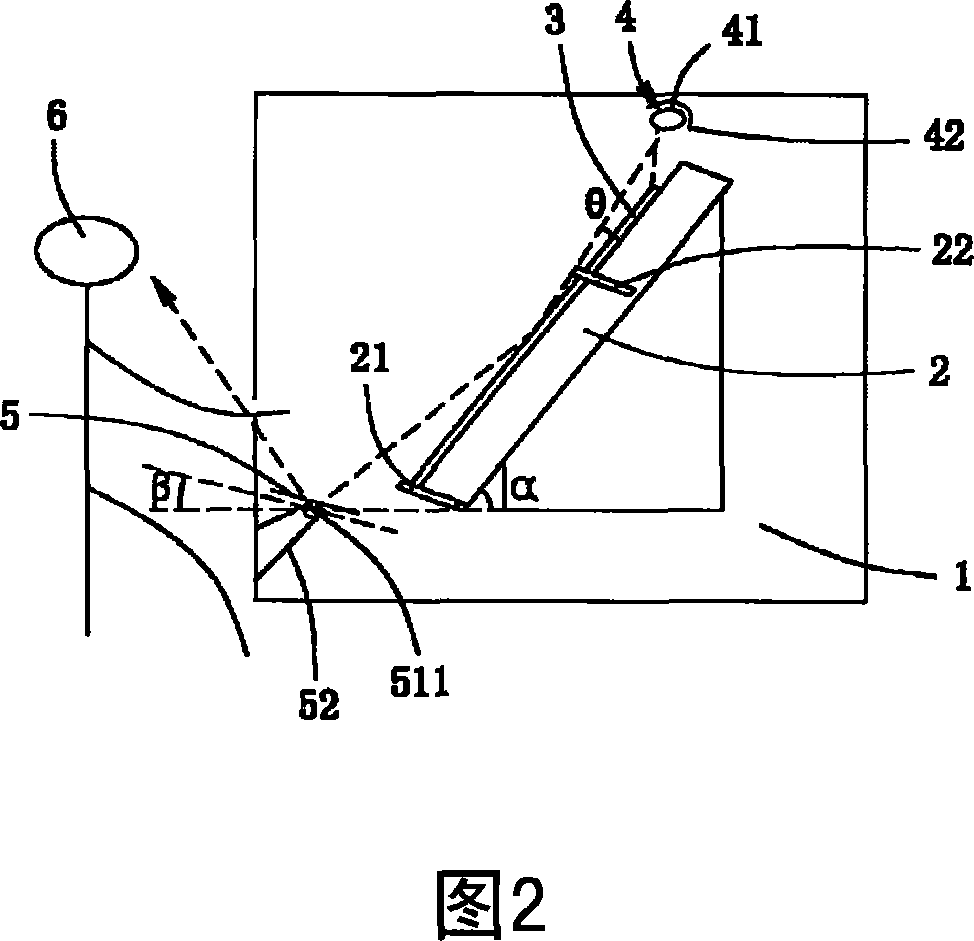

[0023] Please refer to FIG. 2 , the tablet processing equipment 1 of the present invention includes a carrying platform 2 , the upper surface of which is an inclined surface. The carrying platform 2 is a long platform perpendicular to the drawing, and only its side view is shown in the drawing. The size of the inclination angle α of the aforementioned inclined surface is suitable for the convenience of the operator 6 to operate the products on the flat plate processing equipment. According to a preferred embodiment of the present invention, referring to the size of the liquid crystal panel, the tilt angle α is 60±5°.

[0024] A baffle plate 21 exceeding the surface of the carrying platform 2 is arranged at the bottom of the carrying platform 2, and a positioning member 22 is respectively arranged on both sides of the carrying platform 2; At this time, the substrate 3 can be restricted from the bottom and both sides of the carrying platform 2 to prevent the substrate 3 from fa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com