Slit yarn knitting method in circular knitting machine, apparatus therefor and knit fabric

A technology for circular knitting machines and knitted fabrics, applied in the field of knitted fabrics, which can solve problems such as turning over and forming folds on the front and back, and achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

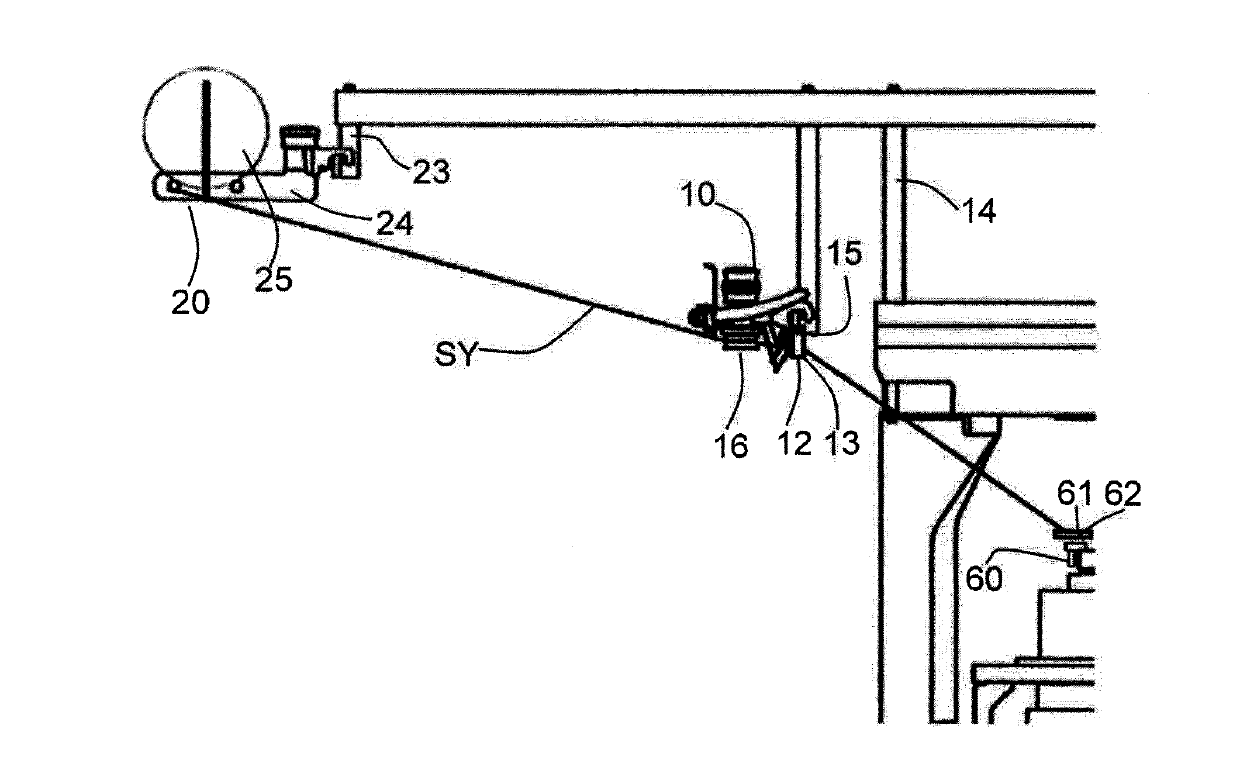

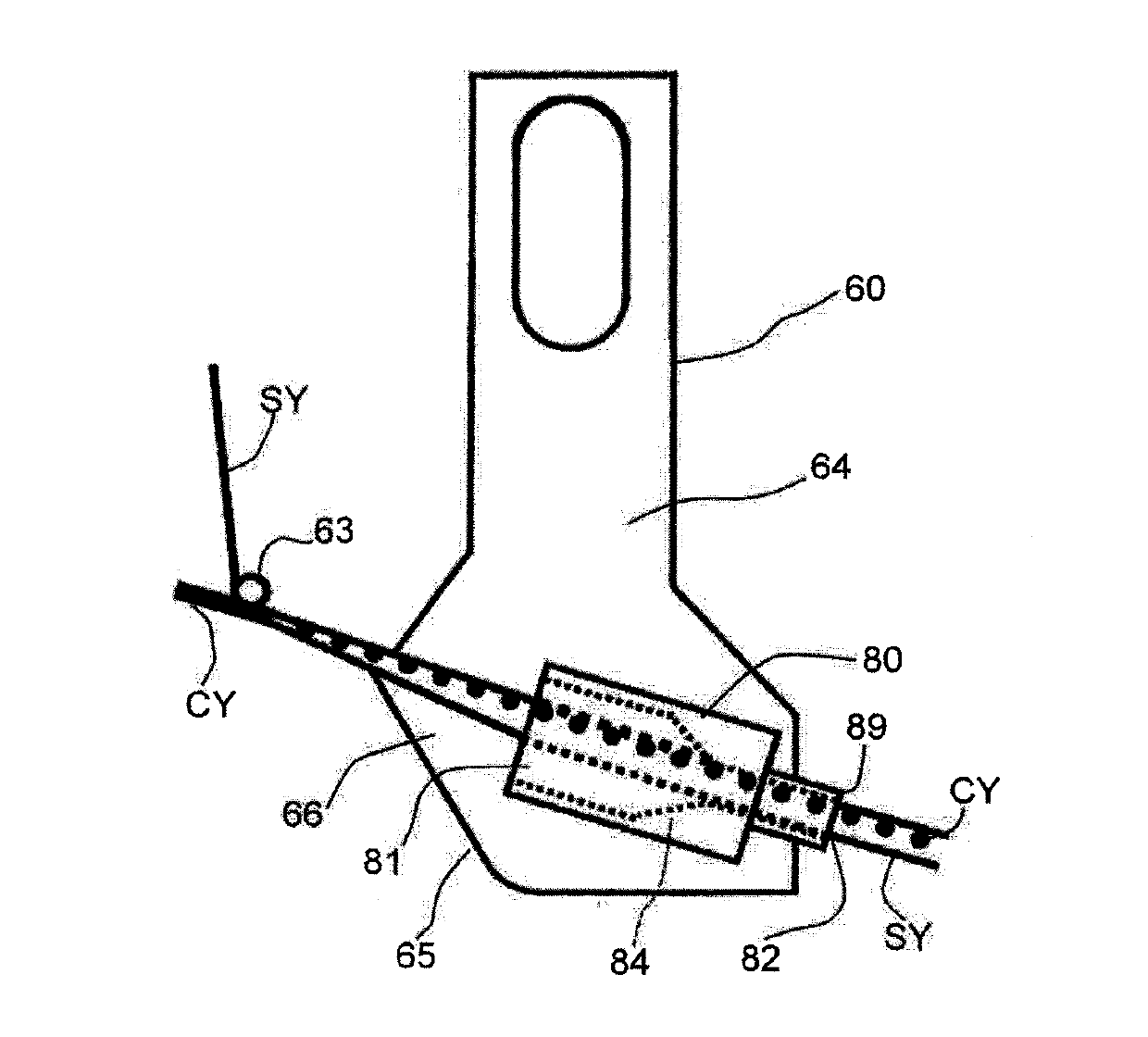

[0037] 1. Outline of circular knitting machine

[0038] figure 1 It is an overall view of a knitting machine, showing two types of first yarn feeding device 10 and second yarn feeding device 20, first driving wheel 11 and second driving wheel 21 for driving the yarn feeding device, and a plurality of machine feet 30. The needle bed 40 supported by the machine foot 30, and the knitting section 50 arranged on the needle bed. The first yarn feeding device 10 and the second yarn feeding device 20 are driven from the first driving wheel 11 and the second driving wheel 21 via a driving belt, but the driving belt is not shown for convenience.

[0039] Although not shown, the knitting unit 50 accommodates a plurality of cylinder needles in the needle grooves of the cylinder that can slide in the vertical direction. The cam seat which is opposite to the syringe and has a needle for controlling the syringe is installed on the cam seat supporting ring. As will be described in detail l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com