cover film

A technology of covering film and body film, which is applied in the direction of film/sheet adhesive, non-metallic protective layer, circuit bendable/stretchable parts, etc., which can solve the problem of lack of flexibility and poor processing suitability , Poor operability and other problems, to achieve the effect of reduced FPC protection performance, excellent flexural characteristics, and reduced adverse conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

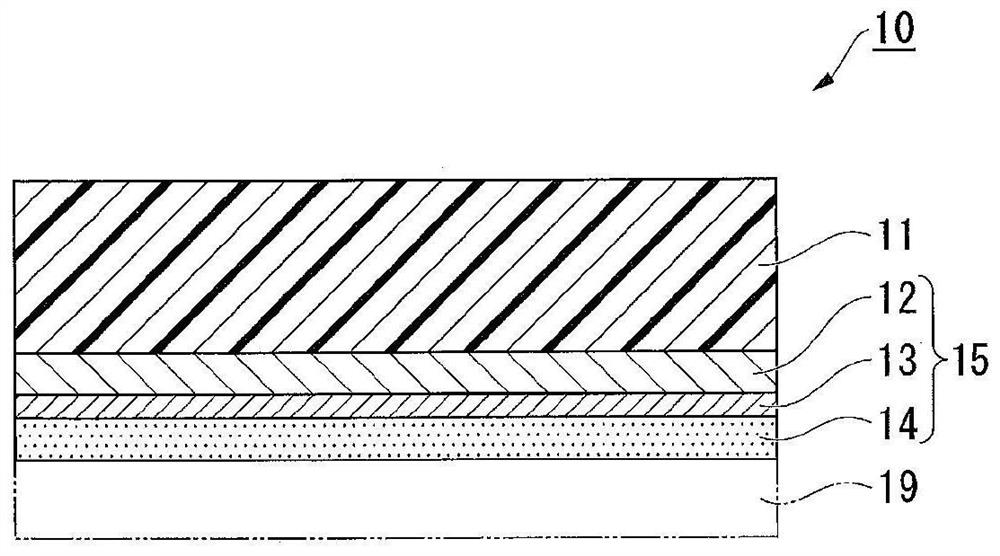

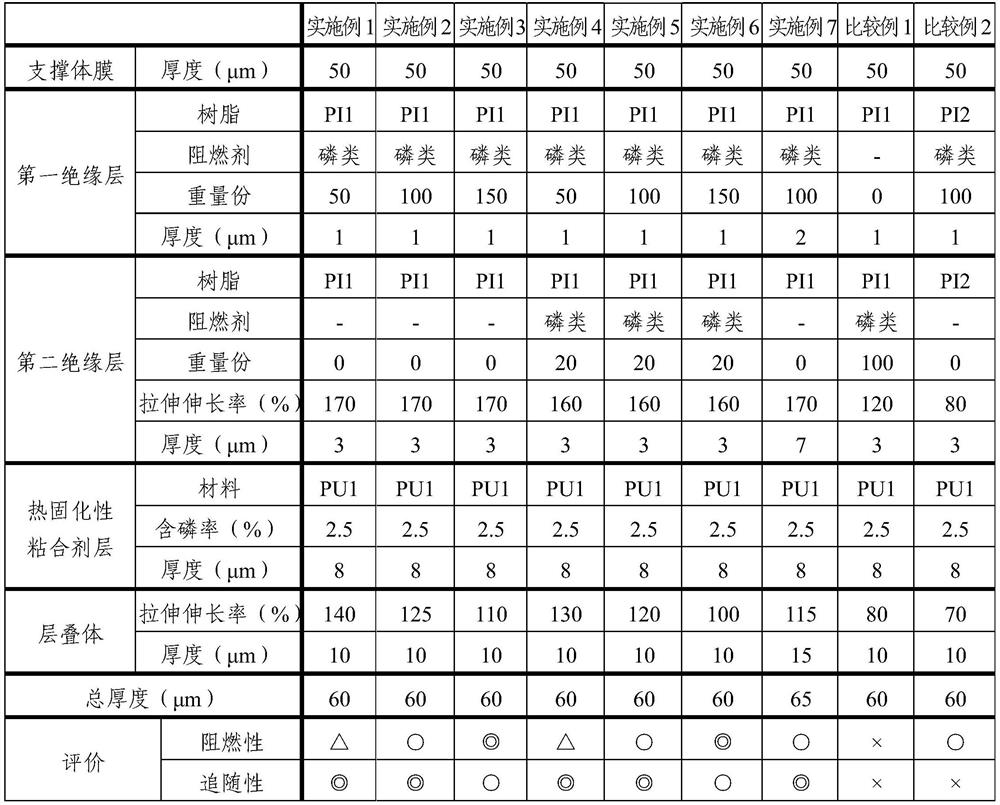

[0084] A polyethylene terephthalate (PET) film having a thickness of 50 μm subjected to release treatment on one surface was used as the support film 11 .

[0085] A solvent-soluble polyimide resin containing 50 parts by weight of a phosphorus-based flame retardant per 100 parts by weight of the resin was cast-coated on one surface of the support film 11 so that the thickness after drying was 1 μm. The coating solution was dried to form the first insulating layer 12 .

[0086] On the first insulating layer 12, a coating of a solvent-soluble polyimide resin that does not contain a flame retardant and has a tensile elongation after drying of 170% is cast on the first insulating layer 12 so that the thickness after drying is 3 μm. The liquid is applied and dried to form the second insulating layer 13 .

[0087] A thermosetting adhesive was applied on the second insulating layer 13 so that the thickness after drying was 8 μm, and dried to form a thermosetting adhesive layer 14, a...

Embodiment 2、3

[0089] In the same manner as in Example 1, except that the ratio of the phosphorus-based flame retardant contained in the first insulating layer 12 was set to 100 parts by weight in Example 2 and 150 parts by weight in Example 3, , Obtain the covering film of embodiment 2,3.

Embodiment 4~6

[0091] Except that the coating liquid for forming the second insulating layer 13 is a coating liquid of a solvent-soluble polyimide resin containing 20 parts by weight of a phosphorus-based flame retardant with respect to 100 parts by weight of the resin, and In the same manner as in Examples 1 to 3, the covering films of Examples 4 to 6 were obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com