Yarn and gland packing

A yarn and gland technology, applied in yarn, engine sealing, textile and papermaking, etc., can solve the problems of reduced sealing performance of expanded graphite, unsatisfactory, and the minimum bending radius of yarn cannot be sufficiently small, and achieve good sealing performance, avoid the effect of reducing the sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

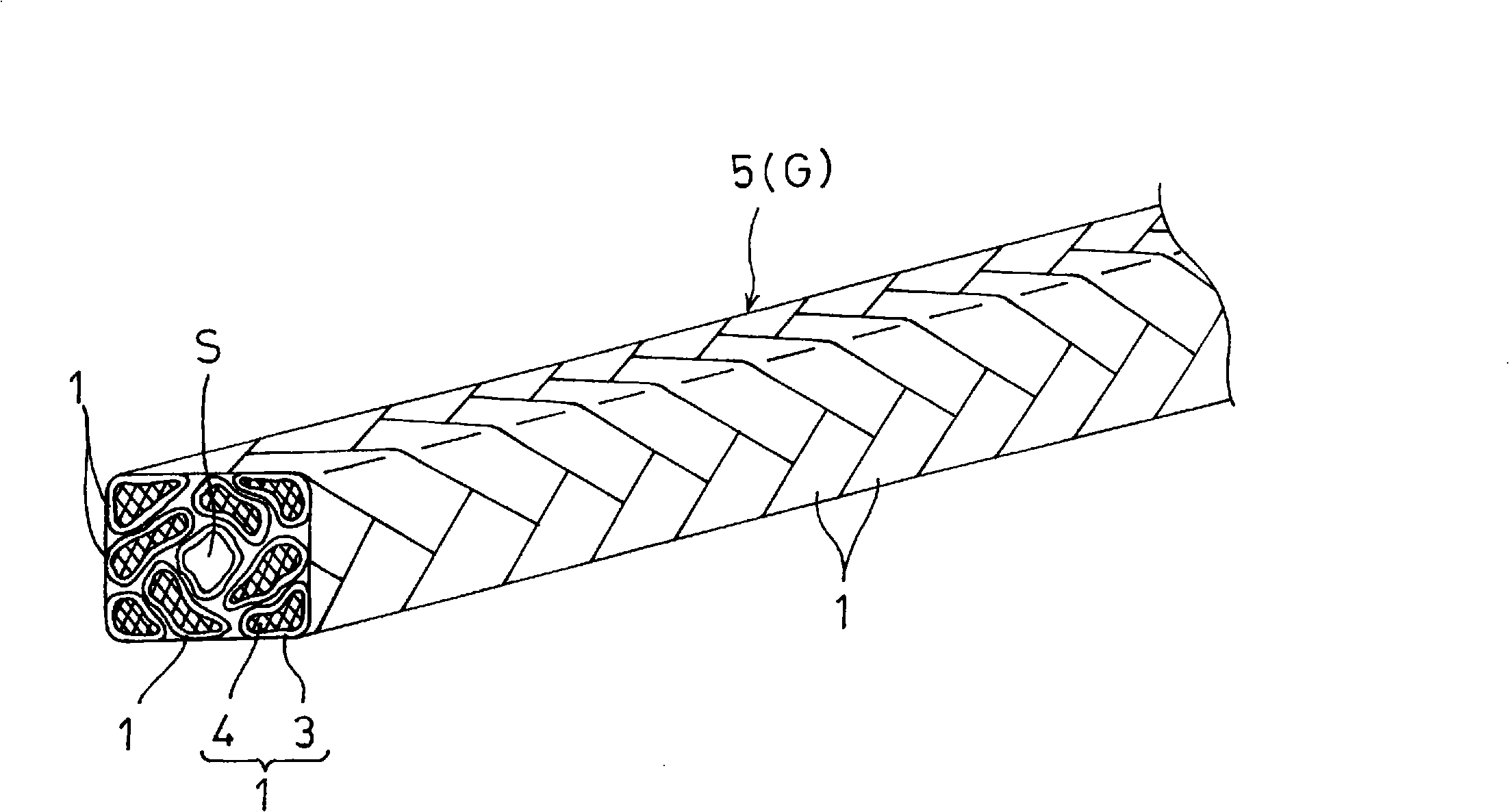

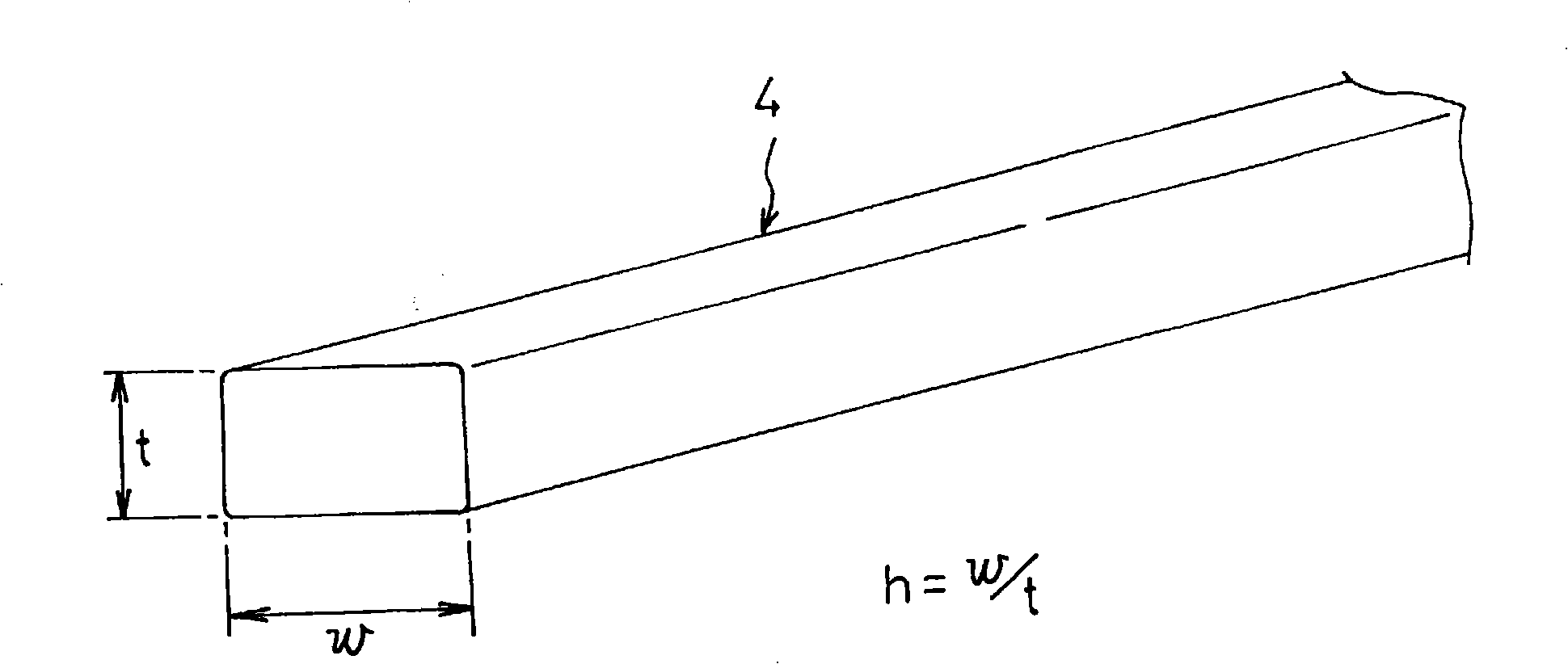

[0039] The yarn of Example 1 was made in the following manner. As the fiber material 2, a heat-resistant Inconel wire (or stainless steel wire, etc.) with a diameter of about 0.1 m is used, and in the tubular member 3 formed by weaving (knitting), a plurality of wires with a thickness of 0.38 mm × a width of 1.0 The fibrous expanded graphite 4 having a rectangular cross-sectional shape of mm and a length of about 200 mm is pressed and filled with its ends shifted by 20 mm from each other to form a yarn 1 with a circular (circular) cross-sectional shape. In the first yarn 1 of Example 1, the aspect ratio h of the section of the fibrous expanded graphite 4 is h=1.0 / 0.38≈2.63, and the weight of the first yarn 1 is 5 g / m.

[0040] figure 2 Gland packing 5 made using yarn 1 of Example 1 is shown in . After the gland packing 5 is braided (octagonal braiding) with eight yarns 1 of Example 1, graphite is coated on the surface to make a square gland packing 5 with a cross section of...

Embodiment 2

[0042] The yarn of Example 2 was made in the following manner. The fibrous expanded graphite 4 with a cross-sectional size of 0.38 mm in thickness, 1.0 mm in width, and 200 mm in length is gathered together to form an elongated product by staggering its ends by 30 mm, and the outer periphery of the elongated product is covered with a cylinder Shaped member 3 is covered, thus the cross-sectional shape is circular (circular) yarn 1, and wherein, tubular member 3 is to be woven with the fiber material 2 that is constituted by Inconel heat-resistant alloy wire that wire diameter is 0.1mm. into, made. In the second yarn 1 of Example 2, the aspect ratio h of the fibrous expanded graphite 4 is h=1.0 / 0.38≈2.63, and the weight of the second yarn 1 is 4 g / m.

[0043] After utilizing the yarn 1 of 8 basic embodiments 2 to weave, graphite is coated on its surface, and the gland packing 5 (see figure 2 ).

[0044] For reference, Fig. 7 shows a comparison table of characteristics of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com