Wafer detecting apparatus

A detection device and wafer technology, which is applied to measurement devices, optical devices, instruments, etc., can solve the problems of complex structure, difficult to detect error slot state, difficult to implement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

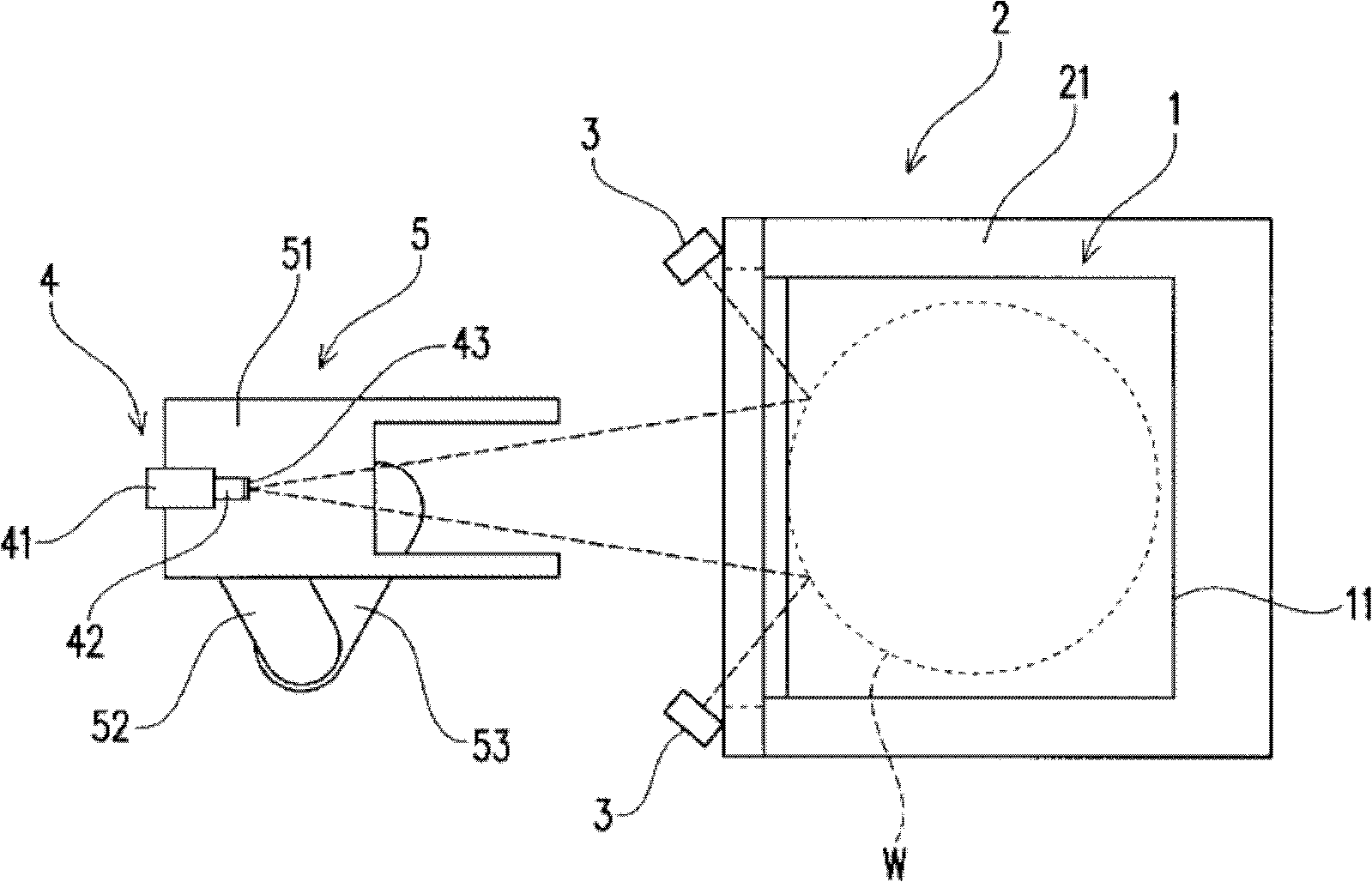

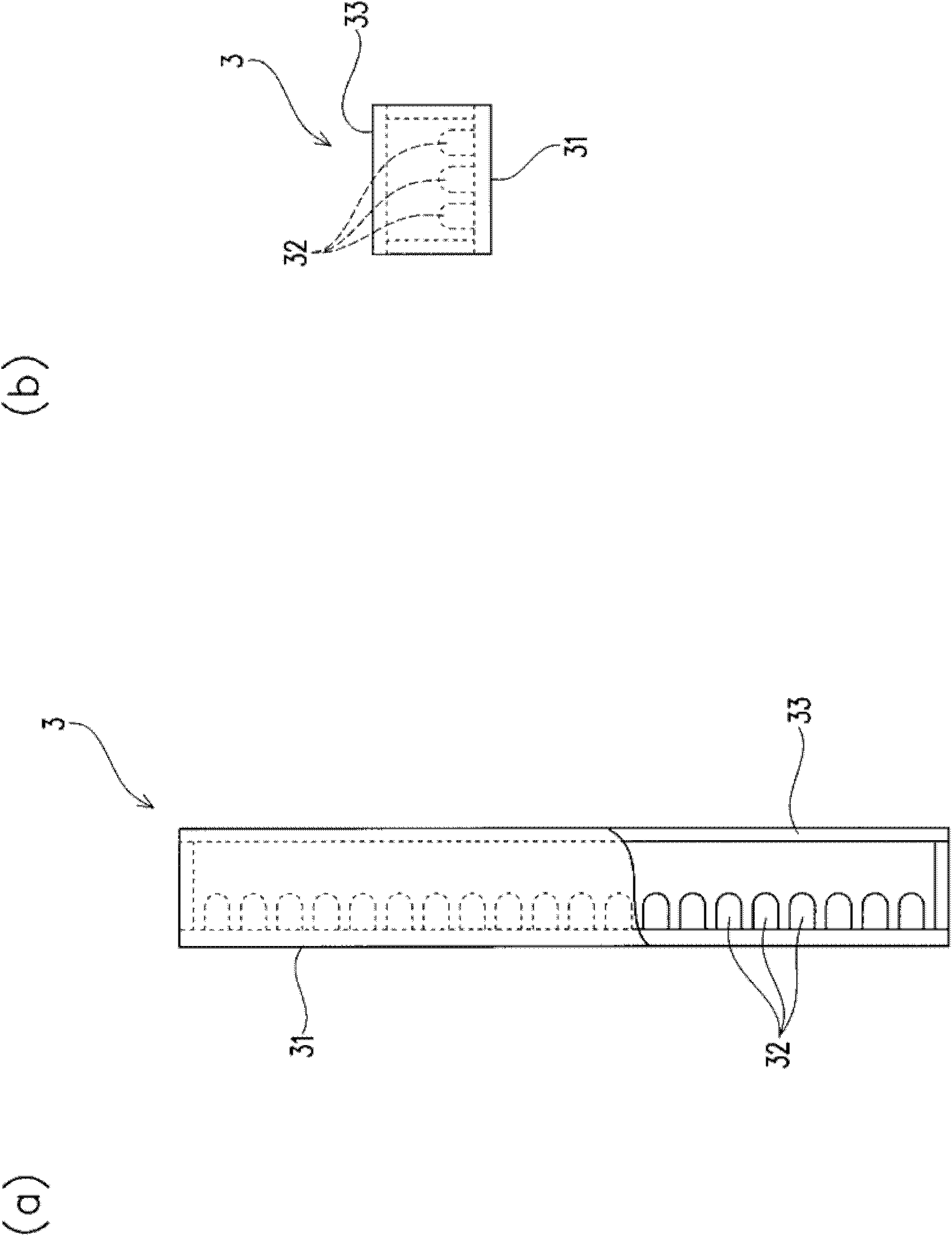

[0036] figure 1 and figure 2 The wafer inspection device of this embodiment is shown. The wafer inspection device has lighting devices 3, 3 and an imaging device 4, and the lighting devices 3, 3 are arranged on the left and right sides of the loading port 2 for loading the wafer container 1 for The wafer W is accommodated; the light from the illuminating devices 3 and 3 is irradiated on the end face of the wafer W, and the reflected light from the end face is incident on the camera 4, and the camera 4 is used to take pictures of the end face. In this way, by using the reflective wafer inspection device, it is possible to detect the wafer without causing any problems even if the wafer is warped or warped.

[0037] The above-mentioned wafer storage container 1 has a casing 11 opened at the front, and a plurality of slots 12 for stacking and storing wafers W in the casing 11 at predetermined intervals in the vertical direction (refer to Figure 5 (a)) and a cover 13 for clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com