Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Mobile synchronization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

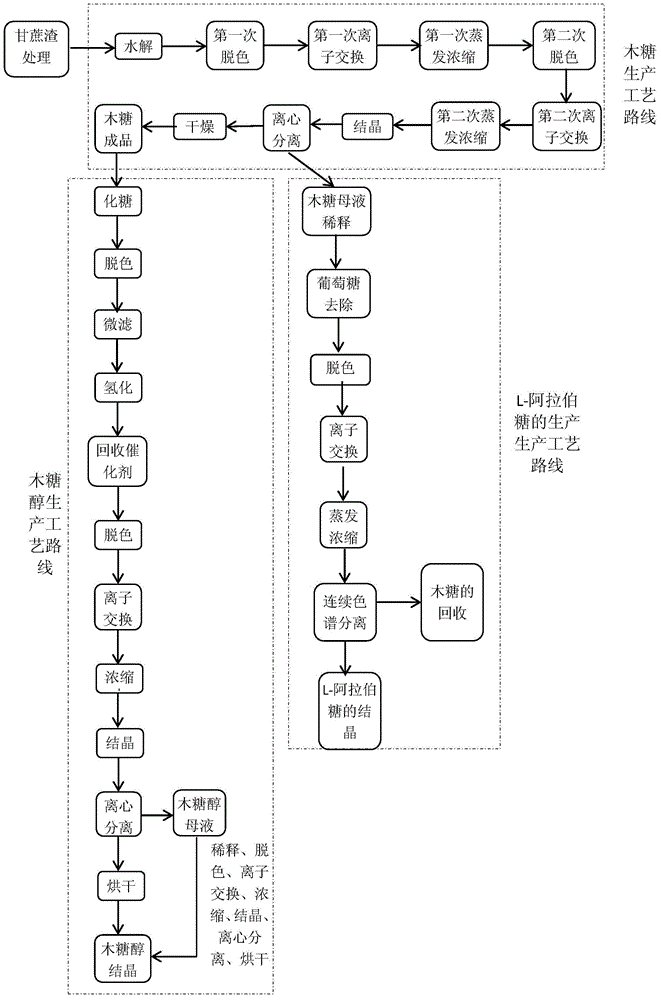

Method of producing xylose and xylitol and co-producing L-arabinose by bagasse

InactiveCN104046705AIncrease profitIncrease added valueSugar derivativesOrganic compound preparationRare sugarAlcohol sugars

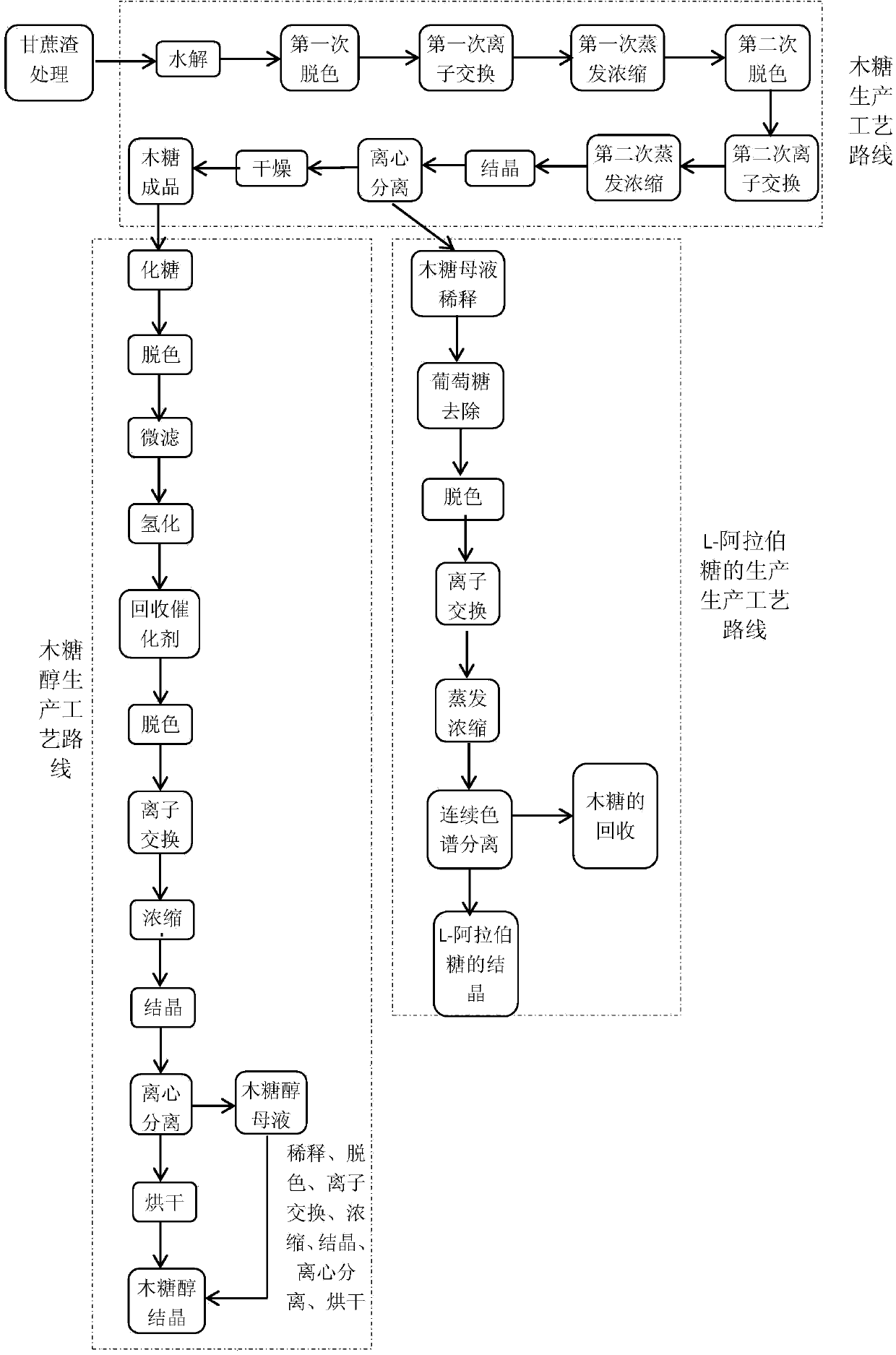

The invention relates to a method of producing xylose and xylitol and co-producing L-arabinose by bagasse. The method comprises the following steps: first, treating the bagasse; then, producing xylose by the bagasse; and respectively producing xylitol and arabinose by the product xylose and a xylose mother liquid. By using the bagasse as a raw material, the method provided by the invention obtains crystallized xylose and further products of xylitol and L-arabinose which are high in additional value and are widely applied to the fields of foods and medicines through a whole set of process line. The method provided by the invention is simple to operate, novel in technology, low in cost, diversified in product and high in economic value, is a process method which is initiated at home for co-producing functional sugar alcohols and rare sugar products by bagasse, and has an extremely wide application value.

Owner:SHANDONG WANSHENG ENVIRONMENTAL TECH DEV

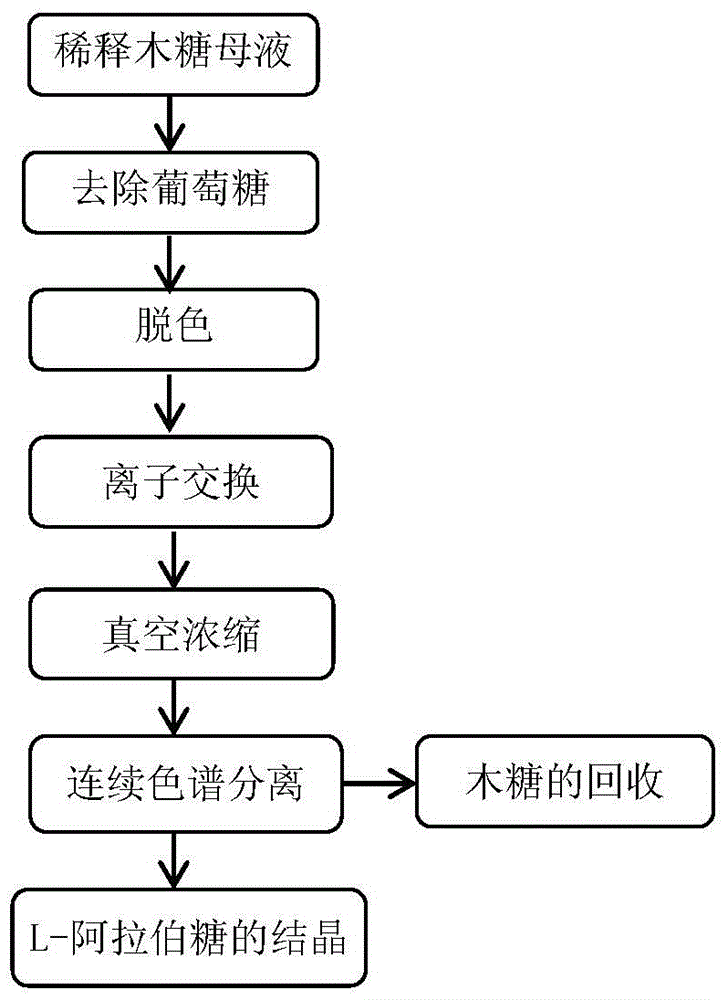

Method of producing L-arabinose by xylose mother liquid

InactiveCN104086607ASimple processLow input costSugar derivativesSugar derivatives preparationChromatographic separationEvaporation

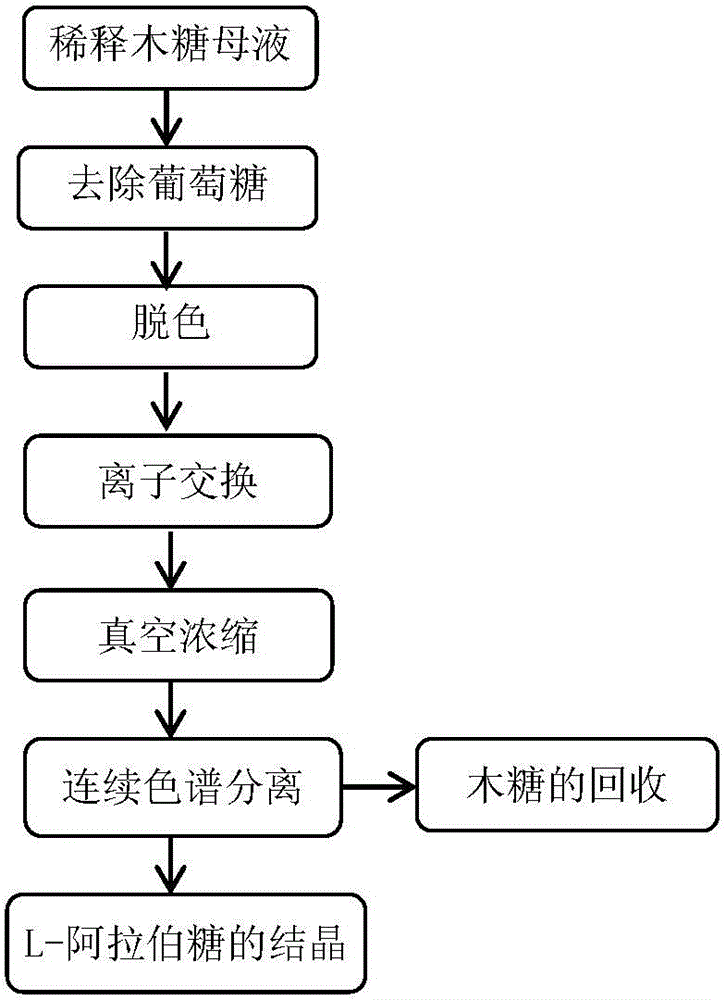

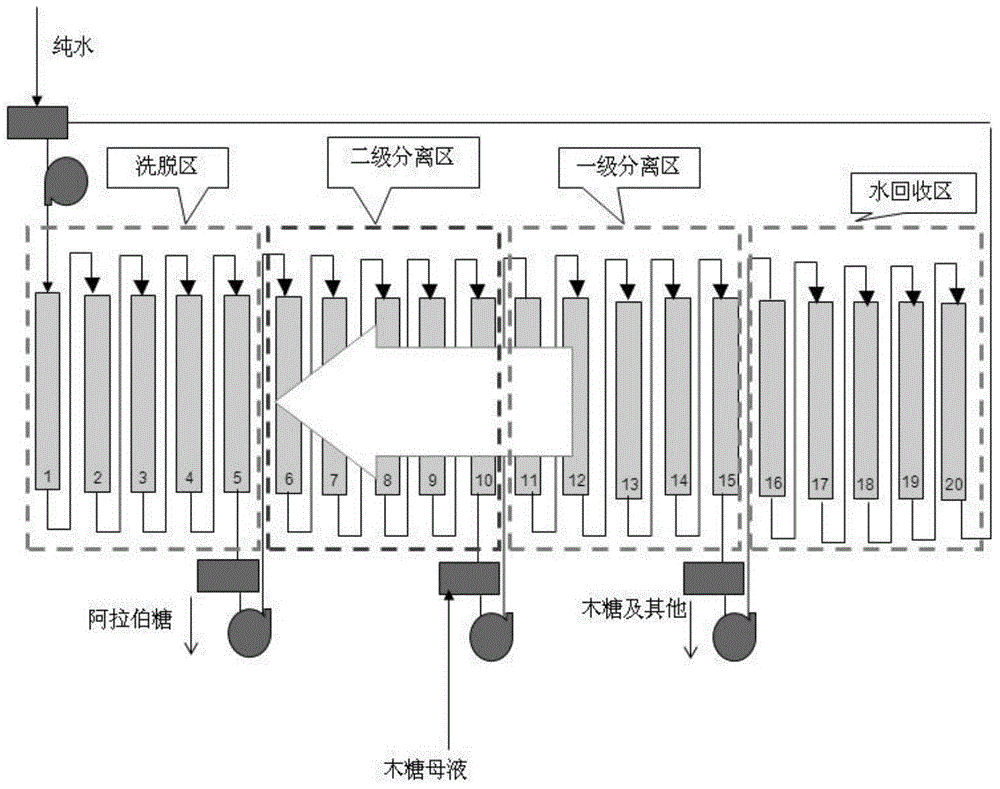

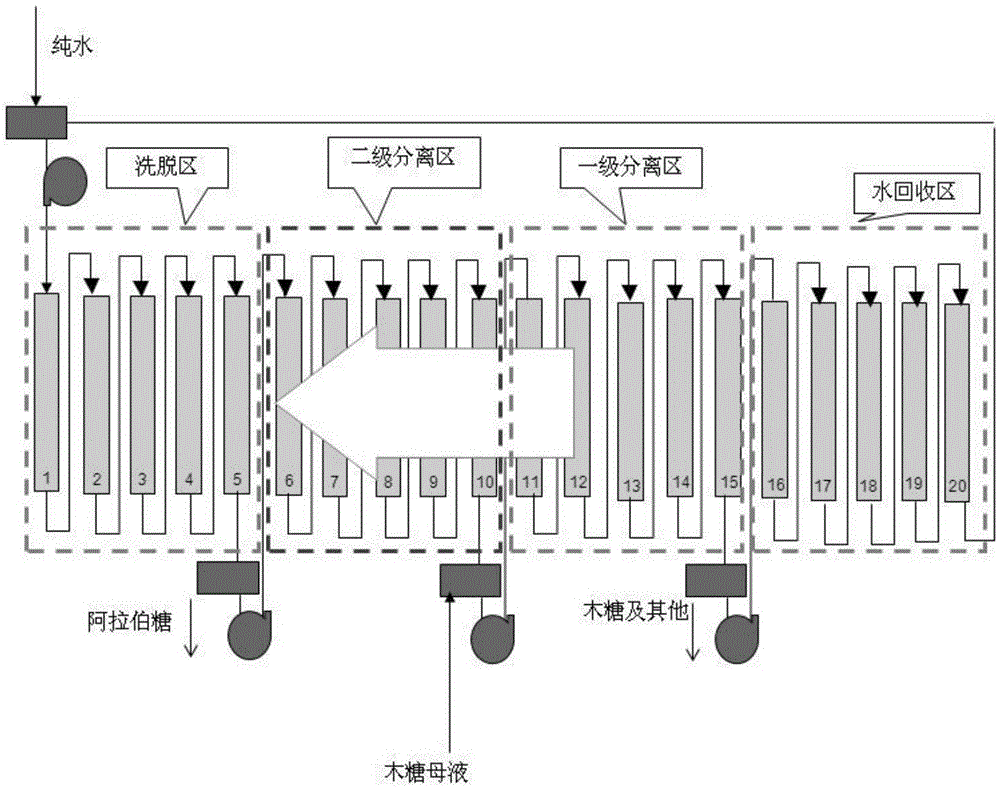

The invention provides a method of producing L-arabinose by a xylose mother liquid. The method comprises the following steps: first, diluting the xylose mother liquid; then, removing glucose by active dry yeast powder; further refining the xylose mother liquid through decoloration, ion exchange and evaporation concentration; then obtaining an L-arabinose component solution and a xylose component solution through a continuous chromatographic mobile bed and respectively crystallizing to obtain an L-arabinose product and a xylose product. The method provided by the invention extracts L-arabinose through the continuous chromatographic mobile bed by using a byproduct xylose mother liquid in production of crystallized xylose by bagasse, is simple in operation, low in technical cost and good in separating effect, and has an extremely wide application valve. The obtained L-arabinose is high in purity and yield.

Owner:SHANDONG WANSHENG ENVIRONMENTAL TECH DEV

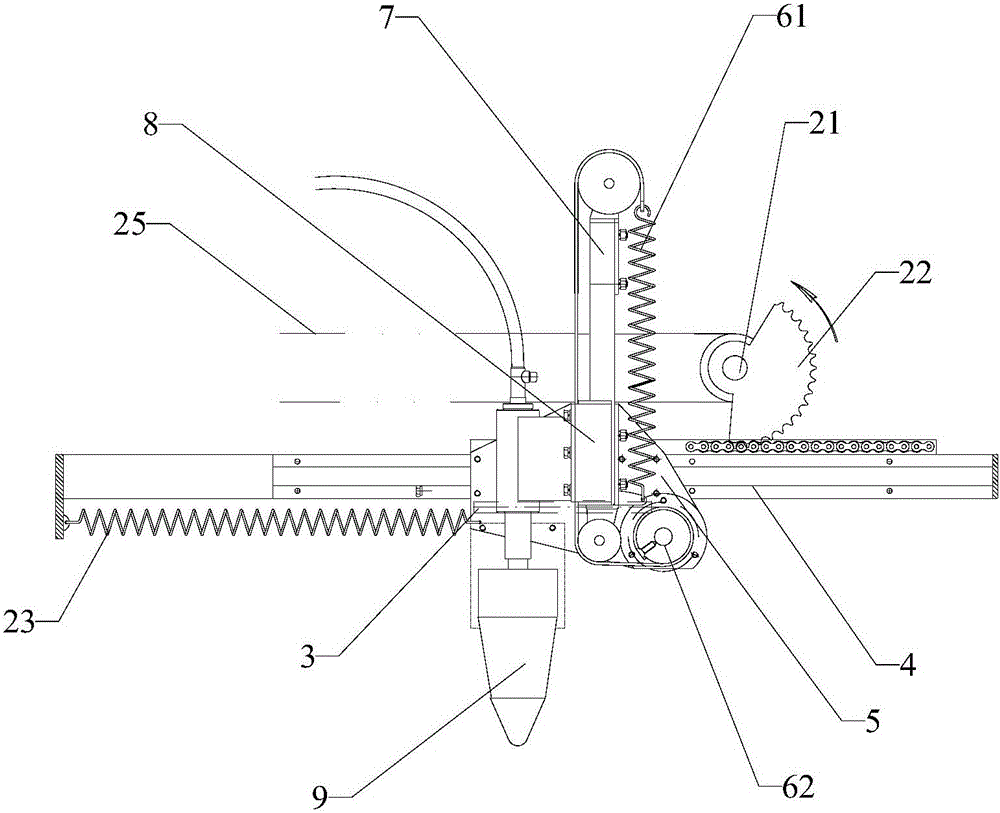

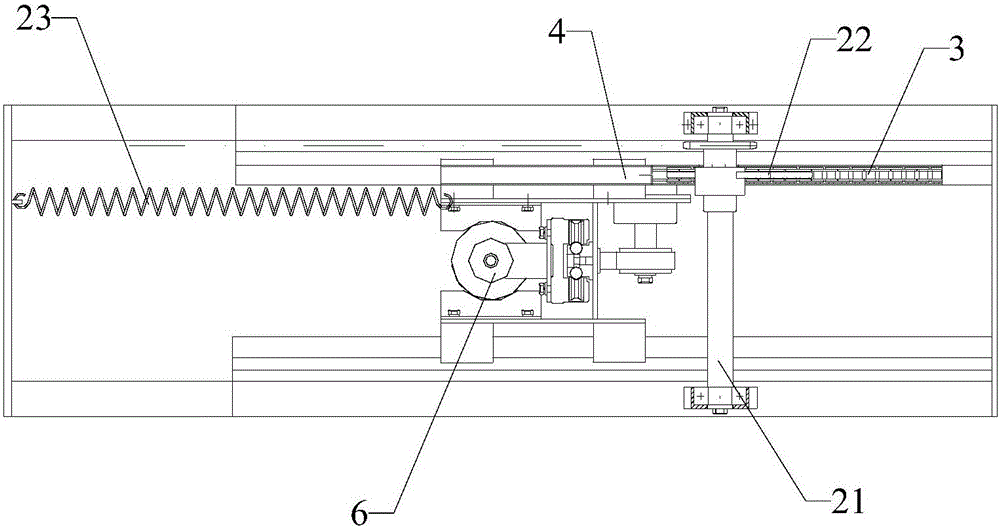

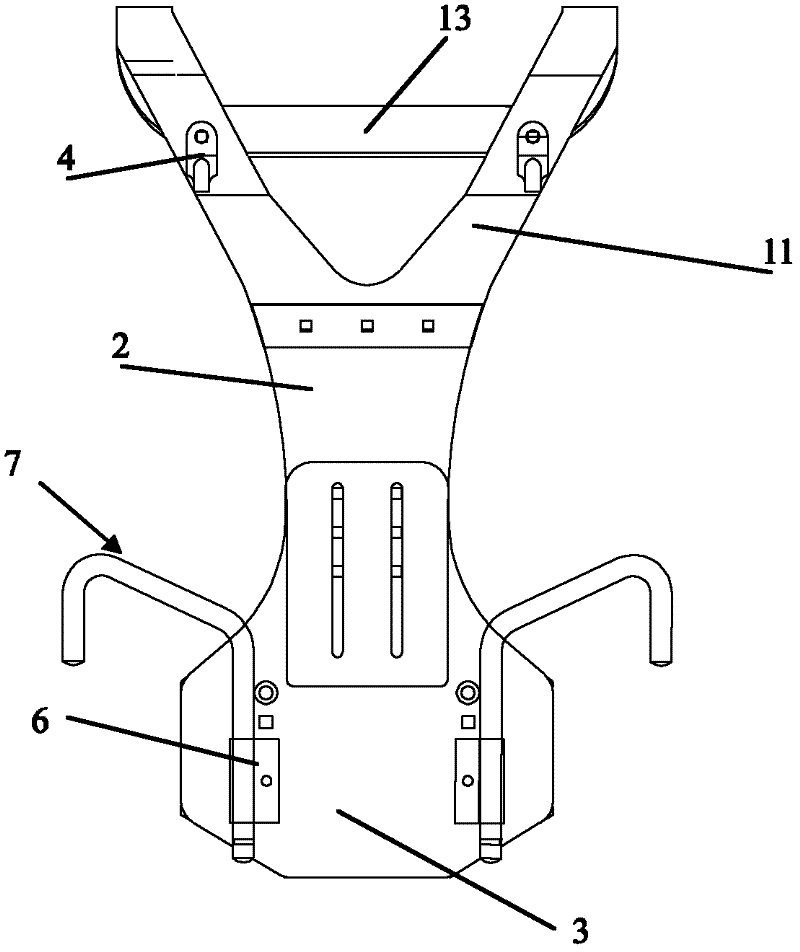

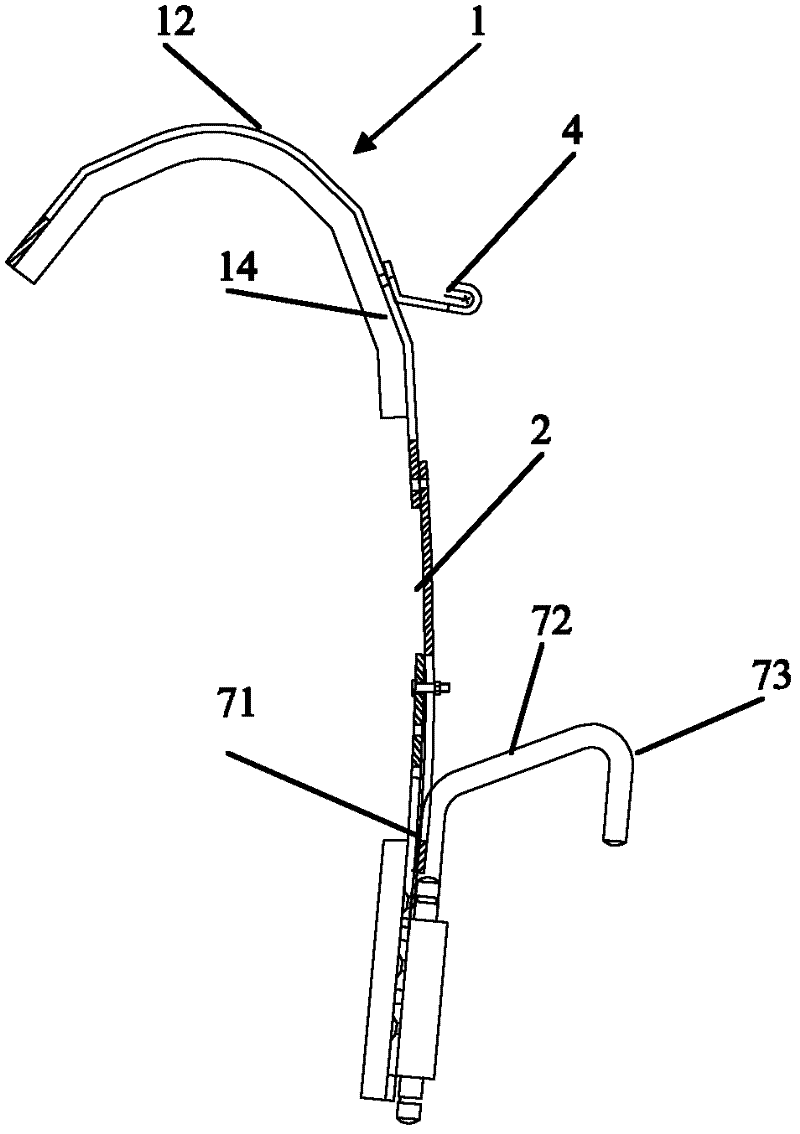

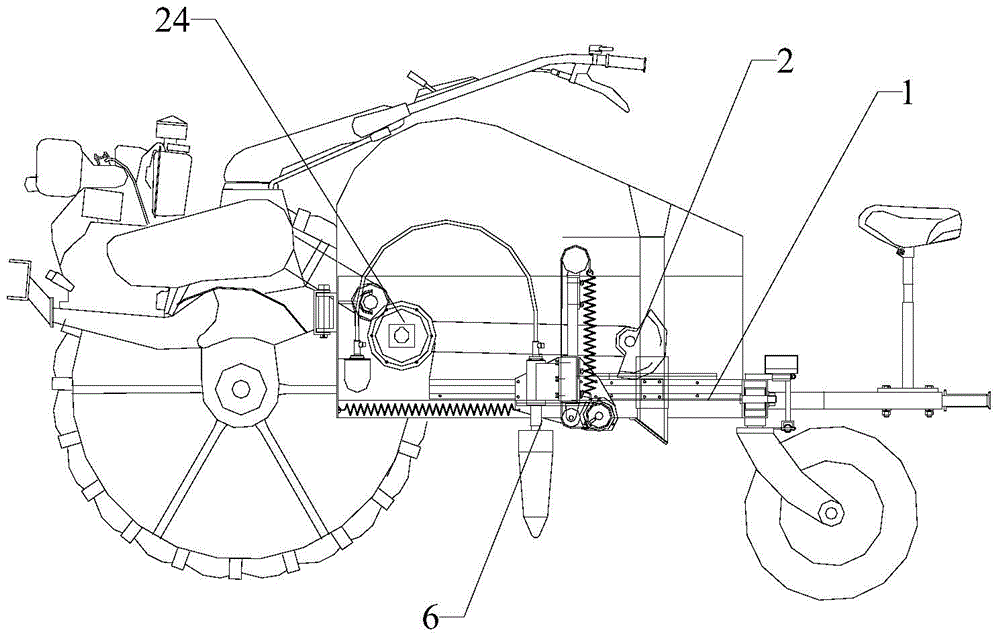

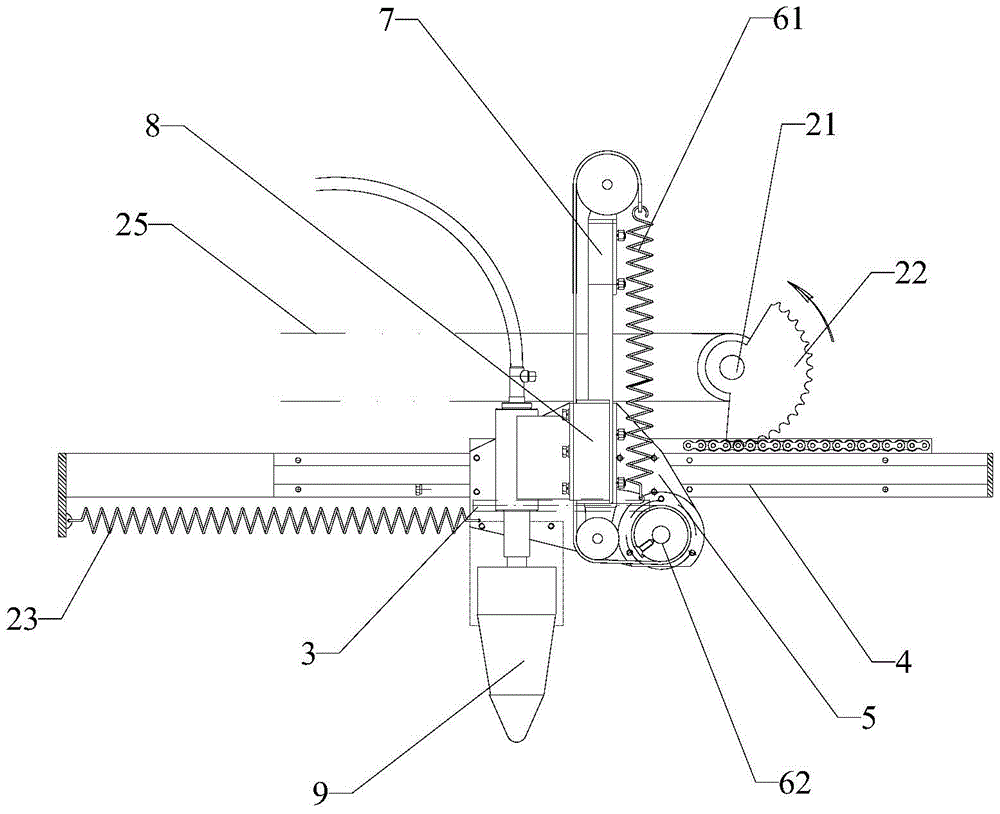

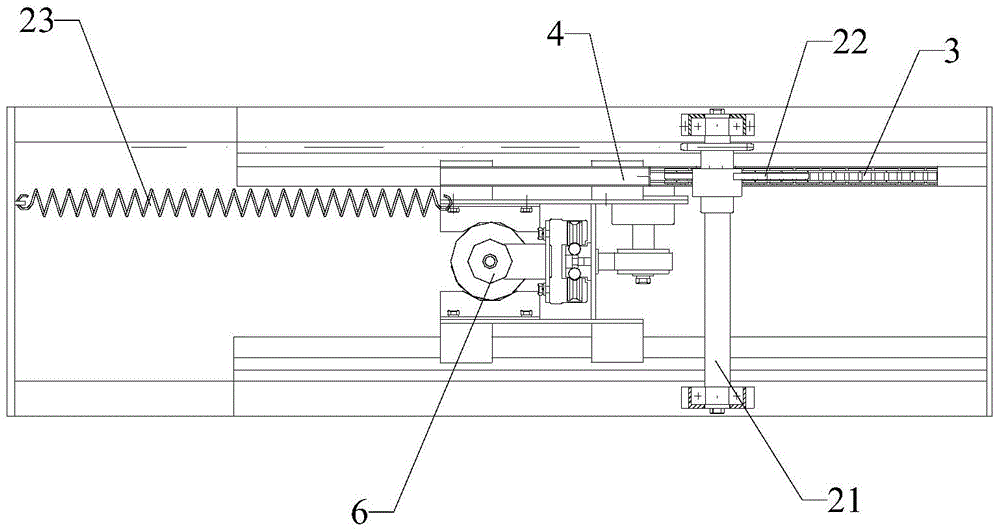

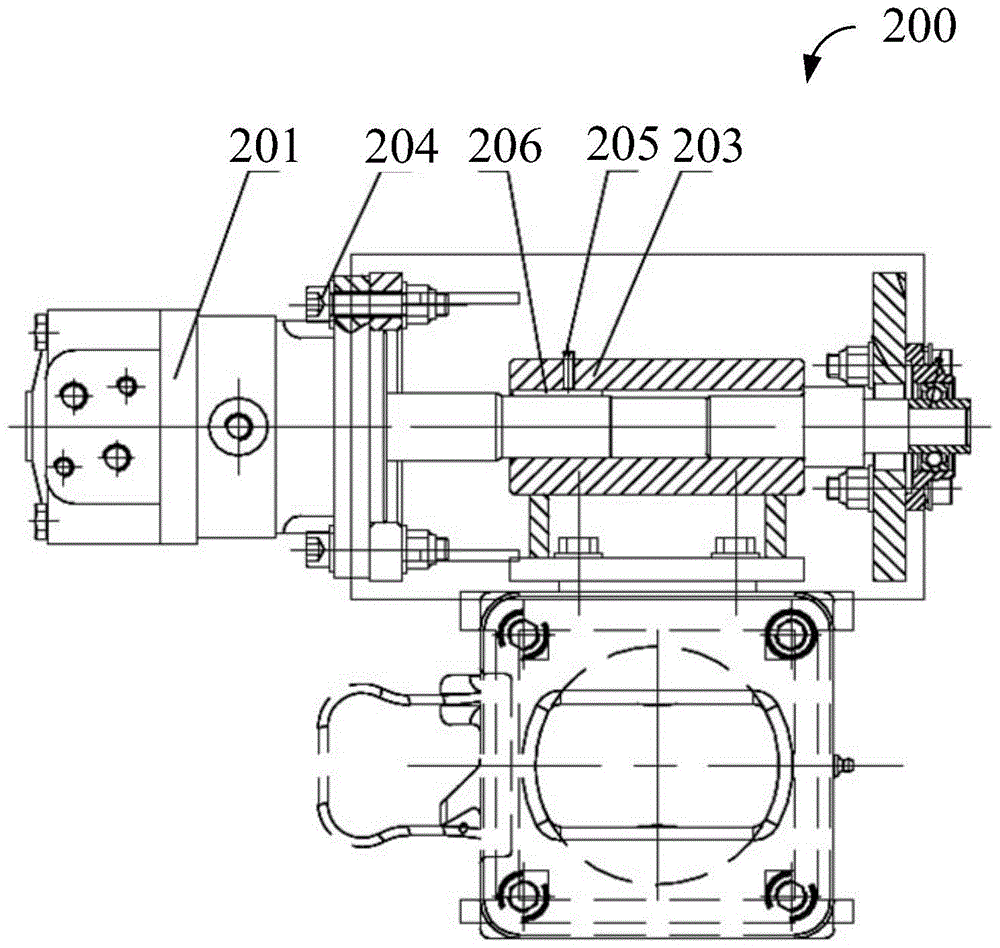

Hole excavating mechanism of transplanting machine

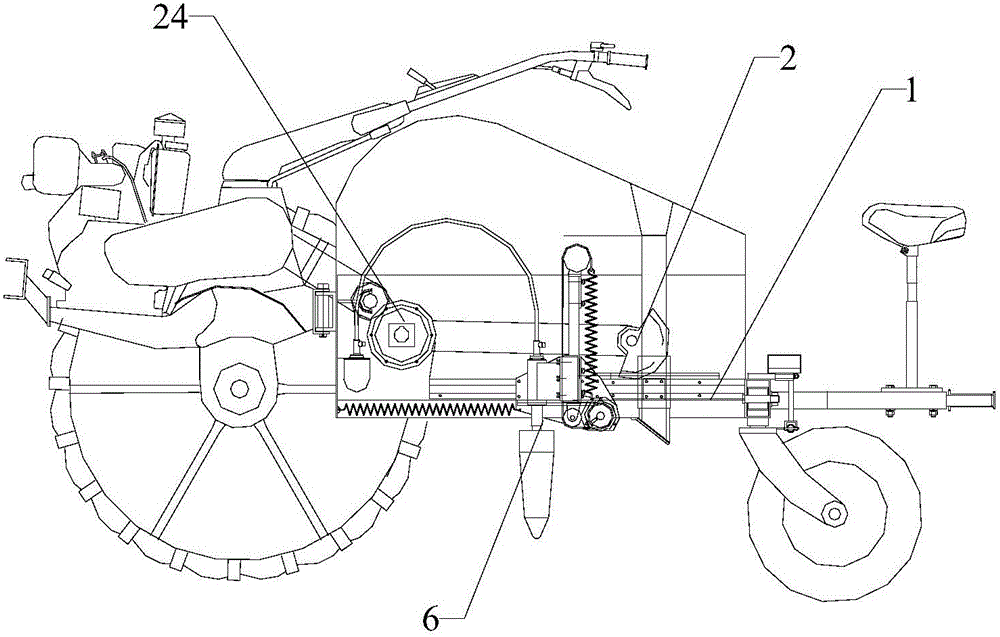

ActiveCN105027756AAvoid destructionImprove the effect of hole punching and transplantingPlantingFurrow making/coveringMechanical engineeringRidge

The invention relates to the field of seedling transplantation and aims at providing a hole excavating mechanism of a transplanting machine. The hole excavating mechanism of the transplanting machine comprises a support, a driving device, a first rack, a first slide rail, a first slider and a hole excavating device. The first slide rail is horizontally fixed to the support. The first slider is matched with the first slide rail. The hole excavating device is fixed to the first slider. The driving device drives the first slider and the hole excavating device to horizontally move on the first slide rail. The hole excavating mechanism of the transplanting machine has the advantages that the hole excavating device moves backwards in the hole excavating process so that the forward movement speed of the transplanting machine can be counteracted, a hole excavating cone can be static relative to a ground ridge when moving up and down for hole excavation, it is avoided that the hole excavating device breaks a thin film, the hole excavating and transplanting effects are improved, the hole excavating device is driven through the first rack fixed to the support, the displacement of the hole excavating device and the hole excavating process are made to be performed at the same time all the time, and synchronous movement is achieved.

Owner:张培坤

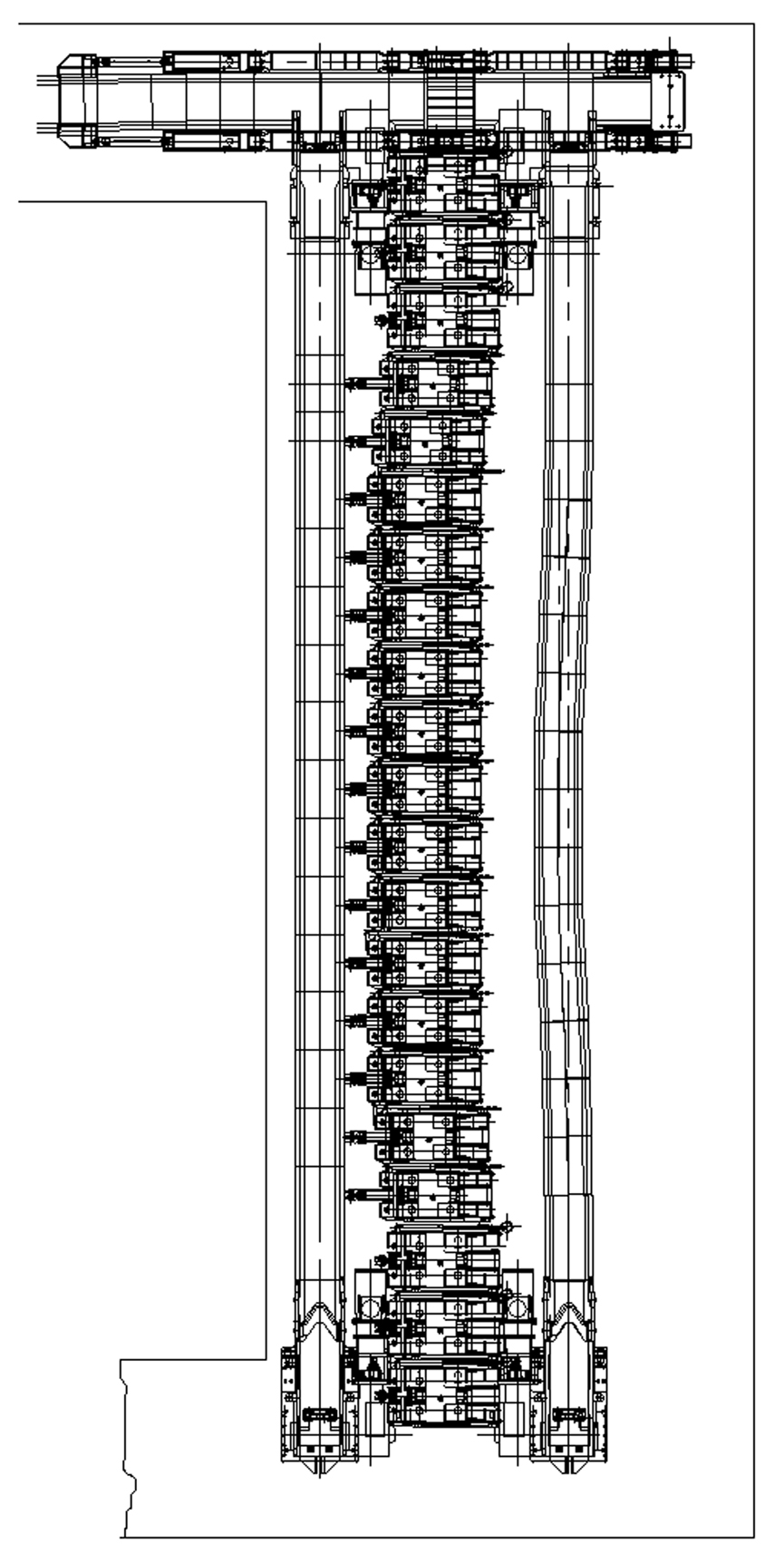

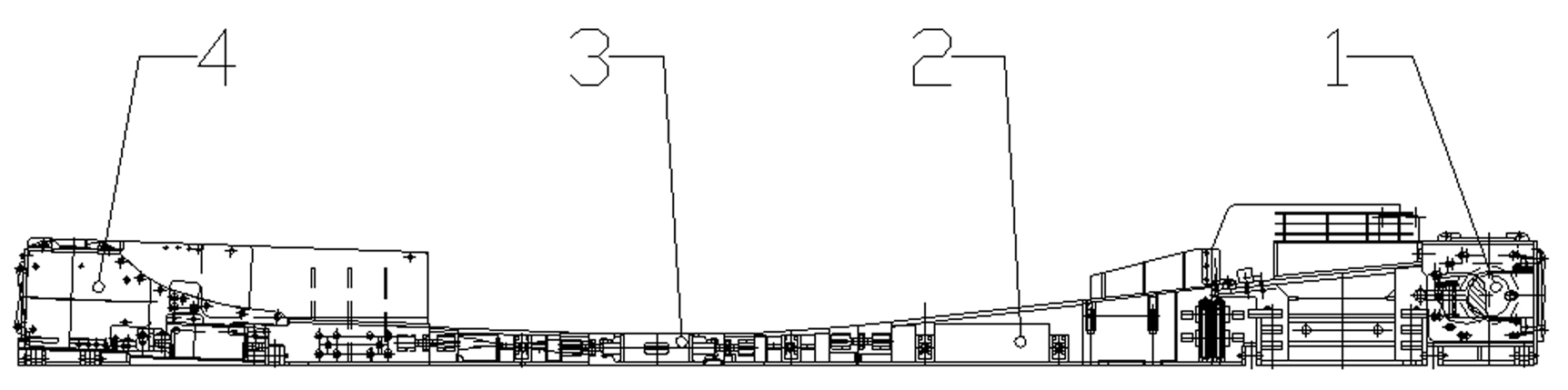

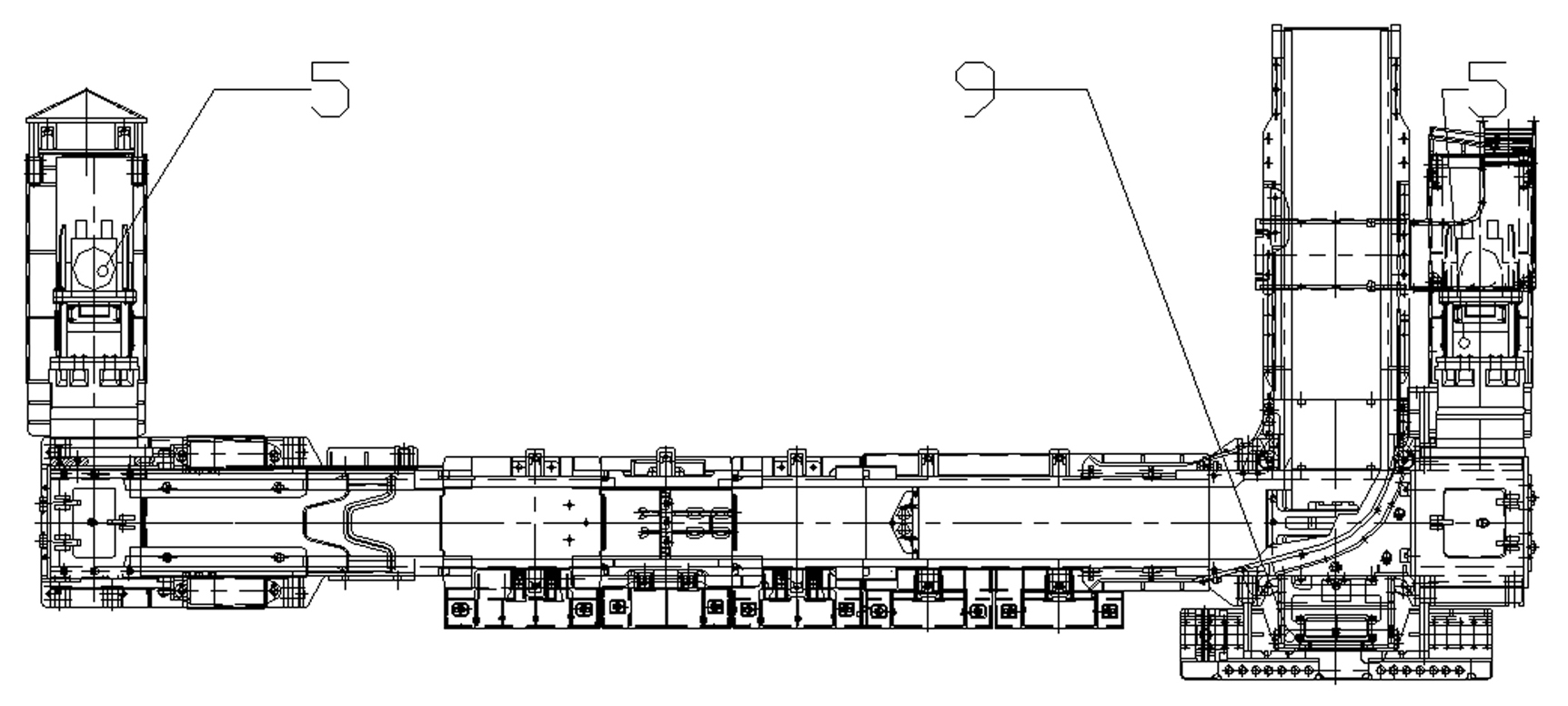

Crossed side dump type rear scraper conveyer

InactiveCN102583037AImprove operating conditionsLower unloading heightConveyorsConveyor partsHysteresisEngineering

The invention relates to a crossed side dump type rear scraper conveyer comprising a conveyer head (1), a conveyer tail, a driving part (6), a scraper chain and a middle section (3). The crossed side dump type rear scraper conveyer is characterized in that an unloading part of the rear conveyer head (1) is fixedly connected with a bearing part of the conveyer tail of an elevating conveyer (9) into a whole. The crossed side dump type rear scraper conveyer is suitable for the mining of a full-mechanized caving mining face and comprises the crossed side dump conveyer head, a transitional groove, the middle section, the conveyer tail, the driving part and the like. According to the crossed side dump type rear scraper conveyer, the conveyer head adopts the crossed side dump form so as to reduce the unloading height of the conveyer head to the greatest degree; the driving part is arranged vertically, the hysteresis phenomena of the conveyer head and the conveyer tail of the rear scraper conveyer can be avoided, so that the running condition of the rear scraper conveyer is improved, and the integral running reliability of the device is improved; and as the unloading part of the conveyer head and the bearing part of the conveyer tail of the elevating conveyer are connected into a whole, the unloading position is fixed, a conveyer head pushing beam is connected with a lane tail bracket, and the movement of the elevating conveyer is synchronous with that of the rear scraper conveyer.

Owner:NINGXIA TIANDI BENNIU IND GRP +1

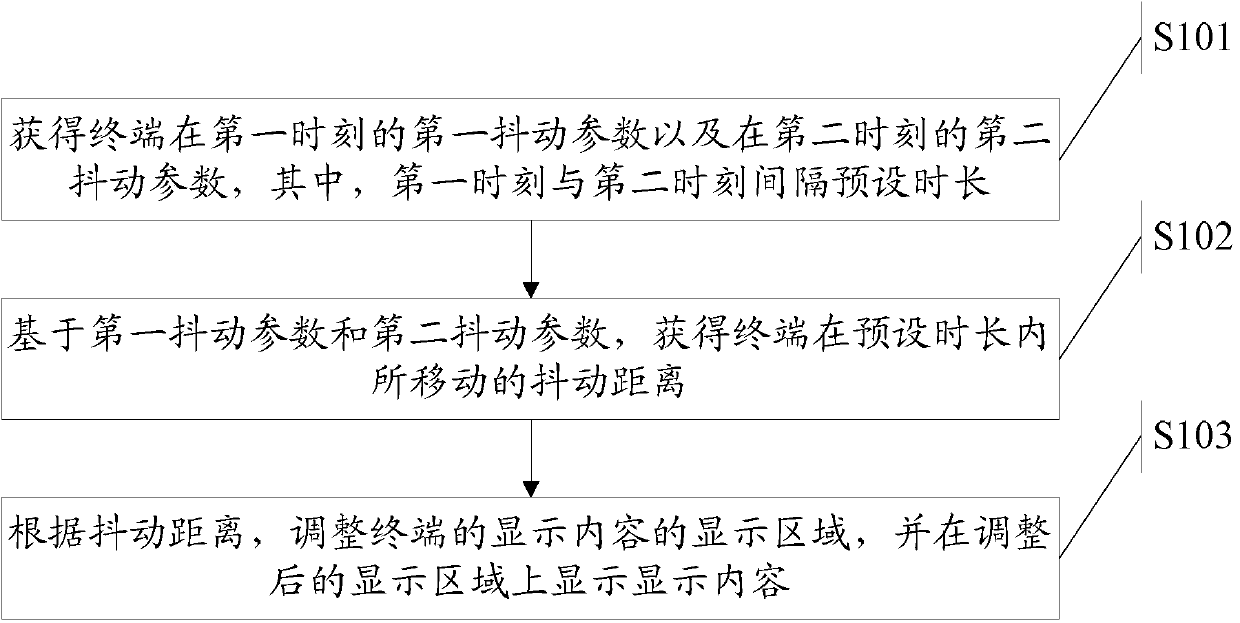

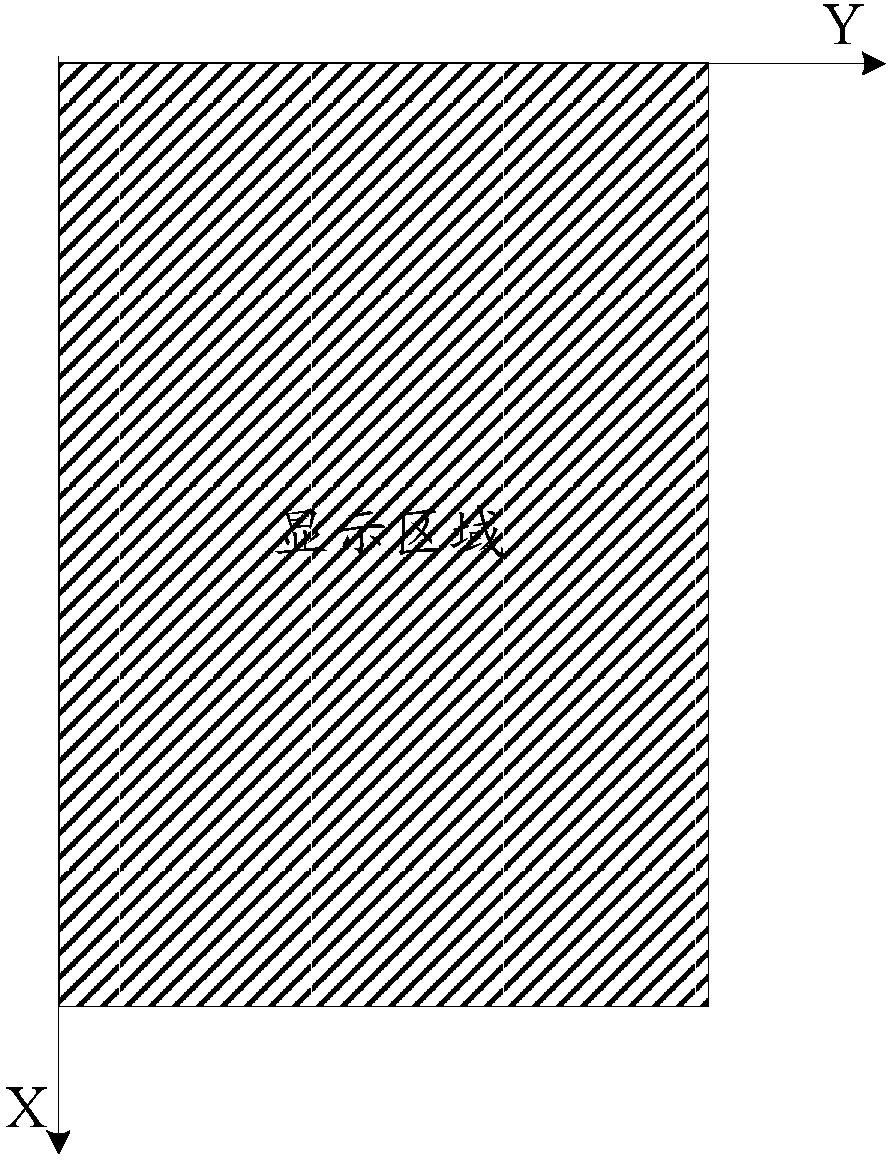

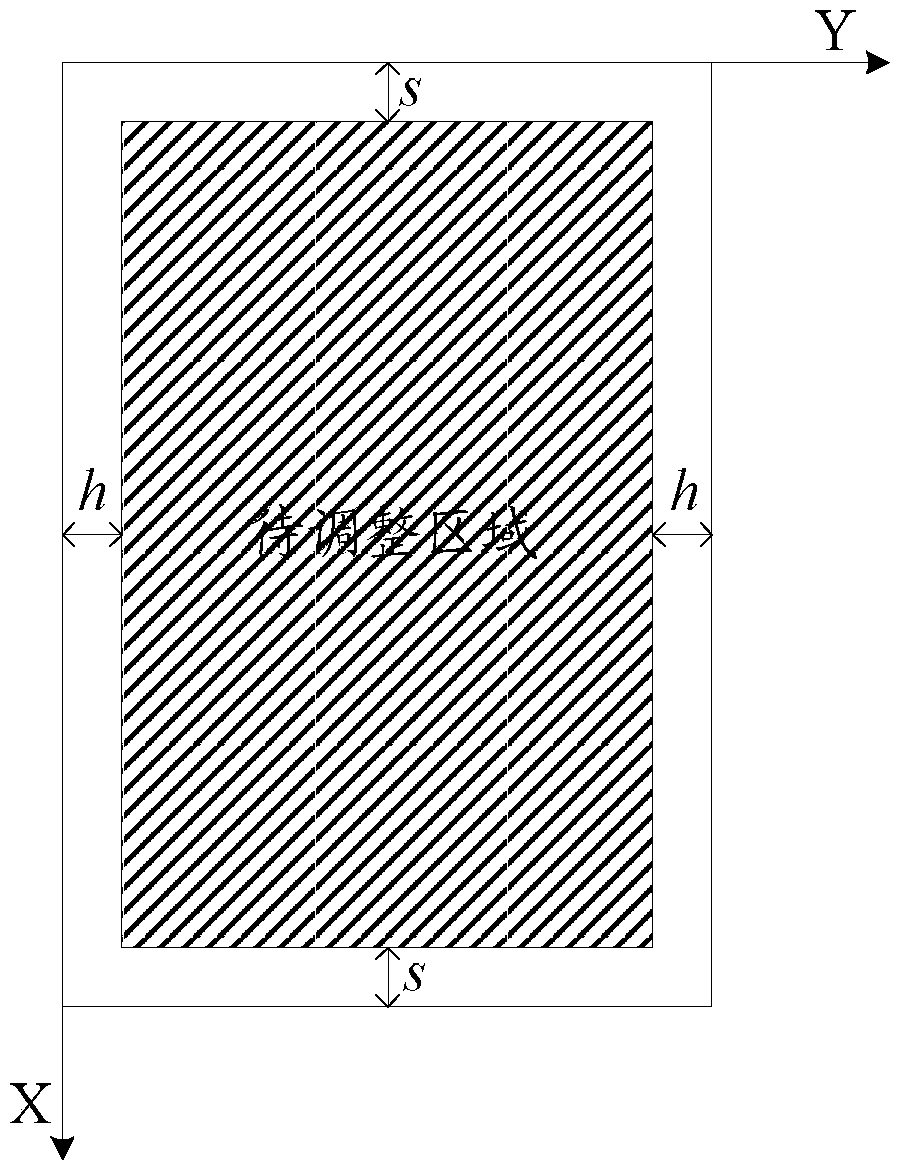

Method and terminal for display adjustment

InactiveCN105511753AImprove experienceMobile synchronizationInput/output processes for data processingComputer science

Owner:ZTE CORP +1

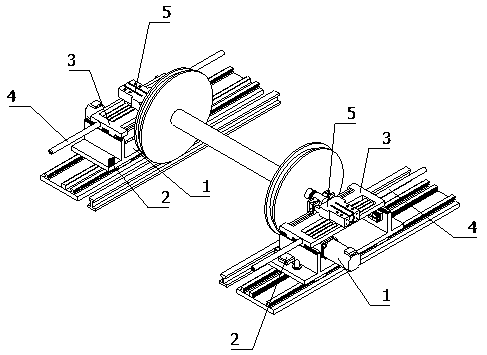

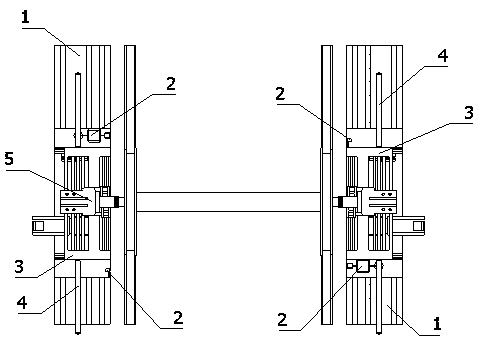

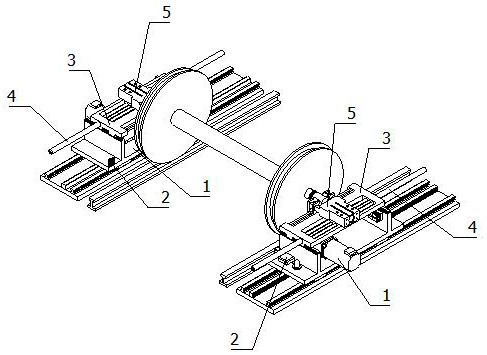

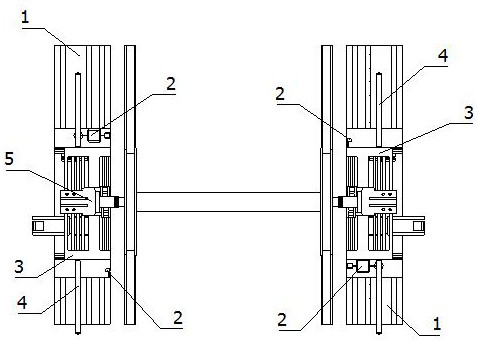

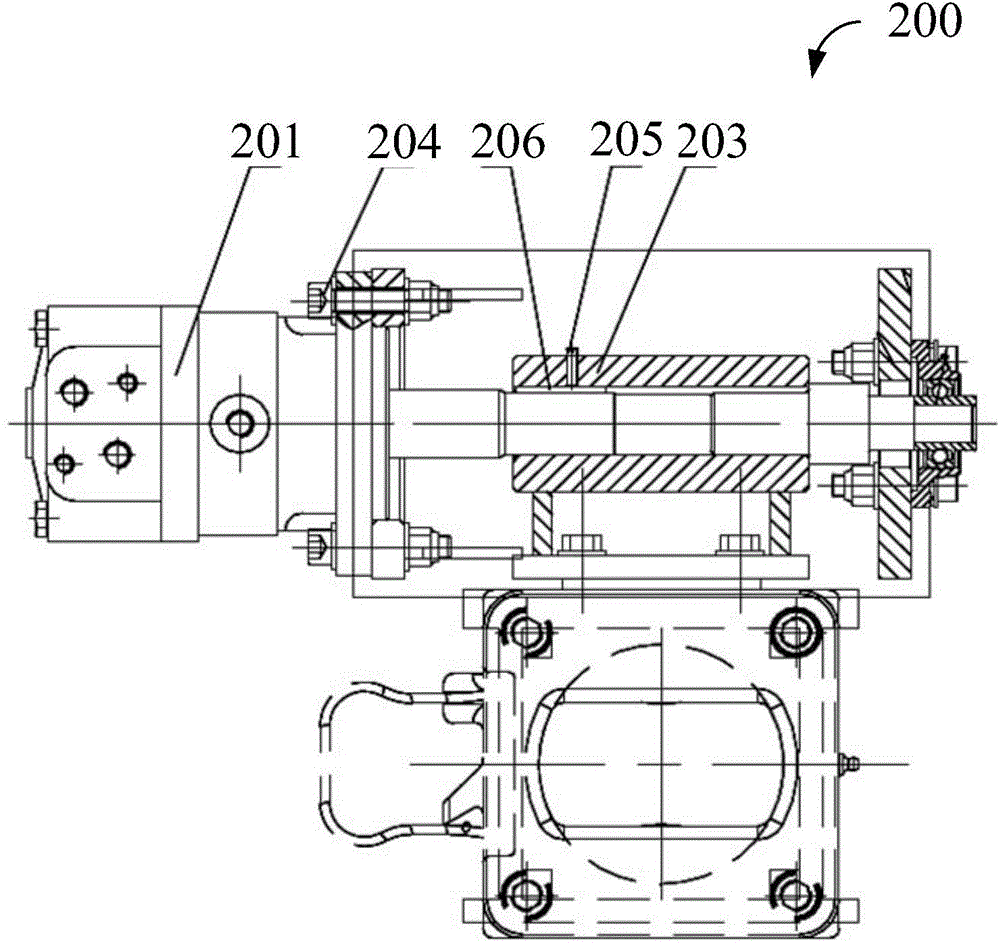

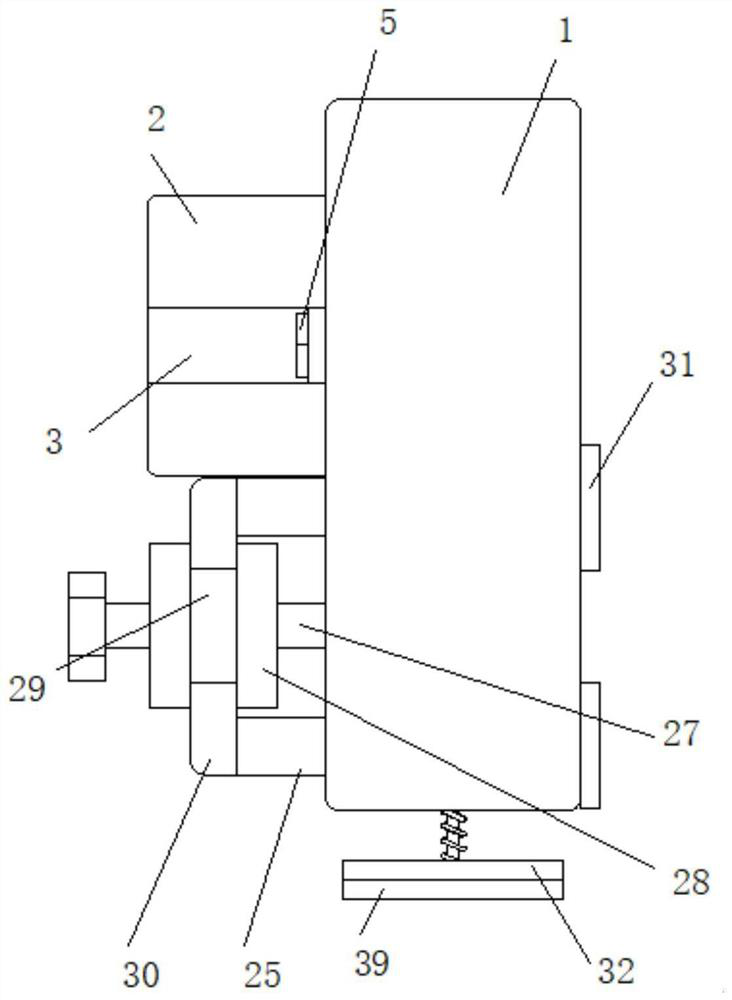

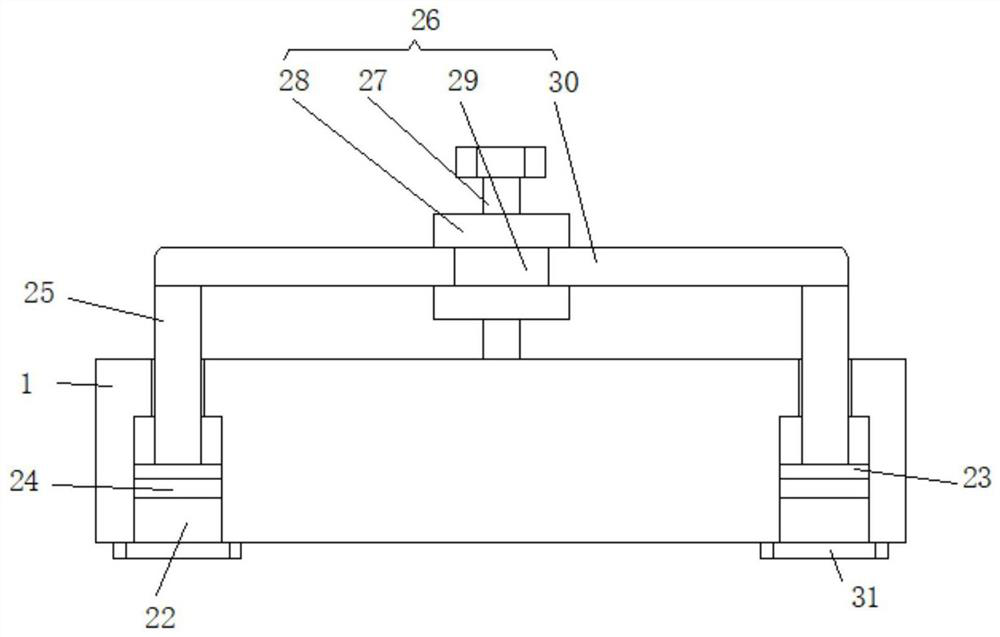

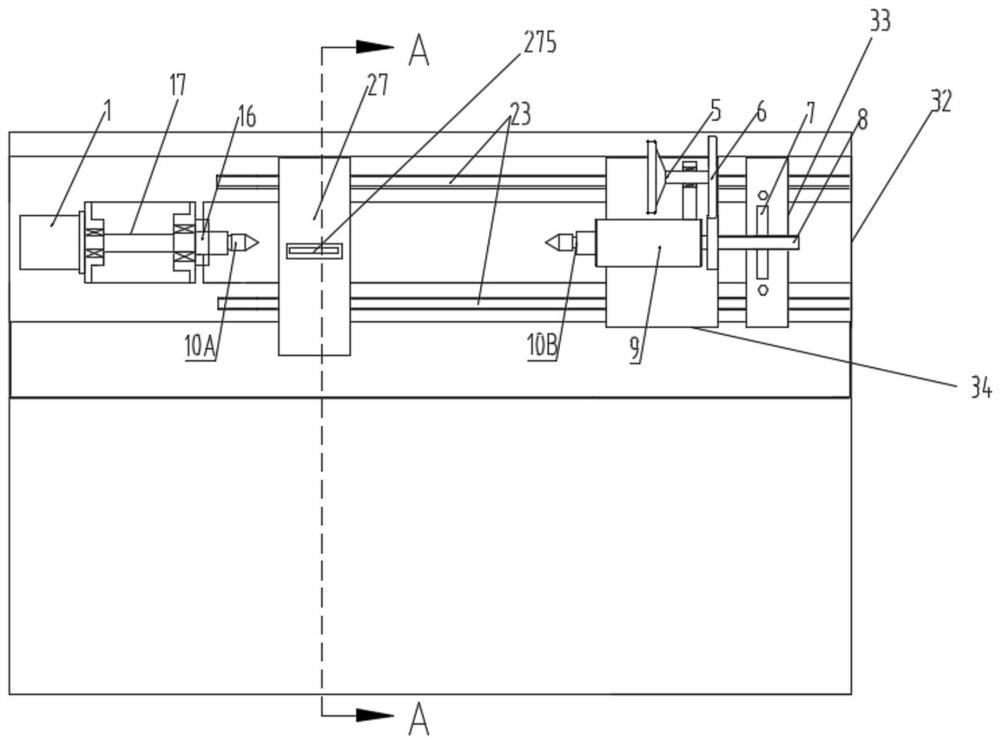

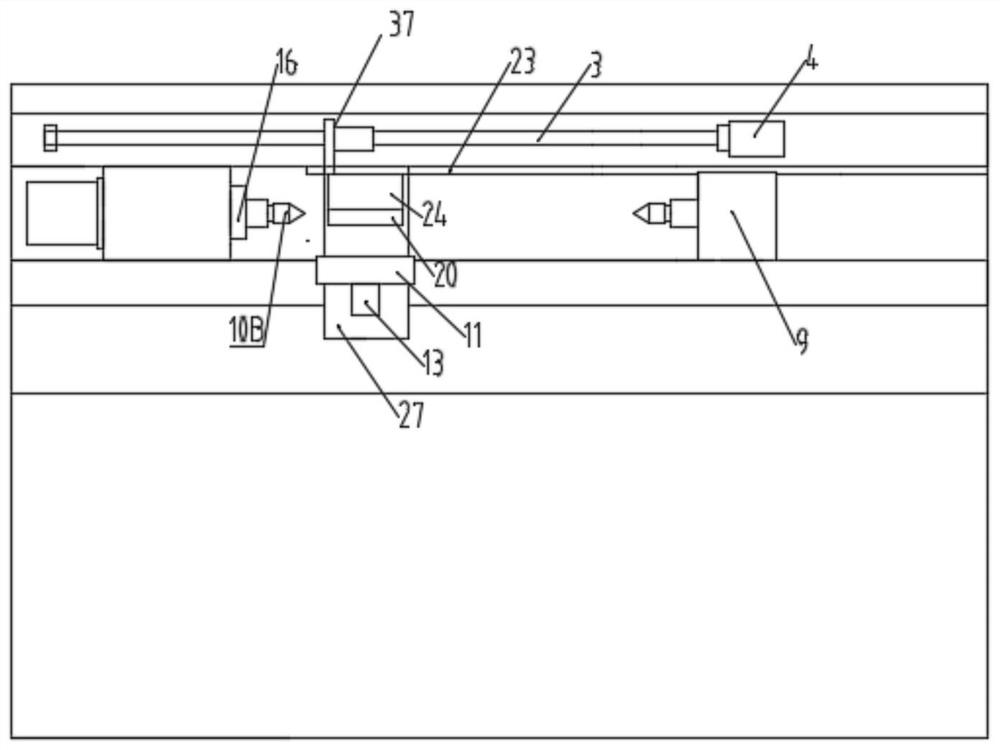

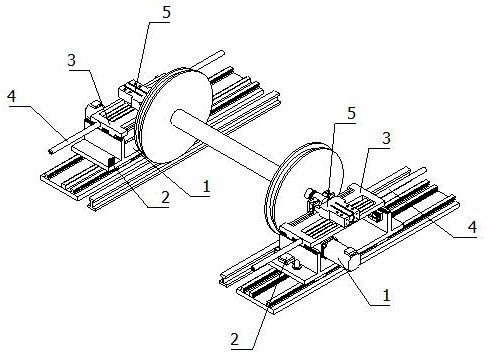

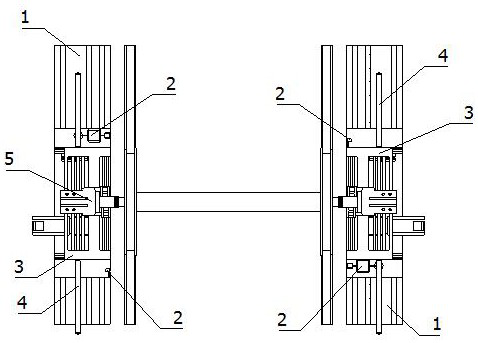

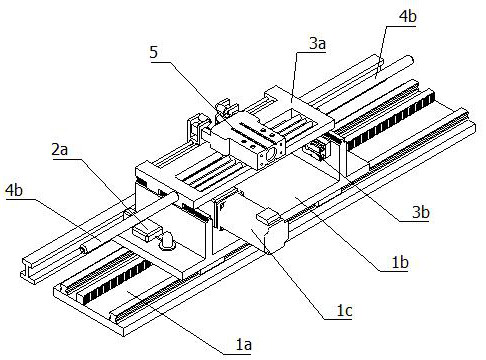

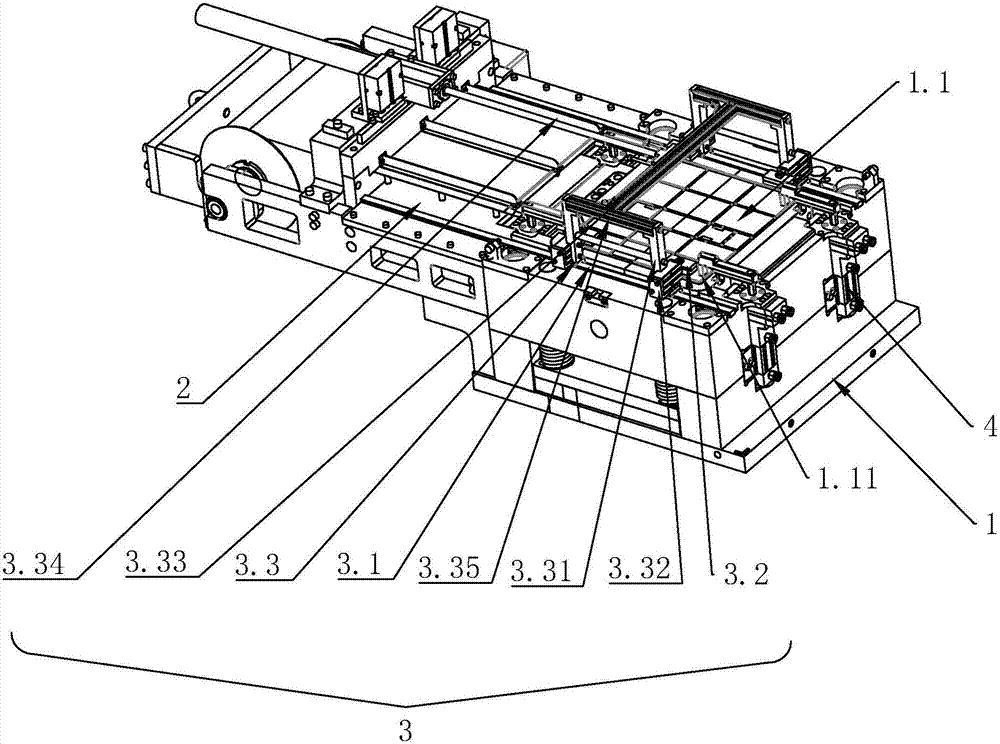

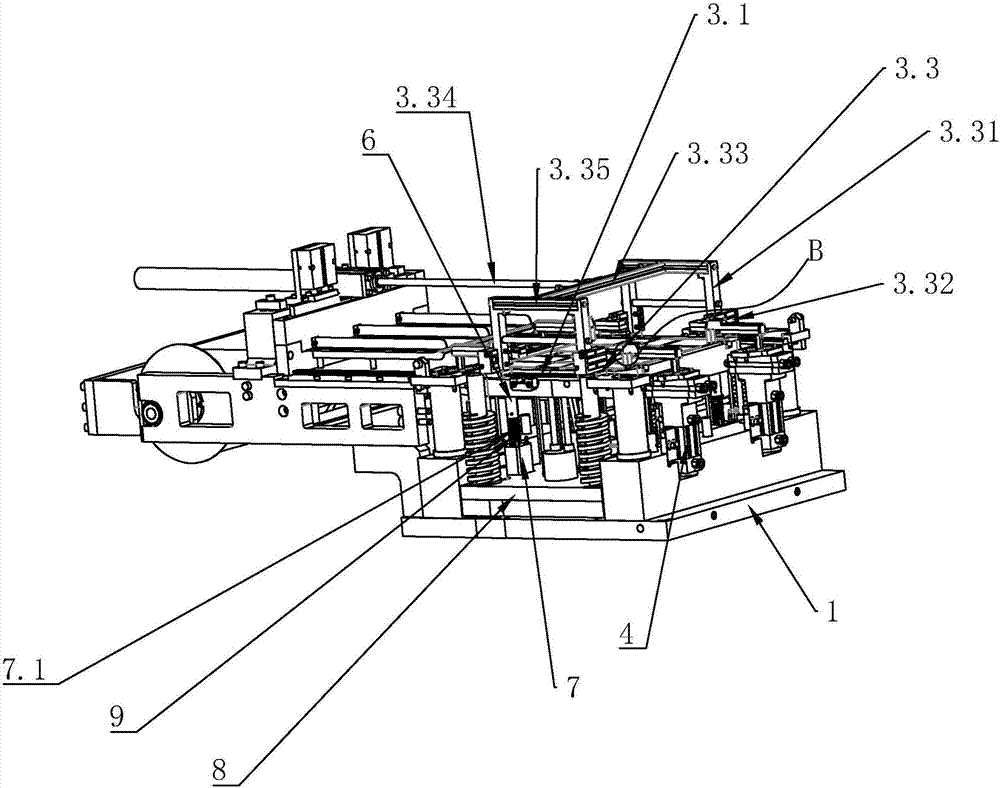

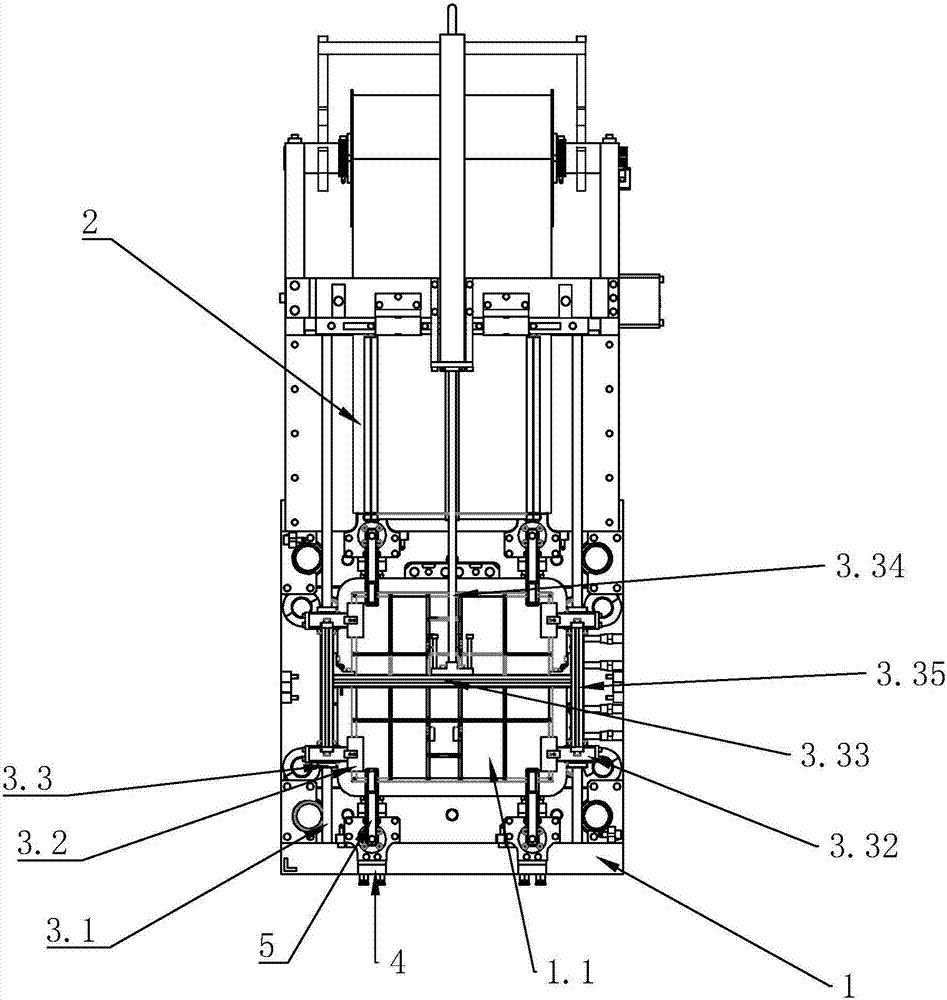

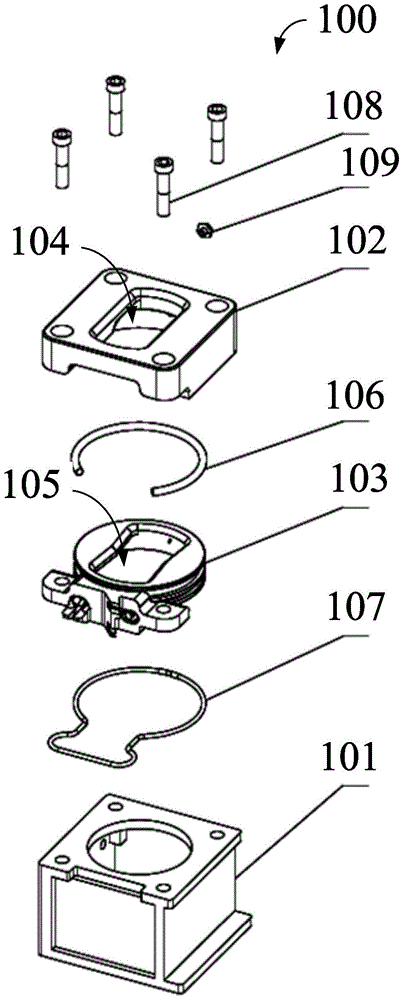

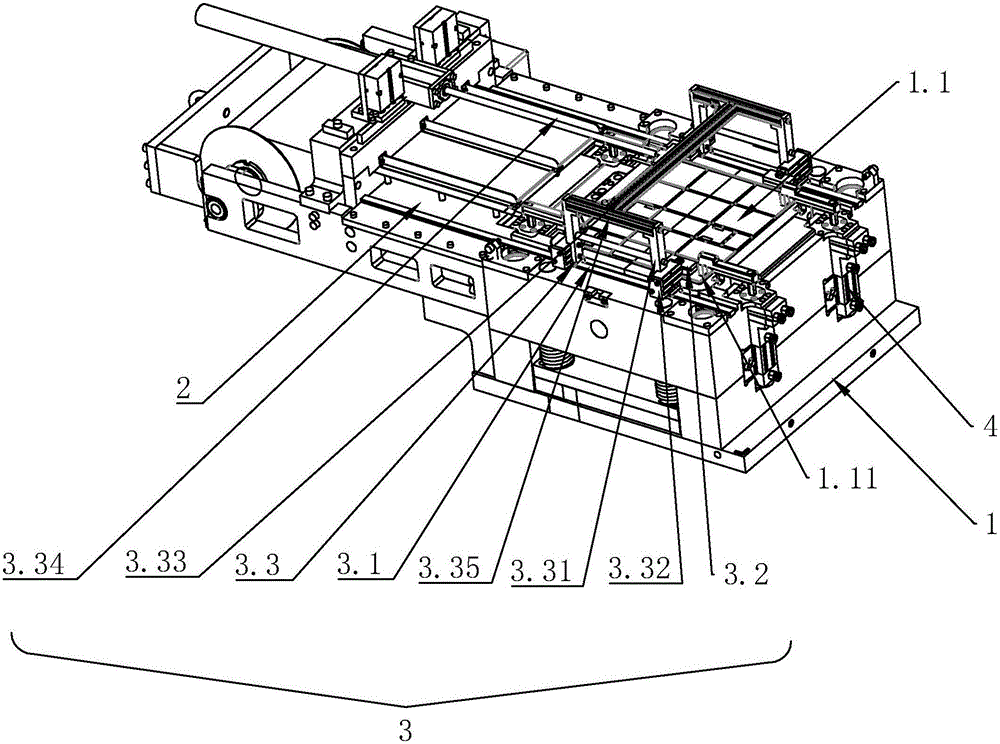

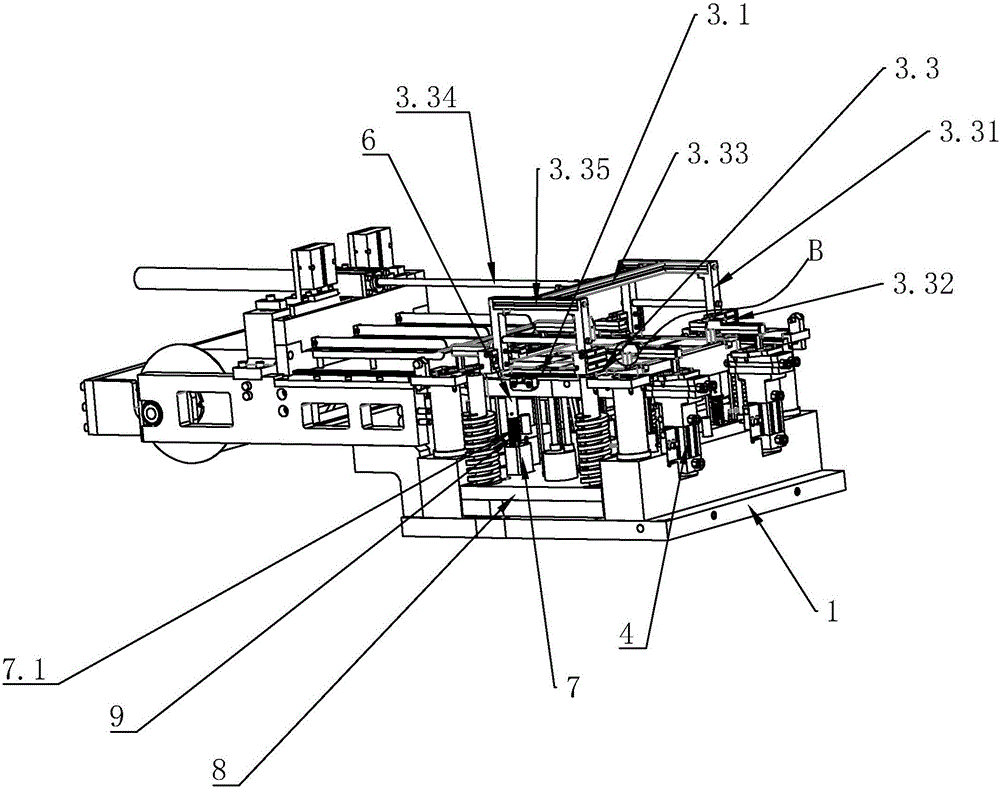

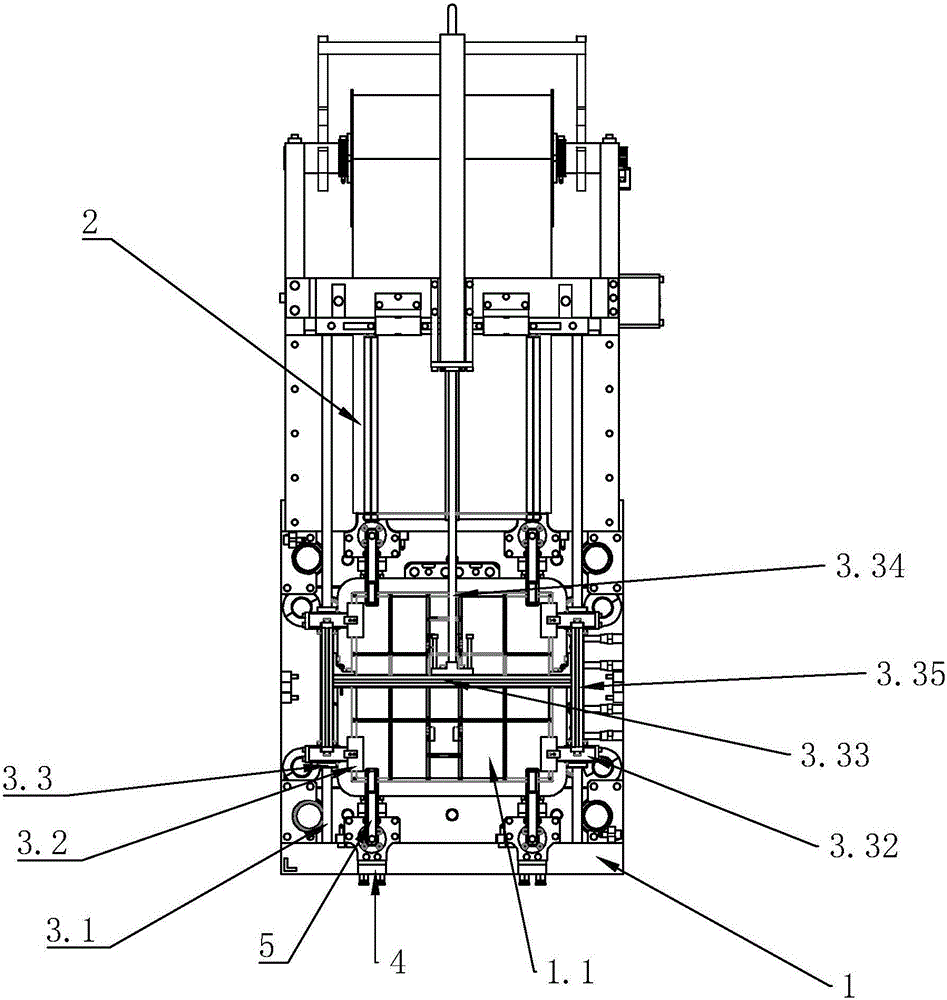

High-precision wheel set positioning and transferring mechanism for railway vehicle production

ActiveCN109987394AAutomatic speed adjustmentMobile synchronizationControl devices for conveyorsMechanical conveyorsTransfer mechanism

The invention relates to the technical field of railway production equipment, in particular to a high-precision wheel set positioning and transferring mechanism for railway vehicle production. The high-precision wheel set positioning and transferring mechanism comprises linear moving devices, a synchronous device and a wheel set positioning device, wherein the wheel set positioning device comprises a movable mechanism, a buffer mechanism and shaft positioning mechanisms, wherein a wheel set is arranged on a rail, the shaft positioning mechanisms are arranged on the two sides of the wheel set and are arranged with a rotating shaft of the wheel set in a clamped mode, the buffer mechanism is installed below the shaft positioning mechanisms, the working direction of the buffer mechanism is thesame as the conveying direction of the wheel set, the movable mechanism is installed below the buffer mechanism and drives the buffer mechanism to move towards the wheel set from the two sides of thewheel set, the synchronous device and the movable mechanism are both installed on the linear moving devices, the linear moving devices are arranged on the two sides of the rail, and the conveying direction of the linear moving devices is the same as the conveying direction of the wheel set. The mechanism does not need a high-precision rack, a safety synchronizing mechanism is installed on the linear moving devices of the mechanism, the wheel set is not prone to derailing during transportation, and the rack is not easy to damage.

Owner:江苏宁铁技术股份有限公司

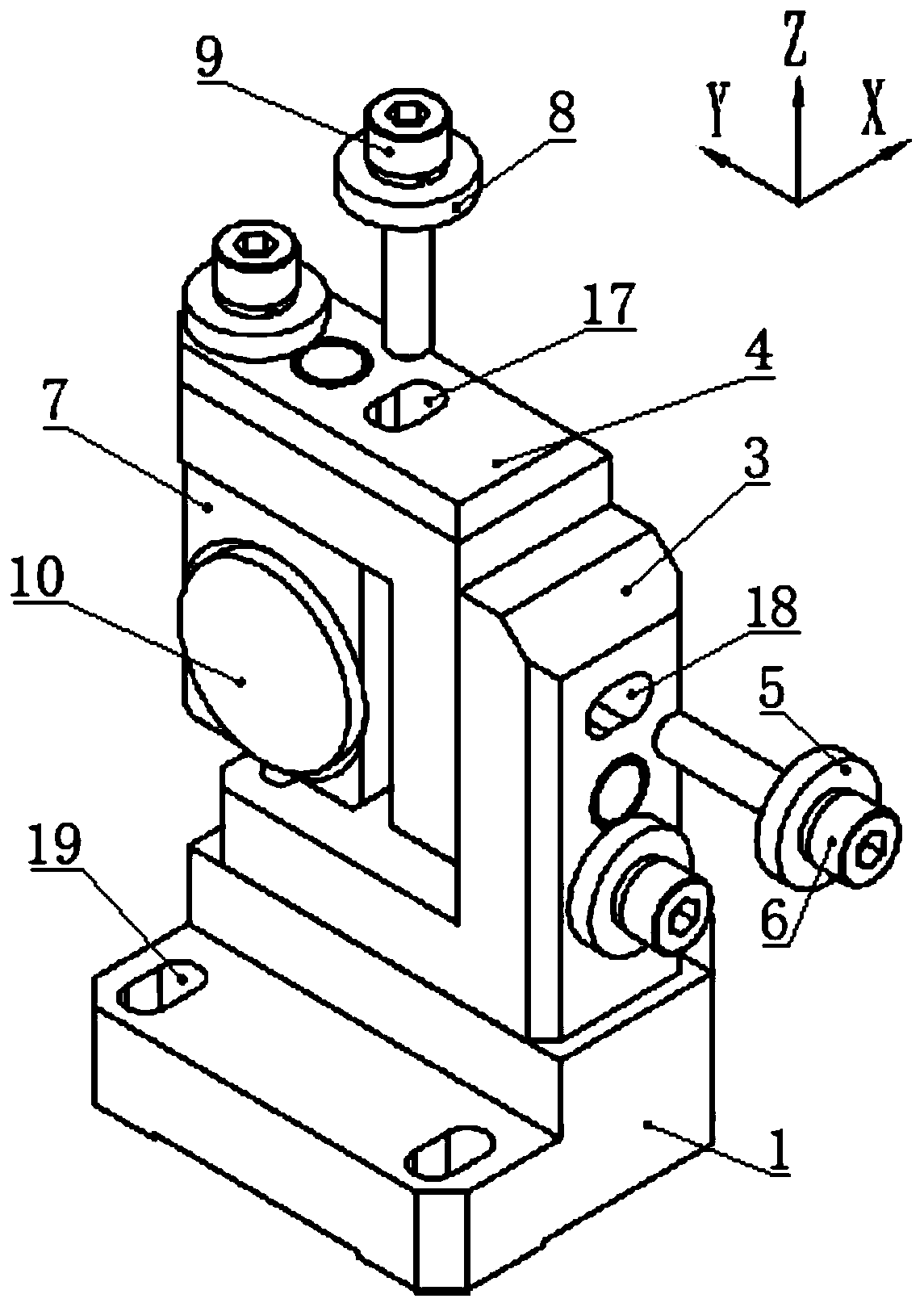

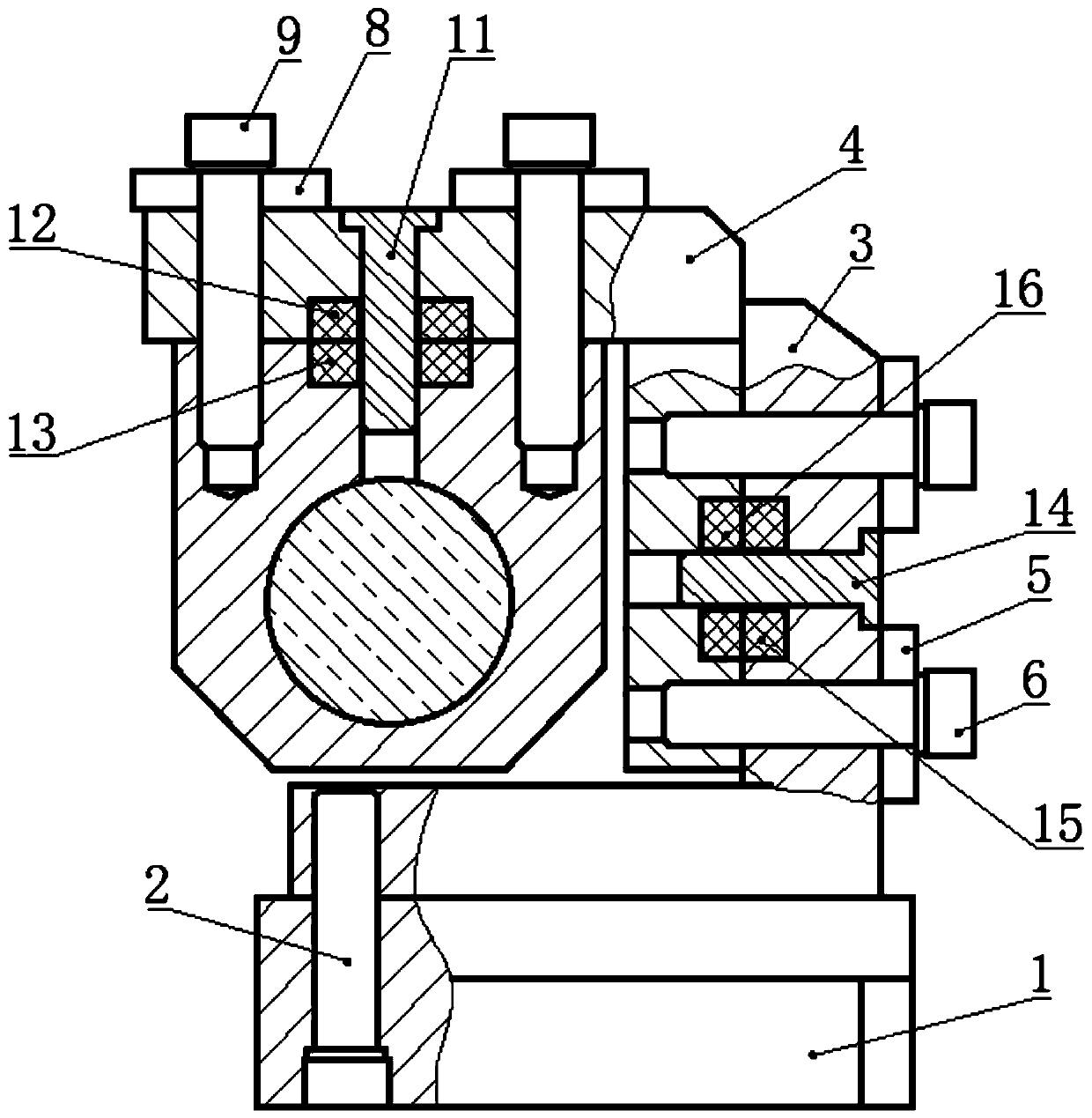

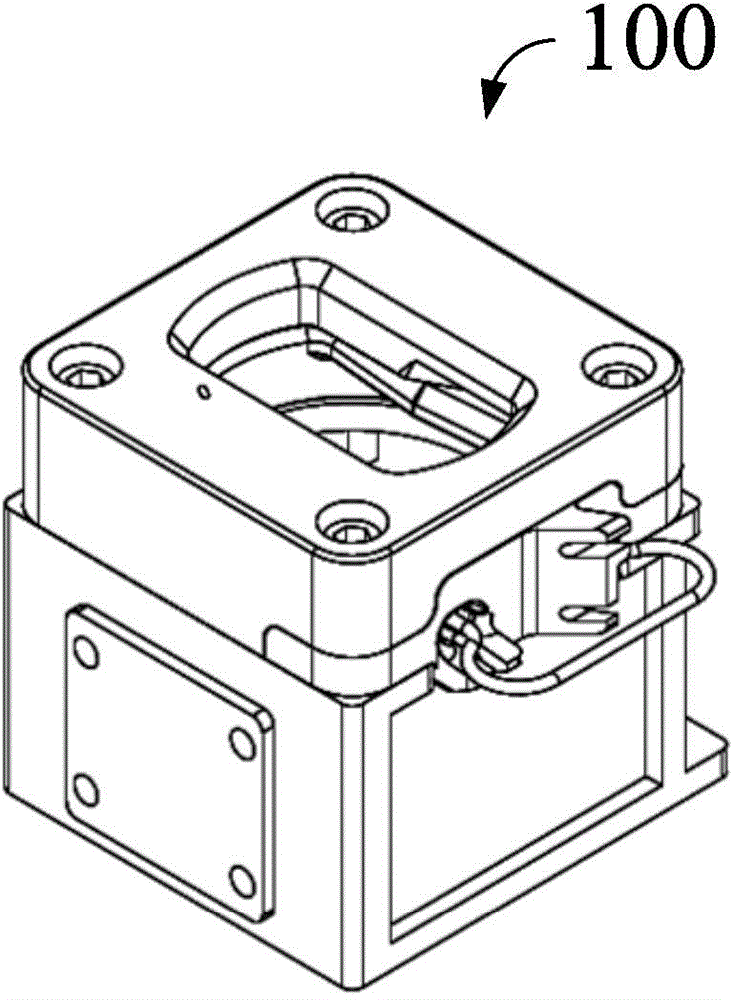

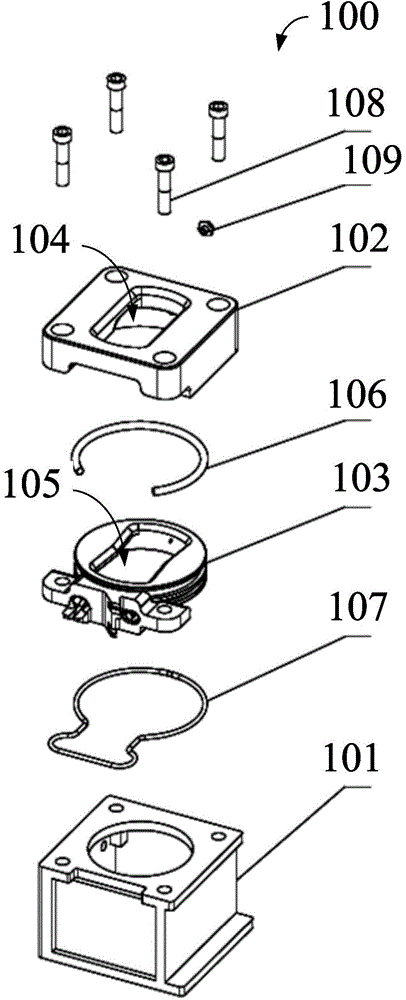

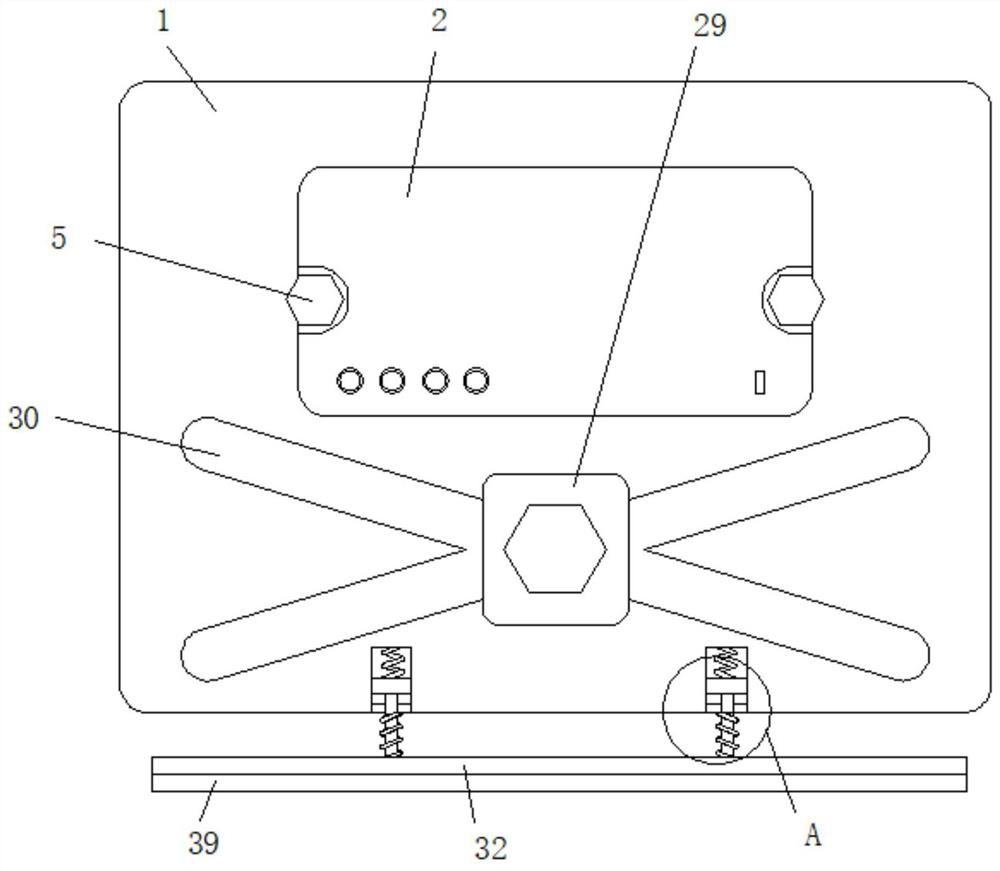

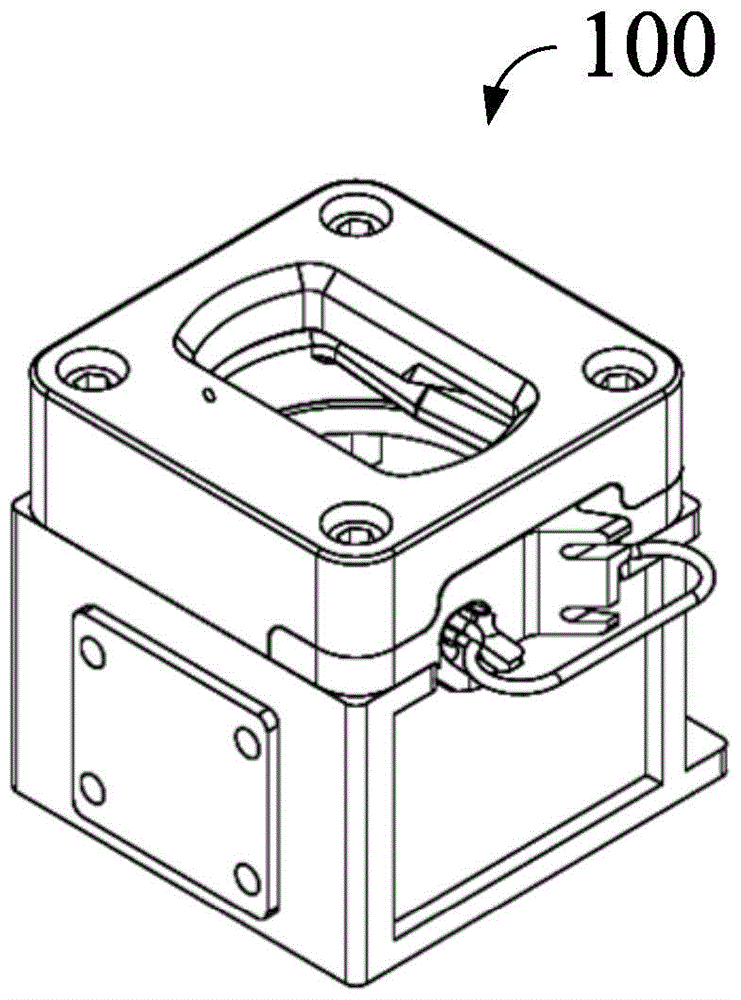

Three-degree-of-freedom laser mirror adjusting device

InactiveCN110515173AIncreased sensitivityNot easy to damageMountingsThree degrees of freedomAngular degrees

The invention discloses a three-degree-of-freedom laser reflector adjusting device, and belongs to the technical field of optical element azimuth adjustment. The three-degree-of-freedom laser reflector adjusting device can realize that three parts of translation along an X axis, swinging around a Y axis and swinging around a Z axis can be independently adjusted in the debugging or using process ofa reflector, the replaceability is strong, the swinging around the Y axis and the swinging around the Z axis can be adjusted within a large angle range of + / -10 degrees, and the X axis direction canbe adjusted within a range of 0-5 mm. Compared with the prior art, the three-degree-of-freedom laser reflector adjusting device effectively enlarges the adjusting range, simultaneously, and after thepitching and the side swinging are adjusted to proper positions in a magnet adsorption mode, the state can be kept for positioning, and compared with the prior art, the condition that the reflector generates displacement due to external interference can be greatly reduced, and furthermore the position of the reflector is not easy to generate angular deviation in the using process, and then the result of use is further improved, the frequency of carrying out the angle readjustment to the reflector is reduced, and the work load is reduced.

Owner:杭州奥创光子技术有限公司

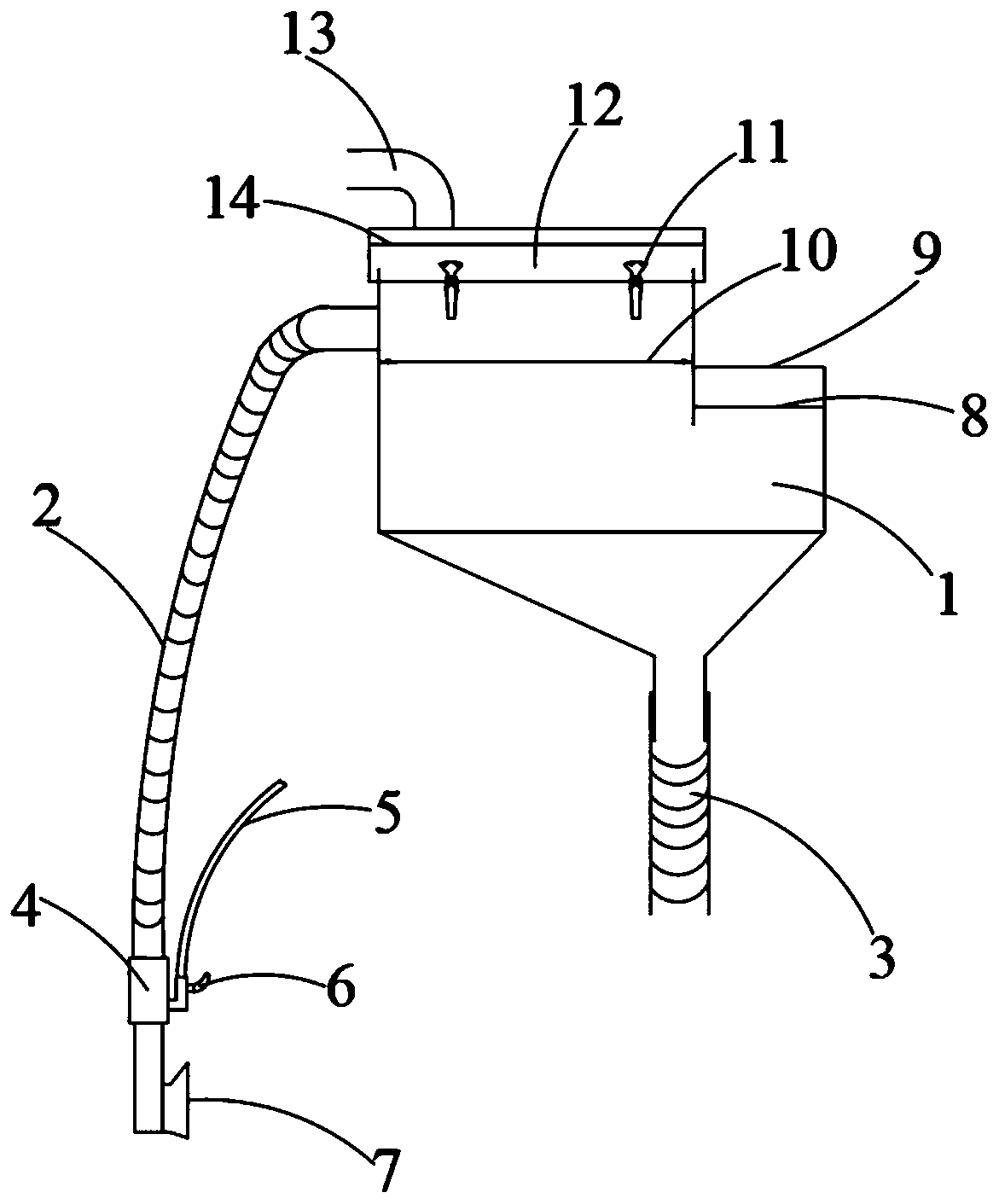

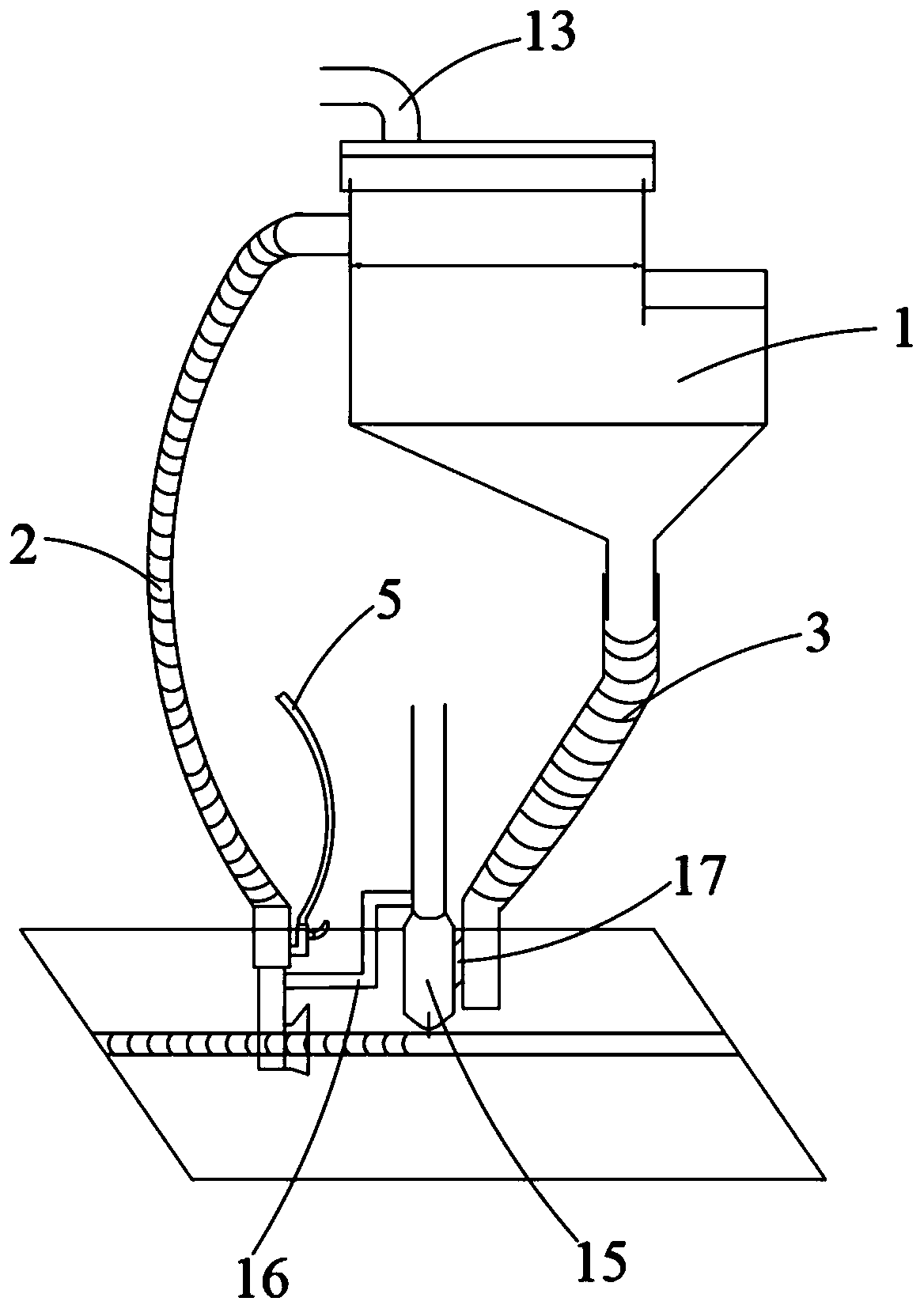

Welding device for synchronously recycling welding flux

InactiveCN110449702AConvenient supplementImprove recycling efficiencyWelding accessoriesEngineeringAirflow

The invention relates to the technical field of welding equipment, in particular to a welding device for synchronously recycling welding flux. The welding device comprises a welding flux box for storing welding flux and an airflow power device, wherein a discharging pipeline and a recycling pipeline are arranged on the welding flux box; a discharging port for discharging the welding flux is arranged on the discharging pipeline; a sucking port for recycling the welding flux into the welding flux box is arranged on the recycling pipeline; the airflow power device is used for forming negative pressure at the sucking port to suck the welding flux into the recycling pipeline, and forming a conveying airflow in the recovery pipeline to convey the sucked welding flux into the welding flux box; and the welding flux box is also provided with a charging port. By means of the welding device, on one hand, the welding flux in the welding flux box can be supplemented and supplied; and on the other hand, the recycling efficiency of the welding flux is accelerated.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

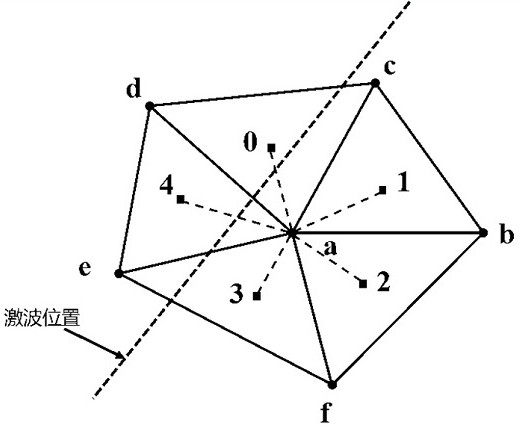

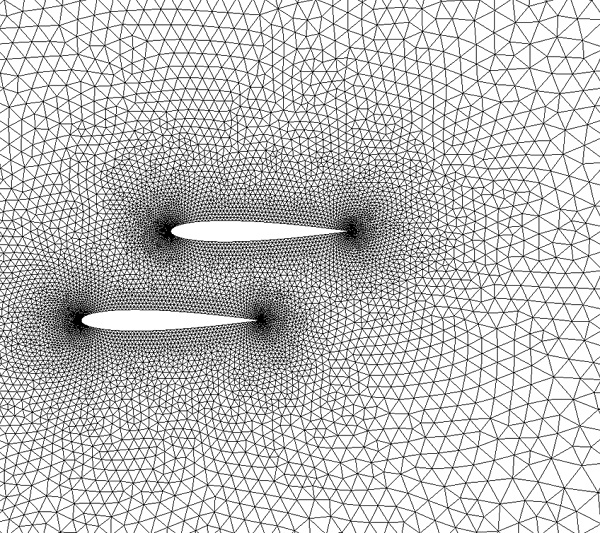

Variable difference and relative displacement-based r-type grid adaptive movement method and equipment

ActiveCN112665820AMobile synchronizationEliminate movement effectsAerodynamic testingMesh adaptationMesh point

The invention discloses a variable difference and relative displacement-based r-type grid adaptive movement method and equipment, two kinds of parameters including the variable difference of normalized grid points and the relative displacement of the grid points are used as a weight function for calculating the movement of the grid points, and the following movement of the grid points is realized by adding the weight function, namely the relative displacement of the grid points. The influence of the magnitudes and dimensions of the two types of parameters on the movement amount of the grid points is eliminated by normalizing, a new combined weight is formed by the two types of parameters so as to determine the displacement of the grid points near the shock wave, and the displacement information of the grid points near the shock wave is transmitted to the adjacent grid points of the grid points. Several rows of grid points near the shock wave can synchronously move to the shock wave position. By normalizing the physical quantity and the grid point position movement amount, the influence of two types of parameter values and dimensions on the grid point movement amount is eliminated, the grid points at the shock wave position can be effectively close to the shock wave position, and meanwhile it can be guaranteed that several rows of grid points near the shock wave synchronously move to the shock wave position.

Owner:CALCULATION AERODYNAMICS INST CHINA AERODYNAMICS RES & DEV CENT

A method for producing l-arabinose from xylose mother liquor

InactiveCN104086607BSimple processLow input costSugar derivativesSugar derivatives preparationYeastChromatographic separation

The invention provides a method of producing L-arabinose by a xylose mother liquid. The method comprises the following steps: first, diluting the xylose mother liquid; then, removing glucose by active dry yeast powder; further refining the xylose mother liquid through decoloration, ion exchange and evaporation concentration; then obtaining an L-arabinose component solution and a xylose component solution through a continuous chromatographic mobile bed and respectively crystallizing to obtain an L-arabinose product and a xylose product. The method provided by the invention extracts L-arabinose through the continuous chromatographic mobile bed by using a byproduct xylose mother liquid in production of crystallized xylose by bagasse, is simple in operation, low in technical cost and good in separating effect, and has an extremely wide application valve. The obtained L-arabinose is high in purity and yield.

Owner:SHANDONG WANSHENG ENVIRONMENTAL TECH DEV

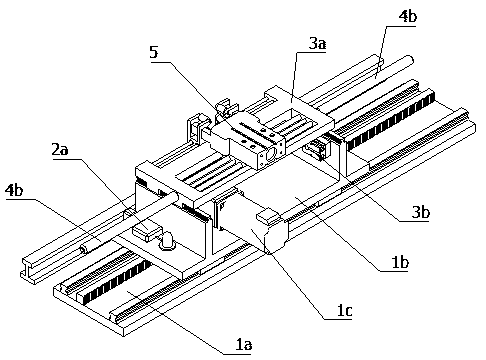

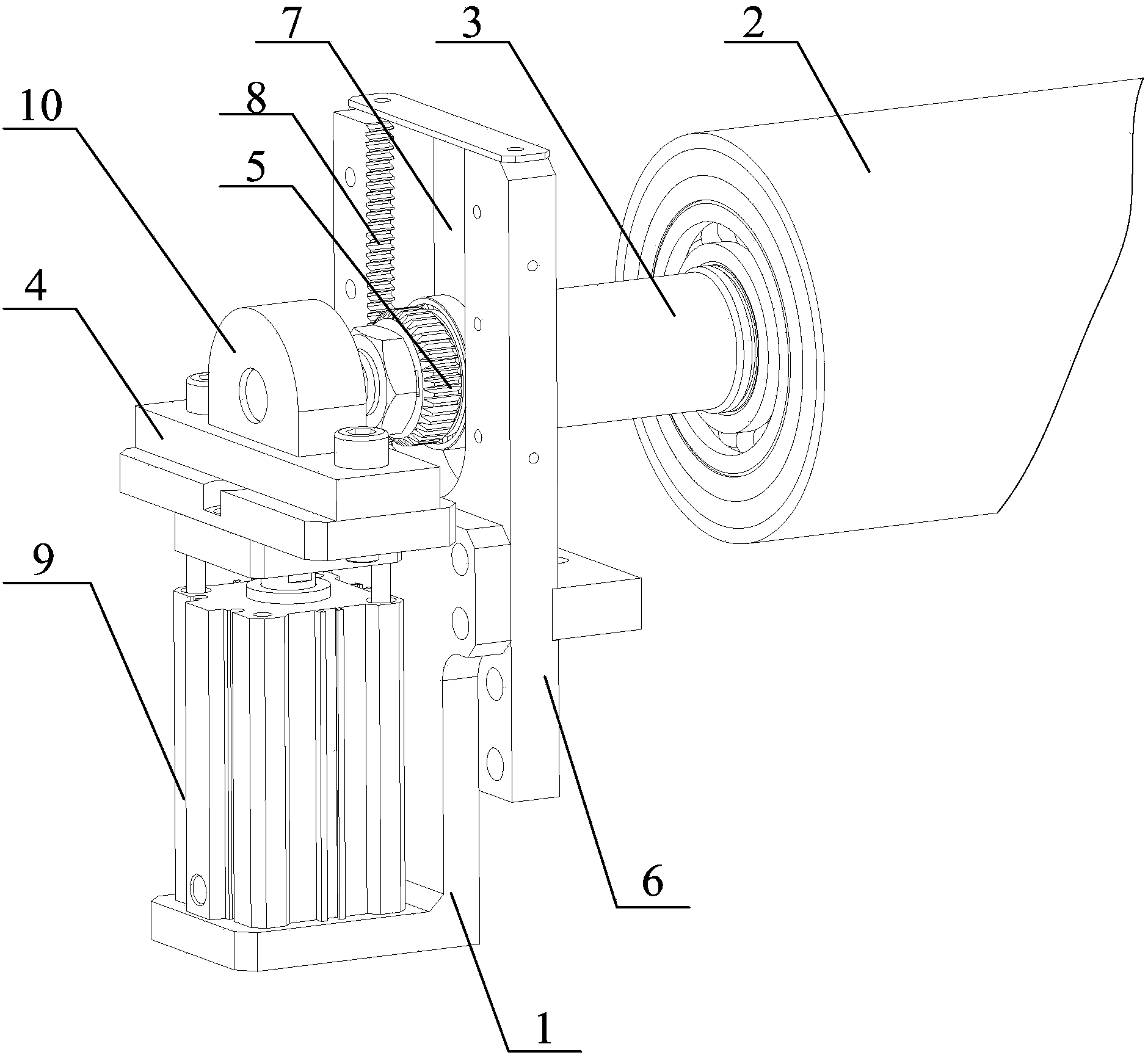

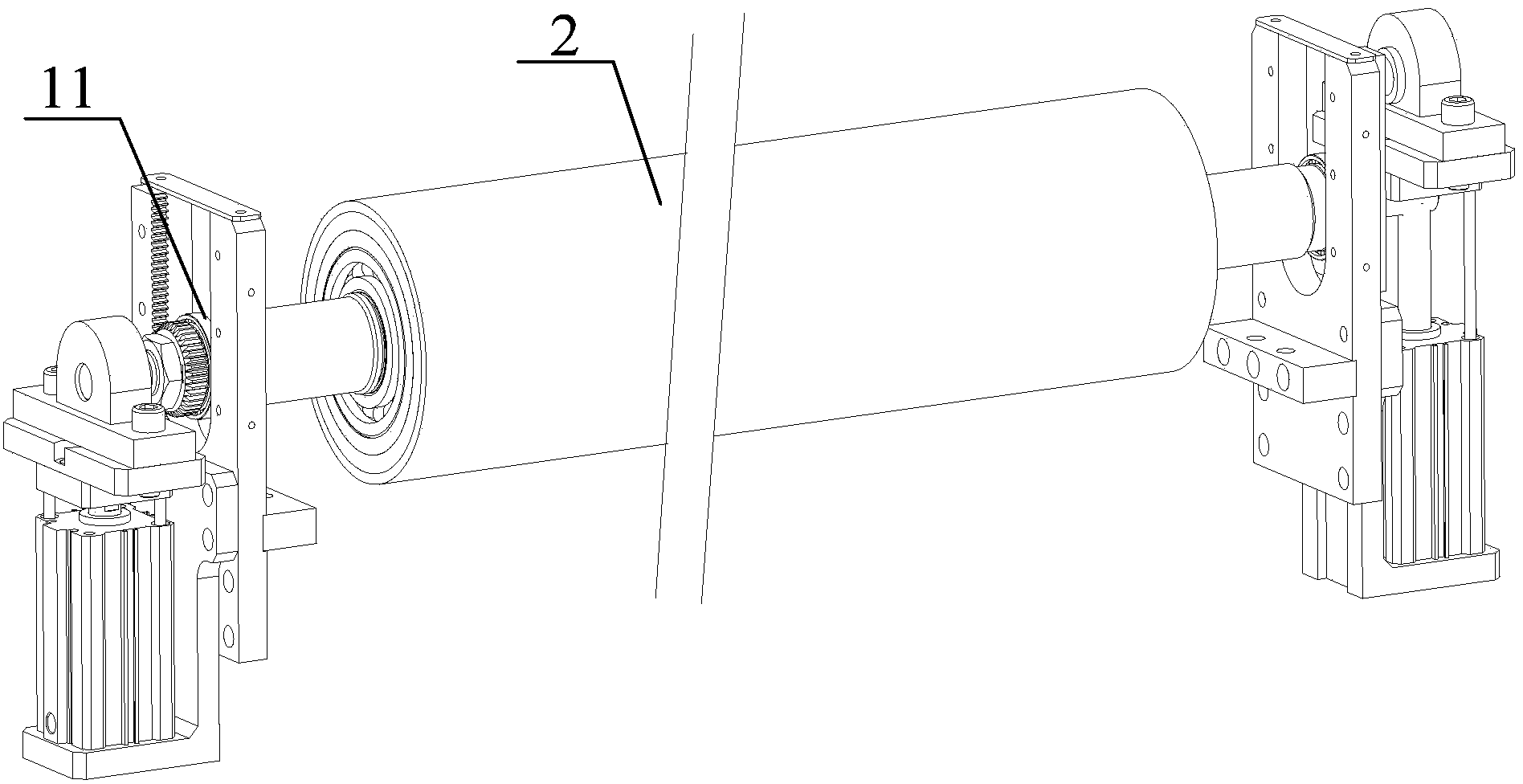

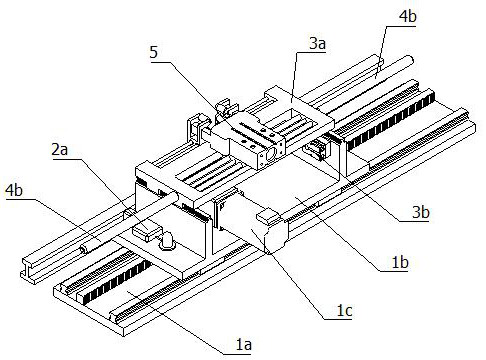

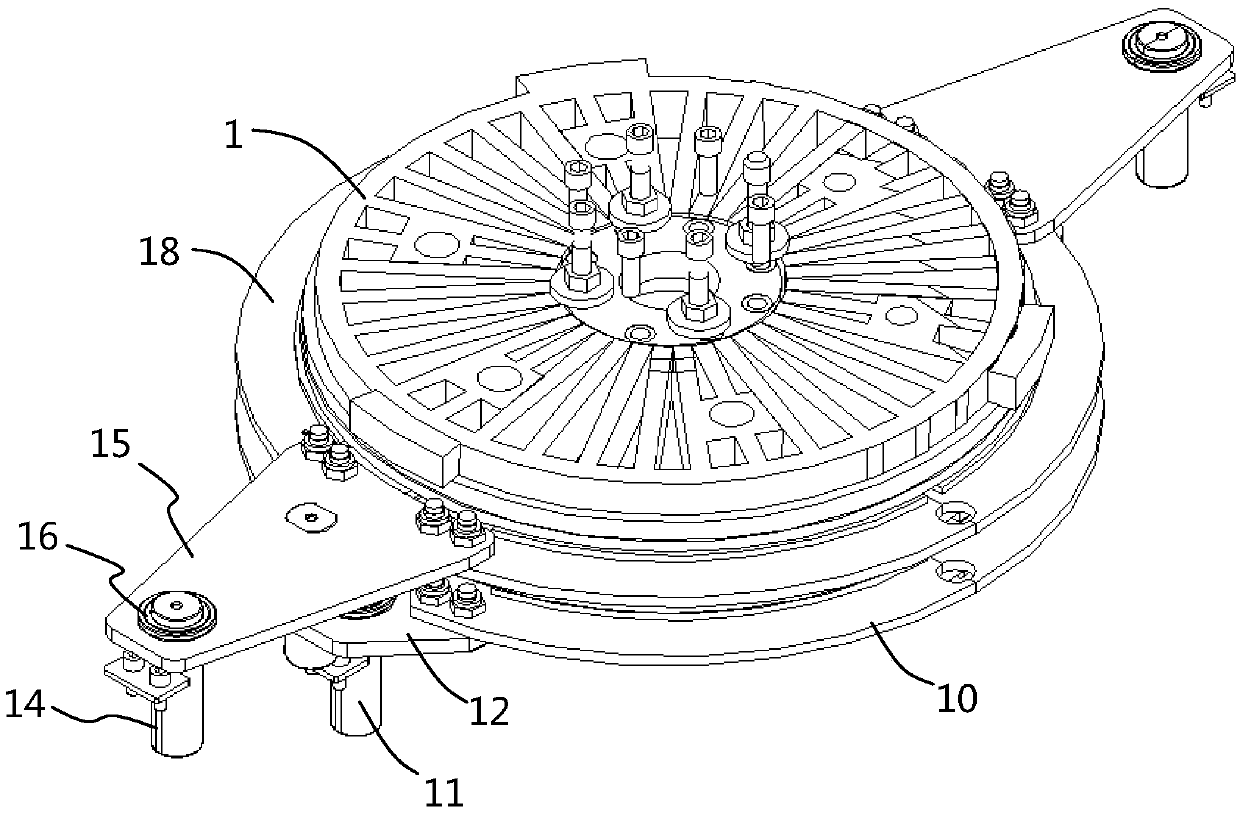

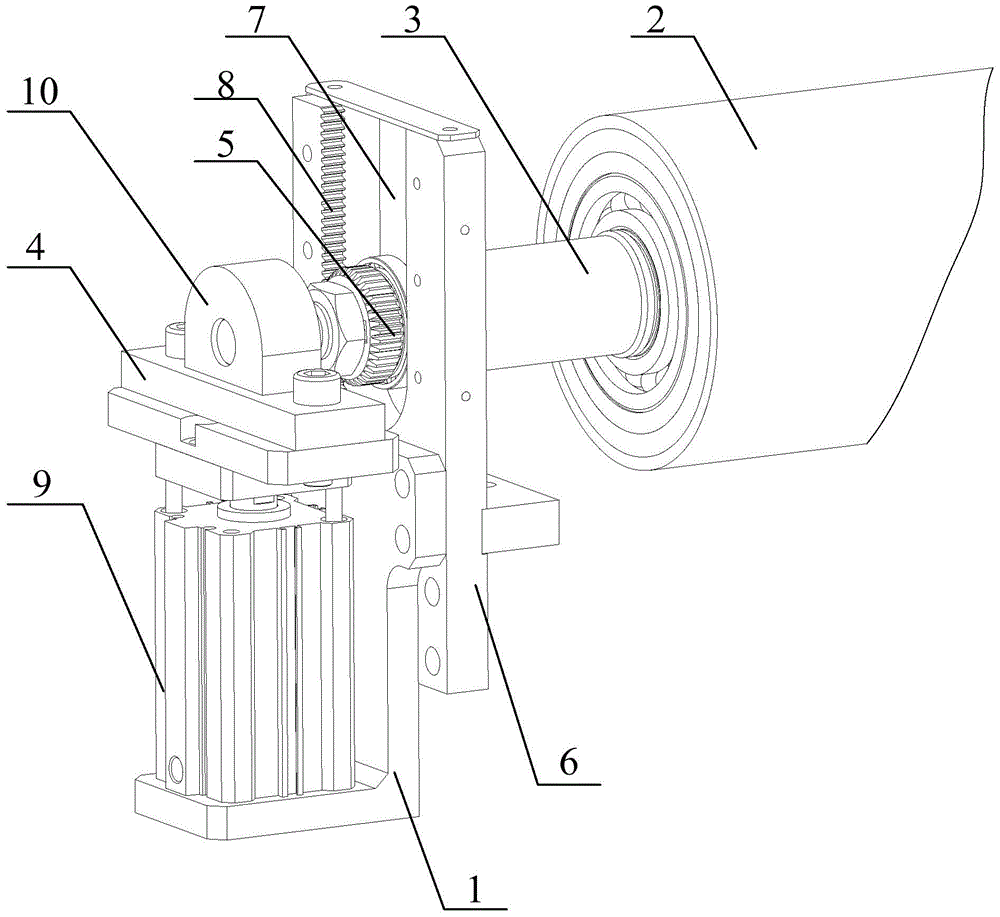

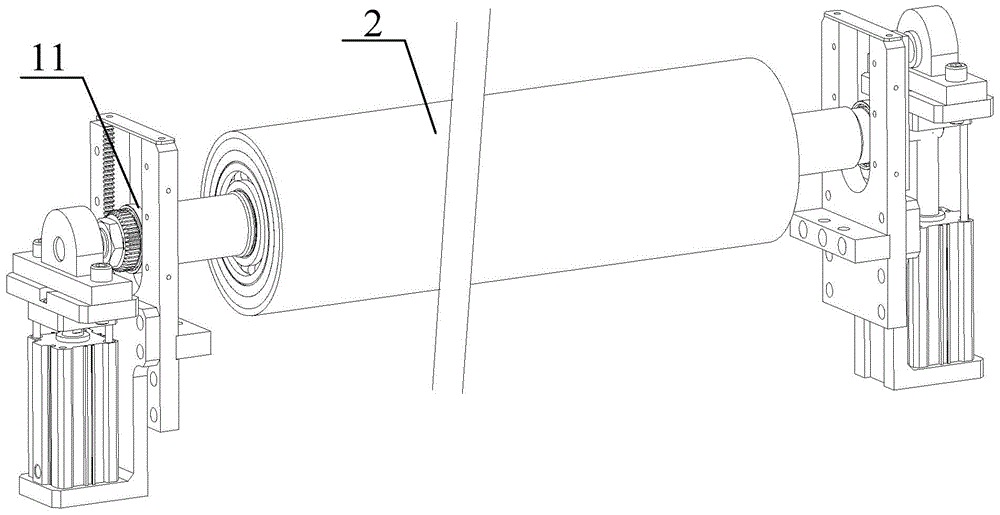

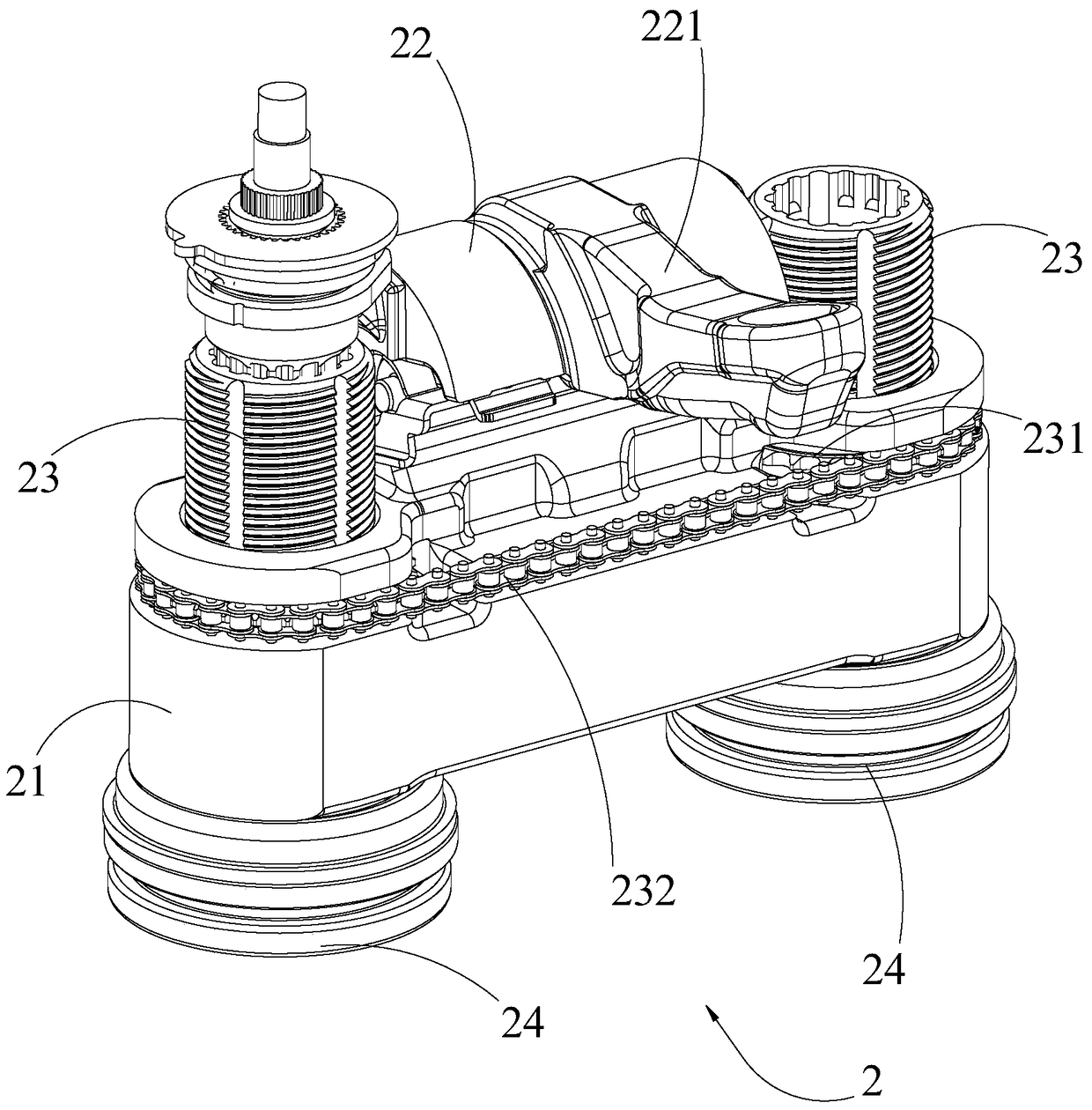

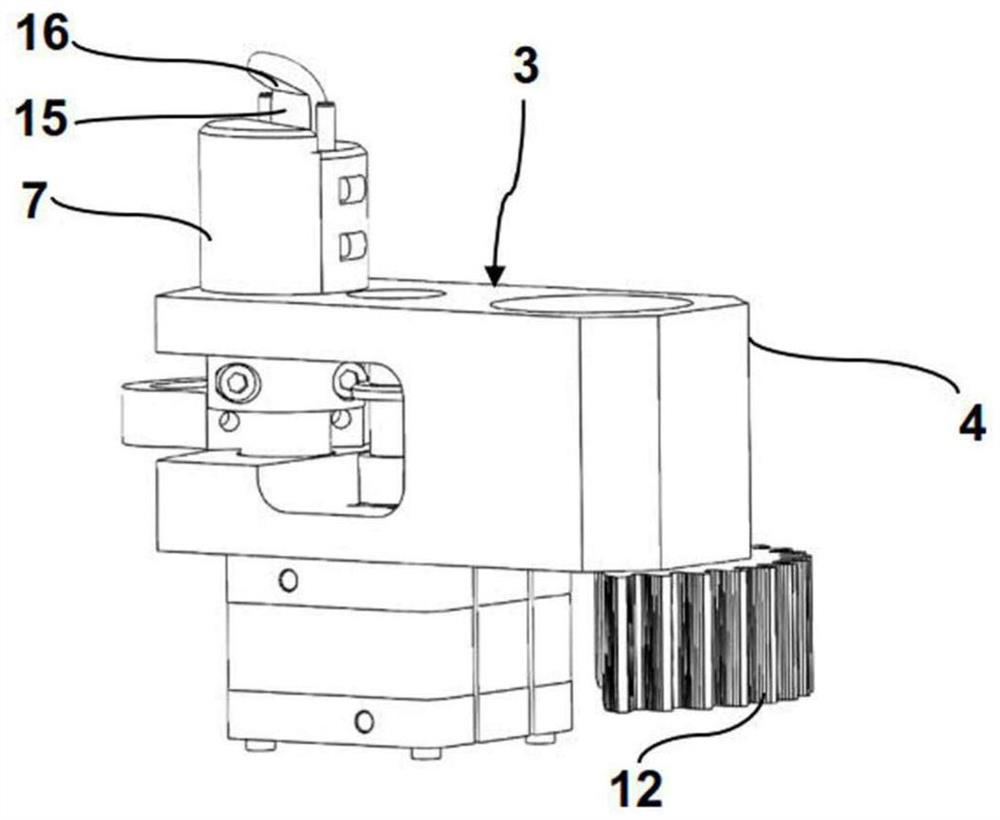

Radial position adjustment assembly for roll shaft revolving body

ActiveCN103591262AMobile synchronizationThe overall structure is simple and reliableGearing detailsRadial positionGear wheel

The invention relates to a radial position adjustment assembly for a roll shaft revolving body. The radial position adjustment assembly comprises bottom frames and a revolving main body, wherein installation shafts which are concentric with the revolving main body are fixedly connected to the two ends of the revolving main body, the installation shafts at the two ends of the revolving main body are arranged on two adjustment bases respectively in a rotatable mode, the adjustment bases are independent of each other and can move along the radial direction of the revolving main body, and at least one of the adjustment bases is connected with a driving end of a drive device. the radial position adjustment assembly further comprises cylindrical gears and guide plates, wherein the cylindrical gears are arranged on the installation shafts at the two ends of the revolving main body and of the same specification, the guide plates are fixedly connected to the bottom frames and located at the two ends of the revolving main body, a radial guide groove is formed in each guide plate, the cylindrical gears are embedded into the radial guide grooves, racks which are matched with each cylindrical gear are arranged on a lateral side of the corresponding guide groove, and the racks are meshed with the gears. The radial position adjustment assembly is simple and reliable in structure and convenient to maintain, the synchronism of movement of the two ends of the revolving main body can be effectively ensured, and therefore each connection part of the revolving main body and the drive device can be effectively protected.

Owner:SHENZHEN RUNTIANZHI DIGITAL EQUIP

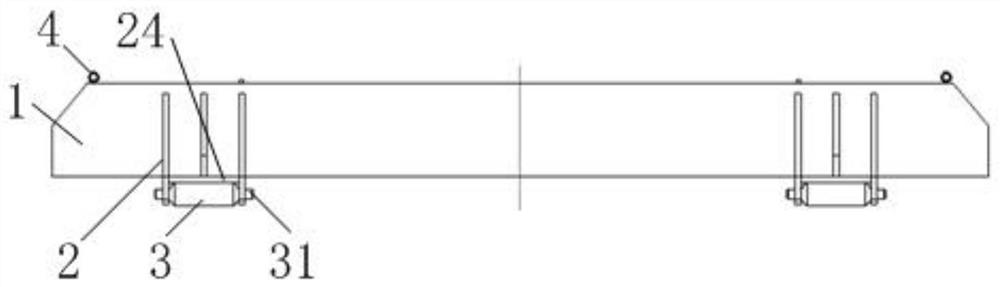

High-precision wheel set positioning and transferring mechanism for production of railway vehicles

InactiveCN111634630APrevent jumpingAutomatic speed adjustmentControl devices for conveyorsAlarmsRotational axisTransfer mechanism

Owner:殷建平

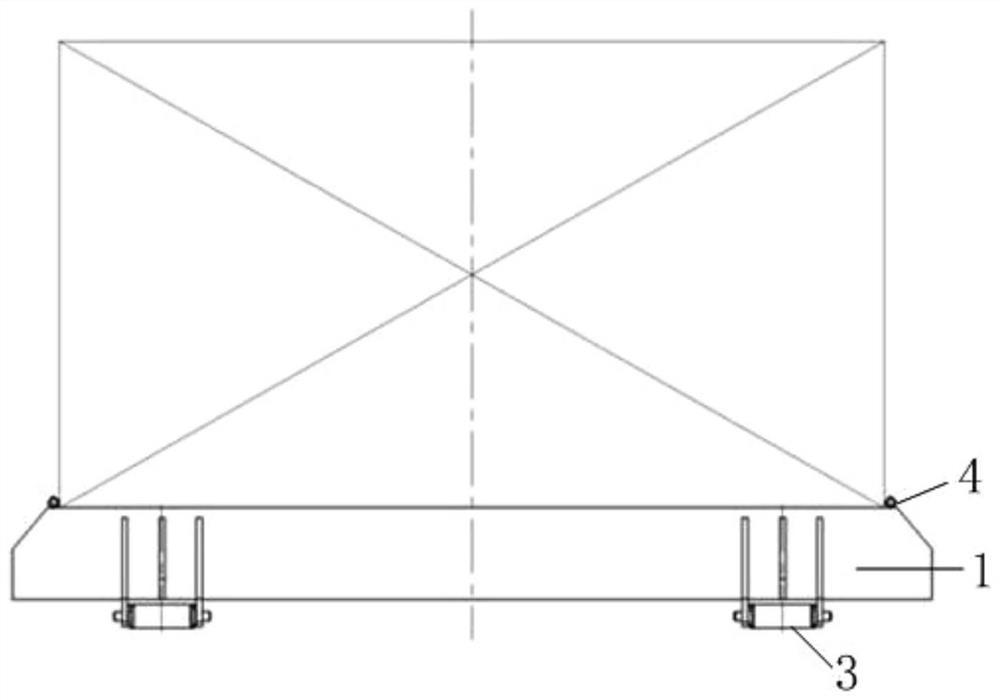

Pin-detaching mechanism and full-automatic container pin-detaching cart

The invention provides a pin-detaching mechanism for detaching lock pins on containers. The pin-detaching mechanism comprises a lock pin detaching base, a guide, and an angled part; the guide is provided with a first elongated opening; the guide is fixed to the lock pin detaching base; the angled part is provided between the lock pin detaching base and the guide and is provided with a second elongated opening. When a lock pin is not inserted in, the length direction of the second elongated opening of the angled part has an acute angle relative to the length direction of the first elongated opening of the guide. Additionally, the invention further provides a full-automatic container pin-detaching cart using the pin-detaching mechanism.

Owner:SHANGHAI ZHENHUA HEAVY IND

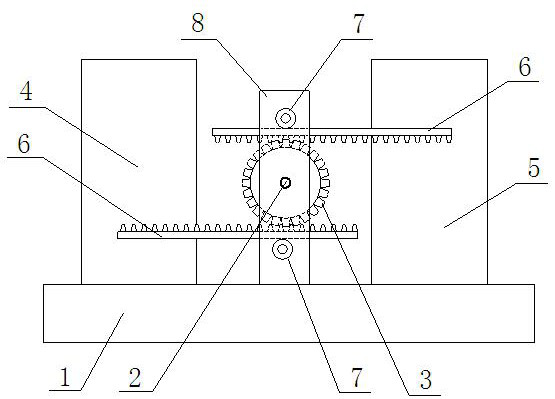

Green brick pressing device

InactiveCN112356234AQuality improvementMobile synchronizationCeramic shaping apparatusBrickGear wheel

The invention aims at providing a green brick pressing device capable of ensuring synchronous movement of molds on the left side and the right side so as to improve the green brick pressing quality. The green brick pressing device comprises a machine frame, the left mold, the right mold, a left mold driving mechanism and a right mold driving mechanism, wherein the left mold and the right mold aremovably arranged on the machine frame. The green brick pressing device is characterized in that a gear is installed on the machine frame through a rotating shaft, the left mold and the right mold areeach provided with a horizontal rack engaged with the gear, and the horizontal racks of the left mold and the right mold are positioned above and below the gear correspondingly. When green bricks arepressed, the left mold and the right mold are driven by the respective driving mechanisms to horizontally move along the machine frame in opposite directions, the respective horizontal racks are driven to synchronously move in the moving process of the left mold and the right mold, and the horizontal racks of the left mold and the right mold are both engaged with the gear, so that the horizontal movement of the left mold and the right mold must be synchronous, otherwise, the gear cannot rotate, and the left mold or the right mold cannot horizontally move.

Owner:恒伟丰(信宜)机械设备制造有限公司

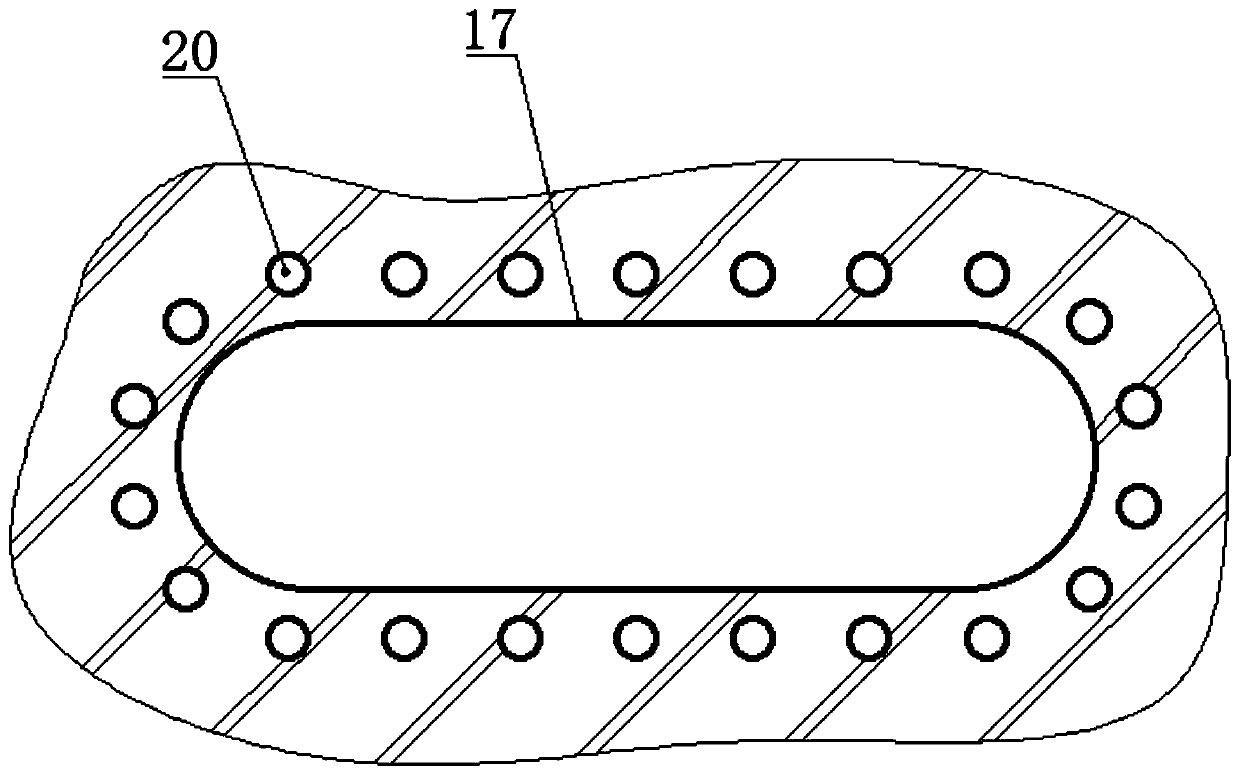

Combined pneumatic dry-type friction clutch brake for forging machine

PendingCN108679127AConsistent wearMove quicklyBraking discsBrake actuating mechanismsMagnetic polesClutch

The invention discloses a combined pneumatic dry-type friction clutch brake for a forging machine, and belongs to the technical field of clutches. The combined pneumatic dry-type friction clutch brakecomprises a clutch disc, first friction blocks, a brake disc and second friction blocks; a plurality of strip-shaped through holes are formed in the disc face of the clutch disc in the circumferential direction, first fixed magnetic pole pieces comprising N poles and S poles are arranged around the strip-shaped through holes, first movable magnetic pole pieces with opposite N poles and S poles are arranged around the first friction blocks, and the first friction blocks are arranged in the strip-shaped through holes in a clearance fit mode; and a plurality of strip-shaped through holes are formed in the disc face of the brake disc in the circumferential direction, second fixed magnetic pole pieces comprising N poles and S poles are arranged around the strip-shaped through holes, second movable magnetic pole pieces with opposite N poles and S poles are arranged around the second friction blocks, and the second friction blocks are arranged in the strip-shaped through holes in a clearancefit mode. Therefore, the first friction blocks and the second friction blocks can move towards one side quickly and basically synchronously, and it is ensured that abrasion of the friction blocks isconsistent.

Owner:ANHUI LIYUAN NUMERICAL CONTROL CUTTING TOOL & PATTERNS MFG

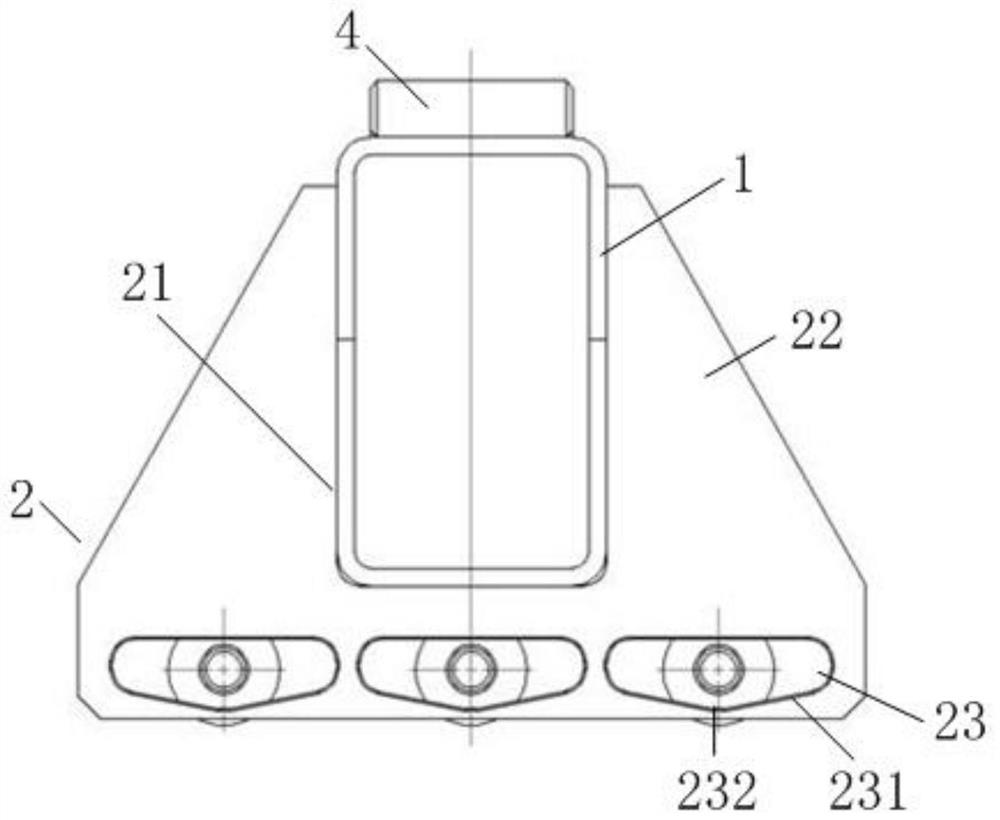

Internet intelligent sound box with self-adsorption function

ActiveCN113225629AEasy to retractPracticalTelevision system detailsColor television detailsSound boxEngineering

The invention discloses an internet intelligent sound box with a self-adsorption function, which comprises a vertically arranged fixing plate, a sound box body is arranged on one side of the fixing plate, the sound box body is in abutting contact with the fixing plate, two mounting grooves are symmetrically formed in two ends of the sound box body, mounting holes are formed in the inner walls of the two mounting grooves, the two ends of the sound box body are symmetrically provided with two mounting screws, the two mounting screws respectively penetrate through the corresponding mounting holes in the same side and are in sliding connection with the mounting holes, the two mounting screws are in threaded connection with the fixing plate, the inner bottom surface of the sound box body is rotationally connected with a main shaft, the main shaft is vertically arranged, and the main shaft is vertical to the inner bottom surface of the sound box body. The piston pieces are arranged to be matched with the connecting grooves, the air pressure in the connecting grooves is changed, the fixing plate and a target are connected and fixed through the internal and external pressure difference, meanwhile, the sliding blocks are arranged to indirectly control the multiple piston pieces to move synchronously, and operation is easier and more convenient.

Owner:深圳市优特杰科技有限公司

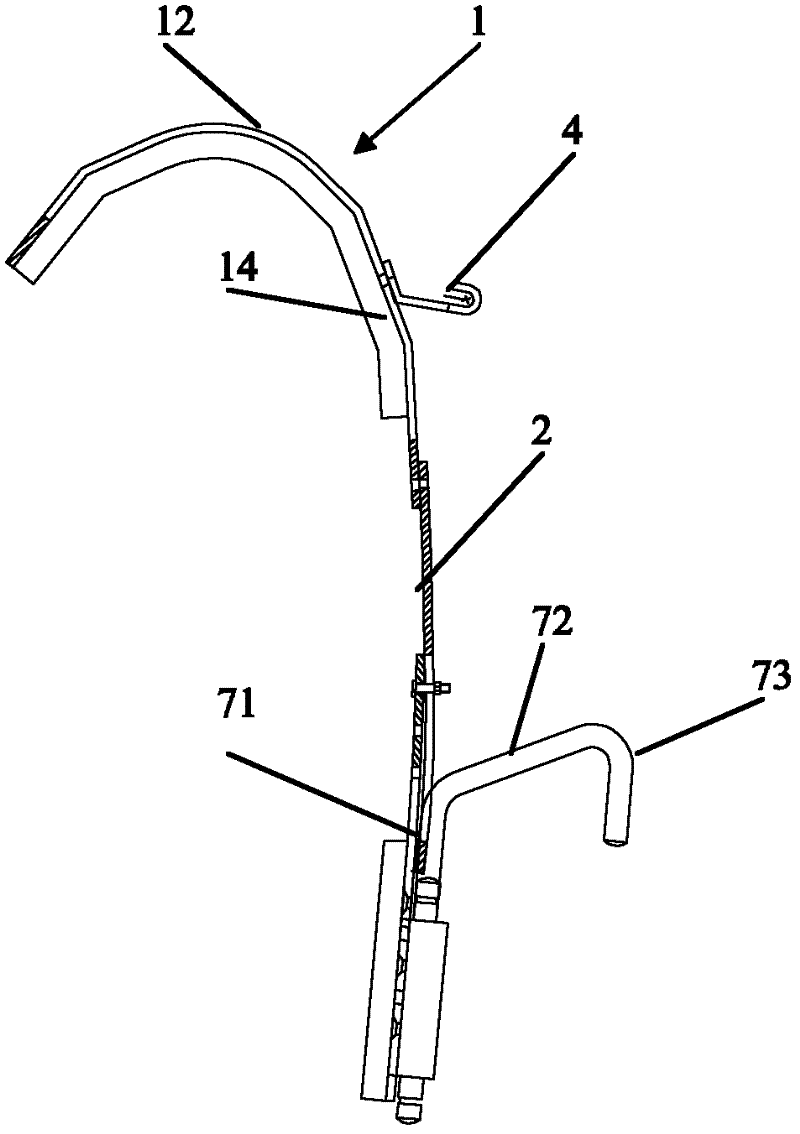

Carrying frame of marching drum

InactiveCN102411919AAvoid mobilityAvoid the situationMusical supportsMechanical engineeringEngineering

The invention discloses a carrying frame of a marching drum. The carrying frame comprises a shoulder hanging board, a junction plate and a waist plate, wherein the shoulder hanging board, the junction plate and the waist plate are fixedly mounted from top to bottom; drum instrument hooks are fixedly arranged at both sides of the front face of the shoulder hanging board; plug seats are symmetrically and fixedly mounted on the waist plate; and supporting hooks for supporting a drum cylinder are rotatably and fixedly arranged in the plug seats. When the carrying frame provided by the invention is used, the supporting hooks are swung to the vertical face of the waist plate so that the drum instrument is placed on the supporting hooks; a supporting section is used for effectively supporting the drum instrument; and then buckles on a drum cavity are correspondingly hung and remained on the hooks on a shoulder rear plate so that the drum instrument can be ensured to be stable and fixed through fixation settings at the upper part and the lower part. The hooks are fixed on the shoulder rear plate and inclined inwards so that the drum can be effectively ensured to be firmly held and be synchronous with the movement of a user; and therefore, the phenomenon that the movement of the drum is delayed or the drum swings without stopping is avoided.

Owner:TIANJIN JINBAO MUSICAL INSTR

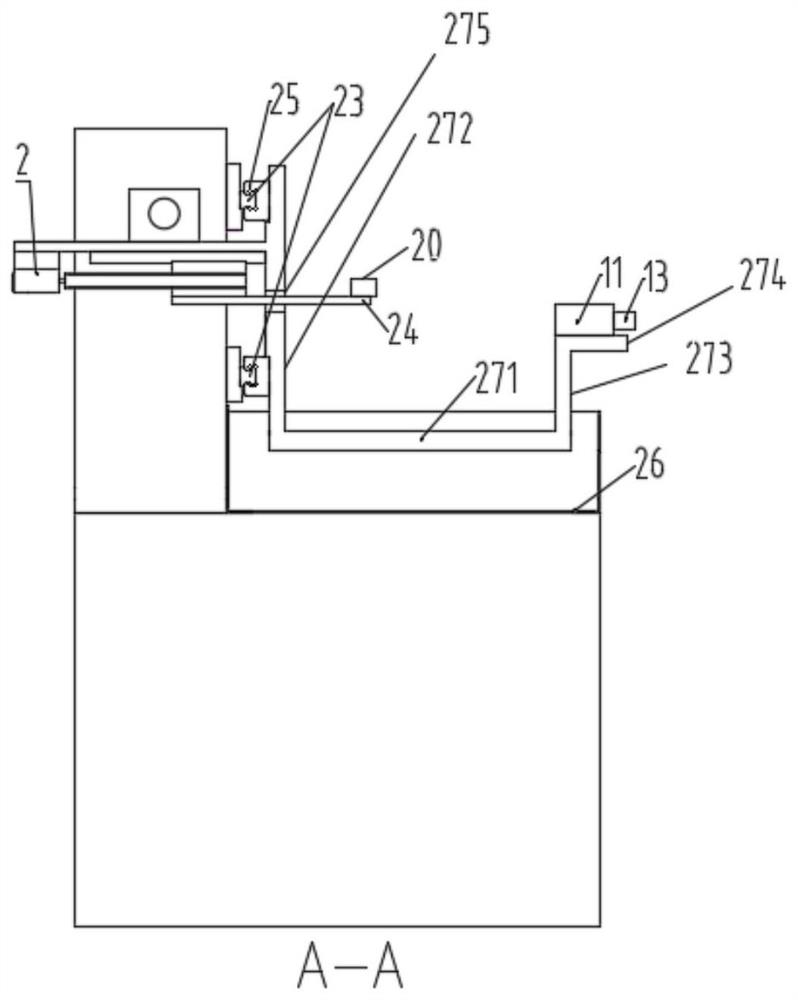

Horizontal electrochemical mechanical composite processing equipment applied to shaft parts

ActiveCN110039312BReduce in quantityMeet processing needsOther manufacturing equipments/toolsElectrolytic agentStructural engineering

The invention discloses a horizontal electrochemical-mechanical composite processing equipment applied to shaft parts, which mainly includes a supporting plate and a side wall. There are cathodes and grinding tools on both sides for processing shaft workpieces; one side of the supporting plate is set up on the linear guide rail on the side wall and can slide, and the cathode and grinding tools can move radially; through this device, the supporting plate can be The plate drives the cathode and the grinding tool to move axially together to realize the axial movement processing of the shaft workpiece, and because the supporting plate is in the shape of a groove, the electrolyte can be accumulated in the groove, so that on the one hand, it can avoid the impact of the electrolyte on the workpiece. Corrosion occurs in other parts of the equipment, and on the other hand, it is also convenient for the recovery of the electrolyte.

Owner:大连汇智工大特种精密机械有限公司

A hole punching mechanism for a transplanting machine

ActiveCN105027756BAvoid destructionImprove the effect of hole punching and transplantingPlantingFurrow making/coveringEngineeringMechanical engineering

Owner:张培坤

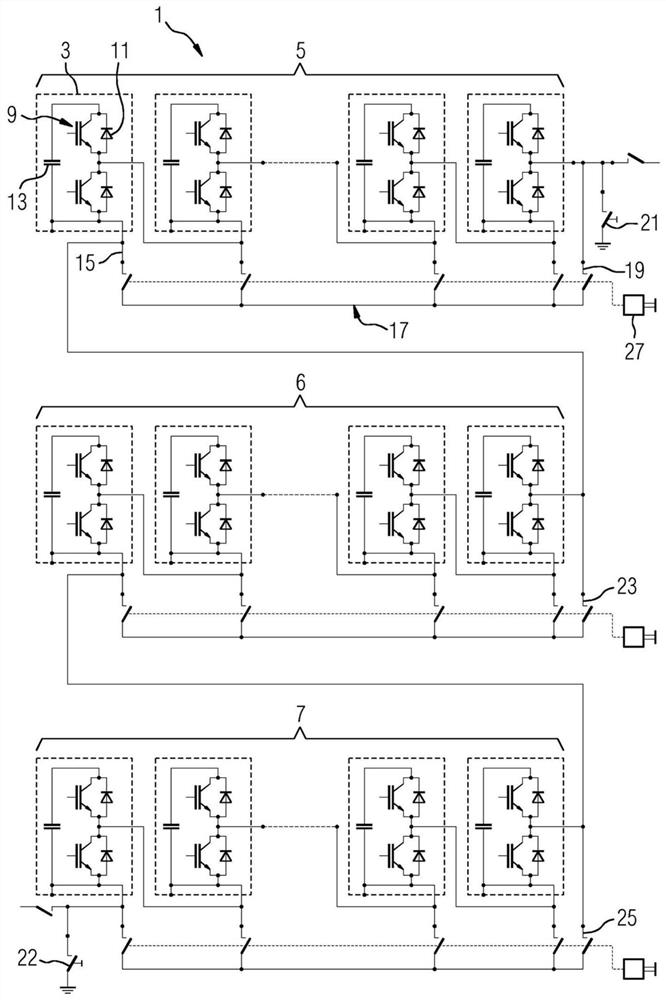

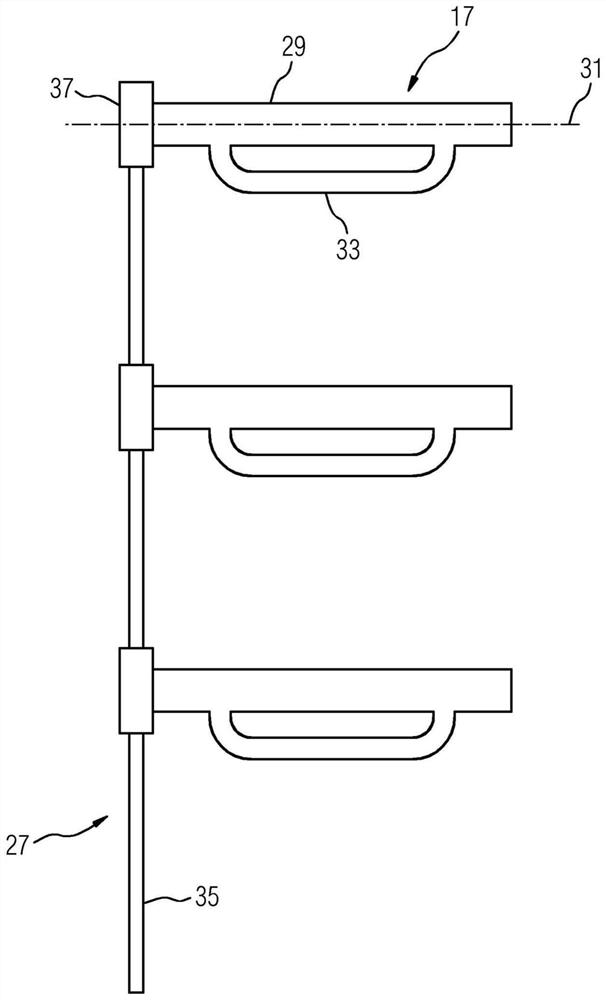

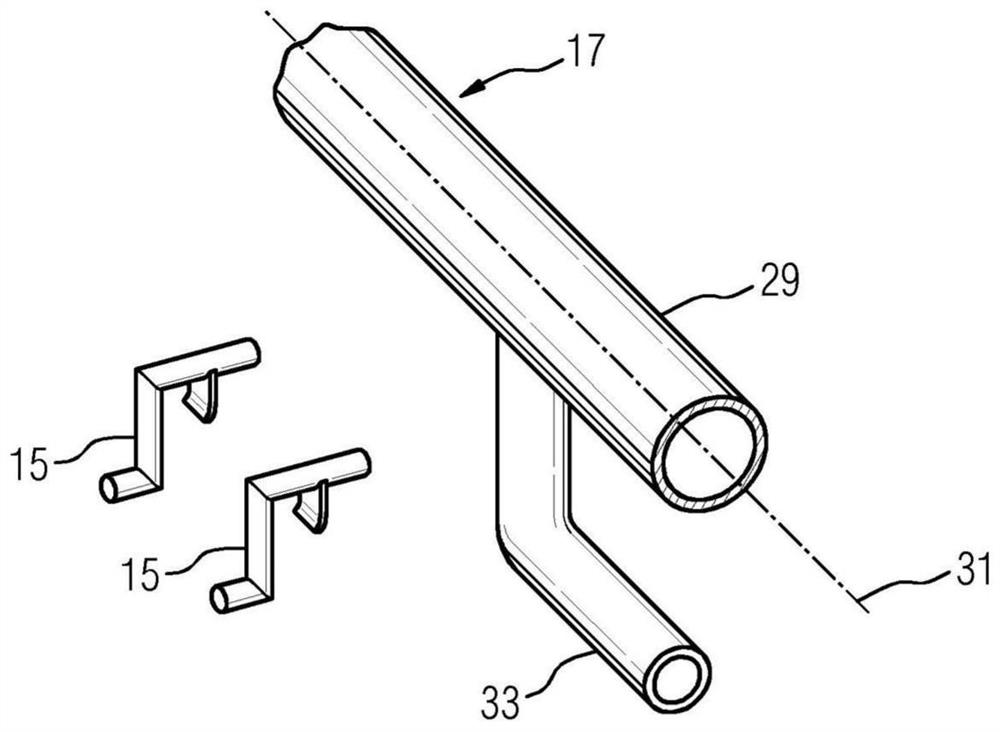

Potential equalisation system for a modular multilevel converter

ActiveCN112425055AImprove securityReduce overheadSwitchgear arrangementsEarthing arrangementsControl engineeringControl theory

The invention relates to a potential equalisation system for a modular multi-level converter (1) having a plurality of converter modules (3) which each have a direct current source (13). The potentialequalisation system comprises pole contacts (15), which are each electrically connected to one pole of a direct current source (13), and at least one electrically conductive contacting element (17),which can be moved between a first end position in which said contacting element is electrically isolated from the converter modules (3) and a second end position in which said contacting element contacts pole contacts (15) of different direct current sources (13) and can be placed onto an earth potential.

Owner:SIEMENS ENERGY GLOBAL GMBH CO & KG

High-precision wheel pair positioning and transferring mechanism for railway vehicle production

InactiveCN111634631APrevent jumpingAutomatic speed adjustmentControl devices for conveyorsAlarmsRotational axisTransfer mechanism

Owner:殷建平

A radial position adjustment assembly for a roller shaft-like revolving body

ActiveCN103591262BMobile synchronizationThe overall structure is simple and reliableGearing detailsRadial positionEngineering

The invention relates to a radial position adjustment assembly for a roll shaft revolving body. The radial position adjustment assembly comprises bottom frames and a revolving main body, wherein installation shafts which are concentric with the revolving main body are fixedly connected to the two ends of the revolving main body, the installation shafts at the two ends of the revolving main body are arranged on two adjustment bases respectively in a rotatable mode, the adjustment bases are independent of each other and can move along the radial direction of the revolving main body, and at least one of the adjustment bases is connected with a driving end of a drive device. the radial position adjustment assembly further comprises cylindrical gears and guide plates, wherein the cylindrical gears are arranged on the installation shafts at the two ends of the revolving main body and of the same specification, the guide plates are fixedly connected to the bottom frames and located at the two ends of the revolving main body, a radial guide groove is formed in each guide plate, the cylindrical gears are embedded into the radial guide grooves, racks which are matched with each cylindrical gear are arranged on a lateral side of the corresponding guide groove, and the racks are meshed with the gears. The radial position adjustment assembly is simple and reliable in structure and convenient to maintain, the synchronism of movement of the two ends of the revolving main body can be effectively ensured, and therefore each connection part of the revolving main body and the drive device can be effectively protected.

Owner:SHENZHEN RUNTIANZHI DIGITAL EQUIP

A method for bagasse to produce xylose and xylitol to co-produce l-arabinose

InactiveCN104046705BIncrease profitIncrease added valueSugar derivativesOrganic compound preparationRare sugarCogeneration

The invention relates to a method of producing xylose and xylitol and co-producing L-arabinose by bagasse. The method comprises the following steps: first, treating the bagasse; then, producing xylose by the bagasse; and respectively producing xylitol and arabinose by the product xylose and a xylose mother liquid. By using the bagasse as a raw material, the method provided by the invention obtains crystallized xylose and further products of xylitol and L-arabinose which are high in additional value and are widely applied to the fields of foods and medicines through a whole set of process line. The method provided by the invention is simple to operate, novel in technology, low in cost, diversified in product and high in economic value, is a process method which is initiated at home for co-producing functional sugar alcohols and rare sugar products by bagasse, and has an extremely wide application value.

Owner:SHANDONG WANSHENG ENVIRONMENTAL TECH DEV

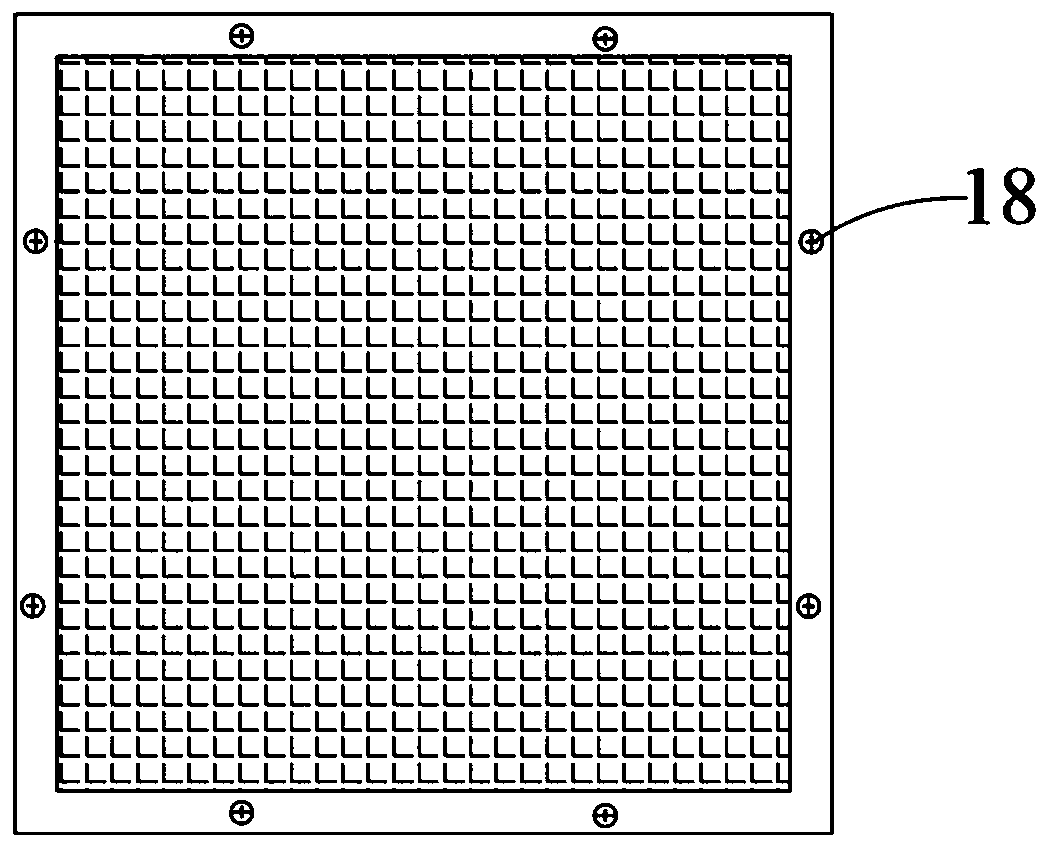

Grid injection mold

Owner:NANJING HUASHUN PRECISION MOLD CO LTD

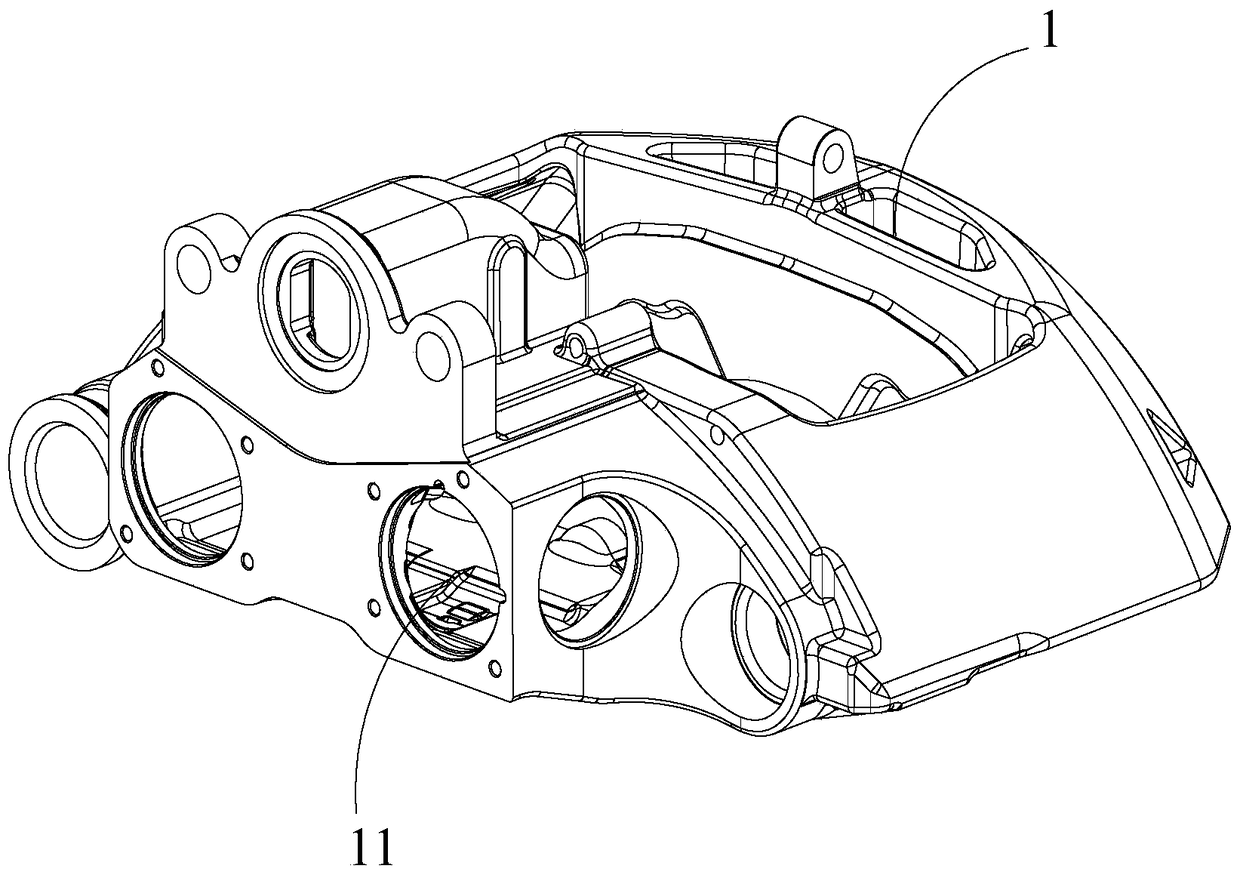

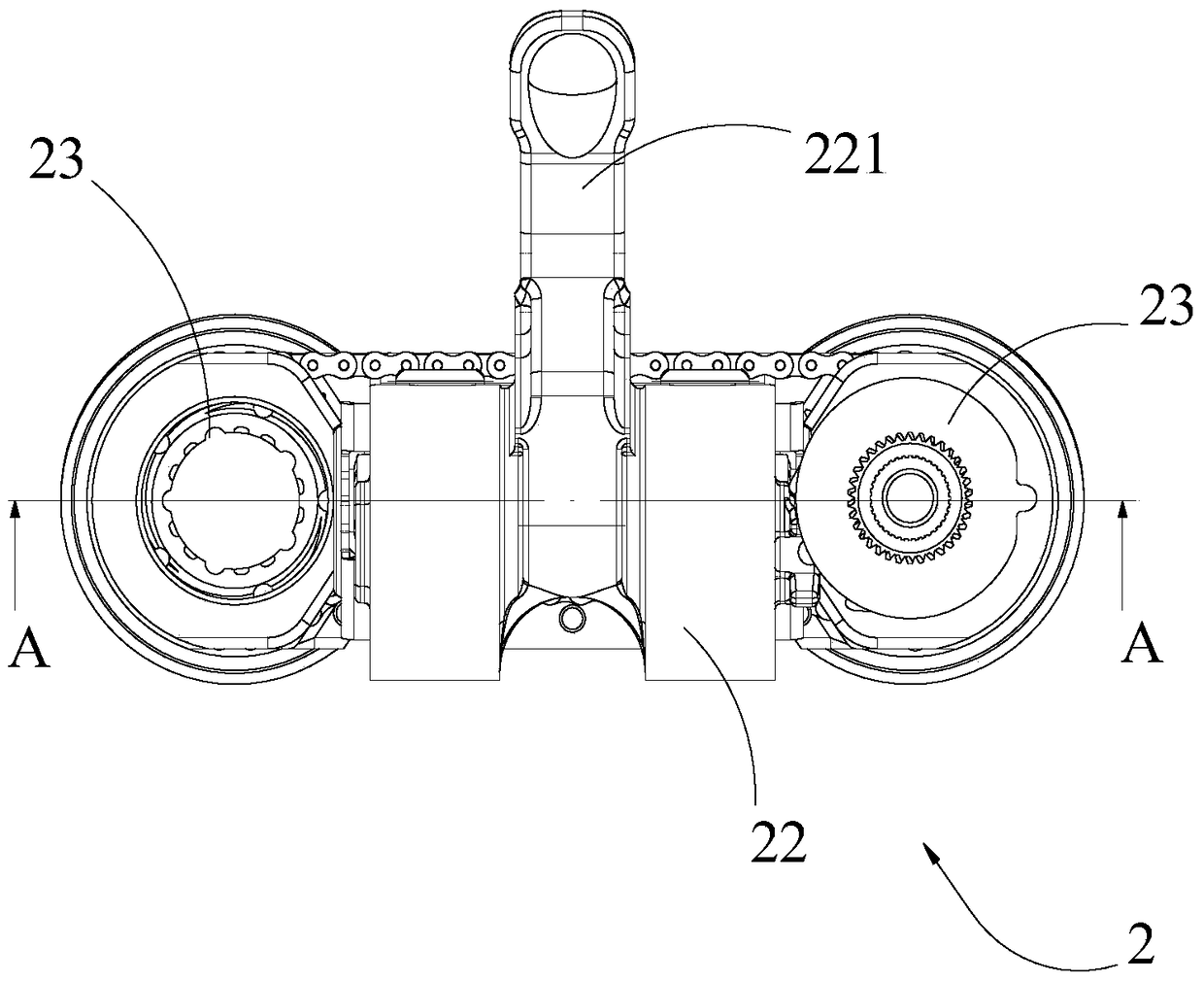

Brake slack adjustment and air disc brakes

The invention relates to a brake, and provides a brake gap adjustment device, which includes a caliper body and an adjustment mechanism. The adjustment mechanism includes a cross bar and an eccentric lever. Each through hole is pierced with a rotation shaft. The axis is perpendicular to the rotation axis of the eccentric lever, and a pusher is provided at one end of each rotation shaft, and a sprocket perpendicular to the axial direction is arranged on the two rotation shafts, and the two sprockets are driven by a chain. And the two sprockets are respectively close to the middle positions of the corresponding rotating shafts along the axial direction; a pneumatic disc brake is also provided, including the above-mentioned adjusting device. In the present invention, when the eccentric lever is subjected to an external force, the two pushing parts can move along the axial direction of the rotating shaft through the threaded cooperation between the cross bar and the two rotating shafts, and then the gap adjustment of the corresponding friction plate can be realized, and the two rotating shafts The position near the middle adopts the transmission method of sprocket chain to ensure that the two rotate synchronously, and the consistency is very high.

Owner:WUHAN YOUFIN AUTOPARTS

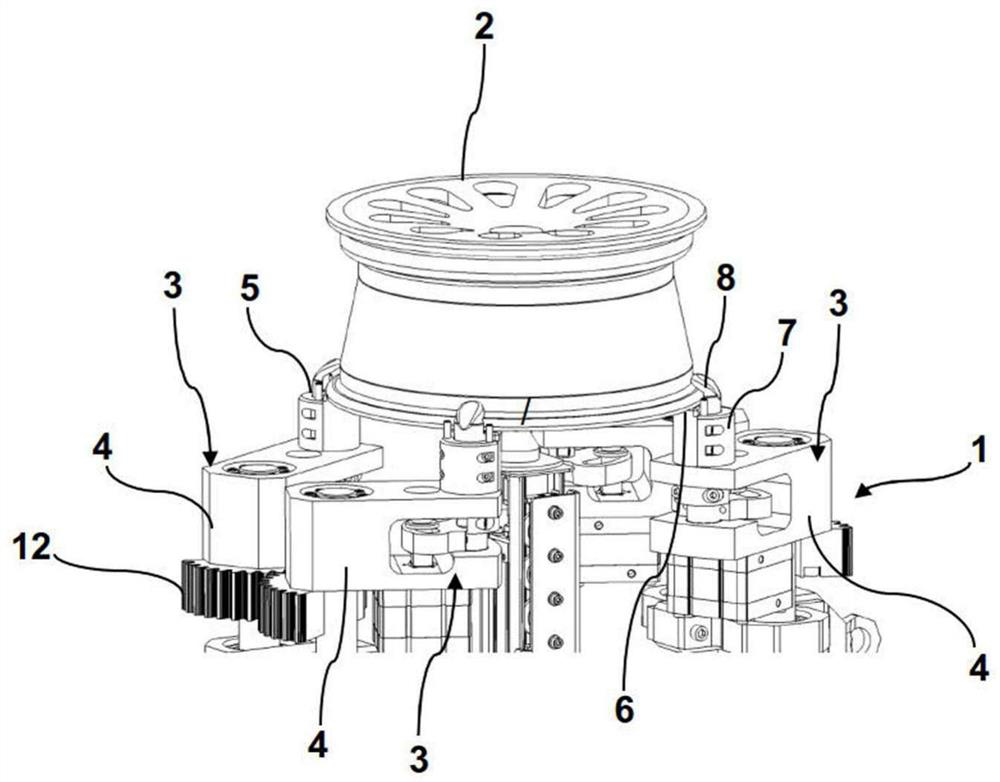

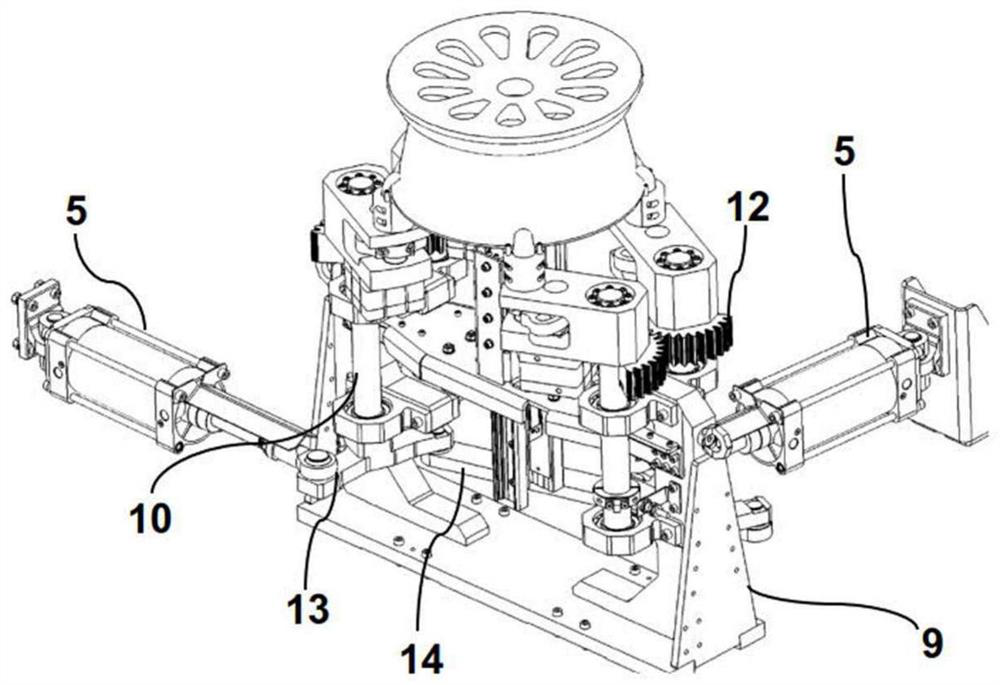

Device for tensioning a rim of a vehicle wheel

PendingCN112848794AAchieve orientationUniform clamping forceStatic/dynamic balance measurementTyresClassical mechanicsEngineering

In a device (1) for clamping a rim (2) of a vehicle wheel, at least four clamping elements (3) are provided which can be moved with respect to the rim (2) and comprise clamping arms (5) and support elements (7) having support surfaces (6). A rim flange of the rim (2) can be placed on the support surfaces. The clamping arms (5) are rotatably mounted, about their longitudinal axis, in the clamping elements (3), and have clamping fingers (8) at the end that protrude beyond the support surfaces (6), which fingers have clamping surfaces which can be brought into clamping contact with the placeable rim flange.

Owner:SCHENCK ROTEC GMBH

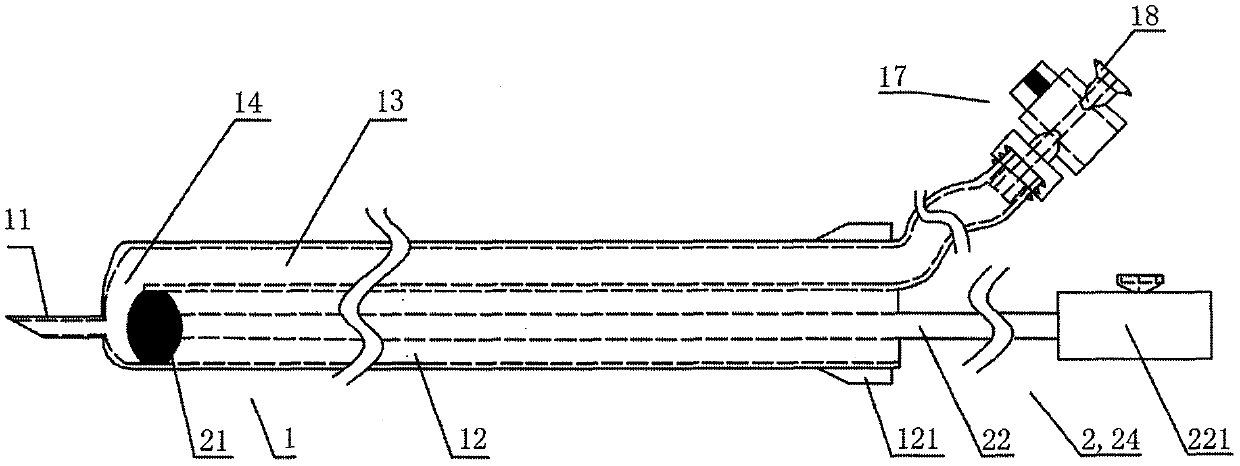

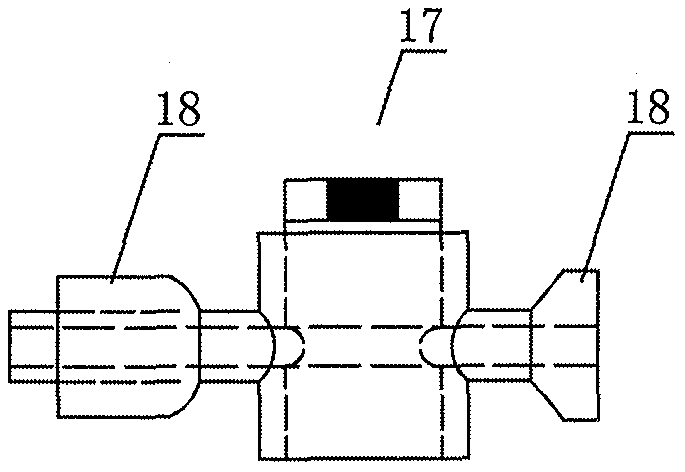

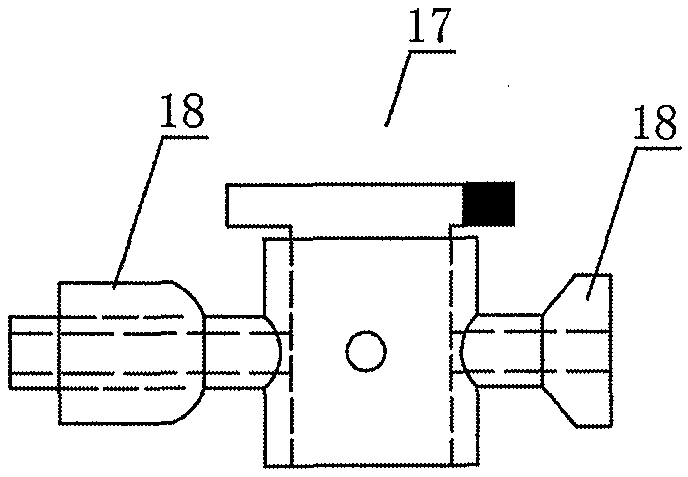

Injection system with far-end feeding function

PendingCN110935080AEnsure safetyReduce size fit design requirementsInfusion syringesIntravenous devicesSurgical operationReoperative surgery

The application relates to an injection system with the far-end feeding function. The injection system comprises a feeding cavity, an injection cavity, a pushing assembly and an injection object contained in the feeding cavity. An injection needle is arranged at the far end of the injection system and has a hollow structure; a non-return mechanism and a communication port are arranged in the injection system; and the communication port enables the feeding cavity to be in fluid communication with the injection cavity and an inner cavity of the injection needle. When the injection object in thefeeding cavity is input into the injection cavity through the communication port, the pushing assembly moves towards the near-end direction so that the interior of the injection cavity can be kept ina negative pressure state. According to the application, the viscous injection objects are easy to add and inject; the injection system is suitable for minimally invasive surgery and minimally invasive interventional operations; the utilization degree of the injection object is high and the injection amount control becomes accurate; feeding can be carried out instantly conveniently at any positionin the body; and the requirement of carrying out multi-times feeding and injection in the body by using one injection system is met.

Owner:NINGBO DIOCHANGE MEDICAL TECH CO LTD

Fully automatic container unlocking trolley

The invention provides a pin-detaching mechanism for detaching lock pins on containers. The pin-detaching mechanism comprises a lock pin detaching base, a guide, and an angled part; the guide is provided with a first elongated opening; the guide is fixed to the lock pin detaching base; the angled part is provided between the lock pin detaching base and the guide and is provided with a second elongated opening. When a lock pin is not inserted in, the length direction of the second elongated opening of the angled part has an acute angle relative to the length direction of the first elongated opening of the guide. Additionally, the invention further provides a full-automatic container pin-detaching cart using the pin-detaching mechanism.

Owner:SHANGHAI ZHENHUA HEAVY IND

Automatic reset fastening-free bearing movable parting strip

PendingCN113930601AStable under pressureGuaranteed qualityFurnace typesHeat treatment furnacesAxis of symmetryStructural engineering

The embodiment of the invention discloses an automatic reset fastening-free bearing movable parting strip which comprises a bearing beam and rolling assemblies, the bearing beam comprises hollow profile steel, and the rolling assemblies comprise limiting plates and rolling wheels. The limiting plates are provided with assembling grooves used for being clamped to the outer side of the bearing beam, reinforcing rib plates are arranged on the two sides of the assembling grooves, rolling wheel mounting holes are formed in the lower portions of the assembling grooves and are horizontal strip-shaped holes, the lower end faces of the strip-shaped holes are symmetrically arranged reset inclined faces, and the lowest points of the reset inclined faces are positioned on the left-right symmetry axes of the strip-shaped holes. The rolling wheels are mounted in the rolling wheel mounting holes through wheel shafts. By the adoption of the automatic reset fastening-free bearing movable parting strip, the parting strip can move along with materials borne by the parting strip, indentations caused by relative displacement between the materials and the parting strip due to thermal expansion and cold contraction are avoided, work is reliable, and the service life is long.

Owner:FOSHAN KELI IND EQUIP

Injection mold for net rack

Owner:NANJING HUASHUN PRECISION MOLD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com