Grid injection mold

A mesh frame injection mold, fixed mold technology, applied in the direction of coating, can solve the problems affecting product quality, easy to move the filter, and achieve the effect of ensuring integrity and aesthetics, saving production materials, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

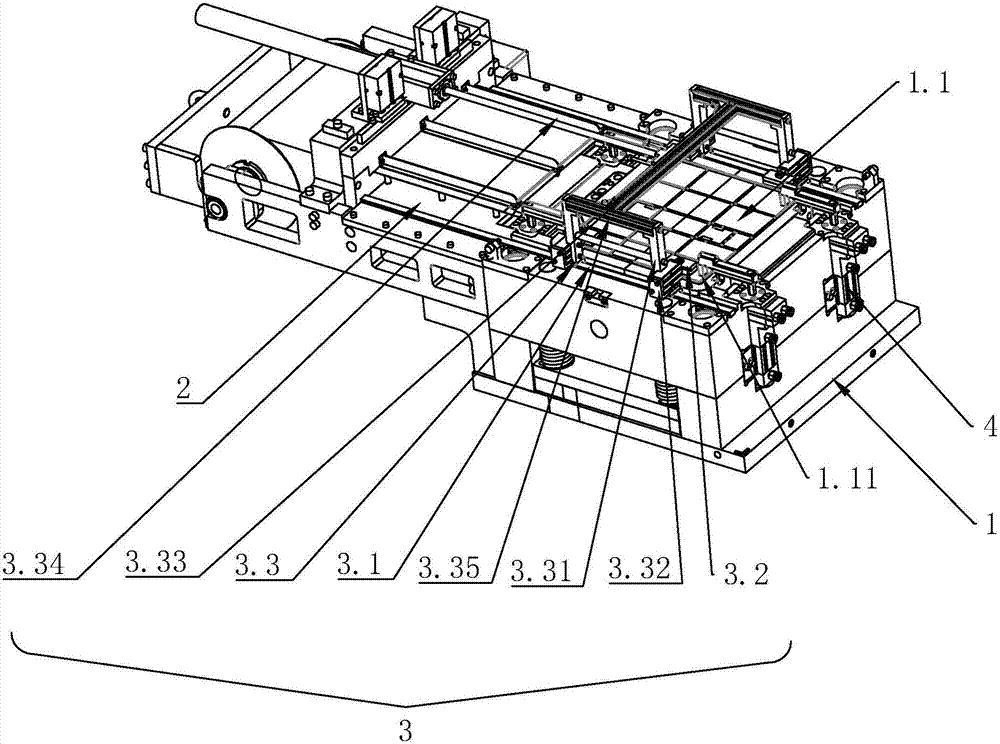

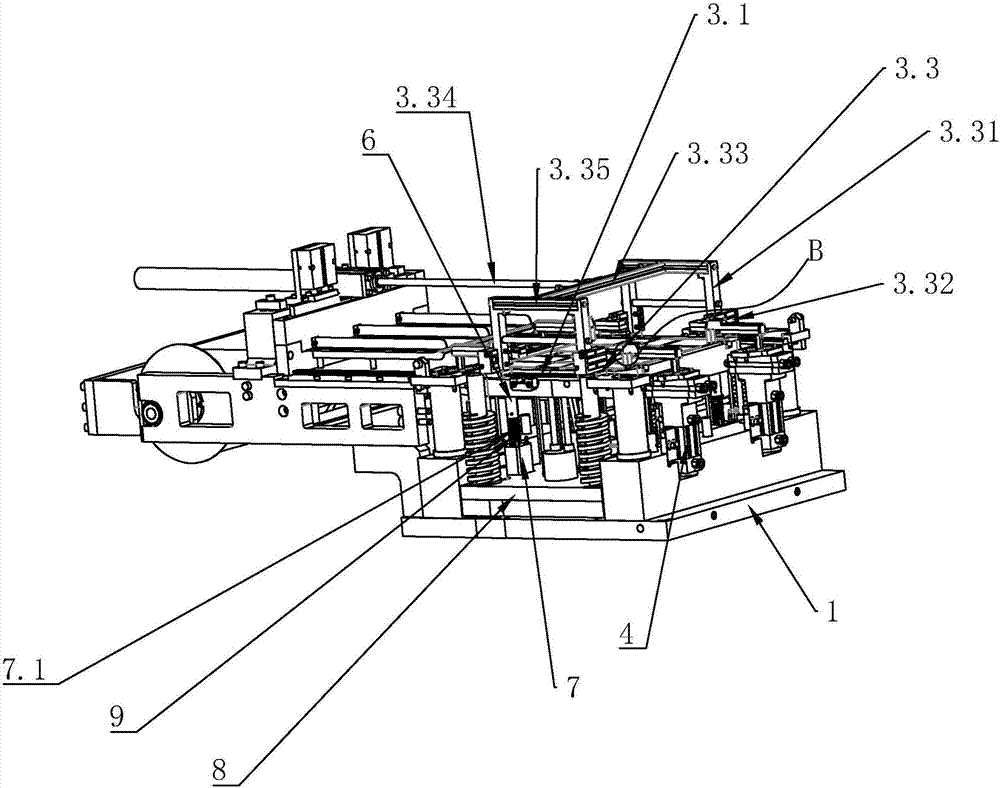

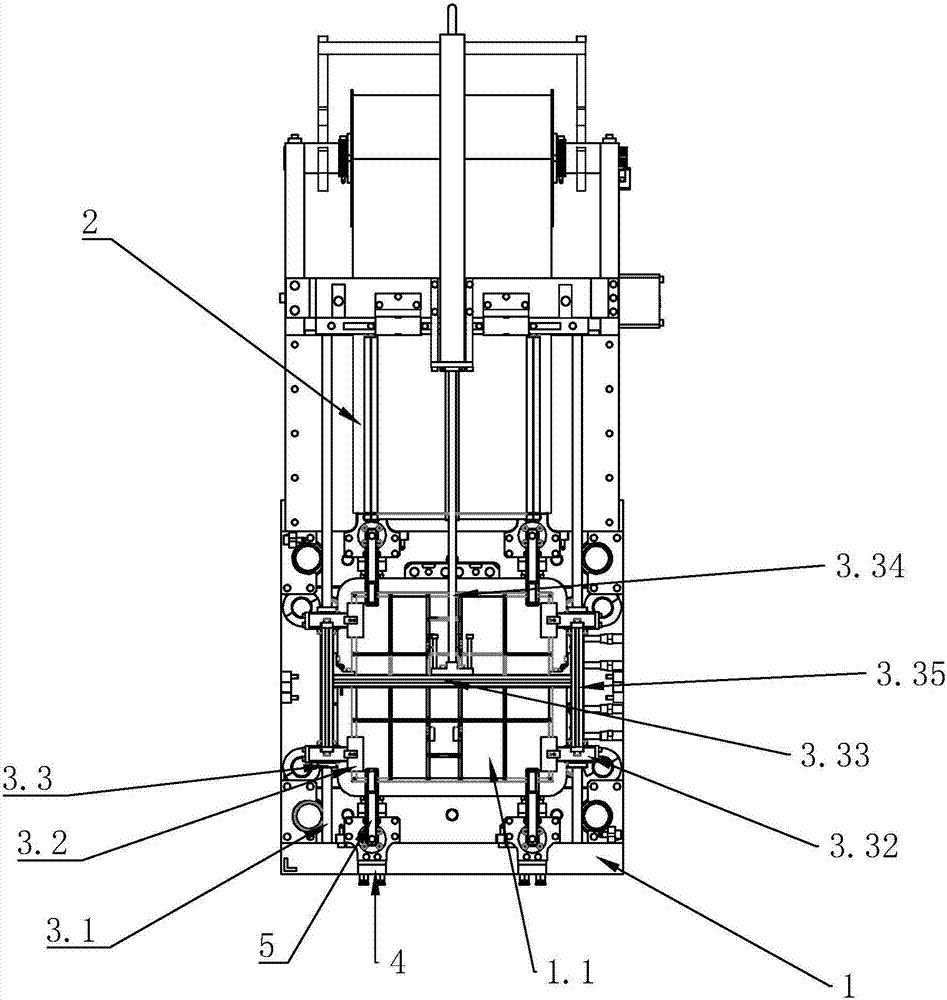

[0028] The following is attached figure 1 to attach Figure 6 The present invention is described in further detail.

[0029] A network frame injection mold, comprising a fixed mold 1 with a die template 1.1, one side of the fixed mold 1 is provided with a connecting plate 2, and the connecting plate 2 and the fixed mold 1 are provided with a conveying device 3 for conveying a filter net The fixed mold 1 is provided with two first air cylinders 4 for lifting symmetrically about the centerline of the fixed mold 1 on both sides along the direction in which the conveying device 3 conveys the filter net. The first cylinder 4 is respectively close to the top angle of the die template 1.1 and the end of the first cylinder 4 is provided with a compression rod 5, and the fixed mold 1 is provided with a lifting rod 6 corresponding to the end of the compression rod 5 , the die formwork 1.1 is provided with a perforation 1.11 for the elevating rod 6 to pass through.

[0030] Firstly, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com