Crossed side dump type rear scraper conveyer

A scraper conveyor and side unloading technology, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as large changes, unstable coal unloading effect, and inability to discharge coal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

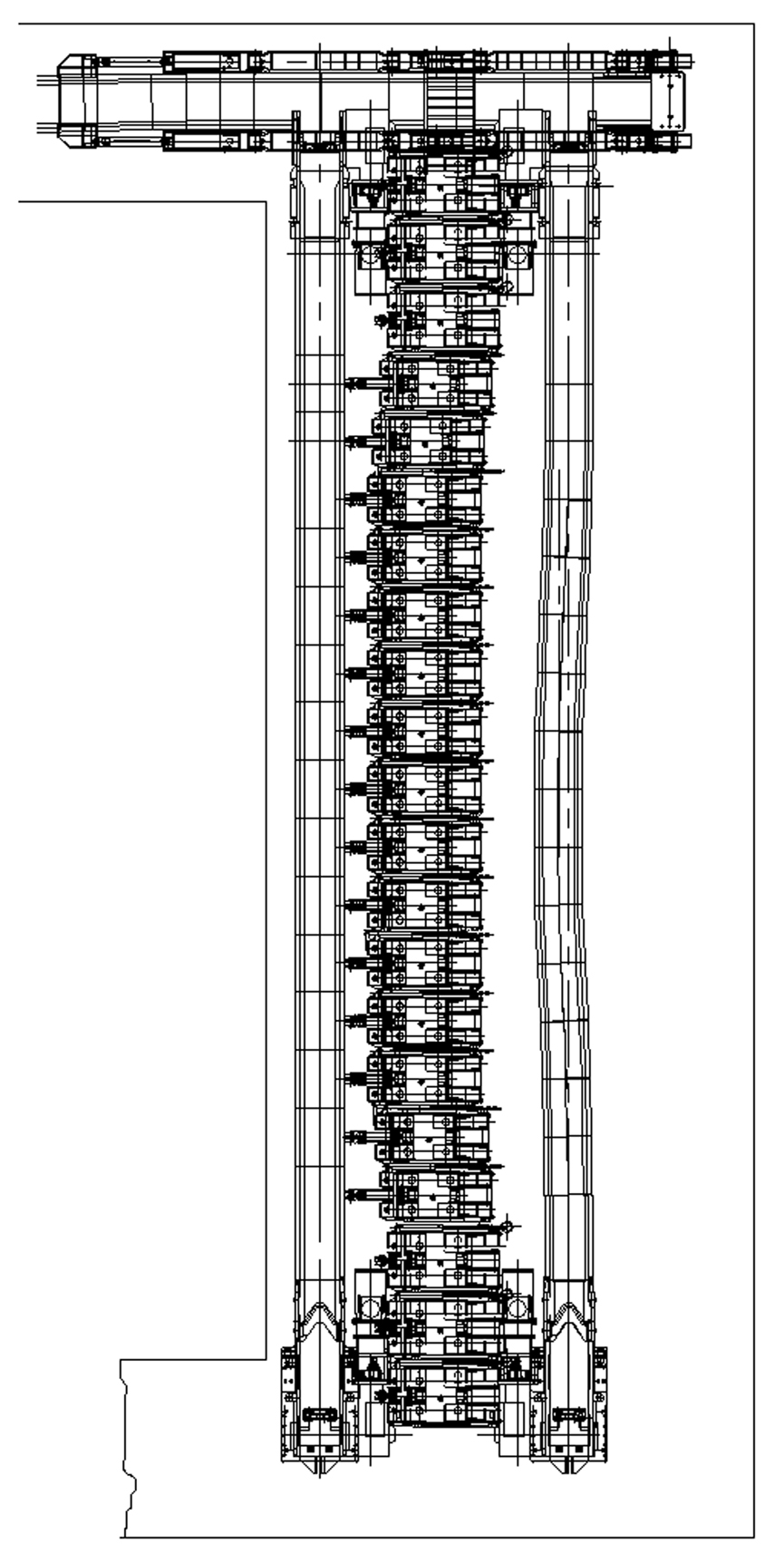

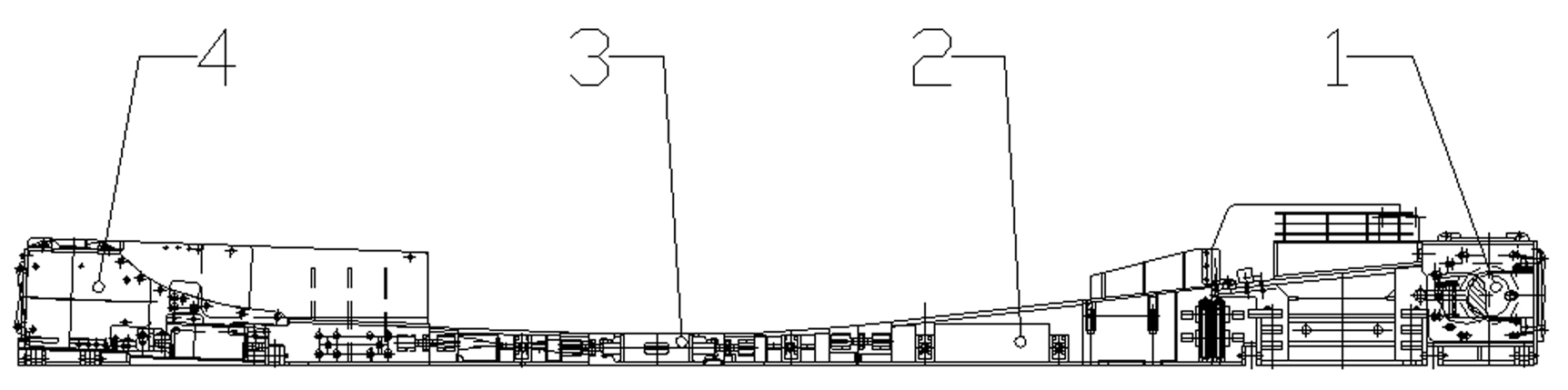

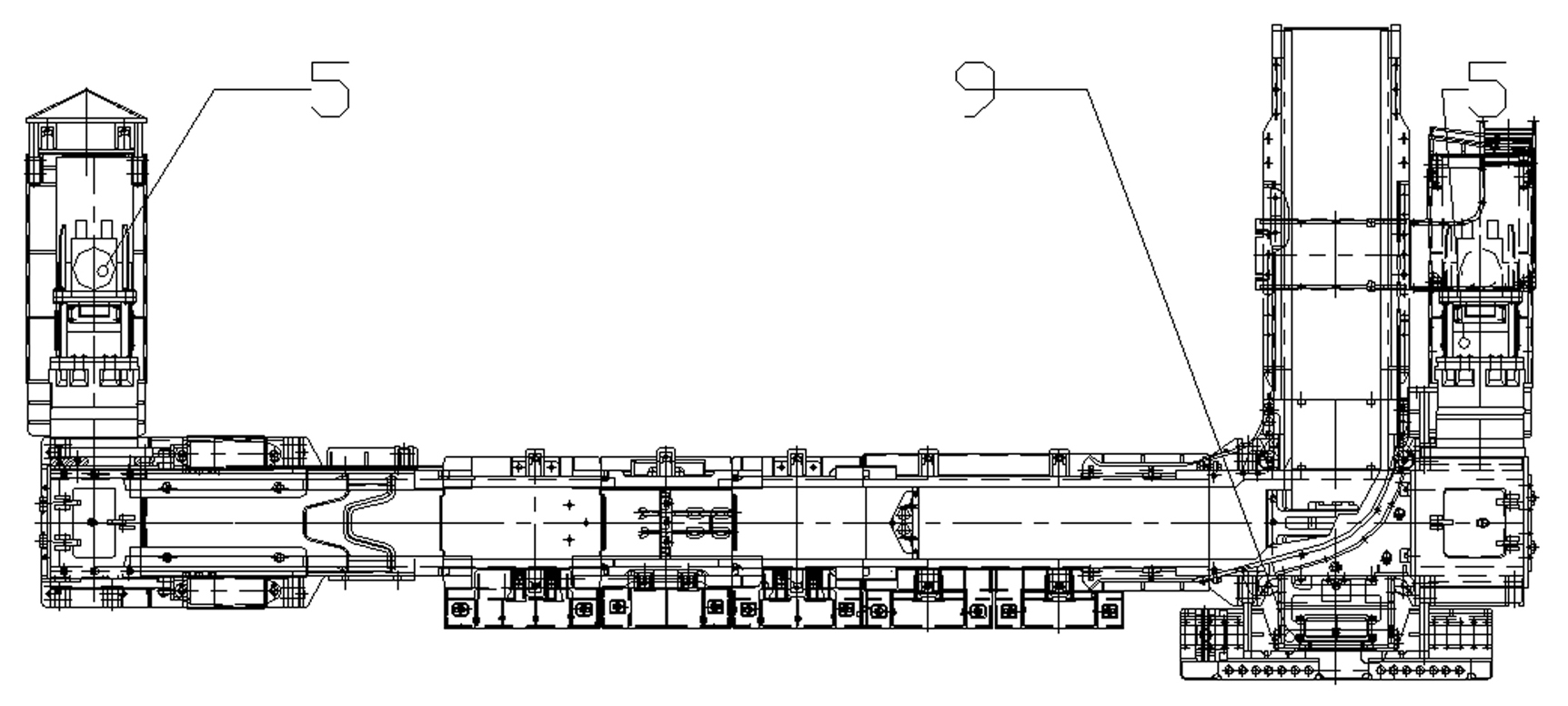

[0014] Such as figure 2 , 3 , 4, a cross-side unloading rear scraper conveyor, including head 1, tail, driving part 6, scraper chain and middle section 3, rear head 1 unloading part and transfer machine 9 The tail bearing part is fixedly connected (which can be welded, connected with fasteners, etc.) into a whole. The middle section 3 and the scraper chain are both perpendicular to the transfer machine 9. The upper loading slot of the transfer machine 9 is inserted between the upper and lower slots of the rear head 1, and the lower slot of the rear head 1 extends into the transfer machine 9 up and down. Between the grooves, the conveyor scraper chain and the transfer machine 9 scraper chain also cross vertically in space.

[0015] The driving part 6 is vertically installed in the trough, and the moving beam of the head 1 is also connected with the end of the lane bracket 8 so that the rear conveyor 5 and the transfer machine 9 move synchronously.

[0016] Such as figure 2 , 3 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com