Device for tensioning a rim of a vehicle wheel

A rim and clamping technology, applied in the field of rim devices, can solve problems such as rim damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

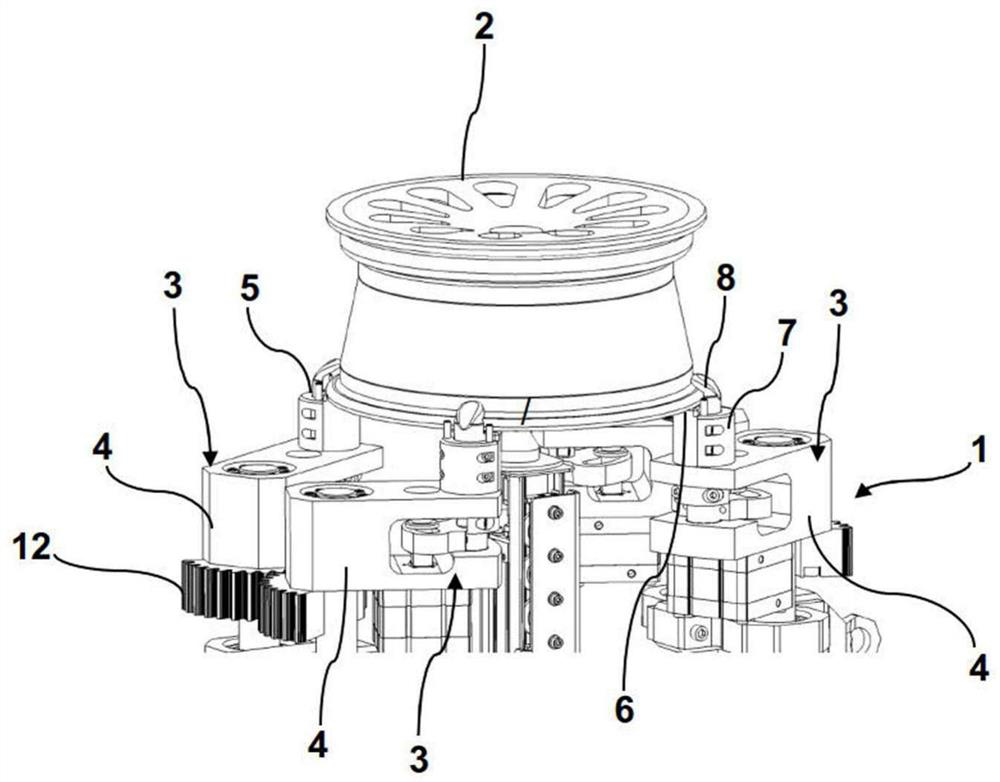

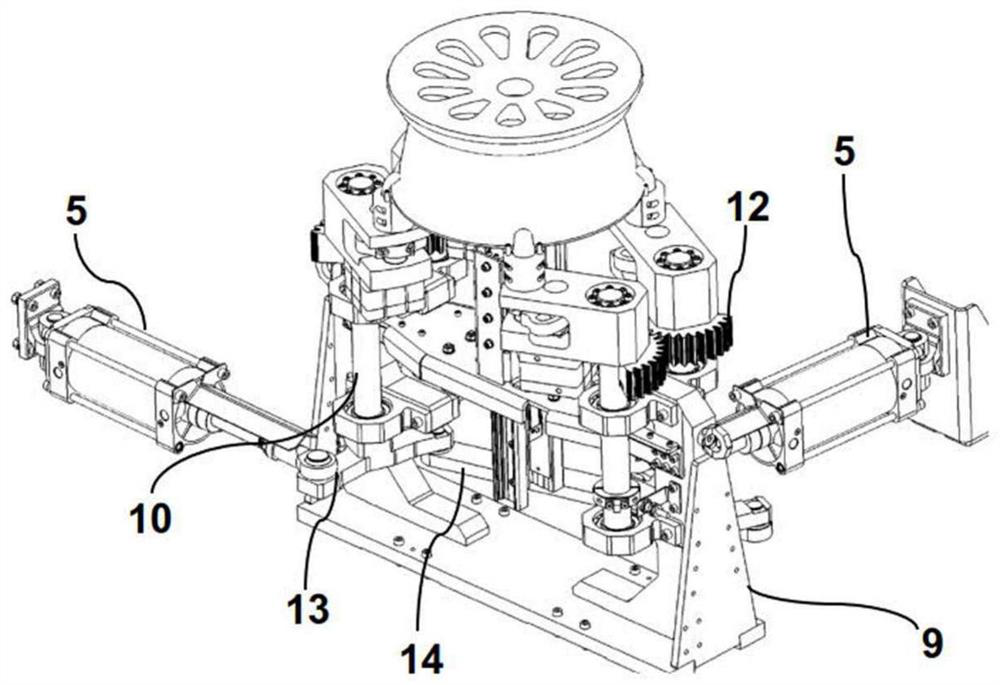

[0026] figure 1 shows a perspective view of the clamping device with clamped rim and figure 2 Another perspective view of the clamping device together with the rim is shown. The clamping device 1 can be part of a tire assembly line, not shown, in which the wheel rim 2 is conveyed to the clamping device 1 by means of a transport device, not shown, in which it is held The rim 2 can thus be fitted with a tire. For this purpose, the rim 2 must be securely clamped by the clamping device 1 in a defined position, so that the tire can be fitted successfully.

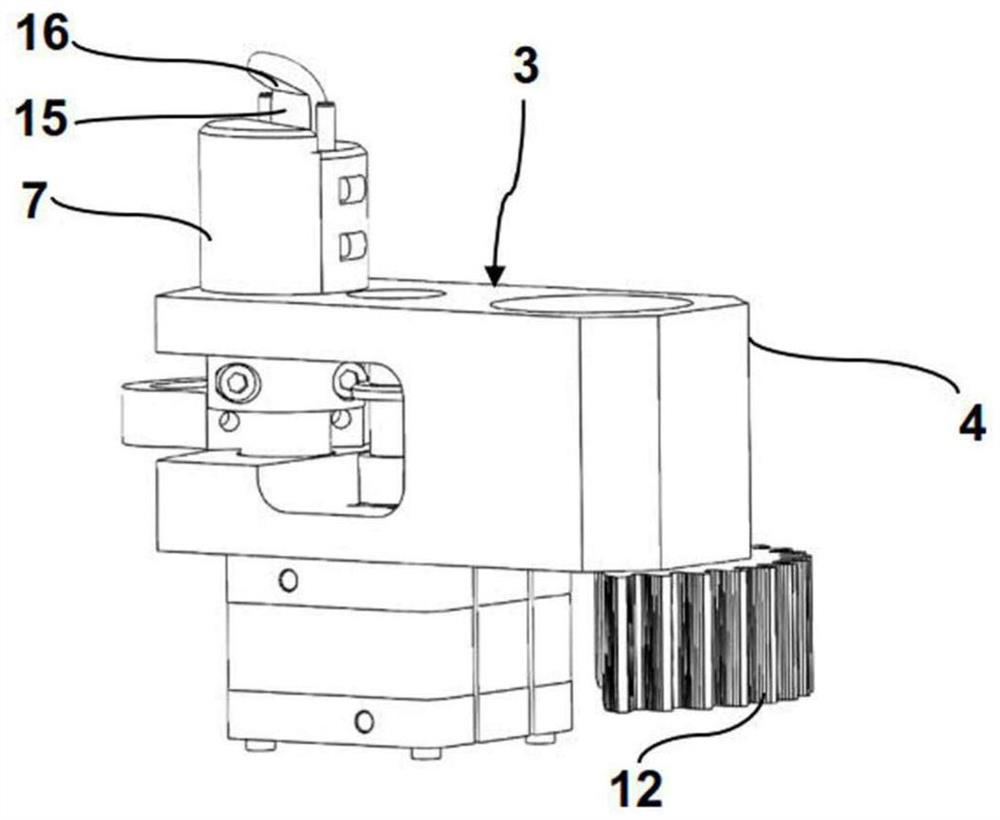

[0027] The clamping device 1 comprises four clamping elements 3 which each have a base body 4 which has, at its free end, a receptacle for a clamping arm 5 which is mounted in a non-rotatable manner. In the matrix 4. The rim 2 rests on a placement surface 6 formed by placement elements 7 . The rim 2 is clamped by clamping pins 8 protruding from the placement surface 6 , which terminate in clamping arms 5 . The clamping ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com