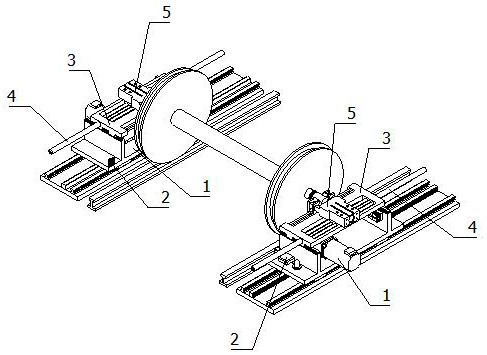

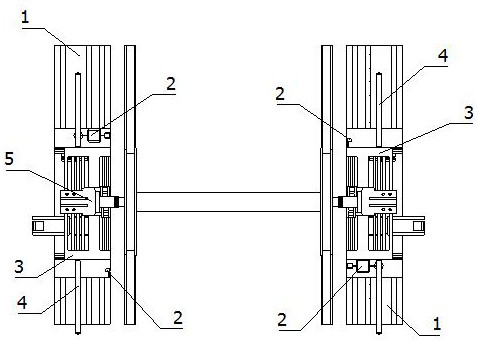

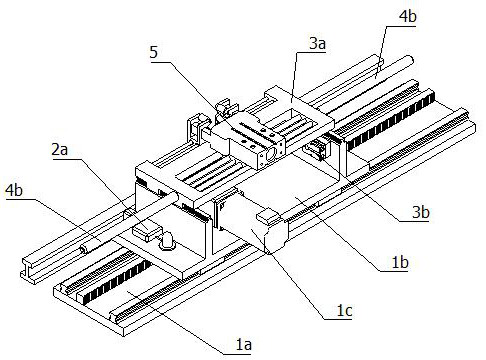

High-precision wheel set positioning and transferring mechanism for production of railway vehicles

A railway vehicle, high-precision technology, applied in conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of no protection mechanism, rack damage, danger, etc., and achieve the effect of reducing accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Several embodiments of the present invention will be disclosed in the following drawings. For clear description, many practical details will be described in the following description. However, it should be understood that these practical details should not be used to limit the present invention. In other words, in some embodiments of the present invention, these practical details are unnecessary. In addition, in order to simplify the drawings, some conventionally used structures and components will be shown in simple schematic ways in the drawings.

[0047] In addition, the descriptions related to "first", "second", etc. in the present invention are only used for descriptive purposes, and do not specifically refer to the order or sequence, nor are they used to limit the present invention. They are only used to distinguish between The same technical terms describe only the components or operations, but cannot be understood as indicating or implying their relative importanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com