Green brick pressing device

A brick and rack technology, which is applied in the field of brick making, can solve the problems of poor brick quality and brick movement, and achieve the effect of improving quality and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] This embodiment proposes a brick adobe pressing device that can ensure the synchronization of mold movement on the left and right sides, so as to improve the quality of adobe pressing.

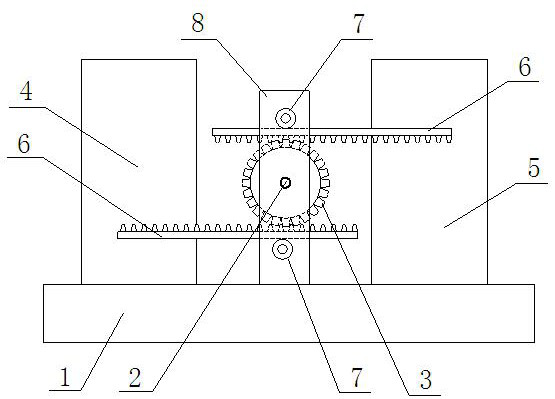

[0015] The adobe pressing device of the embodiment includes a frame, a left mold, a right mold, a left mold driving mechanism and a right mold driving mechanism that are movably arranged on the frame. The key is that, as figure 1 As shown, a gear 3 is installed on the frame 1 through a rotating shaft 2, and the left mold 4 and the right mold 5 are all provided with a horizontal rack 6 meshing with the gear 3, and the horizontal rack 6 of the left mold 4 and the right mold 5 The racks 6 are located above and below the gear 3 respectively, and the machine teeth of the two horizontal racks are opposite; the frame 1 is rotatably equipped with a limit lever 7 above and below the gear 3 through a horizontal shaft, and the gears The outer part of 3 is provided with a vertical limit plate 8, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com