A hole punching mechanism for a transplanting machine

A technology of transplanting machine and sliding rail, applied in the directions of planting method, excavation/covering of trenches, application, etc., can solve the problems of tearing the film, affecting the transplanting effect, easy clay, etc., to achieve the effect of improving the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

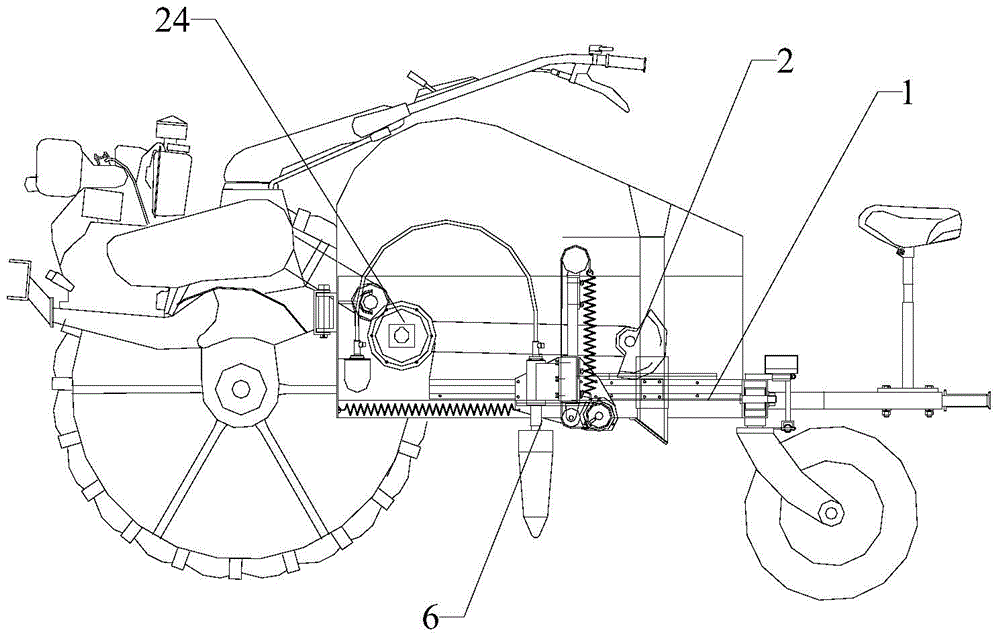

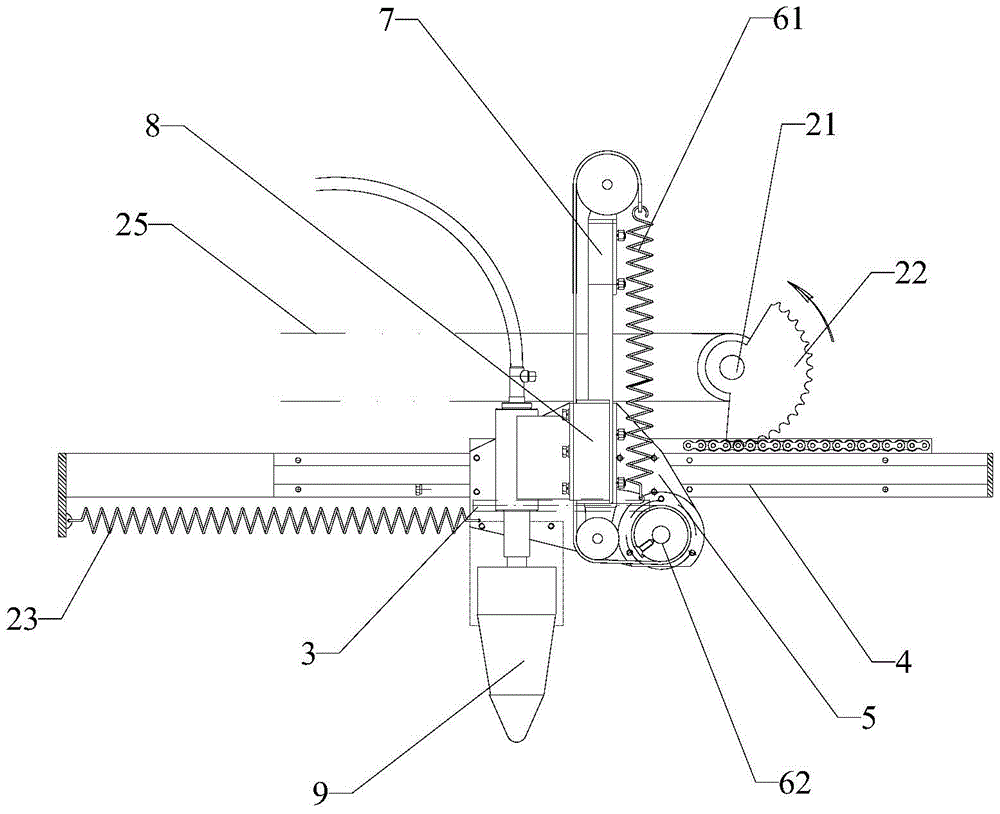

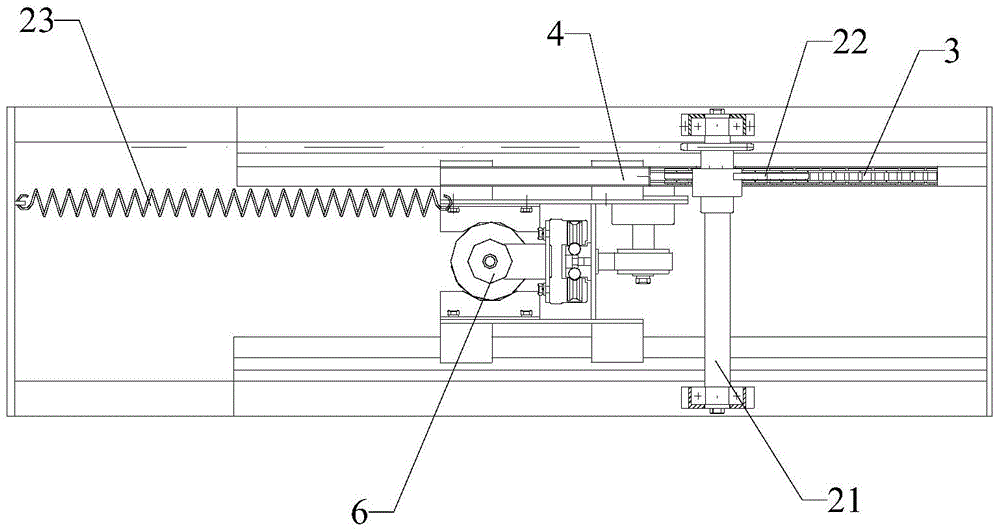

[0043] Please refer to Figure 1 to Figure 5 Shown, embodiment one of the present invention is:

[0044] A hole punching mechanism for a transplanting machine, comprising a bracket 1, a driving device 2, a first rack 3, a first slide rail 4, a first slider 5, a hole punching device 6, a reducer 24 and a chain belt 25; The first sliding rail 4 is horizontally fixed on the bracket 1, the first sliding block 5 cooperates with the first sliding rail 4, the hole punching device 6 is fixed on the first sliding block 5, and the driving device 2 drives the first The slider 5 and the punching device 6 move horizontally on the first slide rail 4; the first rack 3 is fixed on the support 1, and the punching device 6 is provided with a drive shaft. The rack 3 drives the driving shaft to rotate. The driving device 2 includes a rotating shaft 21, a sector gear 22 and a first spring 23. Two racks 26, the rotating shaft 21 is rotatably installed on the bracket 1, the sector gear 22 is mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com