Welding device for synchronously recycling welding flux

A welding device and flux technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of low circulation efficiency of submerged arc welding flux, and achieve the effects of accelerating recycling efficiency, convenient replenishment, and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

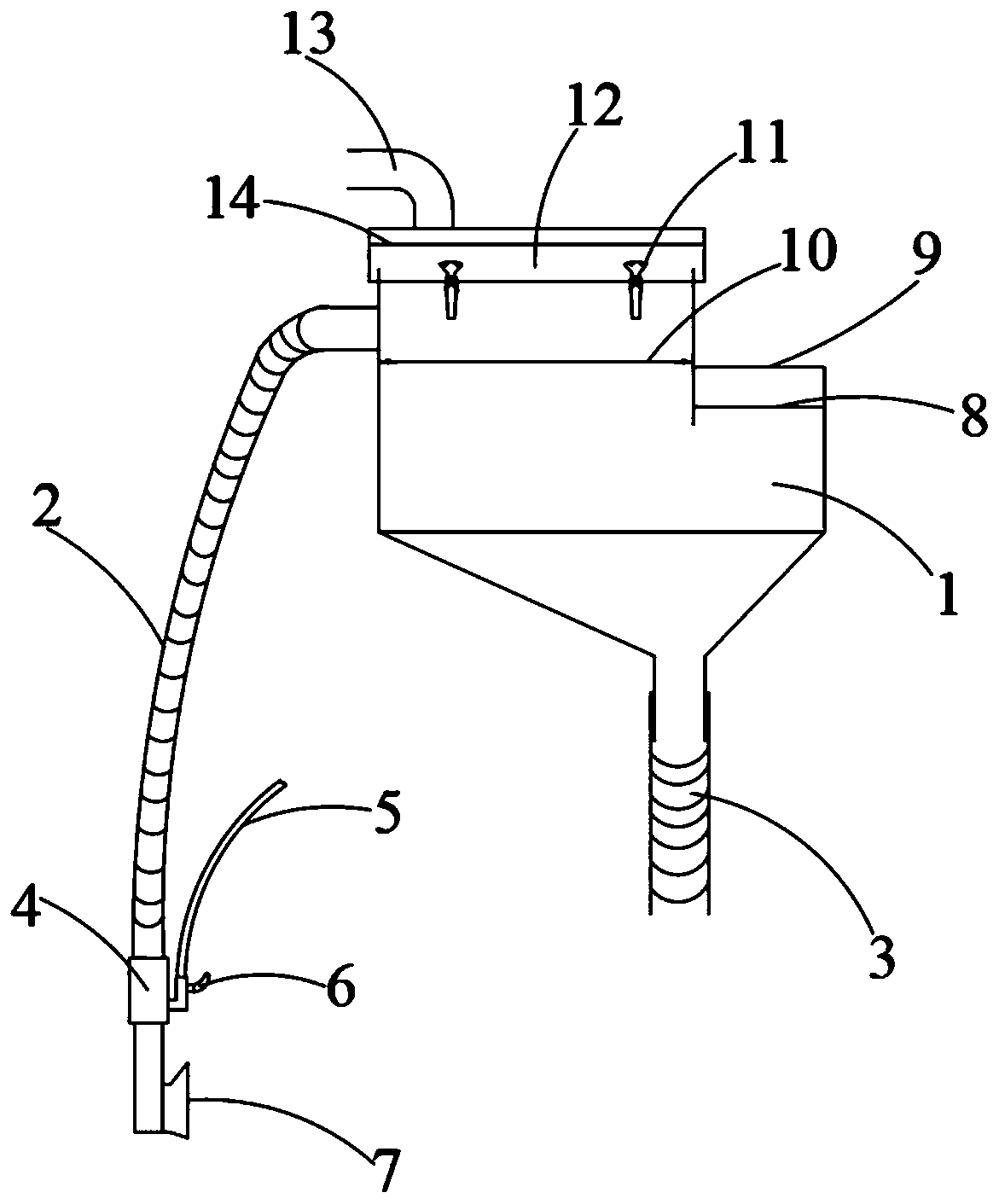

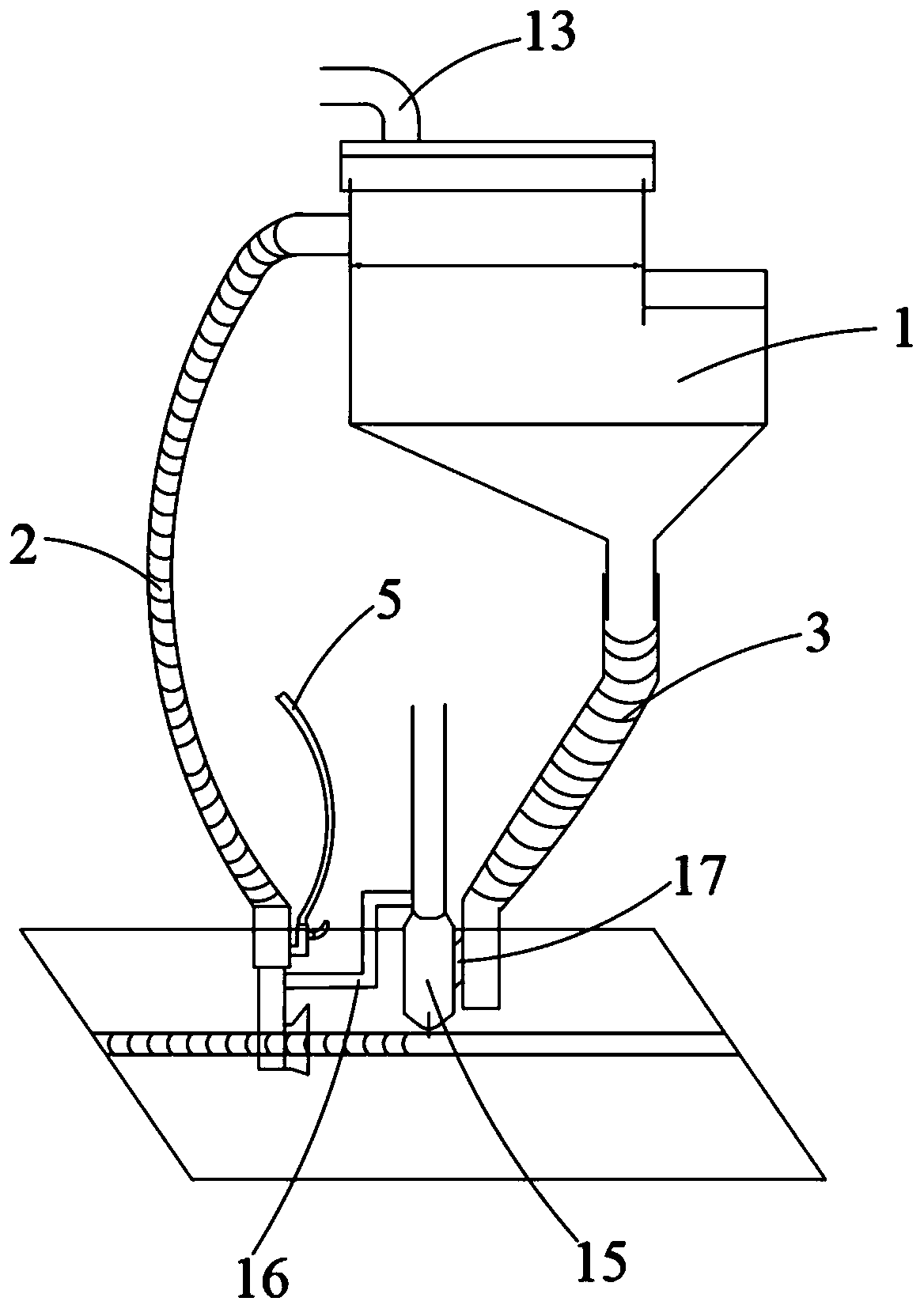

[0023] like Figure 1 to Figure 3 As shown, the welding device includes a flux box 1 for storing flux. The flux box 1 is provided with a discharge pipeline 3 and a recovery pipeline 2. The discharge pipeline 3 is provided with a discharge port for flux to flow out. The recovery pipeline 2 is provided with a suction port 7 for recycling welding into the flux box 1, and also includes an air flow power device, which is used to form a negative pressure at the suction port 7 to suck and recycle the flux In the pipeline 2 , the airflow power device is also used to form a conveying airflow in the recovery pipeline 2 to transport the inhaled flux into the flux box 1 , and the flux box 1 is also provided with a feeding port 9 .

[0024] Specifically, in this embodiment, the flux box 1 is in the shape of a bin or a tank. The flux box 1 includes a cylindrical part located above and a conical part located below. The function of the conical part is similar to a funnel. On the one hand, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com