Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Metal Thickness Reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

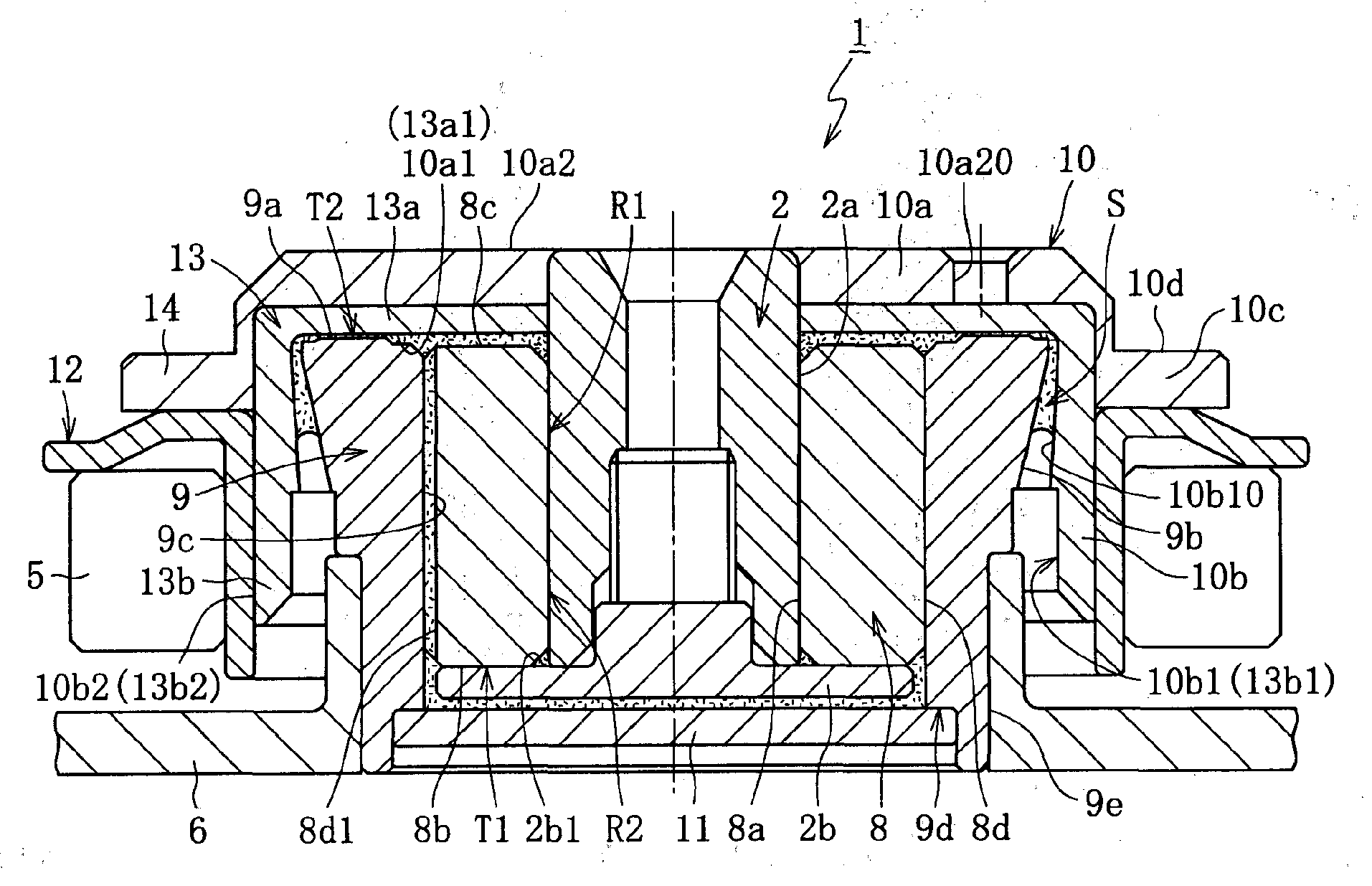

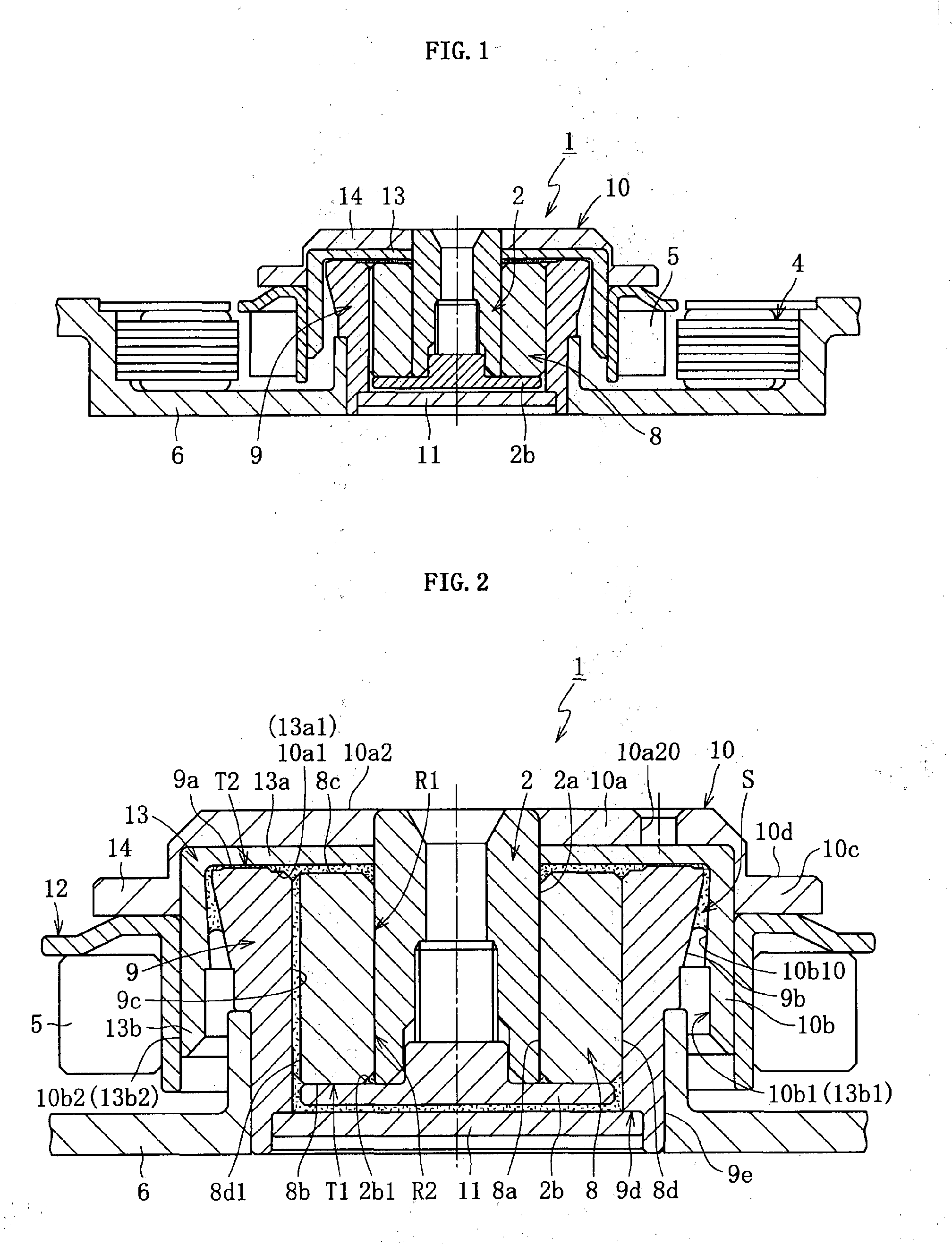

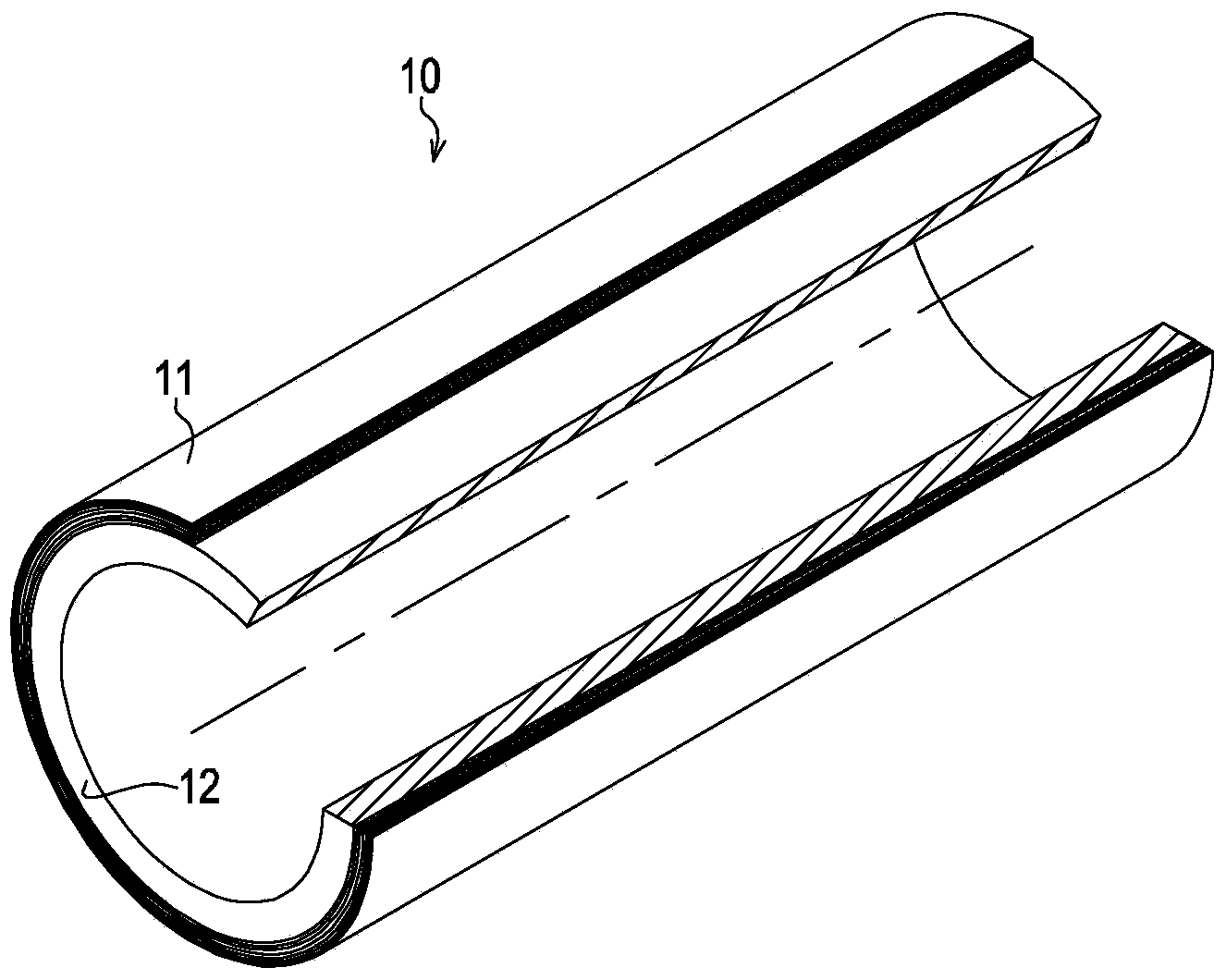

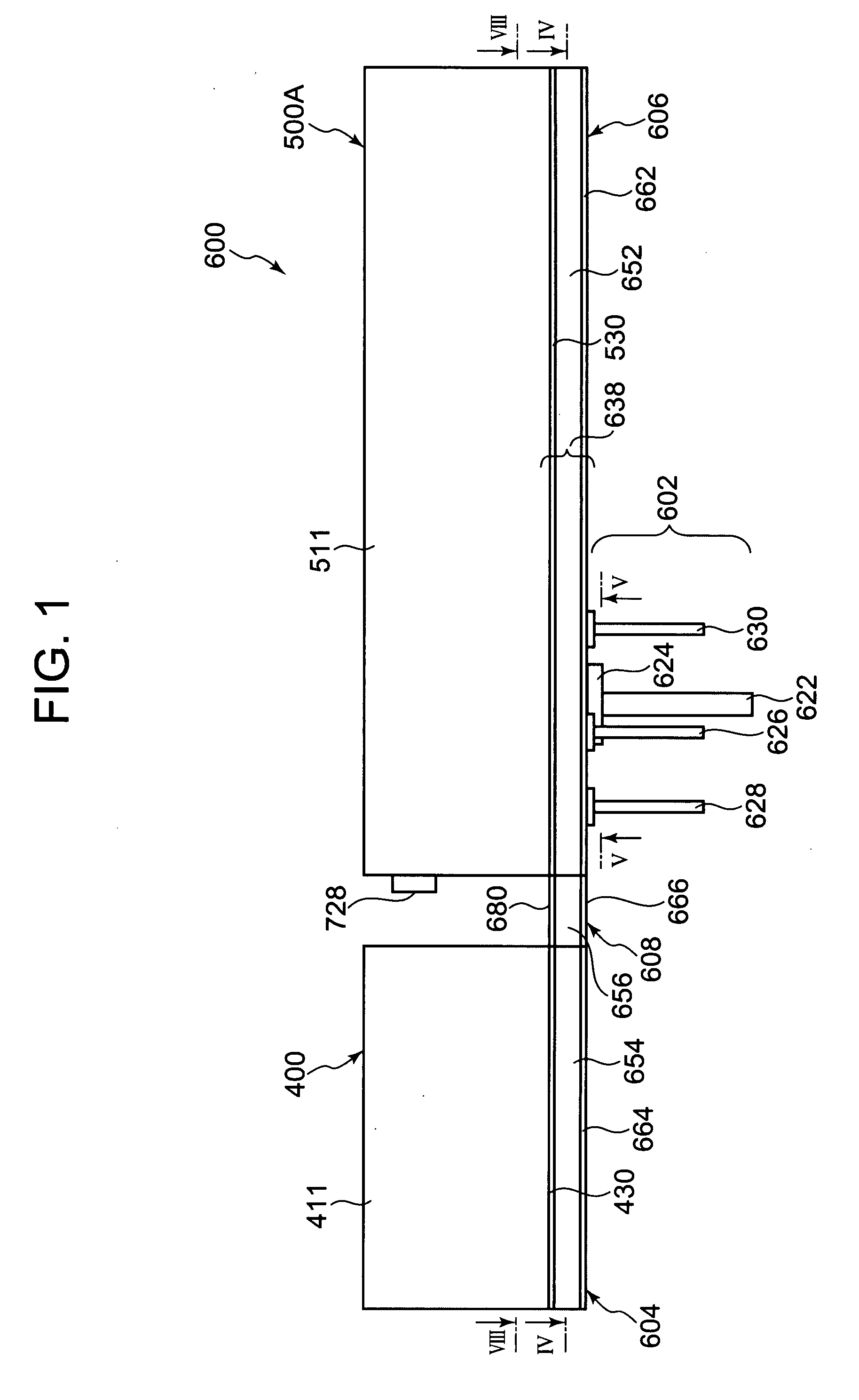

Fluid dynamic bearing device

InactiveUS20100226601A1High riskImprove fixation accuracyShaftsRecord information storageEngineeringFluid power

A hub (10) is a product formed by injection molding of a resin together with a core metal (13) as an inserted component, and the core metal (13) is exposed on a surface of the hub (10). With this configuration, a cavity of a die for molding the hub (10) is not divided by the core metal (13), and hence it is possible to suppress deterioration in fluidity of a resin due to arrangement of the core metal (13) in the cavity.

Owner:NTN CORP

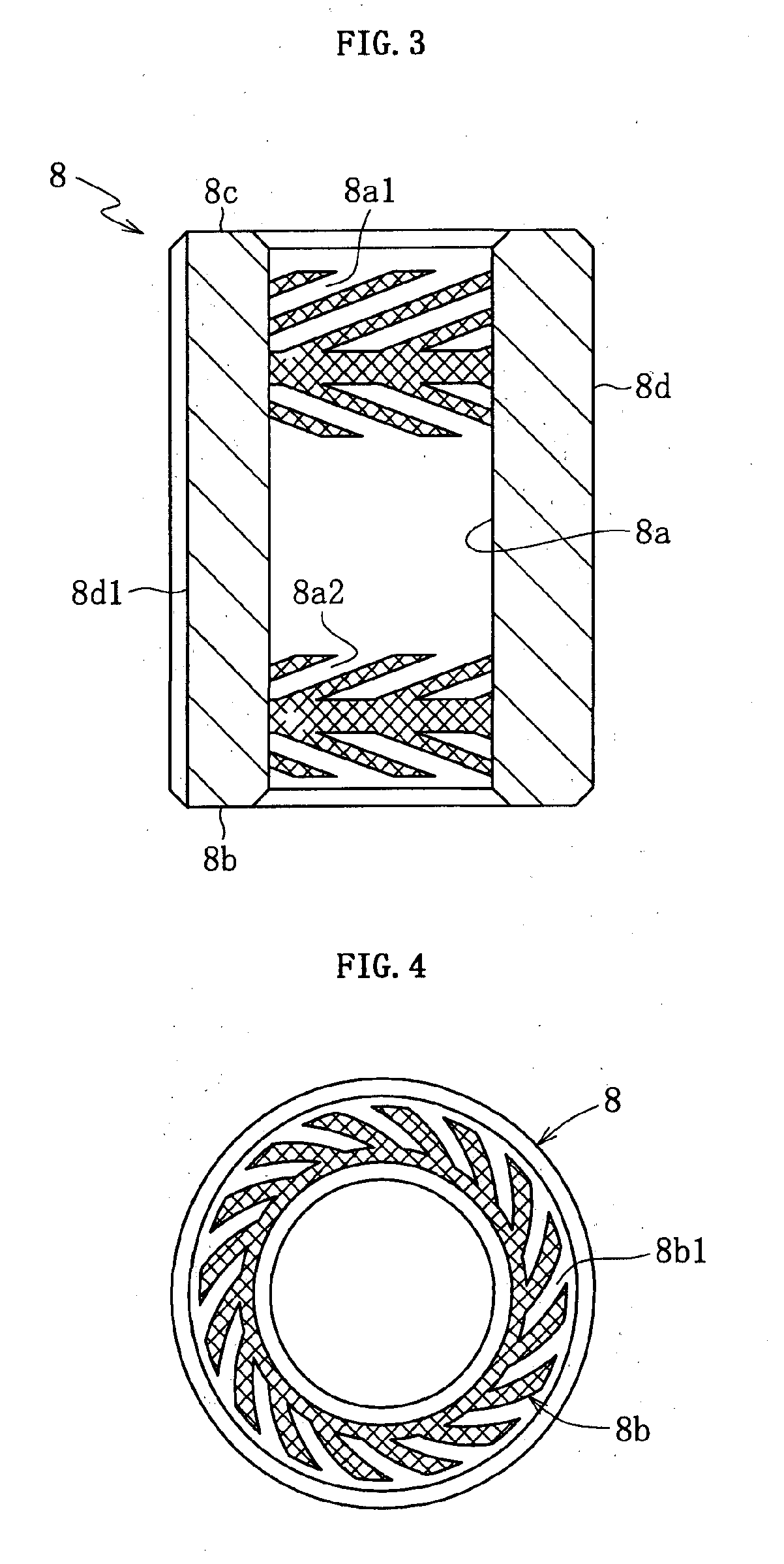

Frame for solar module

InactiveUS20110155127A1Improve bending strengthReduce thicknessSolar heating energySolar heat devicesMechanical engineeringSolar module

A frame for solar module to fix a solar panel within is disclosed. The frame for solar panel includes two first fastening members arranged at two opposite sides of the solar panel, two second fastening members arranged at another two opposite sides of the solar panel, and plural screws to screw the first fastening members and the second fastening members. Each first fastening member and each second fastening member includes a supporting portion for supporting the solar panel, a base portion, a connecting portion for connecting the supporting portion and the base portion, and a beam disposed between the supporting portion and the base portion.

Owner:DU PONT APOLLO

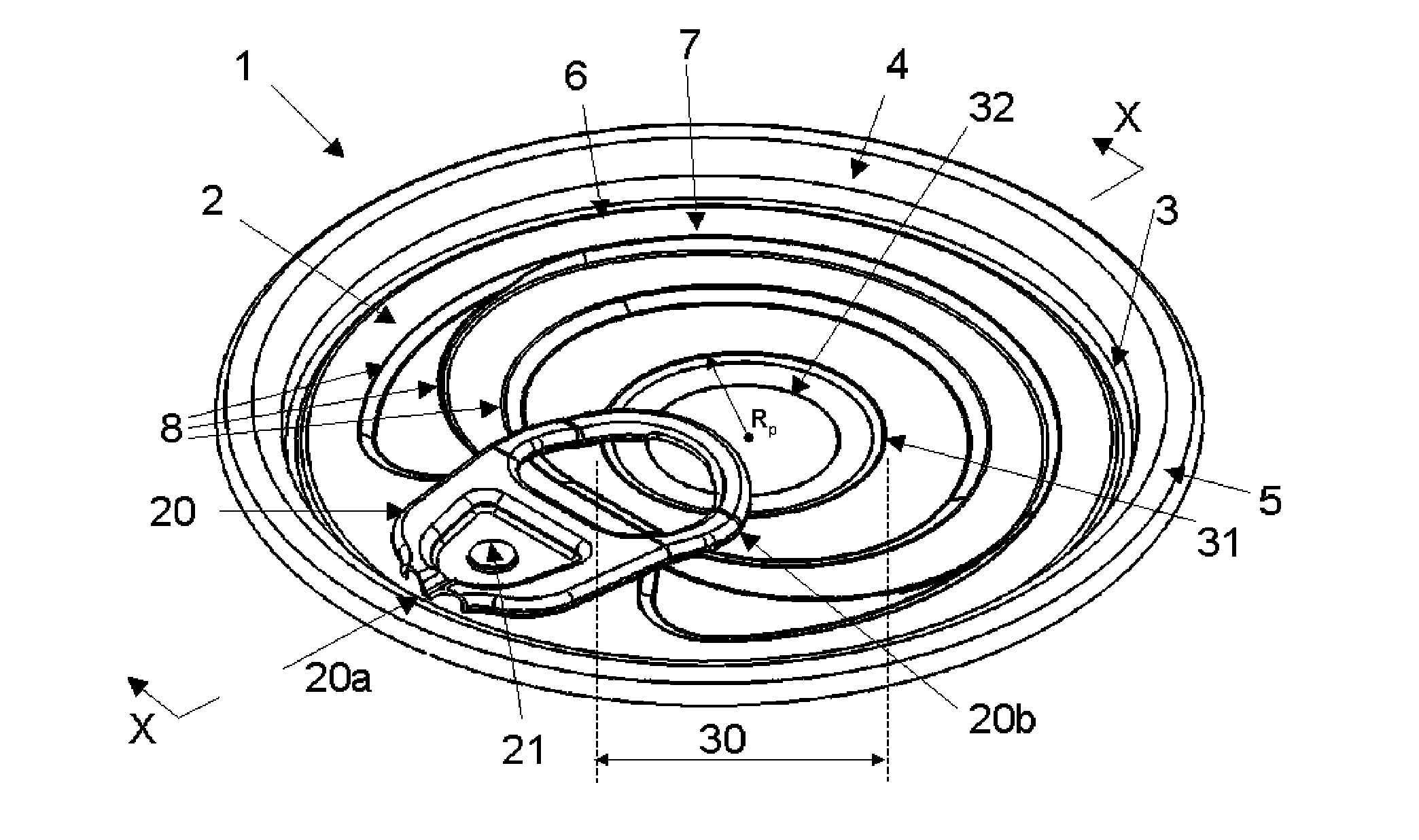

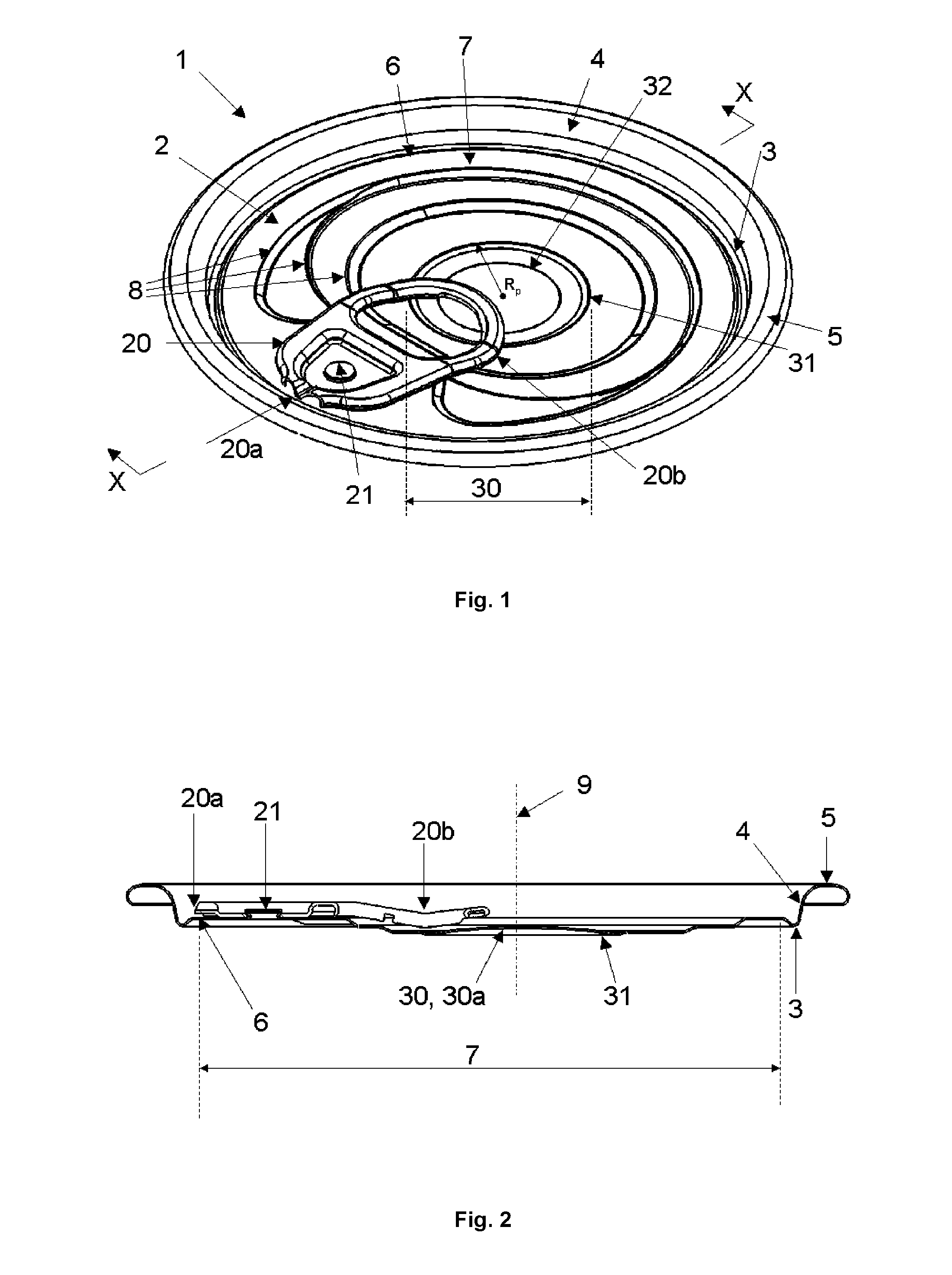

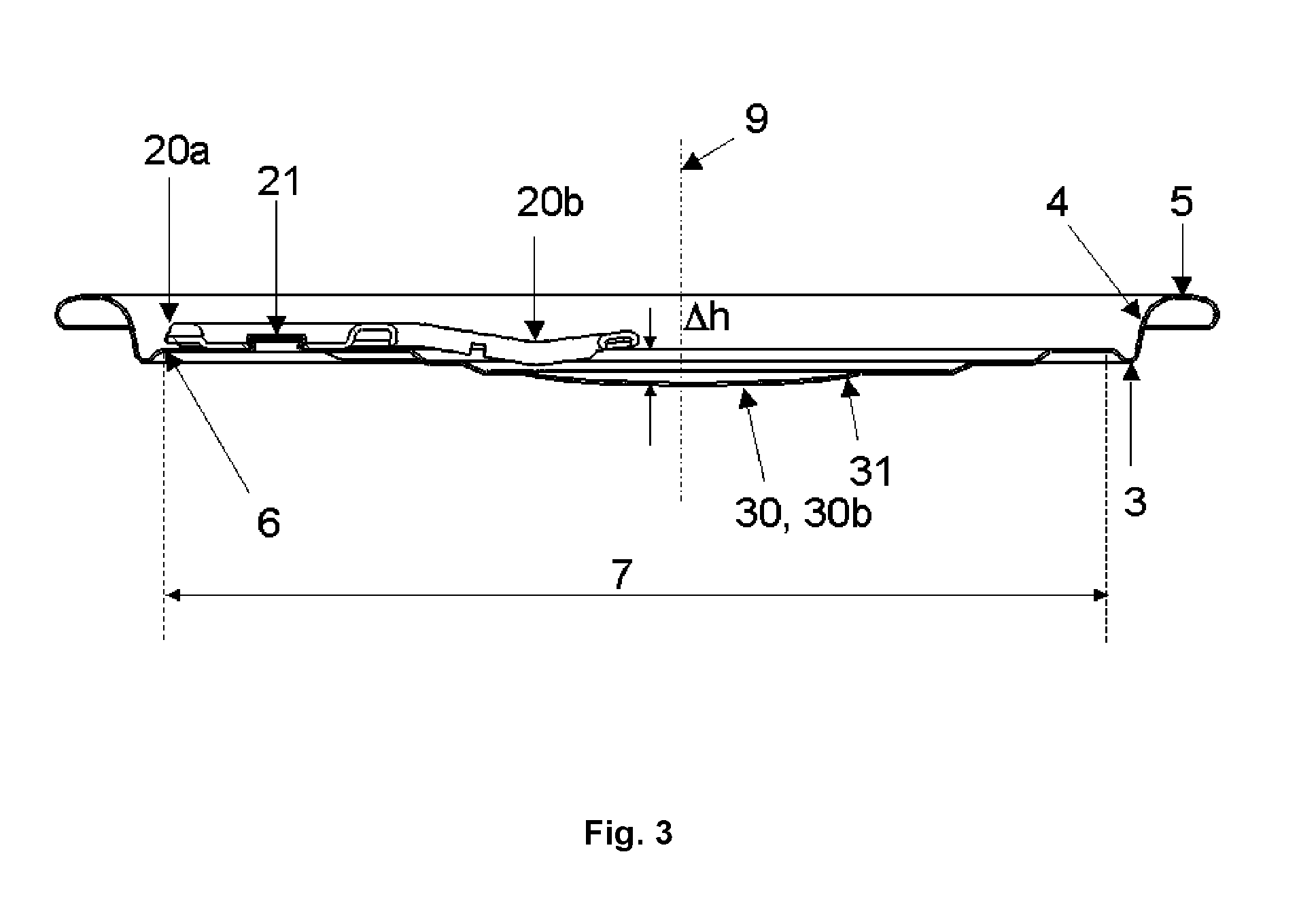

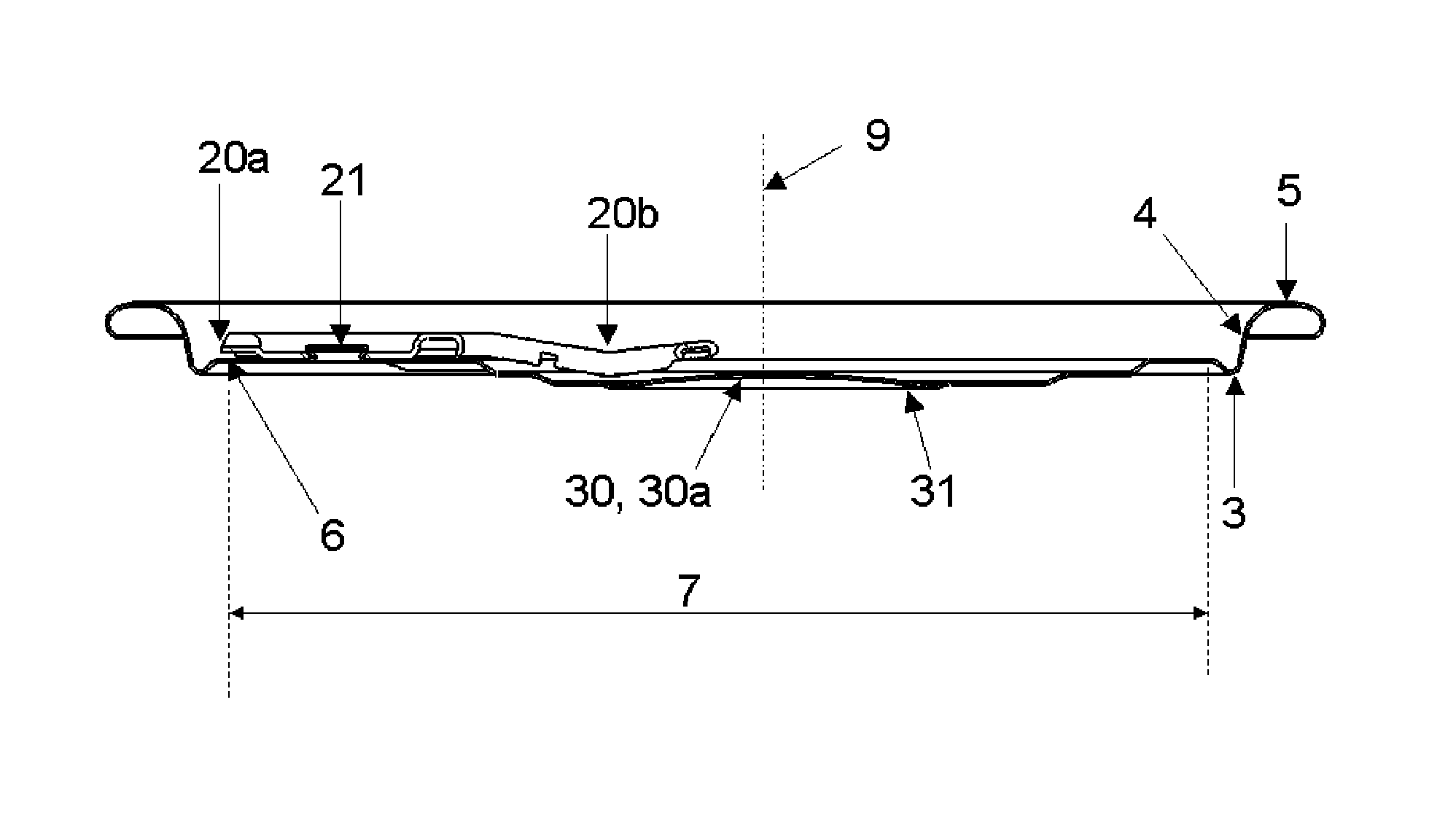

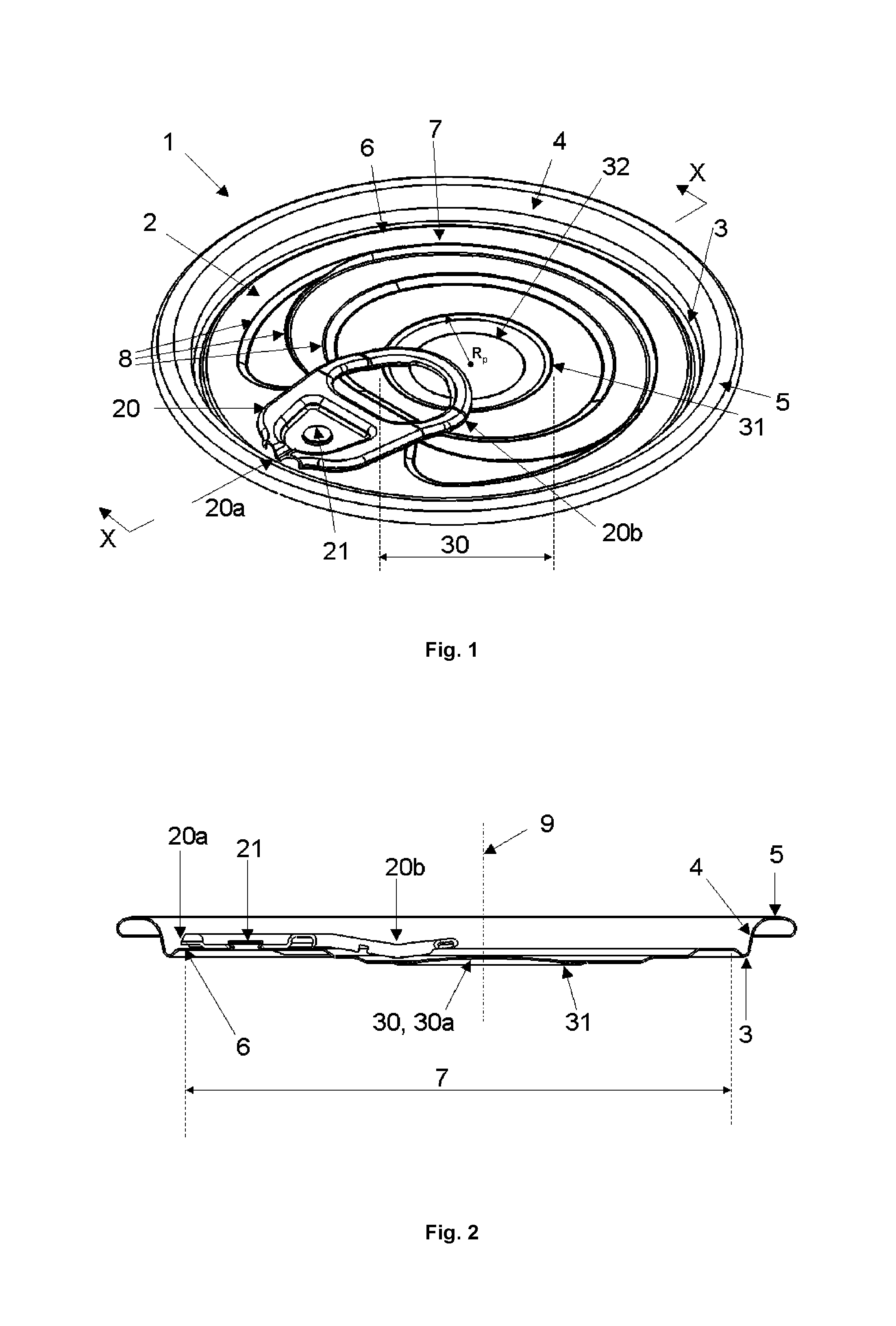

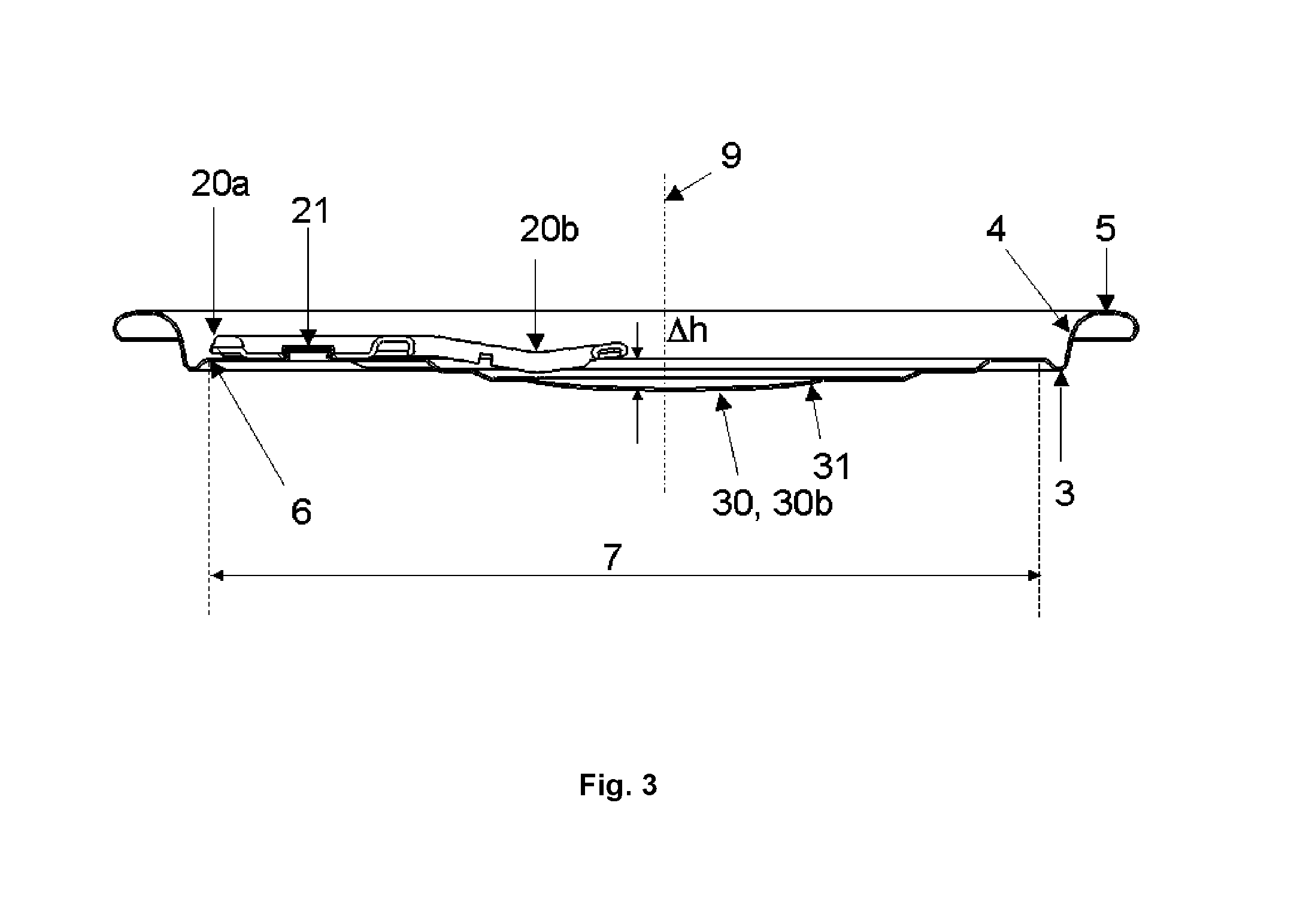

Can end

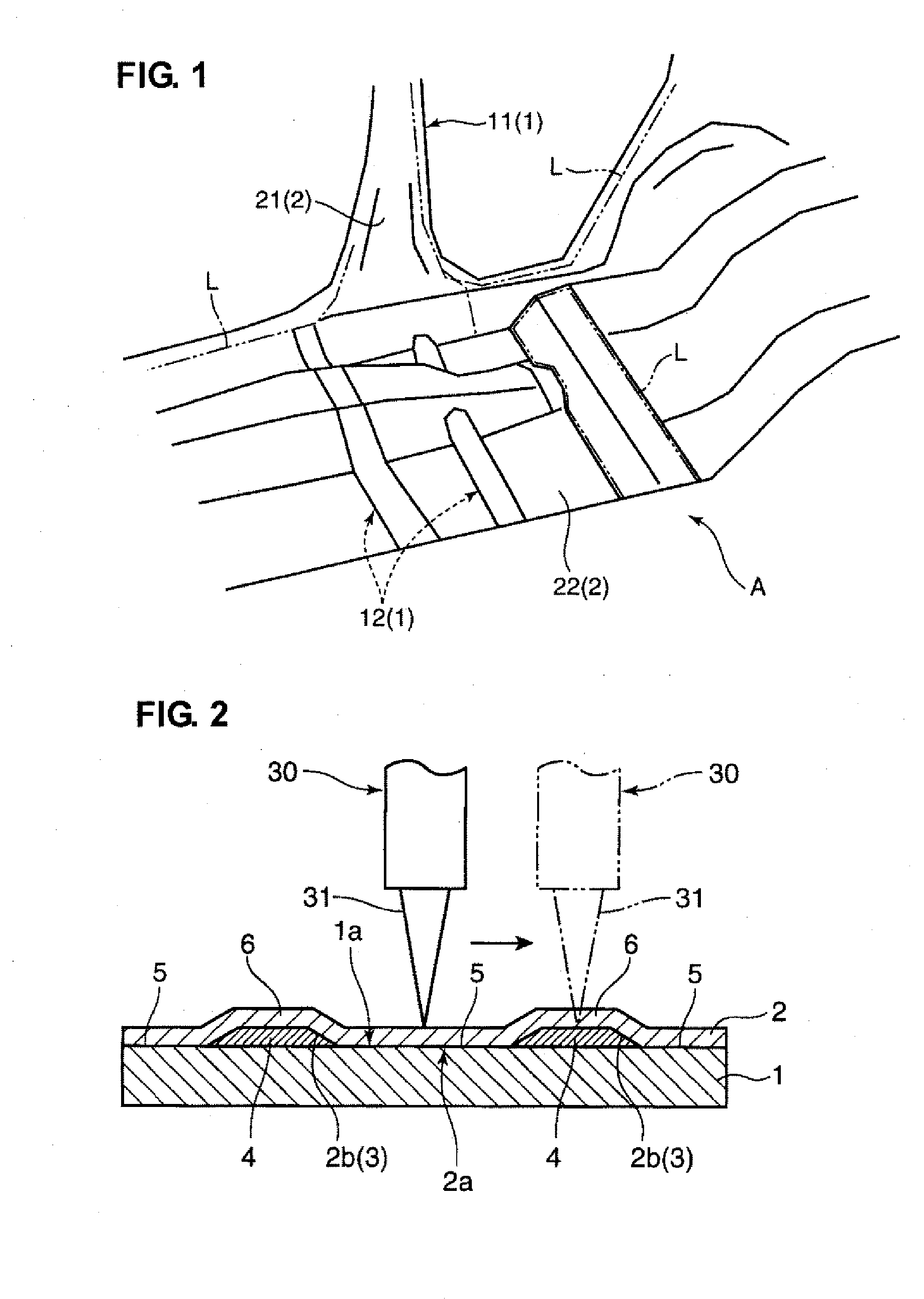

This invention relates to a can end (1) providing improved tab access for a consumer. A further aspect of the present invention relates to a container incorporating such a can end (1). The can end (1) includes a moveable portion (30) located beneath all or part of the handle (20b) of the can end, with the moveable portion deformable from an ‘up’ position (30a) to a ‘down’ position (30b) to provide increased tab access for a consumer. The can end (1) is provided with one or more downwardly inclined annular steps (31), which has been found to greatly increase the force required to deform the panel from the ‘down’ to the ‘up’ position, therefore resulting in a far greater likelihood of the consumer receiving a container (40) incorporating the can end (1) with the moveable portion (30) in the ‘down’ position (30b), thereby facilitating tab access.

Owner:CROWN PACKAGING TECH

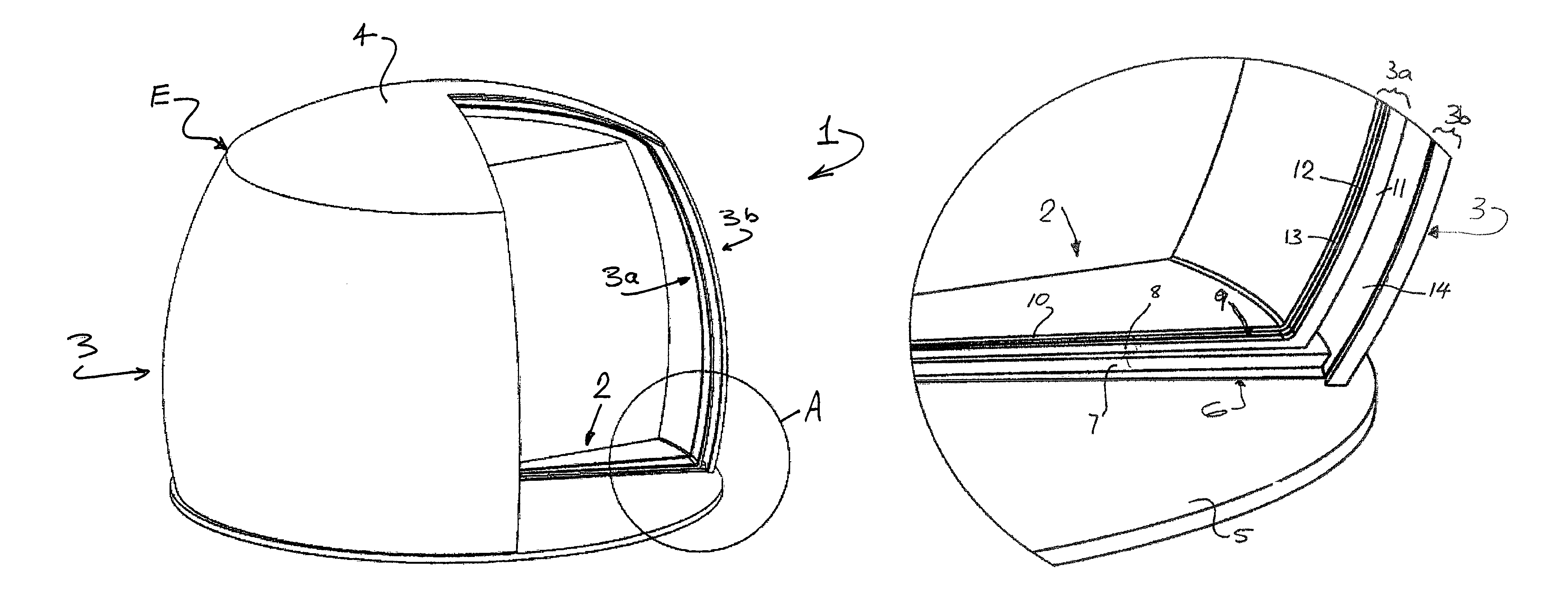

Cryogenic liquid storage tank

InactiveUS20110315691A1High qualityMetal Thickness ReductionVessel manufacturingVessel geometry/arrangement/sizeRebarReinforced concrete

A cryogenic liquid storage tank includes a base plate and side wall extending upwardly. The base plate and side wall include an outer leaf enveloping an inner leaf The outer leaf part of the base plate includes a lower, outer leaf concrete bottom plate on a substrate. The bottom plate is continuous with an outer leaf reinforced concrete layer of the outer side wall. An inward surface of the bottom plate and concrete layer of the outer leaf are lined with a continuous outer leaf metallic membrane. A bottom insulation layer is arranged above the outer leaf metallic membrane on the bottom plate. The inner leaf includes an inner leaf concrete bottom layer on the bottom insulation portion. The inner leaf metal membrane is lined with an inner leaf inner concrete layer. The outer leaf hoop stress reinforced outer concrete wall supporting an insulated dome structure.

Owner:IGLO CONTRACTORS

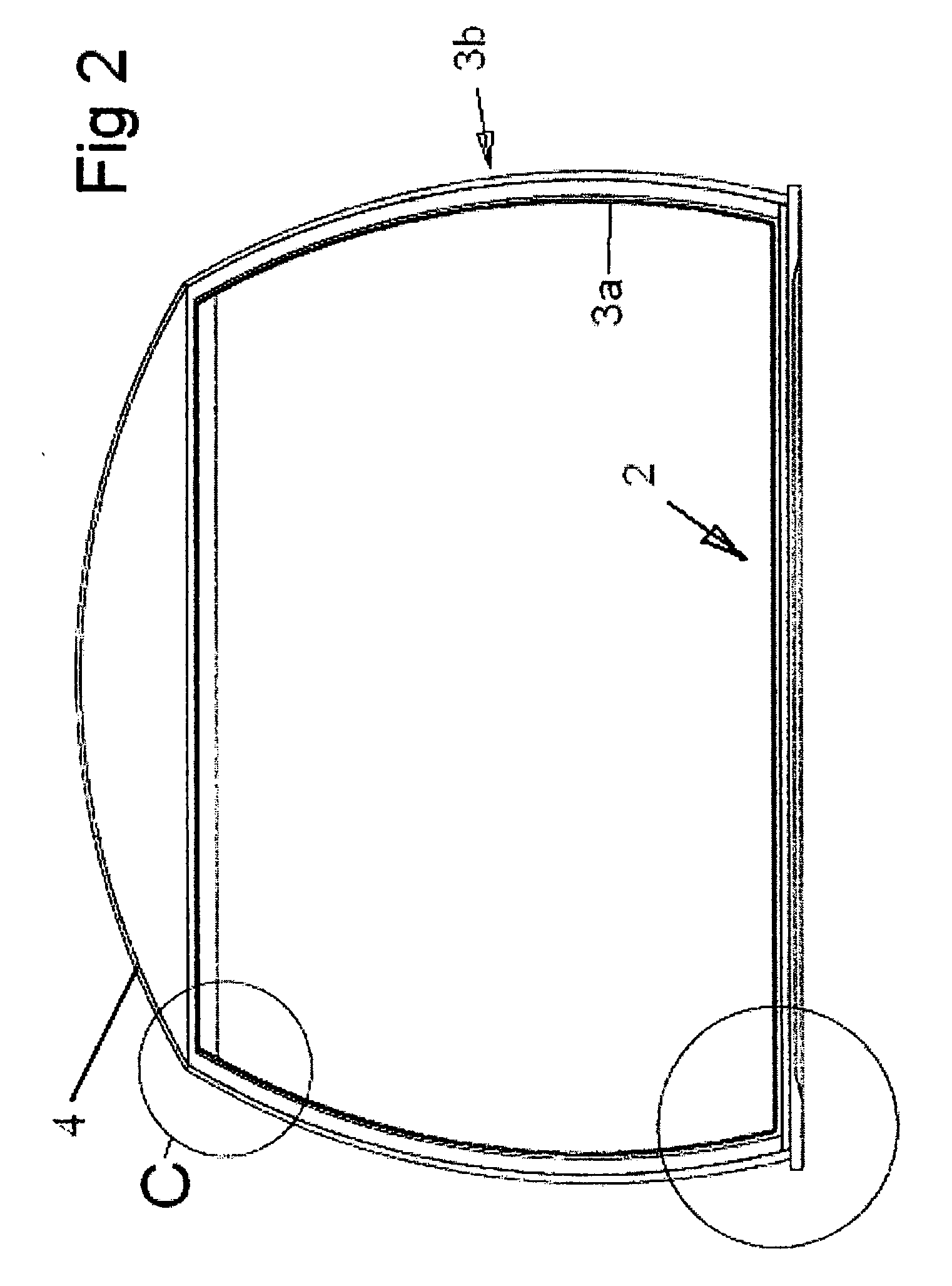

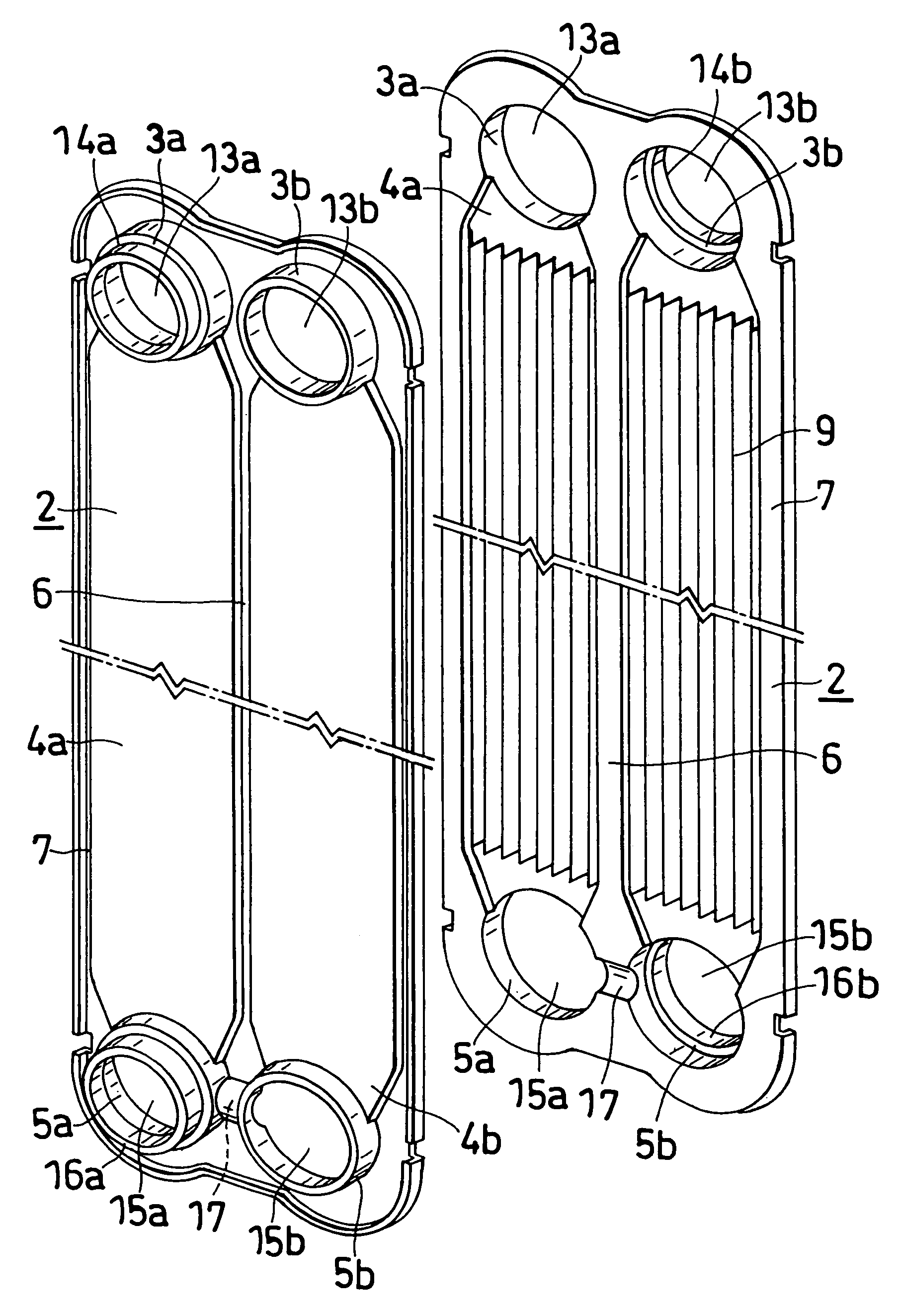

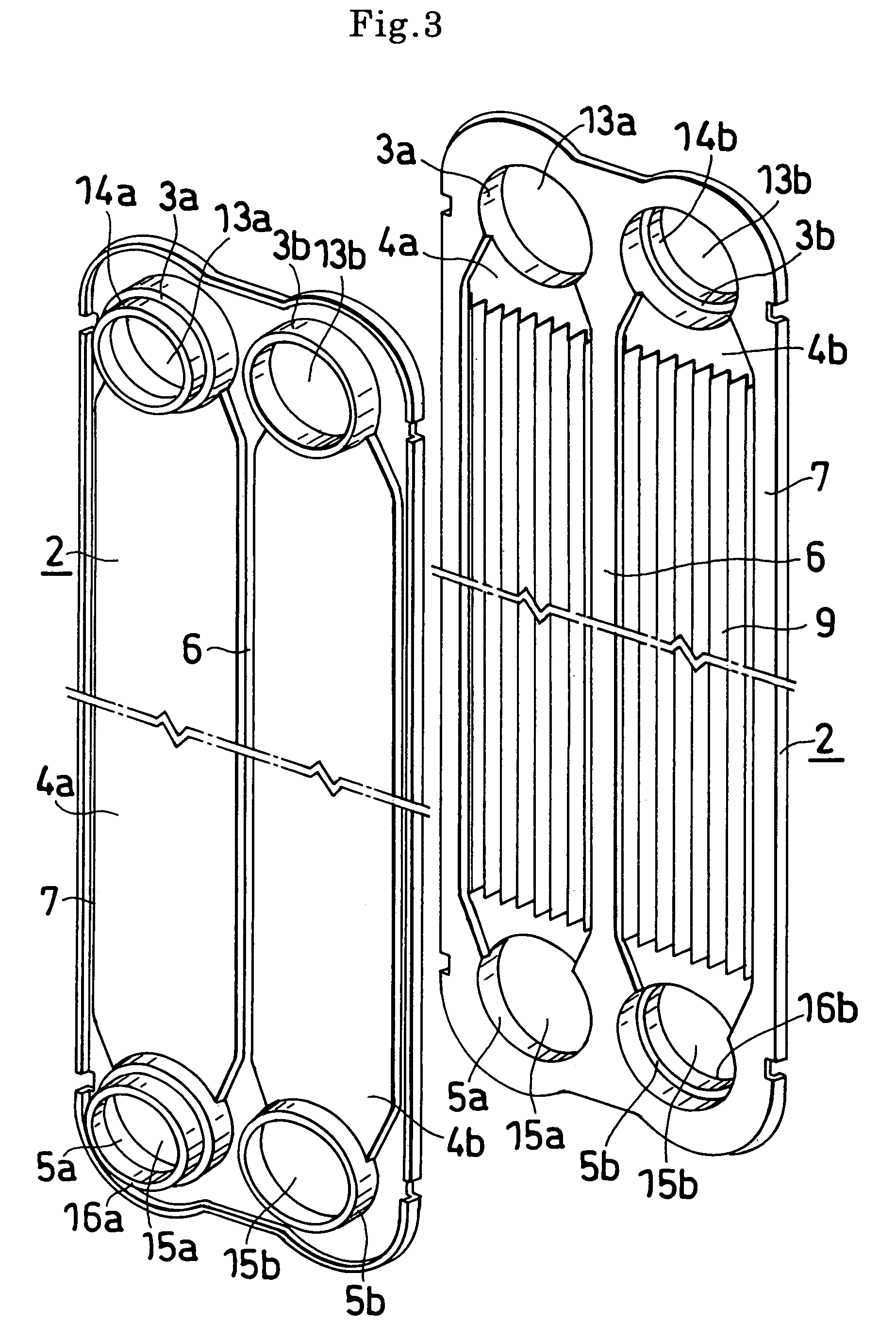

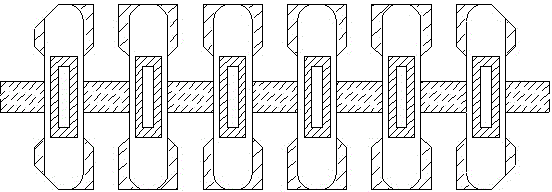

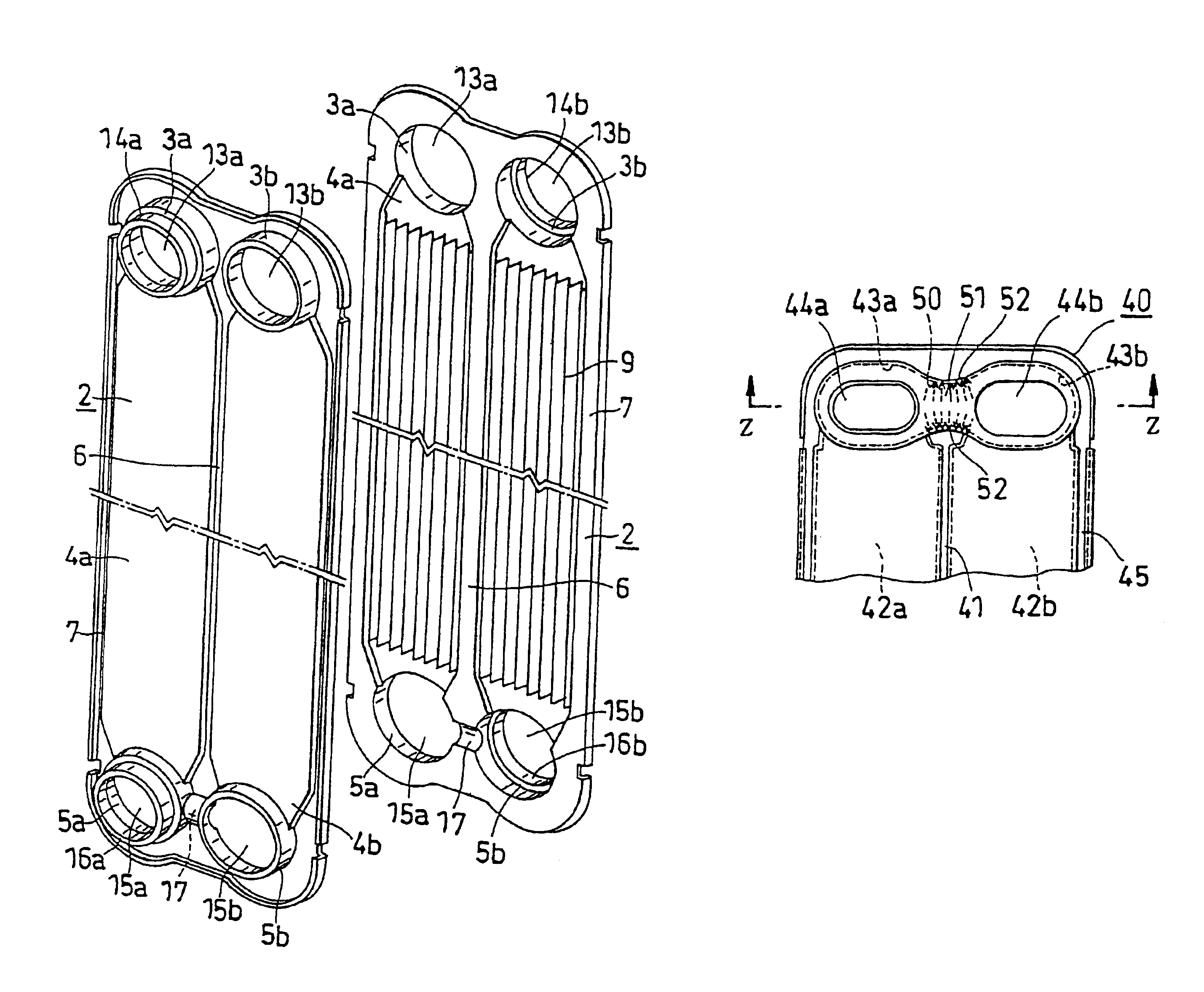

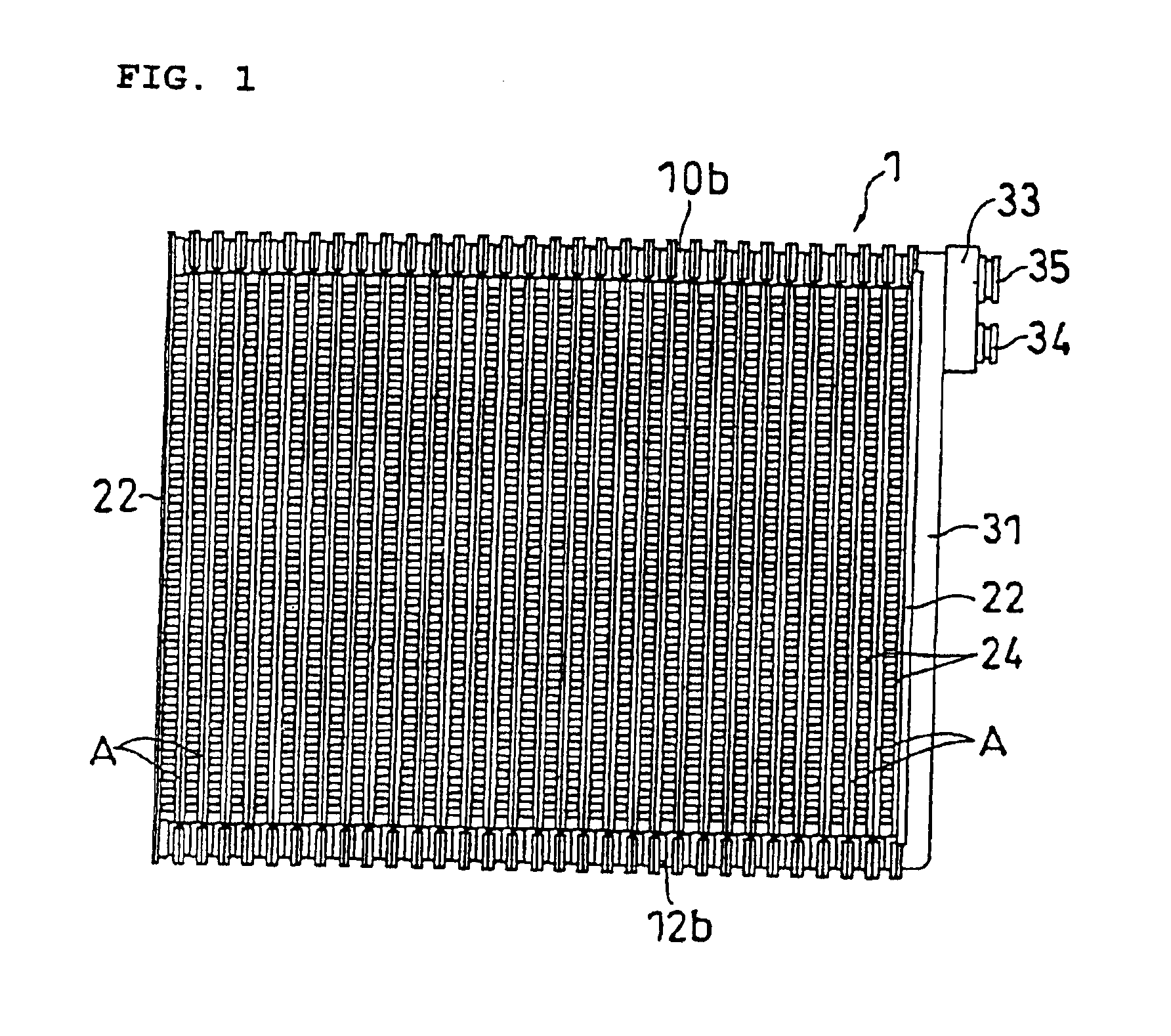

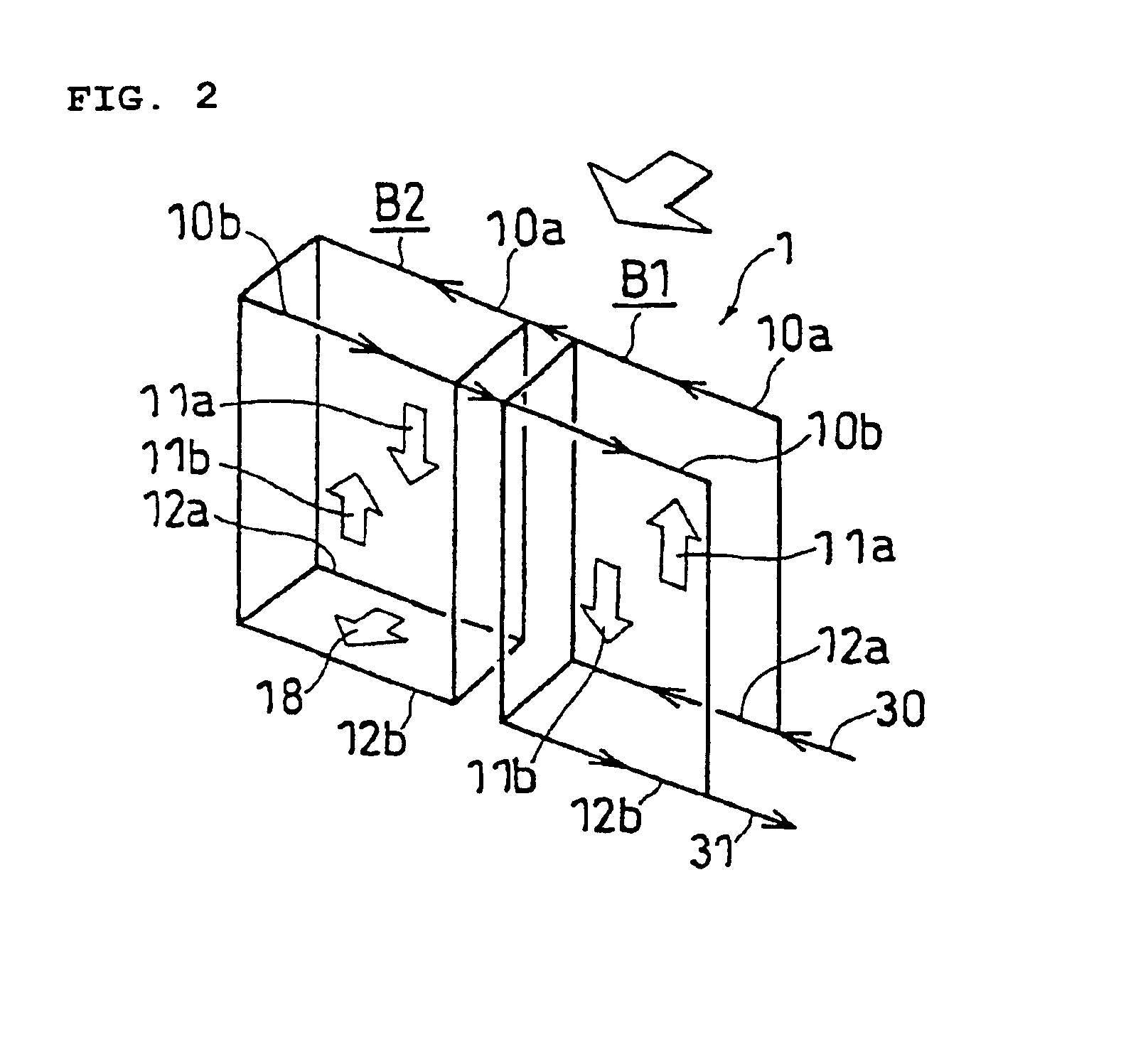

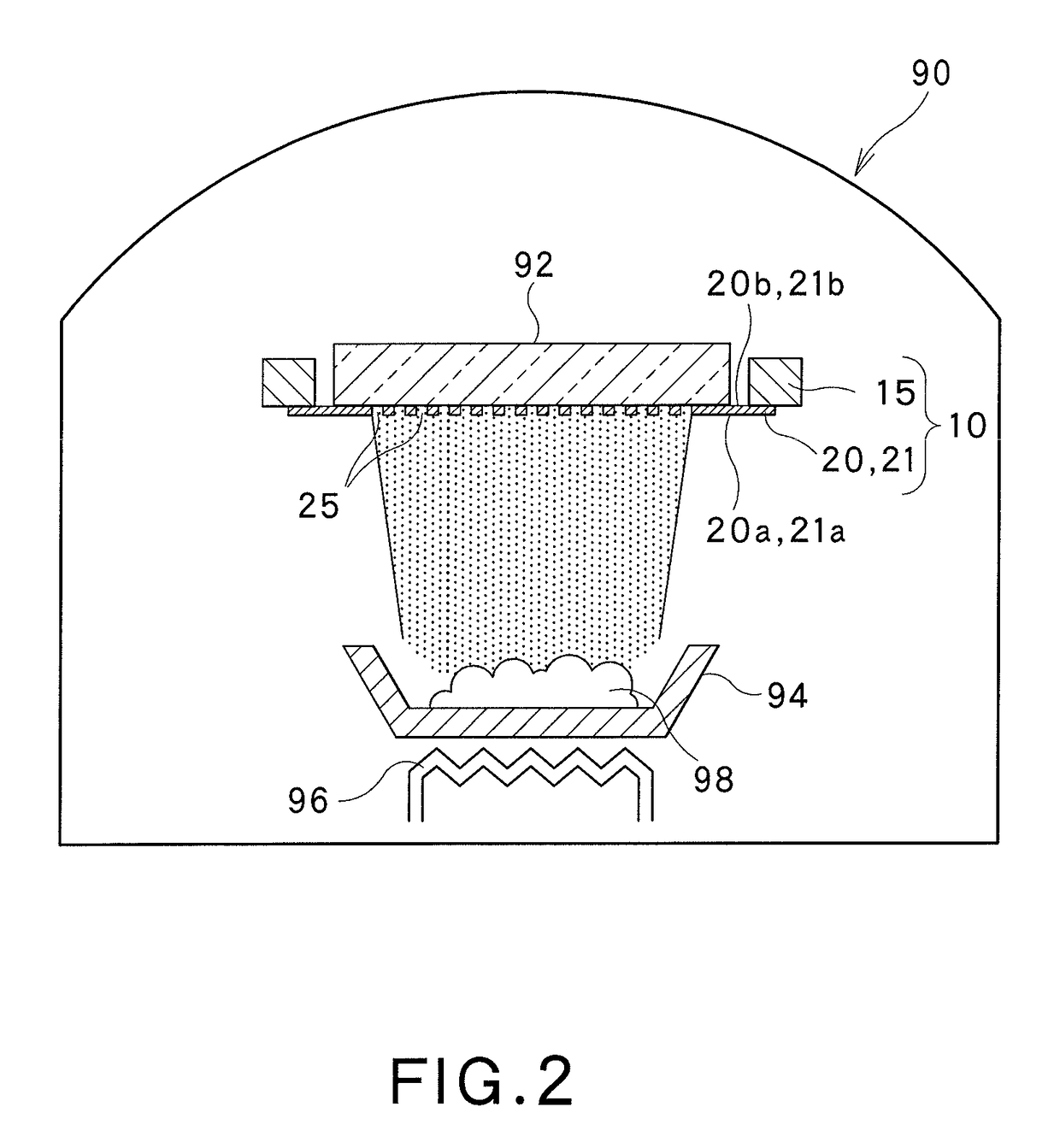

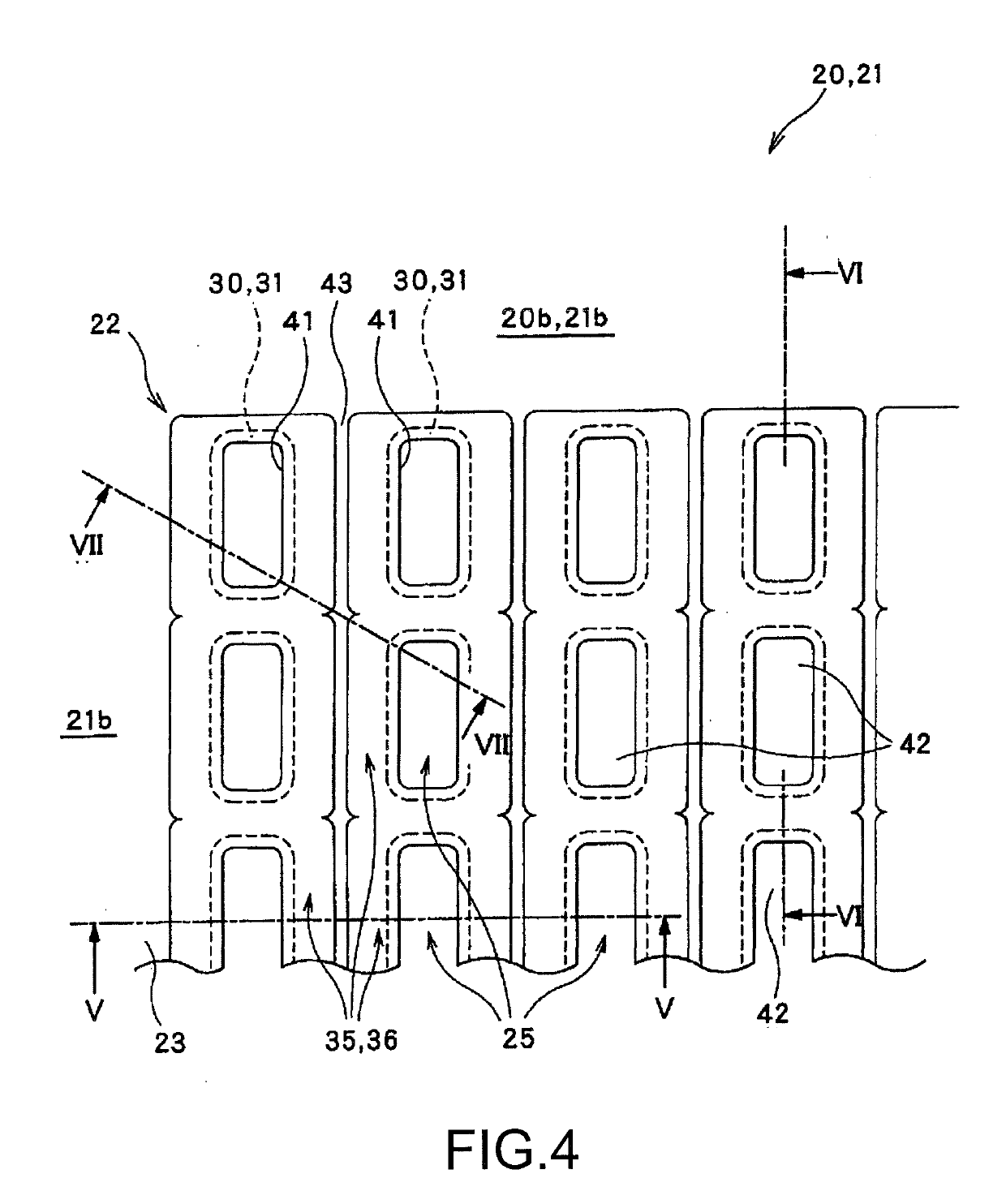

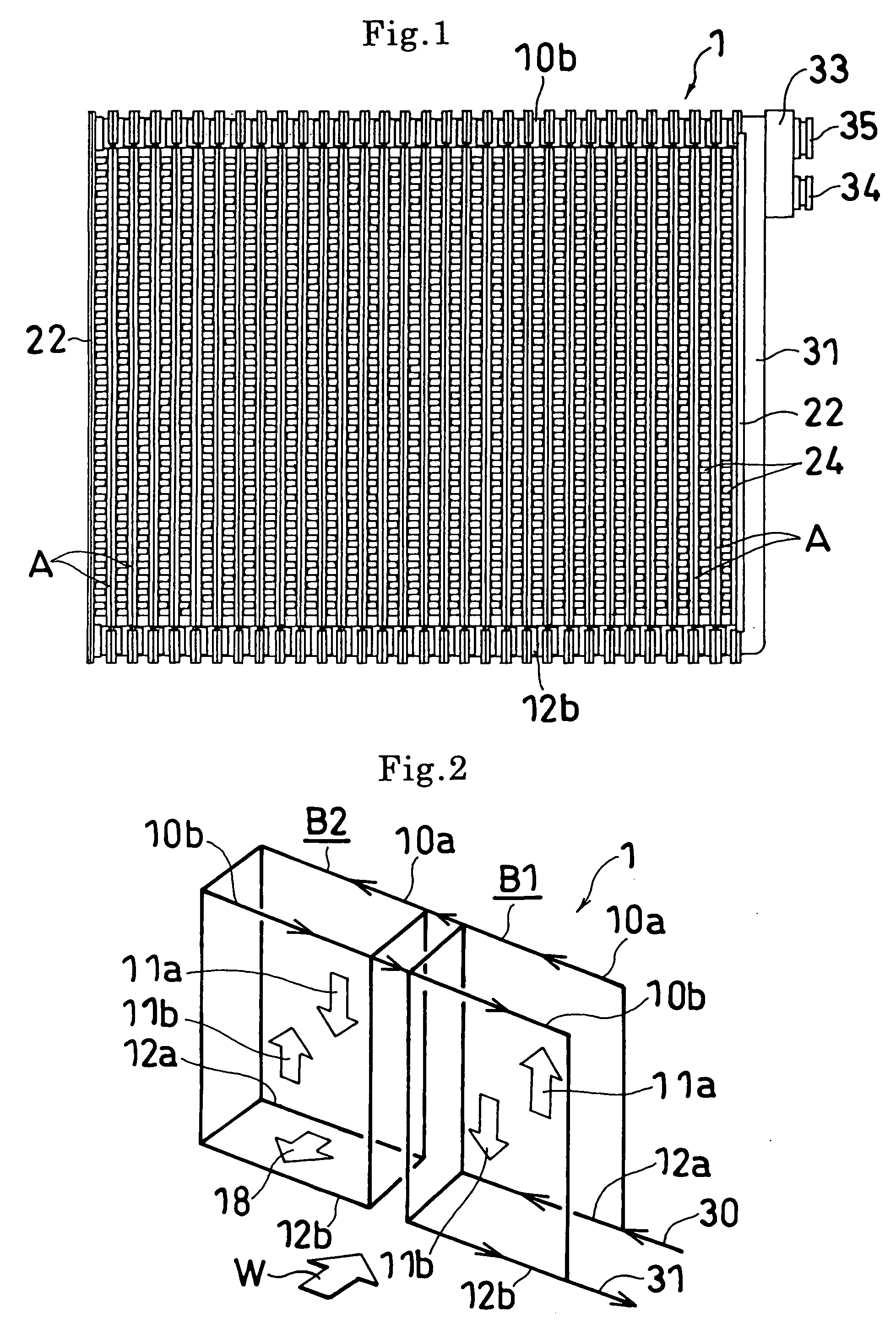

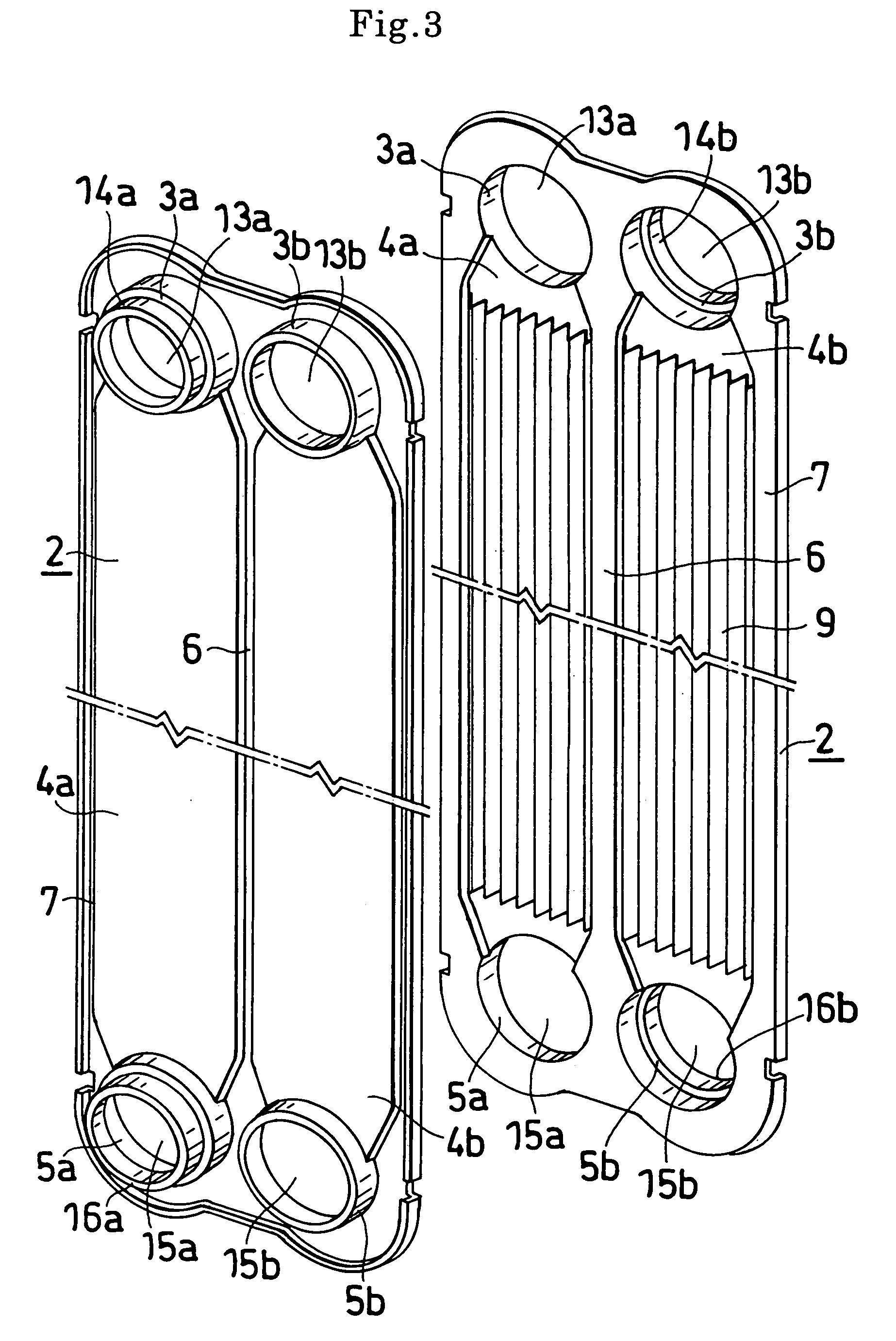

Layered heat exchangers

InactiveUS7044205B2Increase ultimate strengthReduce stress concentrationReinforcing meansEvaporators/condensersInternal pressurePlate heat exchanger

A layered heat exchanger, for example for use for motor vehicle coolers. To provide a turn portion in the heat exchanger for changing flow direction of a fluid flowing zigzag through a fluid circuit, a metal plate is provided at the upper or lower ends of a partition ridge with a fluid flow direction changing passage forming caved portion having a bottom wall of circular-arc cross section. Front and rear upper or lower tank portions are held in communication with each other through a fluid flow direction changing passage of approximately circular cross section and formed by the caved portions opposed to each other. The turn portion is diminished in stress concentrated thereon due to fluid internal pressure and given an increased resistance to pressure to effectively prevent tank side walls from breaking, consequently making it possible to decrease the metal plates thicknesses, to achieve a cost reduction by the decreased thickness and to assure an improved heat exchange efficiency.

Owner:KEIHIN THERMAL TECH CORP

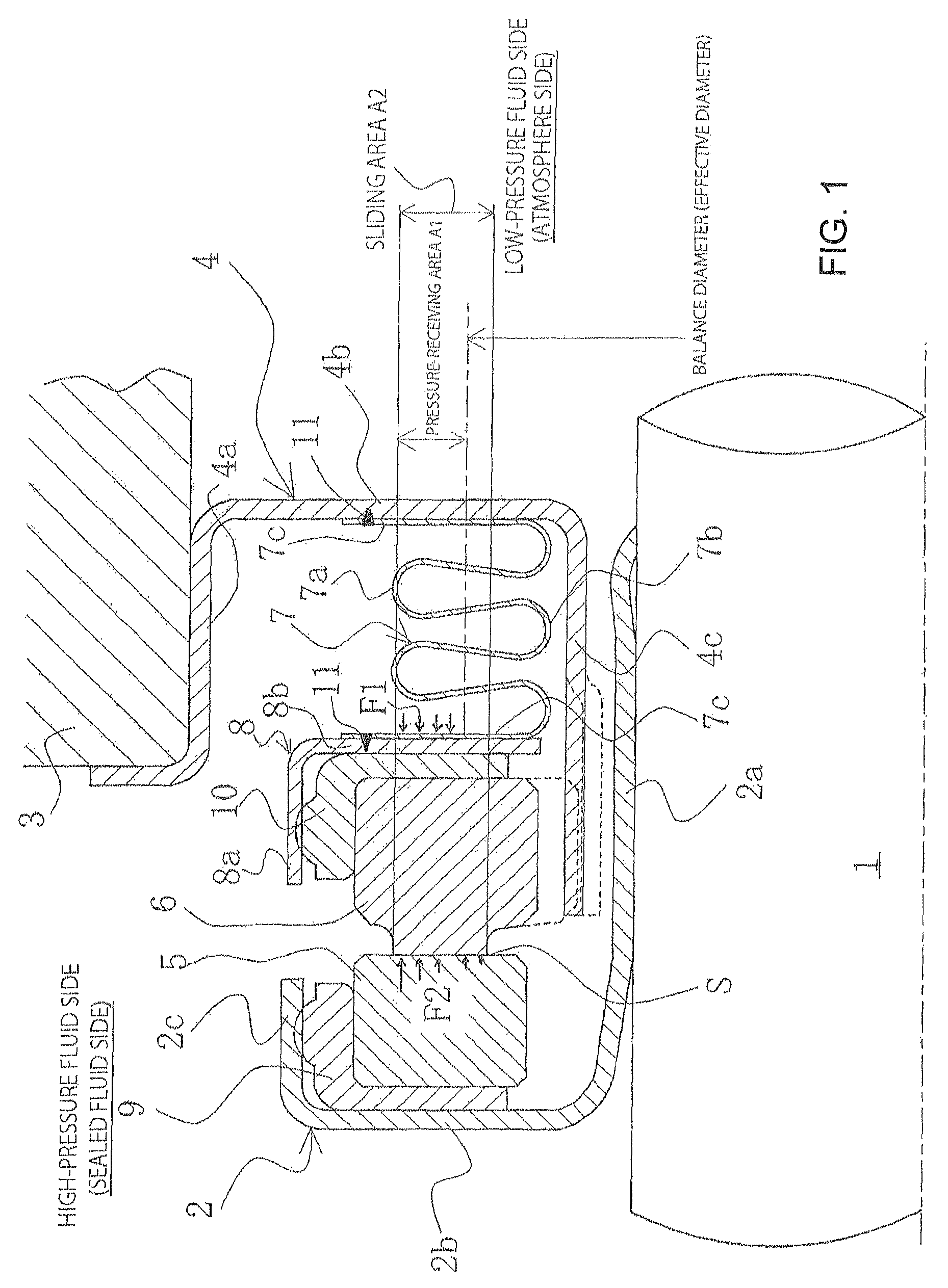

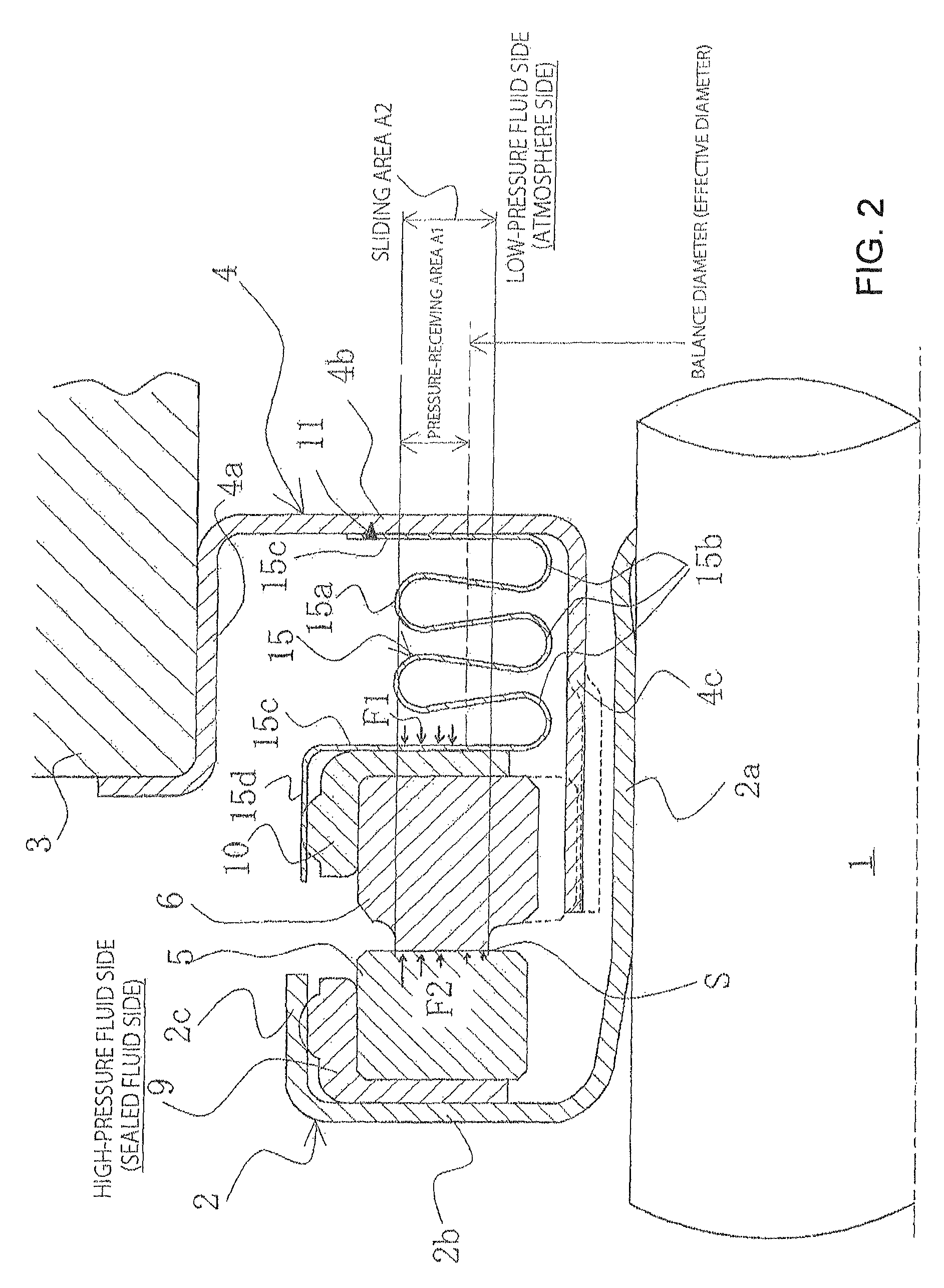

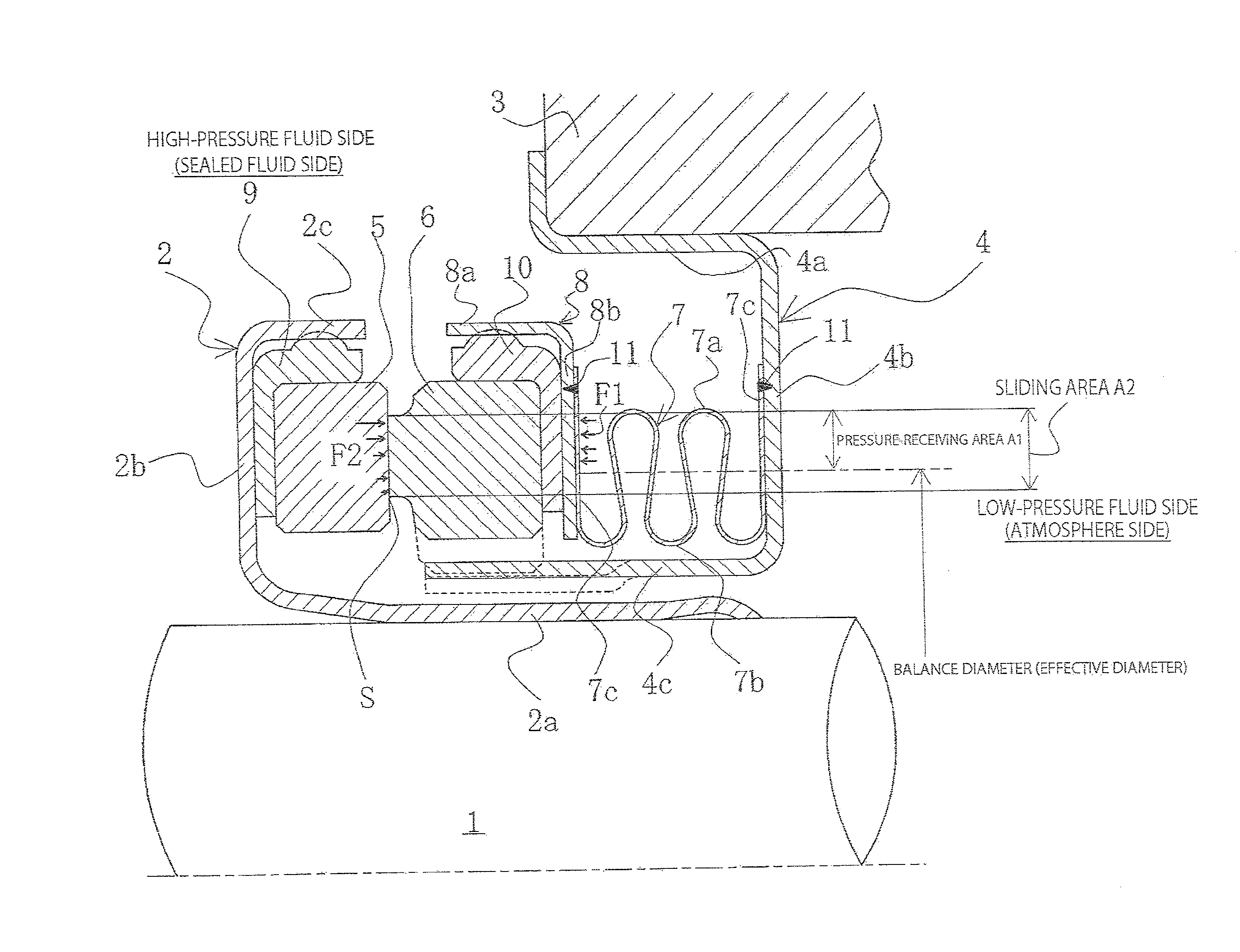

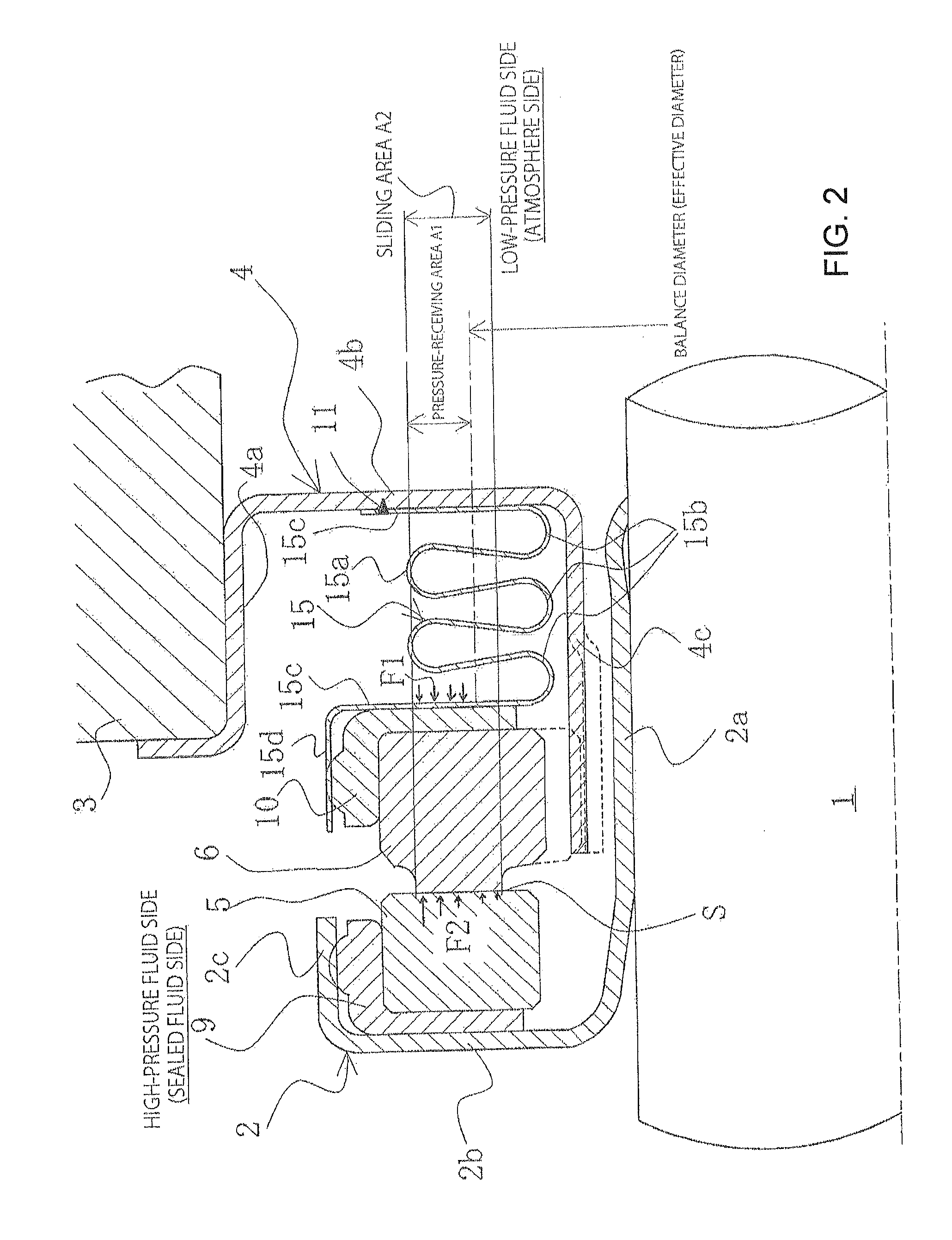

Mechanical seal

ActiveUS9581248B2Prevents degradation and tearingMetal Thickness ReductionEngine sealsEngineeringMetal bellows

To provide a mechanical seal in which degradation or tearing of a bellows does not occur, the spring constant of the bellows is reduced, and the fluctuation in the load due to stretching and contracting of the bellows is reduced. An inside-type mechanical seal includes a sleeve fixed to a rotating shaft, and a cartridge fixed to a housing. A rotation-side sealing ring is provided to the sleeve. A fixed-side sealing ring, which slides against the rotation-side sealing ring, and a bellows for axially urging the fixed-side sealing ring is provided to the cartridge. The bellows is made from a metal; and the metal bellows has one end fixed to a case for holding the fixed-side sealing ring and another end fixed to the cartridge. The plate thickness of the metal bellows is set so as to be smaller than the plate thickness of the case or the cartridge.

Owner:EAGLE INDS

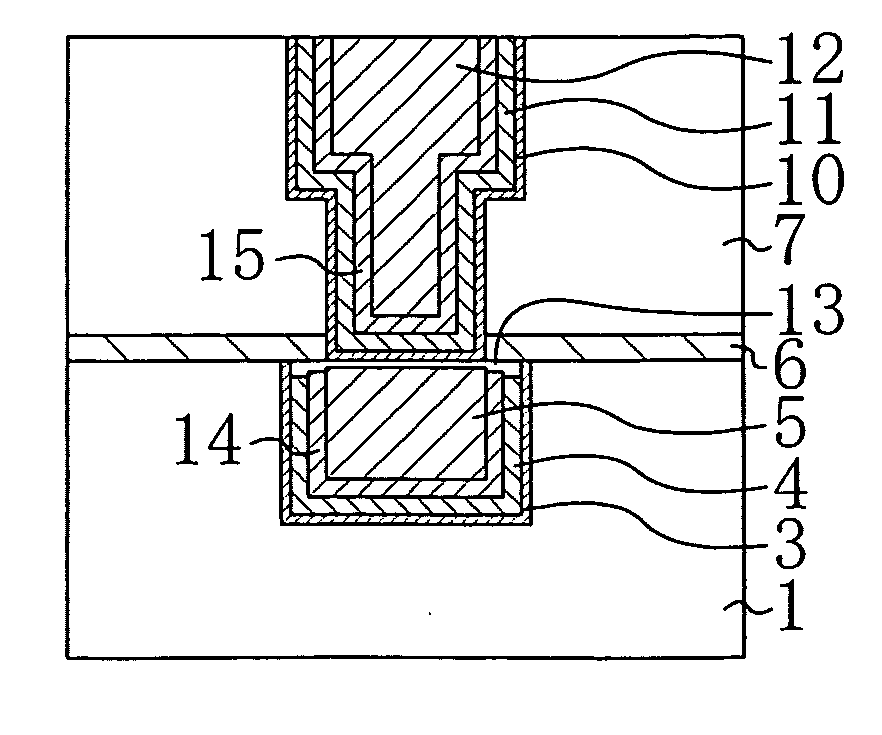

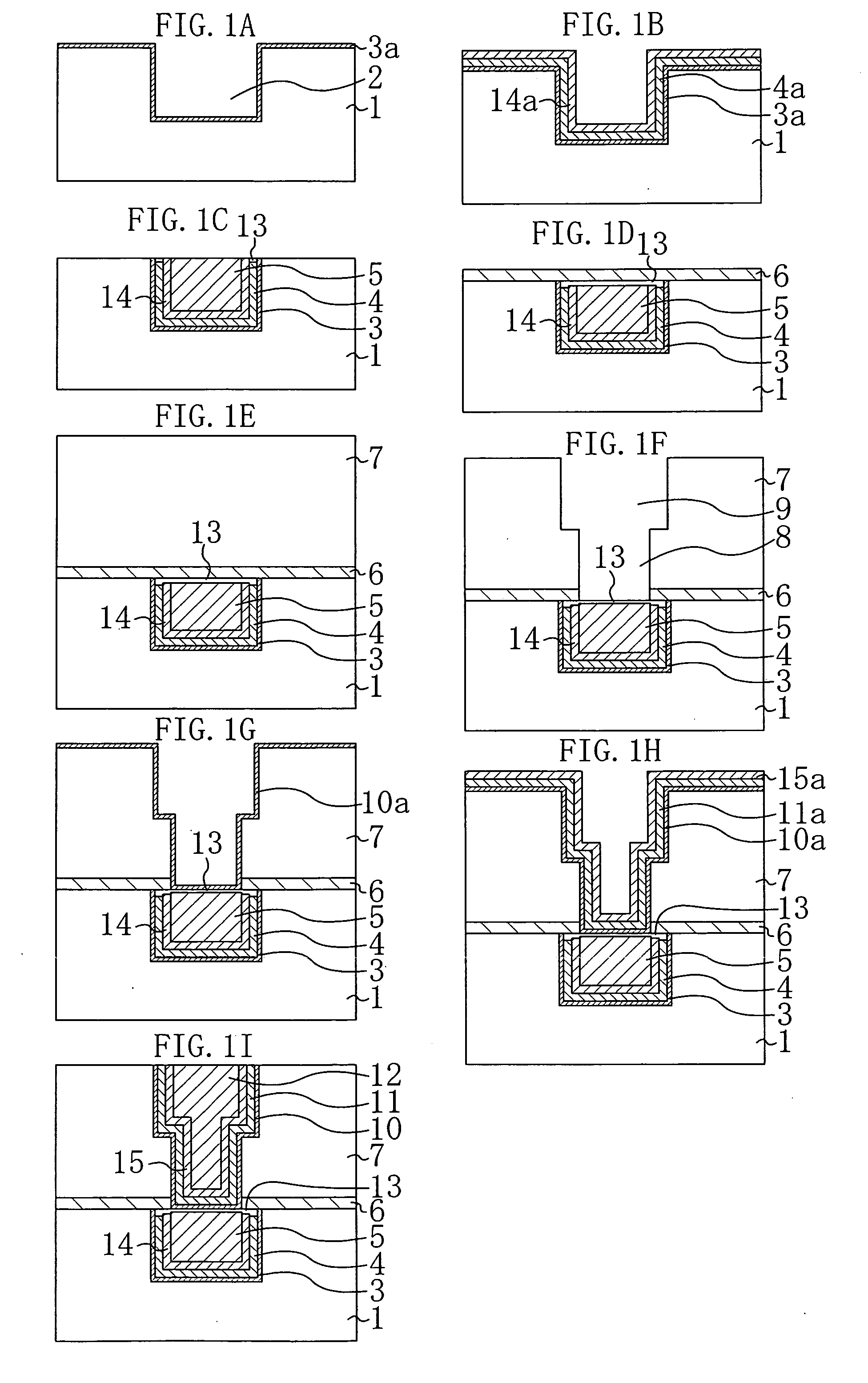

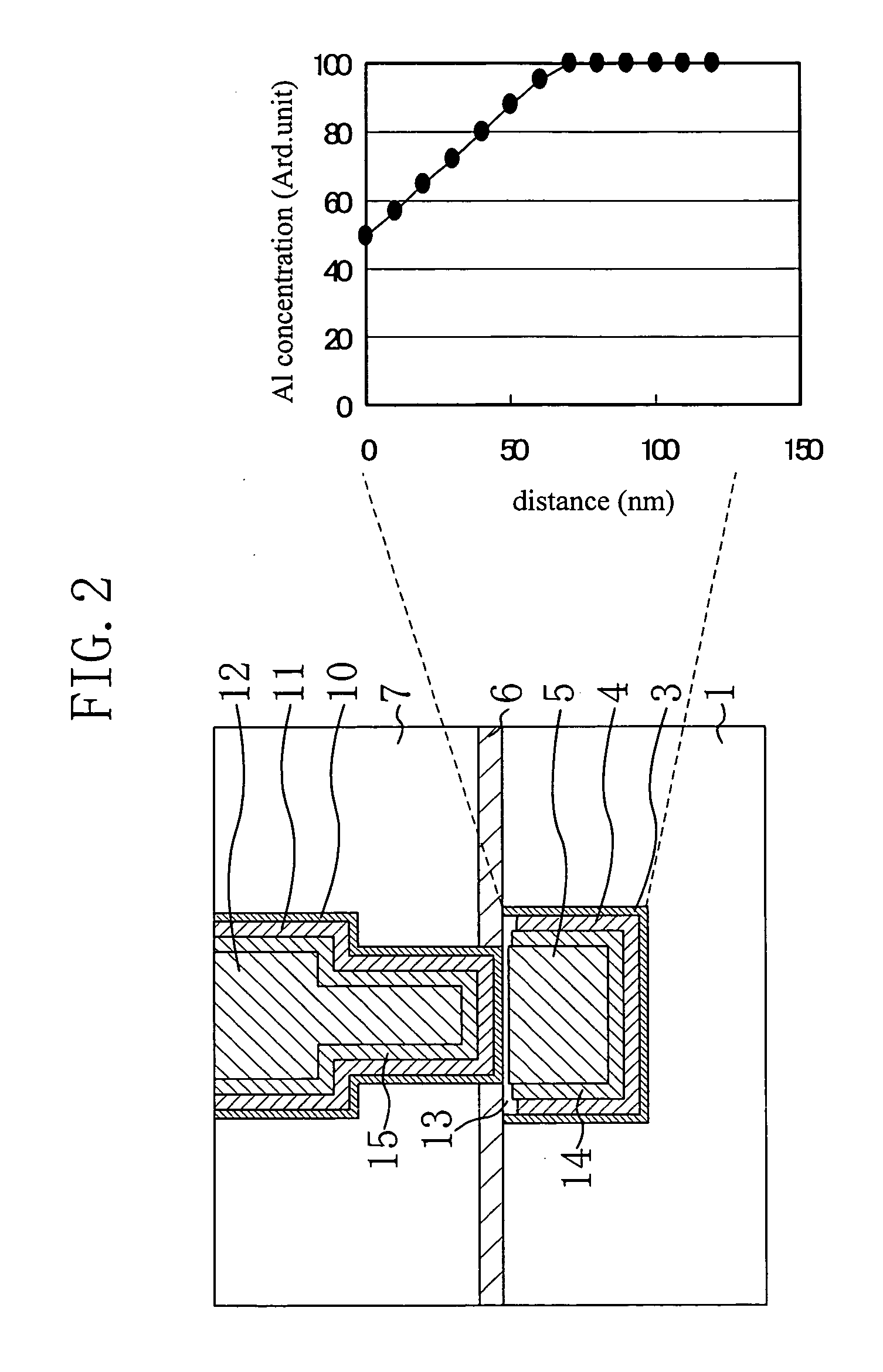

Semiconductor device and manufacturing method thereof

InactiveUS20070145600A1High yieldImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesDielectricCopper

A semiconductor device includes an embedded wire in a first wire trench formed in a first interlayer dielectric film, the embedded wire having a barrier metal, a first seed film, a second seed film, and a copper film. The first seed film is formed by a copper film containing metal, and the second film is formed by a copper film. The second seed film suppresses that the metal contained in the first seed film diffuses into a wiring material film in a manufacturing process.

Owner:PANASONIC CORP +1

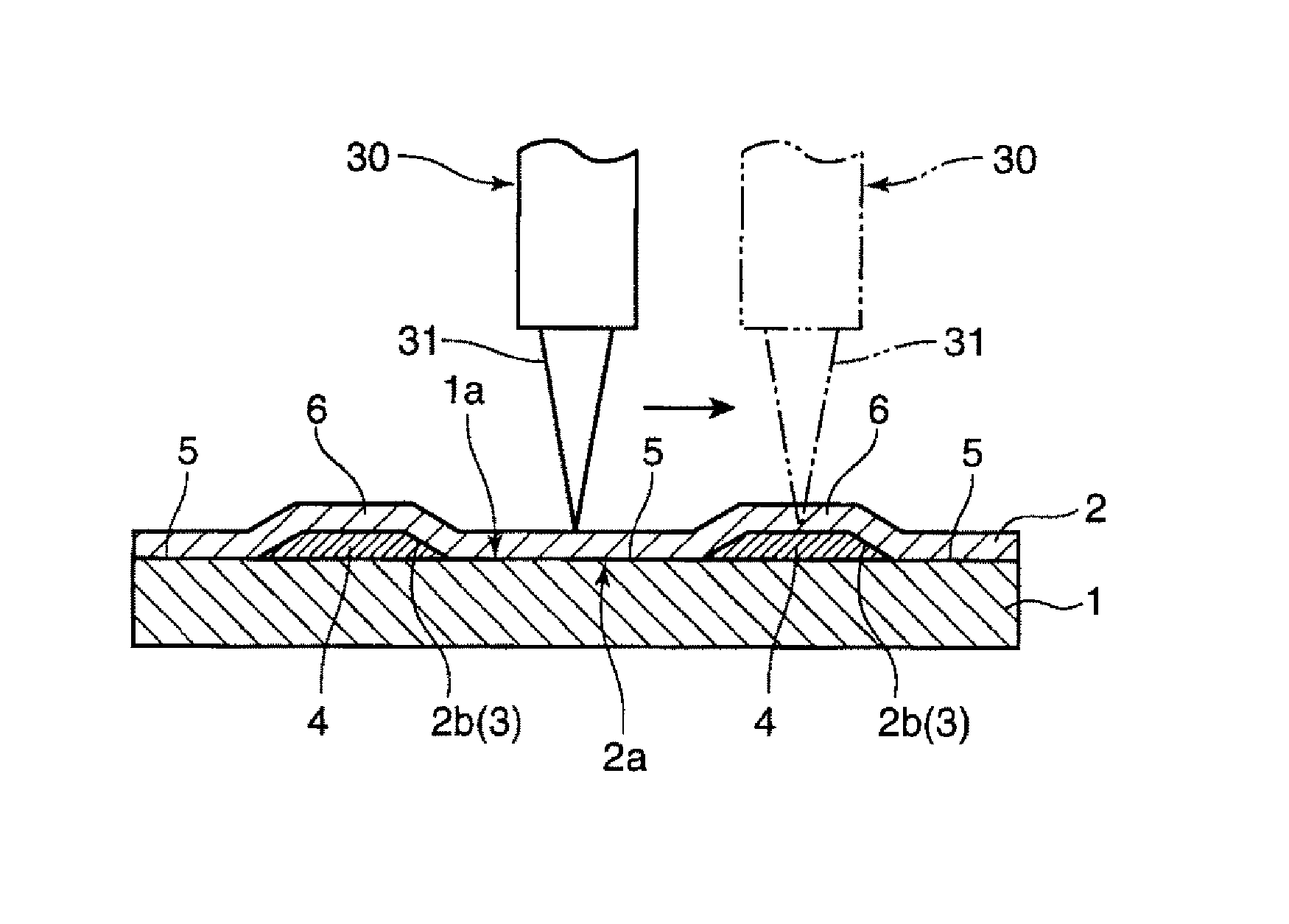

Joining structure and method of metal works

InactiveUS20080237203A1Less limitationLess-controlExhaust apparatusSilencing apparatusEngineeringMetal working

A gap is provided at joining faces of a pair of metal works with an uneven shape when the metal works contact one another for joining. An adhesive agent having a chain-reacting curing reaction function is disposed within the gap. The adhesive agent is cured by an autogenously-generated curing reaction heat caused by an outer energy and an additional heat that is successively generated by the autogenously-generated curing reaction heat within the adhesive agent. A welding portion, where the works contact one another substantially directly, is welded by a laser beam, and the above-described energy for causing the autogenously-generated curing reaction heat for the adhesive agent is provided by the laser beam. Accordingly, a joining structure and method of metal works that can has less limitation in a joining location is provided.

Owner:MAZDA MOTOR CORP

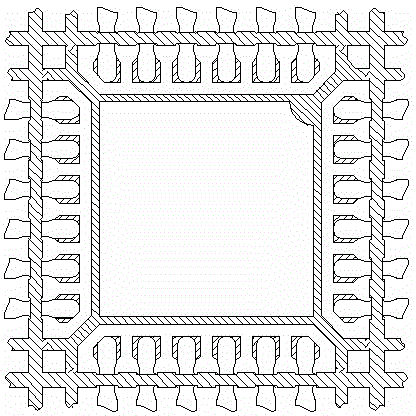

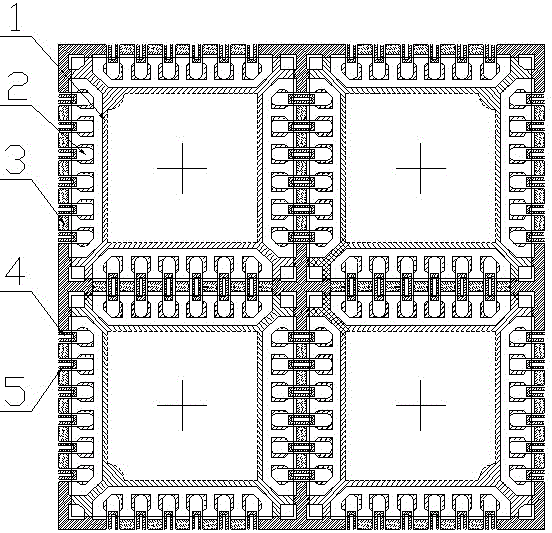

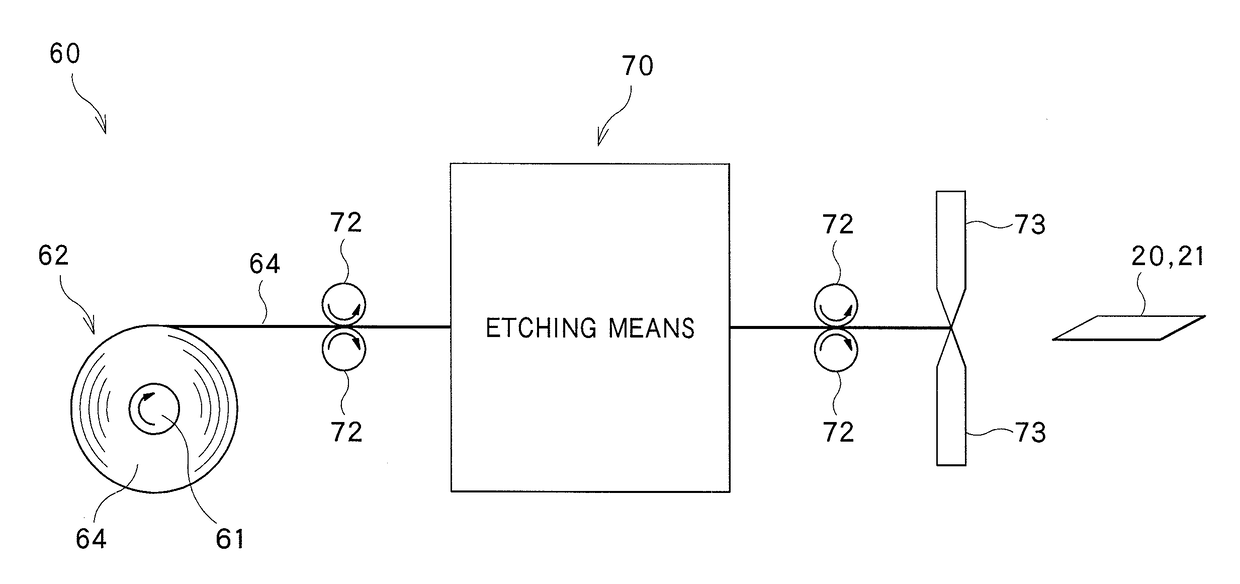

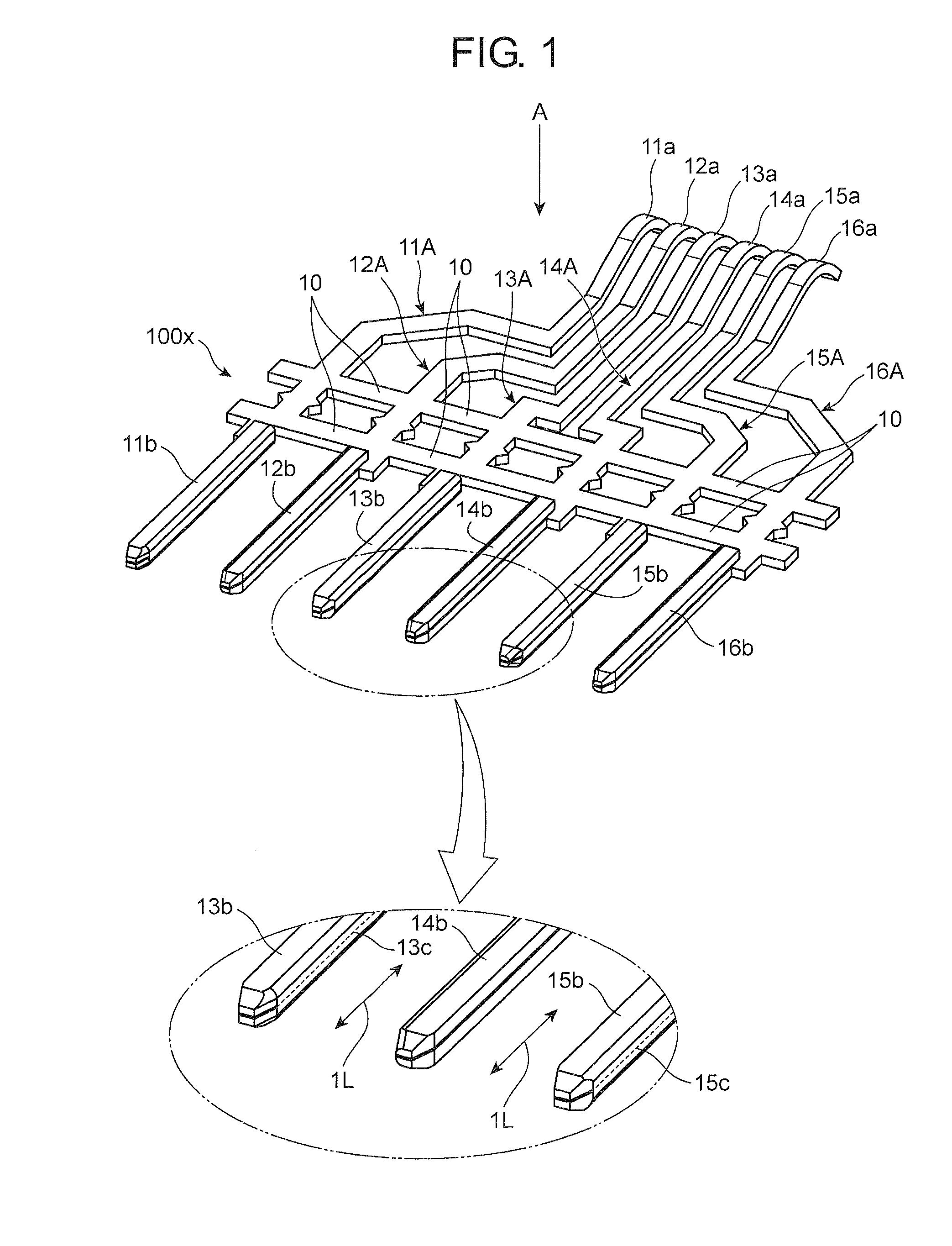

Quad flat no-lead package lead frame structure and package structure

ActiveCN104659010AMetal Thickness ReductionReduce thicknessSemiconductor/solid-state device detailsSolid-state devicesGlutenEngineering

The invention relates to a quad flat no-lead package lead frame structure. The quad flat no-lead package lead frame structure comprises a plurality of bearing units in matrix arrangement and middle glutens (3) arranged between and used for fixing the bearing units, wherein each bearing unit comprises a chip carrier (1) and a pin array (2) arranged at the periphery of the chip carrier; each middle gluten (3) is connected between the pin arrays (2) of two adjacent bearing units of the bearing units; a half-etched groove (4) is formed in the back, close to the corresponding middle gluten (3) , of each of the pin arrays (2). According to the quad flat no-lead package lead frame structure, as the half-etched grooves are formed in the root parts of pins, during applying of solder paste to a PCB, the solder paste can more successfully climb to the side edges of the pins through the siphonic effect, and accordingly, combination of the pins and the PCB is enhanced; as the half-etched grooves are formed in the root parts of the pins, the thickness of metal at the root parts of the pins is reduced, accordingly, tool abrasion is reduced and the quad flat no-lead cutting efficiency is greatly improved.

Owner:JCET GROUP CO LTD

Layered heat exchangers

InactiveUS6920916B2Increase ultimate strengthReduce stress concentrationReinforcing meansEvaporators/condensersInternal pressurePlate heat exchanger

A layered heat exchanger, for example for use for motor vehicle coolers. To provide a turn portion in the heat exchanger for changing flow direction of a fluid flowing zigzag through a fluid circuit, a metal plate is provided at the upper or lower ends of a partition ridge with a fluid flow direction changing passage forming caved portion having a bottom wall of circular-arc cross section. Front and rear upper or lower tank portions are held in communication with each other through a fluid flow direction changing passage of approximately circular cross section and formed by the caved portions opposed to each other. The turn portion is diminished in stress concentrated thereon due to fluid internal pressure and given an increased resistance to pressure to effectively prevent tank side walls from breaking, consequently making it possible to decrease the metal plates thicknesses, to achieve a cost reduction by the decreased thickness and to assure an improved heat exchange efficiency.

Owner:KEIHIN THERMAL TECH CORP

Cryogenic liquid storage tank

InactiveUS8857650B2Reduce thicknessQuality improvementBuilding roofsDomestic cooling apparatusInsulation layerReinforced concrete

Owner:IGLO CONTRACTORS

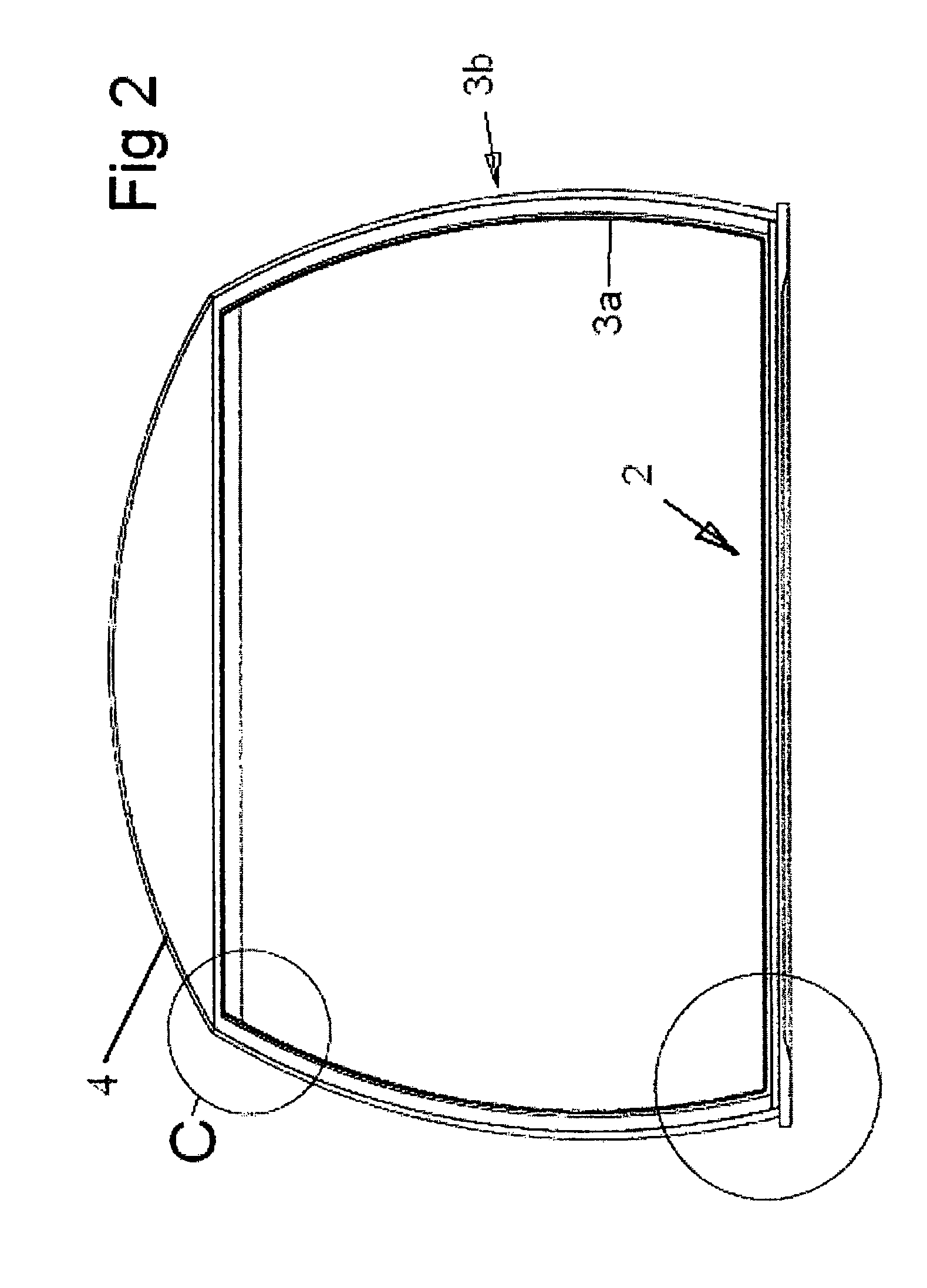

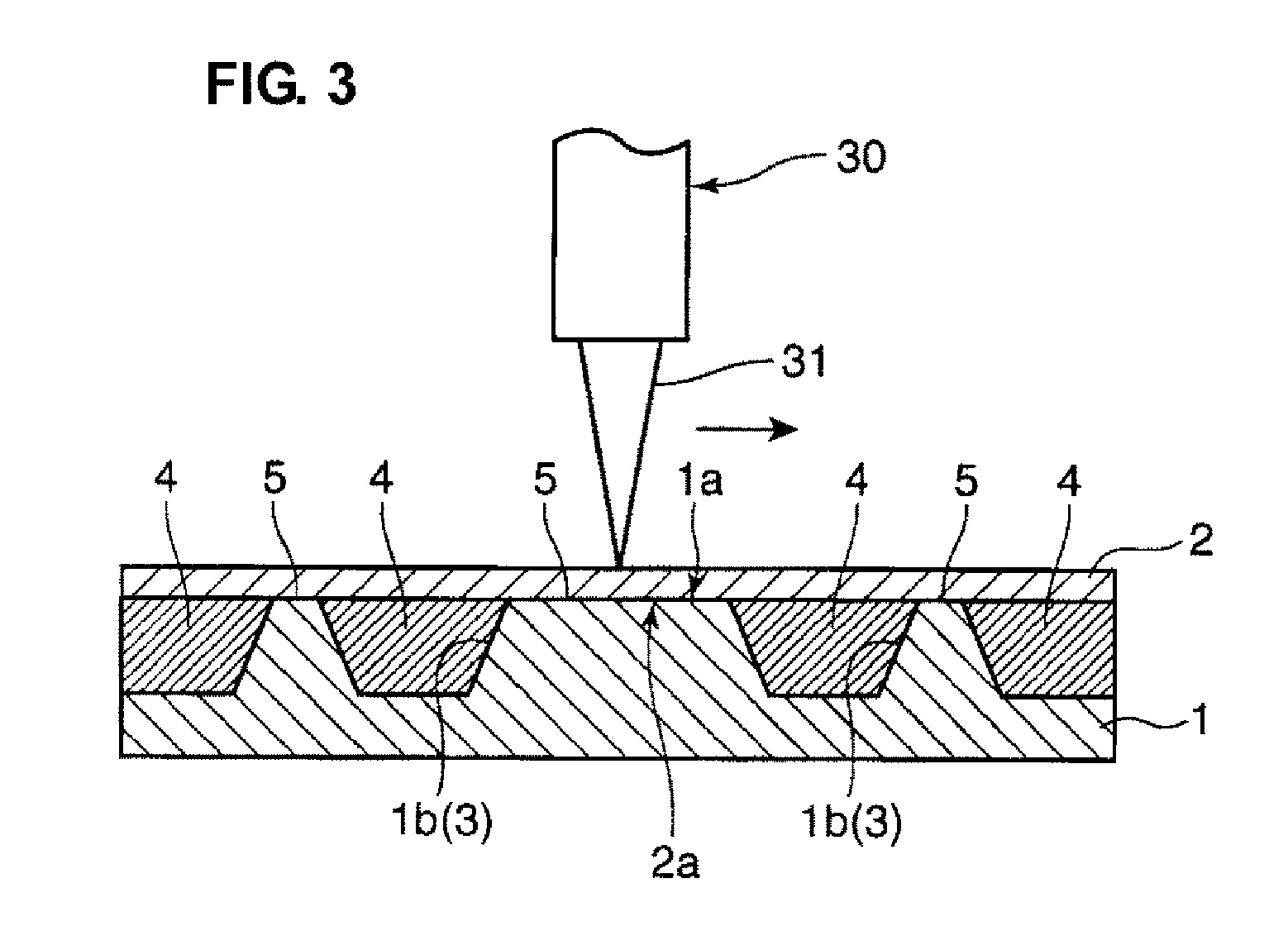

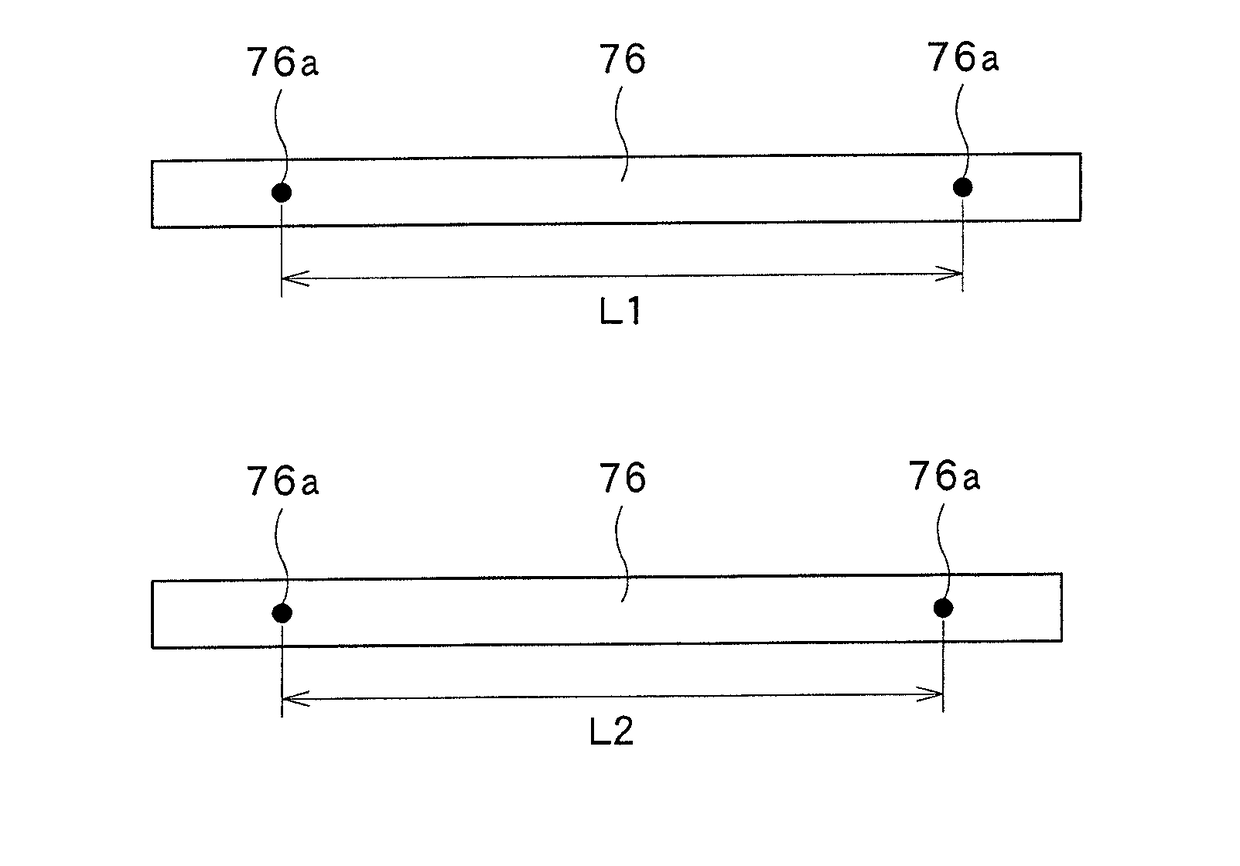

Metal plate, method of manufacturing metal plate, and method of manufacturing deposition mask by use of metal plate

ActiveUS9828665B2Reduced luminous efficiencySolve high precisionDecorative surface effectsVacuum evaporation coatingMeasurement pointHeat treated

The object of the present invention is to provide a metal plate capable of manufacturing a deposition mask in which dispersion of positions of through-holes is restrained. A thermal recovery rate is defined as parts per million of a difference a distance between to measurement points on a sample before a heat treatment and a distance therebetween after the heat treatment, relative to the distance therebetween before the heat treatment. In this case, an average value of the thermal recovery rates of the respective samples is not less than −10 ppm and not more than +10 ppm, and (2) a dispersion of the thermal recovery rates of the respective samples is not more than 20 ppm.

Owner:DAI NIPPON PRINTING CO LTD

Deposition mask package and deposition mask packaging method

ActiveUS20190237349A1Reduce thicknessReduce height of wallSolid-state devicesVacuum evaporation coatingElectrical and Electronics engineeringEngineering

A deposition mask package according to the present embodiment includes a receiving portion, a lid portion that faces the receiving portion, a deposition mask that is arranged between the receiving portion and the lid portion and has an effective region in which a plurality of through-holes is formed. The receiving portion has a first opposing surface facing the lid portion and a concave portion provided on the first opposing surface. The concave portion is covered by a first flexible film. The effective region of the deposition mask is arranged on the concave portion with the first flexible film interposed therebetween.

Owner:DAI NIPPON PRINTING CO LTD

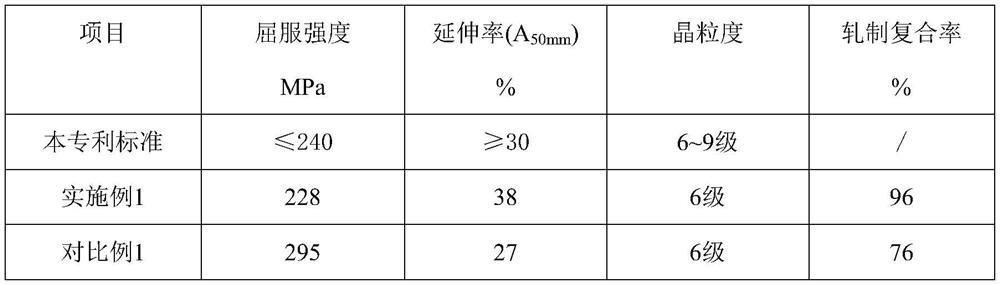

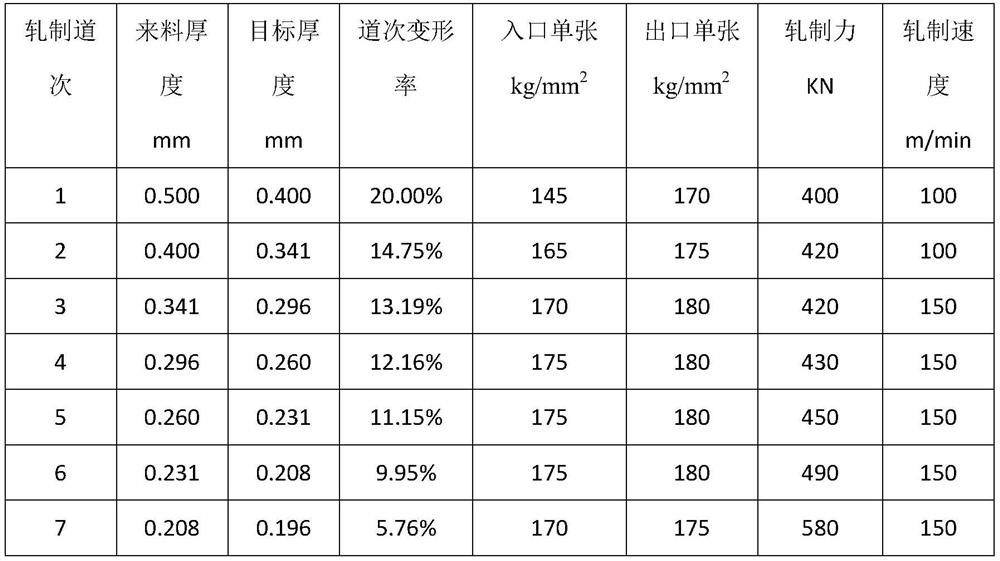

Preparation process method of wide ultrathin cold-rolled titanium strip coil for rolling bonding

ActiveCN112122382AExcellent overall performanceImprove compound rateMetal rolling arrangementsTitanium metalDissimilar metal

The invention relates to a preparation process method of a a wide ultrathin cold-rolled titanium strip coil for rolling bonding. The preparation process method comprises that a plate blank is preparedby adopting an EB furnace die casting slab ingot through process routes and parameters such as innovation, component design optimization, plate blank preparation, cold coiling rolling, heat treatment, leveling and shape correction and the like, the surface is machined by using a large integral cutterhead, a treatment method of first performing edge cutting and then performing annealing is adoptedafter cold rolling of a mother strip, a small-tension rolling control manner is adopted in the finished product rolling stage, finished product heat treatment is carried out in a long-time heat preservation and furnace cooling cover type annealing manner, and a rolling leveling method is selected to further improve the strip shape of the annealed strip coil; the width of the prepared cold-rolledtitanium strip coil can reach 1000 mm or above, the thickness can reach 0.1-0.3 mm, the strip shape is flat and straight, the comprehensive mechanical property is excellent, the rolling bonding rate with dissimilar metal is high, and meanwhile, the cost of the composite material titanium metal can be remarkably reduced.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

Mechanical seal

ActiveUS20160281856A1Prevents degradation and tearingMetal Thickness ReductionEngine sealsEngineeringMetal bellows

To provide a mechanical seal in which degradation or tearing of a bellows does not occur, the spring constant of the bellows is reduced, and the fluctuation in the load due to stretching and contracting of the bellows is reduced. An inside-type mechanical seal includes a sleeve fixed to a rotating shaft, and a cartridge fixed to a housing. A rotation-side sealing ring is provided to the sleeve. A fixed-side sealing ring, which slides against the rotation-side sealing ring, and a bellows for axially urging the fixed-side sealing ring is provided to the cartridge. The bellows is made from a metal; and the metal bellows has one end fixed to a case for holding the fixed-side sealing ring and another end fixed to the cartridge. The plate thickness of the metal bellows is set so as to be smaller than the plate thickness of the case or the cartridge.

Owner:EAGLE INDS

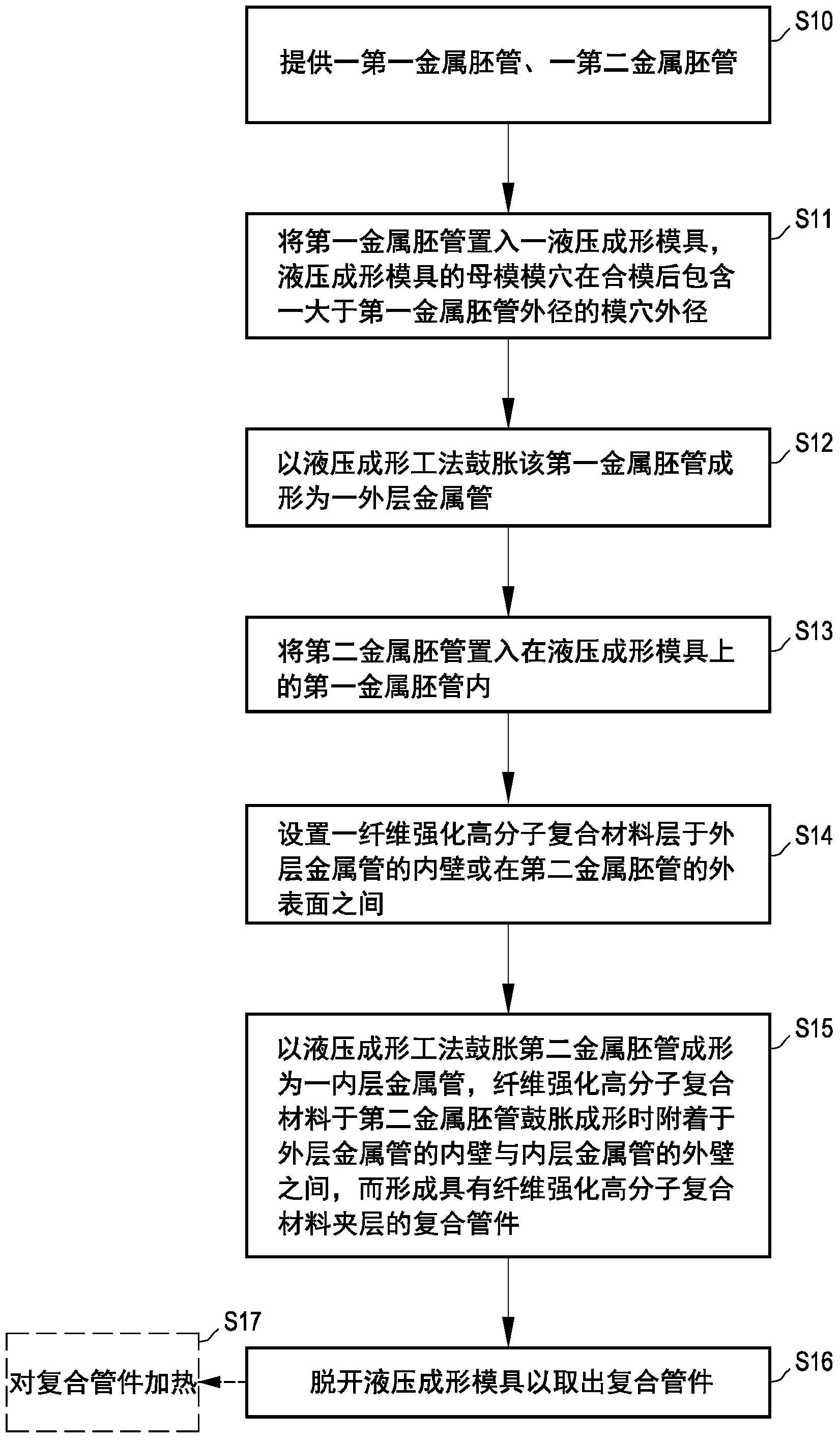

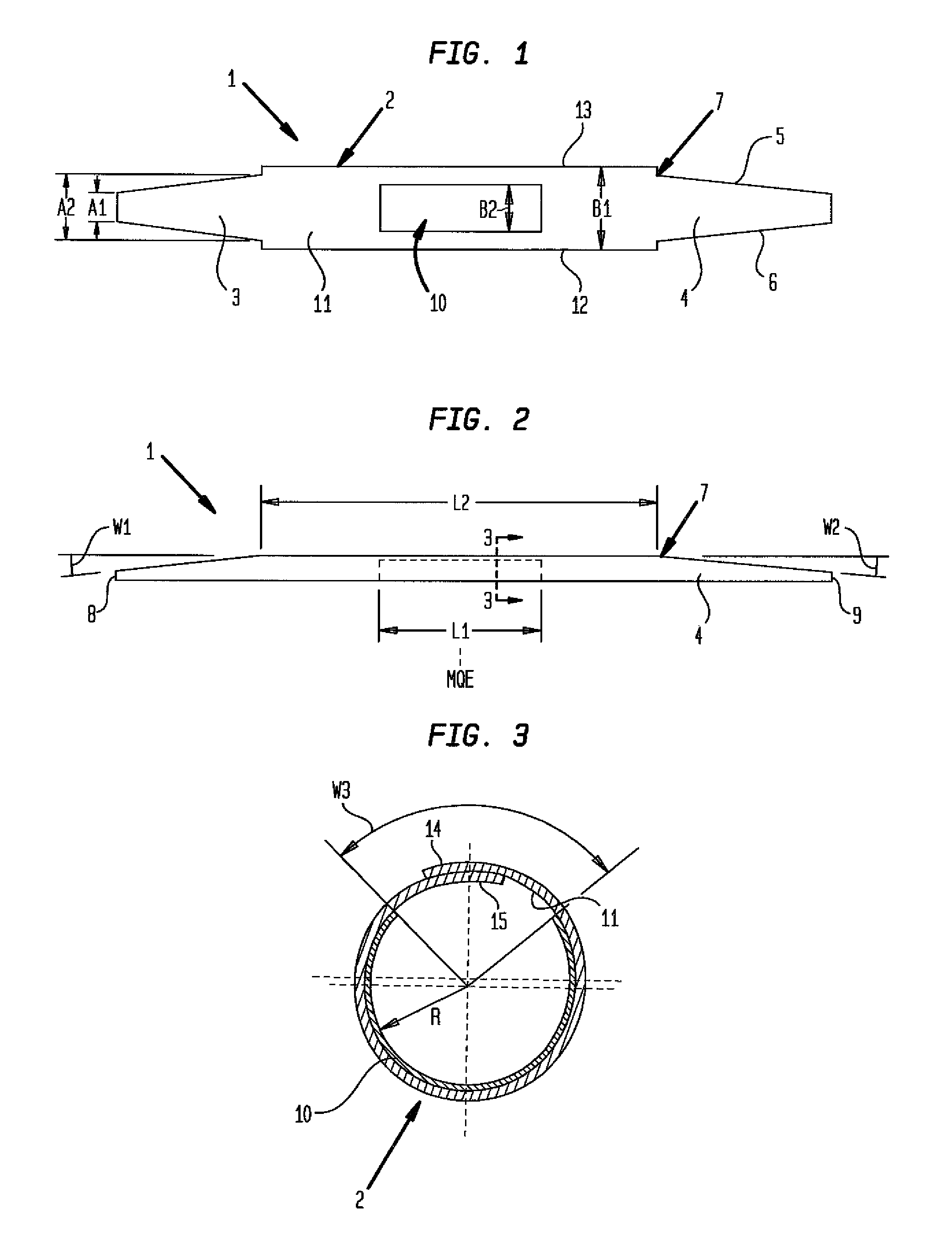

Tubing with sandwich layer made of fiber reinforced polymer composite material and method for manufacturing same

ActiveCN103894501AOvercoming the vulnerability to scratches caused by foreign objectsOvercome the disadvantage of crackingRigid pipesFiberMaterials science

A tubing with a sandwich layer made of fiber reinforced polymer composite material and a method for manufacturing same. The method comprises the step of providing a first metallic billet pipe, a second metallic billet pipe, of which the outer diameter is smaller than or equal to the inner diameter of the first metallic billet pipe, placing the first metallic billet pipe into a hydraulic forming die, of which the master die hole has a greater die hole outer diameter than the outer diameter of the first metallic billet pipe after the die is closed, swelling the first metallic billet pipe to form a first outer metallic pipe through hydraulic forming method, placing the second metallic billet pipe into the first metallic billet pipe, arranging the fiber reinforced polymer composite material layer on the inner wall of the outer metallic pipe or between the outer surfaces of the second metallic billet pipe, swelling the second metallic billet pipe to form an inner metallic pipe,and demoulding the to take out the composite tubing.

Owner:METAL INDS RES & DEV CENT

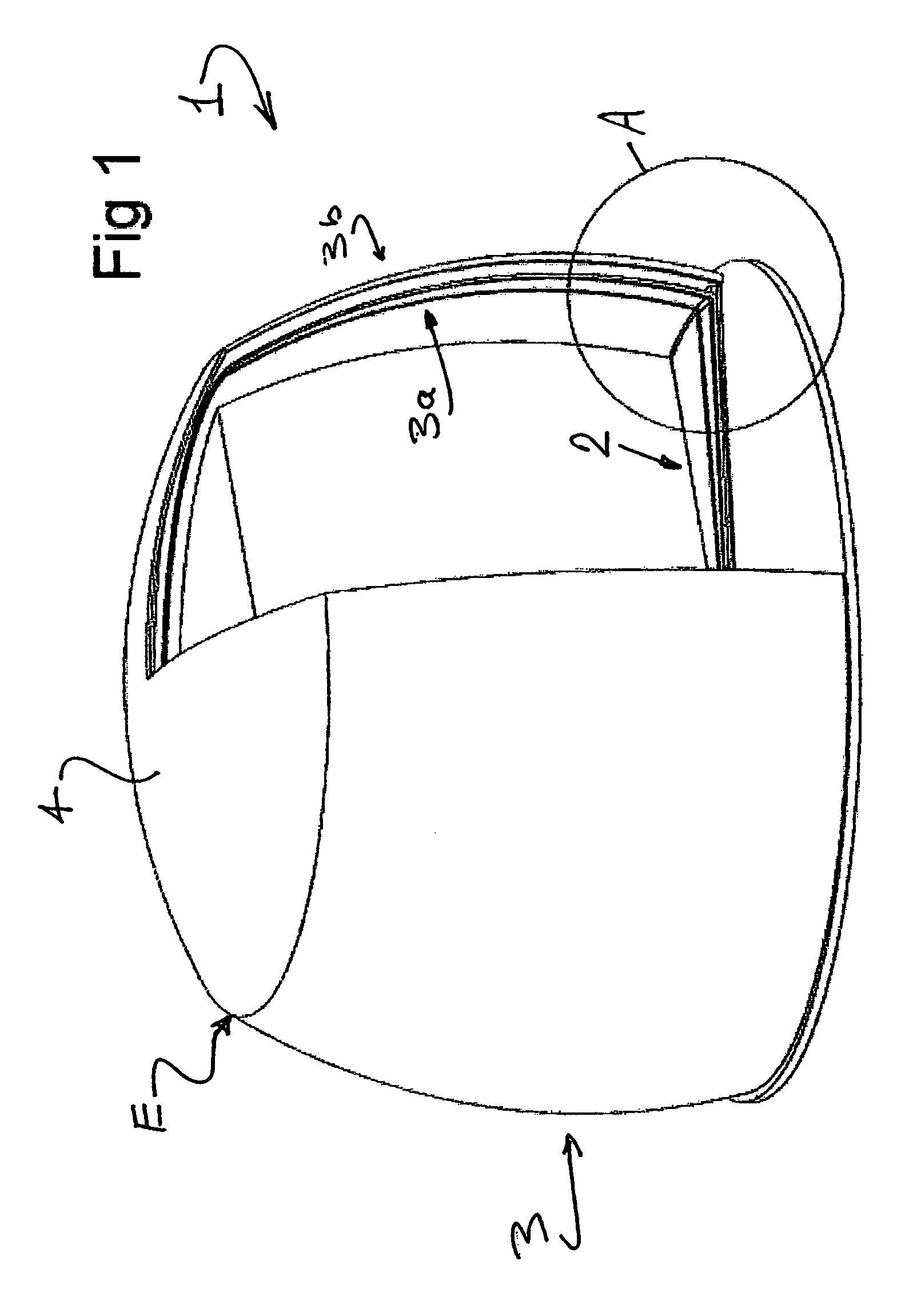

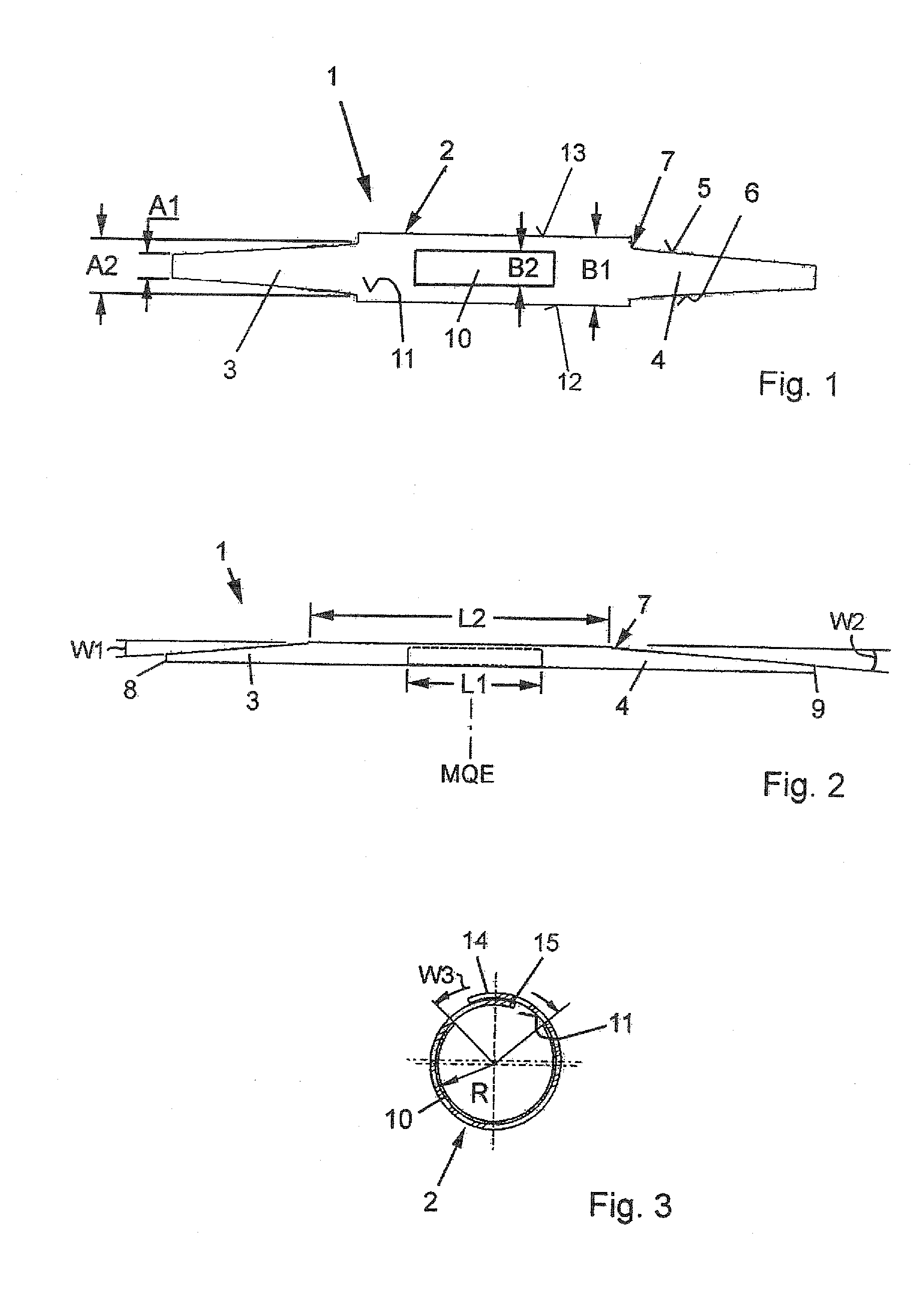

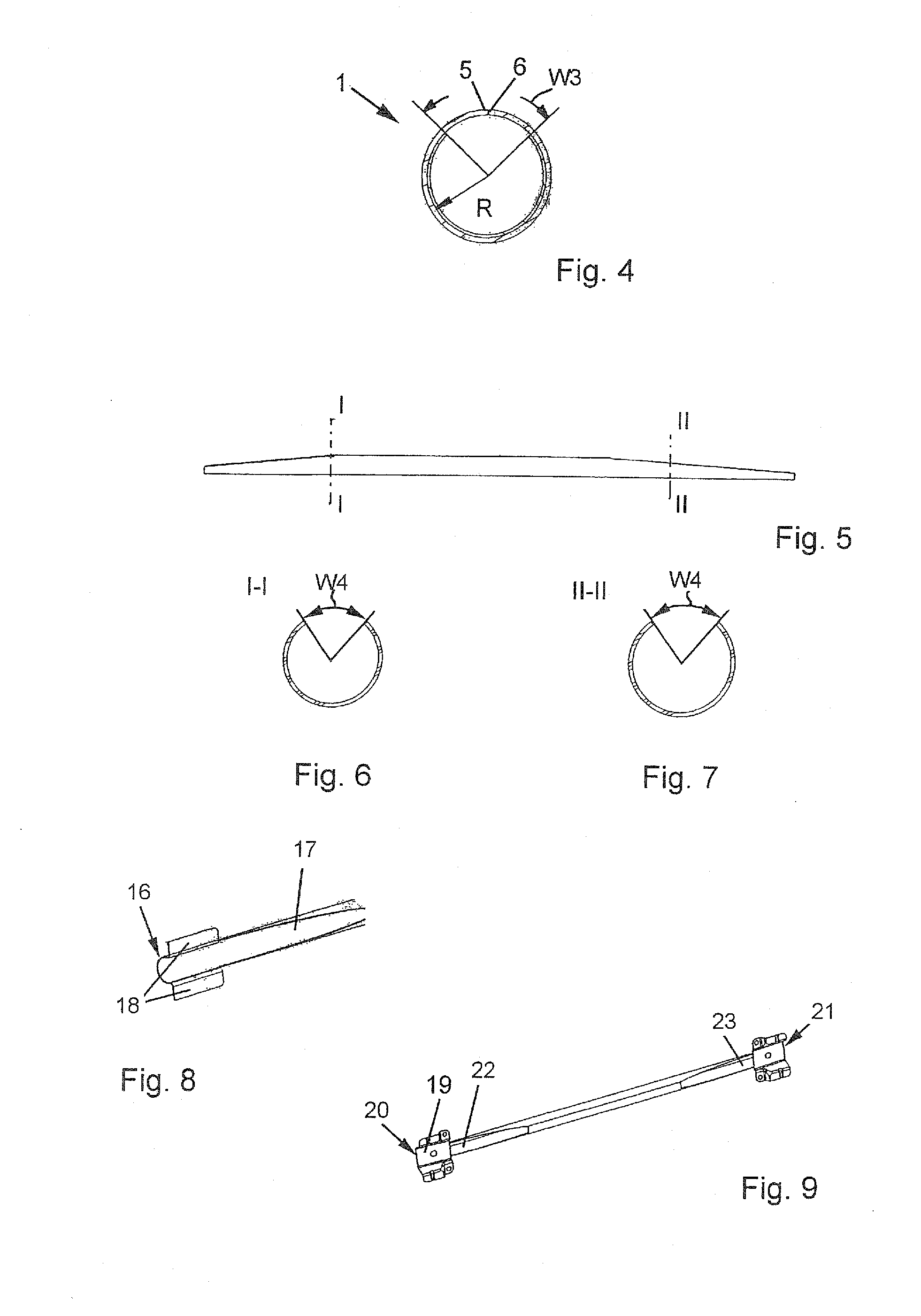

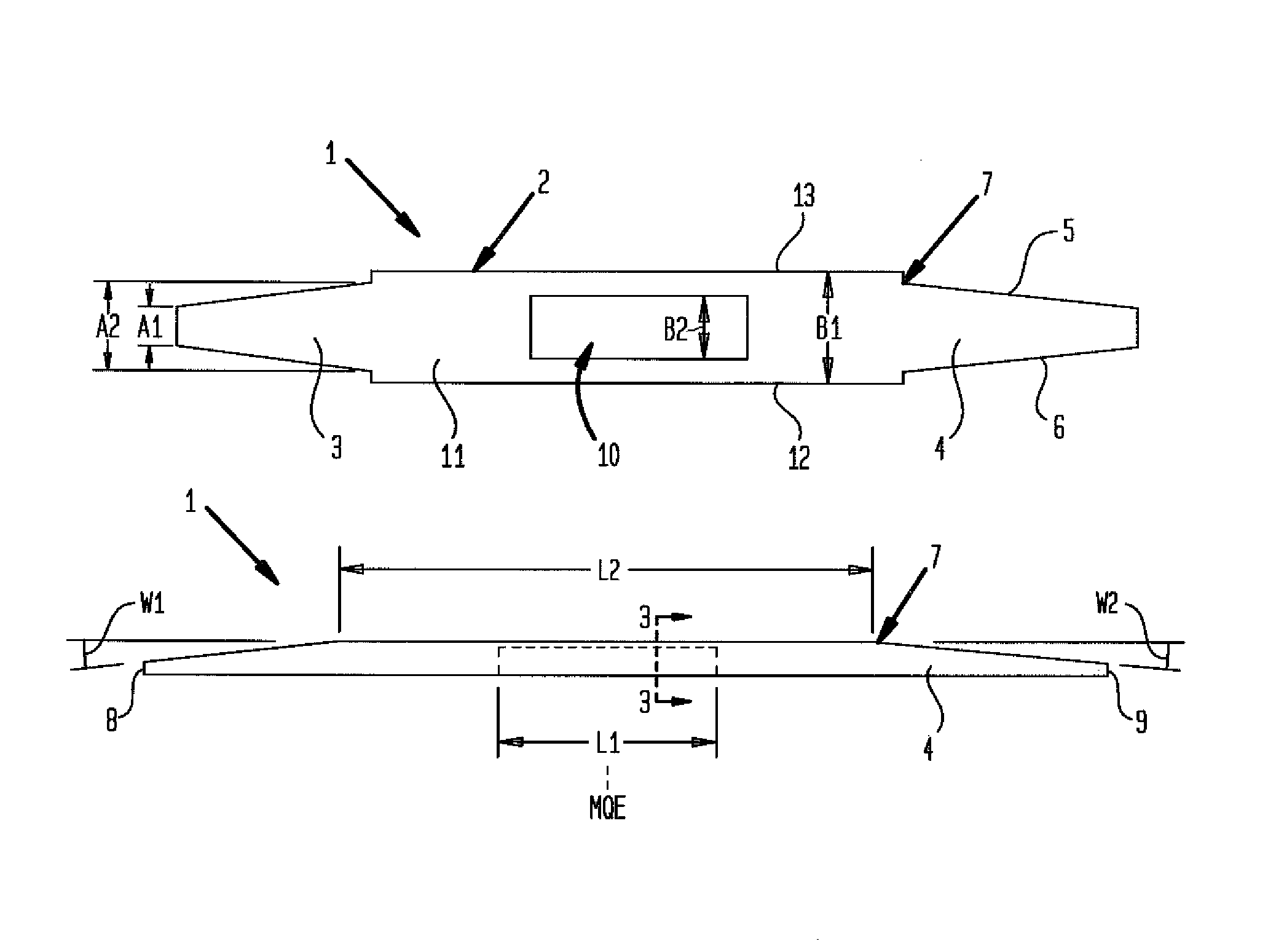

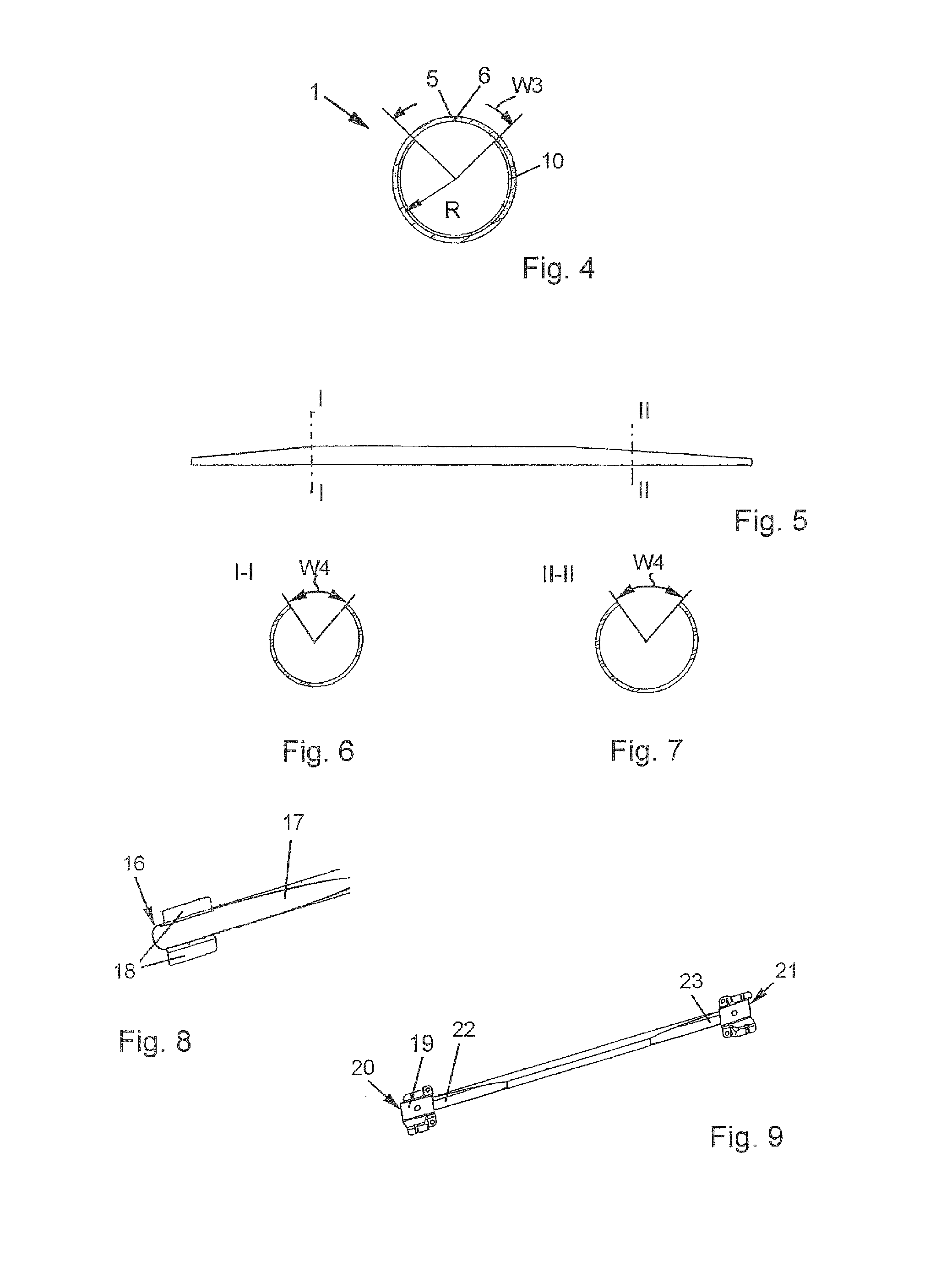

Door impact beam

InactiveUS20100230997A1Metal Thickness ReductionReduce weightMonocoque constructionsVehicle bodiesEngineeringMetal sheet

A door impact beam for a motor vehicle includes a formed metal sheet defined by a longitudinal axis and having a tubular cross section which has a closed circumference in a center portion of the metal sheet, and is configured with open circumference at both end portions of the metal sheet which adjoin the center portion in a direction of the longitudinal axis. Each end portion is defined by an opening angle which continuously increases from the center portion to respective ends of the end portions.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

Can end

This invention relates to a can end (1) providing improved tab access for a consumer. A further aspect of the present invention relates to a container incorporating such a can end (1). The can end (1) includes a moveable portion (30) located beneath all or part of the handle (20b) of the can end, with the moveable portion deformable from an ‘up’ position (30a) to a ‘down’ position (30b) to provide increased tab access for a consumer. The can end (1) is provided with one or more downwardly inclined annular steps (31), which has been found to greatly increase the force required to deform the panel from the ‘down’ to the ‘up’ position, therefore resulting in a far greater likelihood of the consumer receiving a container (40) incorporating the can end (1) with the moveable portion (30) in the ‘down’ position (30b), thereby facilitating tab access.

Owner:CROWN PACKAGING TECH

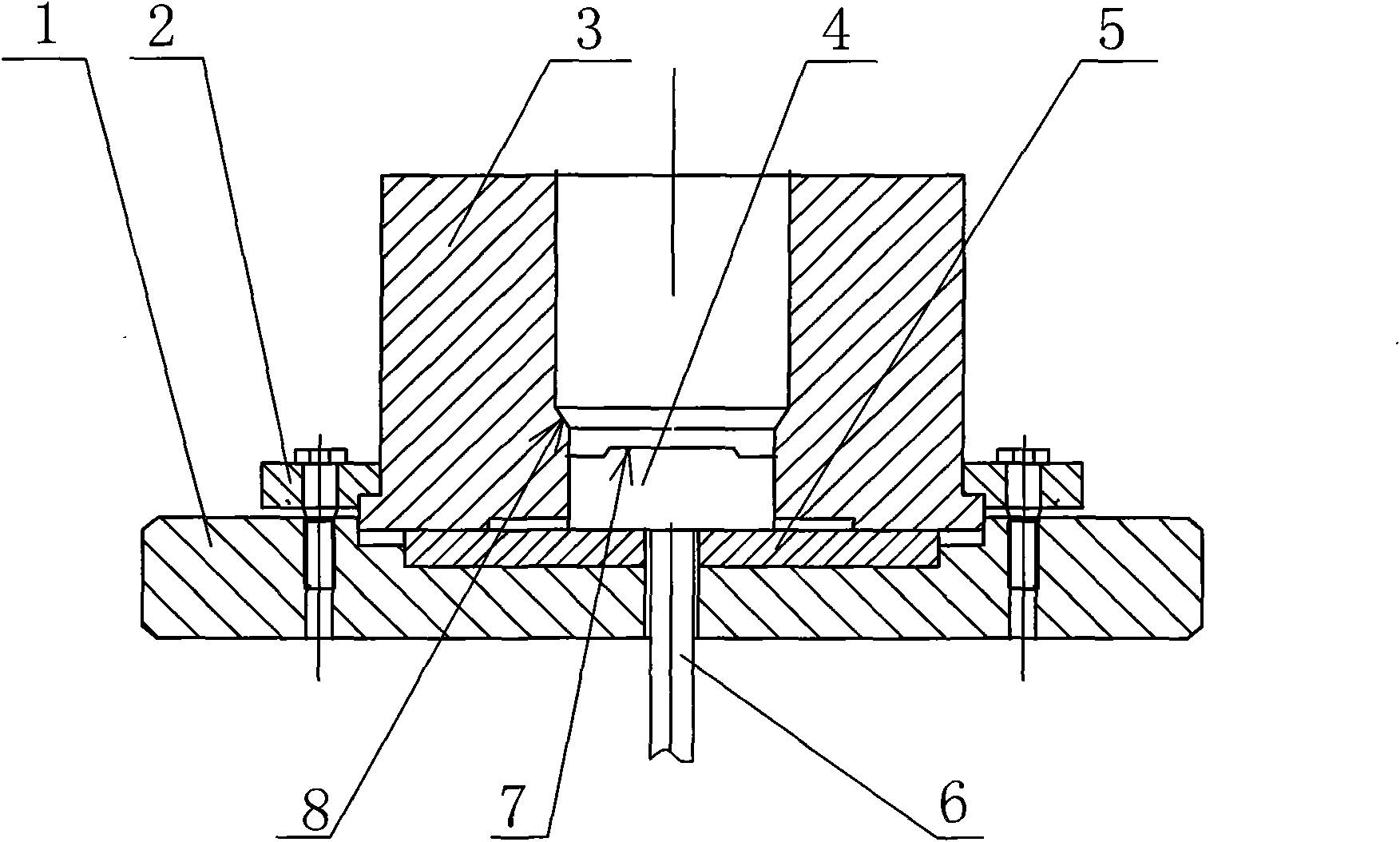

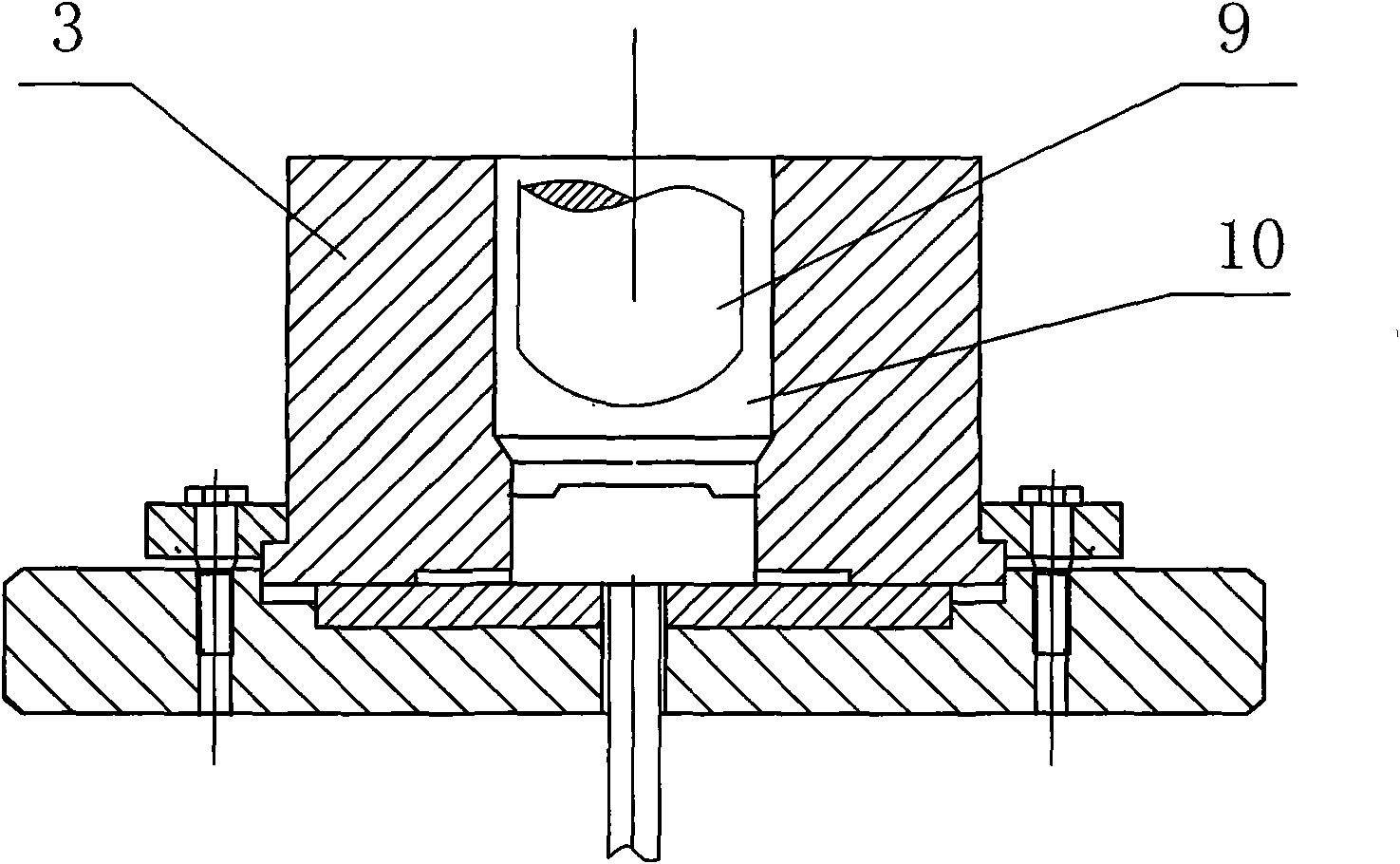

Specially-shaped extruding female die of aluminium alloy seamless gas cylinder

InactiveCN102114497AMetal Thickness ReductionAddress outstanding deficienciesExtrusion diesGas cylinderSharp angle

The invention discloses a specially-shaped extruding female die of an aluminium alloy seamless gas cylinder, which comprises a bottom plate, an edge pressing ring, a specially-shaped backward extruding female die, an ejection block, a quenching hard plate and an ejection rod, wherein the specially-shaped backward extruding female die is in fit with the ejection block arranged on the bottom of the specially-shaped backward extruding female die to form a specially-shaped backward extruding female die semi-closed cavity, of which the bottom is a stepped variable section and which is provided with a sloped outline circumferentially; the quenching hard plate is arranged on the bottom plate; the combined ejection block and the specially-shaped backward extruding female die are placed on the quenching hard plate and connected to the bottom plate fixedly through the edge pressing ring and an edge pressing bolt sleeved on the specially-shaped backward extruding female die; and the ejection rod passes through the bottom plate and the quenching hard plate sequentially and is connected to the ejection block to form the specially-shaped backward extruding die of the aluminium alloy seamless gas cylinder. In the forming process of backward extrusion drawing of the gas cylinder, by the unique structural design of the specially-shaped extruding female die of the aluminium alloy seamless gas cylinder, the thickness of the metal of a sharp angle part at an edge of the bottom is reduced, the volume of the metal flowing to the centre of the bottom is reduced, the defect that the centre of the bottom of a cup body of the gas cylinder protrudes is solved, the process of subsequent processing of a protrusion on the bottom is cancelled, and the processing cost of a product is reduced.

Owner:沈阳中复科金压力容器有限公司

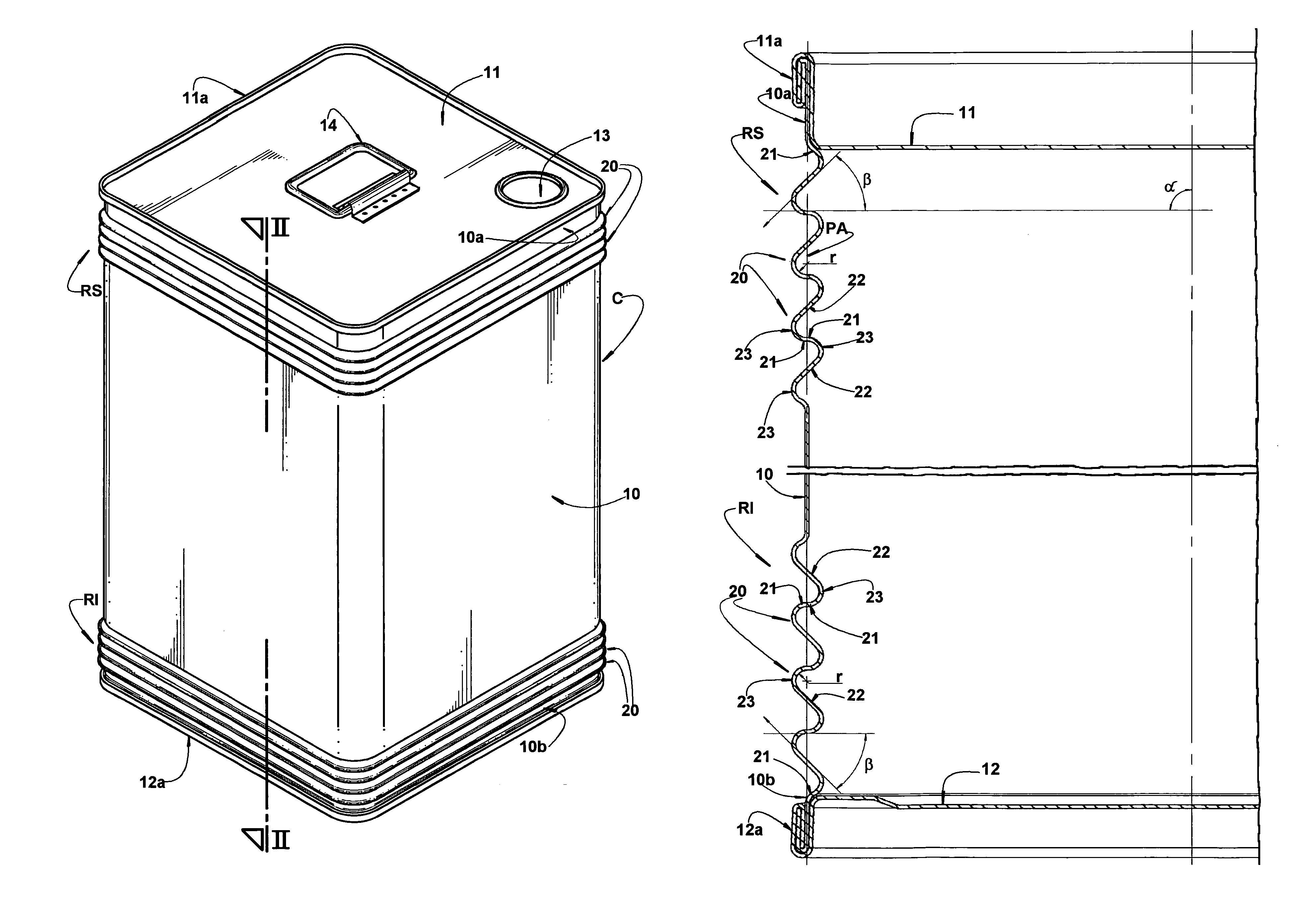

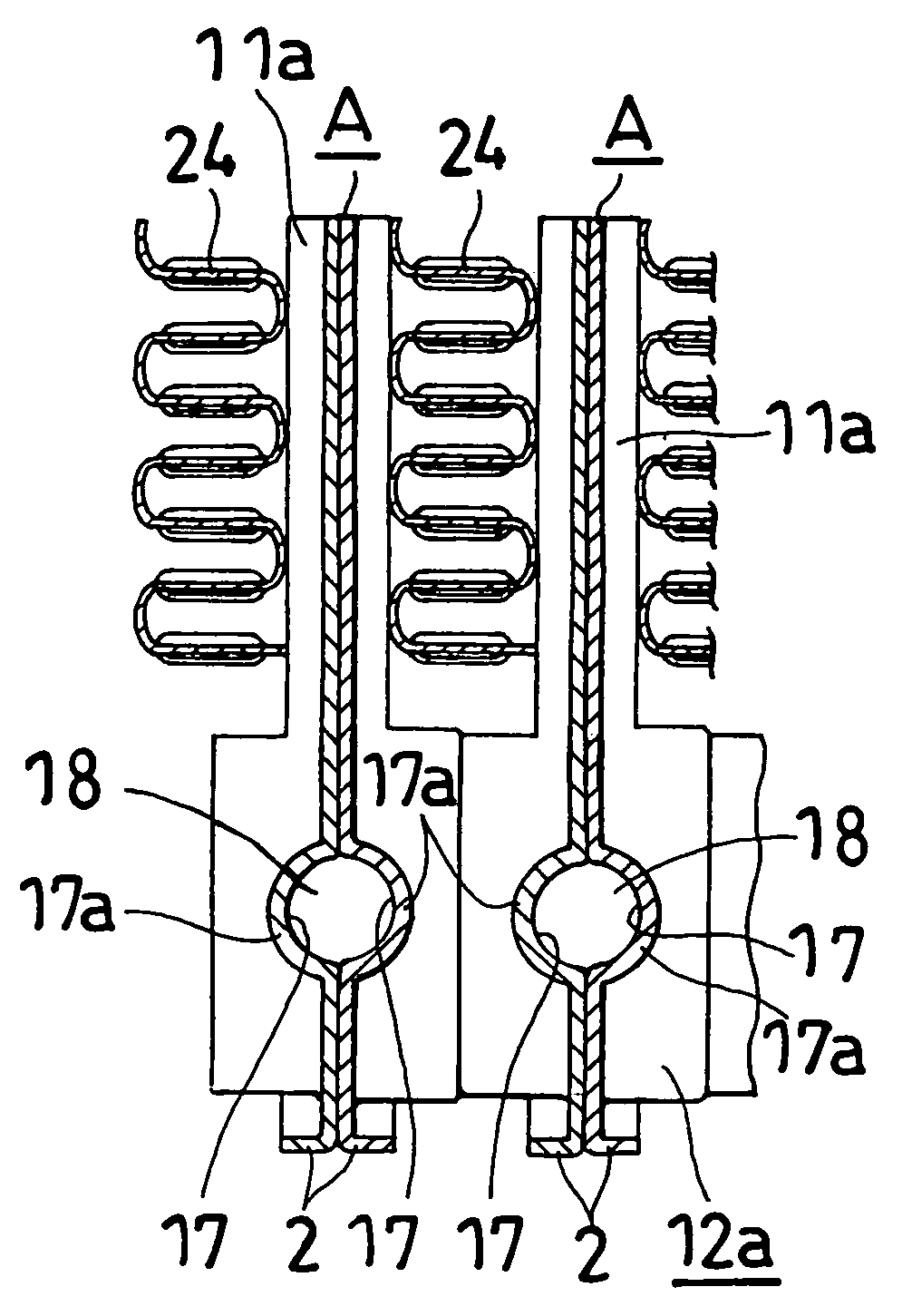

Metal sheet container for transporting dangerous products

InactiveUS8800807B2Avoid tensionImpairing required stacking strengthLarge containersRigid containersIn planeMetal sheet

Owner:BRASILATA S A EMBALAGENS METALICAS

Layered heat exchangers

InactiveUS20050230090A1Increased pressure lossReduce drynessReinforcing meansIce productionInternal pressureEngineering

A layered heat exchanger, for example for use for motor vehicle coolers. To provide a turn portion in the heat exchanger for changing flow direction of a fluid flowing zigzag through a fluid circuit, a metal plate is provided at the upper or lower ends of a partition ridge with a fluid flow direction changing passage forming caved portion having a bottom wall of circular-arc cross section. Front and rear upper or lower tank portions are held in communication with each other through a fluid flow direction changing passage of approximately circular cross section and formed by the caved portions opposed to each other. The turn portion is diminished in stress concentrated thereon due to fluid internal pressure and given an increased resistance to pressure to effectively prevent tank side walls from breaking, consequently making it possible to decrease the metal plates thicknesses, to achieve a cost reduction by the decreased thickness and to assure an improved heat exchange efficiency.

Owner:KEIHIN THERMAL TECH CORP

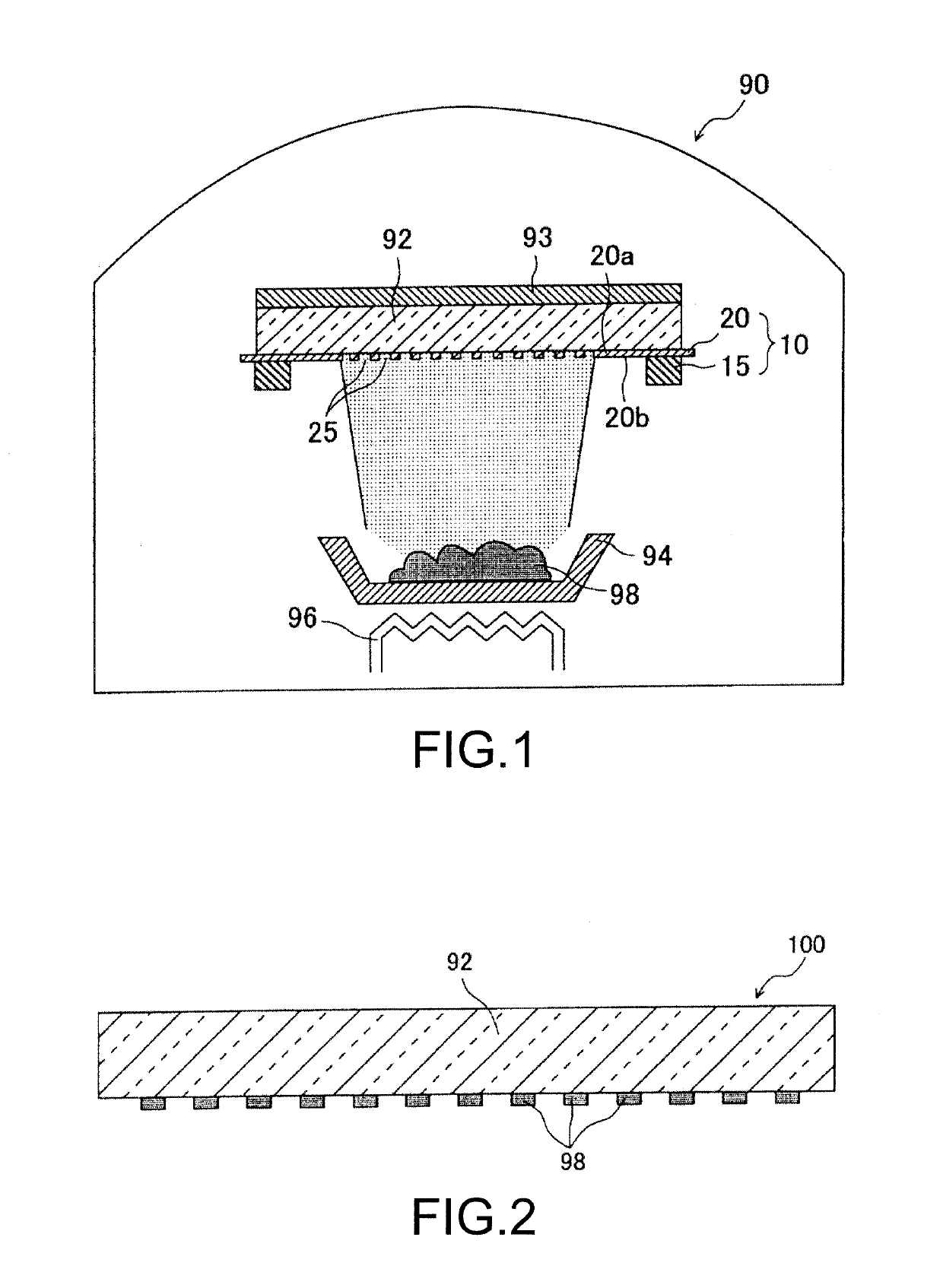

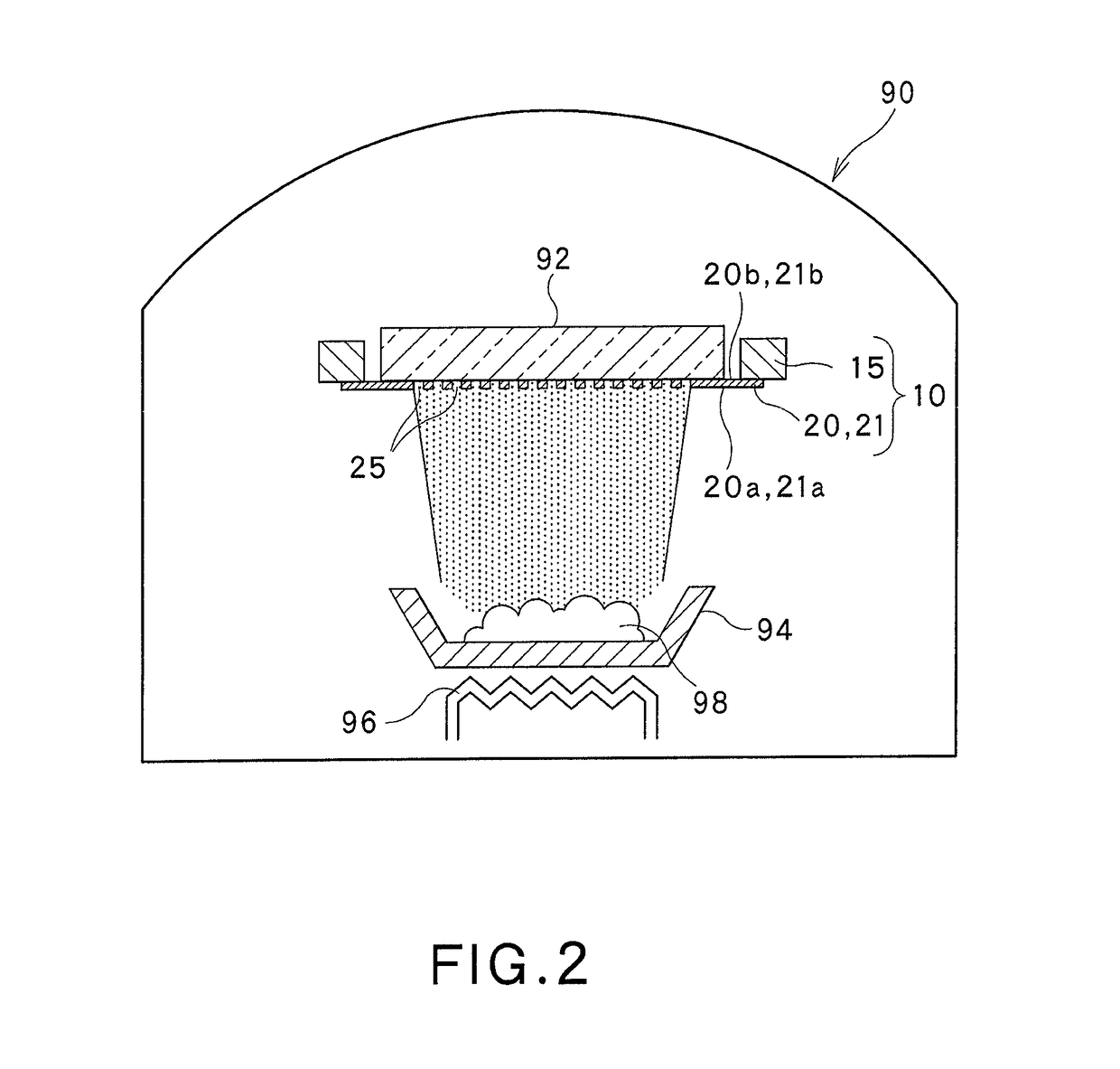

Reaction apparatus

InactiveUS20070217970A1Maintain strengthMetal Thickness ReductionHydrogenChemical industryEngineeringPerpendicular direction

Disclosed is a reaction apparatus, comprising a reaction container to receive a supply of a reactant and to cause a reaction of the reactant supplied thereto, wherein the reaction container comprises a hollow box member having a first plate wherein a supplying passage of the reactant is formed, a second plate opposite to the first plate, and a third plate provided continuously with edges of the first and second plates, at least one partition plate which is disposed to partition a space inside the box member and to form a reaction passage through which the reactant flows, the partition plate or each of the partition plates including a diaphragm portion provided substantially in a perpendicular direction to the second plate and a joint portion provided at an end of the diaphragm portion substantially perpendicularly thereto, and the joint portion being joined to an inner surface of the second plate.

Owner:CASIO COMPUTER CO LTD

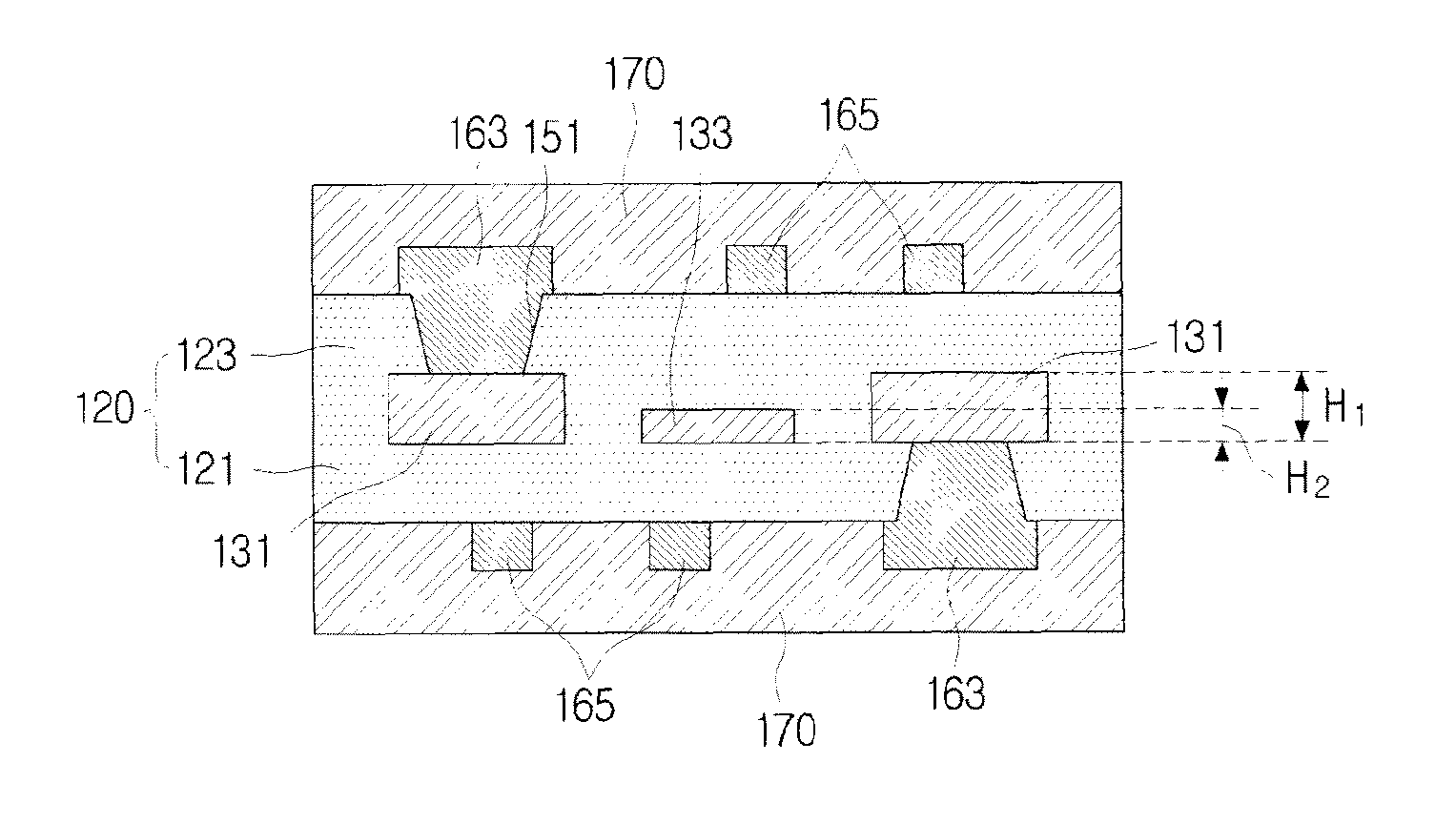

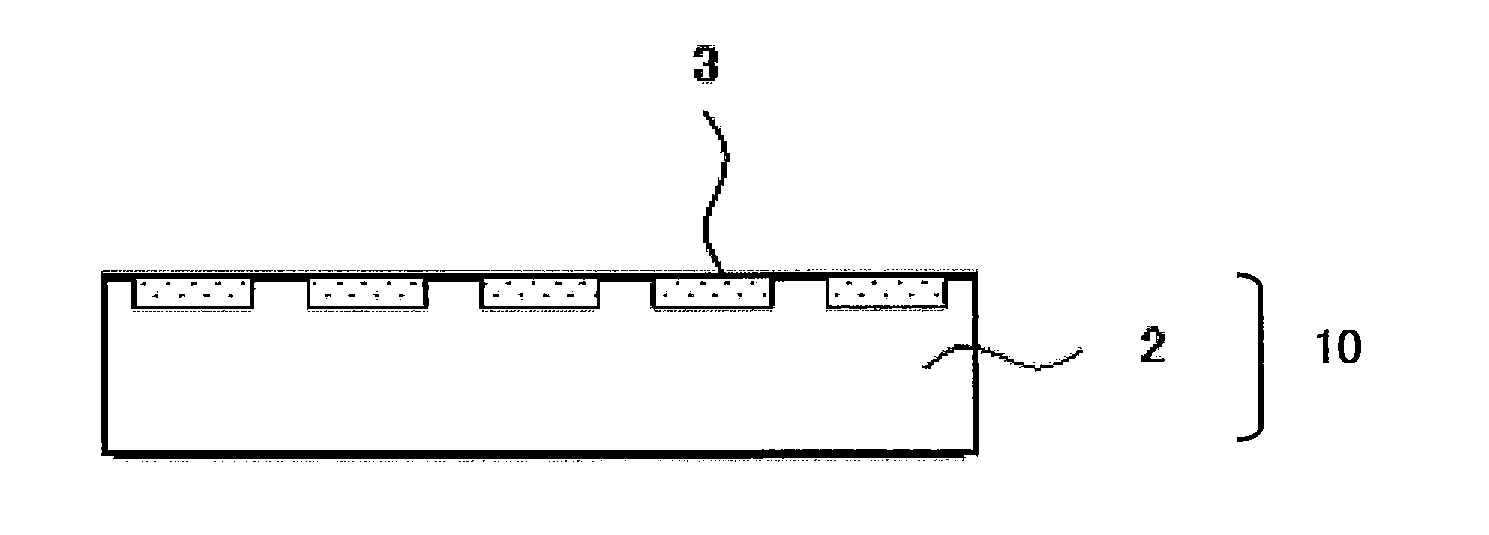

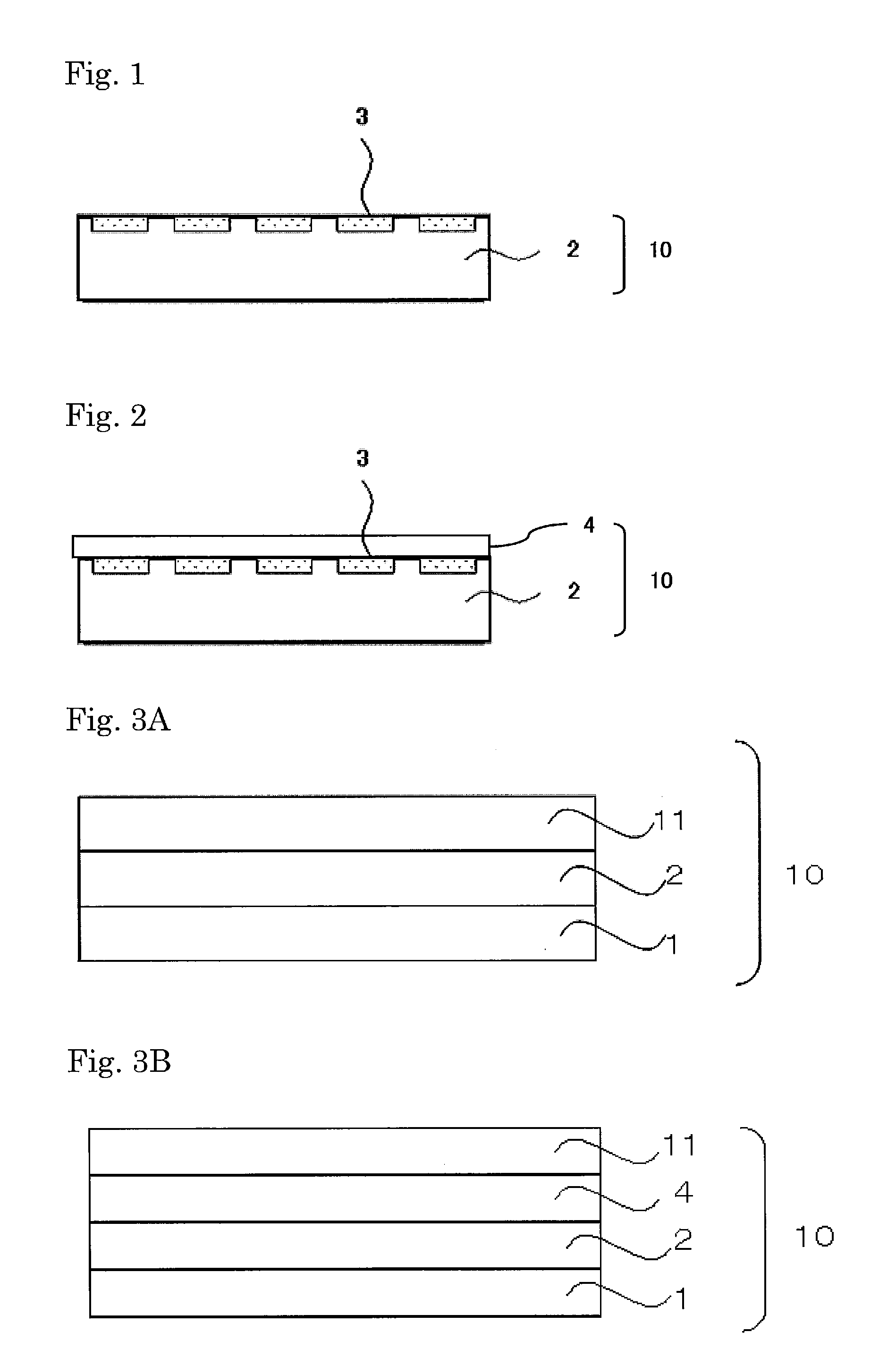

Multi-layered printed circuit board and manufacturing method thereof

InactiveUS20130146337A1Avoid it happening againMetal Thickness ReductionPrinted circuit aspectsConductive material chemical/electrolytical removalInsulation layerEngineering

A multi-layered printed circuit board and a method of manufacturing the multi-layered printed circuit board are disclosed. The multi-layered printed circuit board in accordance with an embodiment of the present invention includes: an insulation layer; an inner-layer pad disposed inside the insulation layer; an inner-layer circuit wiring disposed inside the insulation layer and formed to be thinner than that of the inner-layer pad; a via connected with the inner-layer pad by penetrating the insulation layer; and an outer-layer circuit wiring formed on an outside surface of the insulation layer.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Joining structure and method of metal works

InactiveUS8981249B2Less limitationThin thicknessExhaust apparatusAdhesive processes with adhesive heatingEngineeringMetal working

Owner:MAZDA MOTOR CORP

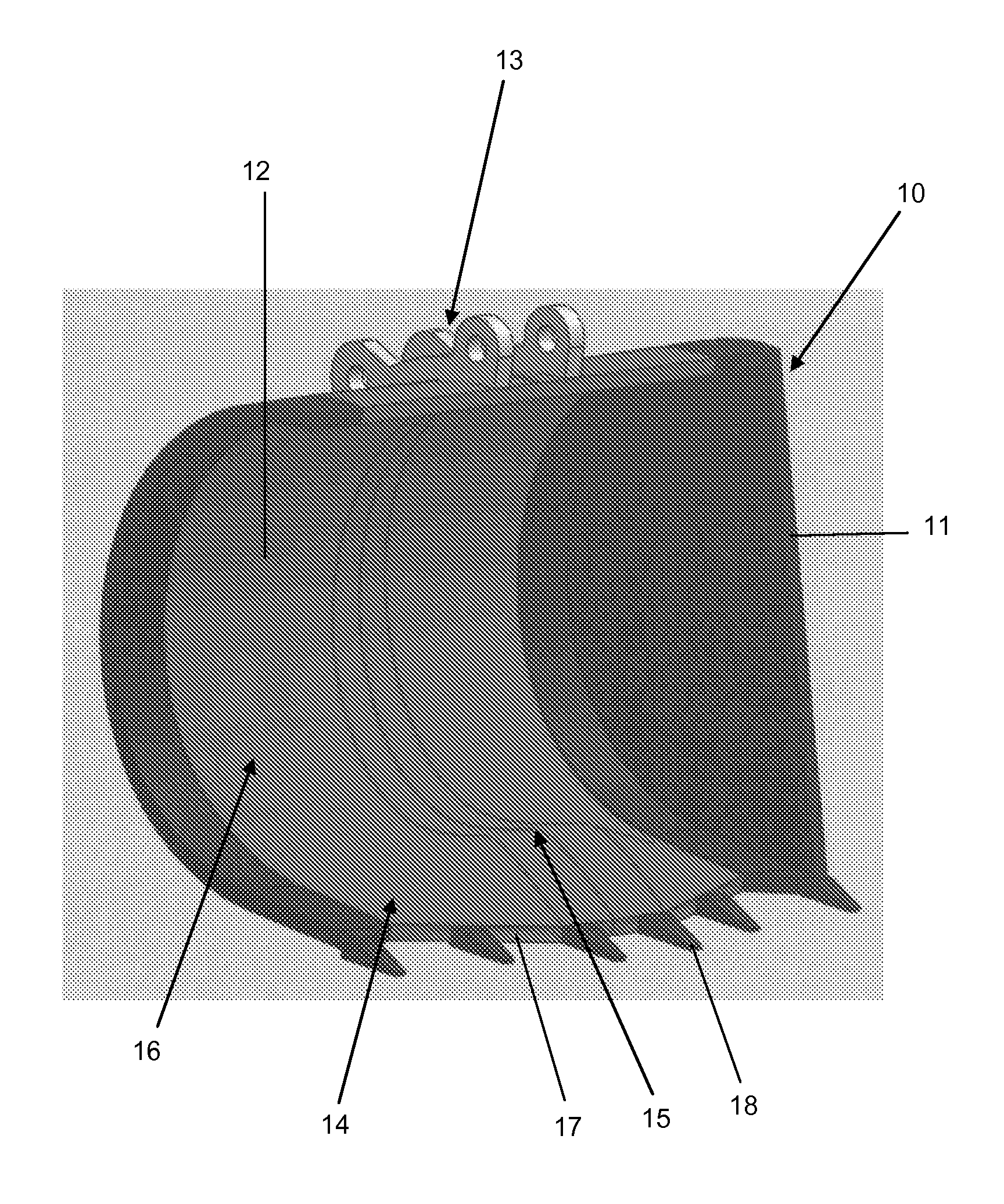

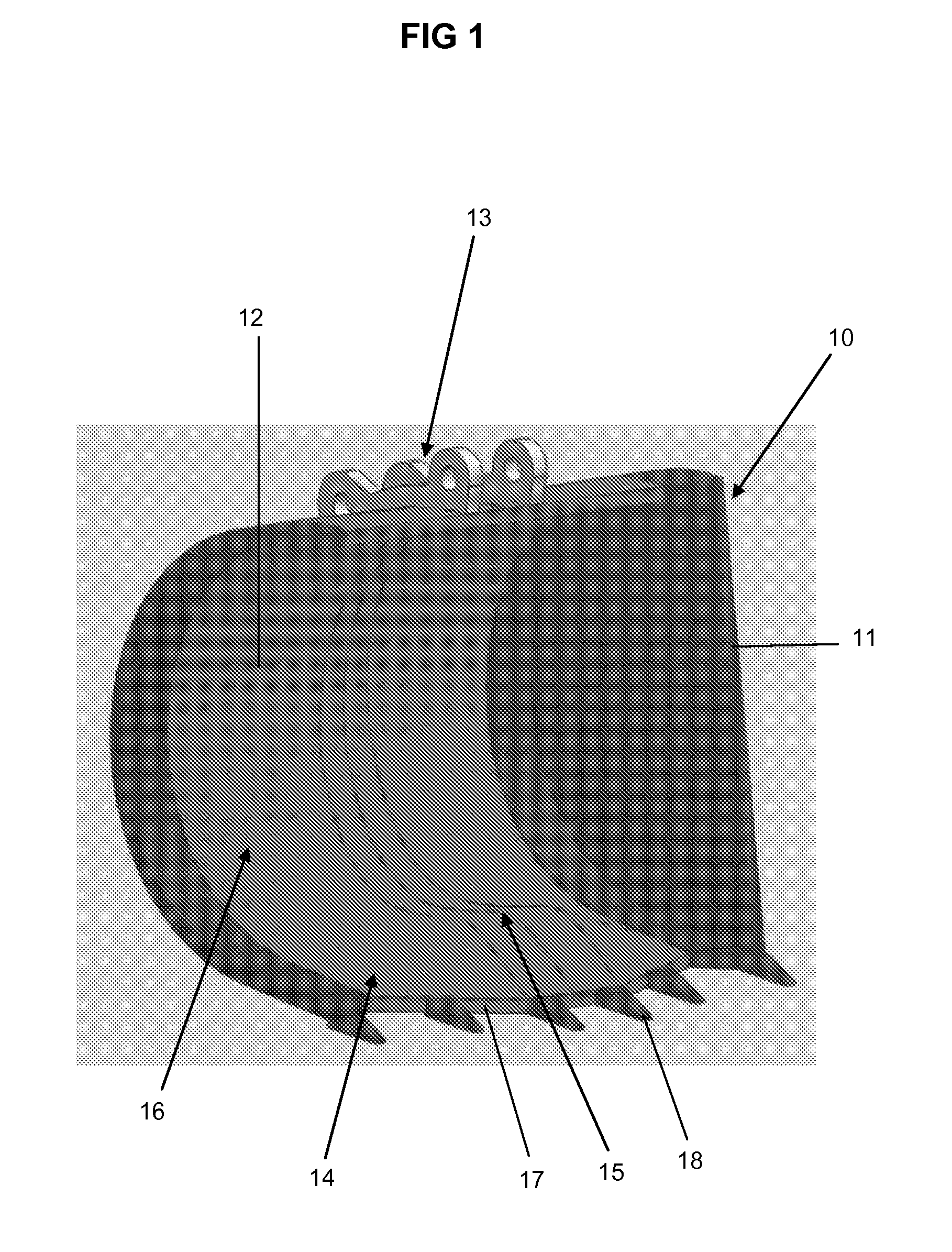

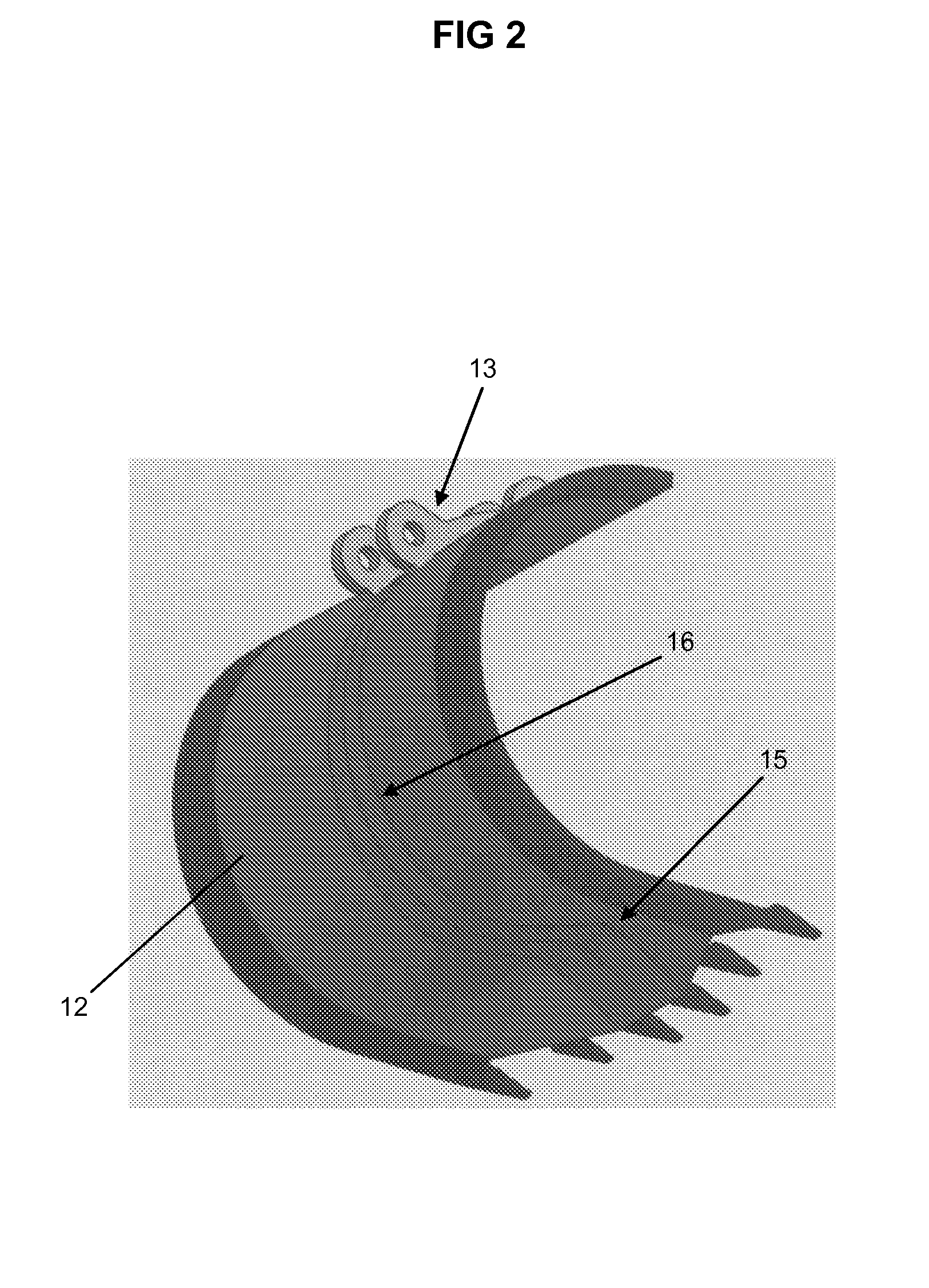

Excavator bucket

ActiveUS20150275467A1Metal Thickness ReductionReduce thicknessMechanical machines/dredgersEngineeringExcavator

The invention is directed to a bucket for an excavator or loader and includes a base wall having a side with a substantial or partly concave shape, the side with the substantial or partly concave shape has a front section that is raised, flat or concave and a rear section that has a concave arc. The base wall side has a discontinuous curve from the front section to the rear section. The bucket has two side walls spaced apart by the base wall. The bucket has a mounting mechanism for mounting the bucket to the excavator or loader. The raised, flat or concave front section assists in retaining excavated material within the bucket.

Owner:SPADEBLADE

Method of fabricating connector terminals

InactiveUS20150188273A1Avoid complex processPerformance requirementContact member manufacturingElectrically conductive connectionsEngineeringMetal sheet

A method of fabricating connector terminals, includes (a) preparing a single electrically conductive metal sheet including a plurality of pre-terminals, and a plurality of carriers connecting adjacent pre-terminals to each other, each of the pre-terminals having at one end thereof in a length-wise direction thereof an elastically deformable contact portion, and at the other end in the length-wise direction a first area, a pitch between adjacent contact portions being unequal to a pitch between adjacent first areas, (b) folding each of the first areas around a line extending in a length-wise direction thereof to thereby form a male tab having a predetermined thickness, and (c) removing the carriers out of the metal sheet.

Owner:DAIICHI SEIKO CO LTD

Metal plate

InactiveUS20180010231A1Reduced luminous efficiencySolve high precisionVacuum evaporation coatingSputtering coatingMeasurement pointThermal recovery

The object of the present invention is to provide a metal plate capable of manufacturing a deposition mask in which dispersion of positions of through-holes is restrained. A thermal recovery rate is defined as parts per million of a difference a distance between to measurement points on a sample before a heat treatment and a distance therebetween after the heat treatment, relative to the distance therebetween before the heat treatment. In this case, an average value of the thermal recovery rates of the respective samples is not less than −10 ppm and not more than +10 ppm, and (2) a dispersion of the thermal recovery rates of the respective samples is not more than 20 ppm.

Owner:DAI NIPPON PRINTING CO LTD

Heat ray shielding material

InactiveUS20140186608A1Good visible light transmittanceEasy to peelFilm/foil adhesivesSynthetic resin layered productsTransmittanceRubbing

A heat ray shielding material having a metal particles-containing layer that contains at least one type of metal particles, in which the thickness of the metal particles-containing layer is from 10 nm to 80 nm, the metal particles contain tabular metal particles having a hexagonal to circular form in a ratio of at least 60% by number, and the mean thickness of the hexagonal to circular, tabular metal particles is at most 14 nm has good visible light transmittance, heat shieldability (solar reflectance), surface profile and rubbing resistance.

Owner:FUJIFILM CORP

Door impact beam

InactiveUS8267463B2Metal Thickness ReductionReduce weightMonocoque constructionsVehicle bodiesMetal sheetCar door

A door impact beam for a motor vehicle includes a formed metal sheet defined by a longitudinal axis and having a tubular cross section which has a closed circumference in a center portion of the metal sheet, and is configured with open circumference at both end portions of the metal sheet which adjoin the center portion in a direction of the longitudinal axis. Each end portion is defined by an opening angle which continuously increases from the center portion to respective ends of the end portions.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

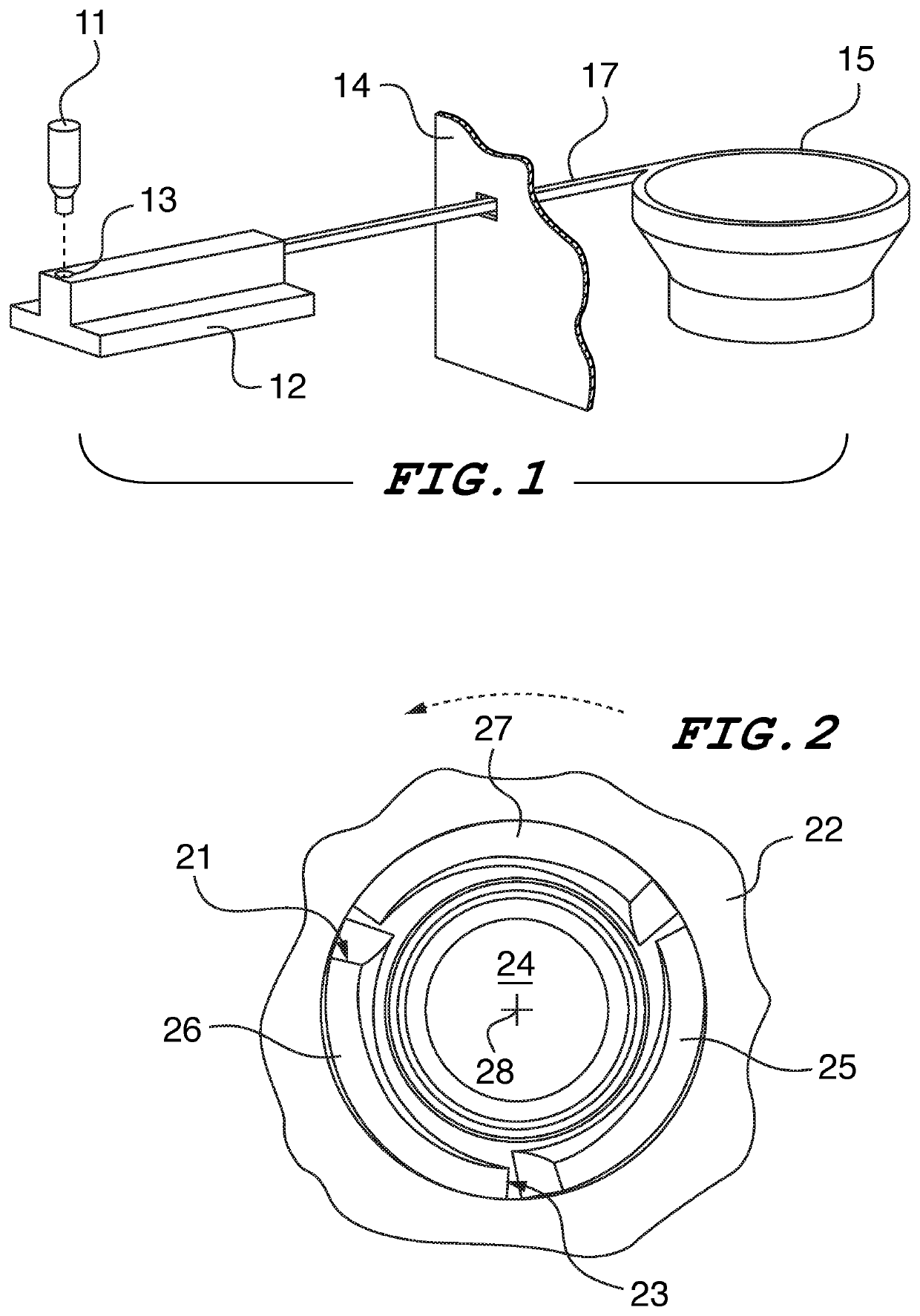

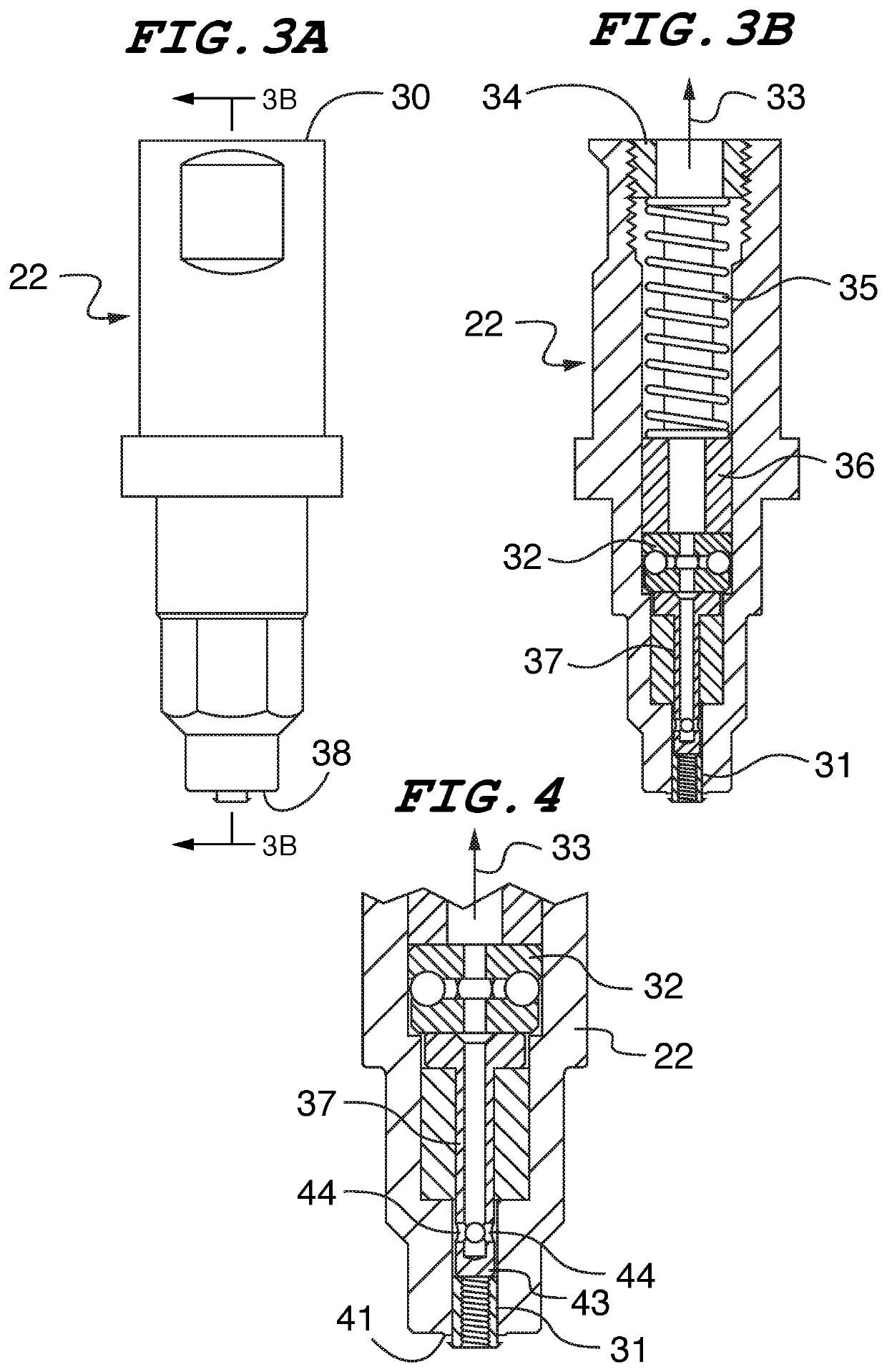

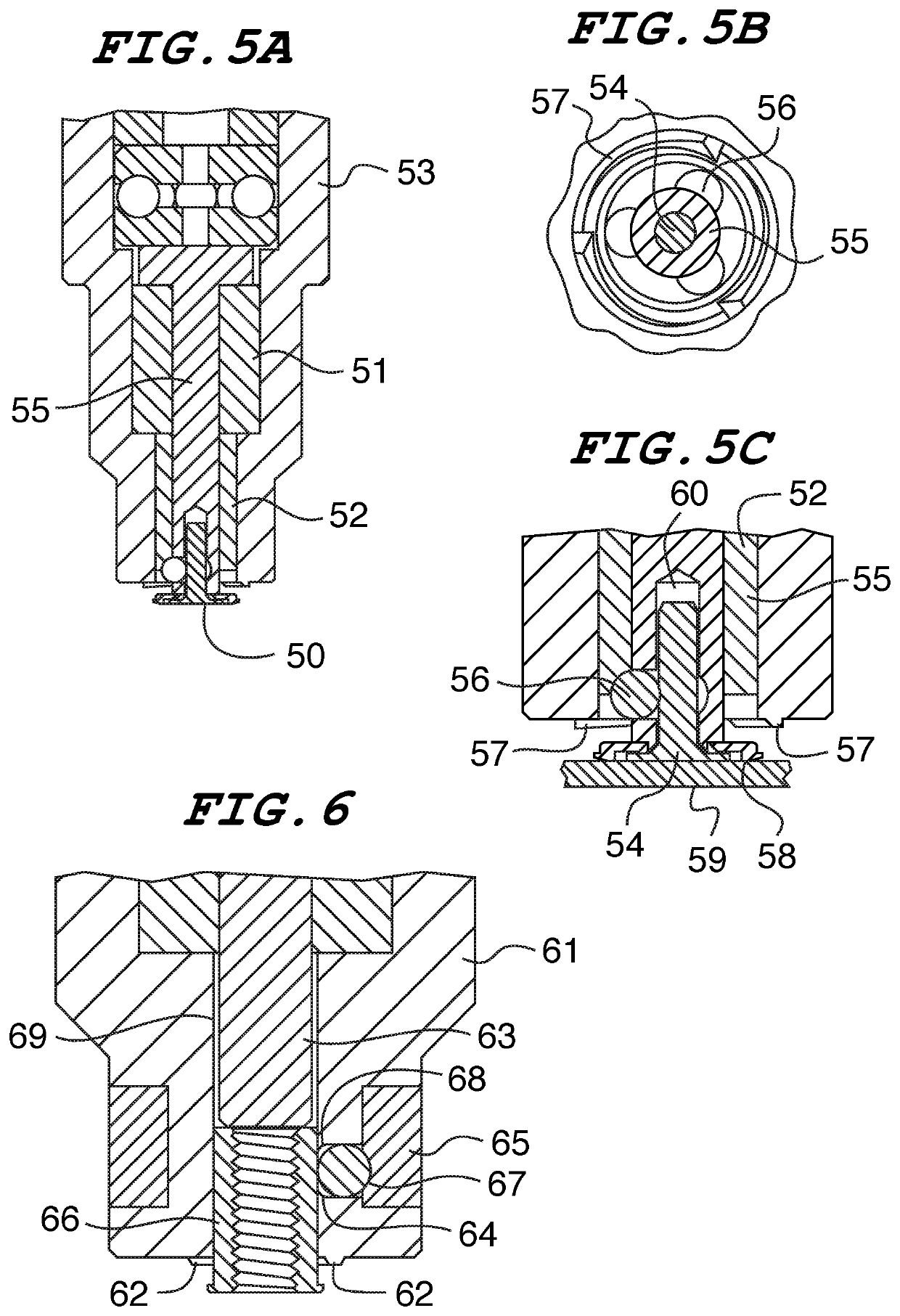

Machine tooling with a rotary punch

A tooling system has means for applying a vacuum to hold the fastener at the working end of the tool. A cavity in a hollow pusher pin has lateral ports for exclusively providing a airway between the vacuum source and the fastener. In other embodiments of the invention the pusher pin has fastener-gripping jaws in the form of balls moveable within lateral passageways in the pusher pin open into the cavity. The balls are biased inwardly against the fastener by an outer elastic band on the tool body which encircles the pusher pin. When adapted for installing magnetic-release type fasteners, the bottom end of the pusher pin is of reduced diameter for insertion into a magnetic release fastener. The fastener-receiving panel is supported by an anvil having a magnet whereby the fastener is released from the pusher pin as the fastener is pressed into the panel.

Owner:PENN ENG & MFG CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com