Preparation process method of wide ultrathin cold-rolled titanium strip coil for rolling bonding

A technology of rolling composite and preparation process, applied in metal rolling and other directions, can solve the problems of large thickness and specific gravity of composite titanium metal, limited wide-scale promotion and application, and high production cost of composite materials, so as to reduce the risk of strip breakage and solve the problem of Problems in the shape control industry and the effect of eliminating stress on cutting edges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

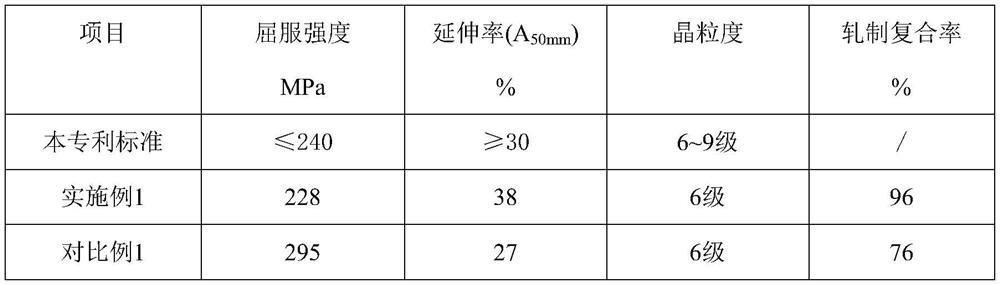

Examples

Embodiment 1

[0043] Example 1: The EB furnace die-casting slab billet with a thickness of 190 mm and a width of 1280 mm was used to produce a 0.3 mm titanium strip, and the Fe content was 0.024%, the C content was 0.010%, the N content was 0.0063%, and the O content was 0.041%, [ O] 当 is 0.076%. The upper and lower surfaces of the ingot are machined as a whole using a large-scale integral cutter head milling machine. The cutter head diameter is greater than 1280mm, the thickness of single-sided milling is 5mm, and the thickness difference of the slab cross-section after machining is 2mm.

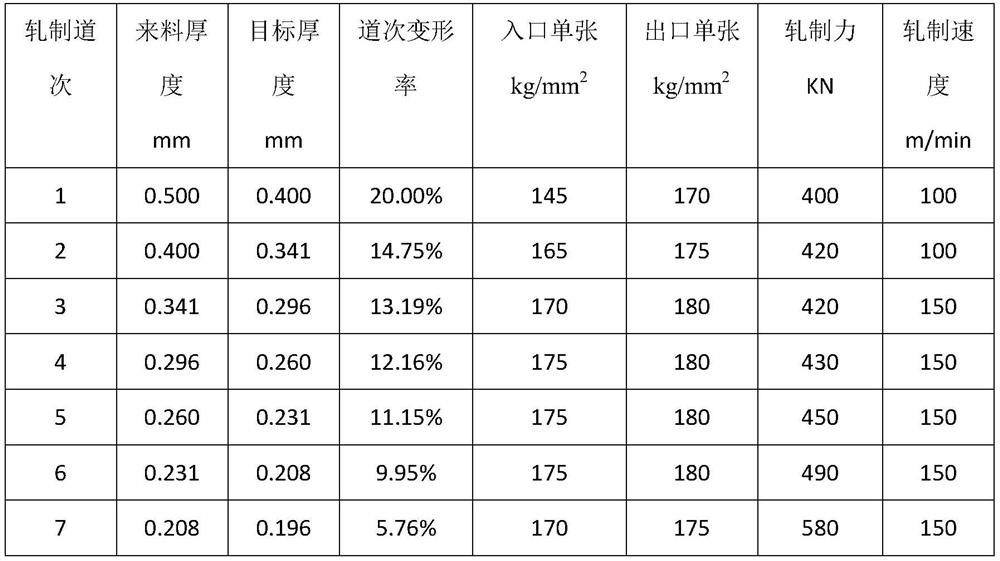

[0044] The slabs are hot rolled to 3.0mm thickness by furnace coiling mill, and subjected to continuous annealing, pickling and grinding; cold rolling to 0.75mm by one pass of 20-high rolling mill, 5mm trimming on each side, using 680℃ Semi-finished product annealing; the second rolling process is rolled to a thickness of 0.3mm, the rolling process deformation rate is 60%, and the rolling parameter tabl...

Embodiment 2

[0050] Example 2: The EB furnace die-cast slab ingot with a thickness of 190 mm and a width of 1280 mm is used to produce a 0.19 mm titanium strip, and the Fe content is 0.025%, the C content is 0.030%, the N content is 0.0012%, and the O content is 0.022%, [ O] 当 It is 0.06%; the upper and lower surfaces of the ingot are machined as a whole using a large overall cutter head milling machine, the cutter head diameter is greater than 1280mm, the thickness of single-sided milling is 5mm, and the thickness difference of the slab cross-section after machining is 2mm. The slabs are hot rolled to 3.5mm thick with a furnace coil mill, and subjected to continuous annealing, pickling and grinding; a twenty-high rolling mill is used for one pass of cold rolling to 1.2mm, and the semi-finished products are annealed at 650°C, followed by two passes of rolling. To 0.5mm, trim 6mm on both sides, and anneal the semi-finished product at 650 °C; the third rolling process is rolled to 0.19mm fin...

Embodiment 3

[0057] Example 3: The EB furnace die-casting slab billet with a thickness of 200 mm and a width of 1290 mm is used to produce a 0.10 mm titanium strip, and the Fe content is 0.016%, the C content is 0.010%, the N content is 0.0065%, and the O content is 0.005%, [ O] 当 is 0.0405%. The upper and lower surfaces of the ingot are machined integrally with a large-scale integral cutter head milling machine. The cutter head diameter is greater than 1280mm, the single-sided milling thickness is 8mm, and the thickness difference of the slab cross-section after machining is 1mm. The slabs are hot rolled to 3.0mm thickness with a furnace coiling mill, and subjected to continuous annealing, pickling and grinding; cold rolling to 0.75mm in one pass using a twenty-high mill, annealing of semi-finished products at 660°C, and then rolling in two passes. to 0.17mm, trimming 6mm on both sides, and annealing the semi-finished product at 650°C; rolling to 0.10mm finished product in the third roll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com