Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Meet a variety of different needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

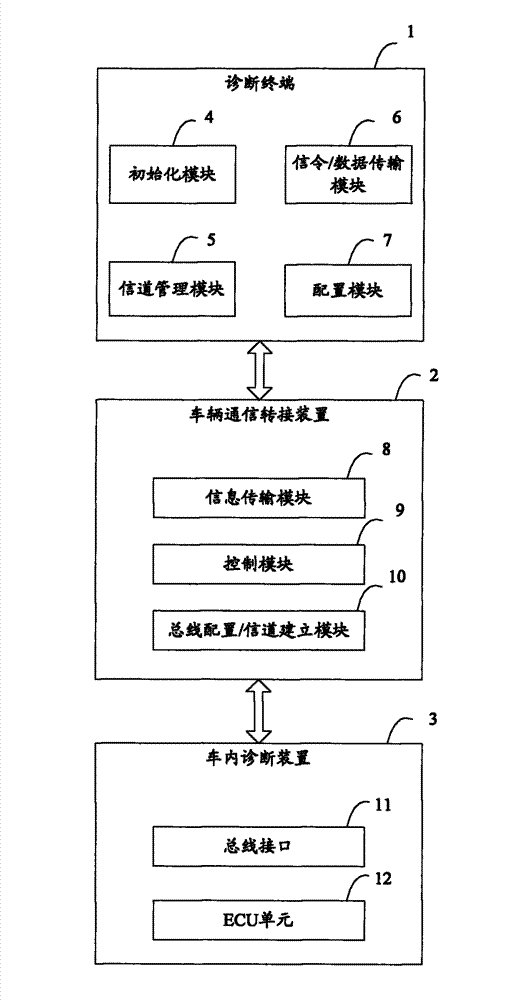

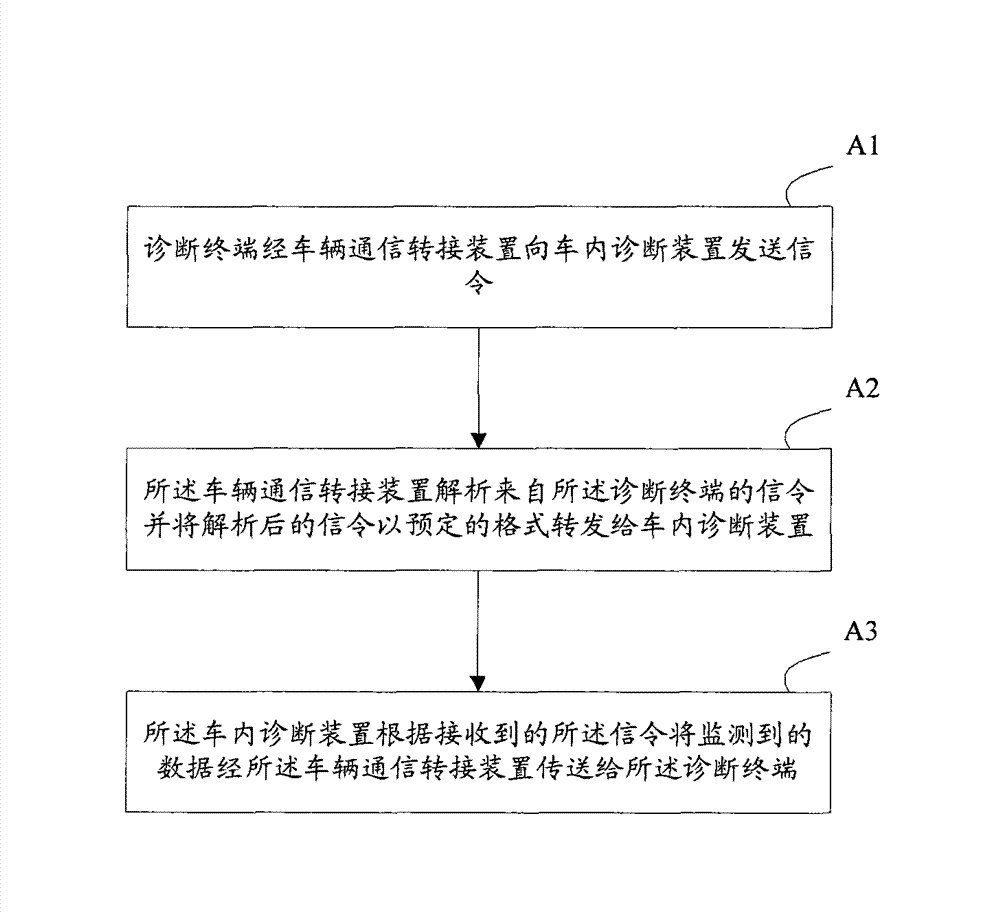

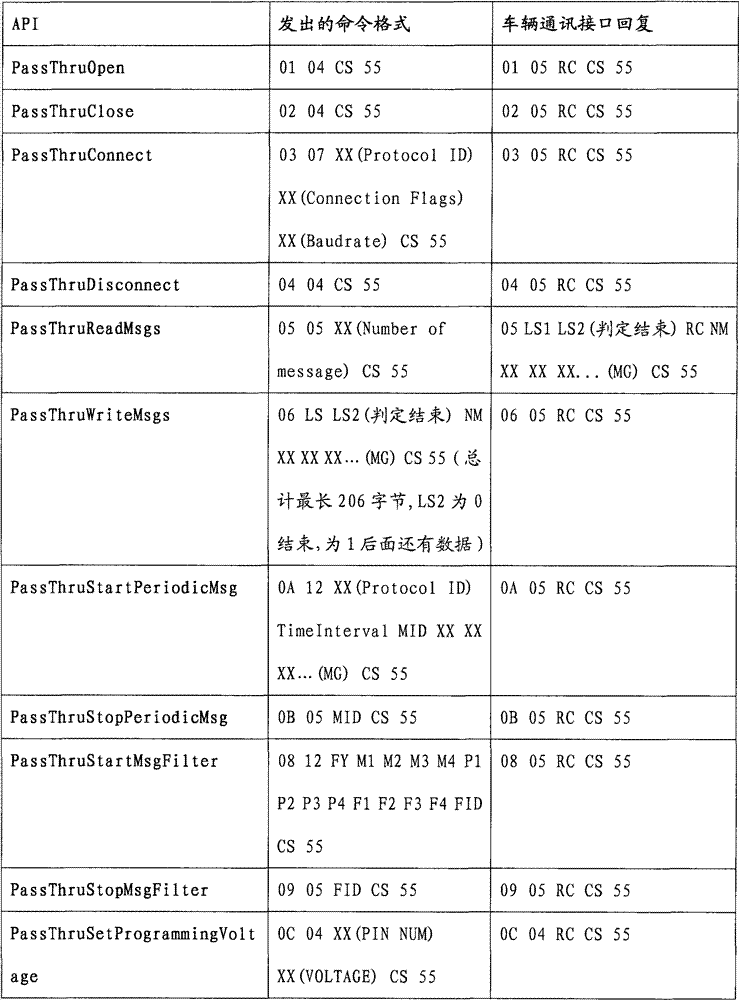

Vehicle diagnostic system and vehicle diagnostic method

InactiveCN102780713ASuitable for useMeet a variety of different needsTransmissionIn vehicleComputer terminal

The invention provides a vehicle diagnostic system and a vehicle diagnostic method. The vehicle diagnostic system comprises a diagnostic terminal, a vehicle communication switching device and an in-vehicle diagnostic device, wherein the diagnostic terminal is used for sending a signaling to the in-vehicle diagnostic device through the vehicle communication switching device and receiving and processing data from the in-vehicle diagnostic device; the vehicle communication switching device is used for analyzing the signaling from the diagnostic terminal and transmitting the analyzed signaling to the in-vehicle diagnostic device by virtue of a preset format; and the in-vehicle diagnostic device is used for transmitting the monitored data to the diagnostic terminal through the vehicle communication switching device according to the received signaling. The vehicle diagnostic system and the vehicle diagnostic method which are disclosed by the invention are suitable for being used by individual users and can adapt to various vehicle bus communication protocols.

Owner:SAIC GENERAL MOTORS +1

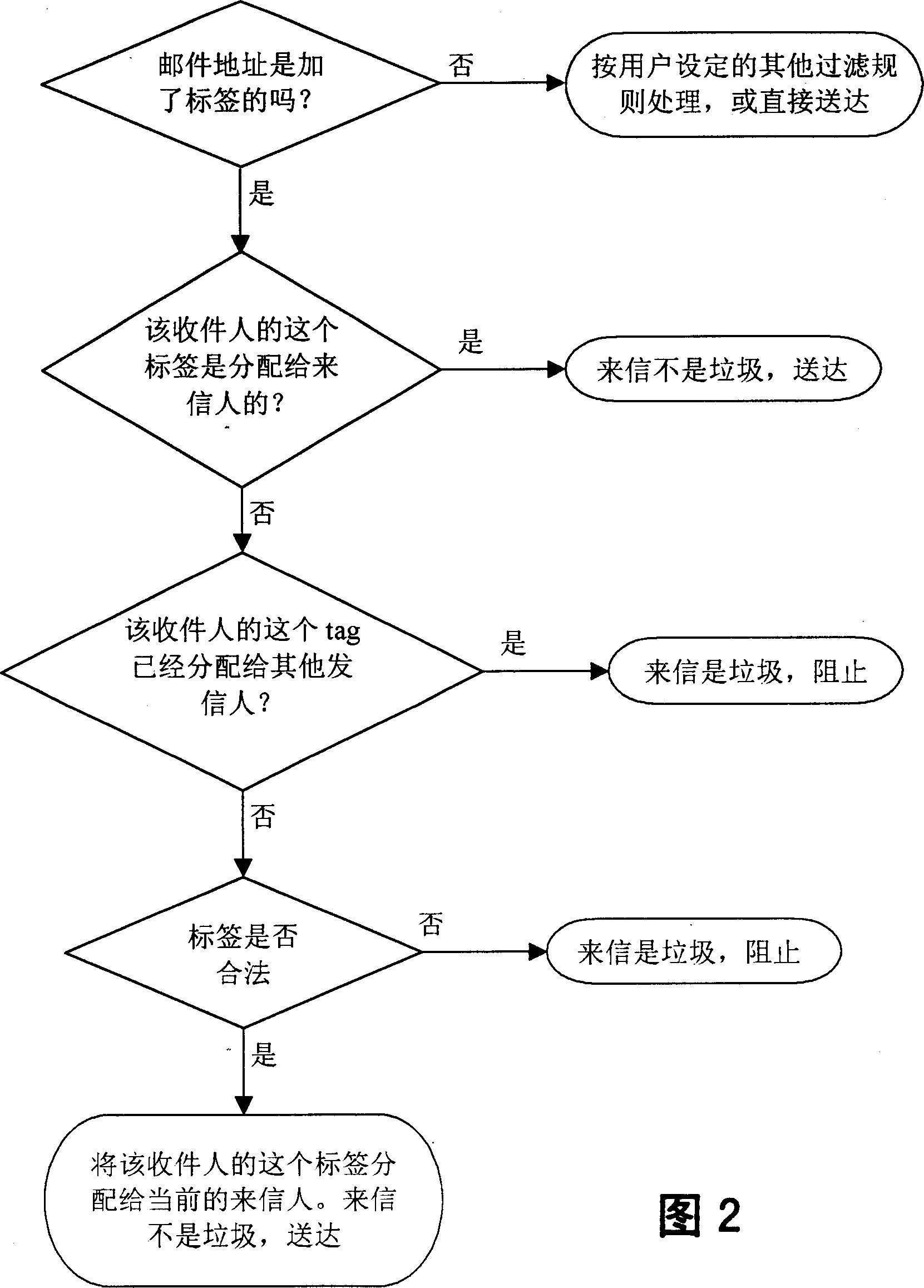

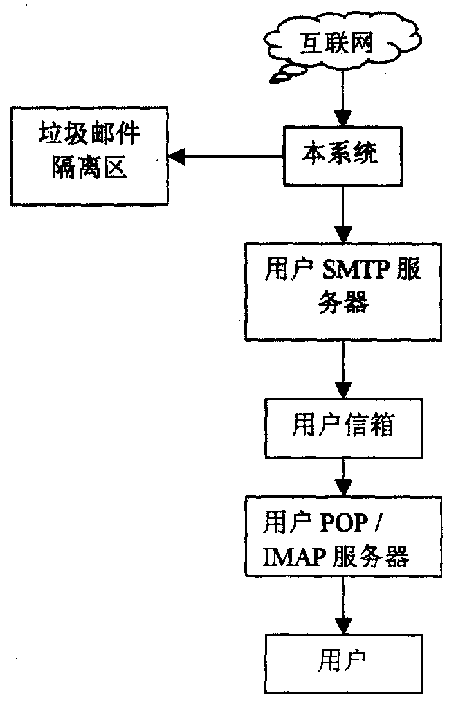

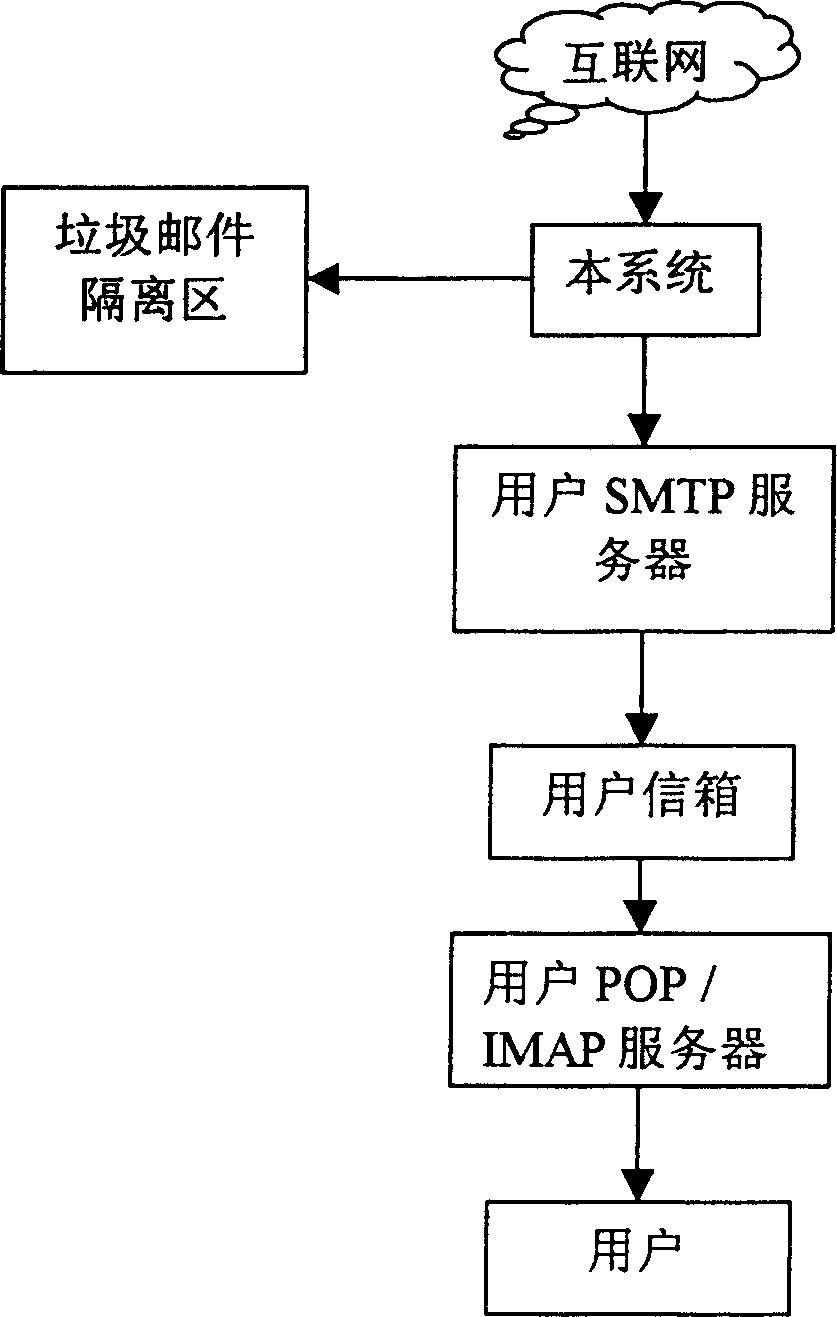

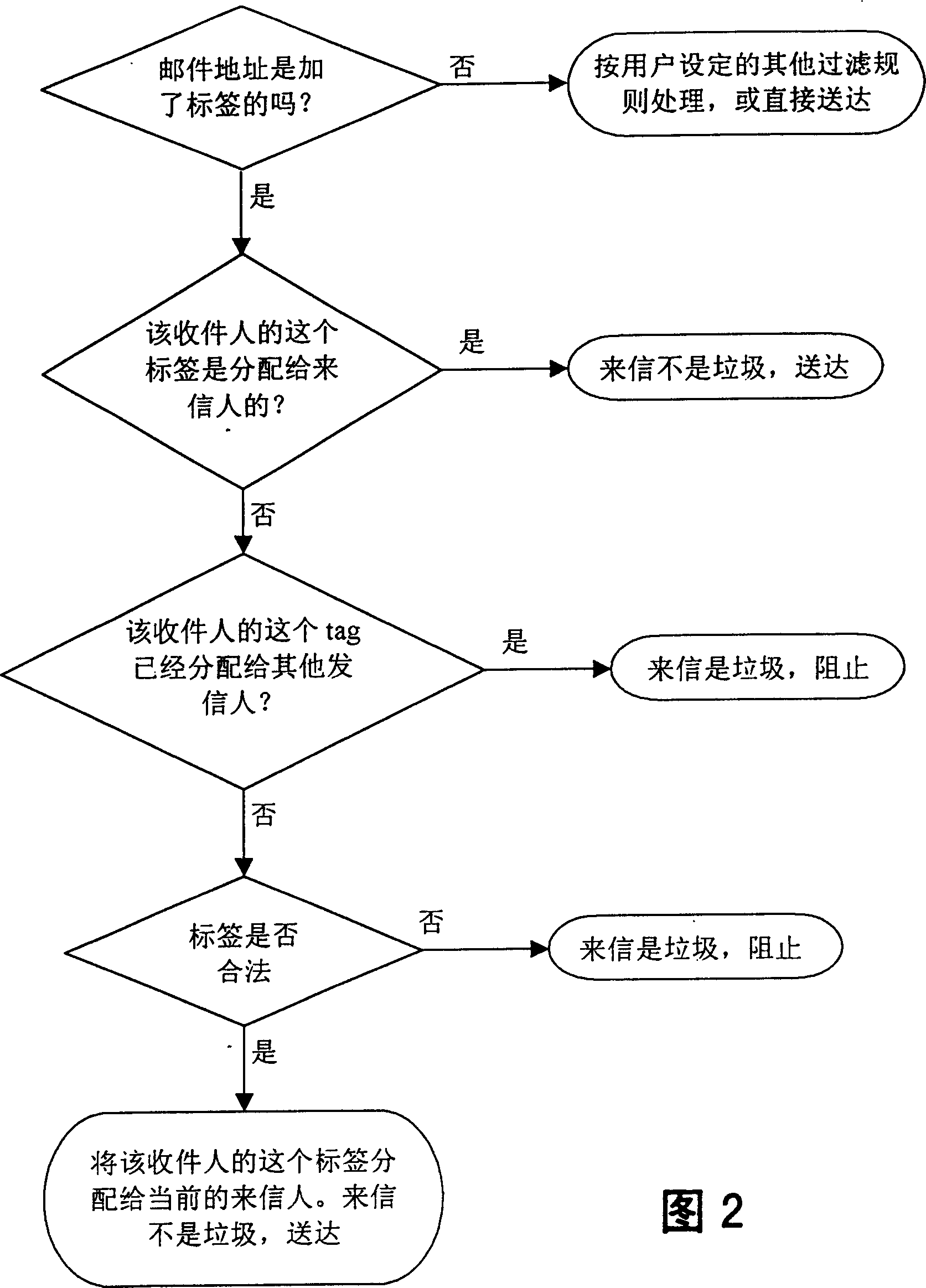

Method for preventing rubbish E-mail

InactiveCN1434390AMeet a variety of different needsUnauthorized memory use protectionSpecific program execution arrangementsDatabaseElectronic mail

There is a method for preventing rubbish e-mail; the key is that it adds a label on the address of E-mail and adds a system which deals with the E-mail according to the prescriptive procedure in mailserver-a SMTP server. The label can be created optional by the user of the mail address and needn't to be set in the mail server, the receiver can control the mail address to be used only by the appointed person or constitute, the mail server processes the mail according to the prescriptive procedure, the receiver can reduce the rubbish mail greatly.

Owner:上海蓝飞通信设备有限公司

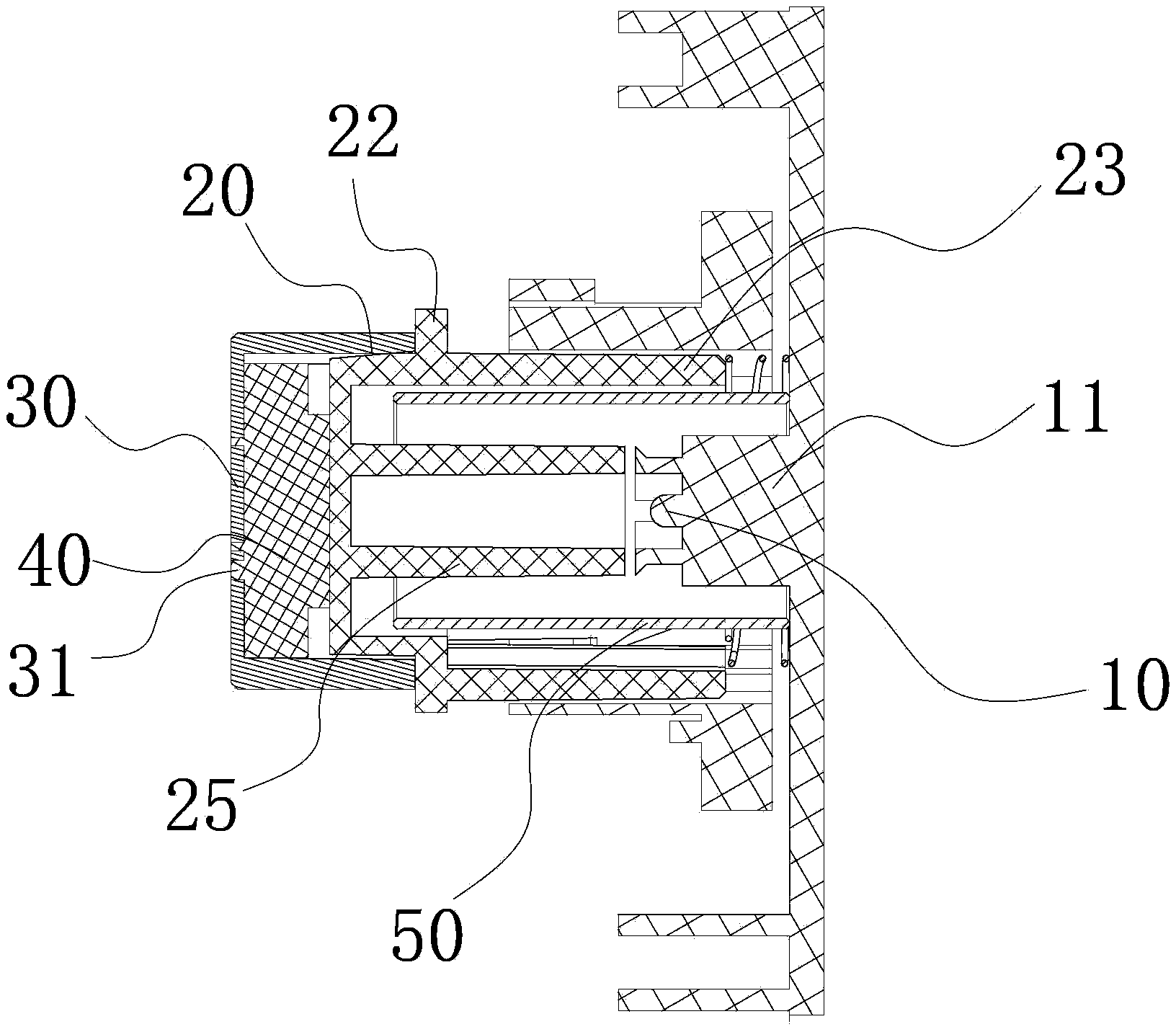

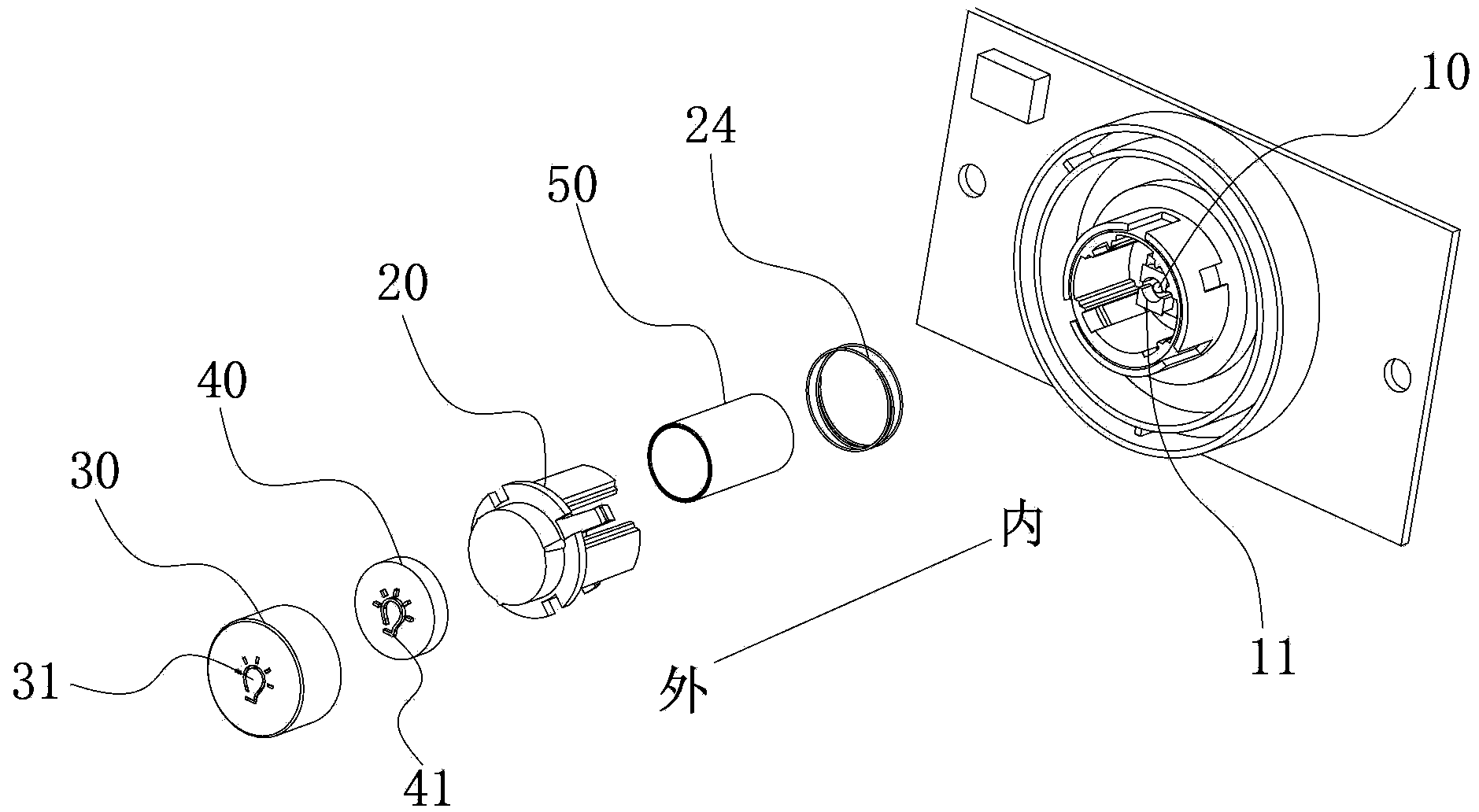

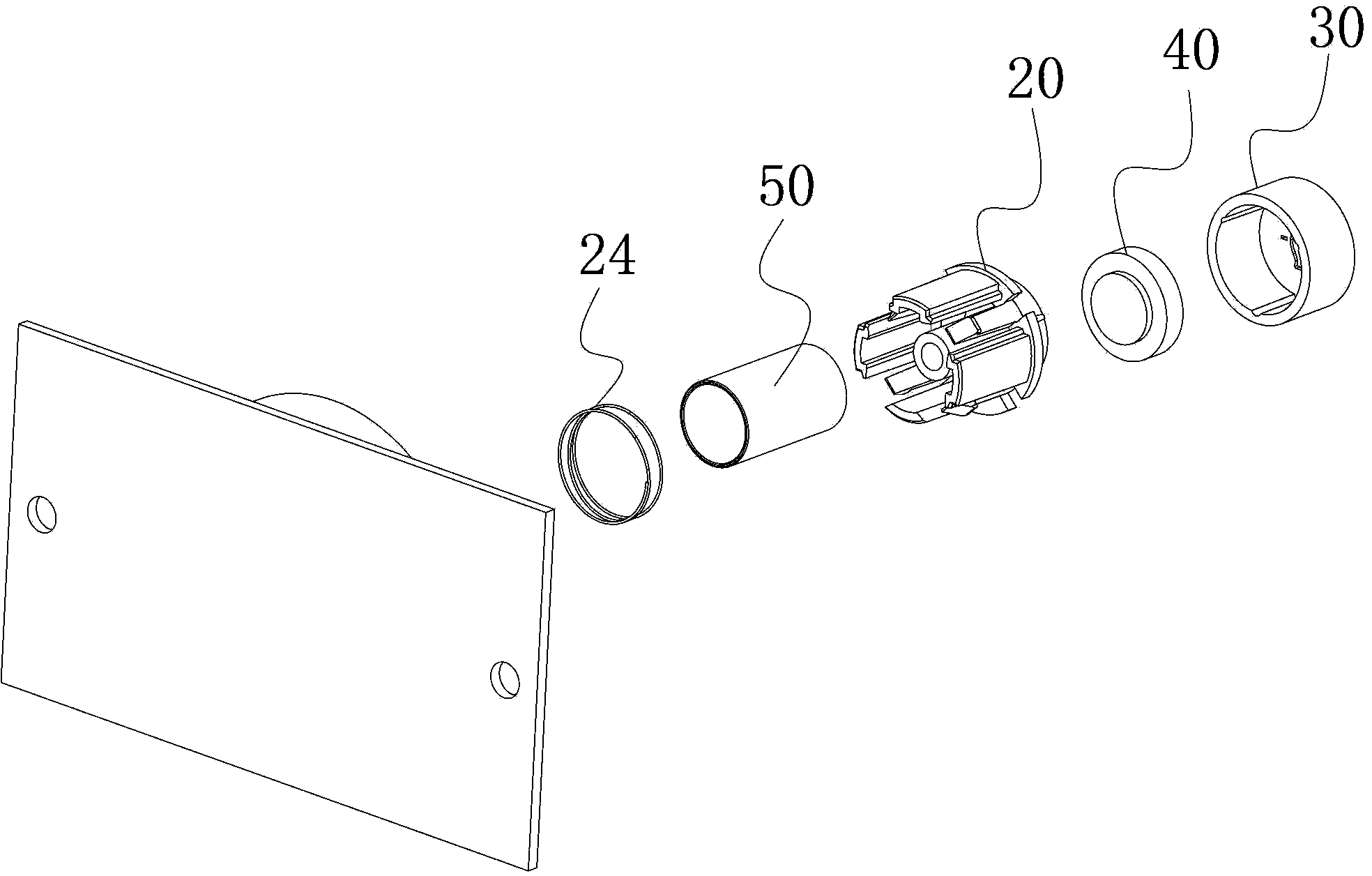

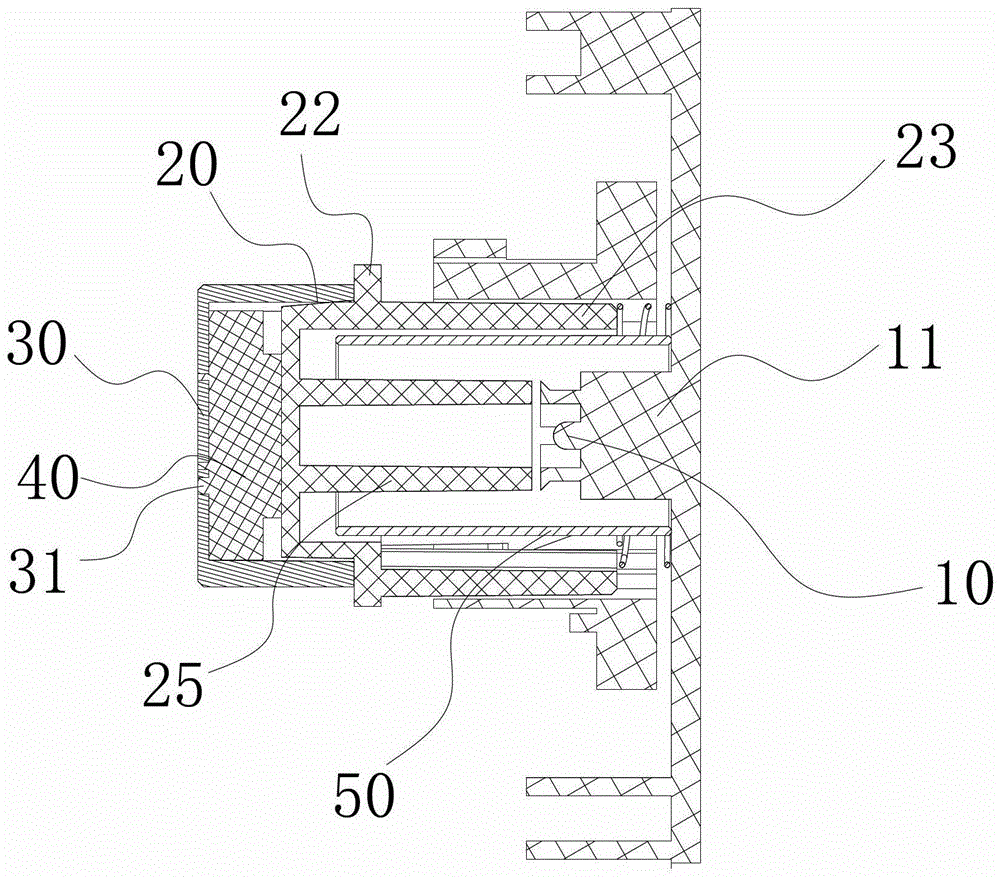

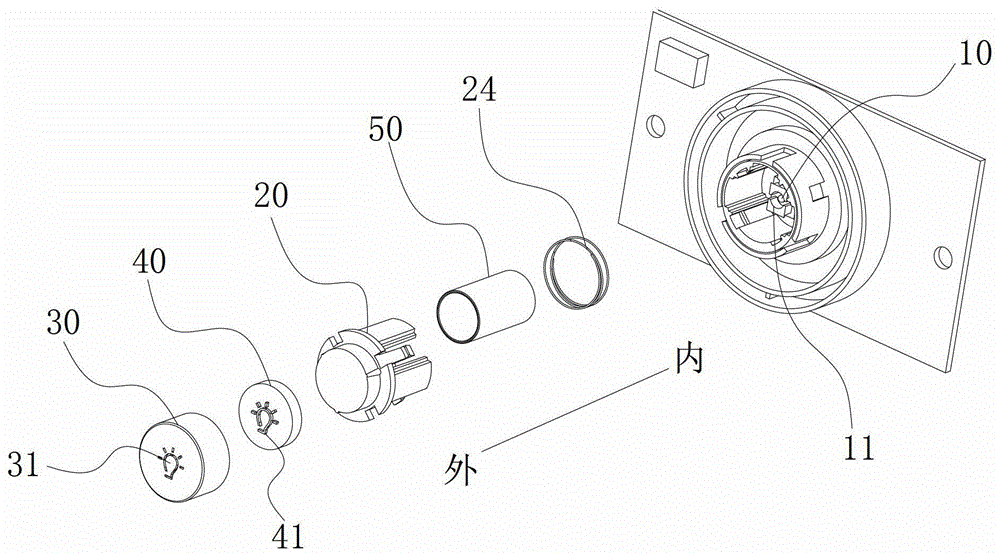

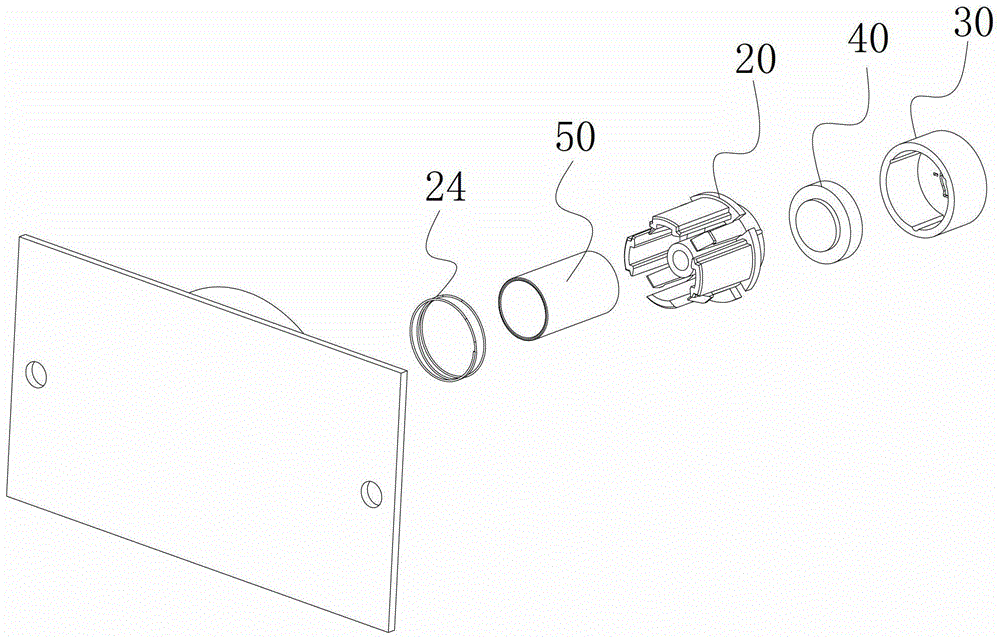

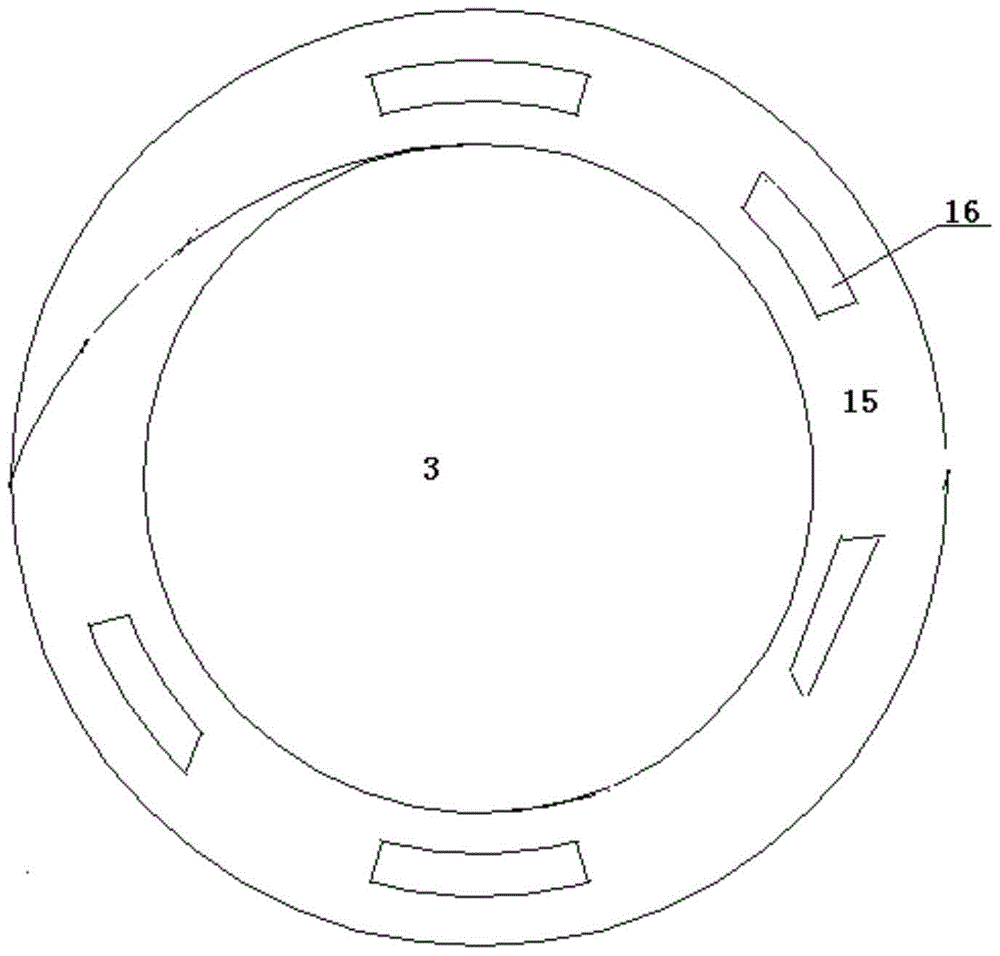

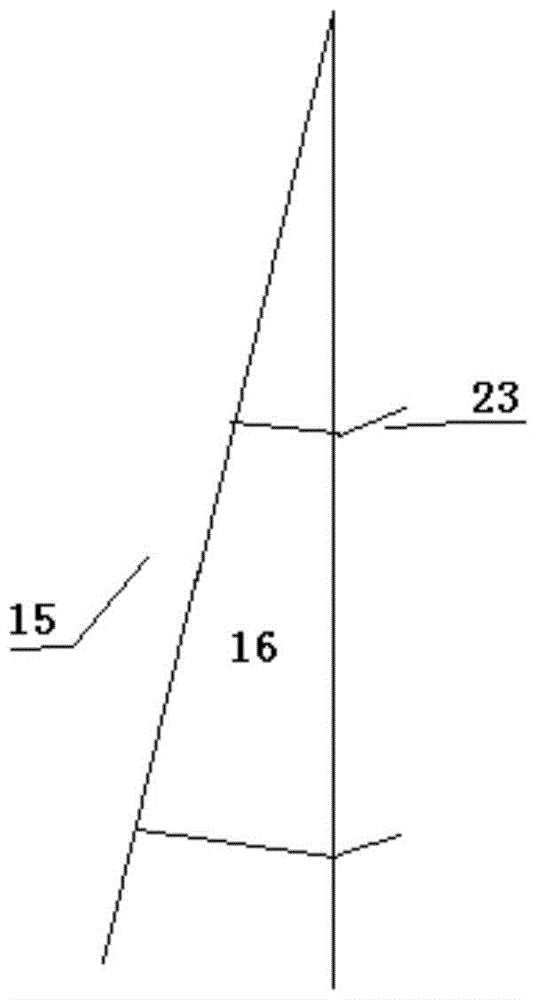

Metal key module, control box module with metal key module, and range hood

ActiveCN104134561AImprove the light transmission effectSafe to useDomestic stoves or rangesLighting and heating apparatusLight transmissionKey pressing

The invention discloses a metal key module, a control box module with the metal key module, and a range hood. The metal key module comprises a lamp, a switch, a transparent key body, a non-transparent lampshade and a light-transmitting sealing element, wherein the lampshade is arranged on the outer side of the transparent key body; a hollow part is arranged on the lampshade; and the light-transmitting sealing element is at least partially embedded into the hollow part of the lampshade. According to the metal key module, the light-transmitting hollow part is arranged on the lampshade, so that a light-transmitting effect is improved; and the light-transmitting sealing element is arranged on the inner wall of the lampshade, so that light transmission can be ensured, outside oil fume and the like can be prevented from entering the switch, and use is safer and more convenient.

Owner:MIDEA GRP CO LTD

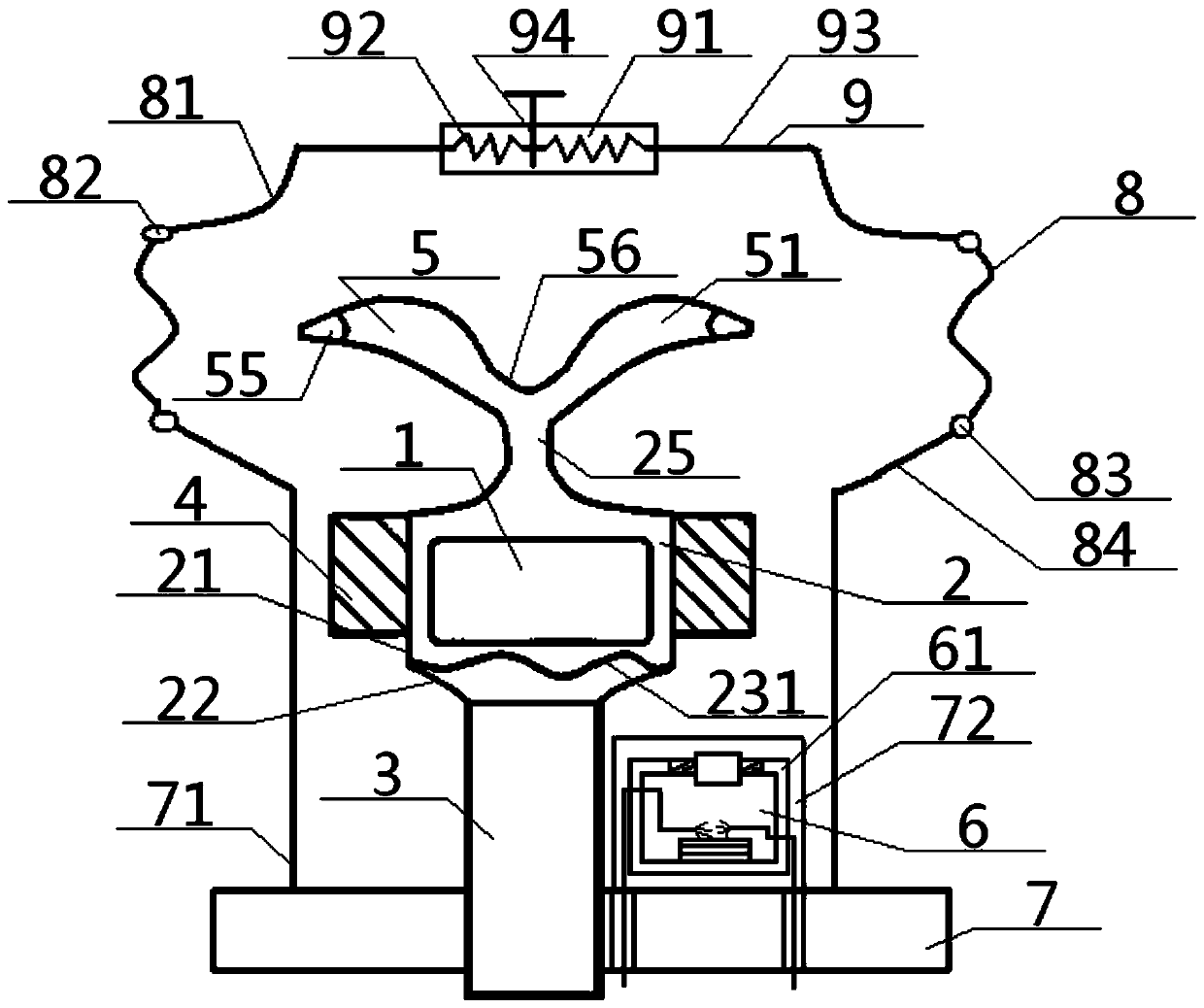

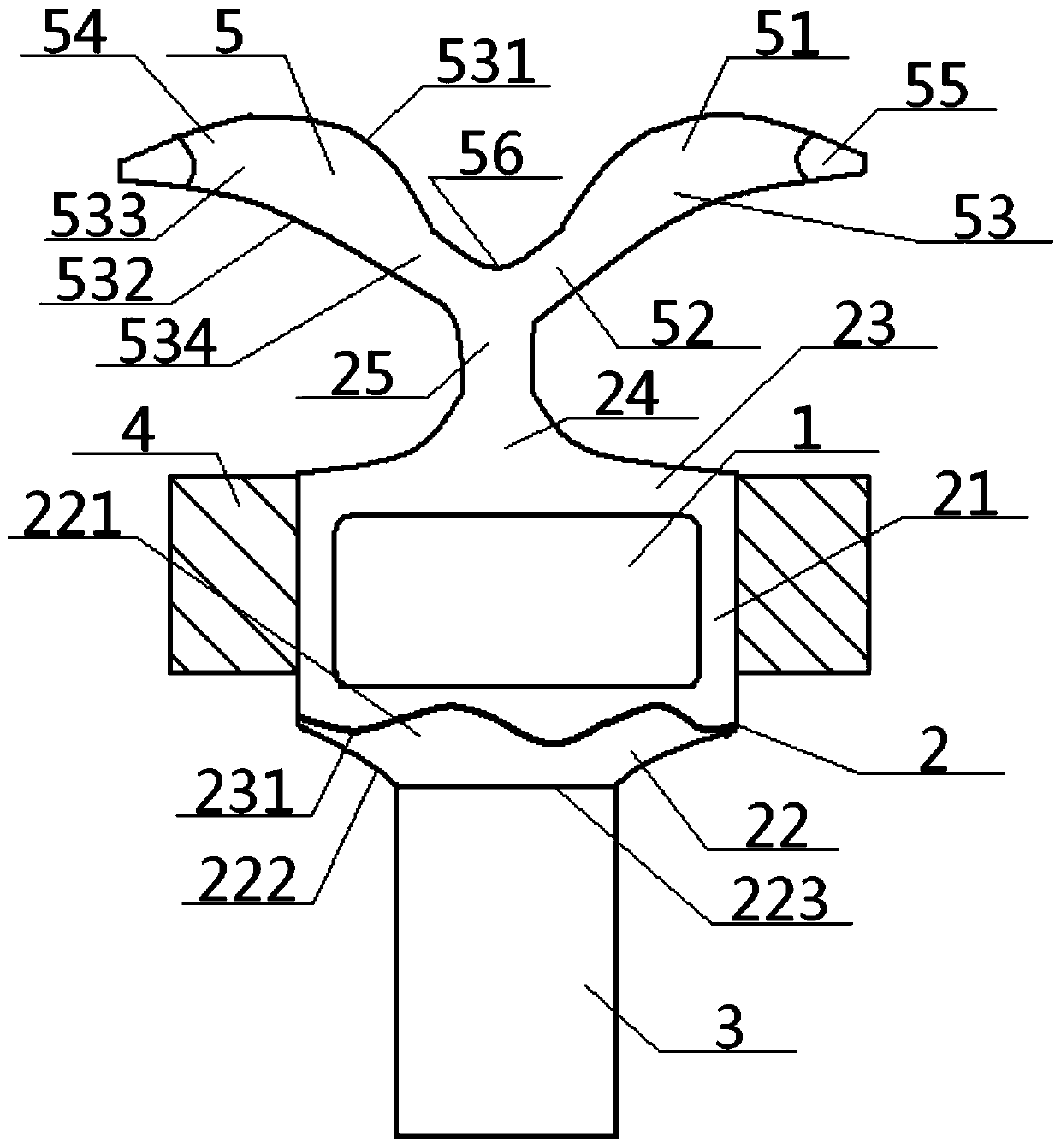

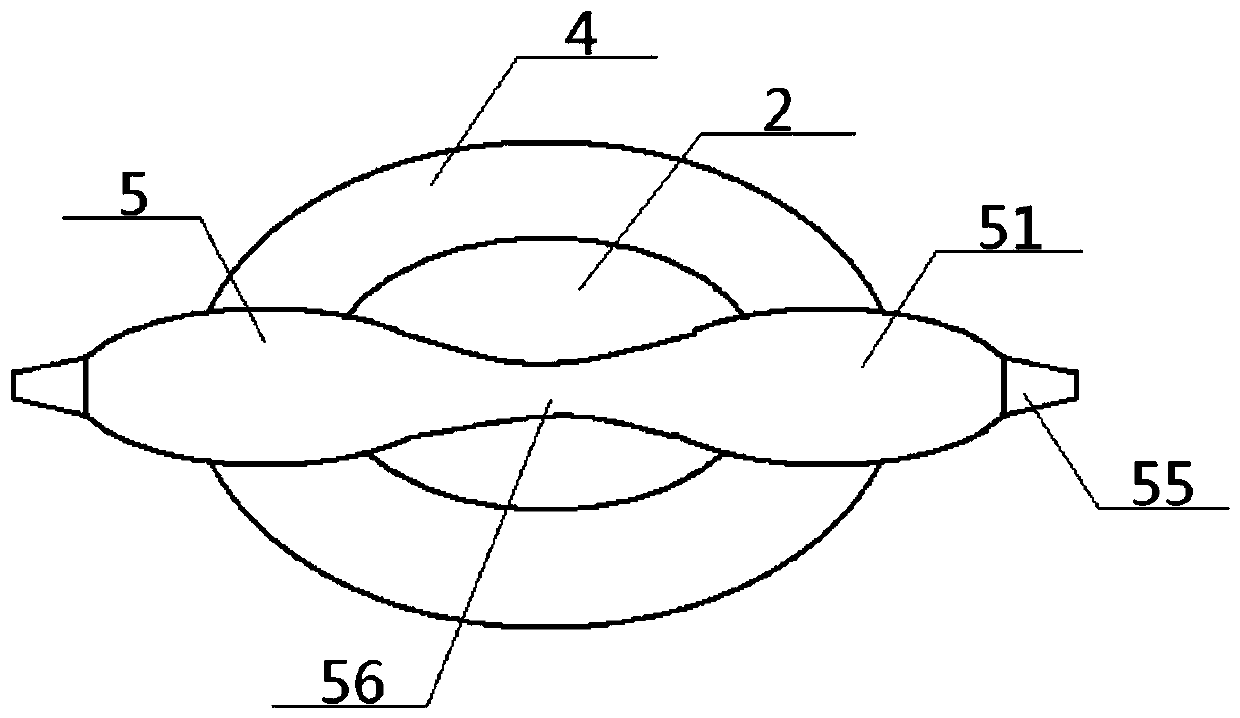

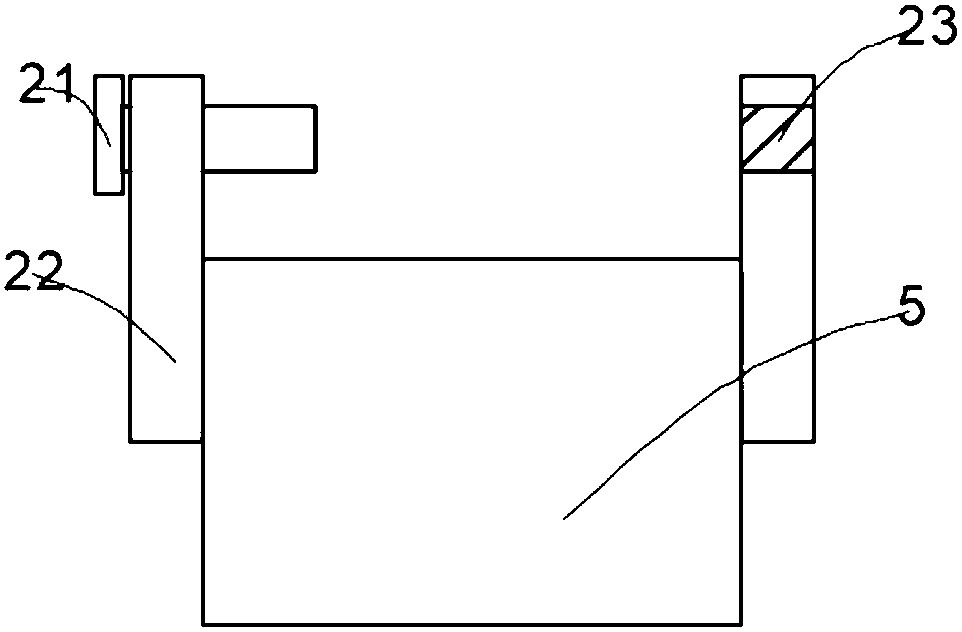

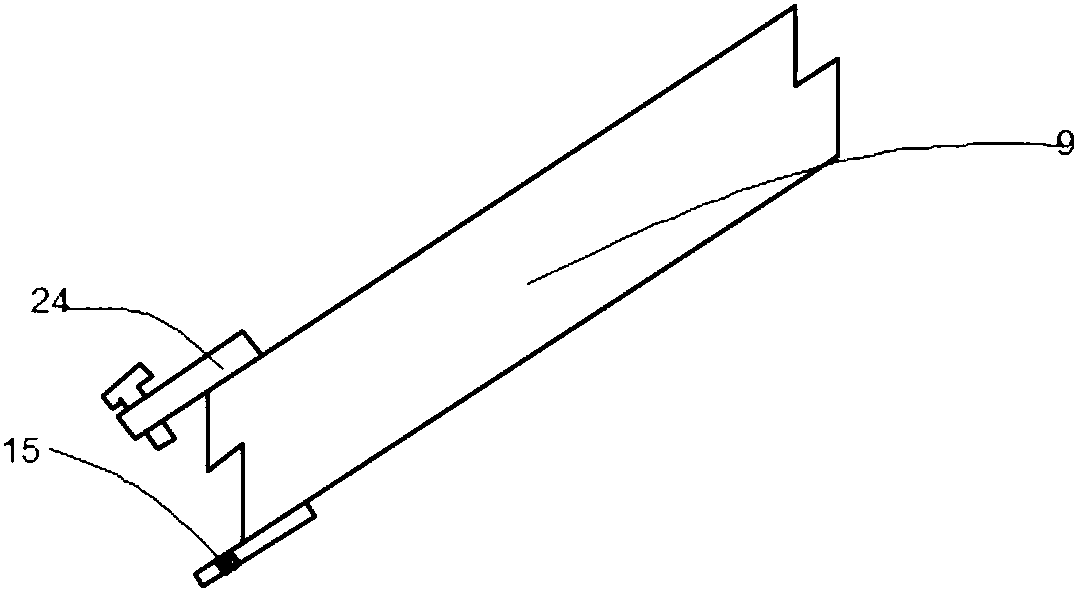

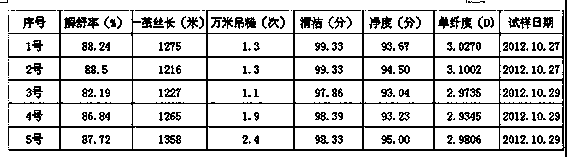

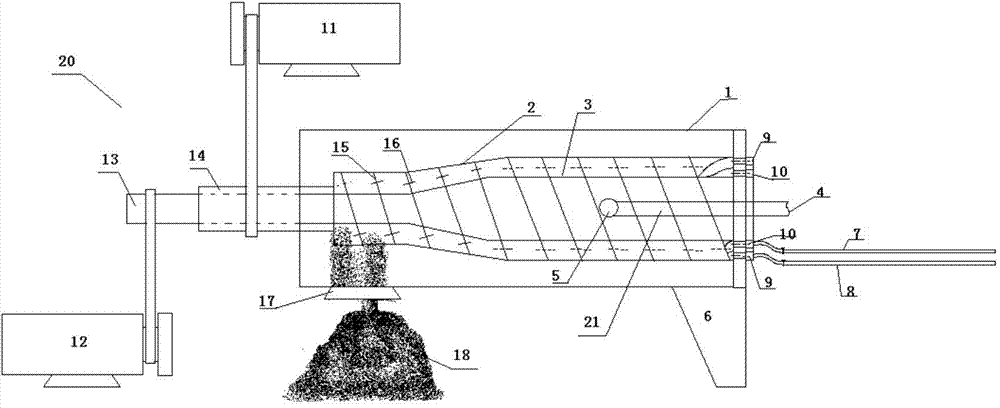

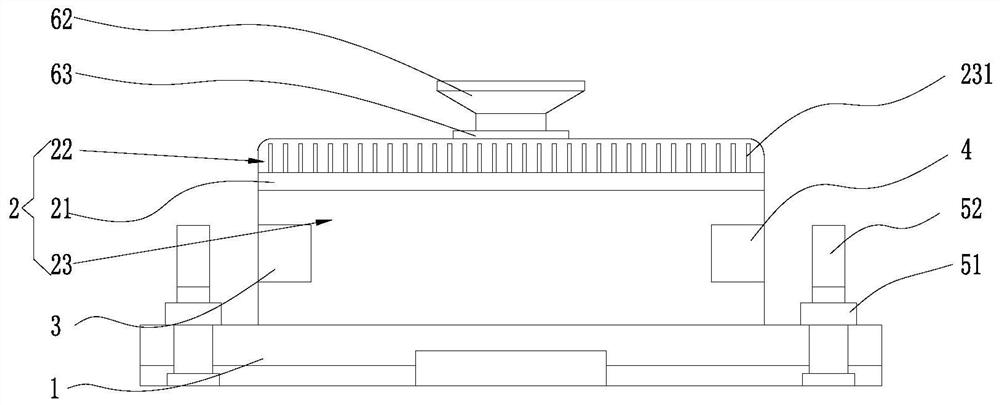

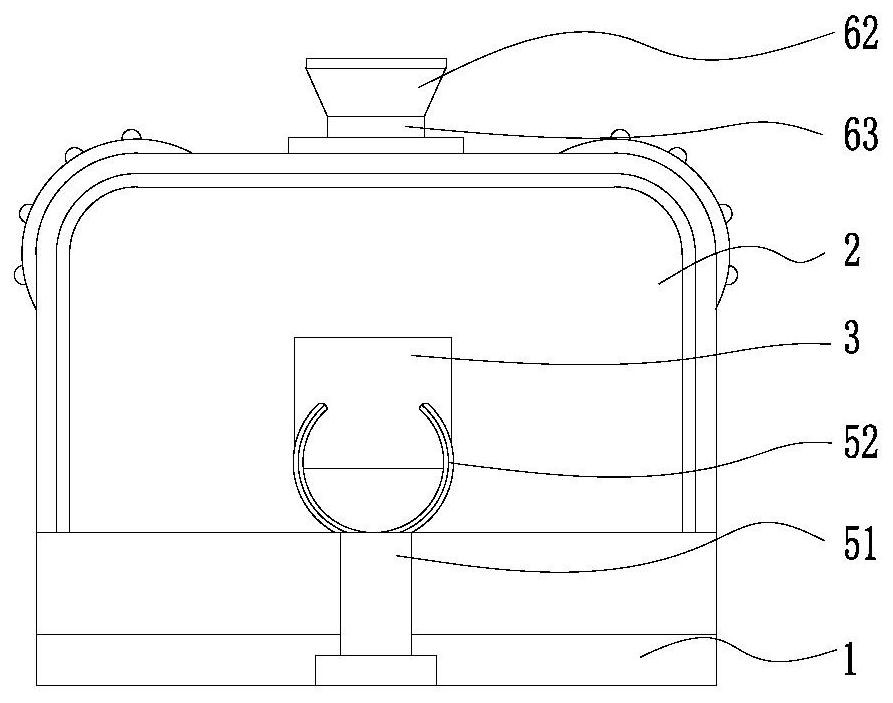

Double-spray-head nanofiber production system

InactiveCN110923832AIncrease productivityEasy to collectArtificial thread manufacturing machinesFilament/thread formingFiberNanofiber

The invention discloses a double-spray-head nanofiber production system. A silk outlet cabin in the system comprises a main cabin shell, a bottom cabin shell and an inner cabin cavity; the exterior ofthe main cabin shell is surrounded by a heating device; the bottom of the main cabin shell is connected with the top end of a centrifugal driving shaft through the bottom cabin shell; the bottom endof the centrifugal driving shaft extends through a base and extends to the lower part of the base; the top surface of the base is connected with the bottom end of a supporting rod; the top end of thesupporting rod is connected with the bottom of a collecting device; the top of the collecting device is connected with a horizontal stabilizing rod; the horizontal stabilizing rod is suspended over aleft spray head and a right spray head; a fiber block is arranged in the inner cabin cavity; a liquid outlet is formed in the top of the main cabin shell; and the liquid outlet is connected with the left spray head and the right spray head located above the liquid outlet. According to the design, nanofibers can be generated, the production efficiency is relatively high, the stability is relativelyhigh, the adjustability is relatively high, and product forms are diversified.

Owner:吴江市欧鑫纺织品有限公司

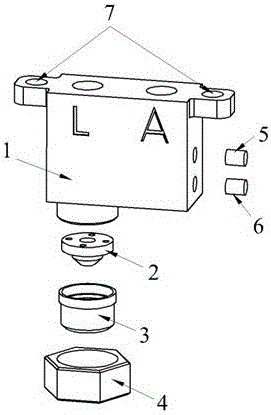

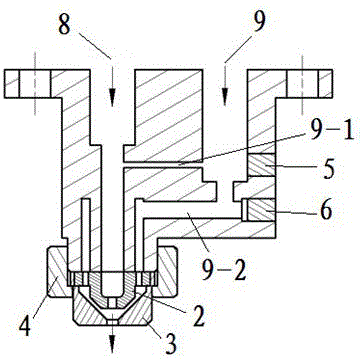

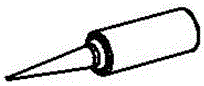

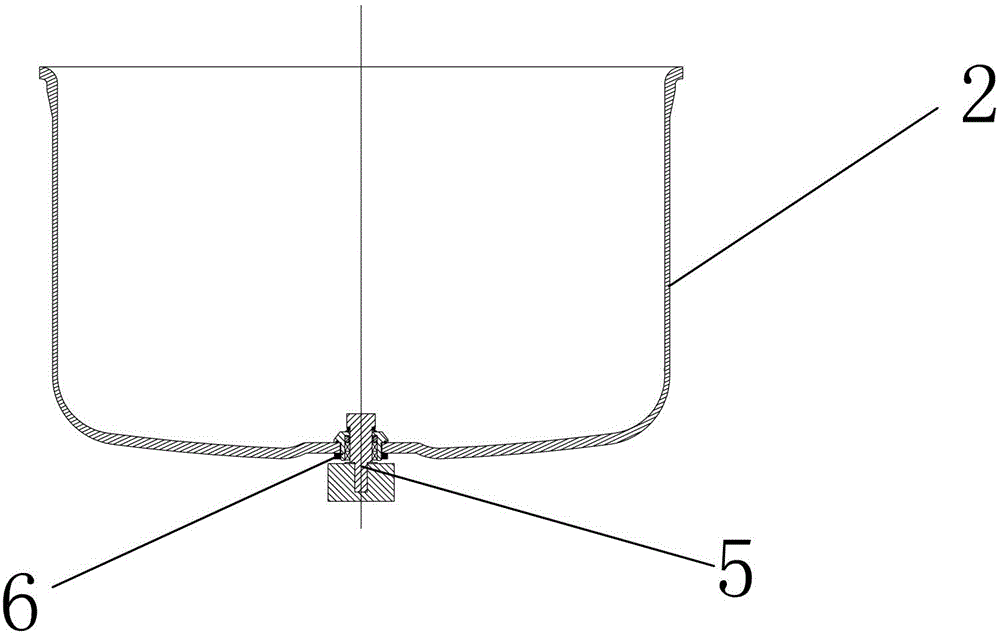

Air atomizing nozzle

An air atomizing nozzle comprises a nozzle body, a gas guide core, a jet nozzle, a locking nut, machining hole plugs and the like. The nozzle body is used for leading in pressurized liquid and gas and is used as an installation base body for the other parts. The gas is divided into two branches through the nozzle body. The gas can be led in a nozzle outlet mixing cavity from the second branch through the gas guide core and is then sprayed out. The jet nozzle is the last-layer part of the nozzle. The gas and the liquid are sprayed out of the jet nozzle after being mixed. The gas guide core and the jet nozzle are fixed to the nozzle body through the locking nut. The machining hole plugs plug outer holes left for machining inner holes of the nozzle body. The nozzle is a multifunctional gas atomizing nozzle; by means of the combined type structure, the nozzle can be changed into a two-time-mixing bubble type and pneumatic atomizing nozzle, a bubble type atomizing nozzle, a pneumatic atomizing nozzle and the like by changing the forms of the parts, and different atomizing effects can be achieved by changing sizes of through holes of all the parts.

Owner:LOW SPEED AERODYNAMIC INST OF CHINESE AERODYNAMIC RES & DEV CENT

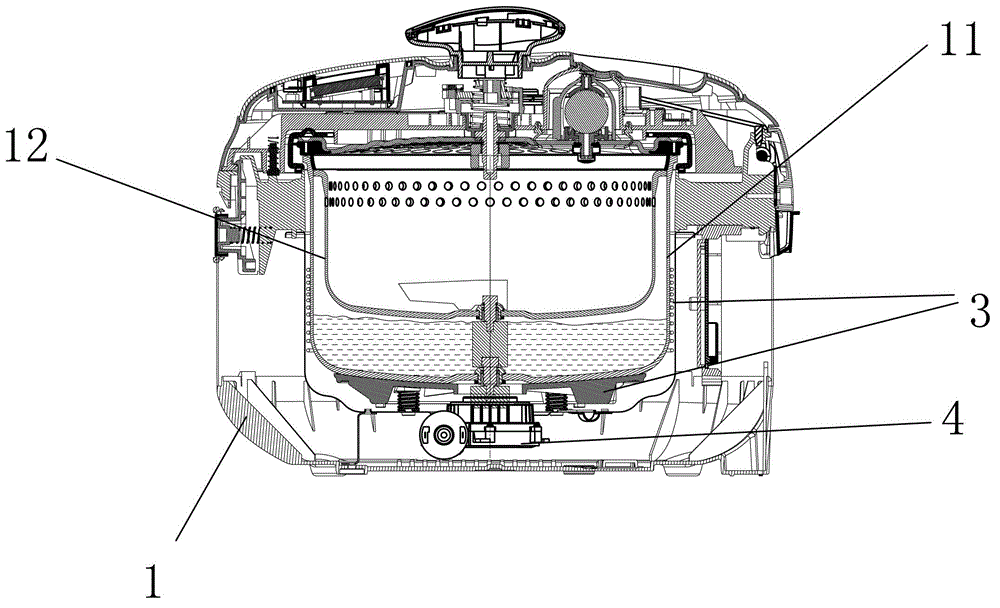

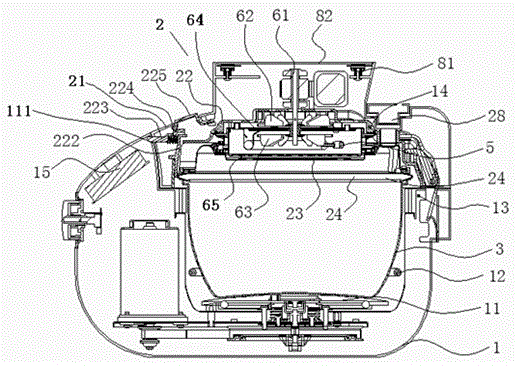

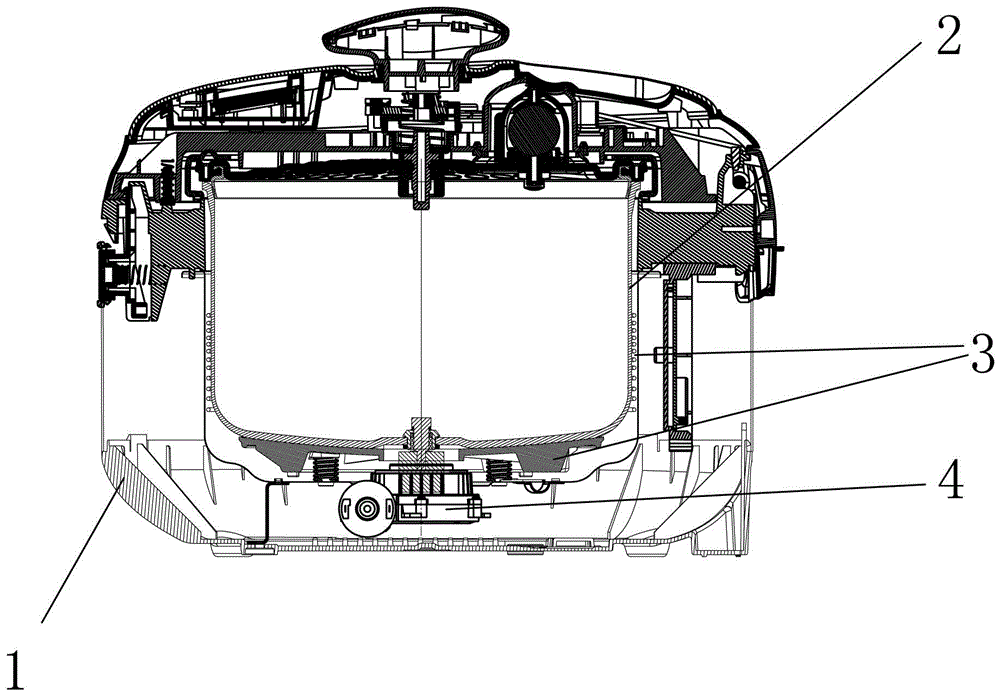

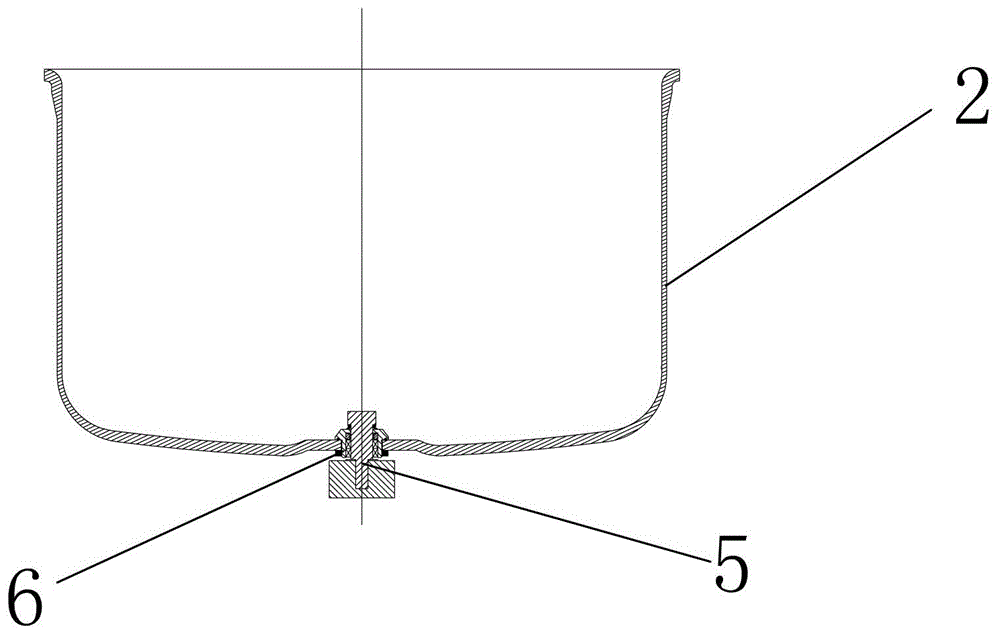

Multifunctional electric cooker

ActiveCN102973129AMeet a variety of different needsSteam cooking vesselsBread-toastersElectricityEngineering

The invention relates to a multifunctional electric cooker which comprises a cooker body, a motor which is arranged in the cooker body, a main cooker which is placed in the cooker body, and a heating element. The motor is provided with an output shaft, the main cooker comprises a rotating shaft which is provided with a first end and a second end, and the first end of the rotating shaft of the main cooker is connected with the output shaft of the motor in a transmitted mode. An electric cooker is further composed of a steaming and baking cooker, the steaming and baking cooker comprises a rotating shaft which comprises a first end and a second end, and the first end of the steaming and baking cooker is connected with the second end of the rotating shaft of the main cooker in a transmitted mode. The invention further provides a method of using of the multifunctional electric cooker. The multifunctional electric cooker has the advantage of being a multipurpose machine.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

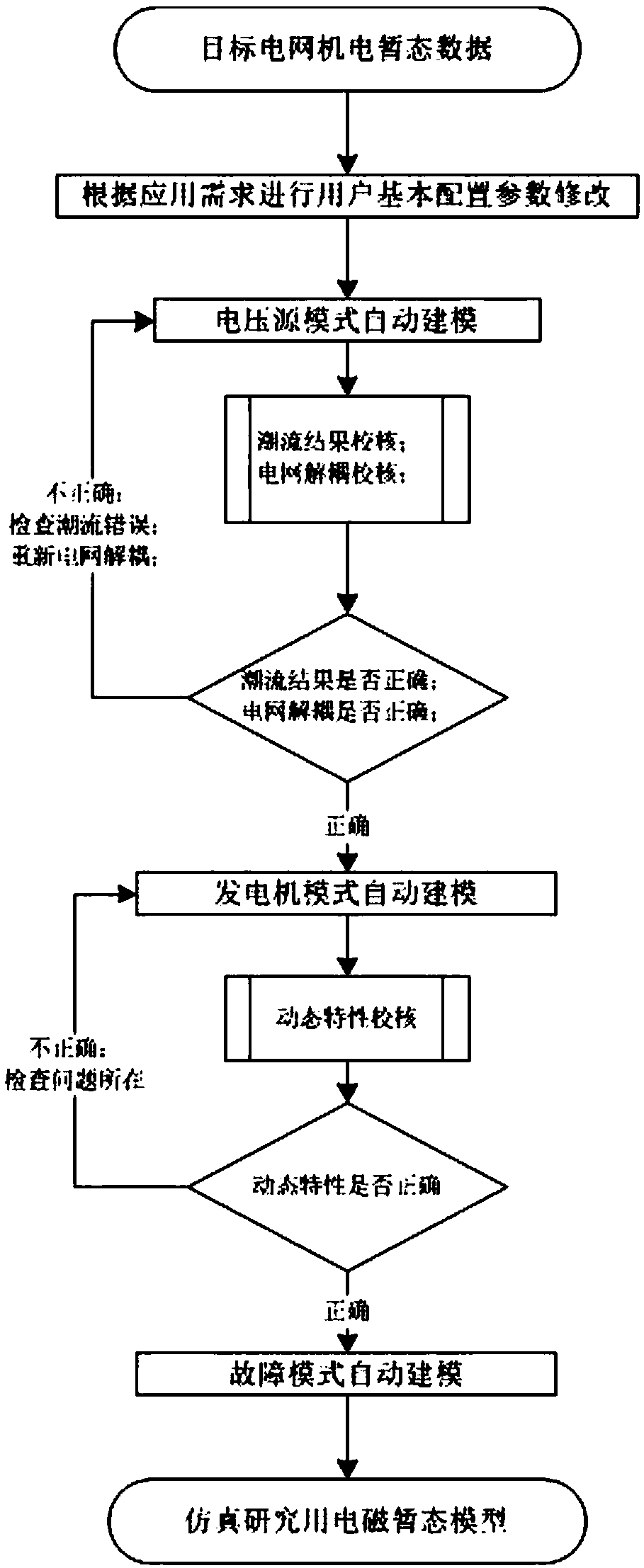

Active control method and system of electromagnetic transient automatic modeling in large-scale power grid

InactiveCN109586290AImprove intelligenceControllable typeAc network circuit arrangementsTransient statePower grid

The invention proposes an active control method and system of electromagnetic transient automatic modeling in large-scale power grid, belonging to the technical field of large-scale power grids. The method of the invention includes the following steps: result configuration parameters are converted, the configuration parameters include: a basic configuration parameter and a default configuration parameter; automatic modeling process control rules are determined, and the automatic modeling process control rules include: voltage source mode power grid modeling, generator mode power grid modelingand fault mode power grid modeling. The active control method and system of electromagnetic transient automatic modeling in the large-scale power grid actively controls generation types and the numberof elements in an electromagnetic transient model, so that the types and output scale of the generated elements in the electromagnetic transient model are controllable, and the intelligence of generation of a conversion model is improved, so as to meet various requirements of users for the simulation scale and simulation accuracy.

Owner:CHINA ELECTRIC POWER RES INST

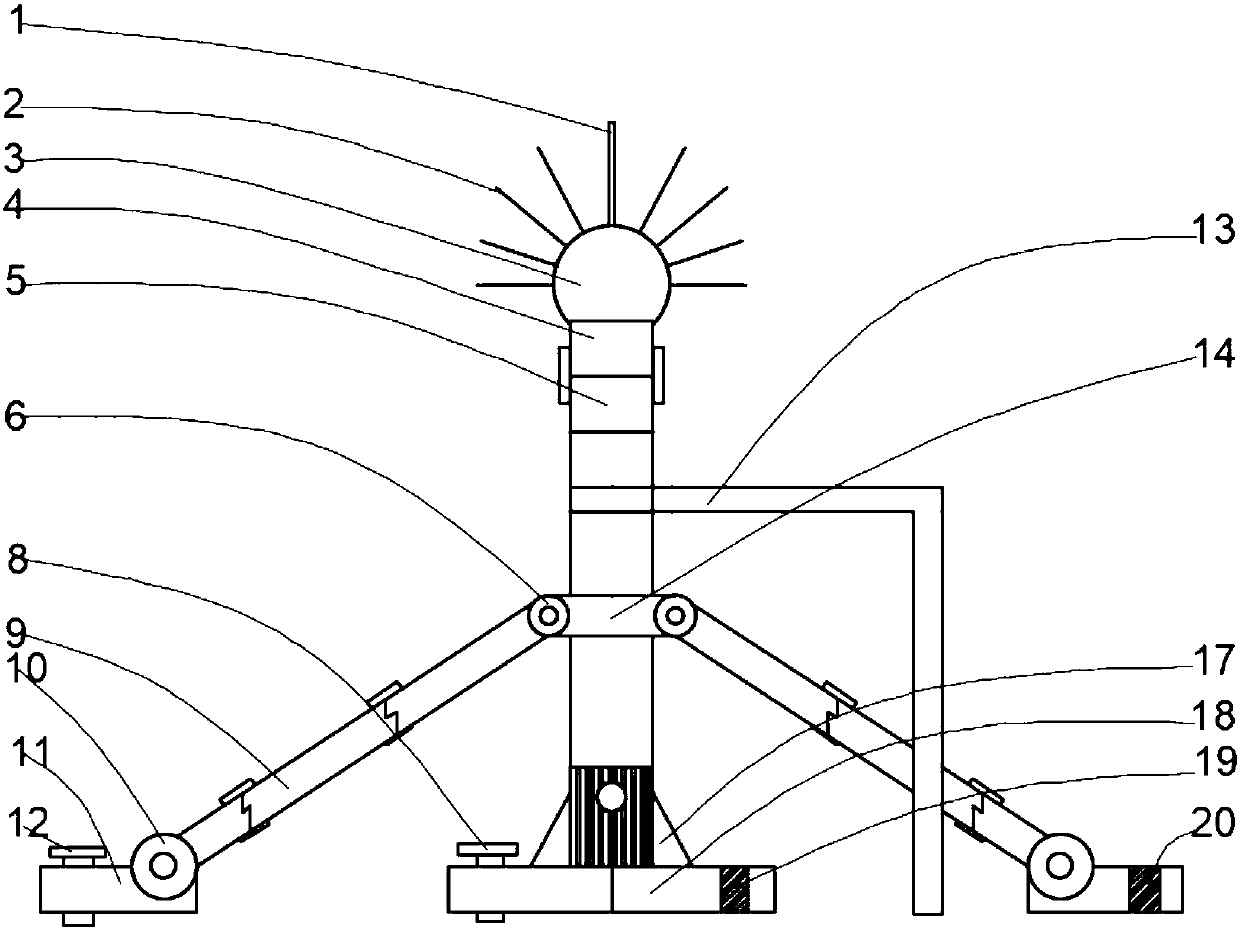

Adjustable lightning arrester for high-rise building

The invention discloses an adjustable lightning arrester for a high-rise building. The adjustable lightning arrester comprises a flash-grounding device, a lightning strip, a conductive rod and a base,wherein a lightning main needle is connected with an upper part of the flash-grounding device, lightning side needles are arranged on a side surface of the lightning main needle, the lightning stripis fixedly connected with a lower part of the flash-grounding device, the conductive rod is fixedly connected with a lower part of the lightning strip, a connection line is connected with a right sideof the conductive rod, the conductive rod is fixedly connected with the base, a first screw hole is formed in the base, reinforcement fixed plates are arranged at two sides of the base, a sleeve ringis arranged at a middle part of the base, first connectors are arranged at two sides of the sleeve ring, a support oblique rod is movably connected with each first connector, a second screw hole is formed in the support oblique rod, an addition rod is arranged on the support oblique rod, and a second connector is arranged on the support oblique rod. By arranging a plurality of lightning needles and by a reinforcement method, the adjustable lightning arrester for the high-rise building is good in lightning effect, large in range and complete in orientation, and is safe and reliable, and the building can be prevented from being damaged by lightning very well.

Owner:赖奇深

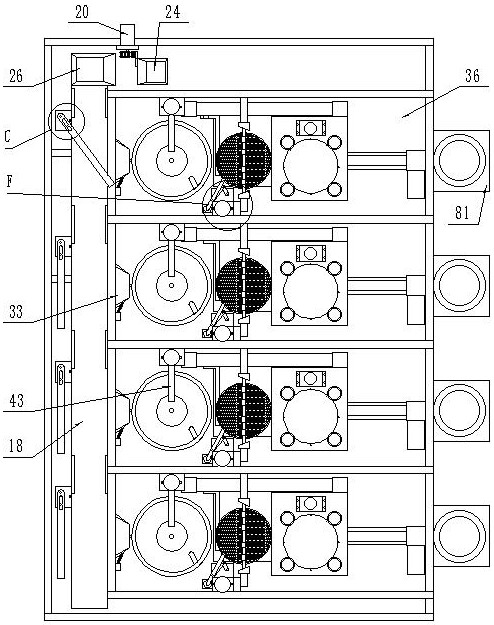

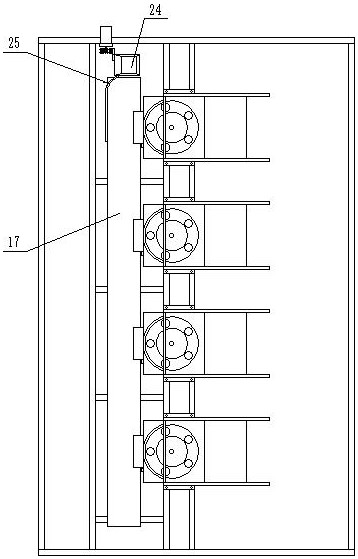

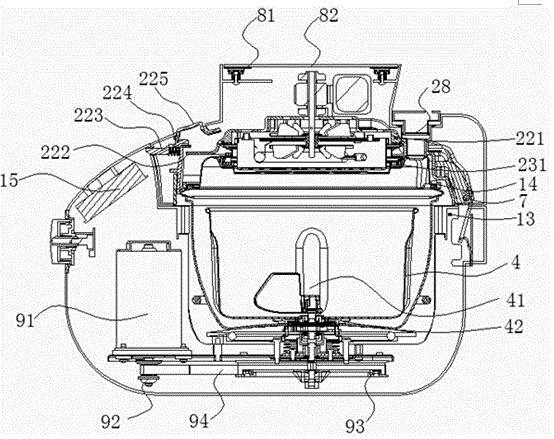

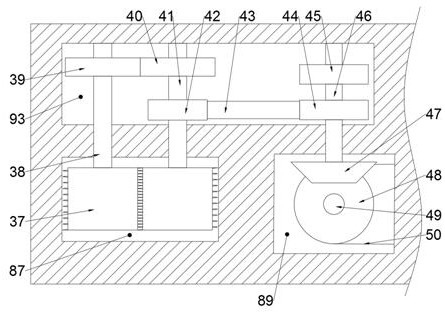

Assembly line type full-automatic dumpling cooking machine

PendingCN111802896AAutomatically achieve quantificationHigh degree of automationBoiling over preventionCooking insertsProcess engineeringAssembly line

The invention discloses an assembly line type full-automatic dumpling cooking machine which comprises a rack, a quantitative discharging mechanism set, a freezing storage mechanism set, a lower-layerconveyor, a lifting mechanism, an upper-layer conveyor, a quantitative feeding mechanism set, a cooking pushing mechanism set, a door stop mechanism and a water supply and drainage system. The assembly line type full-automatic dumpling cooking machine is high in automation degree, dumplings can be automatically and quantitatively put into a pot, cooked, fished out and taken out of a dish, the processing efficiency is greatly improved, a large amount of manpower and material resources are saved, the proper temperature is automatically controlled during cooking, water is automatically added, water is automatically drained, overflowing is prevented, dumplings are automatically stirred, the situation that wrappers are stuck and broken is prevented, the condition and taste of the dumplings areguaranteed, various different dumplings can be cooked at the same time, various different requirements of customers are met, the hot soup tank automatically supplements soup, and the customers can drink hot soup.

Owner:HEBEI YUNDONG NETWORK TECH

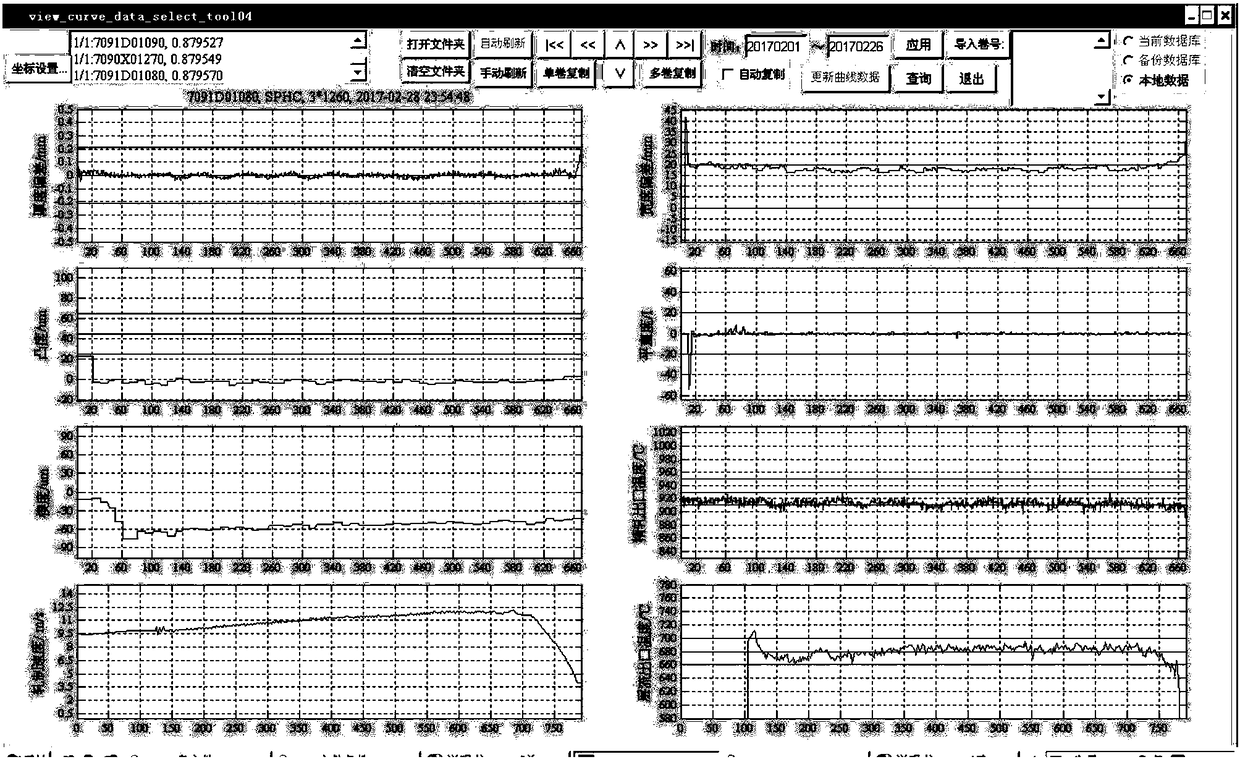

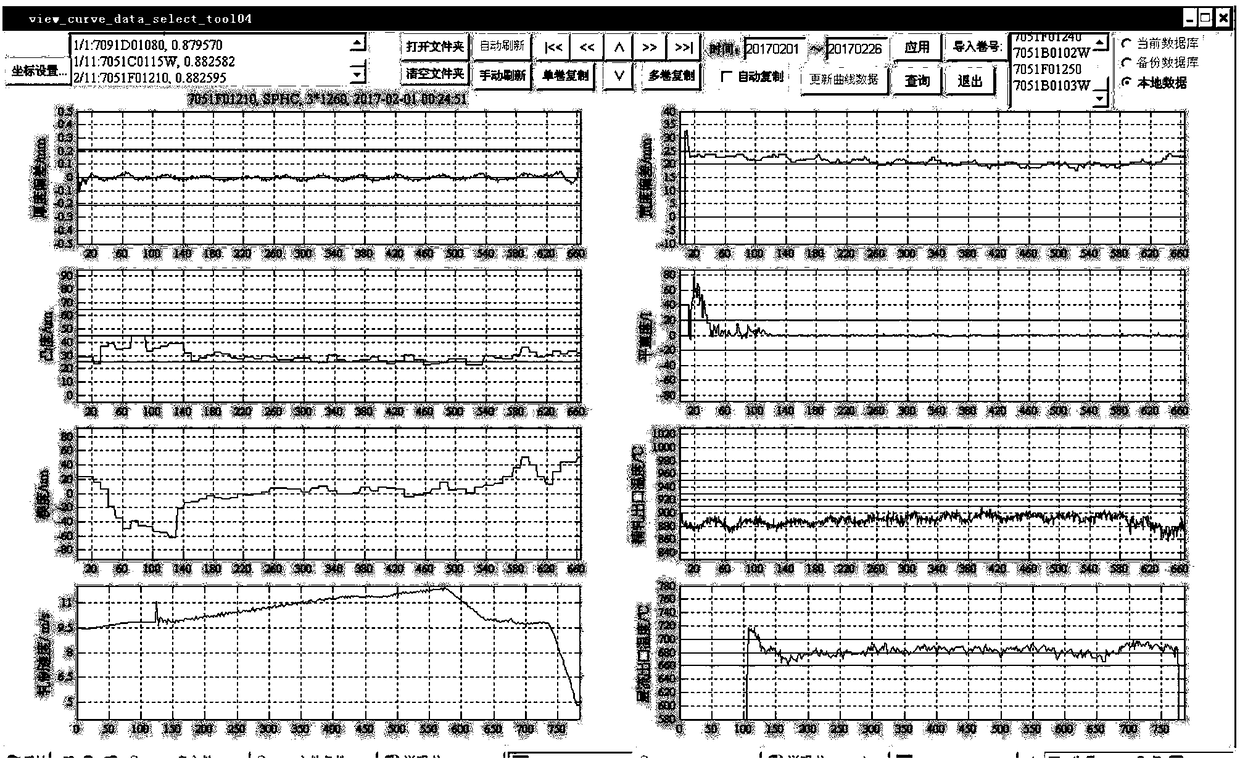

Hot-rolled product quality curve quick query software and query method

InactiveCN108280169AQuick displayQuick searchSpecial data processing applicationsInput/output processes for data processingCritical to qualityComputer science

The invention relates to product quality curve query software and a query method, in particular to hot-rolled product quality curve quick query software and a query method. The query software is characterized by taking thickness, width, convexity, wedge degree, flatness, speed, finishing delivery temperature (FDT) and coiling temperature (CT) as displayed key quality curves. The hot-rolled productquality curve quick query software and the query method are applied to the aspects such as quick viewing of quality of steel reels produced on a certain day, quick viewing of quality of a certain steel type, quick viewing of quality objection reels, quick viewing of quality abnormality reels and the like, the shortcomings of general quality query tools are overcome, the work efficiency is greatlyimproved, and there is a certain positive effect on the stability of database running.

Owner:SD STEEL RIZHAO CO LTD

Preparation method of magnetic immobilized enzyme for producing plant sterol ester

ActiveCN102250869BEasy to introduceThe size is easy to controlChemical industryOn/in organic carrierChemical synthesisDouble bond

The invention relates to a preparation method of a magnetic immobilized enzyme for producing a plant sterol ester, belonging to the field of catalytic materials and chemical synthesis. The preparation method of the magnetic immobilized enzyme for producing the plant sterol ester is characterized by comprising the following steps: 1) carrying out chemical modification on a magnetic substrate with vinylphosphonic acid to introduce a carbon-carbon double bond with reactivity onto the surface of the magnetic substrate; 2) wrapping the surfaces of the modified magnetic particles with polymer layers containing epoxy or sulfonate radical groups to obtain magnetic polymer microspheres; and 3) in a buffer solution, immobilizing an enzyme on the surfaces of the magnetic polymer microspheres by an epoxy ring-opening or electrostatic adsorption method to obtain the magnetic immobilized enzyme for producing the plant sterol ester. The obtained magnetic immobilized enzyme has the characteristics ofhigh catalytic activity, good reuse performance and is simple in separation and recovery.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

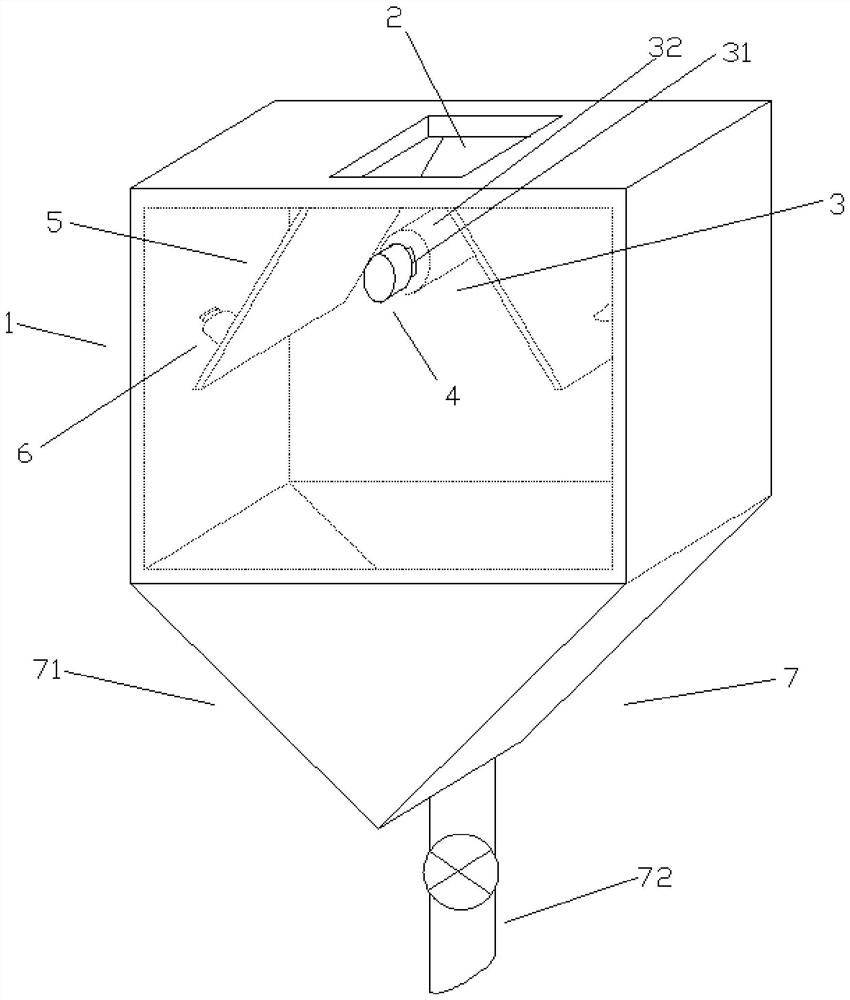

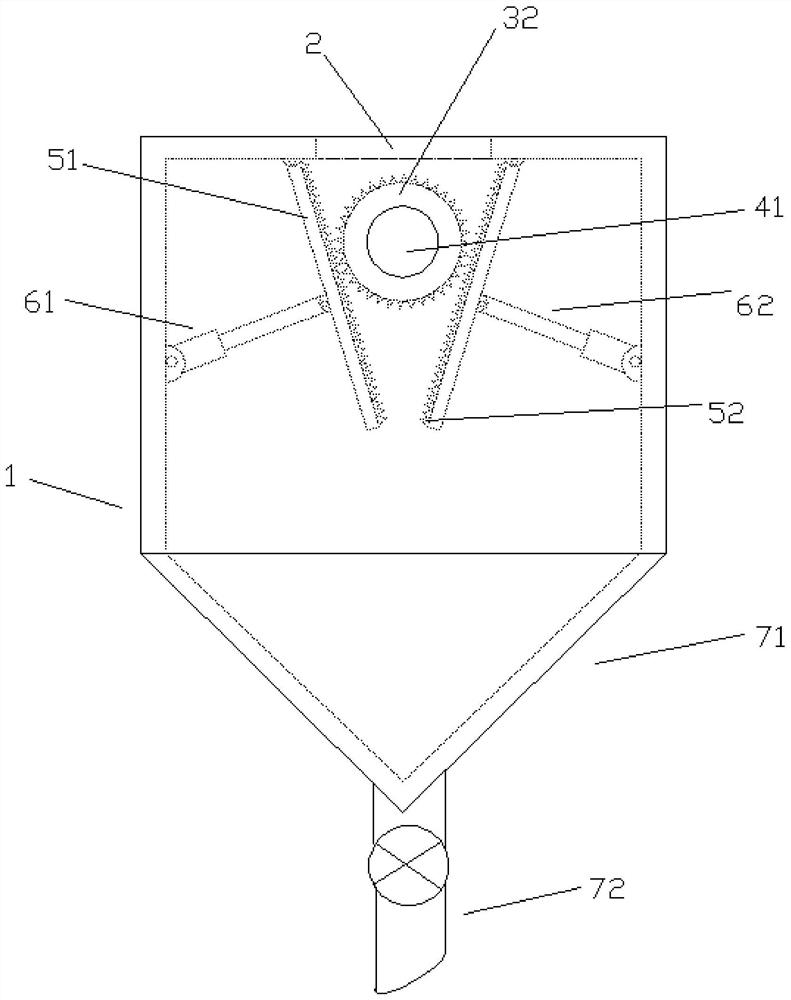

Coal mine crushing device for gypsum mine mining

PendingCN112742524ASimple structureEasy to operateGrain treatmentsMining engineeringMechanical engineering

The invention discloses a coal mine crushing device for gypsum mine mining. The device comprises a crushing box, a feeding opening formed in the top of the crushing box, a crushing structure rotationally connected with the interior of the crushing box, a driving structure arranged outside the crushing box and connected with the crushing structure, crushing plate structures arranged in the crushing box, an adjusting structure arranged between the other ends of the crushing plate structures and the crushing box, and a discharging structure arranged at an opening in the bottom of the crushing box. One ends of the crushing plate structures are hinged to the crushing box; the crushing plate structures are arranged at the two sides of the crushing structure; the crushing structure is arranged right under the feeding opening; and the distance between the crushing plate structures and the crushing structure can be adjusted through the adjusting structure. The coal mine crushing device for gypsum mine mining is simple in structure, convenient to operate, high in practicability and good in crushing effect when used for crushing a coal mine, the crushing degree can be adjusted according to needs, and various different requirements are met, so that the device can be widely applied and is beneficial to application and popularization.

Owner:陈昌军

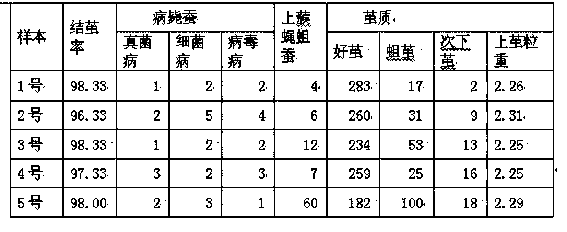

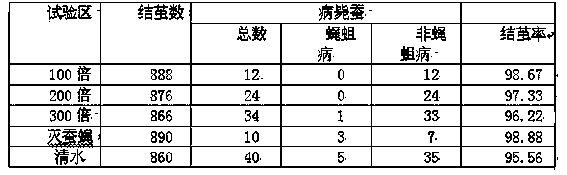

Chlorfenapyr composition for preventing and controlling crossocosmia sericariae as well as preparation method and application method of chlorfenapyr composition

InactiveCN104027330AImprove the effect of prevention and controlHarm reductionAntiparasitic agentsHeterocyclic compound active ingredientsBiotechnologyChlorfenapyr

The invention discloses a chlorfenapyr composition for preventing and controlling crossocosmia sericariae. The chlorfenapyr composition comprises chlorfenapyr agent powder, an assistant and water. The invention discloses a preparation method of the chlorfenapyr composition for preventing and controlling crossocosmia sericariae. A suspending agent stoste containing chlorfenapyr is prepared from the chlorfenapyr powder after a certain ratio of assistant is added. The invention also discloses an application method of the chlorfenapyr composition. A solution containing 0.1-0.03% of chlorfenapyr effective component is prepared from the prepared suspending agent stoste according to the silkworm breeding amount in a manner of diluting by water. The solution is evenly sprayed on the surface of each folium mori, then fed to the silkworms after being evenly mixed, and respectively added to the silkworms at the fifth stage. The composition is simple in preparation step, and the application method is easy to operate, so that the prevention, control and application are convenient, easy and time-saving, the chlorfenapyr composition is small in dosage and is not frequent in usage count, prevention and treatment are just required at the fifth stage of silk and cocoon cultivation of the silkworms, and contribution to research and development of a novel drug for preventing and treating exorista sorbillans is made.

Owner:如皋市蚕桑技术指导站

Oil-sludge-sand three-phase separation treatment system and application thereof

ActiveCN104743757AEfficient separationEfficient three-phase centrifugal separationSludge treatmentRefluxEngineering

The invention relates to an oil-sludge-sand three-phase separation treatment system which comprises a heating and stirring kettle for heating and stirring materials and a three-phase separation machine communicated with the heating and stirring kettle. According to the system, the rotary stirring of the materials is enhanced by a centrifugal barrel and a stirring rotating shaft barrel, which rotate in opposite directions, and meanwhile, the materials are subjected to three-phase separation under a centrifugal force generated by high-speed rotation of the centrifugal barrel; since a screw blade is mutually attached to the inner wall of the centrifugal barrel, a sand phase is conveyed to a sand phase discharge opening as the screw blade rotates, and an oil phase and a water phase are closely attached to the screw blade under the action of the centrifugal force and finally flow back to the large-diameter end of the centrifugal barrel along liquid-phase reflux holes in the screw blade; and according to the stratification condition of the water phase and the oil phase on the wall of the centrifugal barrel, namely that the water phase is closely attached to the inner wall of the centrifugal barrel under the action of the centrifugal force, followed by the oil phase, a water phase outlet and an oil phase outlet are concentrically formed in the large-diameter end of the centrifugal barrel respectively so as to lead the water phase and the oil phase out respectively.

Owner:威海恒荣环保科技有限公司

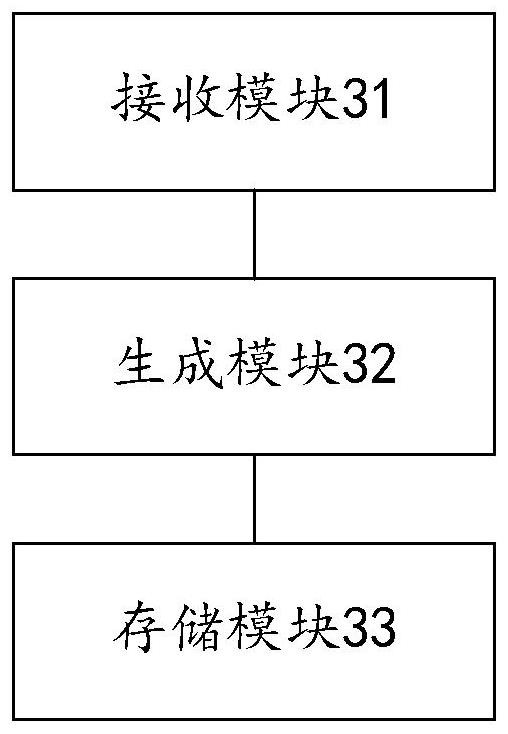

Log data processing method and device, equipment and storage medium

PendingCN114116646AMeet a variety of different needsInterprogram communicationRelational databasesEngineeringUser identifier

The invention discloses a log data processing method and device, equipment and a storage medium. The method comprises the following steps: receiving a log acquisition request message sent by a user, wherein the log acquisition request message carries a user identifier; generating a performance and abnormal record log of the user according to the user identifier of the user; outputting the performance and exception record logs to different storage positions according to preset settings, so that an administrator uses the performance and exception record logs according to different use scenes; the storage position comprises an ES, an sqlserver or an MQ. According to the method, the user logs can be stored in different storage positions according to needs, and various different needs of managers can be met.

Owner:上海异工同智信息科技有限公司

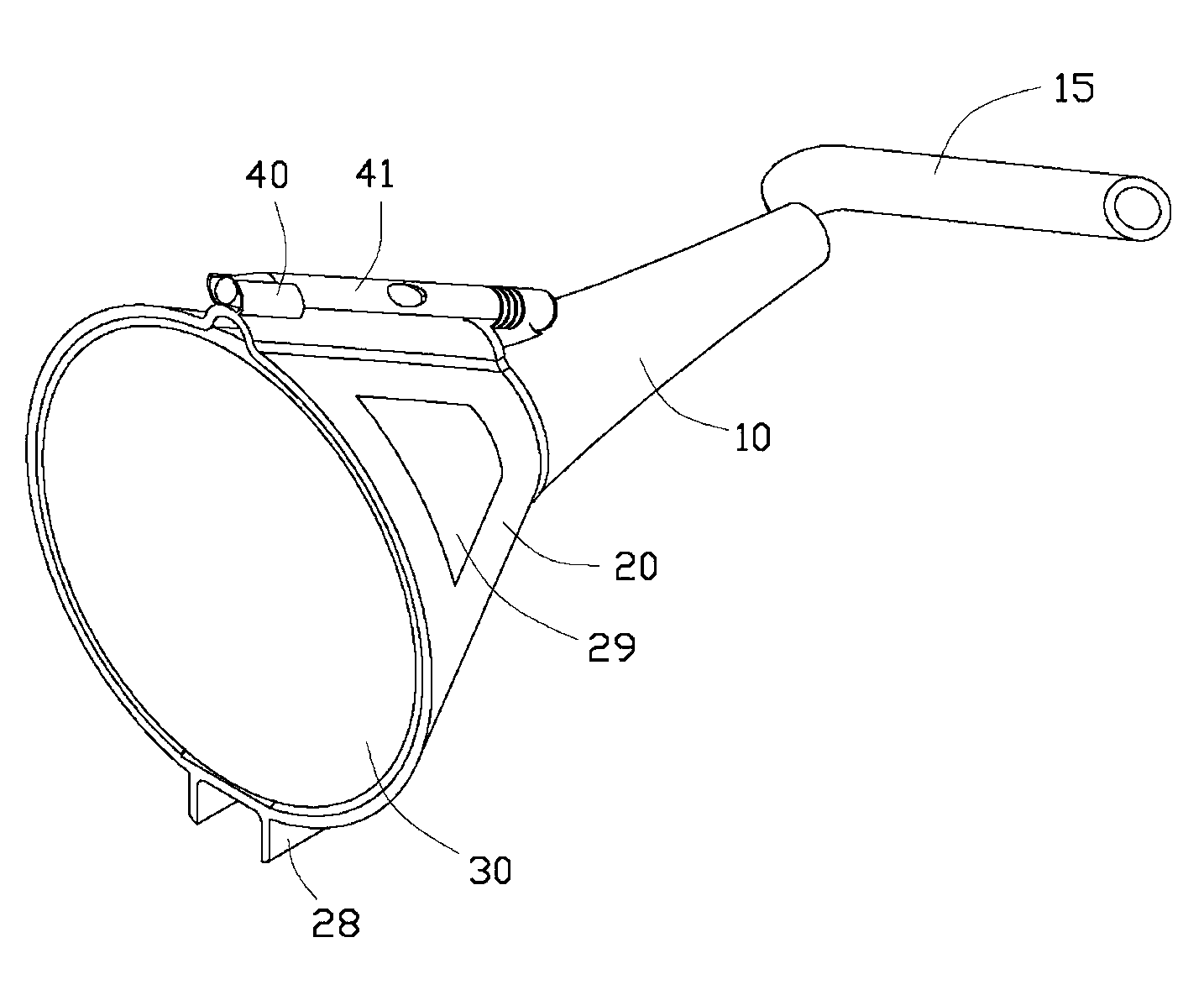

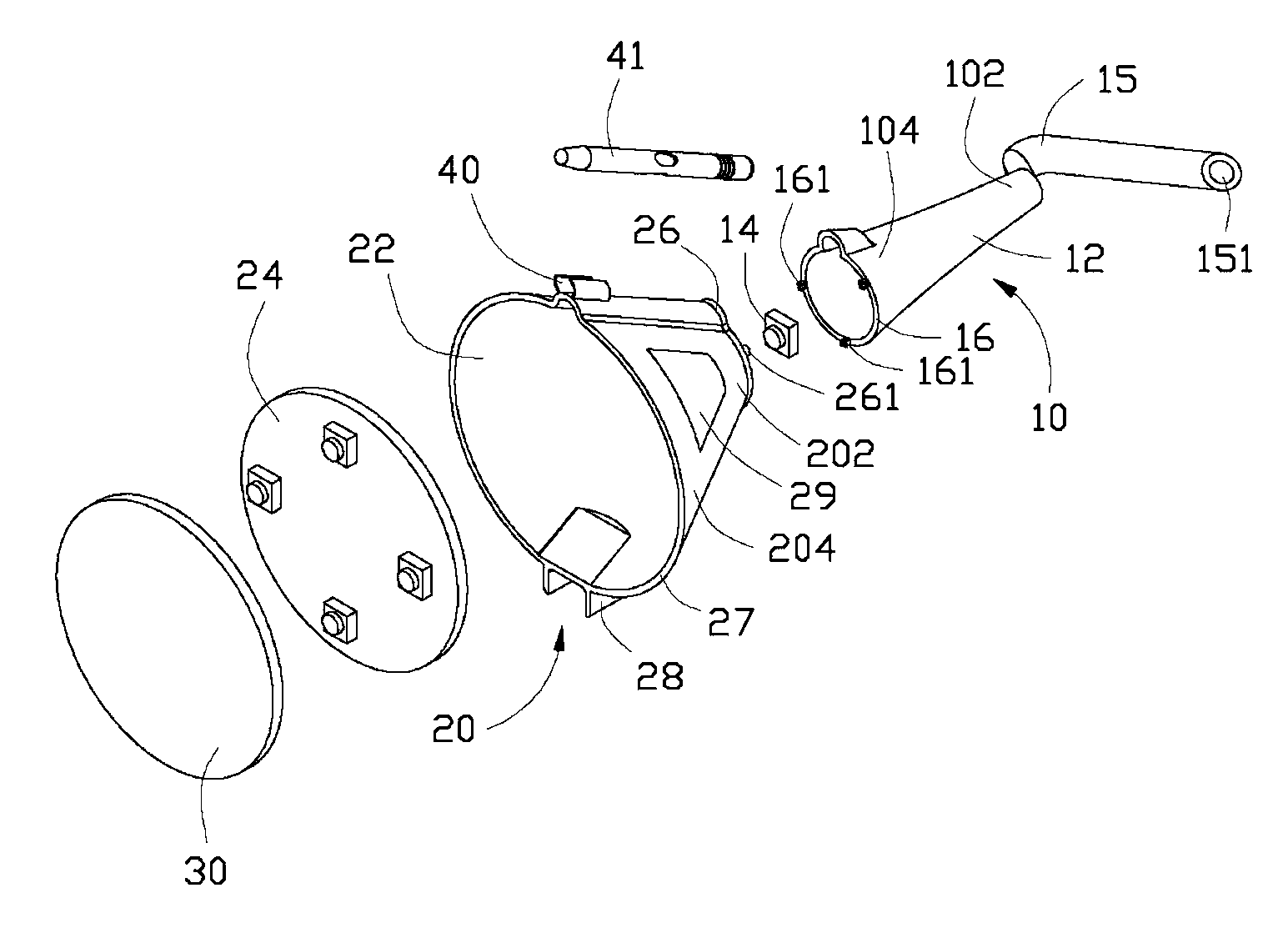

Metal button assembly and its control box assembly and range hood

ActiveCN104134561BOpen controlLow selectivityDomestic stoves or rangesLighting and heating apparatusKey pressingHOOD assembly

The invention discloses a metal button assembly, a control box assembly and a range hood with the same, wherein the metal button assembly includes: an electric lamp; a switch; a transparent button body; an opaque lampshade, and the lampshade is arranged on the transparent button The outside of the main body, and the lampshade is provided with a hollow part; and a light-transmitting sealing part, the light-transmitting sealing part is at least partially embedded in the hollow part of the lampshade. According to the metal button assembly of the embodiment of the present invention, a hollow part that can transmit light is provided on the lampshade, which improves the light transmission effect; and a light-transmitting seal is provided on the inner wall of the lampshade, which can not only ensure the transmission of light, but also prevent the external The oily fume, etc. enter the inside of the switch, which is safer and more convenient to use.

Owner:MIDEA GRP CO LTD

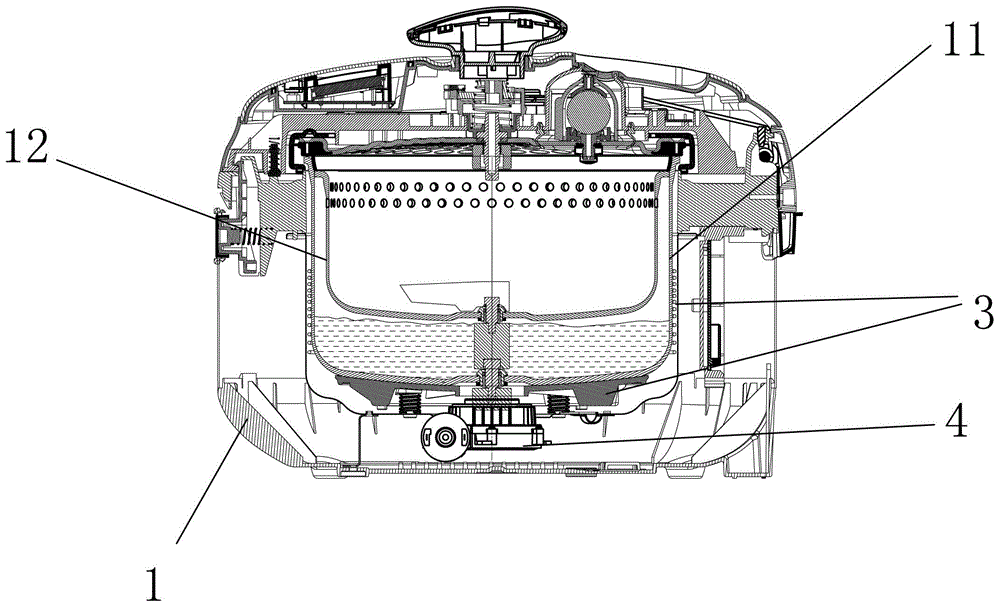

A multifunctional cooking machine

ActiveCN105231802BMeet a variety of different needsMeet different needsCooking-vessel lids/coversRoasters/grillsImpellerEngineering

The present application discloses a multifunctional cooking machine, comprising: a pot body and a cover body hinged together through a rotating shaft, the pot body is provided with a first heating device, a transmission device and an inner pot; the cover body includes a surface cover, a lining cover, a sealing The cover assembly and the movable cover plate, the first heating device includes a heating plate arranged on the bottom of the inner pot and a lower heating pipe arranged on the inner wall of the pot body; a fan device and a second heating device are arranged above the sealing cover assembly, the fan device It includes a shaded pole motor, an upwind impeller and a downwind impeller connected to the output shaft of the shaded pole motor. The shaded pole motor is arranged above the lining cover; a protective plate is provided at the lower end of the lining cover, and several ventilation holes are provided on the protective plate; For the ventilation and heat dissipation of the shaded pole motor itself, the downwind impeller blows the heat generated by the second heating device to the pot body; the multifunctional cooking machine is also provided with an opening induction device, a bread bucket and a stirring device connected to the transmission device; The inner pot and bread bucket can be replaced freely.

Owner:GUANGDONG ENAITER ELECTRICAL APPLIANCES CO LTD

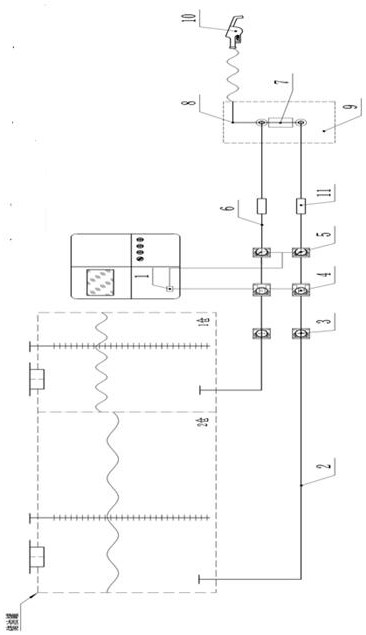

Mixing proportion oil discharging system

InactiveCN111792612AFlexible usageWide applicabilityLiquid transferring devicesPower switchingProcess engineering

The invention discloses a mixing proportion oil discharging system which comprises a control part, a valve body part and an oil adding part forming the oil discharging system jointly. The control partis an integrated anti-explosion control box. The control box is integrated with liquid level display, concentration alarm, medium temperature, a power supply switch, a pump control switch, a sensor module and a signal conversion module. The mixed proportion oil discharging system is flexible in application mode and wide in applicability, can be integrated in a control room of a conventional obstructing anti-explosion skid-mounted oil adding device, an existing double oil product skid-mounted oil adding device can be additionally mounted and modified, and the control room can act as an independent skid-mounted control room of a double-medium mixing proportion oil discharging system.

Owner:辽宁易通智能装备制造有限公司

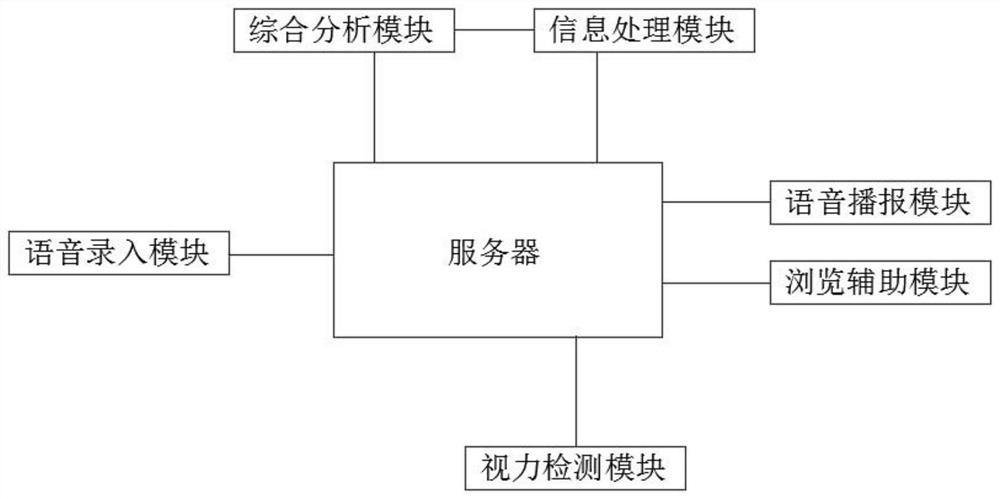

Barrier-free website browsing system

ActiveCN111581575AEasy to browseAdjust font sizeSpeech analysisWebsite content managementVisually impairedInformation processing

The invention discloses a barrier-free website browsing system. The system comprises a vision detection module, a comprehensive analysis module, an information processing module, a voice broadcast module, a voice input module, a server and a browsing auxiliary module. Website browsing users respond to the vision test questions; the vision detection module is used for detecting vision information of a website browsing user and sending the vision information to the server for storage; the comprehensive analysis module is used for analyzing and identifying whether the sound information input by the visually impaired user logging in the browsing website is matched or not; the information processing module is used for adding different adjusting functions to websites browsed by a myopia user, acolor blindness user and a color weakness user respectively, and a website interface adjusting function is added to the myopia user through the browsing auxiliary module. And a website color matchingadjustment function is added to the color blindness user and the color weakness user through the browsing auxiliary module.

Owner:安徽龙讯信息科技有限公司

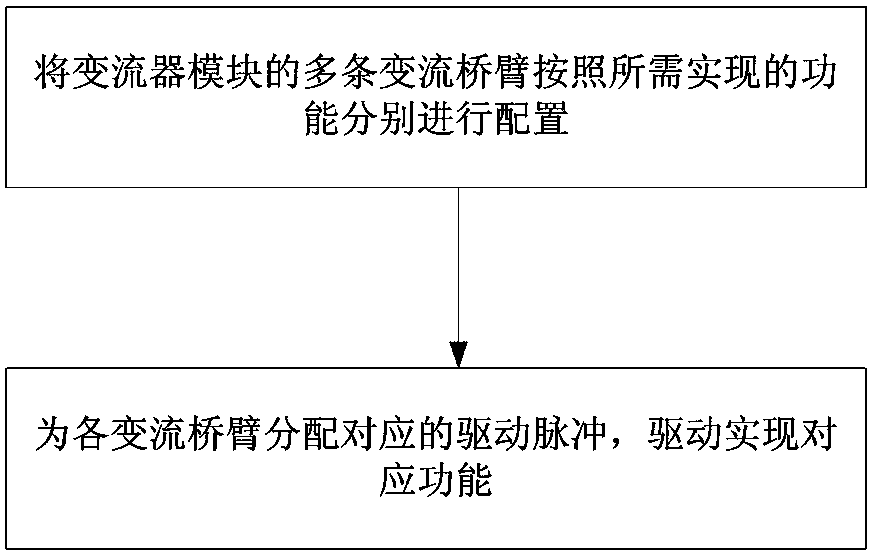

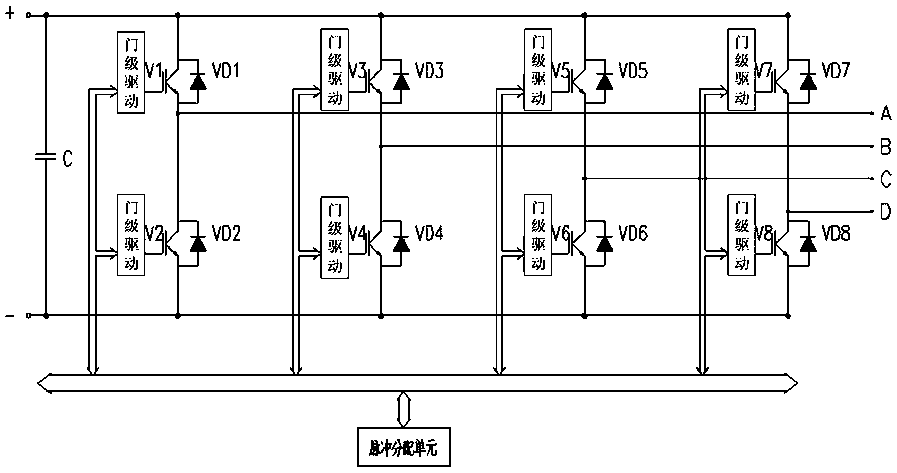

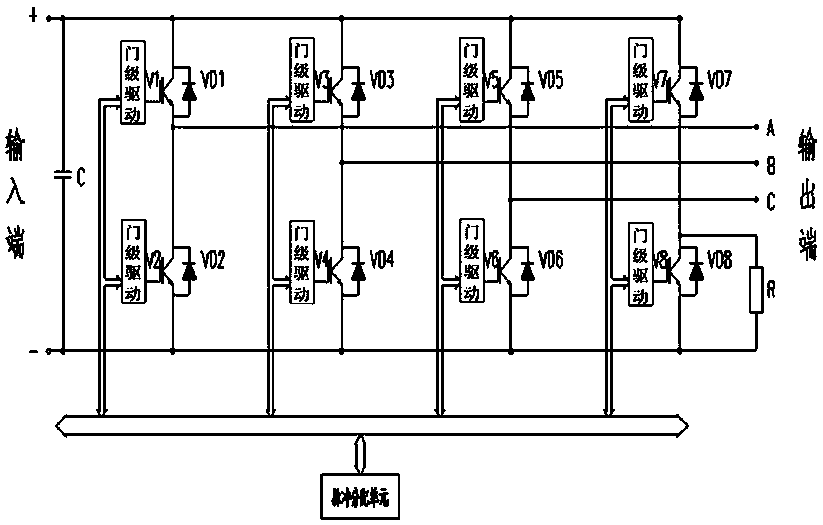

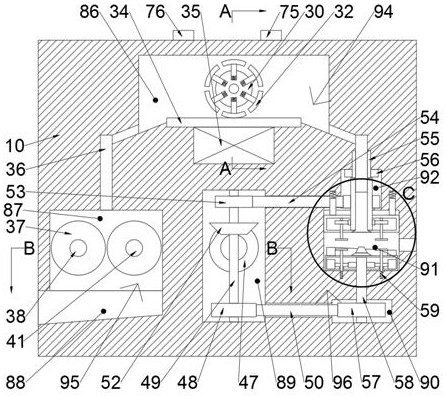

Method and device for realizing a multifunctional converter module

ActiveCN104967332BMeet a variety of different needsMeet different needsAc-dc conversionEmbedded systemMultiple function

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

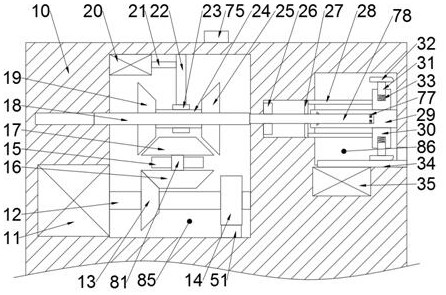

Reading equipment for cleaning and destroying bank cards

InactiveCN112139095AEasy to handleMeet a variety of different needsSensing detailsCleaning using toolsEngineeringMechanical engineering

The invention discloses reading equipment for cleaning and destroying bank cards. The reading equipment comprises a machine body, a power cavity is formed in the machine body, a card feeding cavity isformed in the front side of the power cavity, a transmission cavity is formed in the lower side of the card feeding cavity, a smashing cavity is formed in the left side of the transmission cavity, acard discharging cavity is formed in the lower side of the smashing cavity, a belt wheel cavity is formed in the right side of the transmission cavity, and a cleaning cavity is formed in the upper side of the belt wheel cavity; and a lifting cavity is formed in the upper side of the cleaning cavity, a connecting cavity is formed in the rear side of the smashing cavity, a card feeding device for feeding the bank cards into the equipment is arranged in the card feeding cavity and comprises a main motor fixedly installed on the rear side wall of the power cavity, a smashing device for smashing the bank cards is arranged in the smashing cavity, and a cleaning device for cleaning the bank cards is arranged at the right side of the machine body. The equipment can destroy the unnecessary bank cards when information in the bank cards is read, clean the bank cards with dirt, meet various different requirements and facilitate people to operate and process the different bank cards.

Owner:义乌台维电子科技有限公司

Light-emitting diode (LED) combined lamp

InactiveCN103123053AMeet a variety of different needsMeet different needsPoint-like light sourceElectric lightingEngineeringLight fixture

A light-emitting diode (LED) combined lamp comprises a first lighting unit, a second lighting unit and a lampshade covering the second lighting unit. The first lighting unit comprises a first shell and a first LED module arranged in the first shell, wherein the first shell is provided with a fixed end located at the top and a first connecting end located at the bottom. The second lighting unit comprises a second shell, a second LED module and a fixed seat, wherein the second LED module is arranged in the second shell, the fixed seat is arranged outside the second shell and used for being connected with an external power supply, the second shell is provided with a second connecting end located at the top and a combining end located at the bottom, the lampshade and the combining end are combined, and connecting pieces connecting the first lighting unit and the second lighting unit are arranged on the first connecting end and the second connecting end. The first lighting unit and the second lighting unit are detachably connected together through the connecting pieces, and the fixed seat is arranged on the second lighting unit and can be used alone, so that multiple different needs of a user can be met.

Owner:FOXSEMICON INTEGRATED TECHNOLOGY (SHANGHAI) INC +1

An air atomizing nozzle

A gas atomizing nozzle, including a nozzle body, a gas guide core, a spray nozzle, a lock nut, a processing hole plug, etc., the nozzle body is used to introduce pressurized liquid and gas, and is used as a mounting base for other components, the nozzle The main body divides the gas into two branches; the gas guide core can introduce the gas from the second branch to the nozzle outlet mixing chamber and then spray it out; the injection nozzle is the last part of the nozzle. The spray nozzle sprays out; the lock nut fixes the air guiding core and the spray nozzle to the nozzle main body; the processing hole plug is used to block the outer hole left by processing the inner hole of the nozzle main body. This nozzle is a multifunctional gas atomizing nozzle. The combined structure can change the nozzle into a double-mixed bubble type + pneumatic atomizing nozzle, bubble atomizing nozzle, pneumatic atomizing nozzle, etc. by changing the shape of the parts. The size of the through holes can also achieve different atomization effects.

Owner:LOW SPEED AERODYNAMIC INST OF CHINESE AERODYNAMIC RES & DEV CENT

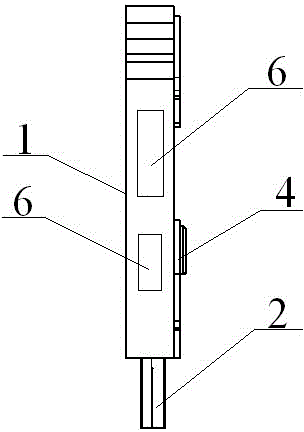

A single network cable extender for data transmission

ActiveCN110943336BExtended service lifePlay a protective effectTelevision system detailsCouplings bases/casesData signalTrunking

The present invention provides a single network cable extender for data transmission, which is arranged between the first network cable used for signal transmission and the second network cable used for relay transmission, including a base, a housing on the base and a device. For the relay module in the casing, the two ends of the casing are respectively provided with a first plug-in interface for plugging in with the first network cable and a second plug-in port for plugging in with the second network cable. In the single network cable extender for data transmission provided by the present invention, the first network cable and the second network cable are connected through a relay module, so as to achieve the effect of data transfer processing and then continue transmission, thereby increasing the transmission distance of the entire data signal, and can also Adjust the number of network cables according to the required transmission distance. The connection between the first network cable and the second network cable can be realized through the first socket and the second socket, and then the heat generated by the relay module can be dissipated to the Inside the second inner cavity, the relay module is prevented from being damaged due to overheating, which prolongs the service life.

Owner:ZHUHAI DAHENGQIN TECH DEV CO LTD

Connectable USB flash disk

The invention discloses a connectable USB flash disk which comprises a shell, wherein a flash memory card and a circuit board connected with the flash memory card are arranged in the shell; a USB plug is connected with the circuit board by virtue of a flexible circuit; a cavity for containing the USB plug is formed inside the shell; the cavity is communicated with an open slot formed in one end of the shell; sliding rails are symmetrically arranged on cavity walls at the left and right sides of the cavity; slide blocks connected with the USB plug are arranged on the sliding rails; a mounting slot is formed in a part, which corresponds to the sliding rail at one side, of the shell; the USB plug can extend out of the open slot in the mounting slot formed in the slide block at one side by pushing the slide blocks; a USB socket is arranged at the other end, which is opposite to the open slot, of the shell; multiple card reader slots are formed in the left and right sides of the shell; and the USB socket and the card reader slots are connected with the circuit board. The connectable USB flash disk disclosed by the invention is good in practical effect and high in self-utilization rate, can simultaneously meet multiple different requirements and has high market value.

Owner:LUOYANG INST OF SCI & TECH

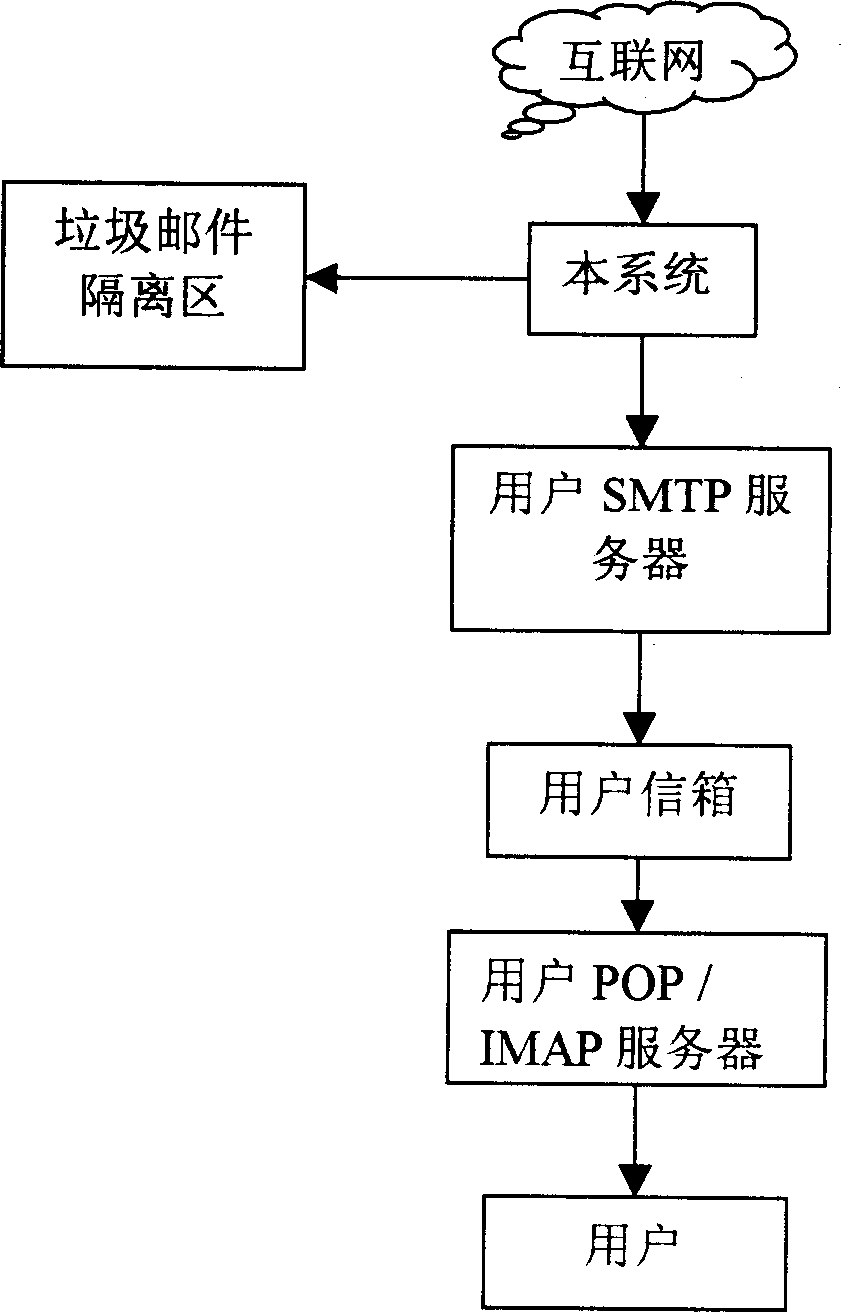

Method for preventing rubbish E-mail

InactiveCN1180353CMeet a variety of different needsUnauthorized memory use protectionSpecific program execution arrangementsSpammingEngineering

There is a method for preventing rubbish e-mail; the key is that it adds a label on the address of E-mail and adds a system which deals with the E-mail according to the prescriptive procedure in mail server-a SMTP server. The label can be created optional by the user of the mail address and needn't to be set in the mail server, the receiver can control the mail address to be used only by the appointed person or constitute, the mail server processes the mail according to the prescriptive procedure, the receiver can reduce the rubbish mail greatly.

Owner:上海蓝飞通信设备有限公司

A three-phase separation treatment system for oil sludge and sand and its application

ActiveCN104743757BEfficient separationEfficient three-phase centrifugal separationSludge treatmentRefluxOil sludge

The invention relates to an oil-sludge-sand three-phase separation treatment system which comprises a heating and stirring kettle for heating and stirring materials and a three-phase separation machine communicated with the heating and stirring kettle. According to the system, the rotary stirring of the materials is enhanced by a centrifugal barrel and a stirring rotating shaft barrel, which rotate in opposite directions, and meanwhile, the materials are subjected to three-phase separation under a centrifugal force generated by high-speed rotation of the centrifugal barrel; since a screw blade is mutually attached to the inner wall of the centrifugal barrel, a sand phase is conveyed to a sand phase discharge opening as the screw blade rotates, and an oil phase and a water phase are closely attached to the screw blade under the action of the centrifugal force and finally flow back to the large-diameter end of the centrifugal barrel along liquid-phase reflux holes in the screw blade; and according to the stratification condition of the water phase and the oil phase on the wall of the centrifugal barrel, namely that the water phase is closely attached to the inner wall of the centrifugal barrel under the action of the centrifugal force, followed by the oil phase, a water phase outlet and an oil phase outlet are concentrically formed in the large-diameter end of the centrifugal barrel respectively so as to lead the water phase and the oil phase out respectively.

Owner:威海恒荣环保科技有限公司

A Web Accessibility Browsing System

ActiveCN111581575BAdjust font sizeAdjust contrastSpeech analysisWebsite content managementVisually impairedInformation processing

The invention discloses a website barrier-free browsing system, which includes a vision detection module, a comprehensive analysis module, an information processing module, a voice broadcast module, a voice input module, a server, and a browsing auxiliary module, and a website browsing user responds to the vision detection question The vision detection module is used to detect the vision information of website browsing users and send the vision information to the server for storage. The comprehensive analysis module is used to analyze and identify whether the sound information entered by visually impaired users when logging in to the website matches, so that the website is sensitive to the visually impaired. The user's browsing has a memory function, which provides convenience for the visually impaired users to browse. The information processing module adds different adjustment functions to the websites browsed by myopic users, color blind users and color weak users, and adds websites for myopic users through the browsing auxiliary module. Interface adjustment function; Add website color adjustment function for color blind users and color weak users through browsing auxiliary module.

Owner:安徽龙讯信息科技有限公司

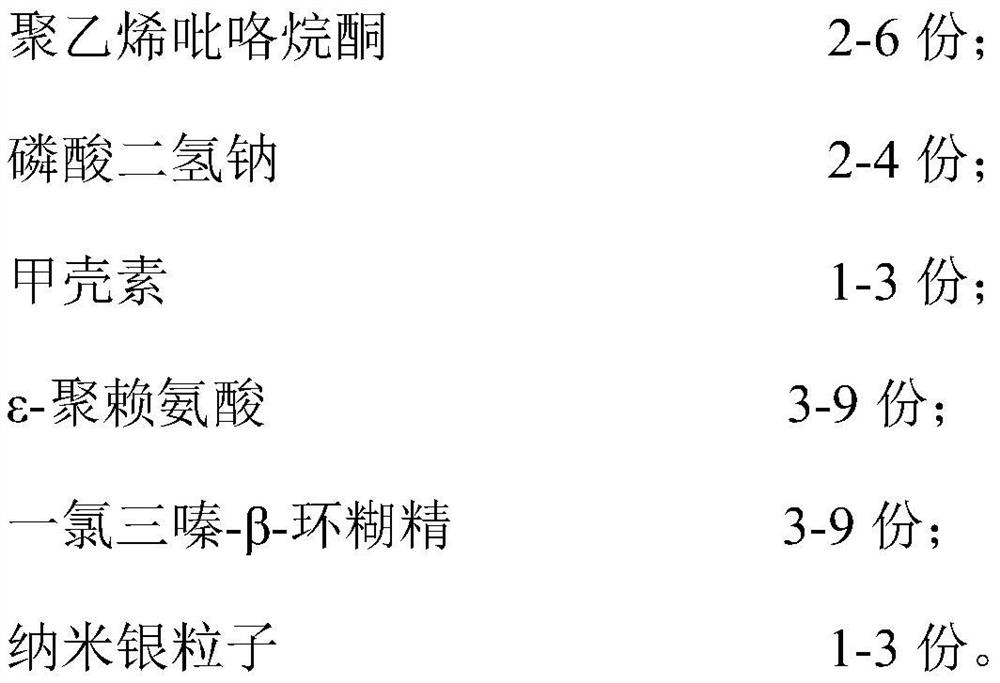

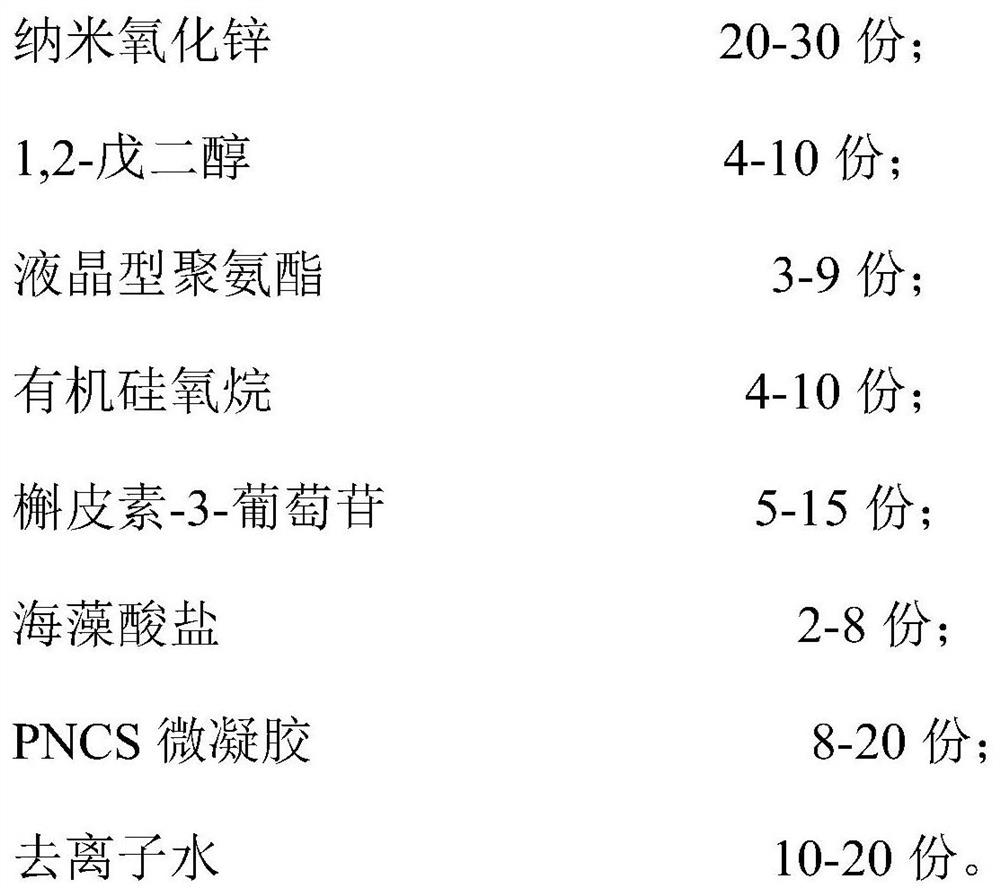

Fabric finishing agent and method for finishing pure cotton fabric by using same

ActiveCN113668233AExtended service lifeIncrease elasticityBiochemical fibre treatmentLight resistant fibresPolymer scienceMoisture absorption

The invention discloses a fabric finishing agent. The fabric finishing agent comprises a first finishing agent and a second finishing agent, and the first finishing agent and the second finishing agent both comprise raw materials with specific components. The invention also discloses a method for finishing a pure cotton fabric by using the fabric finishing agent. The fabric finishing agent disclosed by the invention is divided into two parts with different purposes, the specific raw materials and proportions are adopted, and the method for finishing the pure cotton fabric by using the fabric finishing agent is simple to operate. The pure cotton fabric finished by the finishing method has quick perspiration, drying and heat conduction properties, clothes made of the cotton fabric have excellent moisture absorption and cooling properties, can meet various different requirements of people, and is high in practicability and wide in application range; and meanwhile, the finished pure cotton fabric also has ultraviolet resistance, waterproofness and tearing strength, and also has antibacterial and bacteriostatic properties, so that mould breeding is avoided.

Owner:JIANGXI INST OF FASHION TECH

A multifunctional electric cooker

ActiveCN102973129BMeet a variety of different needsSteam cooking vesselsBread-toastersElectricityEngineering

The patent of the present invention relates to a multifunctional electric cooker, which includes a pot body, a motor installed in the pot body, a main pot placed in the pot body, and a heating element. The motor has an output shaft, and the main pot includes a The rotating shaft at the first end and the second end, the first end of the rotating shaft of the main body is connected to the output shaft of the motor, and the electric cooker also includes a steaming and roasting pot, and the steaming and roasting pot has a first end and a second The rotating shaft at the end, the first end of the rotating shaft of the steaming and roasting pot can be connected by transmission with the second end of the rotating shaft of the main body pot. The invention also provides a method for using the multifunctional electric cooker. Beneficial effects of the present invention: realize one machine with multiple functions.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com