Fabric finishing agent and method for finishing pure cotton fabric by using same

A fabric finishing agent and pure cotton fabric technology, which is applied in fiber treatment, plant fiber, biochemical fiber treatment, etc., can solve the problems of insufficient comfort, complex moisture-conducting cotton fabric process, and poor antibacterial ability, so as to avoid bacterial growth, Enhance mechanical properties, durability and water resistance, and prevent oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

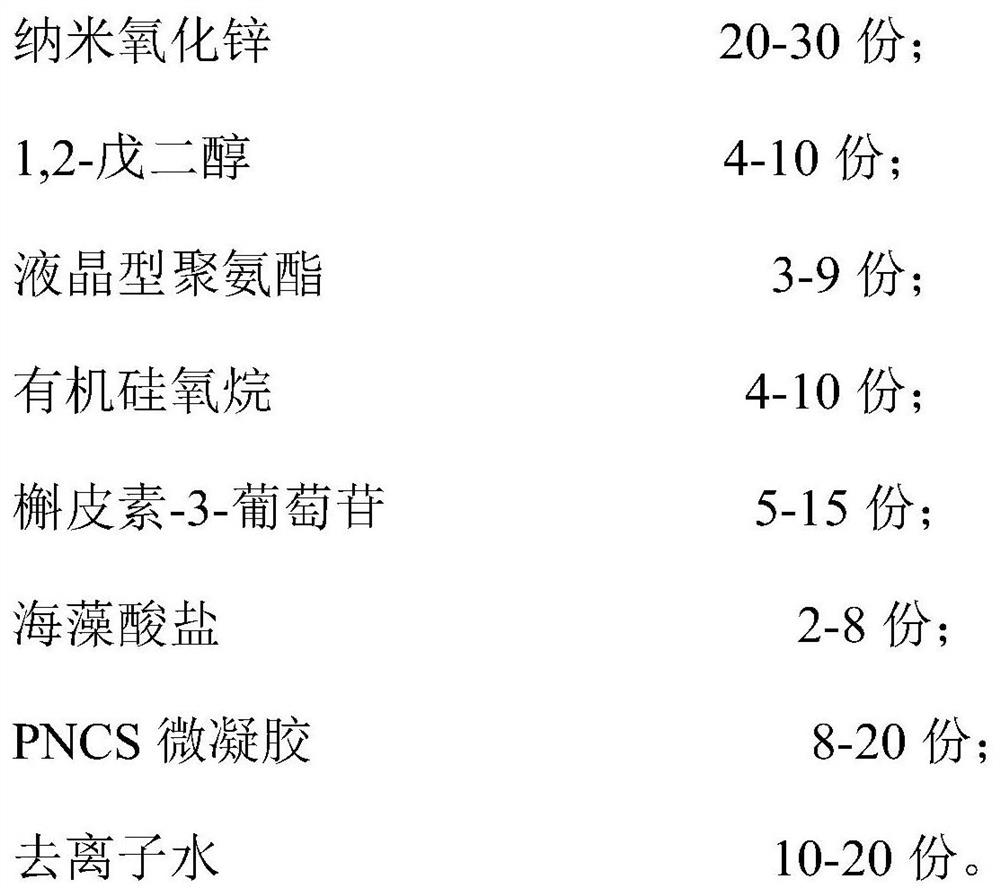

[0035] This embodiment provides a fabric finishing agent, including a first finishing agent and a second finishing agent. Among the raw materials, the first finishing agent includes 200g of nanometer zinc oxide, 40g of 1,2-pentanediol, 30g of liquid crystal polyurethane, organic 40g of siloxane, 50g of quercetin-3-glucoside, 20g of alginate, 80g of PNCS microgel and 100g of deionized water; the second finishing agent includes 20g of polyvinylpyrrolidone, 20g of sodium dihydrogen phosphate, and 10g of chitin , ε-polylysine 30g, chlorotriazine-β-cyclodextrin 30g, nano silver particles 10g.

[0036] This embodiment also provides a method for finishing pure cotton fabrics, the specific steps are as follows:

[0037] (1) Pour the first finishing agent into the padding machine, put the pure cotton fabric into the oven after the second dipping and second rolling, and dry it at 60°C;

[0038] (2) Spray the second finishing agent on the pure cotton fabric surface after padding, adopt ...

Embodiment 2

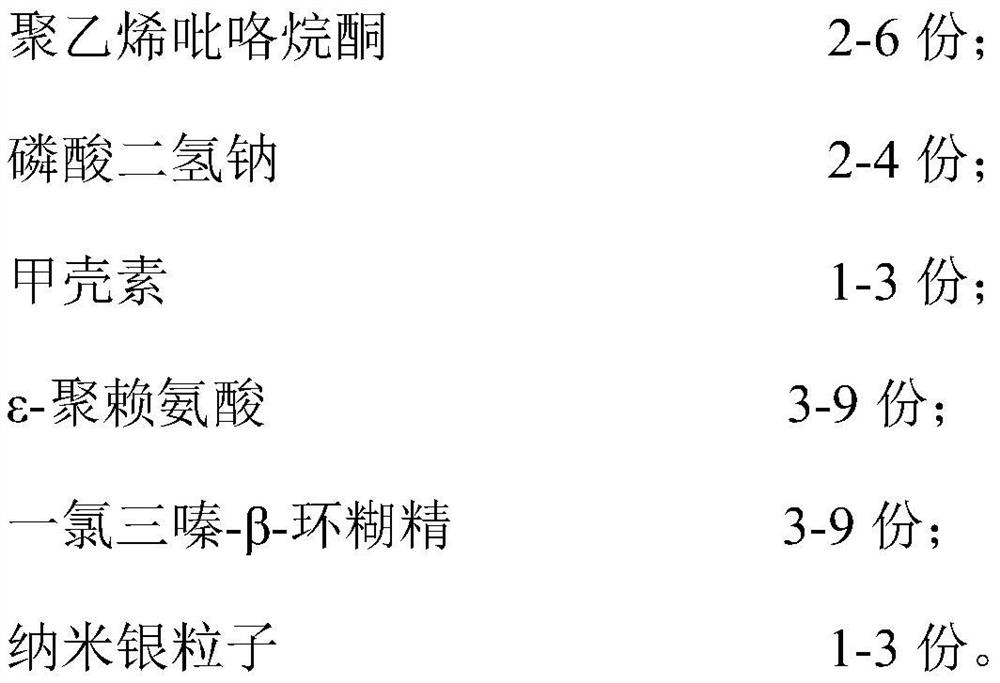

[0041] This embodiment provides a fabric finishing agent, including a first finishing agent and a second finishing agent. Among the raw materials, the first finishing agent includes 300g of nanometer zinc oxide, 100g of 1,2-pentanediol, 90g of liquid crystal polyurethane, organic 100g of siloxane, 150g of quercetin-3-glucoside, 80g of alginate, 200g of PNCS microgel and 200g of deionized water; the second finishing agent includes 60g of polyvinylpyrrolidone, 40g of sodium dihydrogen phosphate, and 30g of chitin , ε-polylysine 90g, chlorotriazine-β-cyclodextrin 90g, nano silver particles 30g.

[0042] This embodiment also provides a method for finishing pure cotton fabrics, the specific steps are as follows:

[0043] (1) Pour the first finishing agent into the padding machine, put the pure cotton fabric into the oven after the second dipping and second rolling, and dry it at 80°C;

[0044] (2) Spray the second finishing agent on the pure cotton fabric surface after padding, ad...

Embodiment 3

[0047] This embodiment provides a fabric finishing agent, including a first finishing agent and a second finishing agent. Among the raw materials, the first finishing agent includes 220g of nanometer zinc oxide, 50g of 1,2-pentanediol, 40g of liquid crystal polyurethane, organic 60g of siloxane, 70g of quercetin-3-glucoside, 30g of alginate, 100g of PNCS microgel and 120g of deionized water; the second finishing agent includes 30g of polyvinylpyrrolidone, 30g of sodium dihydrogen phosphate, and 10g of chitin , ε-polylysine 50g, chlorotriazine-β-cyclodextrin 40g, nano-silver particles 20g.

[0048] This embodiment also provides a method for finishing pure cotton fabrics, the specific steps are as follows:

[0049] (1) Pour the first finishing agent into the padding machine, put the pure cotton fabric into the oven after the second dipping and second rolling, and dry it at 65°C;

[0050] (2) Spray the second finishing agent on the pure cotton fabric surface after padding, adopt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com