Assembly line type full-automatic dumpling cooking machine

An assembly line, fully automatic technology, applied in the direction of overflow prevention, the structure of cooking utensils, plug-ins, etc., can solve the problems of inconvenient operation, easy to boil dumpling skin, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

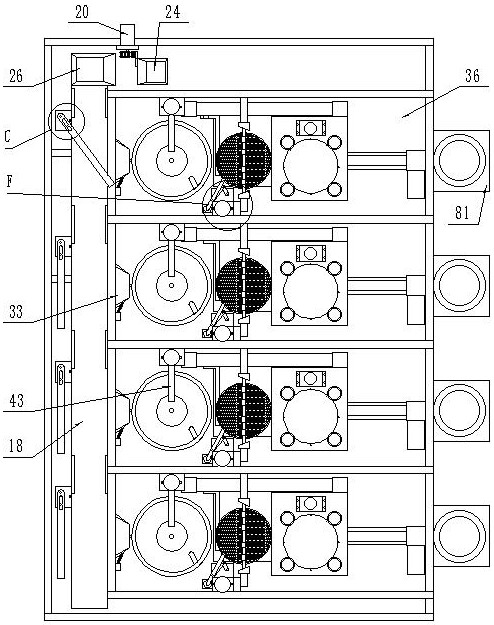

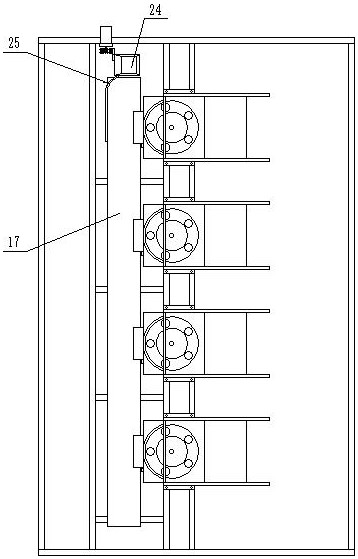

[0042] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-22 Shown, a kind of assembly line type full-automatic dumpling cooking machine, is provided with quantitative discharging mechanism group, frozen storage mechanism group, lower conveyor 17, lifting mechanism, upper conveyor 18, quantitative feeding mechanism group, cooking on frame 1. The push mechanism group, the quantitative discharge mechanism group is composed of several quantitative discharge mechanisms arranged equidistantly, the quantitative discharge mechanism includes the first support member 2, the first bottom plate 3, the side plate 4, the rotating disk 5, and the inclined falling plate 6 , the first material guide plate 7, the first photoelectric sensor 8 and the reduction motor 9, the first support members 2 are fixed on the frame 1 in pairs, the first bottom plate 3 is fixed on the two first support members 2, the first A bottom plate 3 has a groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com