Coal mine crushing device for gypsum mine mining

A crushing device and gypsum mine technology, applied in the direction of grain processing, etc., can solve the problems of inability to adjust the crushing effect of coal mines, restrict development, and high cost, and achieve the effect of being conducive to popularization, good crushing effect, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

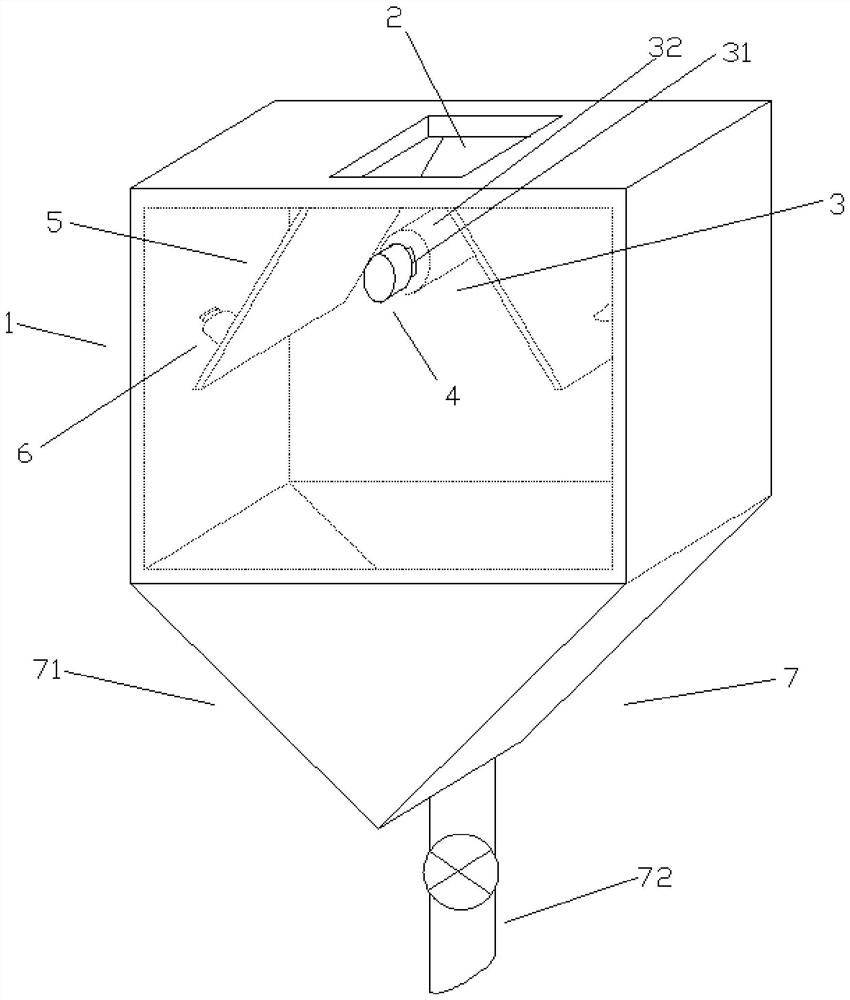

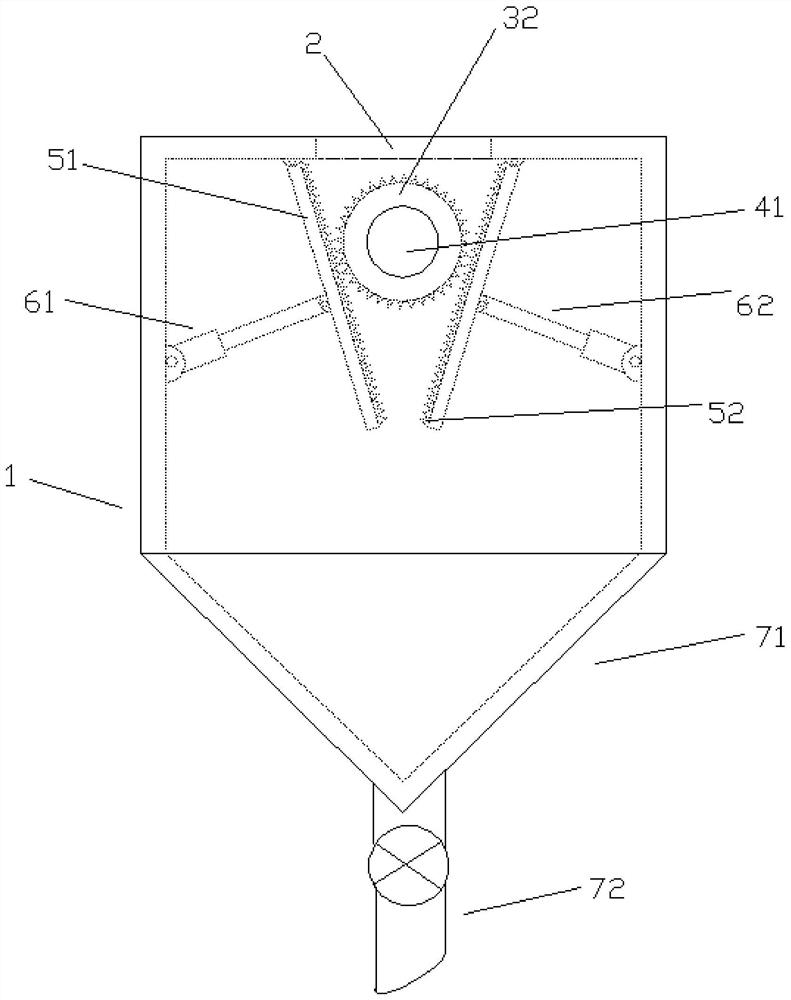

[0019] picture- figure 2 Shown is a coal mine crushing device for gypsum mine development, the coal mine crushing device for gypsum mine development includes a crushing box 1, a feed port 2 placed on the top of the crushing box 1, placed inside the crushing box 1 and connected to the crushing box 1 The crushing structure 3 that is rotatably connected to the crushing box 1, the driving structure 4 placed outside the crushing box 1 and connected to the crushing structure 2, placed in the crushing box 1 and hinged to the crushing box 1 at one end The crushing plate structure 5, the adjustment structure 6 placed between the other end of the crushing plate structure 5 and the crushing box 1, and the discharge structure 7 placed at the bottom opening of the crushing box 1,

[0020] The pulverizing plate structure 5 is placed on both sides of the pulverizing structure 3, the pulverizing structure 3 is placed directly below the feeding port 2, and the distance between the pulverizing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com