Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Low coloration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquid crystal display device

ActiveUS20090322997A1Low contrastReducing normal contrastLiquid crystal compositionsNon-linear opticsIn planeBlue phase liquid crystal

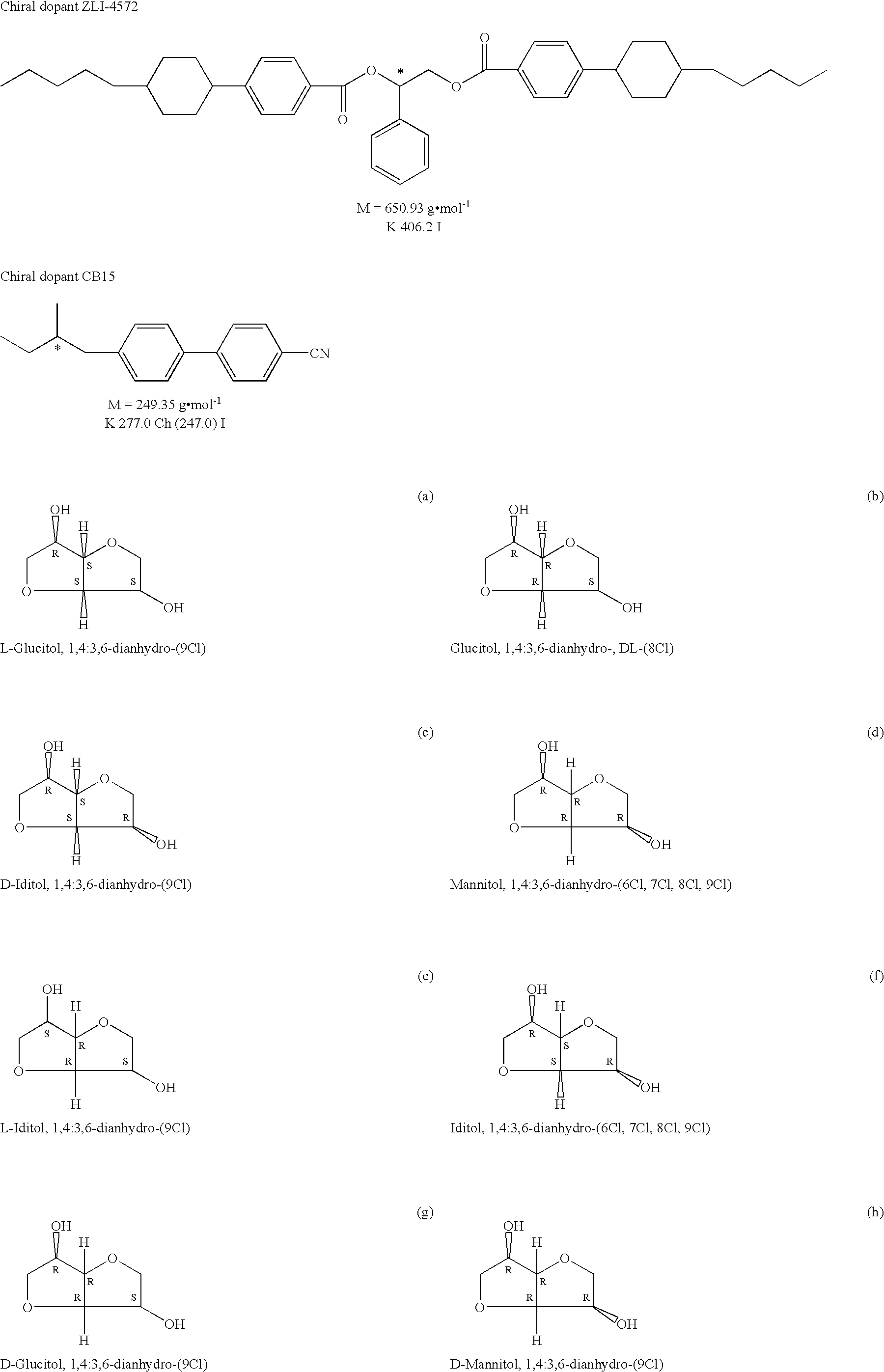

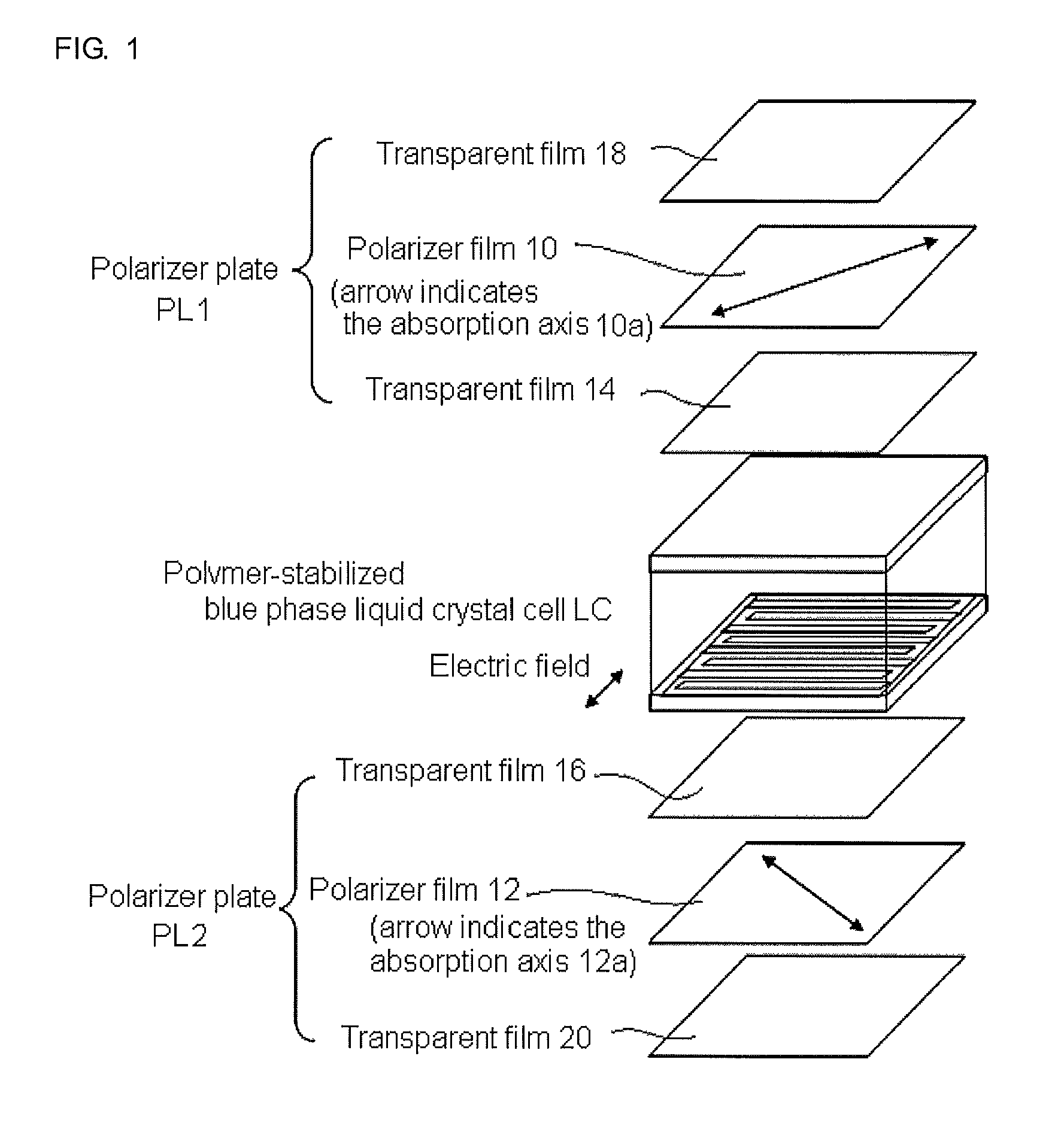

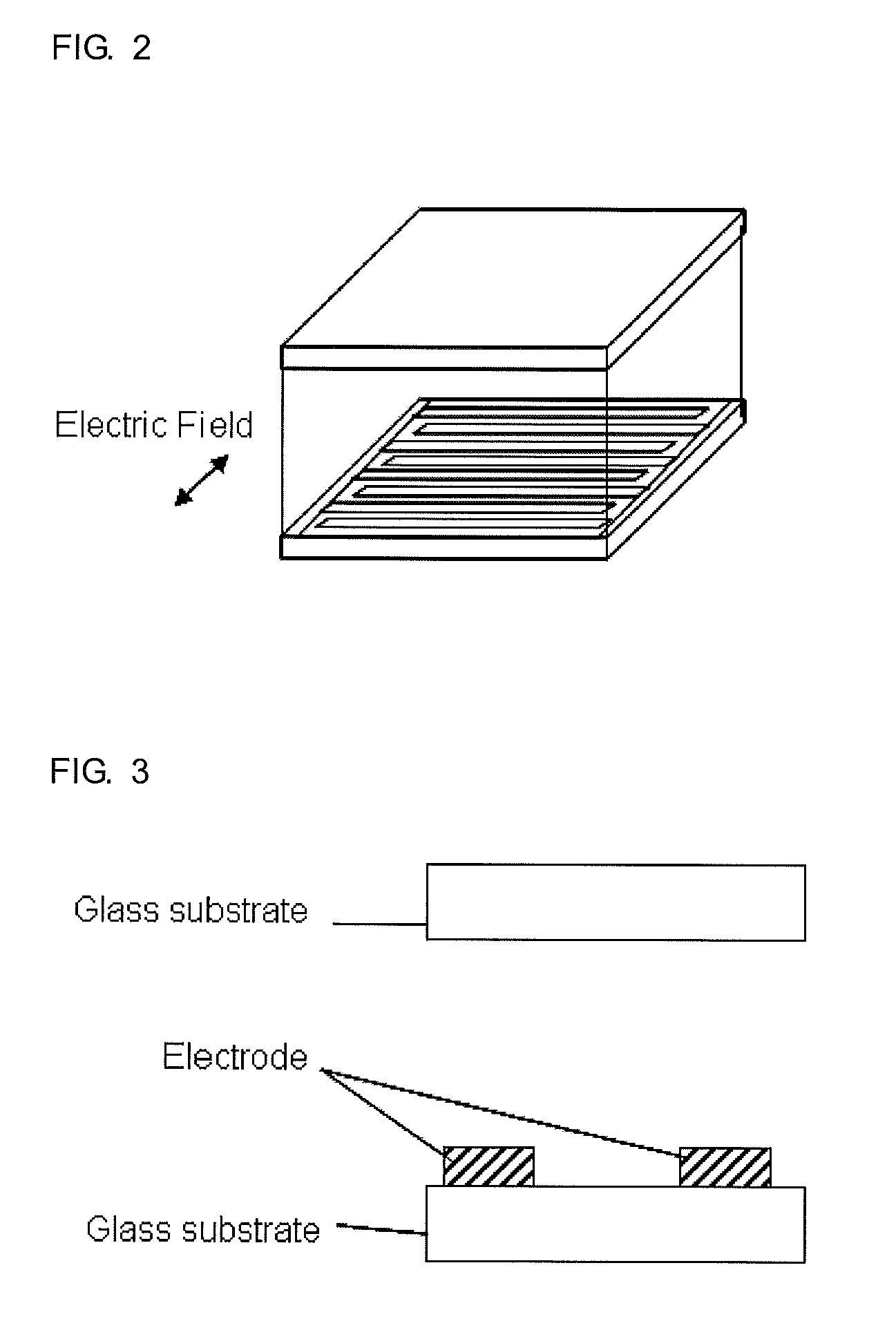

The invention relates to a liquid crystal display device of the present invention has at least a pair of transparent substrates, polymer-stabilized blue phase liquid crystal layer disposed therebetween, and a transparent film having an absolute value |Re| of in-plane retardation Re of 10 nm or smaller in the visible light region, having an absolute value |Rth| of thickness-wise retardation Rth of 30 nm or smaller in the visible light region, having an absolute value |Re(400)−Re(700)| of difference between values of in-plane retardation Re at 400 nm and 700 nm of 10 nm or smaller, and having an absolute value |Rth(400)−Rth(700)| of difference between values of thickness-wise retardation Rth at 400 nm and 700 nm of 35 nm or smaller.

Owner:FUJIFILM CORP

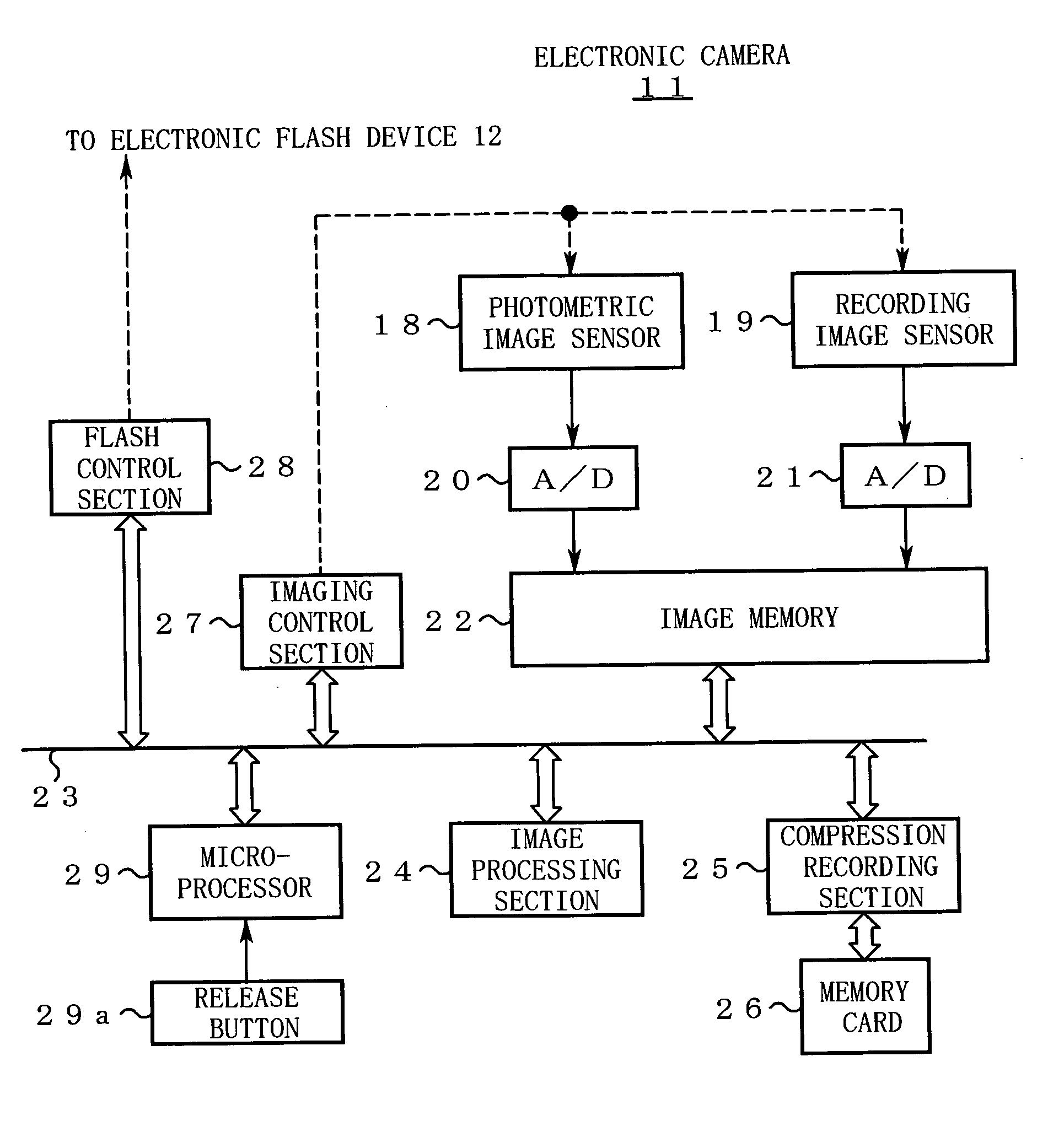

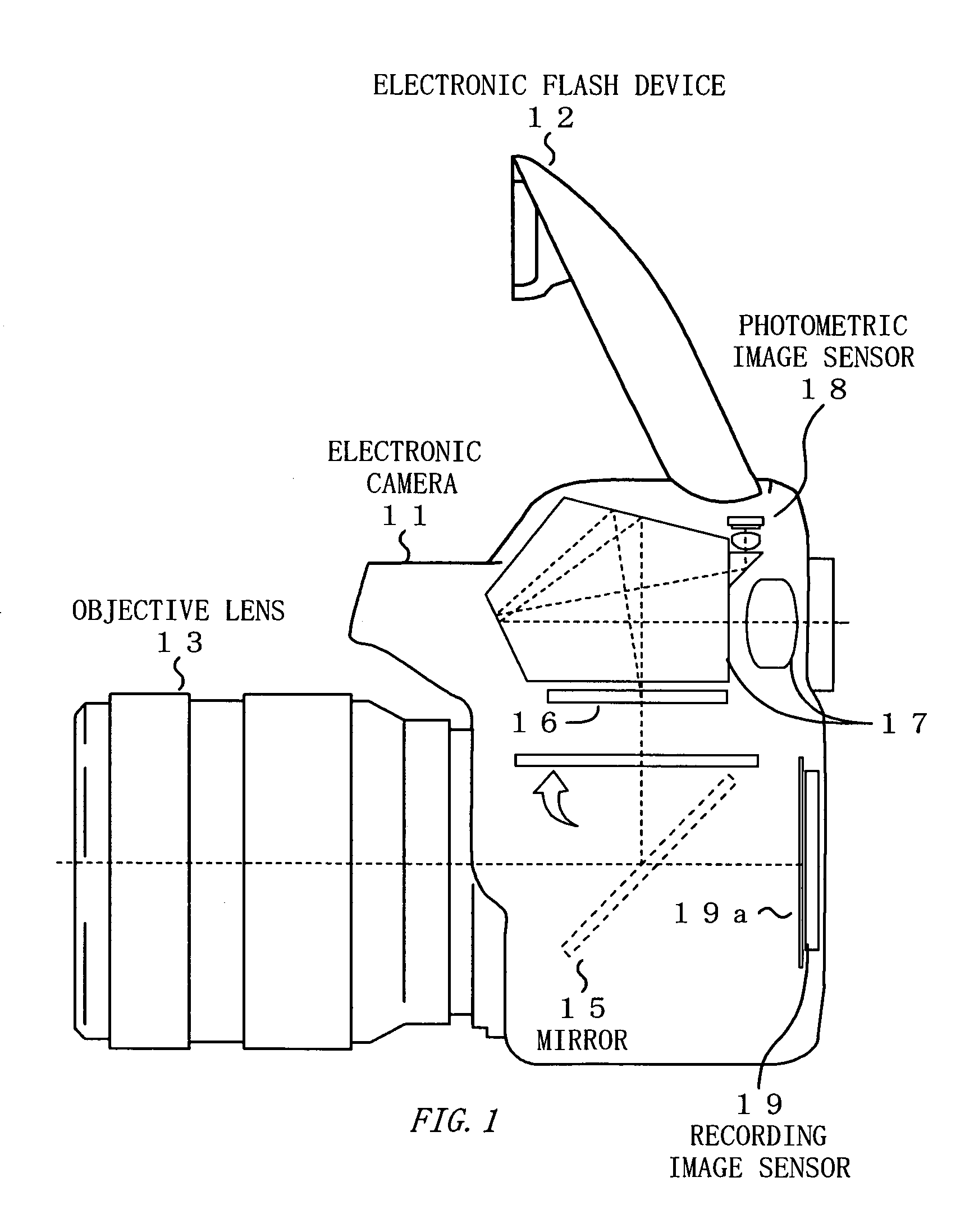

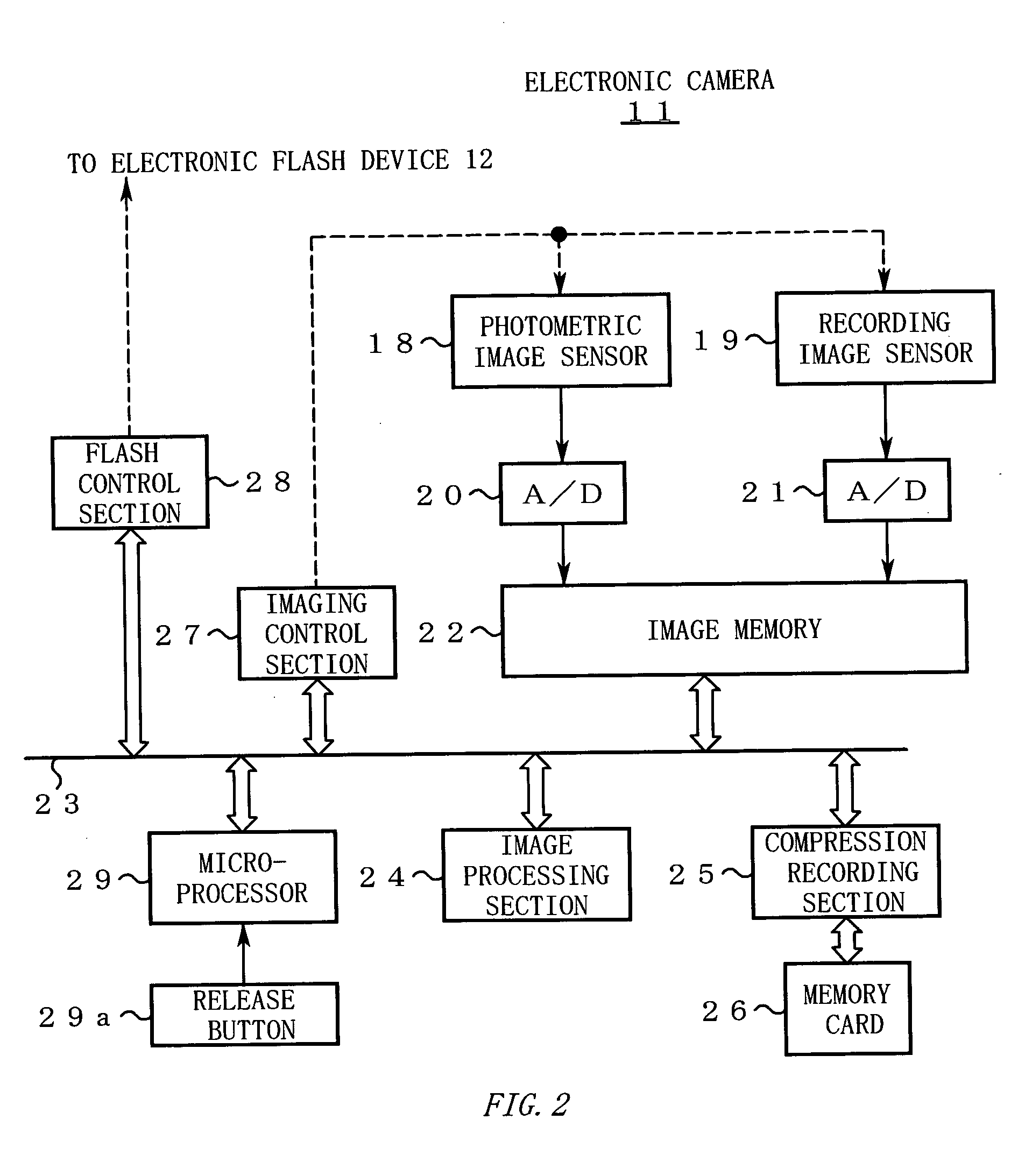

Electronic camera having color adjustment function and program therefor

InactiveUS20050122409A1Reduce separation of chromaticityLow colorationColor signal processing circuitsColor temperatureCamera control

An electronic camera controls an imaging section to generate a test image without flash and a main image with flash. Then, the electronic camera judges correlation between histogram distributions of the test image and the main image. If the correlation between the histogram distributions is low, the electronic camera judges that the flash illumination is uneven and performs white balance adjustments, placing greater importance on the color temperature of the flash. Conversely, if the correlation between the histogram distributions is high, the electronic camera judges that the flash illumination is uniform and performs white balance adjustments, placing greater importance on the color temperature of the main image.

Owner:NIKON CORP

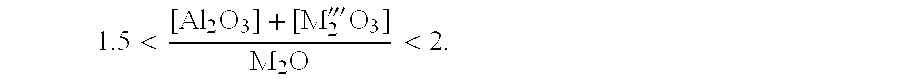

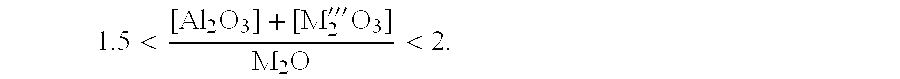

Aluminoborosilicate glass and method for the production of crystallite-free gradient index lenses

ActiveUS20050137075A1Reduce crystallization tendencyImprove optical qualityOptical elementsAlkali metal oxideIon exchange

The invention is directed to an aluminoborosilicate glass containing alkali metals for the production of optical components with refractive index gradients which are generated by ion exchange of monovalent metal ions in a base glass comprising at least silicon oxide, boron oxide, aluminum oxide and an alkali metal oxide, particularly for the production of gradient index lenses (GRIN lenses). The object of the invention, to find a novel possibility for producing GRIN lenses based on aluminoborosilicate glasses in which the glass has an appreciably reduced tendency toward crystallization in subsequent thermal treatment processes, is met according to the invention in an alkali-containing aluminoborosilicate glass for the production of optical components with refractive index gradients generated by ion exchange of monovalent, refractive index-changing metal ions in a base glass of SiO2, A12O3, a metal-(III)-oxide (of B and / or Ga) and at least one metal-(I)-oxide (of Li, Na, K and / or Rb) in that defined molar ratios of metal-(III)-oxides to the metal-(I)-oxides of the base glass are adjusted within a given range in order to appreciably reduce the tendency toward crystallization of the glass for subsequent thermal treatment processes. Point defects caused by crystallites in the GRIN lenses produced in this manner are drastically reduced in this way.

Owner:GRINTECH

Aluminoborosilicate glass and method for the production of crystallite-free gradient index lenses

ActiveUS7482296B2Reduce crystallization tendencyImprove optical qualityOptical elementsAlkali metal oxideRefractive index

The invention is directed to an aluminoborosilicate glass containing alkali metals for the production of optical components with refractive index gradients which are generated by ion exchange of monovalent metal ions in a base glass comprising at least silicon oxide, boron oxide, aluminum oxide and an alkali metal oxide, particularly for the production of gradient index lenses (GRIN lenses). The object of the invention, to find a novel possibility for producing GRIN lenses based on aluminoborosilicate glasses in which the glass has an appreciably reduced tendency toward crystallization in subsequent thermal treatment processes, is met according to the invention in an alkali-containing aluminoborosilicate glass for the production of optical components with refractive index gradients generated by ion exchange of monovalent, refractive index-changing metal ions in a base glass of SiO2, Al2O3, a metal-(III)-oxide (of B and / or Ga) and at least one metal-(I)-oxide (of Li, Na, K and / or Rb) in that defined molar ratios of metal-(III)-oxides to the metal-(I)-oxides of the base glass are adjusted within a given range in order to appreciably reduce the tendency toward crystallization of the glass for subsequent thermal treatment processes. Point defects caused by crystallites in the GRIN lenses produced in this manner are drastically reduced in this way.

Owner:GRINTECH

Phosphorus crown optical glass with medium refractive index and high Abbe number

The invention is phosphorus crown optical glass with a medium refractive index and a high Abbe number. The invention belongs to the technical field of optical glass. The invention mainly solves the problems of poor heat stability and increased production difficulties of current phosphate system glass. The invention is mainly characterized in that the glass comprises, by weight: 60-83% of Ba(PO3)2; 3-15% of Al(PO3)3; 0.5-5% of Al2O3; 3-10% of B2O3; 2-10% of La2O3; 0-5% of Gd2O3; 0-5% of Y2O3; 2.5-10% of Sigma (La2O3+Y2O3+Gd2O3); 0-2% of ZrO2; 3-10% of BaO; 0-10% of CaO; 0-10% of SrO; 3-10% of Sigma (CaO+SrO+BaO); 0-0.5% of Sb2O3. The invention has a refractive index of 1.59-1.62, an Abbe number of 63-69, a transition temperature of less than 610 DEG C, a specific gravity of 3.50-3.80 g / cm3, and a glass Dw of grade 1 determined according to 'GB / T17129-1997 determination method of optical glass chemical stability', also has the characteristics of low tinting strength, good stability, excellent process performance, and suitability for batch production, and is mainly used for removing chromatic aberration in lens groups so as to reach the purpose of chromatic aberration correction.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

Li2O-Al2O3-SiO2-BASED CRYSTALLIZED GLASS

ActiveUS20130130887A1Large degree of influenceLower melting temperatureOptical elementsMaterials science

Provided is a Li2O—Al2O3—SiO2-based crystallized glass, comprising, as a composition in terms of mass %, 55 to 75% of SiO2, 20.5 to 27% of Al2O3, 2% or more of Li2O, 1.5 to 3% of TiO2, 3.8 to 5% of TiO2+ZrO2, and 0.1 to 0.5% of SnO2, and satisfying the relationships of 3.7≦Li2O+0.741MgO+0.367ZnO≦4.5 and SrO+1.847CaO≦0.5.

Owner:NIPPON ELECTRIC GLASS CO LTD

High-viscosity polyester with improved impact properties

The invention relates to a thermoplastic polymer comprising at least one 1,4:3,6-dianhydrohexitol unit (A), at least one alicyclic diol unit (B) other than the 1,4:3,6-dianhydrohexitol units (A) and at least one high-viscosity terephthalic acid unit (C).

Owner:ROQUETTE FRERES SA

Optical glass, optical element and method of manufacturing thereof

ActiveUS20070249480A1High refractive indexMedium dispersion characteristicGlass reforming apparatusGlass severing apparatusEngineeringOptical glass

An optical glass comprises, denoted as weight percentages, SiO2: 2-22%, B2O3: 3-24%, ZnO: >8% and ≦30%, CaO+BaO+ZnO: 10-50%, MgO: 0-3%, La2O3+Y2O3+Gd2O3+Yb2O3: 1-33%, TiO2: 2-20%, ZrO2: 0-10%, Nb2O5: 2-32%, Li2O: 0-5%, Na2O: 0-8%, K2O: 0-10%, WO3: 0-20%. The ratio by weight of La2O3 to the combined contents of La2O3, Y2O3, Gd2O3, and Yb2O3 (La2O3 / (La2O3+Y2O3+Gd2O3+Yb2O3)) falls within a range of 0.7 to 1.

Owner:HOYA CORP

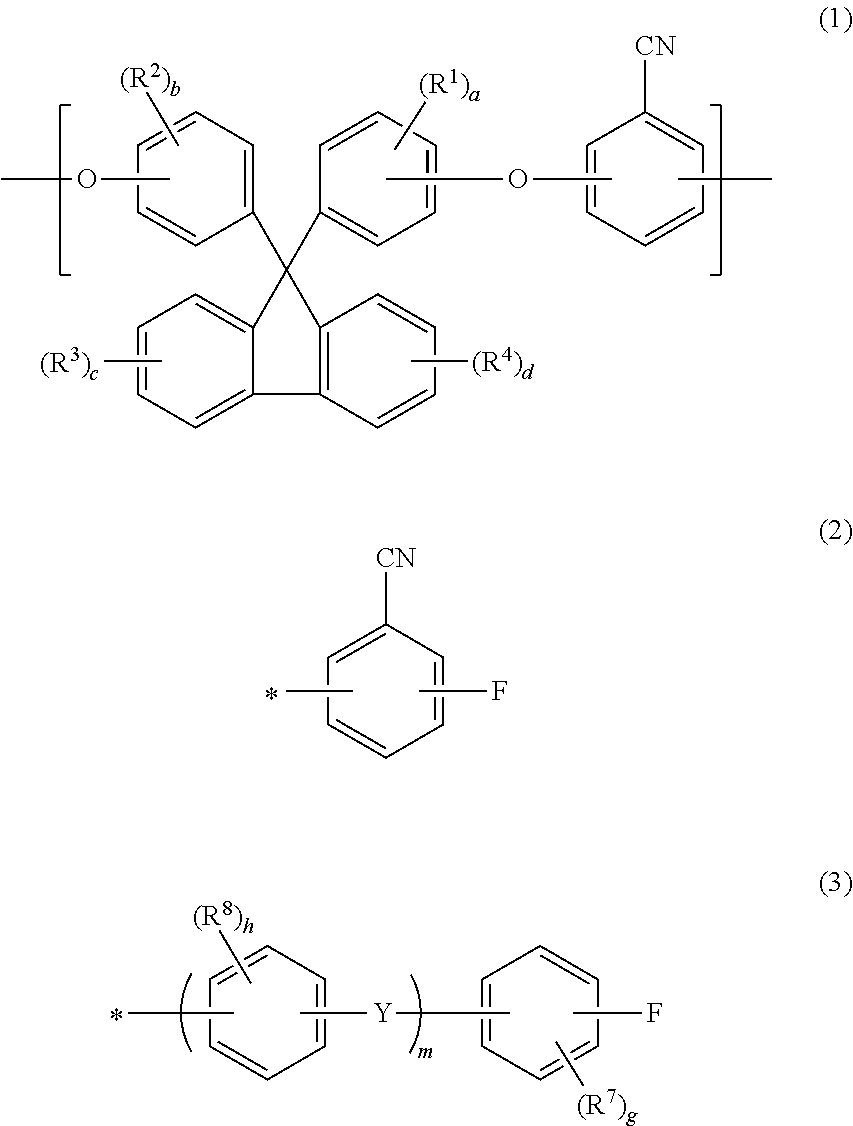

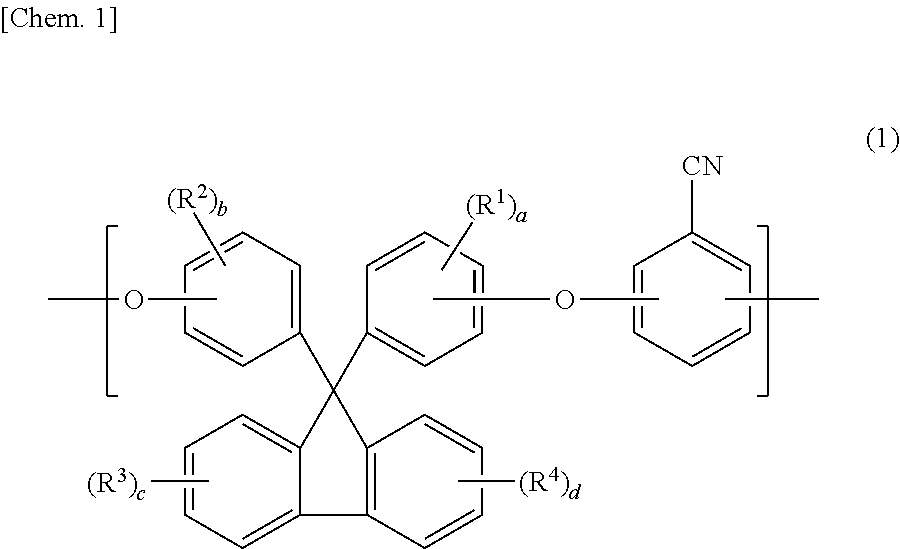

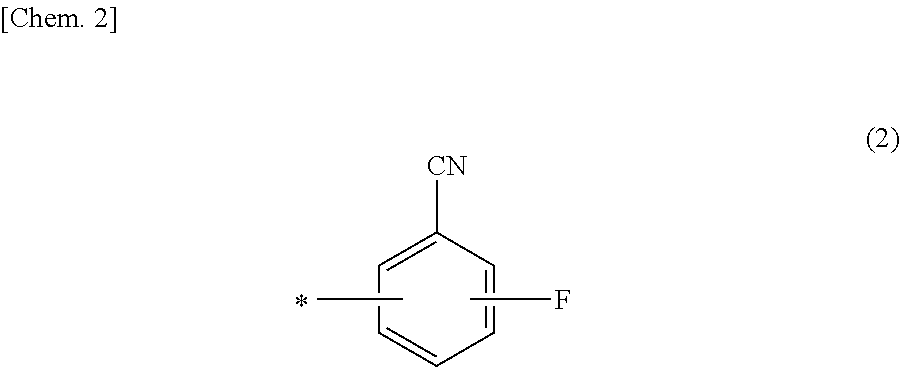

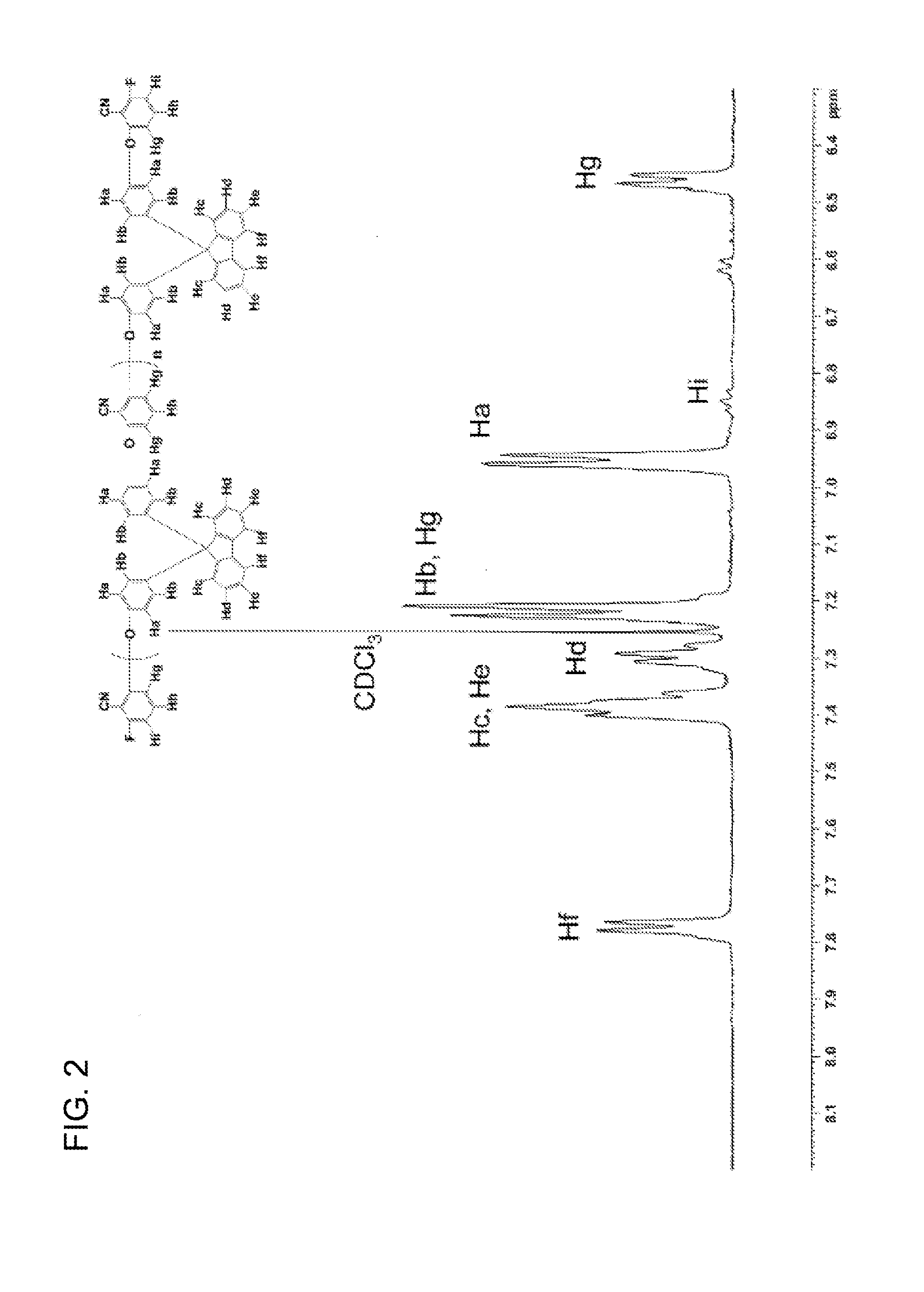

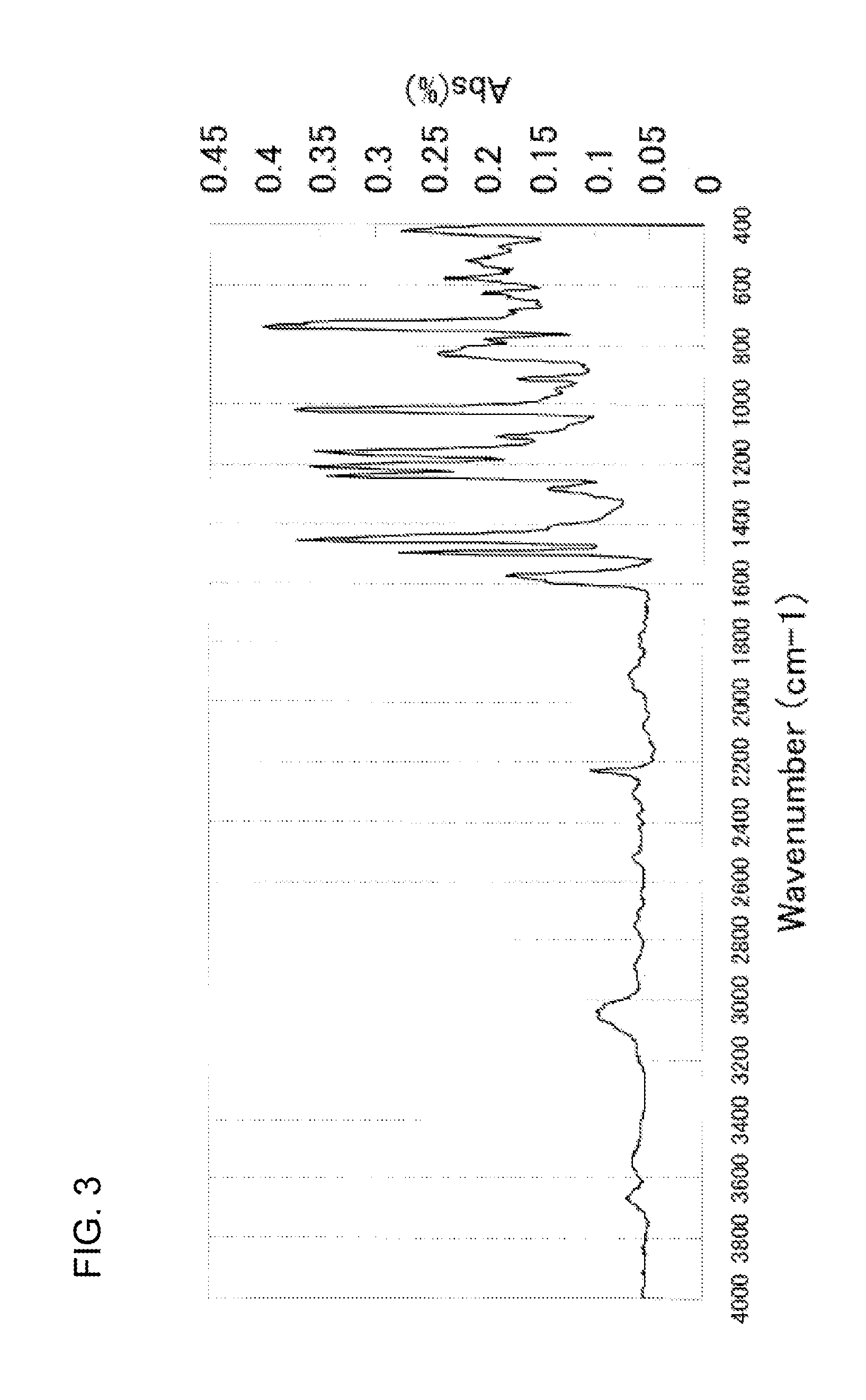

Film, resin composition and polymer

InactiveUS20130030116A1Low colorationImprove heat resistancePlastic/resin/waxes insulatorsPretreated surfacesPolymer scienceStructural unit

Provided is a film comprising a polymer that comprises a structural unit represented by the following formula (1), wherein at least part of the terminal structure of the polymer is at least one structure selected from the group consisting of structural units represented by the following formula (2) and structural units represented by the following formula (3).

Owner:JSR CORPORATIOON

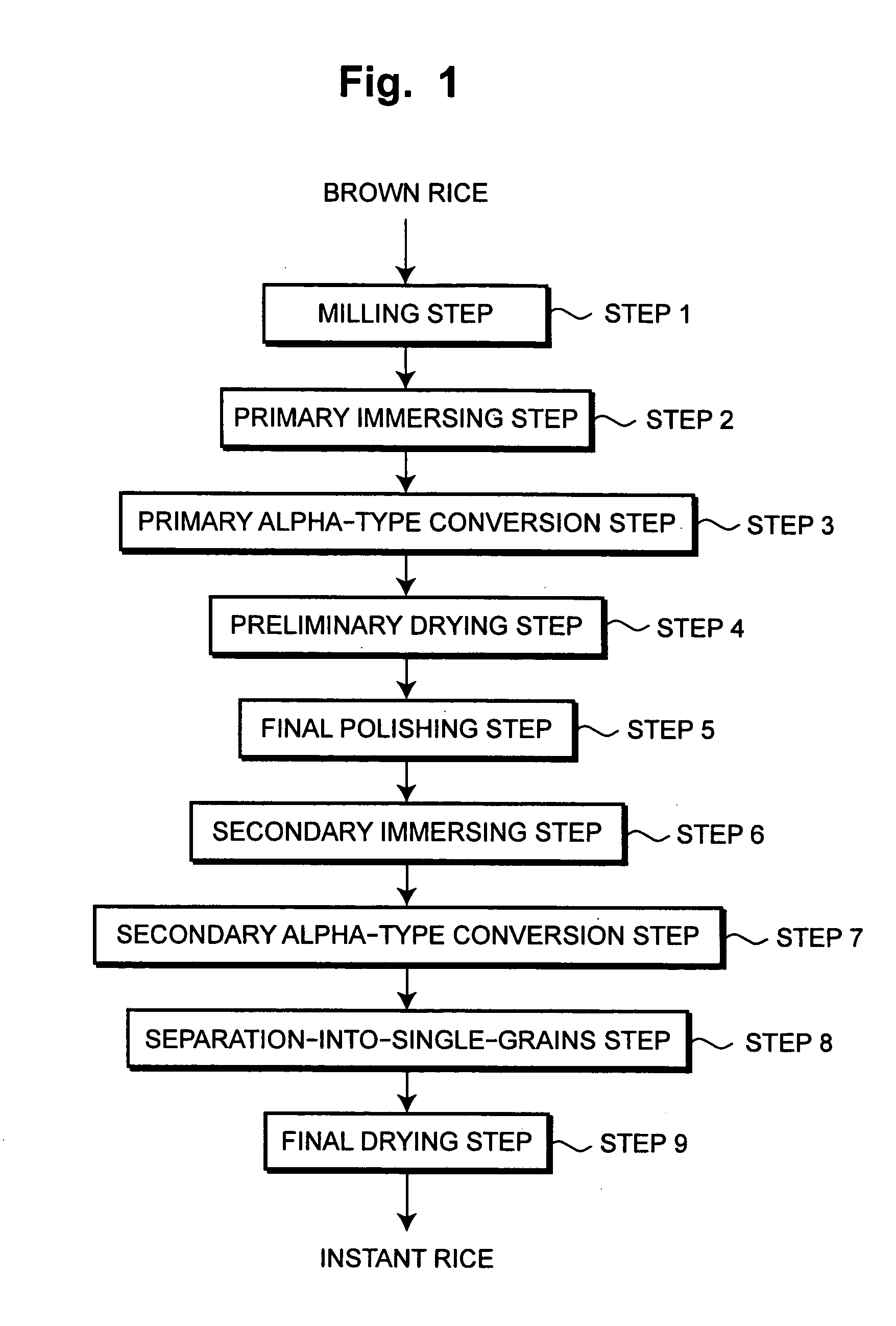

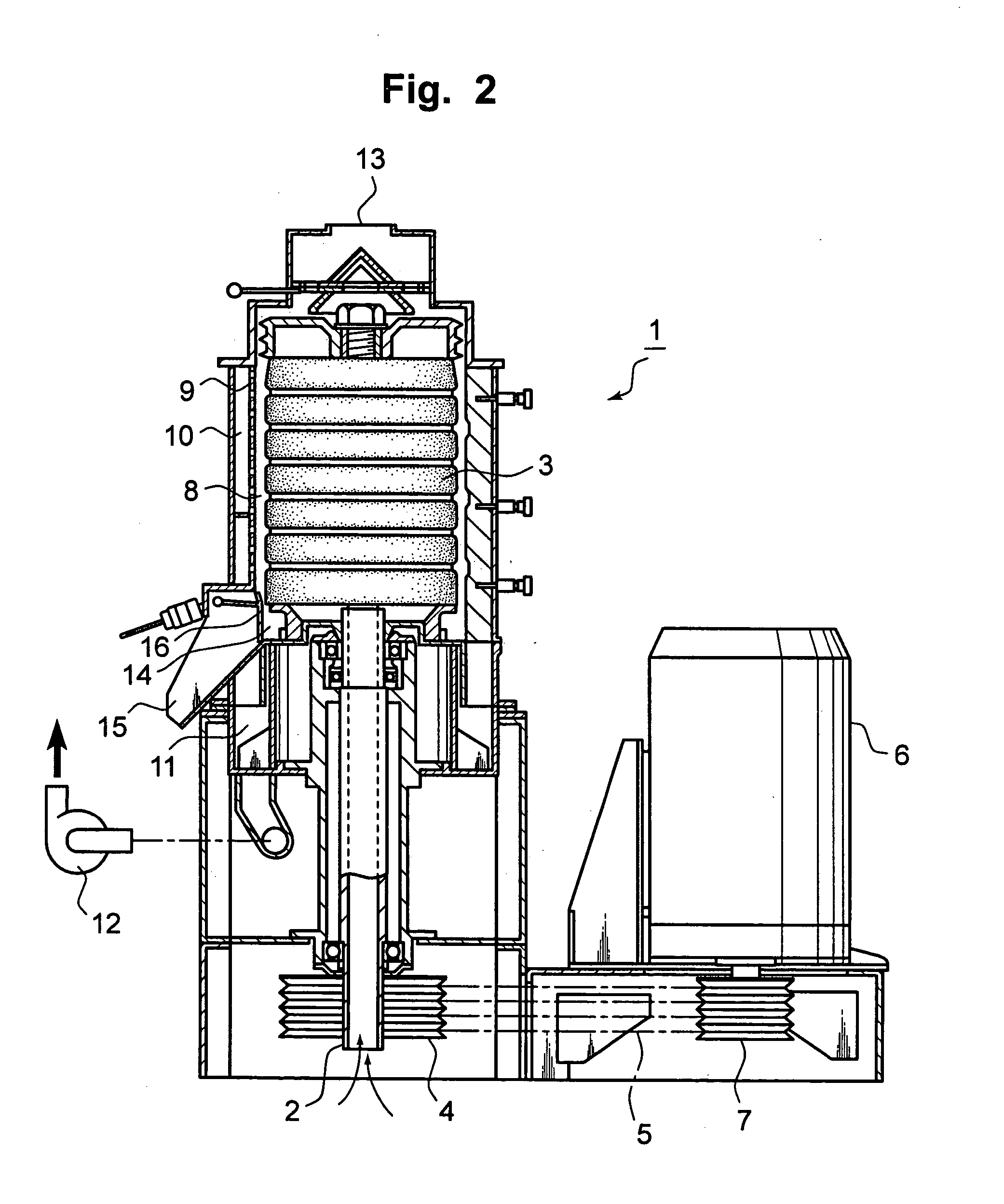

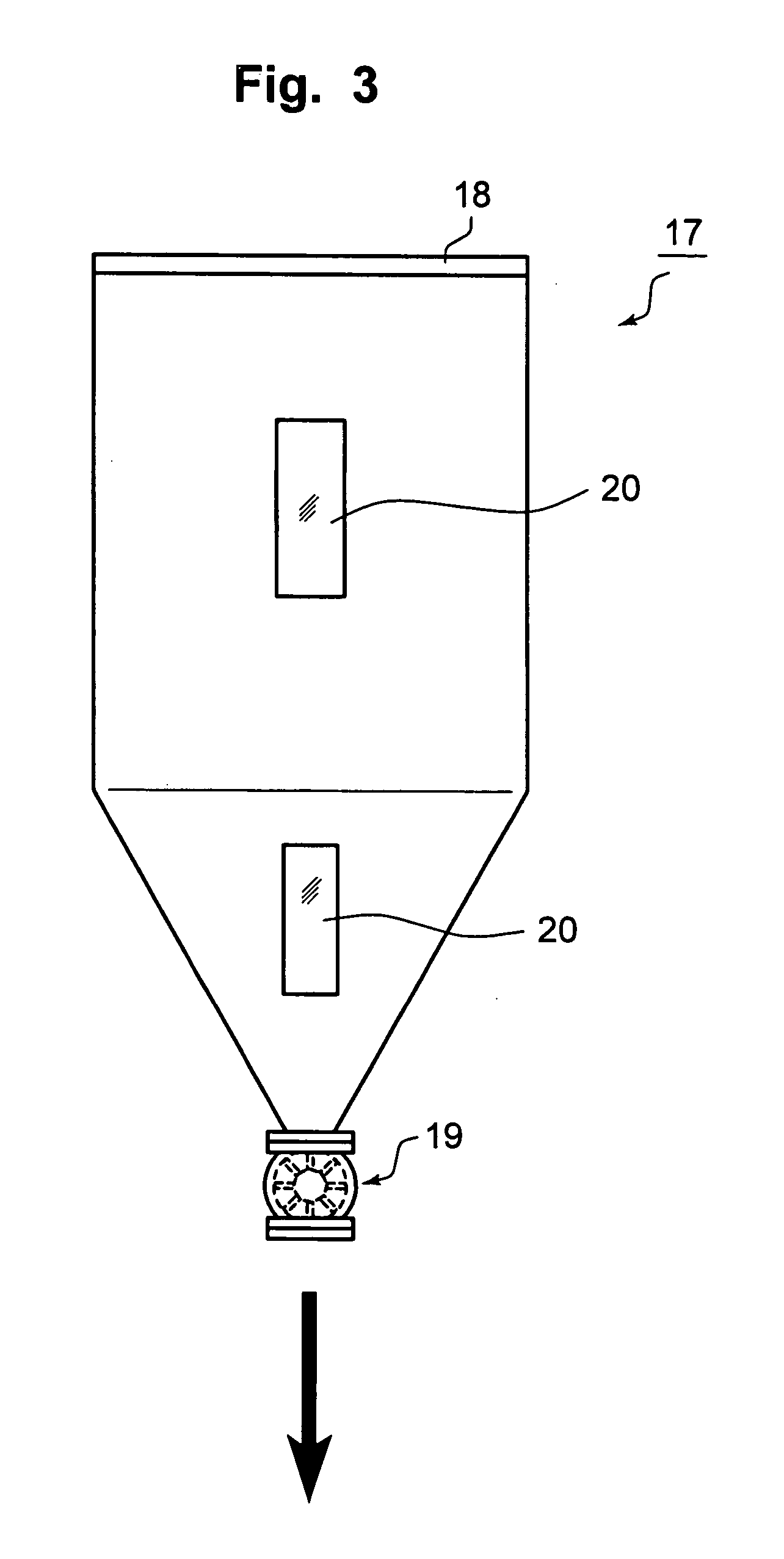

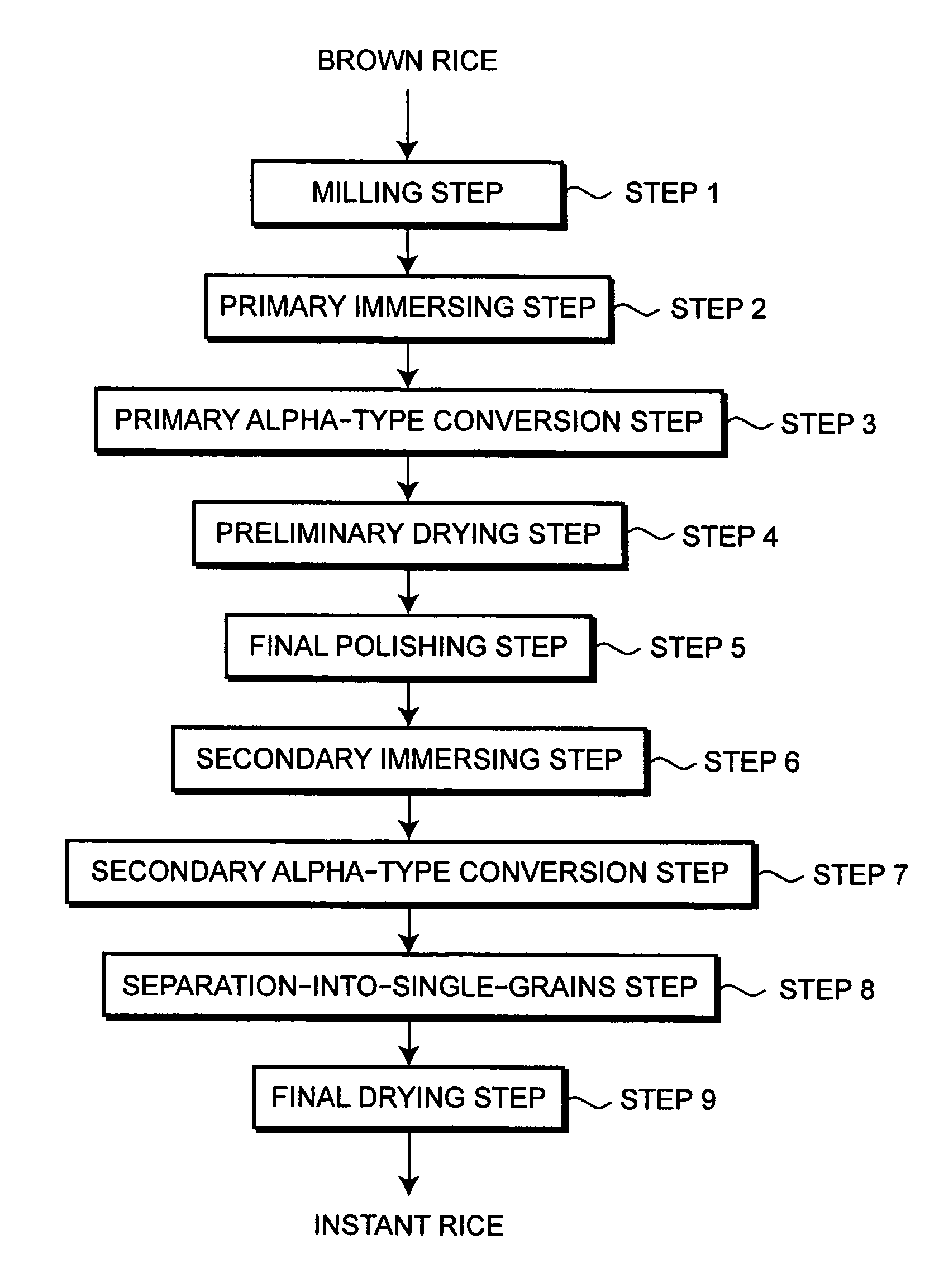

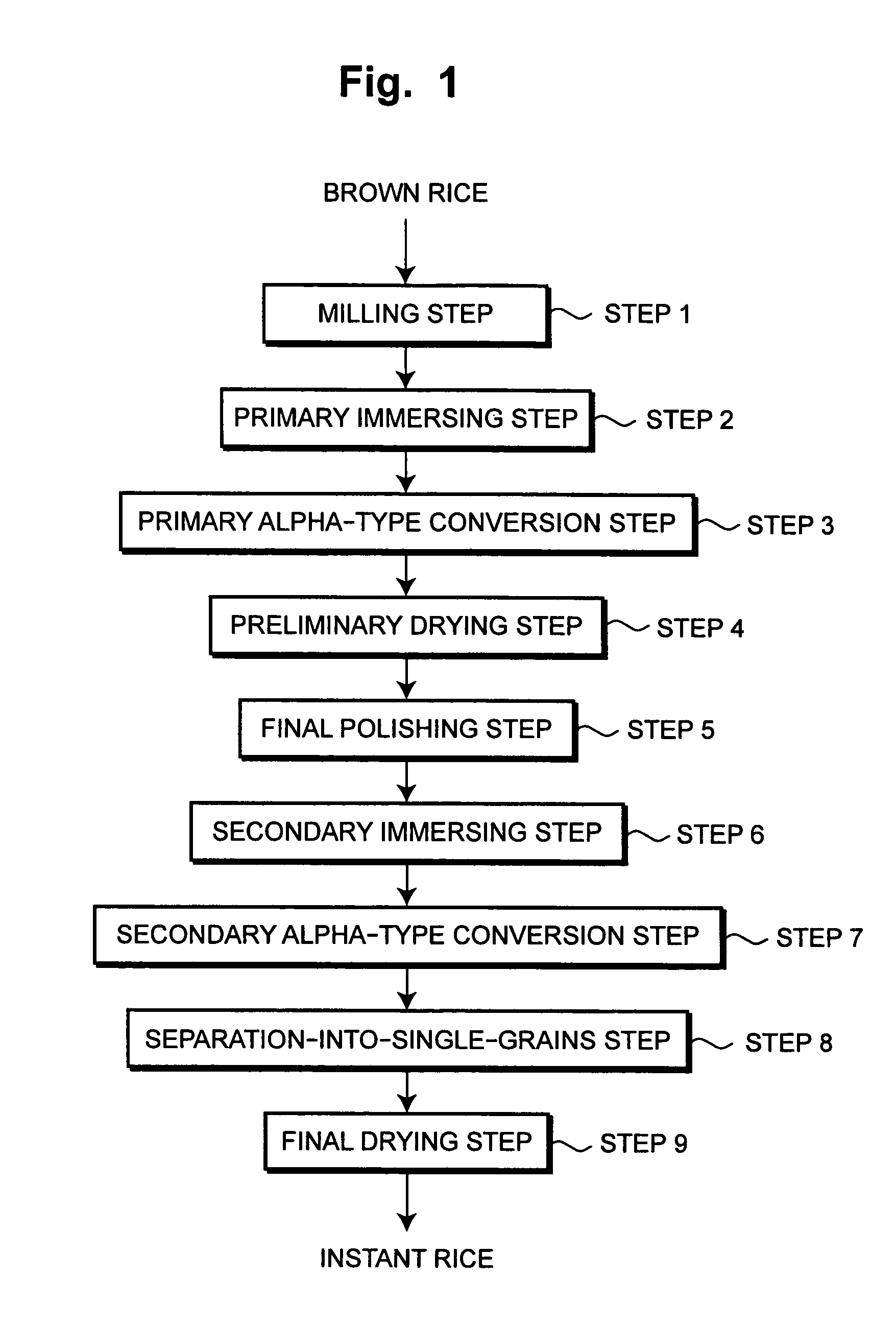

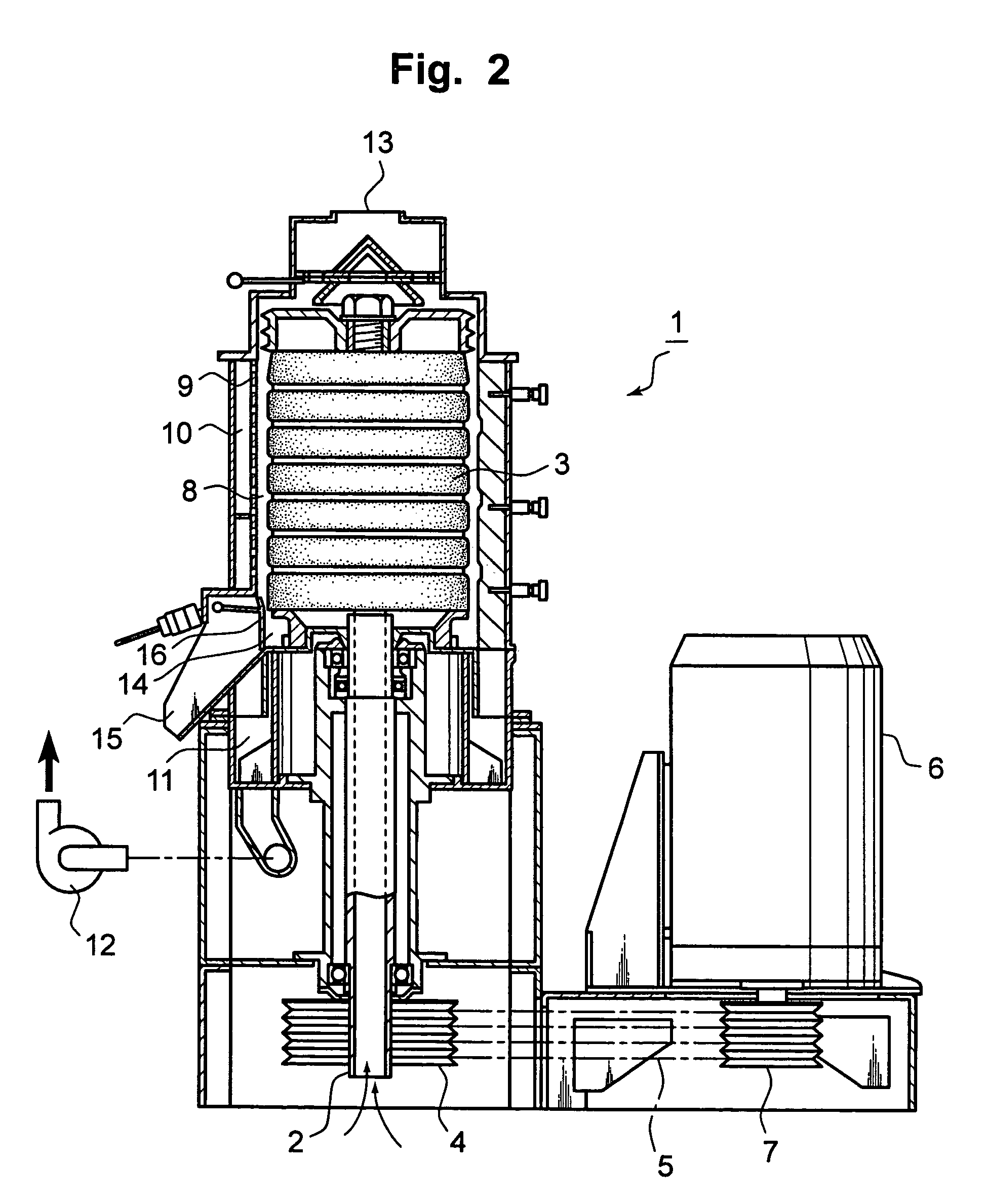

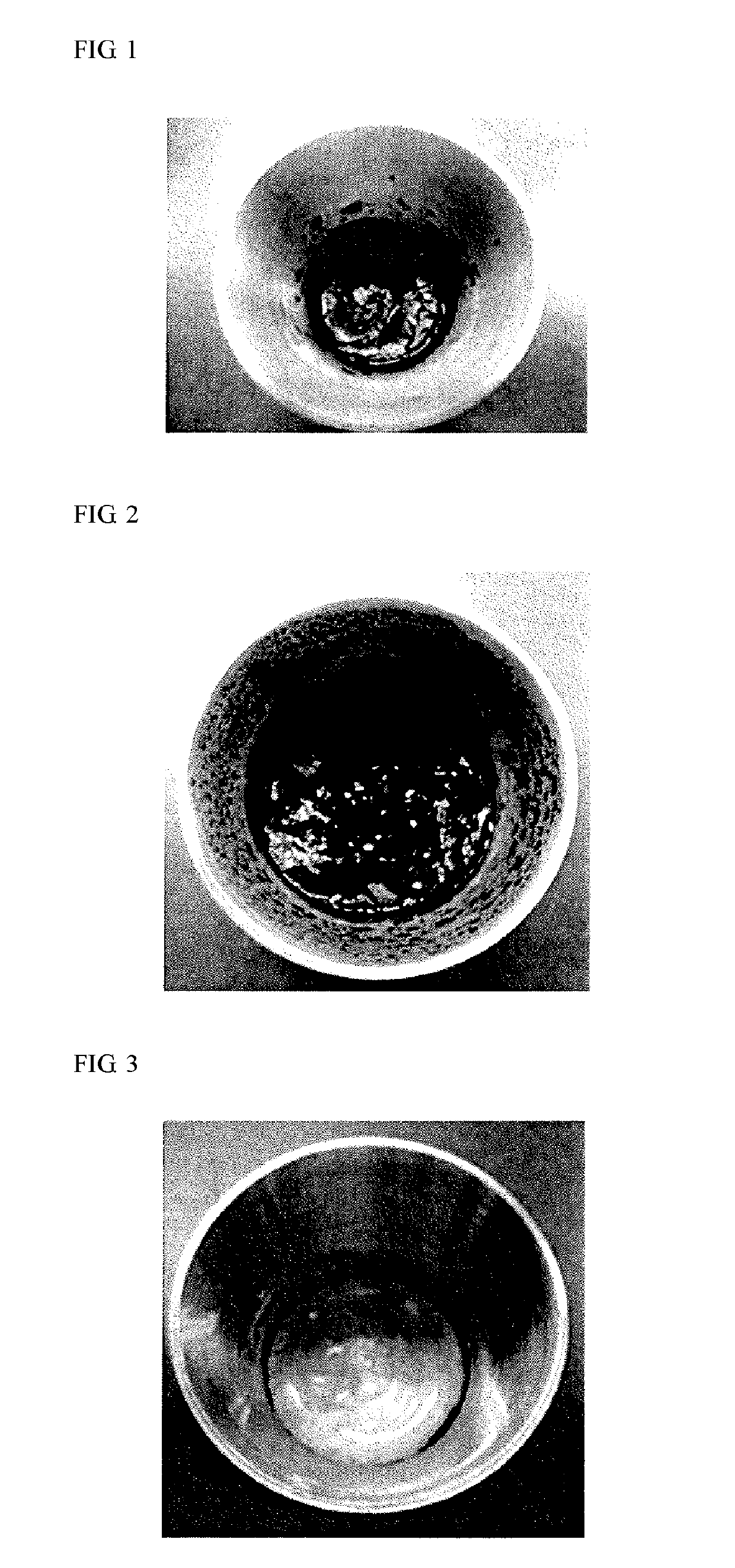

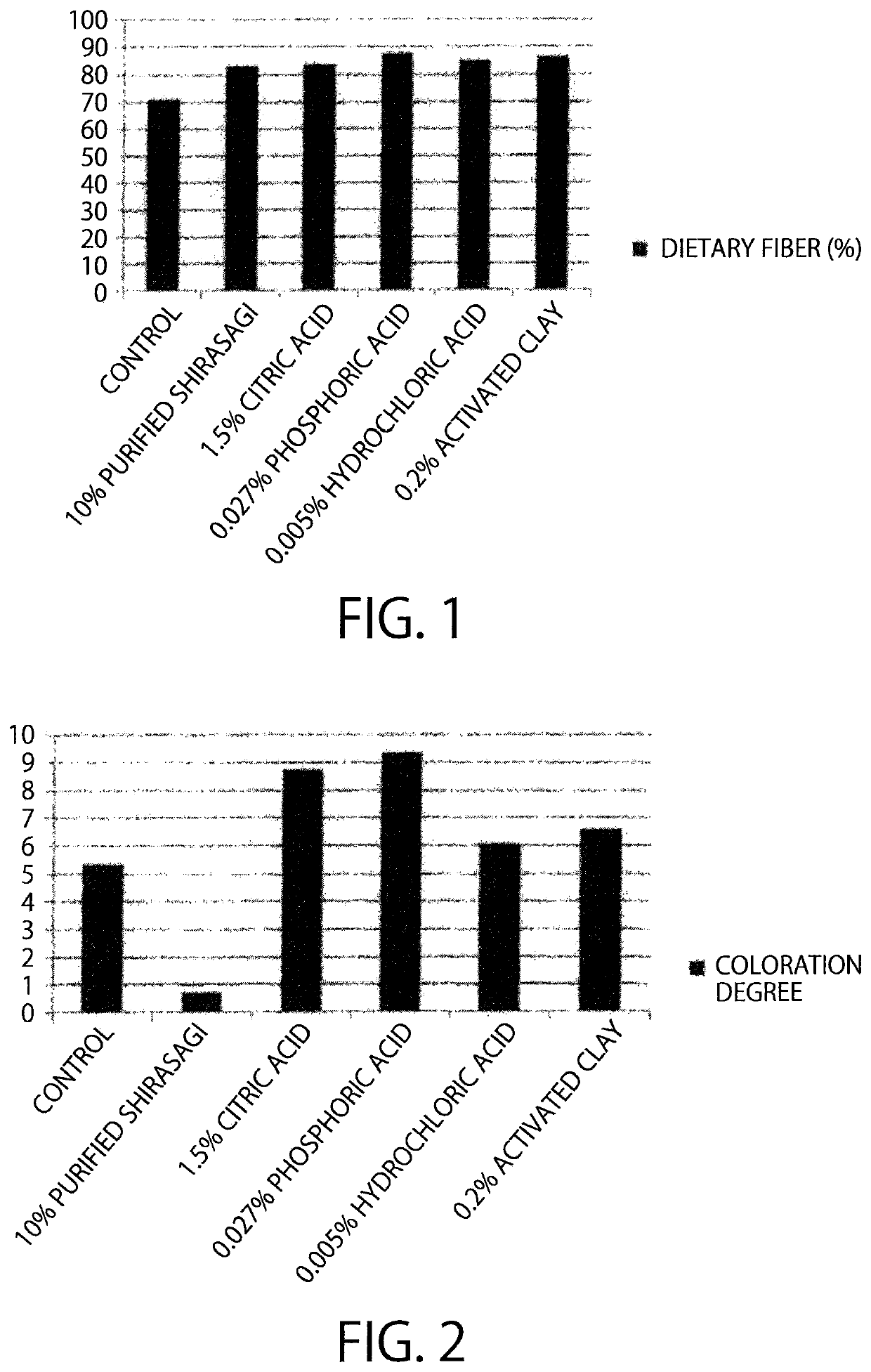

Process for preparing instant rice and product thereof

InactiveUS20040126476A1Low colorationDegree of reductionAnimal feeding stuffFood preparationSurface layerEngineering

Milled rice grains are primarily immersed, and at least surface layers of the grains are converted to the alpha-type. The rice grains are then preliminarily dried and consummatively polished, and are further subjected to secondary immersing and secondary alpha-type conversion. During these processes, there occurs no cracking on the surfaces of the rice grains. The consummatively polished rice grains are then separated into individual single grains. The separated individual single grains are finally dried whereby the finished product of instant rice is obtained. The instant rice containing polished rice has good appearance and quality.

Owner:SATAKE CORP +1

Li2O—Al2O3—SiO2—based crystallized glass

ActiveUS9126859B2Large degree of influenceLower melting temperatureOptical elementsMaterials scienceSilicon dioxide

Provided is a Li2O—Al2O3—SiO2-based crystallized glass, comprising, as a composition in terms of mass %, 55 to 75% of SiO2, 20.5 to 27% of Al2O3, 2% or more of Li2O, 1.5 to 3% of TiO2, 3.8 to 5% of TiO2+ZrO2, and 0.1 to 0.5% of SnO2, and satisfying the relationships of 3.7≦Li2O+0.741MgO+0.367ZnO≦4.5 and SrO+1.847CaO≦0.5.

Owner:NIPPON ELECTRIC GLASS CO LTD

Process for preparing instant rice and product thereof

InactiveUS7357954B2Low colorationDegree of reductionAnimal feeding stuffFood preparationSurface layerEngineering

Owner:SATAKE CORP +1

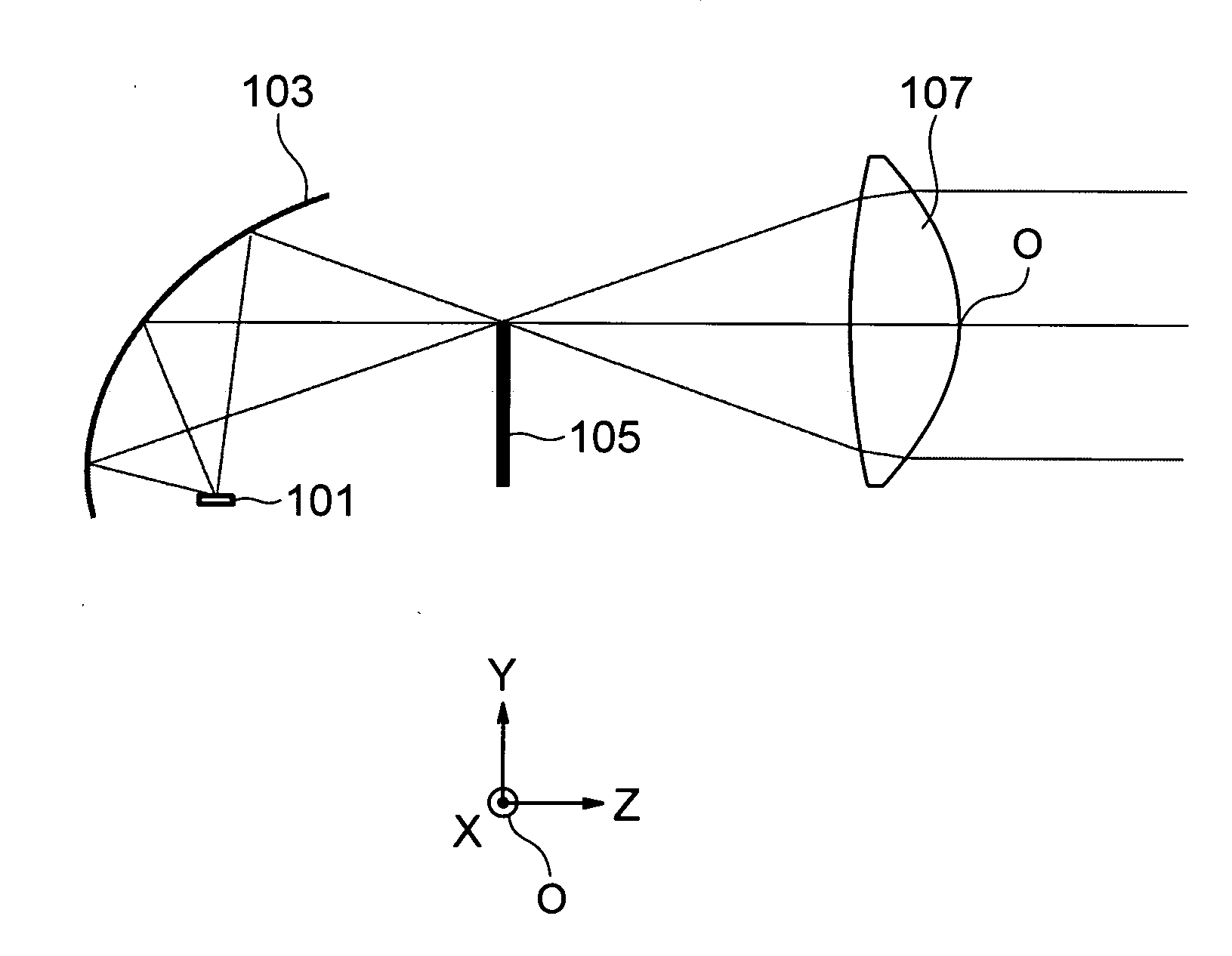

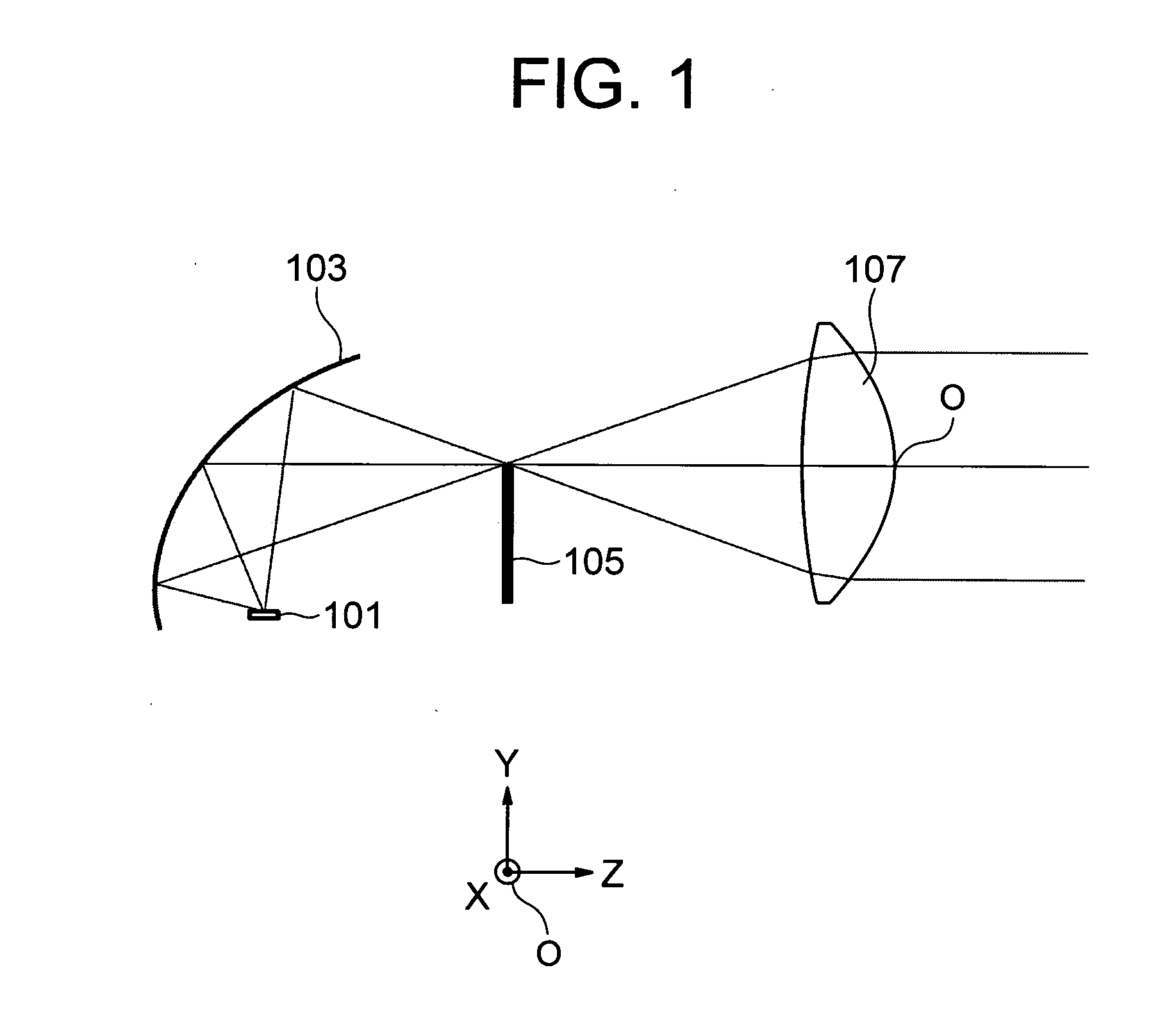

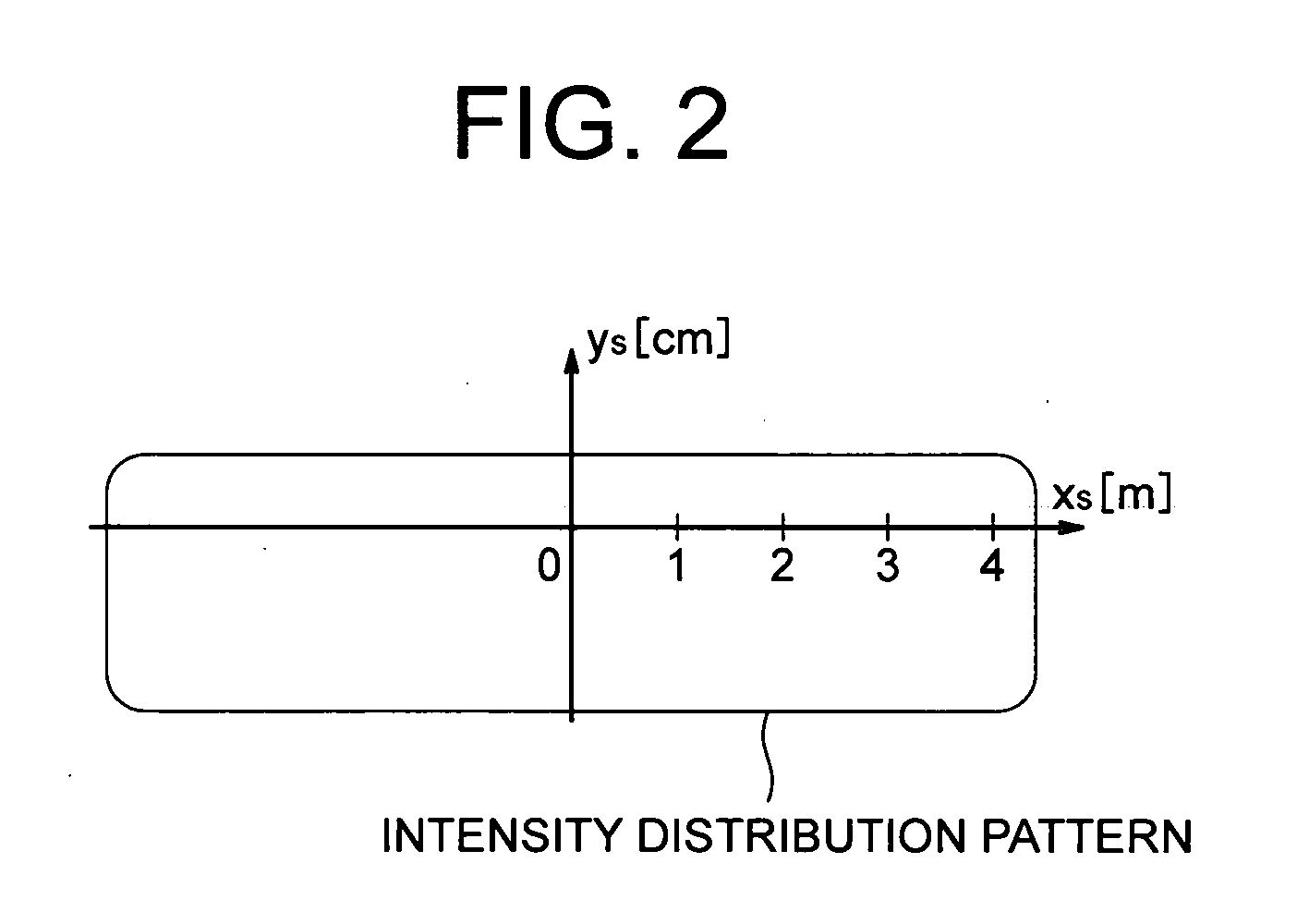

Vehicular lamp

ActiveUS20090310377A1Reduce light transmittanceReduce lightVehicle headlampsVehicle interior lightingOptical axisHue

A vehicular lamp includes a light source, a reflector, a shade, and the projector lens. Light emitted from the light source is reflected by the reflector, and the light is partially blocked by the shade. Light which is not blocked is transmitted through the projector lens, and an object ahead of a vehicle is irradiated with the light. A diffraction grating is provided in a region including an end portion of a light passing region of at least one surface in the projector lens in order to reduce color separation. Magnitude of fD / f / Abbe and a position of the shade on an optical axis are determined according to a correlated color temperature of the light source so as to reduce the color separation caused by a characteristic of the light source. f is a focal distance of the projector lens, with the focal distance of the projector lens being determined by a marginal ray passing through the end portion. fD is a focal distance caused by a grating pitch of a diffraction surface, with the focal distance caused by the grating pitch being determined by the marginal ray passing through the end portion. Abbe is an Abbe number.

Owner:NALUX CO LTD

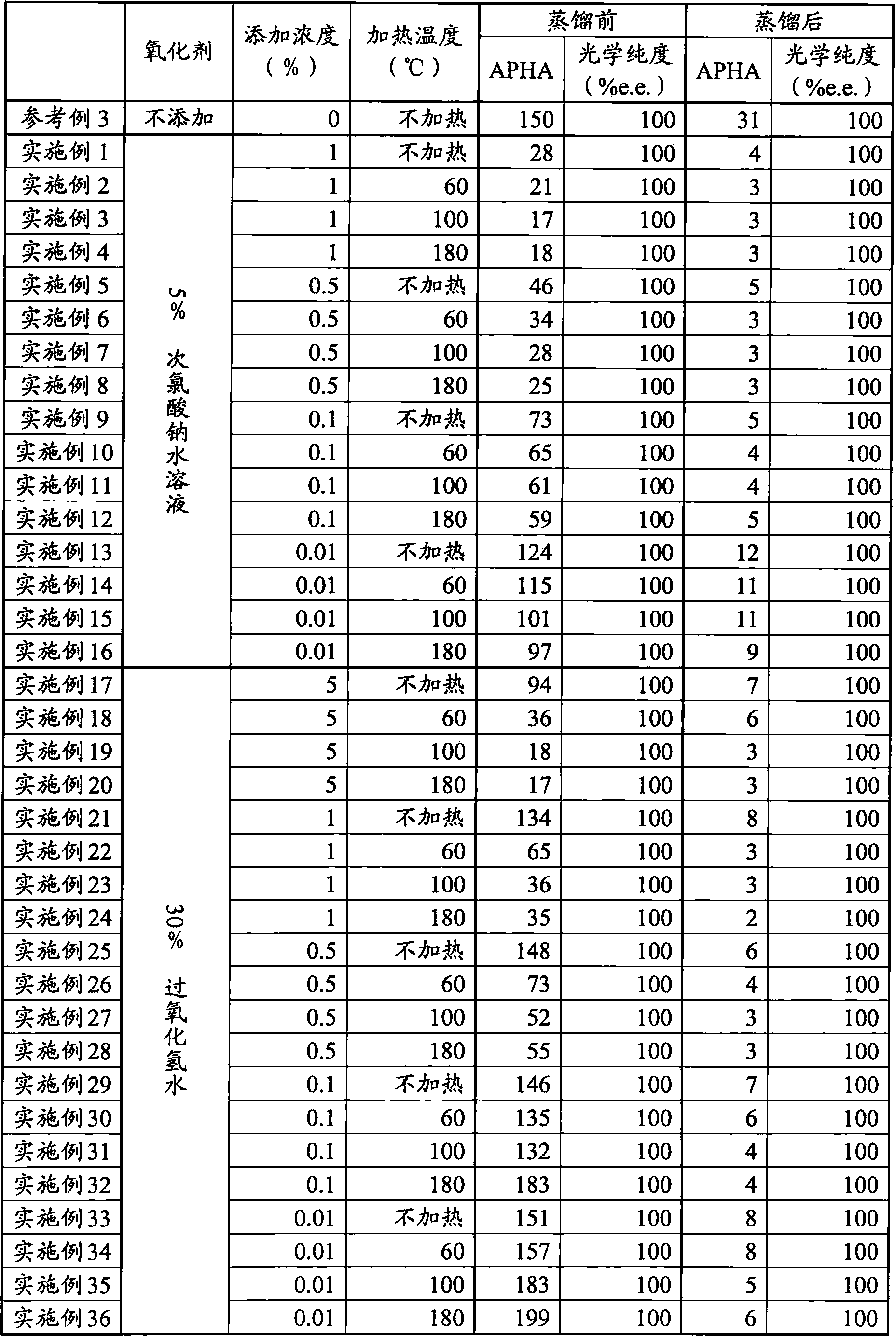

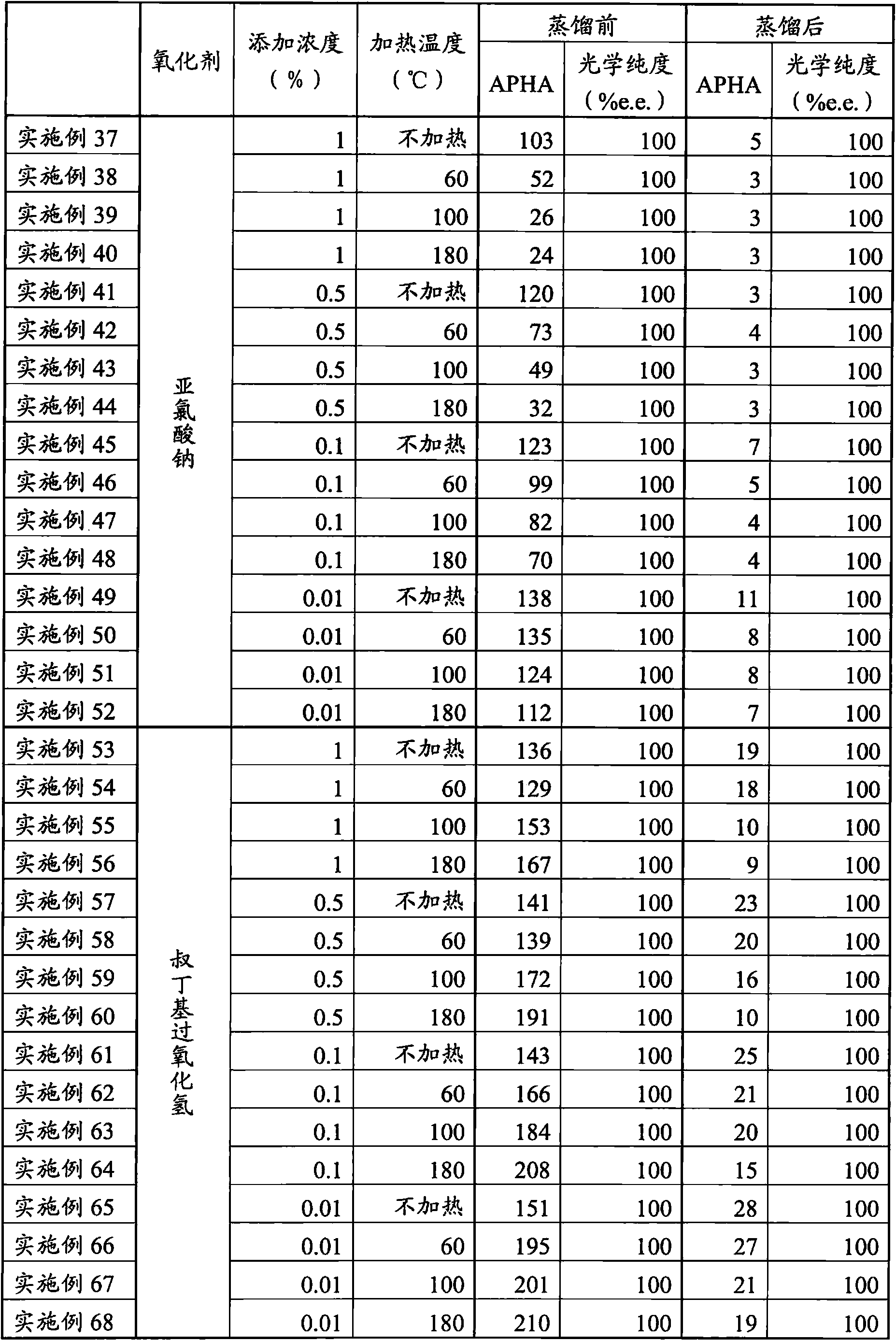

Method for producing organic acid

InactiveCN103649322ALow colorationWill not harmOrganic compound preparationFermentationOrganic acidHydrogen peroxide

Any colored impurity contained in an organic acid derived from a biomass resource can be removed by oxidizing the organic acid derived from the biomass resource with an oxidizing agent such as hydrogen peroxide, tert-butylhydroperoxide, ozone, sodium hypochlorite and sodium chlorite.

Owner:TORAY IND INC

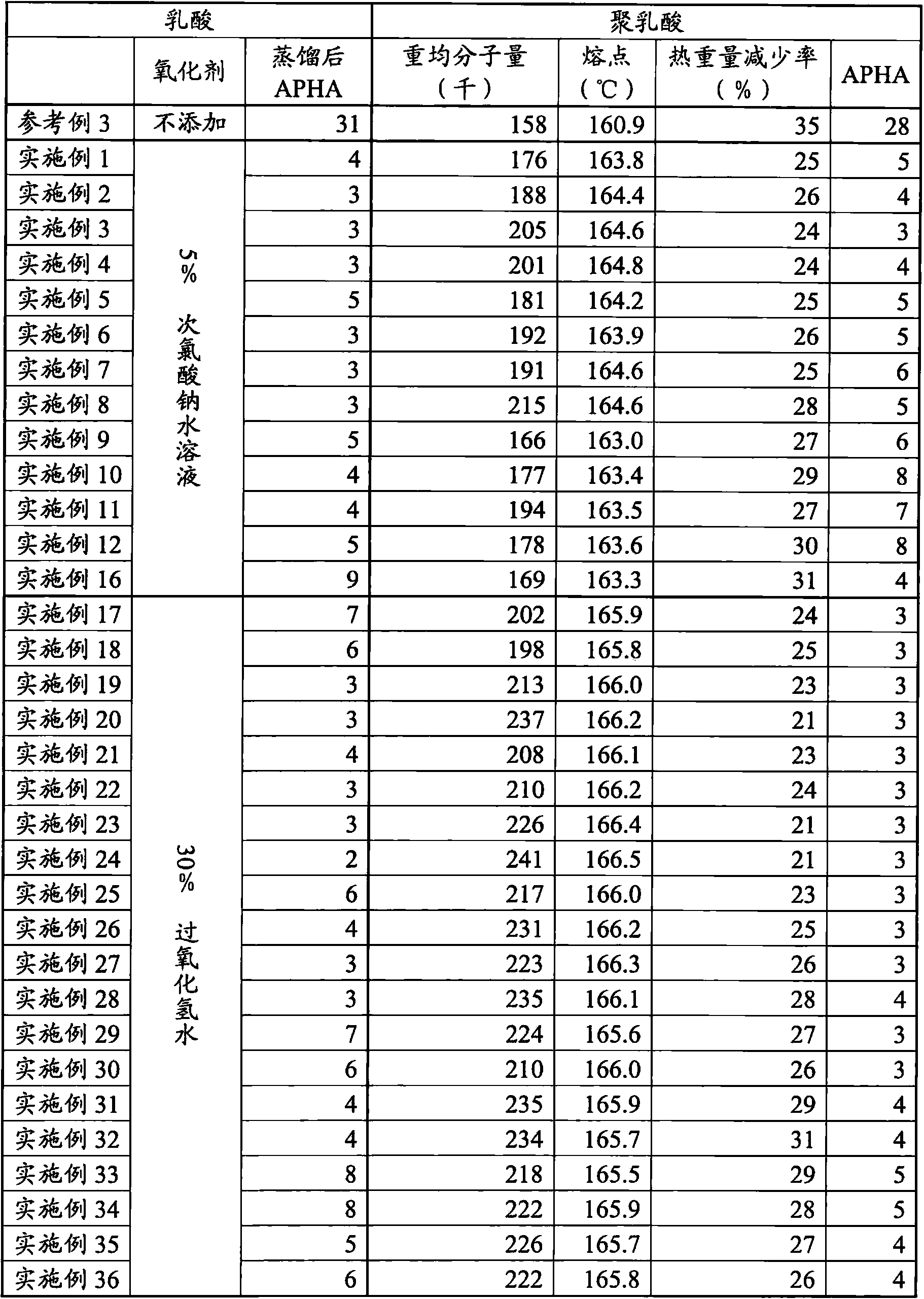

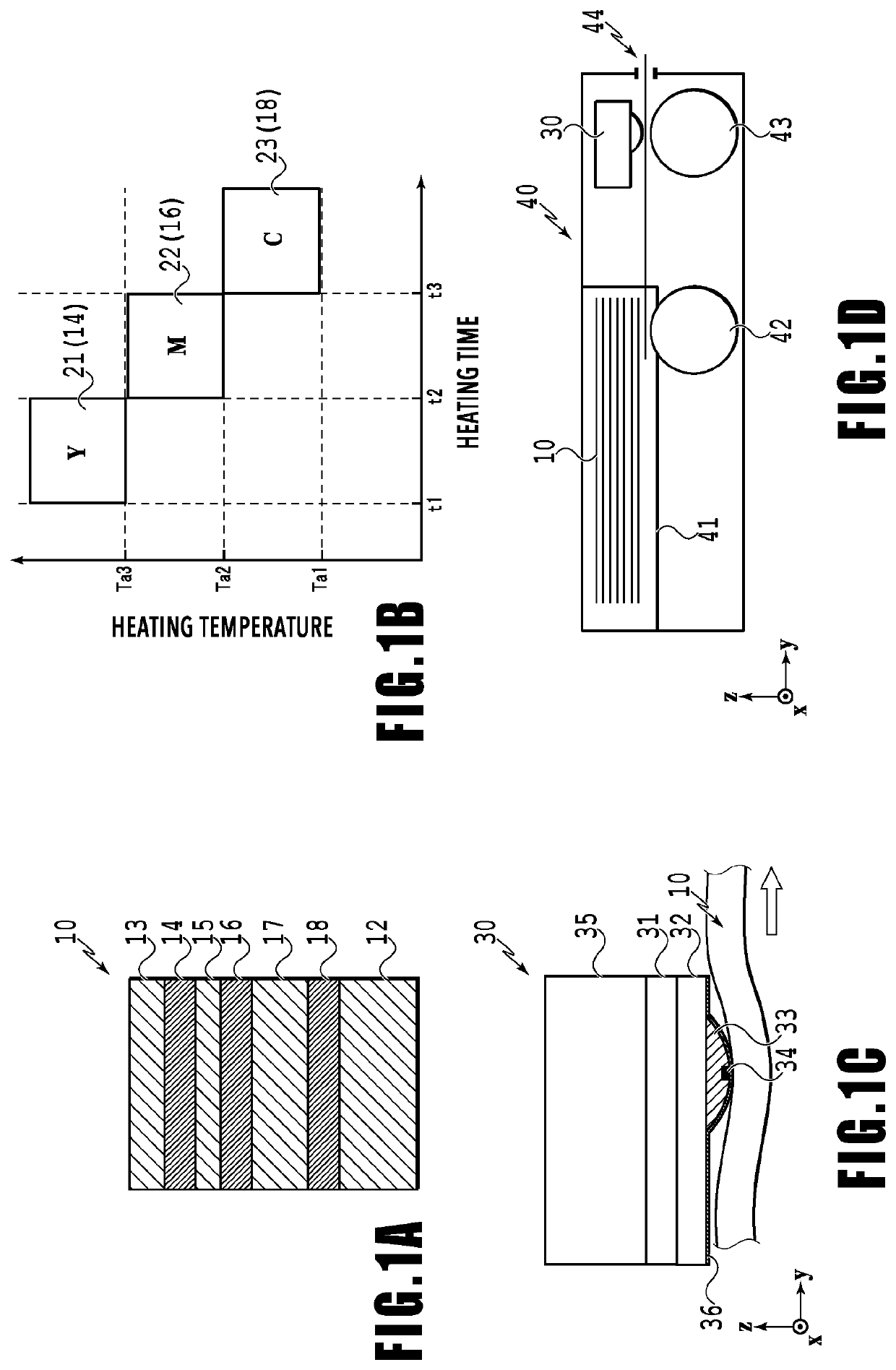

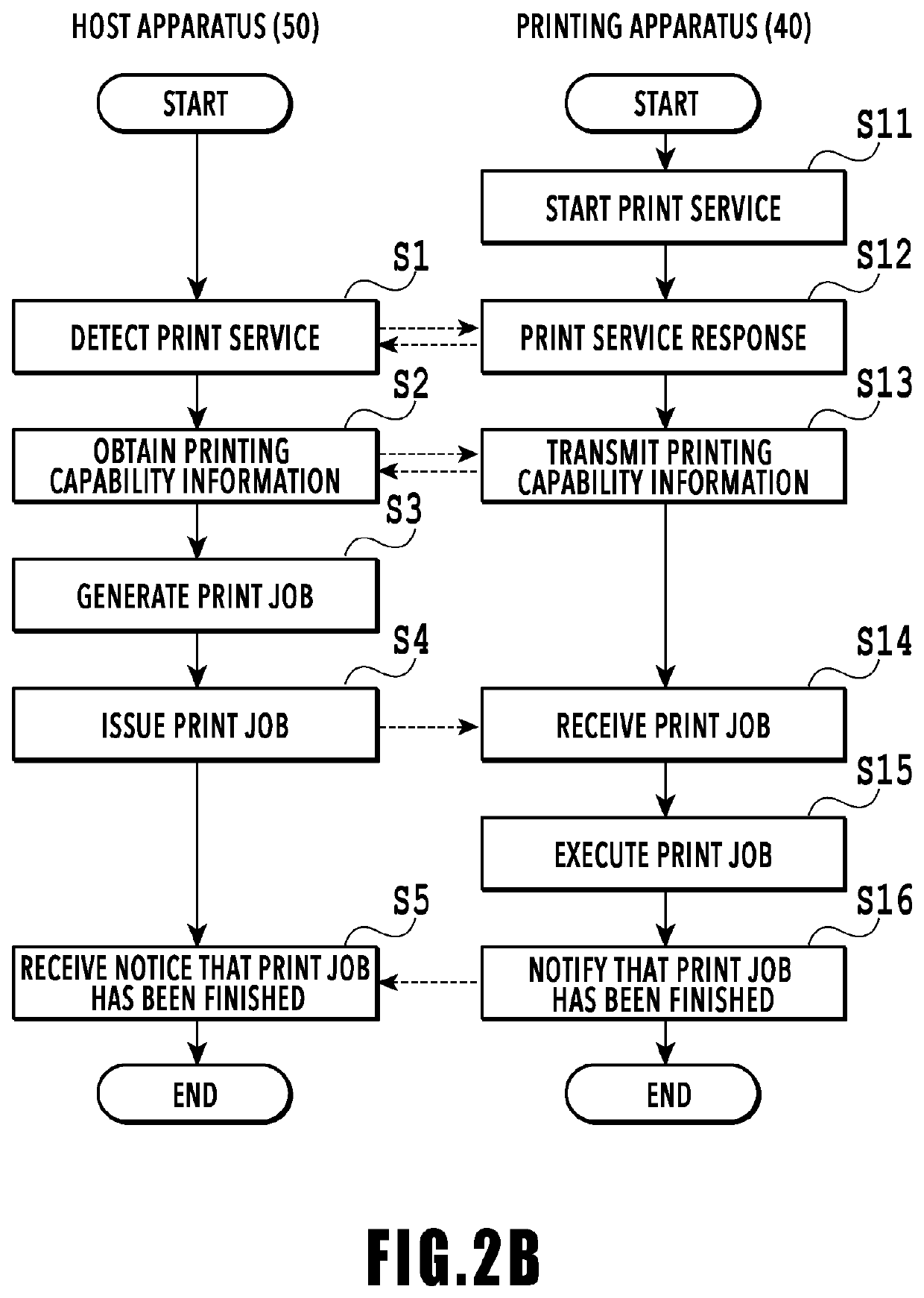

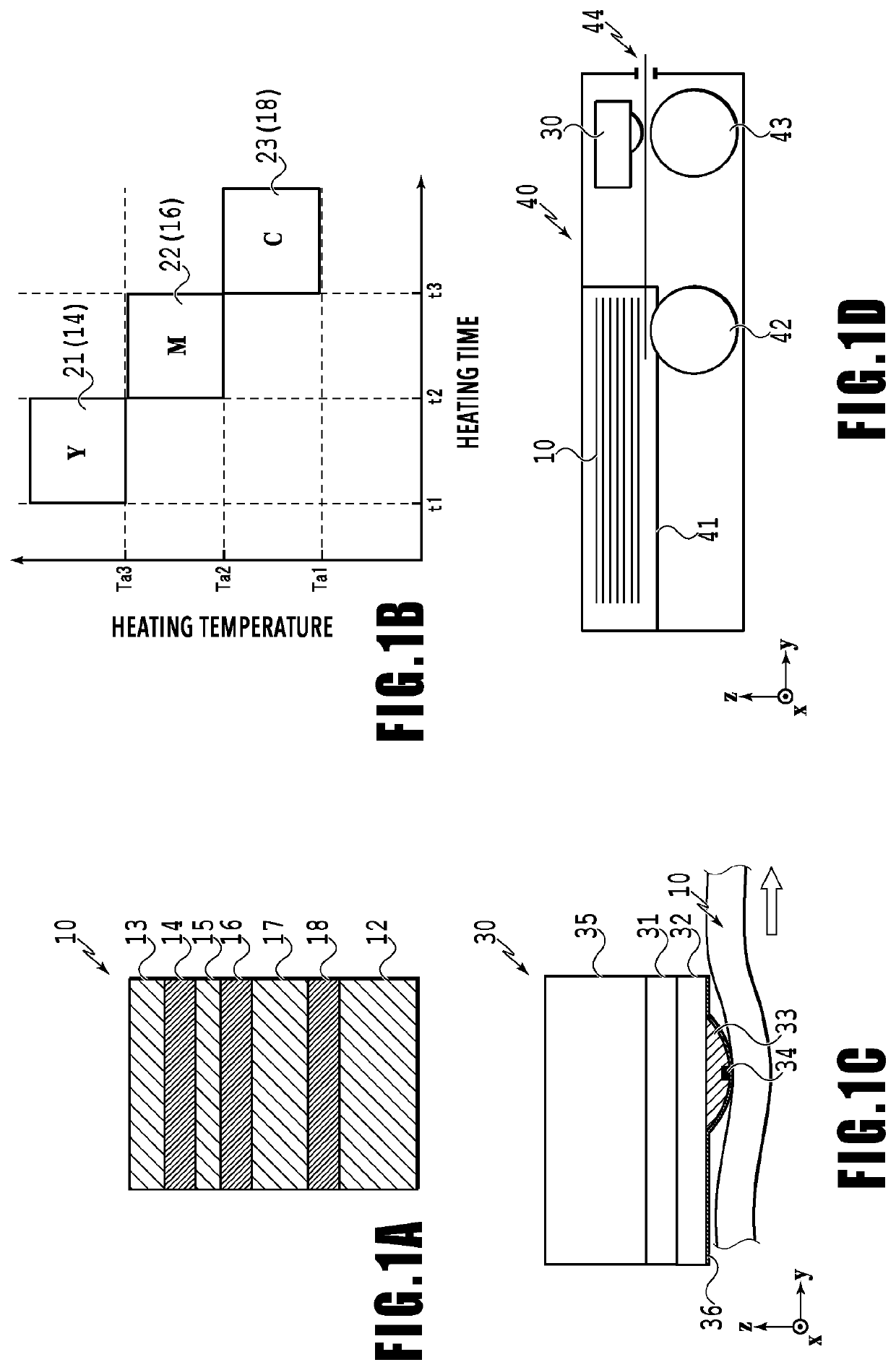

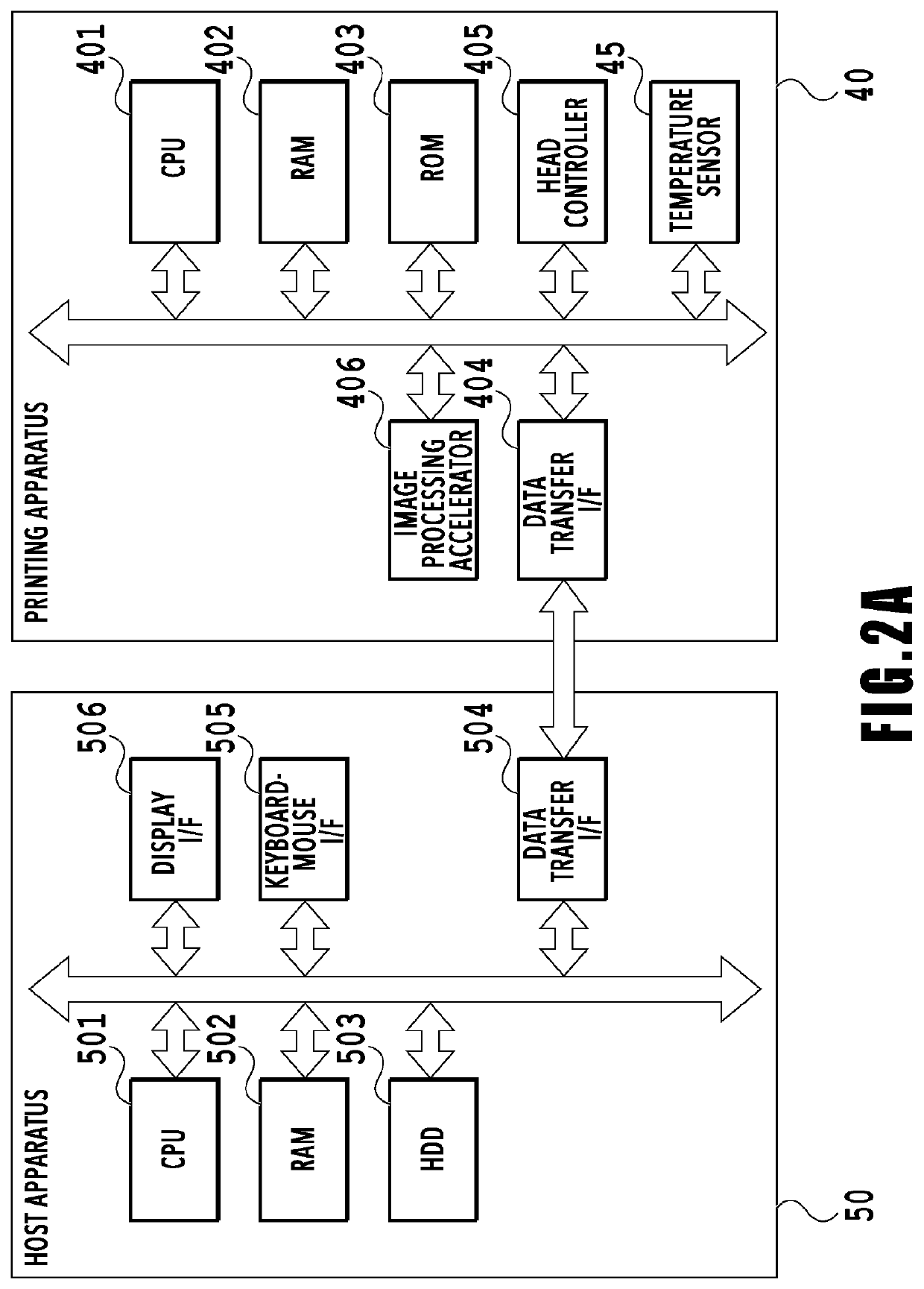

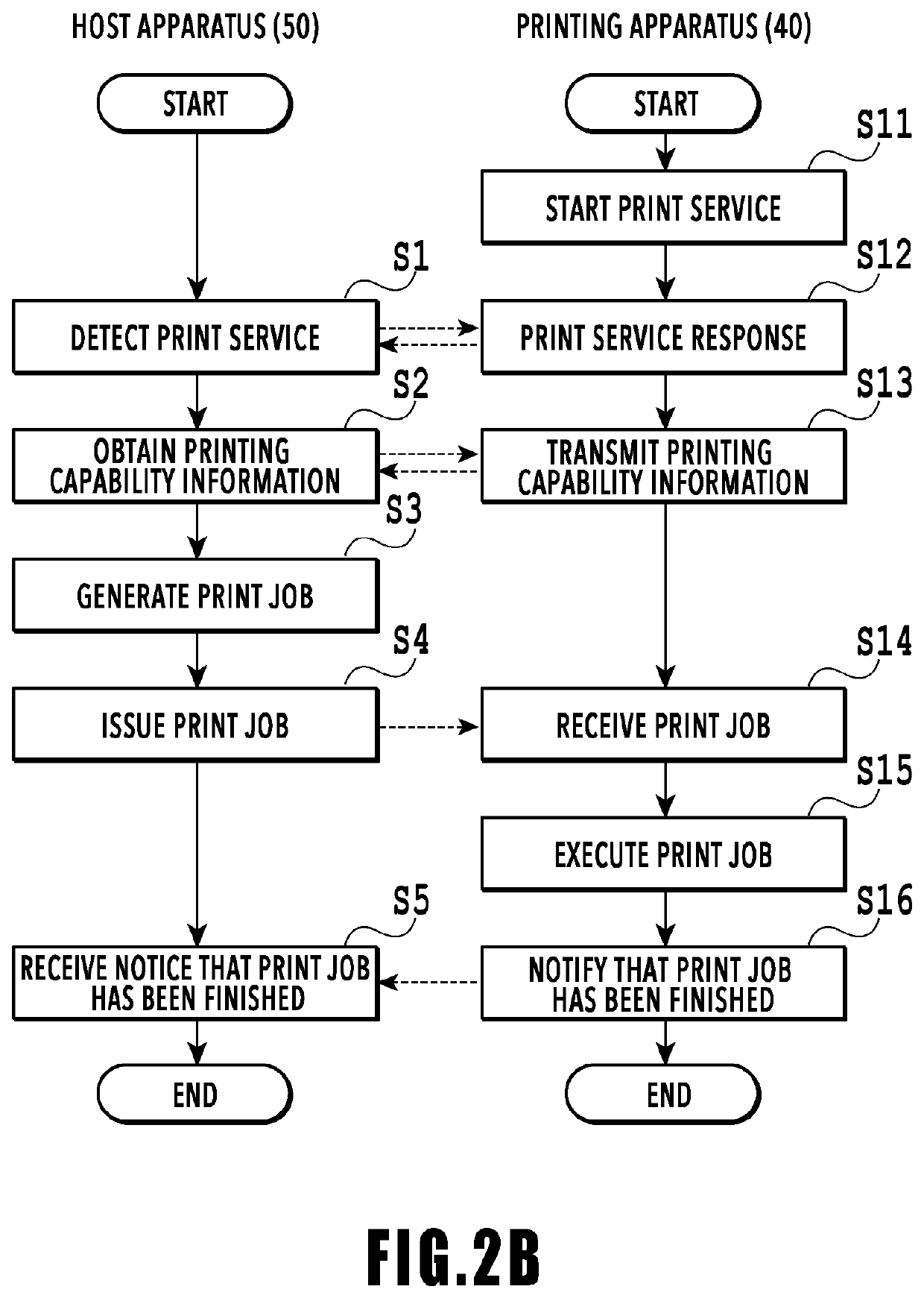

Printing apparatus, printing method, and storage medium

ActiveUS20200016904A1Reduce areaLow colorationThermographyOther printing apparatusPhysicsImage resolution

A print medium in which a plurality of color development layers that develop colors to obtain colored portions by being heated are formed at different positions in the thickness direction is conveyed in a first direction. A plurality of heat generation elements that heat the print medium are controlled so as to selectively cause the plurality of color development layers to develop the respective colors. Heating positions on the print medium are controlled such that, in at least one of the color development layers in the print medium, in a case where lines each including a plurality of pixels which are formed by the colored portions and arranged at a predetermined resolution in the first direction are arranged in a second direction, positions of the plurality of pixels are shifted between the lines in the first direction by a distance smaller than an interval corresponding to a resolution.

Owner:CANON KK

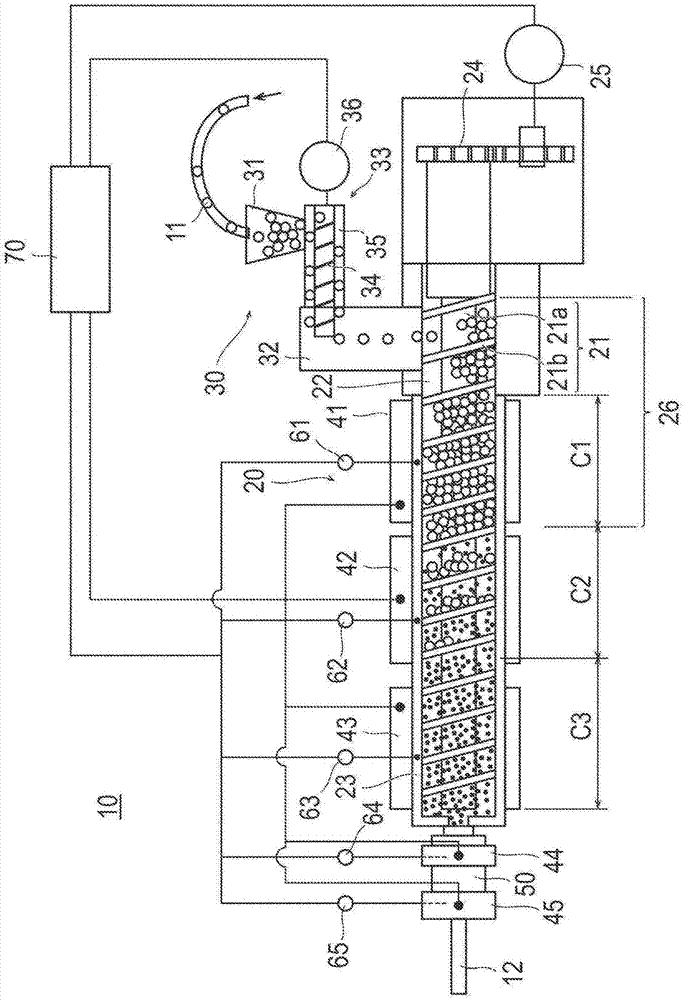

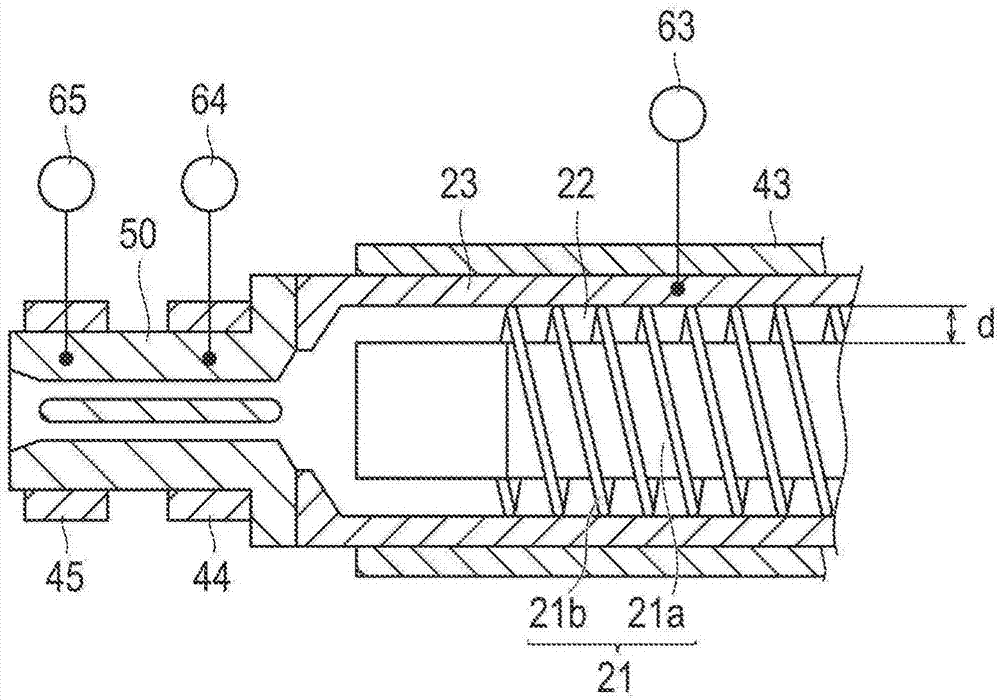

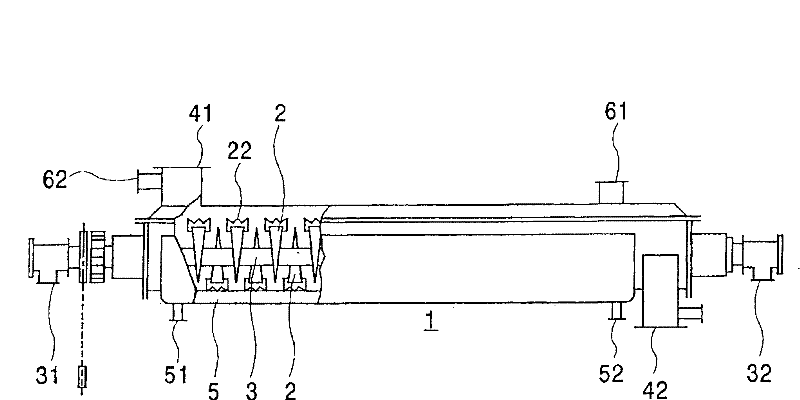

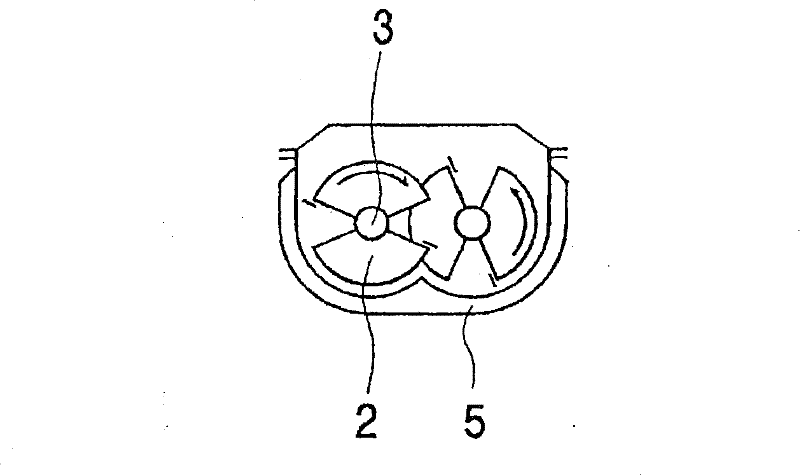

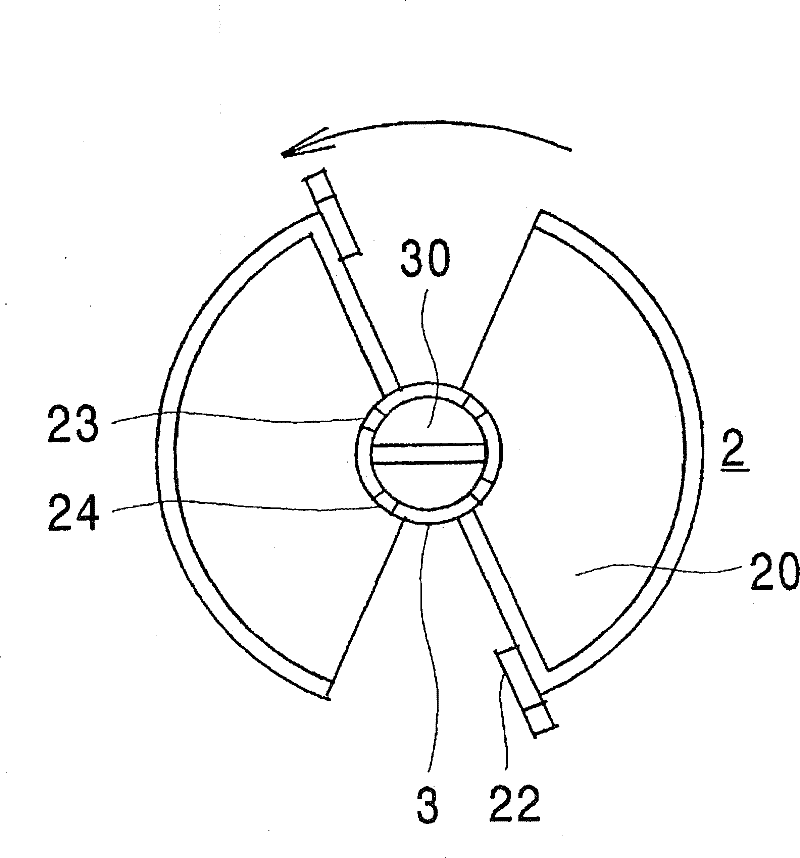

Molded article for medical use, extrusion molding method for molded article for medical use, and extrusion molding device for molded article for medical use

To provide a technology whereby a hardly colored molded article for medical use can be manufactured at a low cost. A molded article for medical use that is manufactured by extrusion molding a composition, said composition comprising, per 100 parts by mass of a polyvinyl chloride resin, 30-160 parts by mass of an ester plasticizer, 5-25 parts by mass of an epoxy plasticizer, and 0.01-0.1 part by mass (in total) of a zinc soap and calcium soap, wherein the white index (W.I.) of the molded article for medical use is 25 or more and the yellow index (Y.I.) thereof is 3.5 or less. In the extrusion molding of the molded article for medical use, a composition 11 in a solid state is supplied to a screw 21 of an extruder 20, said extruder being provided with grooves 22 having the same depth d, at a rate that is regulated so as to prevent shear heat generation in the composition within the extruder. Next, the solid composition supplied to the screw is heat-melted by heaters 41, 42 and 43 and the melted composition extruded from the extruder is molded into the shape of the molded article 12 for medical use in a die 50.

Owner:TERUMO KK

5-hydroxymethyl-2-furfural production method

ActiveUS20190330172A1Inexpensive materialsEasy to disassembleOrganic active ingredientsPhysical/chemical process catalystsIndustrial scaleActivated carbon

An object of the present invention is to provide a method for producing 5-hydroxymethyl-2-furfural (5-HMF) suitable for industrial-scale production and a novel catalyst composition for use in synthesizing 5-HMF. The present invention provides a method for producing 5-HMF comprising performing a dehydration reaction of a carbohydrate comprising a hexose as a constituent sugar or a derivative thereof by using activated carbon as a catalyst; and a catalyst composition for use in the reaction for producing 5-HMF from a carbohydrate comprising a hexose as a constituent sugar through a dehydration reaction, the catalyst composition comprising activated carbon.

Owner:NIHON SHOKUHIN KAKO CO LTD

Optical glass, optical element and method of manufacturing thereof

InactiveUS8034733B2Low colorationGlass reforming apparatusGlass severing apparatusOptical glassMaterials science

An optical glass comprises, denoted as weight percentages, SiO2-2-22%, B2O3: 3-24%, ZnO:>8% and ≦30%, CaO+BaO+ZnO: 10-50%, MgO: 0-3%, La2O3+Y2O3+Gd2O3+Yb2O3: 1-33%, TiO2: 2-20%, ZrO2: 0-10%, Nb2O5: 2-32%, Li2O: 0-5%, Na2O: 0-8%, K2O: 0-10%, WO3: 0-20%. The ratio by weight of La2O3 to the combined contents of La2O3, Y2O3, Gd2O3, and Yb2O3 (La2O3 / (La2O3+Y2O3+Gd2O3+Yb2O3)) falls within a range of 0.7 to 1.

Owner:HOYA CORP

Liquid crystal display device having polymer-stabilized blue phase liquid crystal layer and transparent films

ActiveUS8199291B2Easily causedReduce contrastLiquid crystal compositionsNon-linear opticsIn planeVisible spectrum

A liquid crystal display device has at least a pair of transparent substrates, polymer-stabilized blue phase liquid crystal layer disposed therebetween, and a transparent film having an absolute value |Re| of in-plane retardation Re of 10 nm or smaller in the visible light region, having an absolute value |Rth| of thickness-wise retardation Rth of 30 nm or smaller in the visible light region, having an absolute value |Re(400)−Re(700)| of difference between values of in-plane retardation Re at 400 nm and 700 nm of 10 nm or smaller, and having an absolute value |Rth(400)−Rth(700)| of difference between values of thickness-wise retardation Rth at 400 nm and 700 nm of 35 nm or smaller.

Owner:FUJIFILM CORP

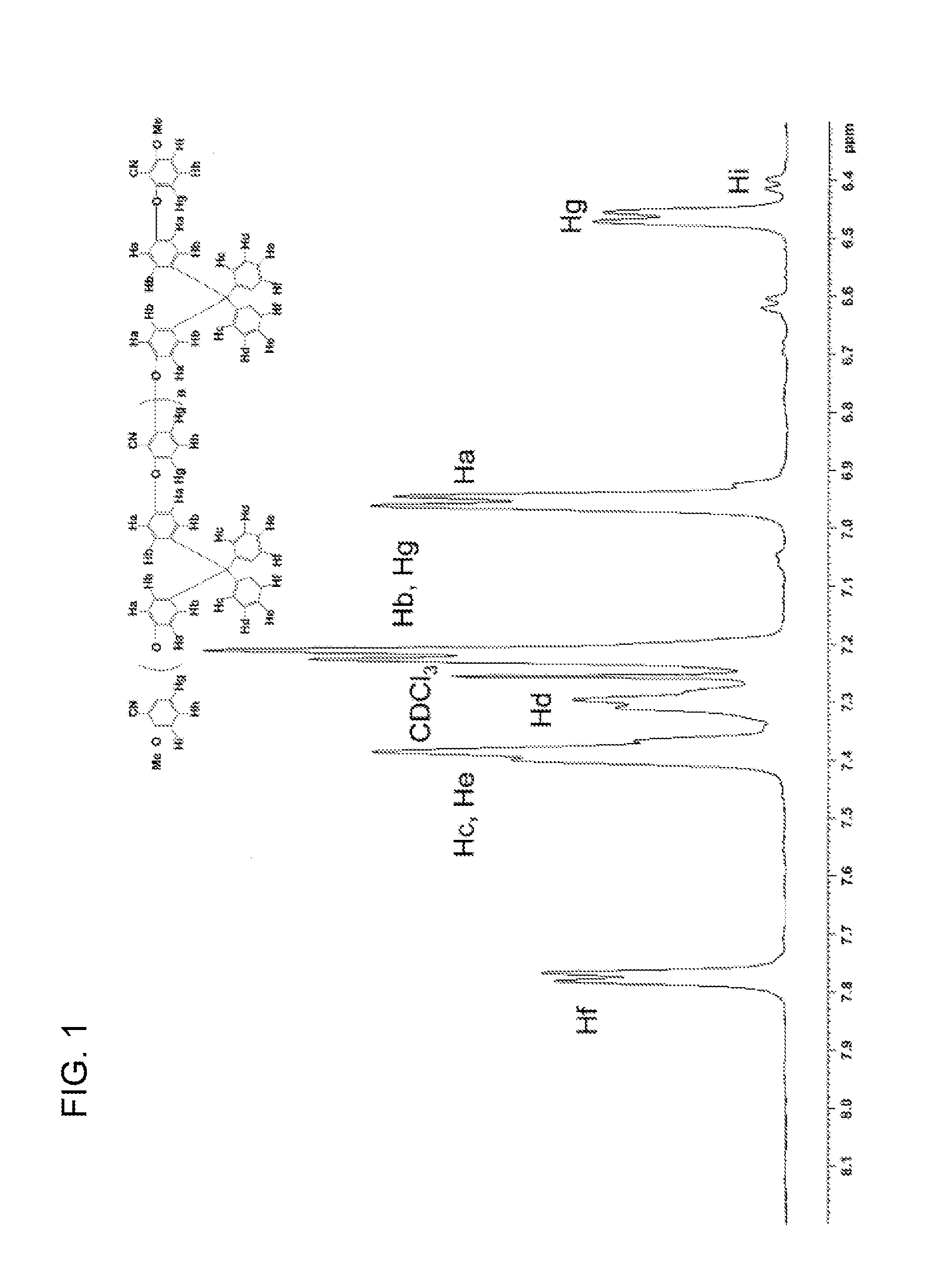

Biphenyltetracarboxylic acid dianhydride, method for producing the same, polyimide using the same and method for producing the same

ActiveCN1976912BInhibit the effect of coloringHigh purityOrganic chemistryMaximum temperatureHigh productivity

Owner:SHINRYOI CORP

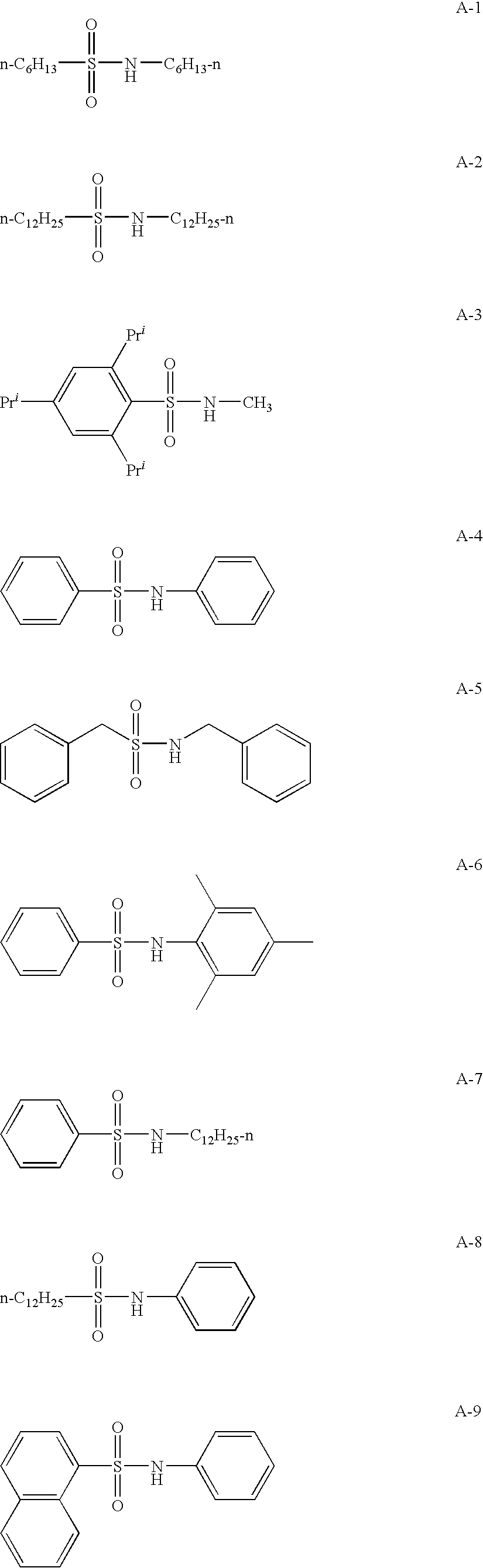

Process for preparation polyisocyanate composition

InactiveUS6888028B2Low colorationUrea derivatives preparationCarbamic acid derivatives preparationAllophaneHydroxy group

Owner:ASAHI KASEI KK

Saccharide polycondensate, method for producing the same, and application therefor

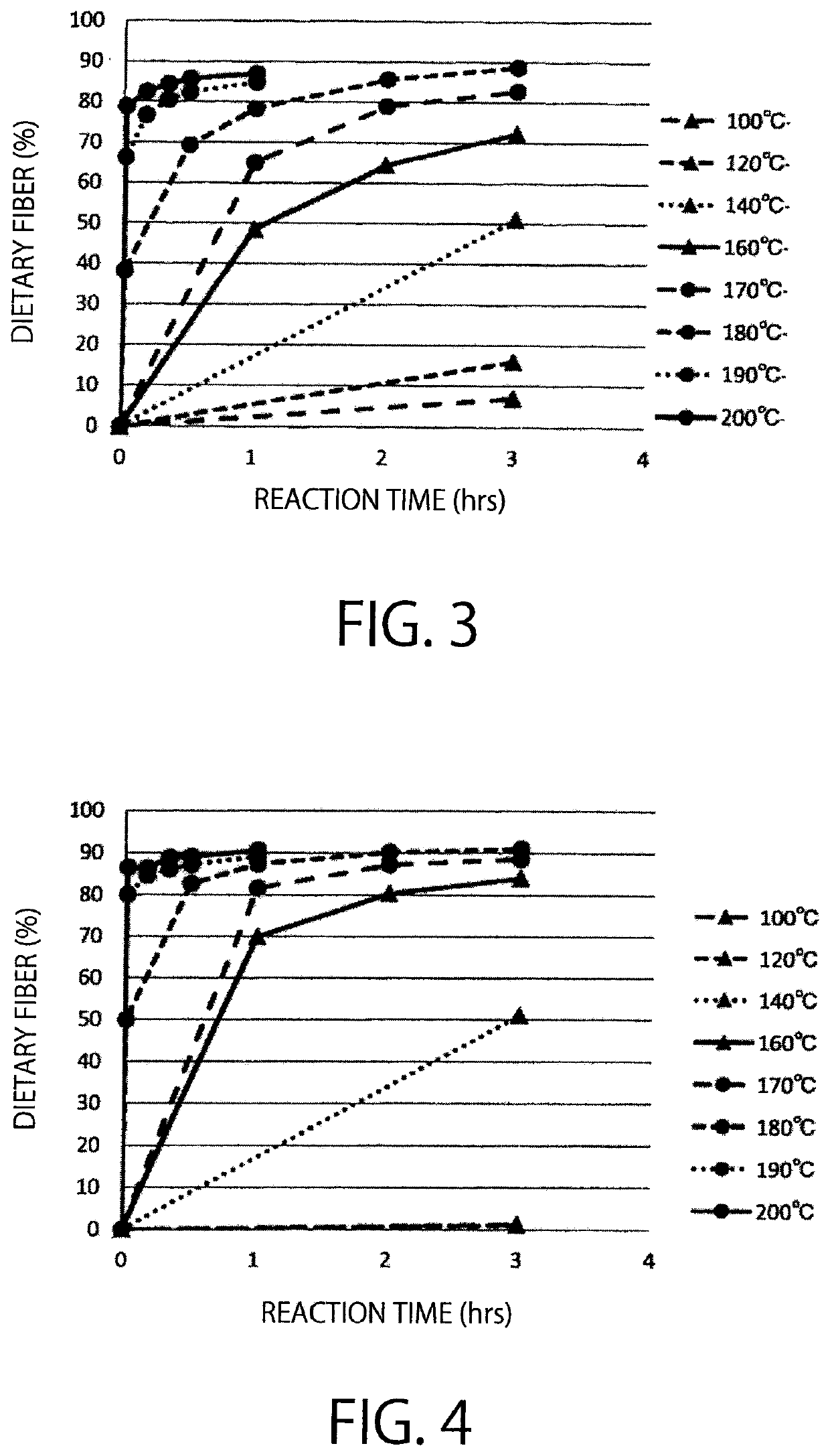

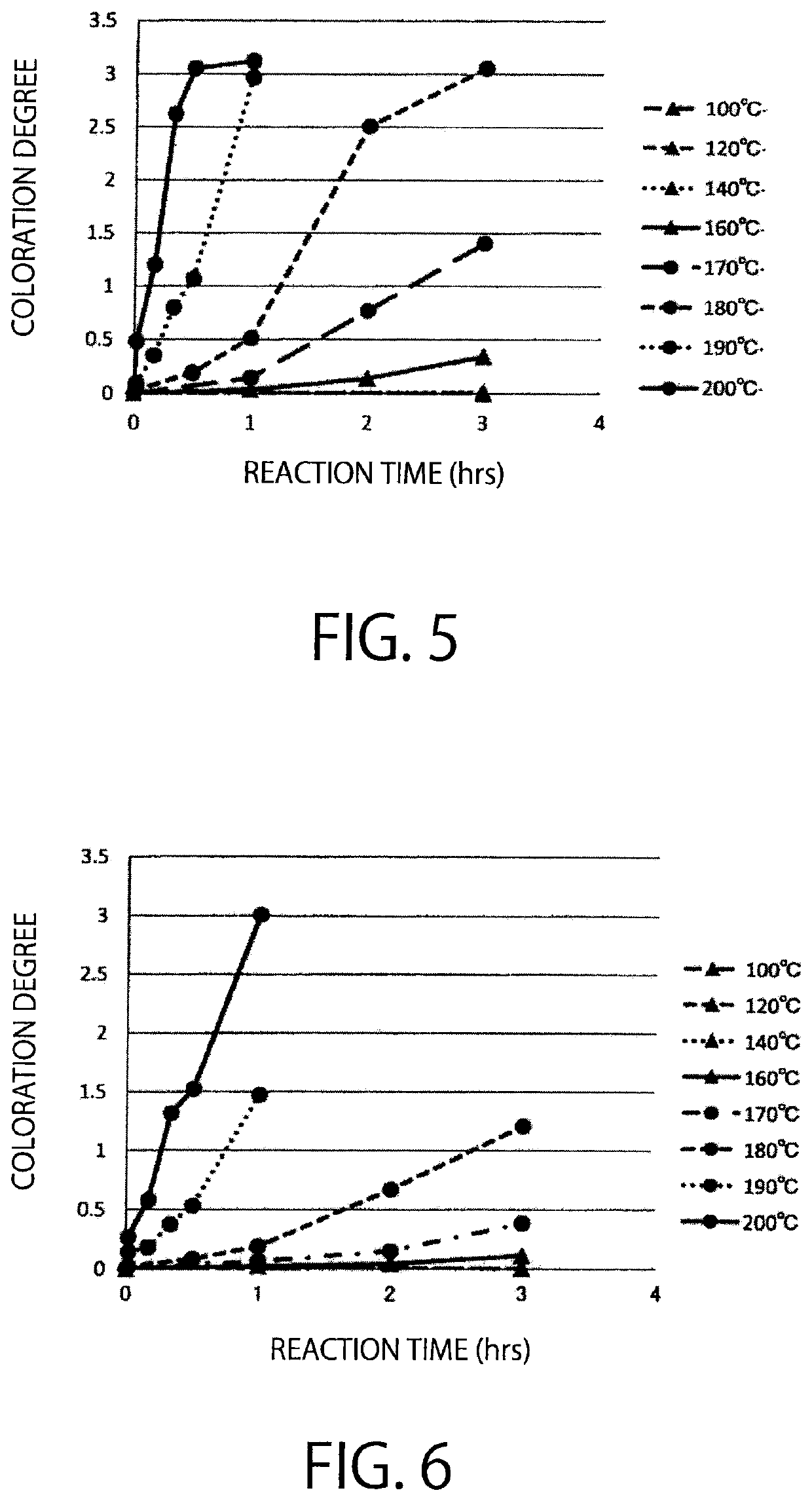

ActiveUS20200123185A1Easy to disassembleSafety is recognizedMilk preparationDough treatmentBiotechnologyActivated carbon

An object of the present invention is to provide a method for producing a saccharide polycondensate which is inexpensive and is applicable to a food or beverage product. Disclosed is a method for producing a saccharide polycondensate, which comprises carrying out a saccharide polycondensation reaction in the presence of activated carbon.

Owner:NIHON SHOKUHIN CO LTD

Method of manufacturing microbially produced plastic and microbially produced plastic

ActiveUS20180087076A1Simple and low-cost methodExcellent toneFatty substance preservation using additivesFermentationThermal treatmentHydrogen peroxide

Provided is a method of manufacturing a microbially produced plastic having low coloration, good tone, and low odor, based on a simple, low-cost method that is suitable for industrial production. The method of manufacturing the microbially produced plastic is characterized in that a step (a) and a step (b), described below, are included: step (a) is a step of applying heat treatment to fat containing hydrogen peroxide, and step (b) is a step of culturing microbes in a culturing liquid containing the fat that has been subjected to the heat treatment in the step (a).

Owner:KANEKA CORP

Method producing for 5-hydroxymethyl-2-furfural with suppressed by-product formation

ActiveUS10988452B2Suppresses attachmentLow colorationOrganic chemistry methodsPtru catalystHydroxymethylfurfural

An object of the present invention is to provide a method for producing 5-hydroxymethyl-2-furfural (5-HMF) with suppressed production of byproducts. The present invention provides a method for producing 5-HMF, comprising the step of performing a dehydration reaction of a carbohydrate comprising a hexose as a constituent sugar or a derivative thereof to produce 5-hydroxymethyl-2-furfural, wherein the dehydration reaction is performed in the presence of activated carbon. The present invention also provides a method for producing a carbohydrate composition comprising 5-hydroxymethyl-2-furfural, comprising the step of heating a carbohydrate composition comprising one or more selected from the group consisting of a carbohydrate comprising a hexose as a constituent sugar and a derivative thereof, in the presence of an acid catalyst and activated carbon at a temperature of 90 to 400° C.

Owner:NIHON SHOKUHIN KAKO CO LTD

Lanthanum crown optical glass, preparation method thereof and optical element

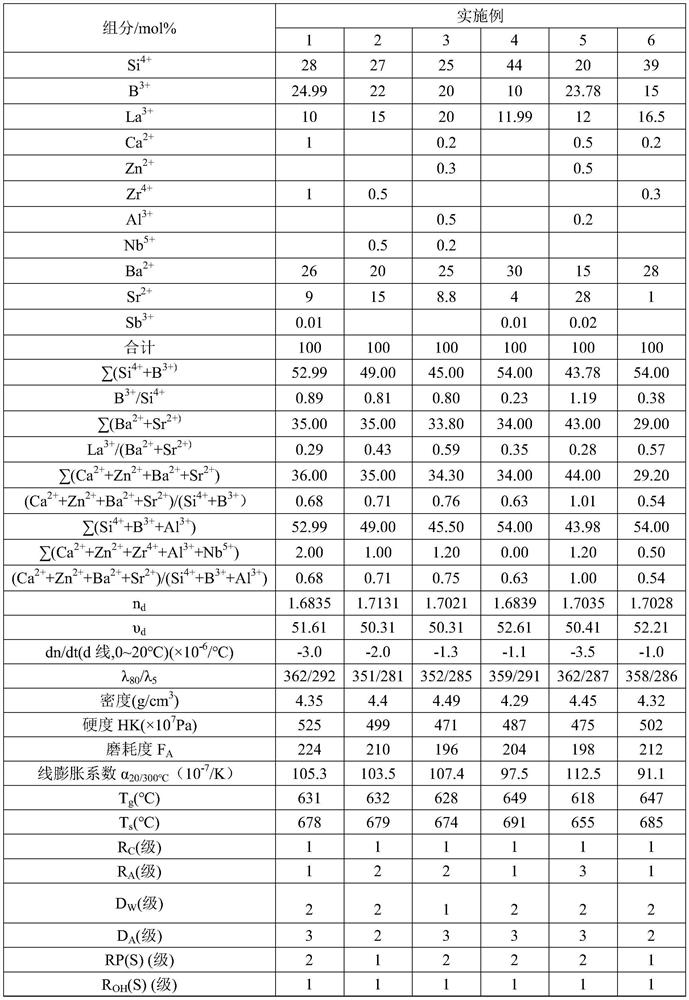

ActiveCN113233757ALow temperature coefficient of refraction indexLow softening temperatureOptical elementsDevitrificationRefractive index

The invention provides lanthanum crown optical glass, a preparation method thereof and an optical element. The lanthanum crown optical glass comprises the following components in percentage by cation mole: 15-52% of Si < 4 + >; 0-24.99% of B < 3 + >; 0-20% of La < 3 + >; 0-5% of Ca < 2 + >; 0-5% of Zn < 2 + >; 0-3% of Zr < 4 + >; 0-3% of Al < 3 + >; 0-3% of Nb < 5 + >; 5-40% of Ba < 2 + >; 0-30% of Sr < 2 + >; 0-0.07% of Sb < 3 + >; the refractive index of the lanthanum crown optical glass is 1.65-1.72; and the abbe number of the material is 50.1-55.0. The lanthanum crown optical glass is low in refractive index temperature coefficient, low in softening temperature, high in hardness, low in abrasion degree, low in density and coloring degree, and excellent in devitrification resistance, chemical stability and mechanical property.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

Method producing for 5-hydroxymethyl-2-furfural with suppressed by-product formation

ActiveUS20200399237A1Raw materials are cheapEasy to disassembleOrganic chemistry methodsPtru catalystHydroxymethylfurfural

An object of the present invention is to provide a method for producing 5-hydroxymethyl-2-furfural (5-HMF) with suppressed production of byproducts. The present invention provides a method for producing 5-HMF, comprising the step of performing a dehydration reaction of a carbohydrate comprising a hexose as a constituent sugar or a derivative thereof to produce 5-hydroxymethyl-2-furfural, wherein the dehydration reaction is performed in the presence of activated carbon. The present invention also provides a method for producing a carbohydrate composition comprising 5-hydroxymethyl-2-furfural, comprising the step of heating a carbohydrate composition comprising one or more selected from the group consisting of a carbohydrate comprising a hexose as a constituent sugar and a derivative thereof, in the presence of an acid catalyst and activated carbon at a temperature of 90 to 400° C.

Owner:NIHON SHOKUHIN KAKO CO LTD

Novel polymer, method for manufacturing the same, and film

ActiveUS20130130012A1Low colorationImprove heat resistanceSynthetic resin layered productsPolymer scienceStructural unit

A polymer comprising: at least one structural unit (i) selected from the group consisting of a structural unit represented by formula (1) below and a structural unit represented by formula (2) below, wherein a terminal structure of said polymer is independently a structural unit represented by formula (5) below or a structural unit represented by formula (6) below.

Owner:JSR CORPORATIOON

Printing apparatus, printing method, and storage medium

ActiveUS10953664B2Reduce areaLow colorationThermographyOther printing apparatusImage resolutionEngineering

Owner:CANON KK

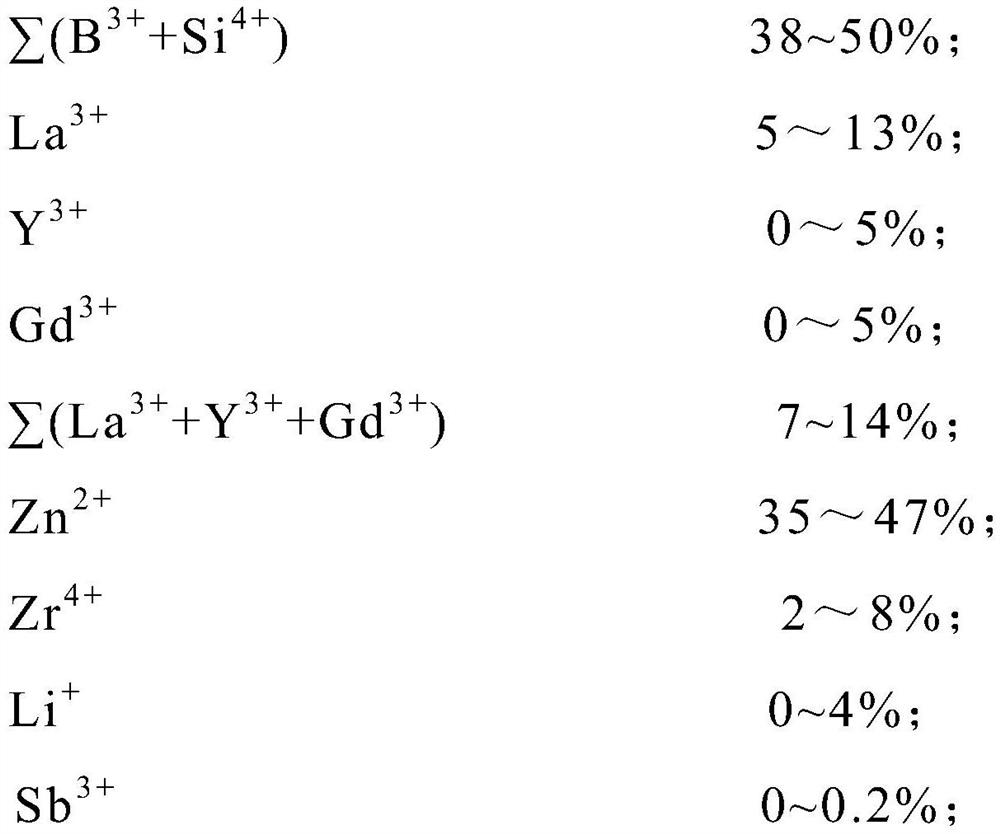

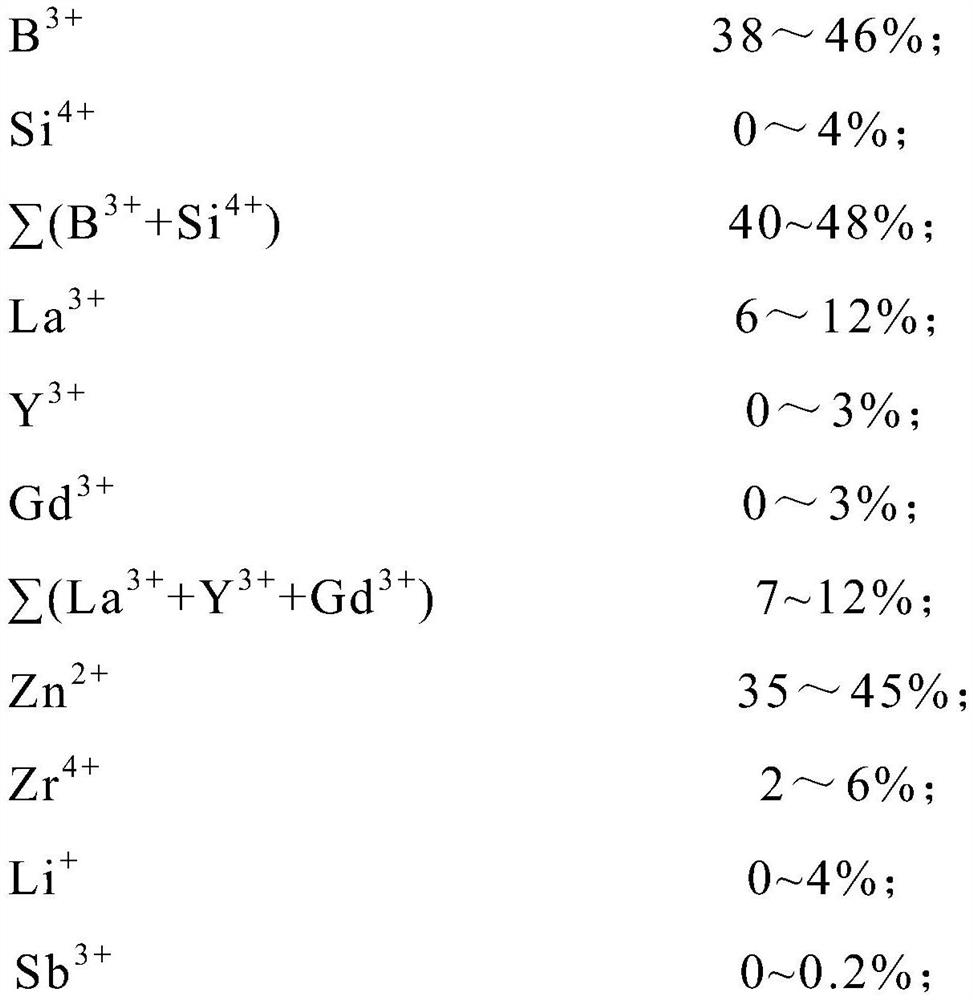

Optical glass and its preparation method, optical element and application

ActiveCN107601855BLow colorationReduced thermal stabilityGlass pressing apparatusOptical elementsThermal stabilityOptical glass

The invention provides optical glass, a preparation method thereof, an optical element and an application. In terms of molar percentage of cations, the optical glass is prepared from components as follows: 35%-48% of B<3+>, 0-6% of Si<4+>, 38%-50% of sigma(B<3+>+Si<4+>), 5%-13% of La<3+>, 0-5% of Y<3+>, 0-5% of Gd<3+>, 7%-14% of sigma(La<3+>+Y<3+>+Gd<3+>), 35%-47% of Zn<2+>, 2%-8% of Zr<4+>, 0-4%of Li<+> and 0-0.2% of Sb<3+>; anions of the optical glass are all O<2->. The optical glass has the advantages of low coloring degree, high thermal stability, lower density, and lower glass transitiontemperature and glass yield temperature; the forming and molding temperature is reduced, and energy consumption is reduced; the glass manufacturing cost is lower, and the optical glass is suitable for batch industrial production.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

Method of manufacturing microbially produced plastic and microbially produced plastic

ActiveUS10612052B2Simple and low-cost methodExcellent toneFatty substance preservation using additivesFermentationMicroorganismHeat processing

Provided is a method of manufacturing a microbially produced plastic having low coloration, good tone, and low odor, based on a simple, low-cost method that is suitable for industrial production. The method of manufacturing the microbially produced plastic is characterized in that a step (a) and a step (b), described below, are included: step (a) is a step of applying heat treatment to fat containing hydrogen peroxide, and step (b) is a step of culturing microbes in a culturing liquid containing the fat that has been subjected to the heat treatment in the step (a).

Owner:KANEKA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com