Molded article for medical use, extrusion molding method for molded article for medical use, and extrusion molding device for molded article for medical use

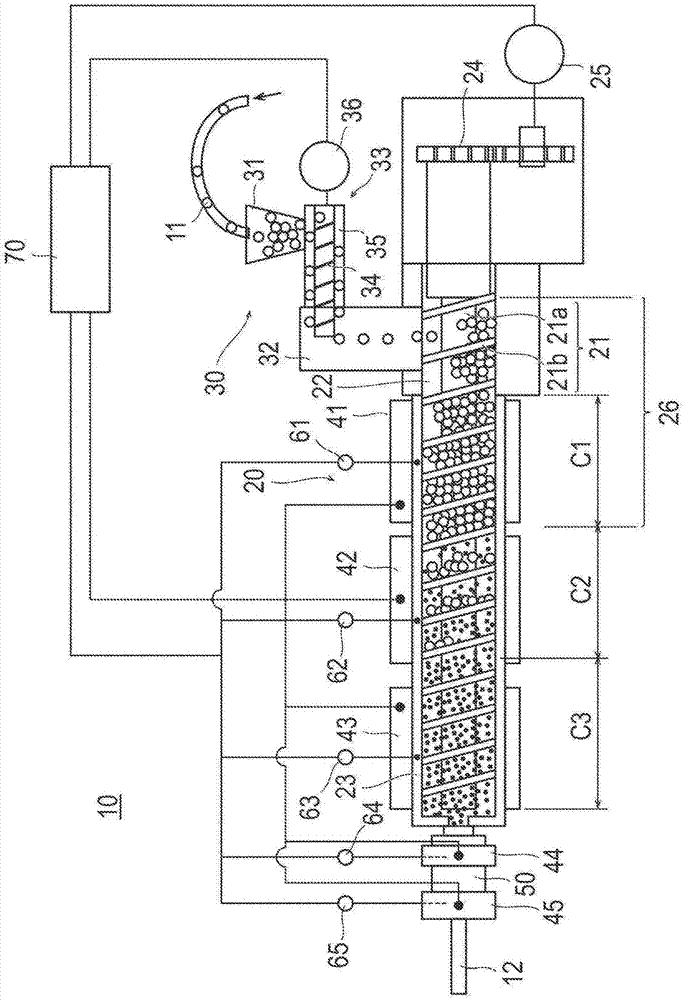

A technology for extrusion molding and medical use, which is applied in the fields of medical molded products, extrusion molding of medical molded products, and extrusion molding devices for medical molded products. It can solve problems such as deterioration and promote coloring, and achieve suppression of retention , low cost, and the effect of suppressing excessive shear heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

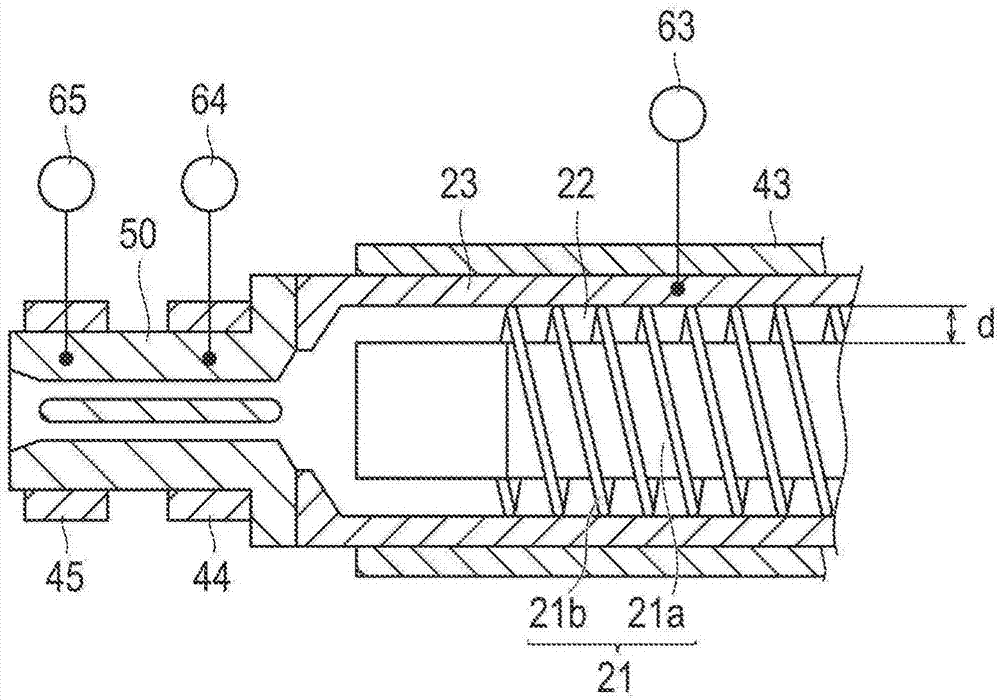

Method used

Image

Examples

Embodiment 1

[0100] 100 kg of polyvinyl chloride resin (manufactured by Kaneca Corporation, KS-1700, average polymerization degree: 1700), 52 kg of bis(2-ethylhexyl) phthalate (DEHP) as an ester plasticizer, and 52 kg of an epoxy Epoxidized soybean oil (manufactured by Co., Ltd. ADEKA, O-130P) 8 kg of plasticizer, Ca-Zn series stabilizer (manufactured by Co., Ltd. ADEKA, trade name: ADEKA STAB 37) as a stabilizer, calcium stearate content: about 7.57% by mass, zinc stearate content: about 10.1% by mass) 0.07 kg, and silicone oil (Shin-Etsu Chemical trade name: KF-50) 0.15 kg were mixed to prepare a polyvinyl chloride resin composition. In addition, in this polyvinyl chloride resin composition, calcium stearate and zinc stearate were contained in the quantity of 0.0053 kg and 0.00707 kg, respectively.

[0101] Next, the polyvinyl chloride resin composition was formed into pellets, and extruded using the above-mentioned extrusion molding device for molded medical products to obtain an inner di...

Embodiment 2

[0104] In Example 1, a tube was manufactured in the same manner as in Example 1 except that the compounding amount of the Ca-Zn-based stabilizer (manufactured by ADEKA Corporation, trade name: ADEKA STAB 37) was changed to 0.21 kg.

[0105] The whiteness and yellowness of the obtained tube were measured, and the results were 28.4 and 1.1, respectively. It can be seen from the above results that the tube of this example can exhibit high whiteness and low yellowness even when the amount of stabilizer (zinc soap and calcium soap) is small.

Embodiment 3

[0107] In Example 1, a tube was manufactured in the same manner as in Example 1 except that the compounding amount of the Ca-Zn-based stabilizer (manufactured by ADEKA Corporation, trade name: ADEKA STAB 37) was changed to 0.35 kg.

[0108] The whiteness and yellowness of the obtained tube were measured, and the results were 28.0 and 1.2, respectively. It can be seen from the above results that the tube of this example can exhibit high whiteness and low yellowness even when the amount of stabilizer (zinc soap and calcium soap) is small.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com