Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

75results about How to "Intuitive inspection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of handling, filling and sealing packaging containers

InactiveUS6256964B1Simplify handling and transportAvoid damage and dirt contaminationOpening closed containersPower operated devicesHermetic packagingProcessing plants

A method of handling, filling and sealing prefabricated packaging containers that are provided with a closure device is disclosed. The packaging containers are transported in the closed state to a processing plant in which the closure device is opened, the packaging container and closure device are sterilized, and thereafter the packaging container is filled with the desired liquid contents. The same closure device that was removed from the packaging container is then reapplied to seal the container.

Owner:TETRA LAVAL HLDG & FINANCE SA

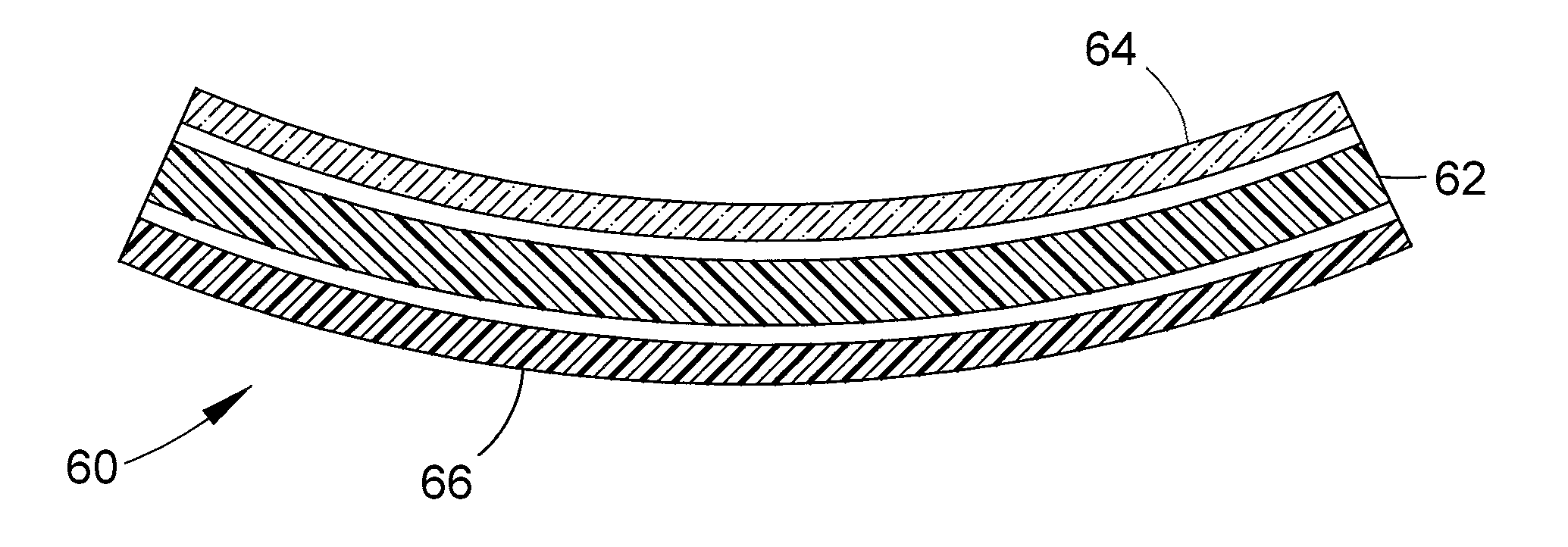

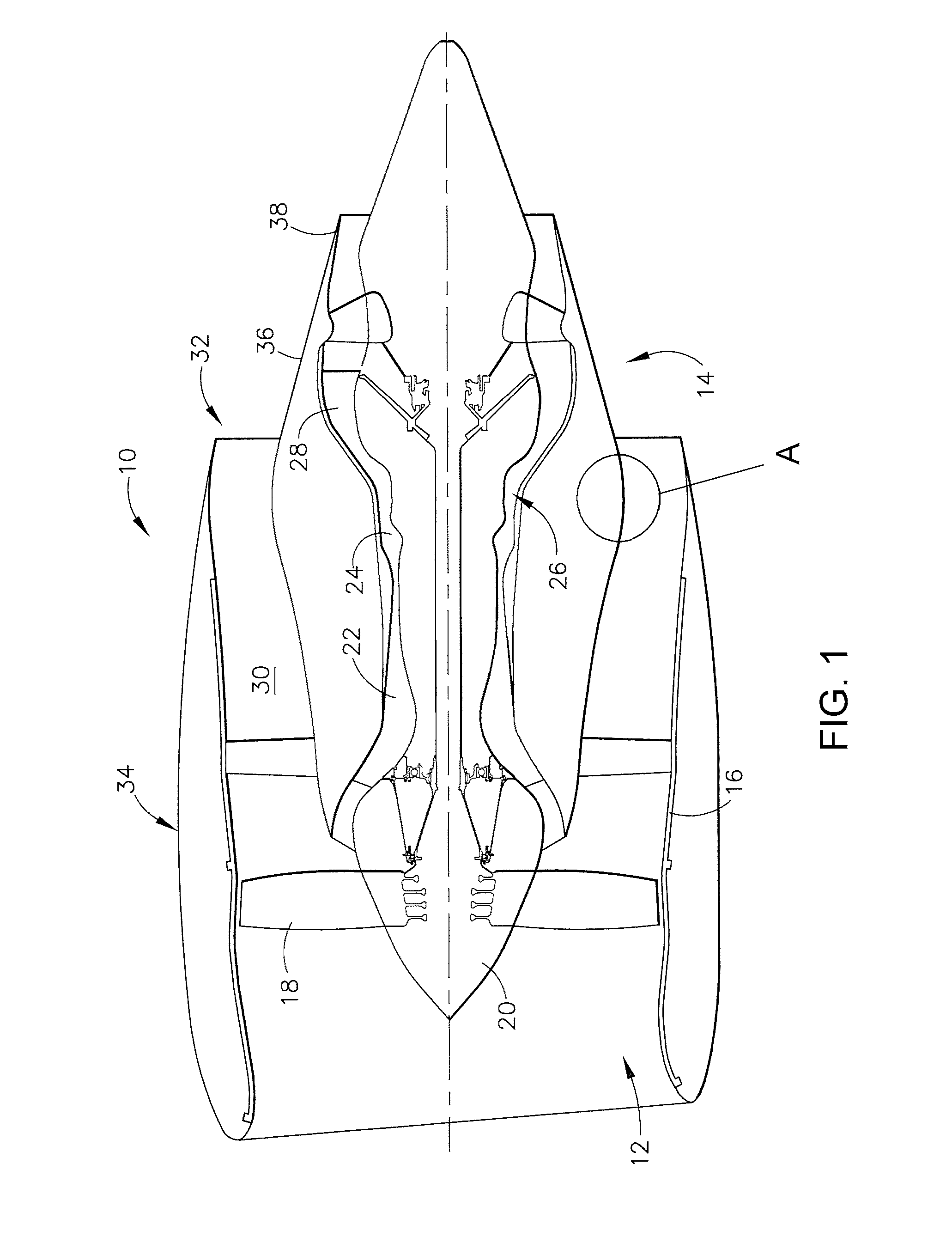

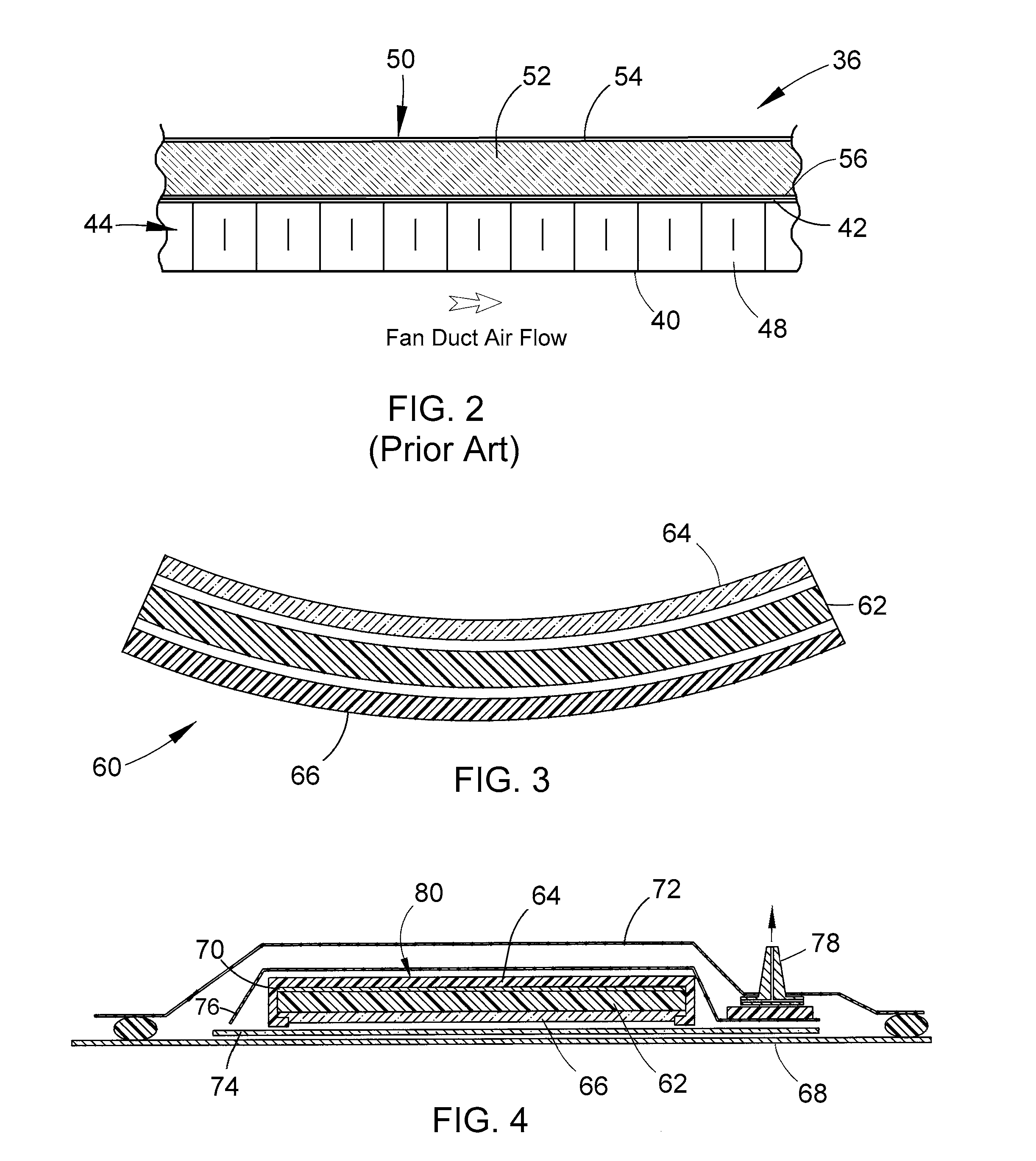

Laminate thermal insulation blanket for aircraft applications and process therefor

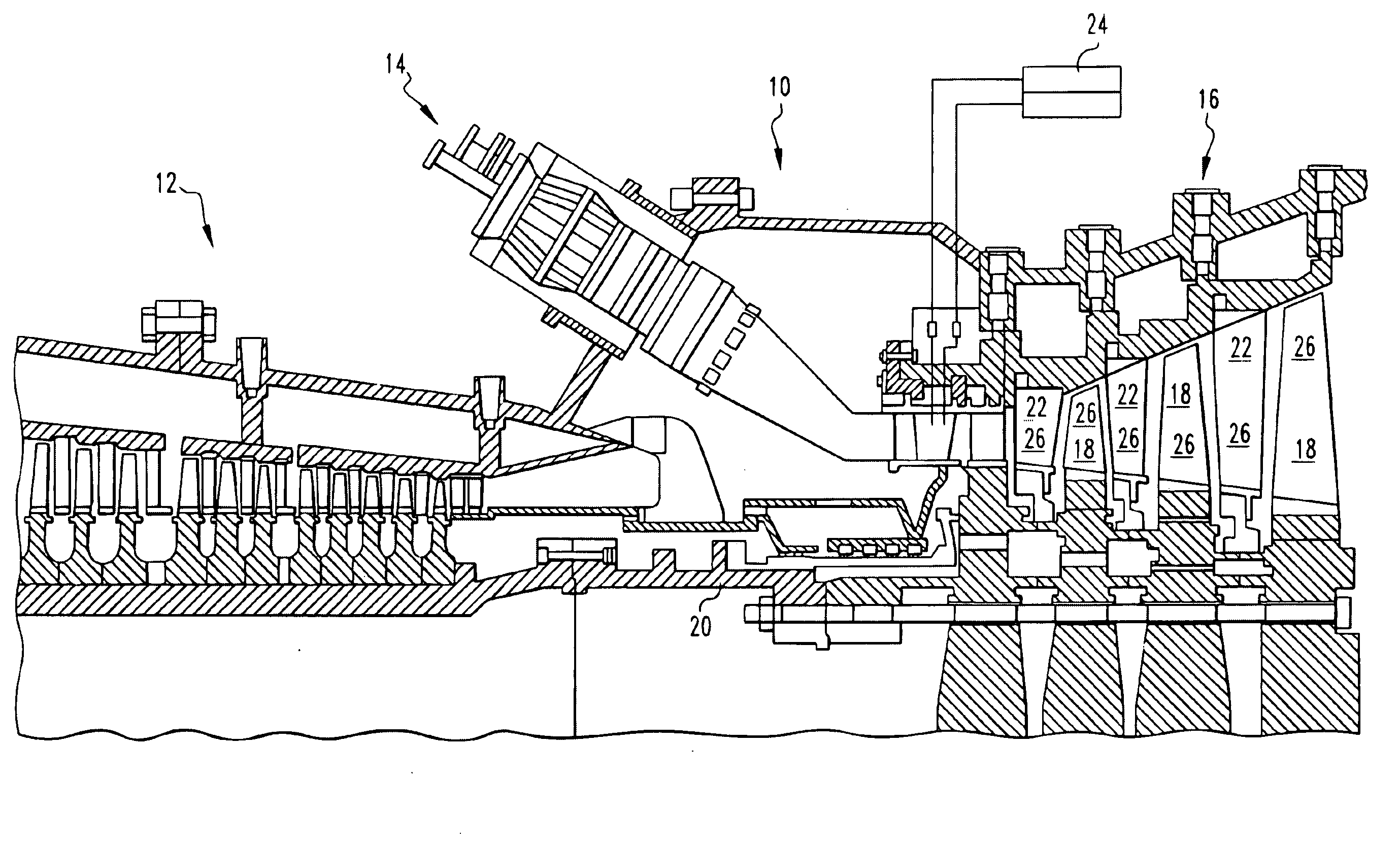

InactiveUS20120308369A1Simpler inspection and maintenance operationLess thickness and weightPump componentsRotary non-positive displacement pumpsThermal insulationLayered structure

A thermal insulation blanket for an aircraft engine, and processes for producing the thermal insulation blanket to have low thermal conductivity and high temperature capability. The thermal insulation blanket has a layered construction that includes an aerogel insulation material, a composite layer disposed at a first surface of the aerogel insulation material, and a backing layer disposed at an opposite surface of the aerogel insulation material so that the aerogel insulation material is encapsulated between the composite and backing layers. The composite layer contains a resin matrix material reinforced with a fiber reinforcement material.

Owner:MRA SYST

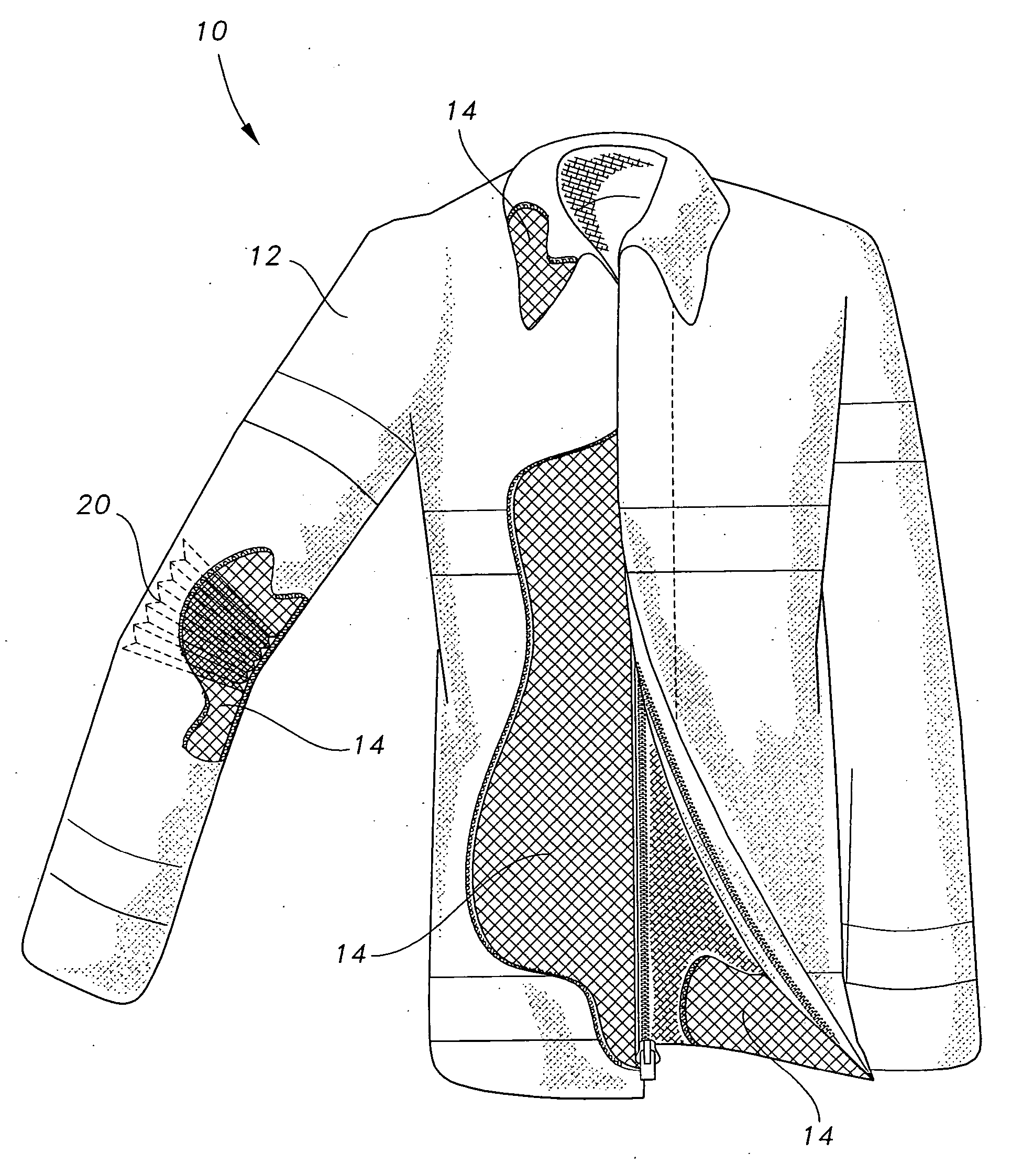

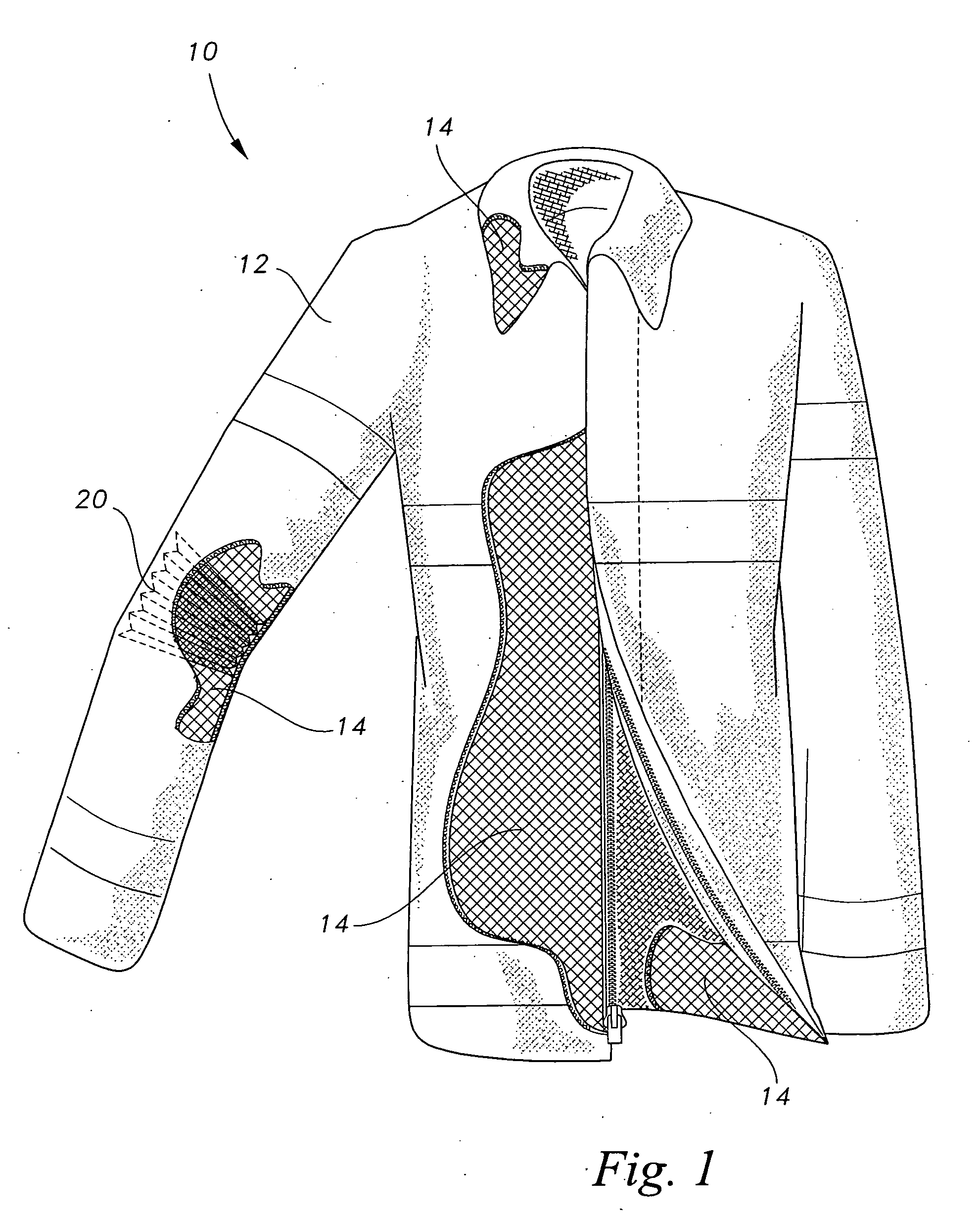

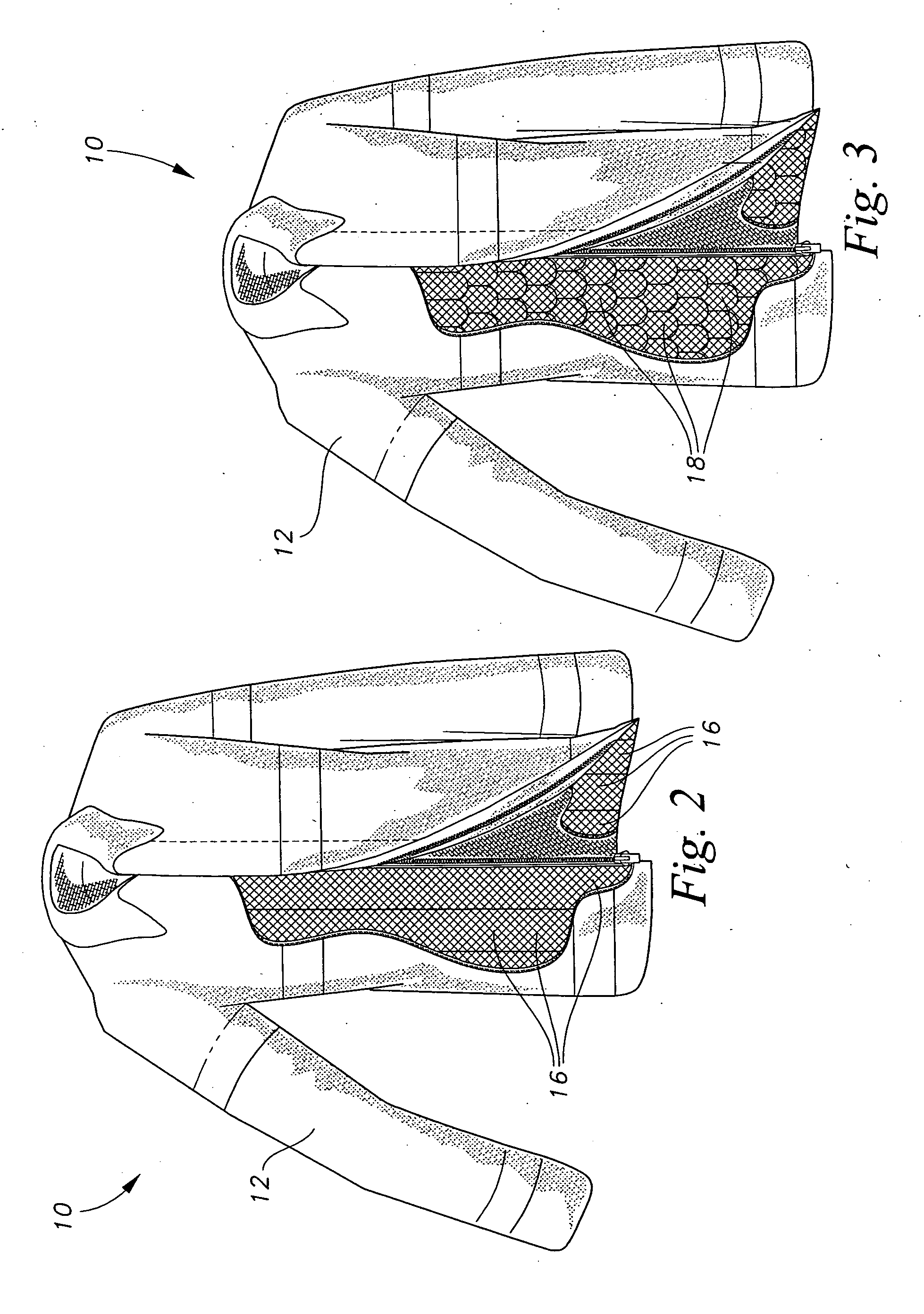

Hazardous duty garments

InactiveUS20050251900A1Permit free movementEasy to checkChemical protectionHeat protectionHeat resistanceThermal insulation

An improved hazardous duty garment system includes an abrasion-resistant, flame-resistant and heat-resistant outer shell, a moisture barrier attached inside the outer shell, and a thermal liner attached to the outer shell and the moisture barrier. The thermal liner includes at least one layer of thermal insulation attached to a layer of a metal screen thermal barrier. The metal screen layer may be made from a plurality of panels and fitted closely together, or a plurality of shingles. The metal screen panels are individually removable and replaceable. The metal screen provides superior heat dissipation properties and superior tolerance of direct heat.

Owner:HARLACKER JOHN A

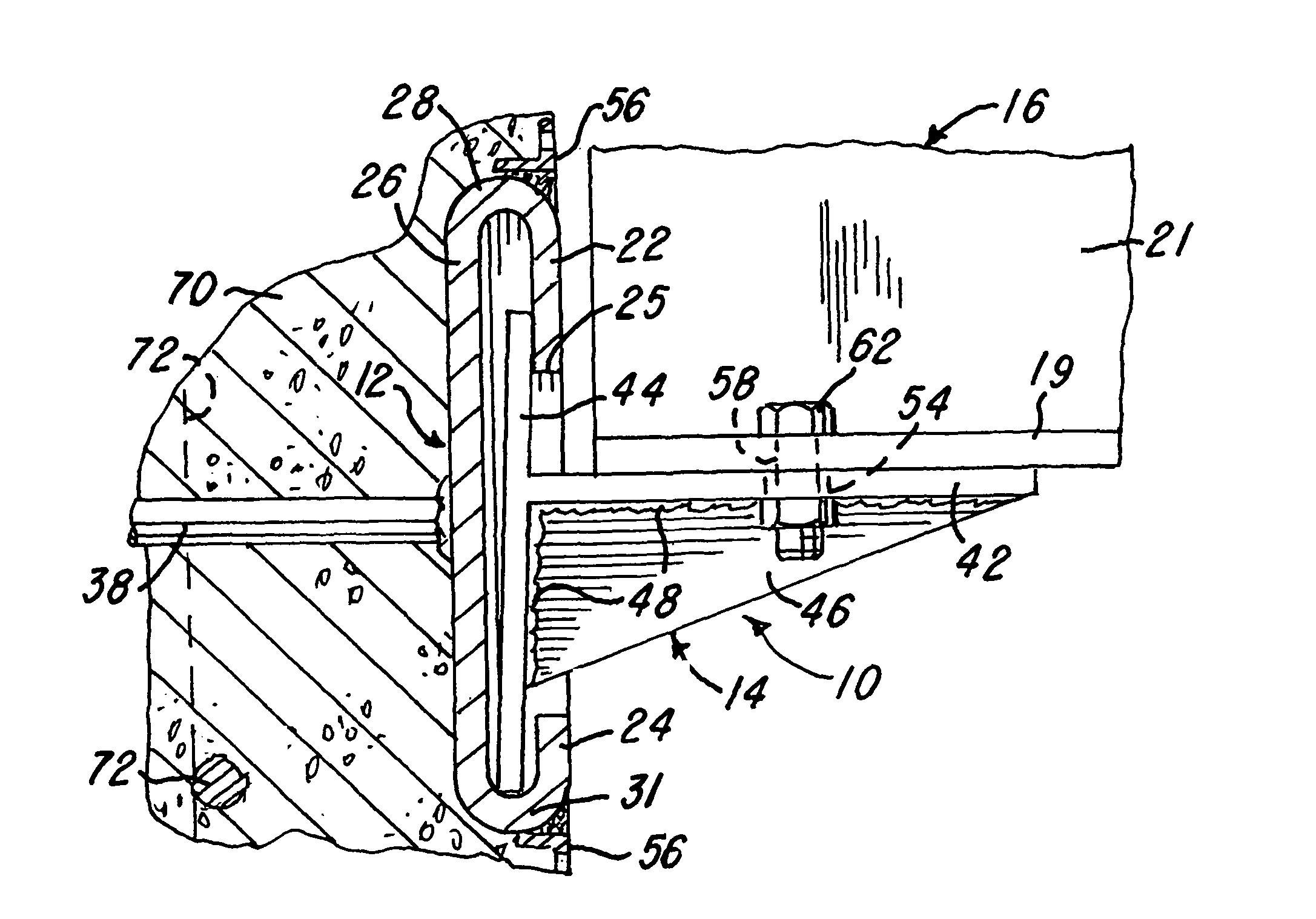

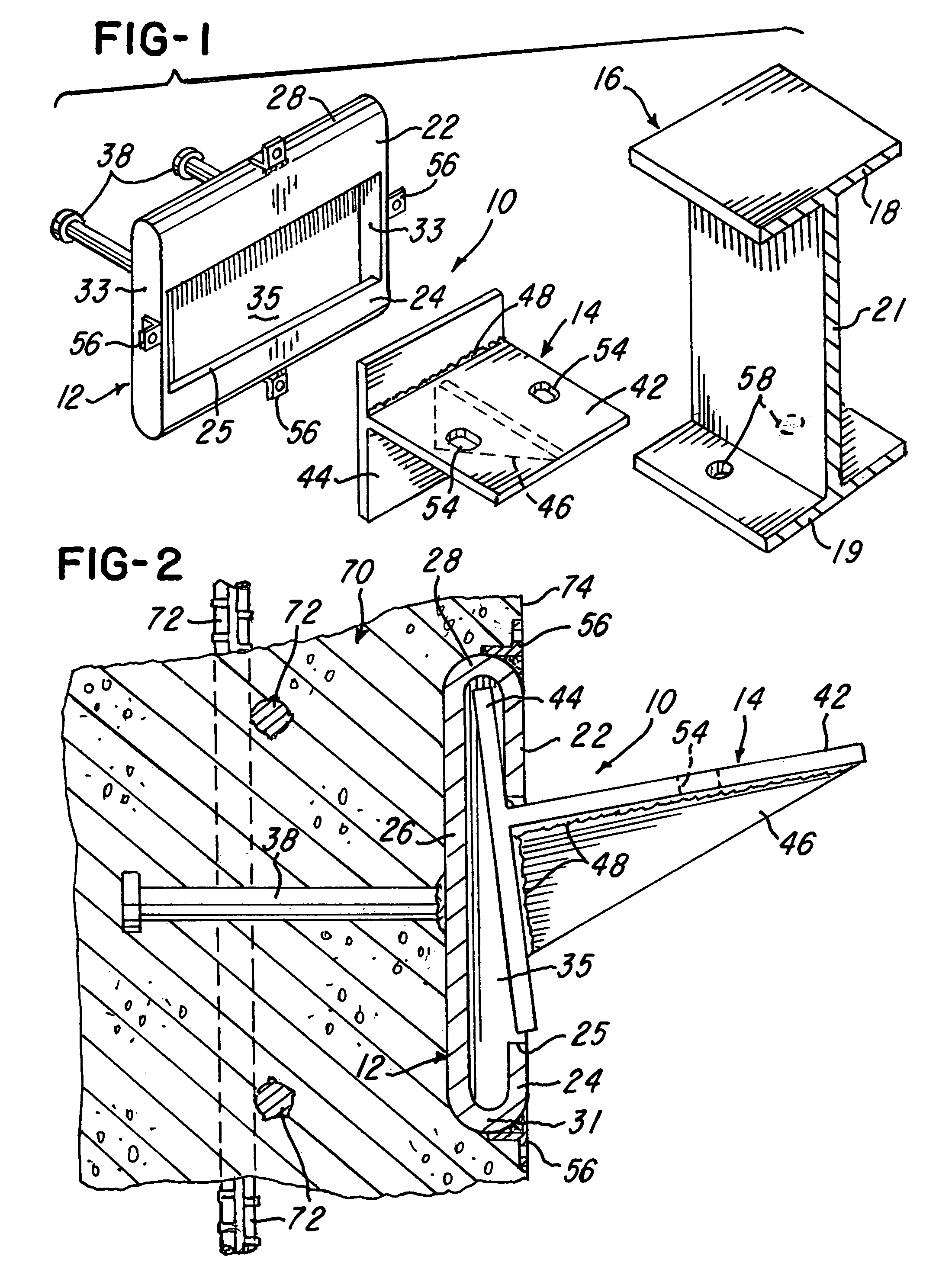

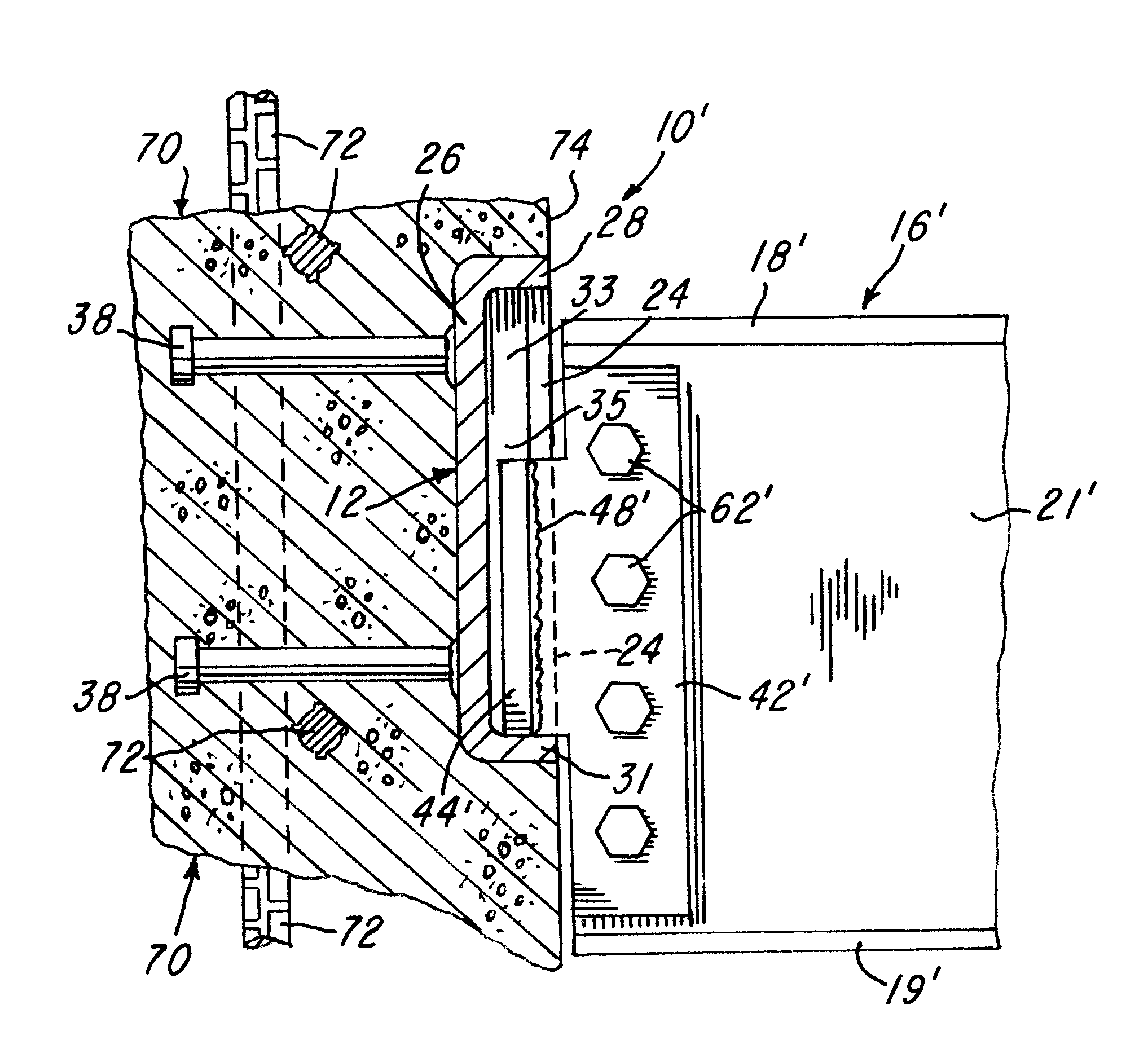

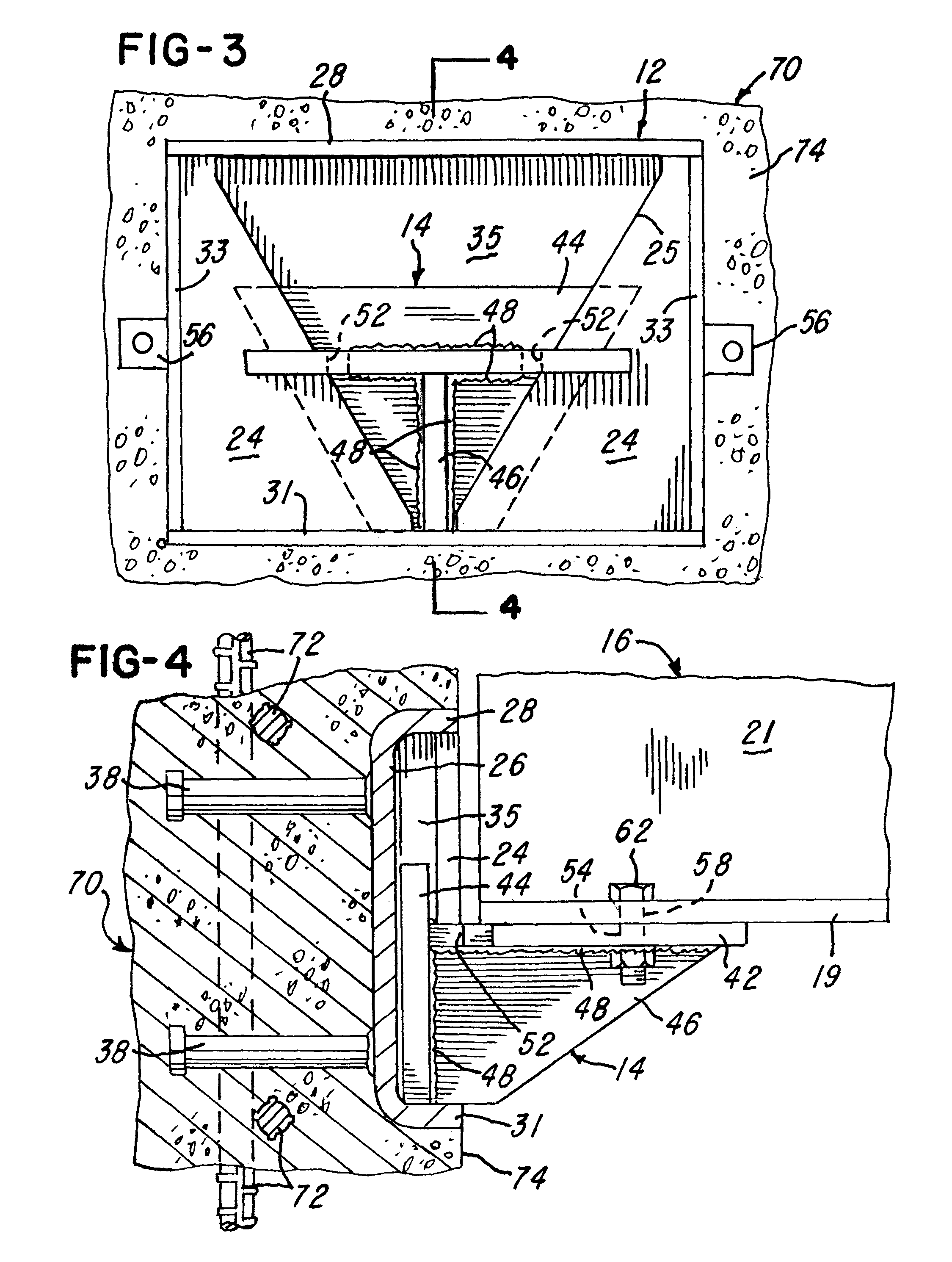

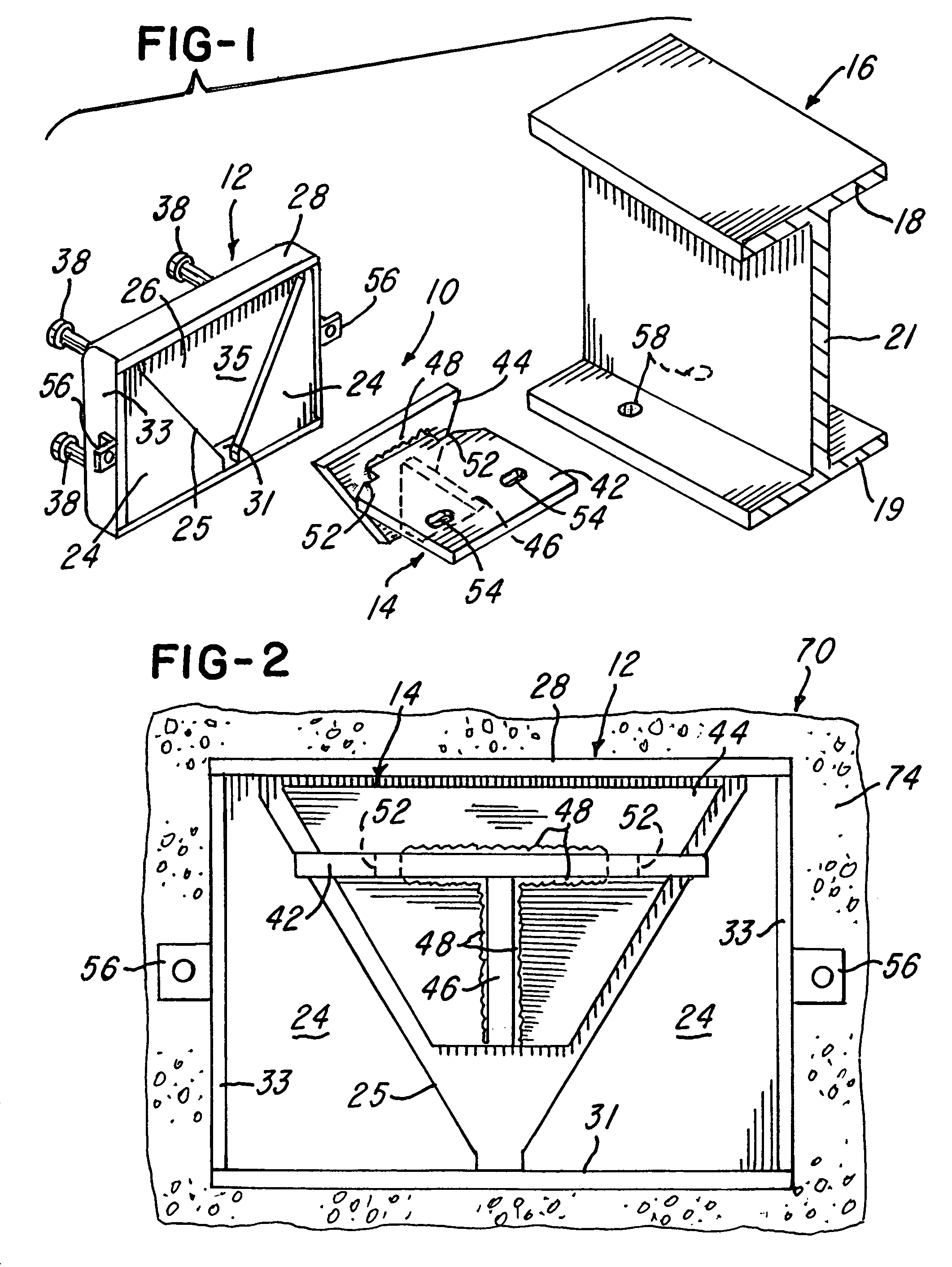

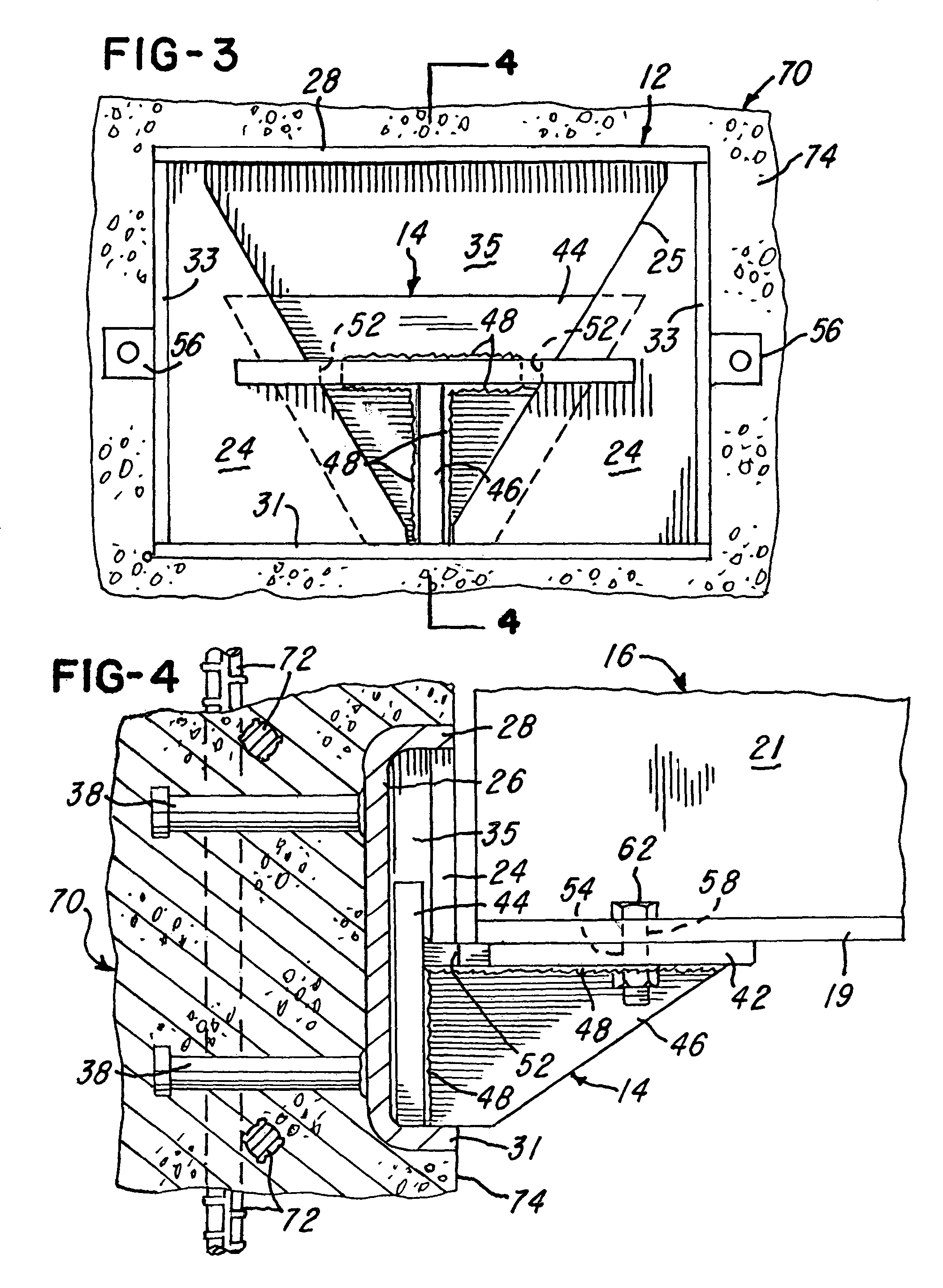

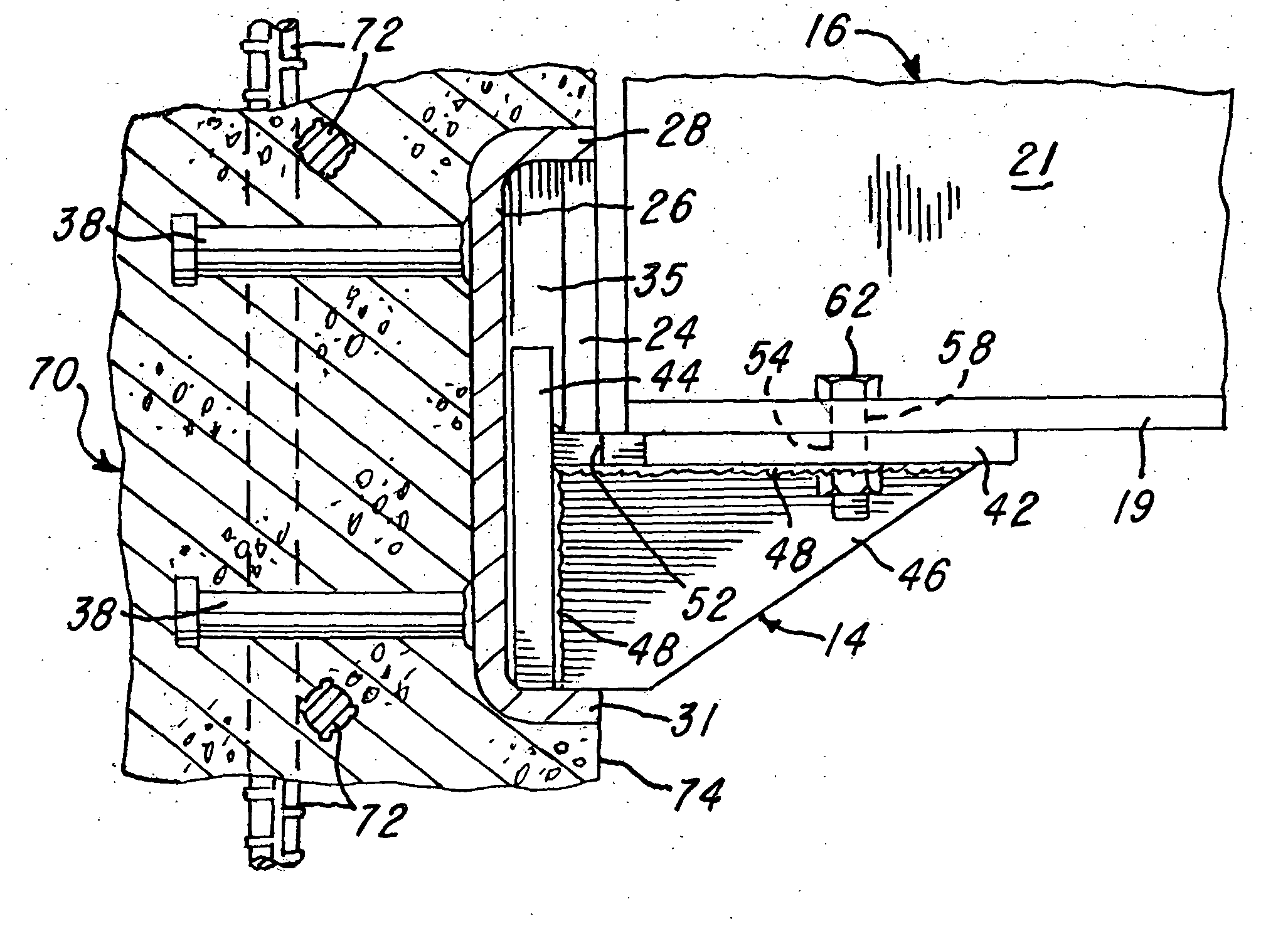

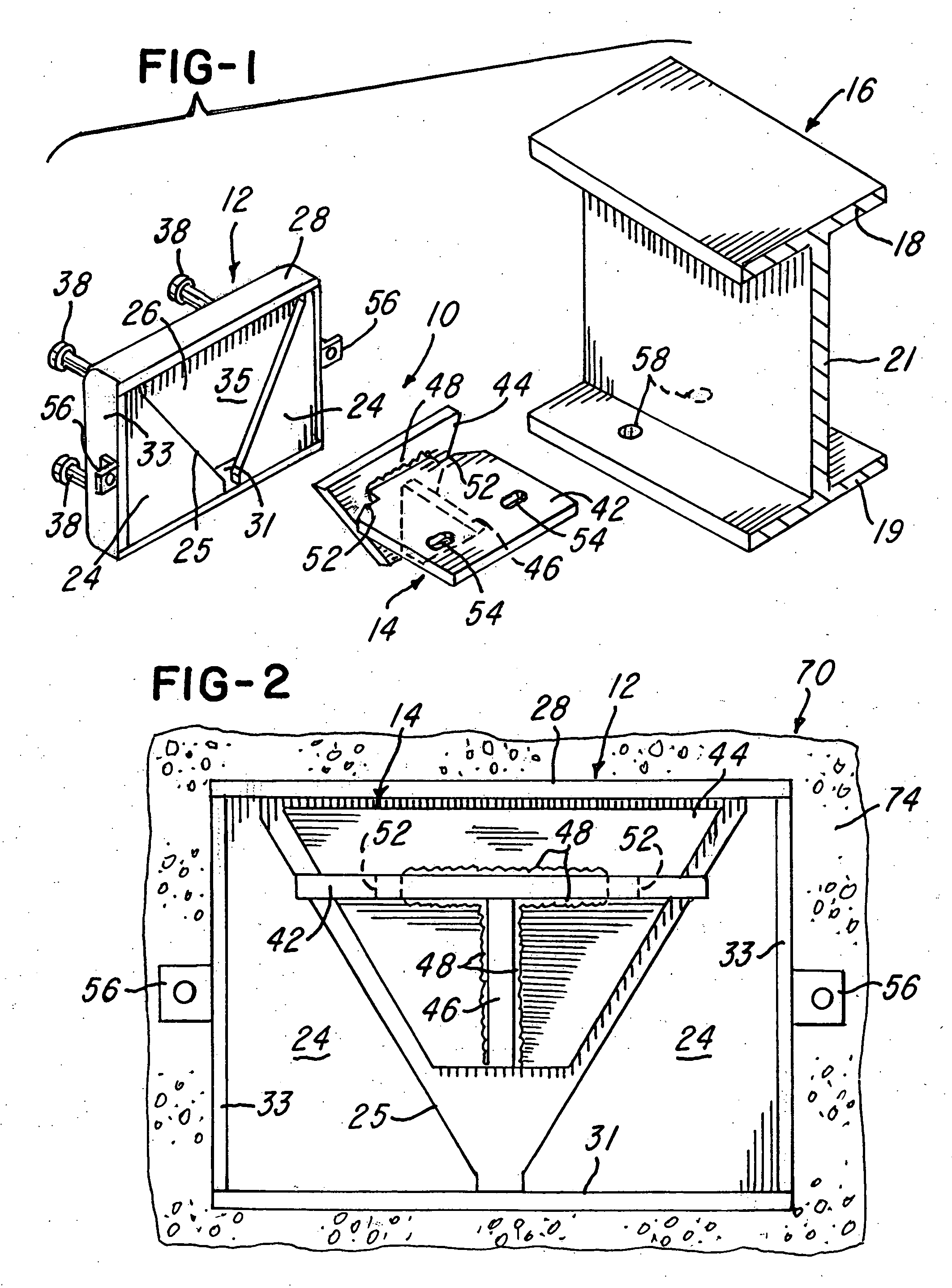

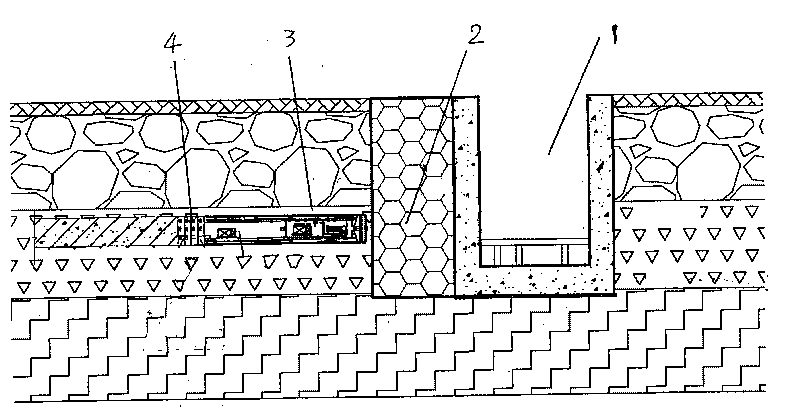

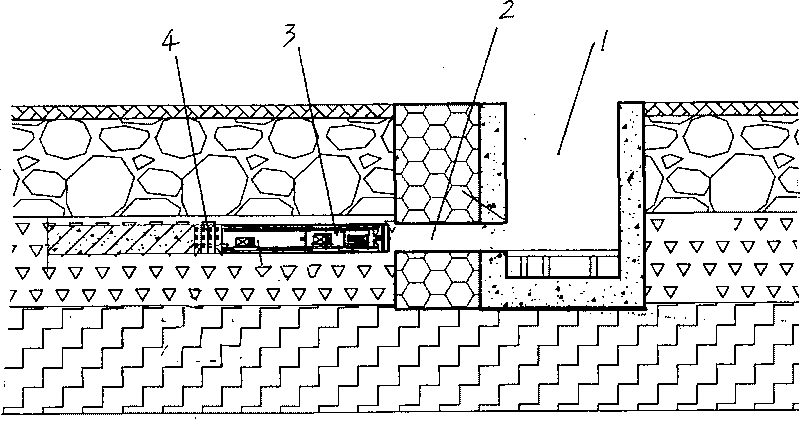

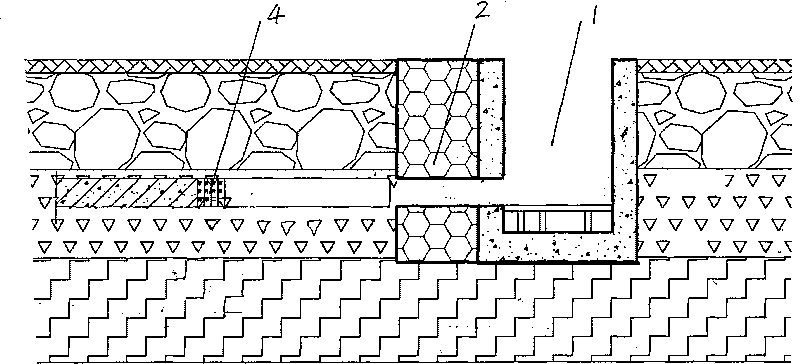

Connector system for securing an end portion of a steel structural member to a vertical cast concrete member

ActiveUS8365484B2Eliminating field weldingLow costBuilding roofsScaffold connectionsSteel structuresEngineering

A steel structural member is secured to a vertical cast concrete member or wall by a connector system including a fabricated steel receiver embedded within the wall. Embedded anchors are attached to the receiver which has upper and lower front wall portions flush with the concrete wall and define a front opening. A support bracket has a horizontal plate attached to the beam and a vertical plate which fits through the front opening within the receiver. The bracket is attached to the beam which is then elevated, and the vertical plate is inserted through the opening into the receiver. The beam and vertical plate are then shifted downwardly until opposite upper and lower edge portions of the vertical plate are blocked by the front wall portions of the receiver. In the illustrated embodiment, the front opening and vertical plate are generally rectangular with the opening wider than the plate.

Owner:CONNECT EZ

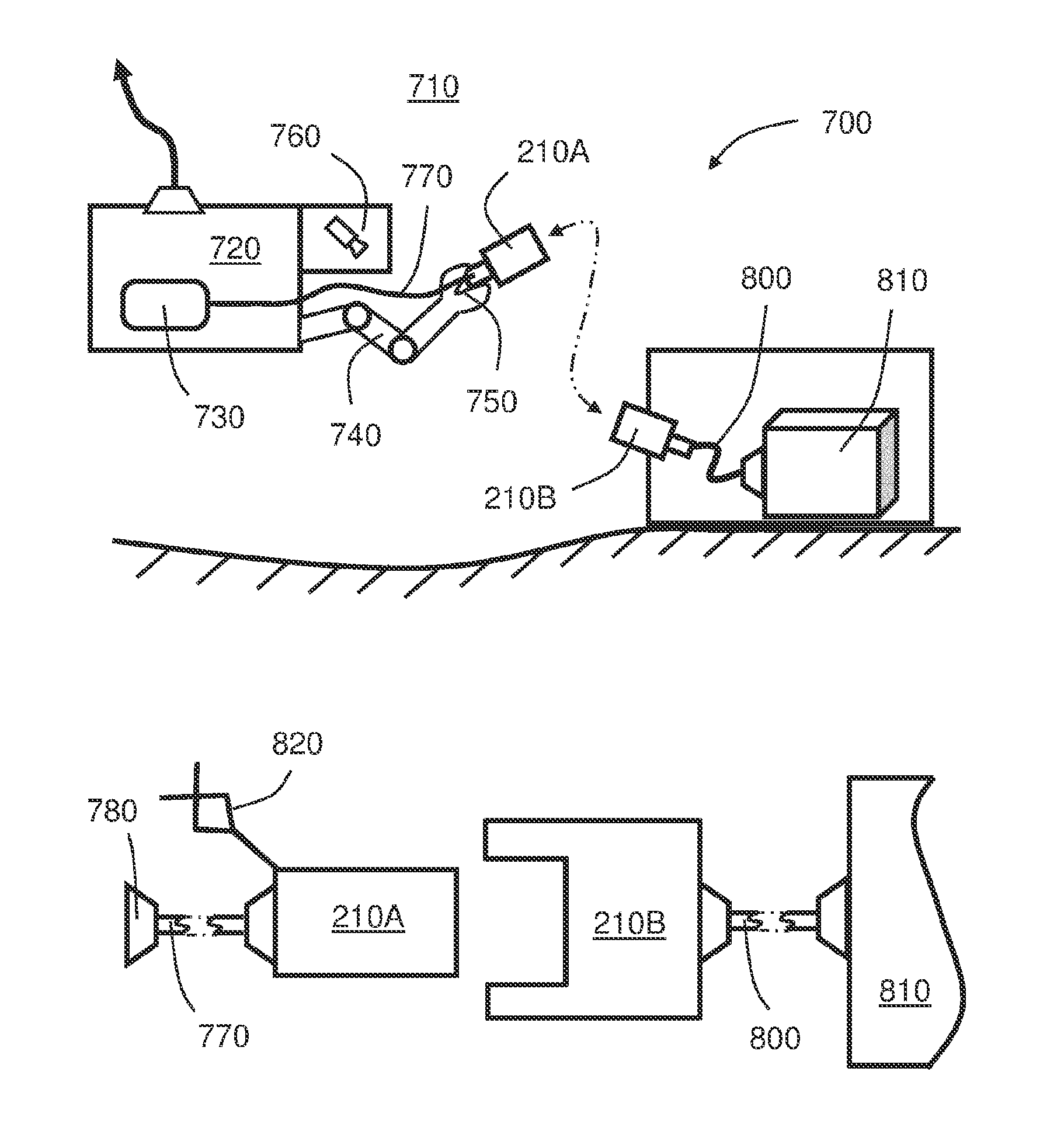

Underwater Connector Arrangement

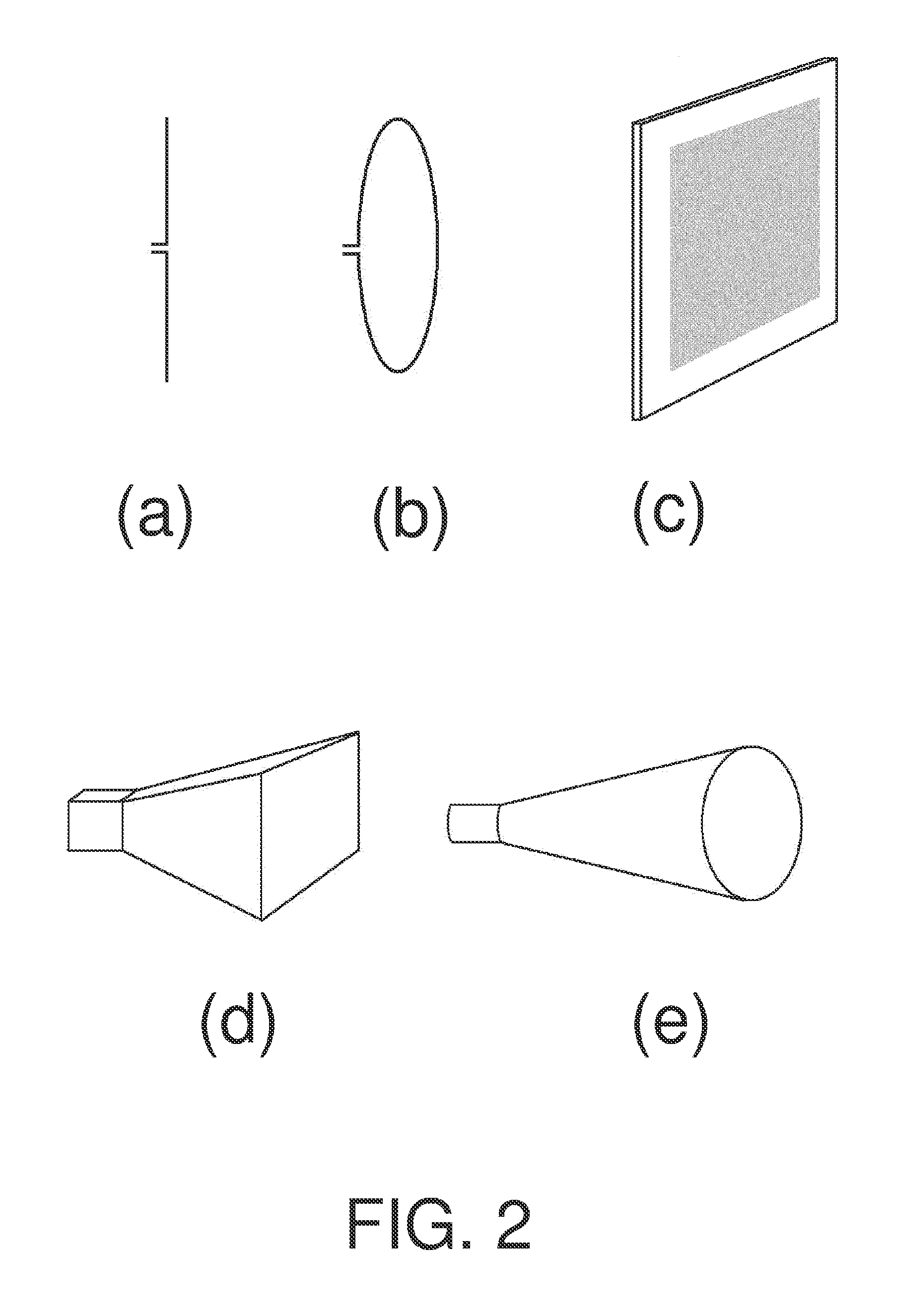

ActiveUS20130321223A1Avoid interferenceReduce and avoid such interferenceSubaqueous/subterranean adaptionNear-field systems with capacitive couplingElectric power transmissionCapacitance

An underwater connector includes a first component and a second component, wherein the components are operable to be coupled together in operation in a first coupled state, and operable to be mutually spatially separated in a second uncoupled state. The first and second components each include communication arrangements which are operable to provide wireless communication between the first and second components when in their first coupled state. The first and second components include a power transfer arrangement for transmitting power between the first and second components. The power transfer arrangement includes inductive coupling devices and / or capacitive coupling devices, wherein the power transfer arrangement is implemented substantially as an annulus, for example circular, elliptical, or polygonal, on the first and second components together with the communication arrangements being disposed within the annulus and / or around a periphery of the annulus. The wireless communication is operable to occur using a wireless signal whose carrier frequency is within a frequency range of 300 MHz to 300 GHz, wherein the wireless communication is implemented using microwave and millimeter wave technologies.

Owner:WISUB

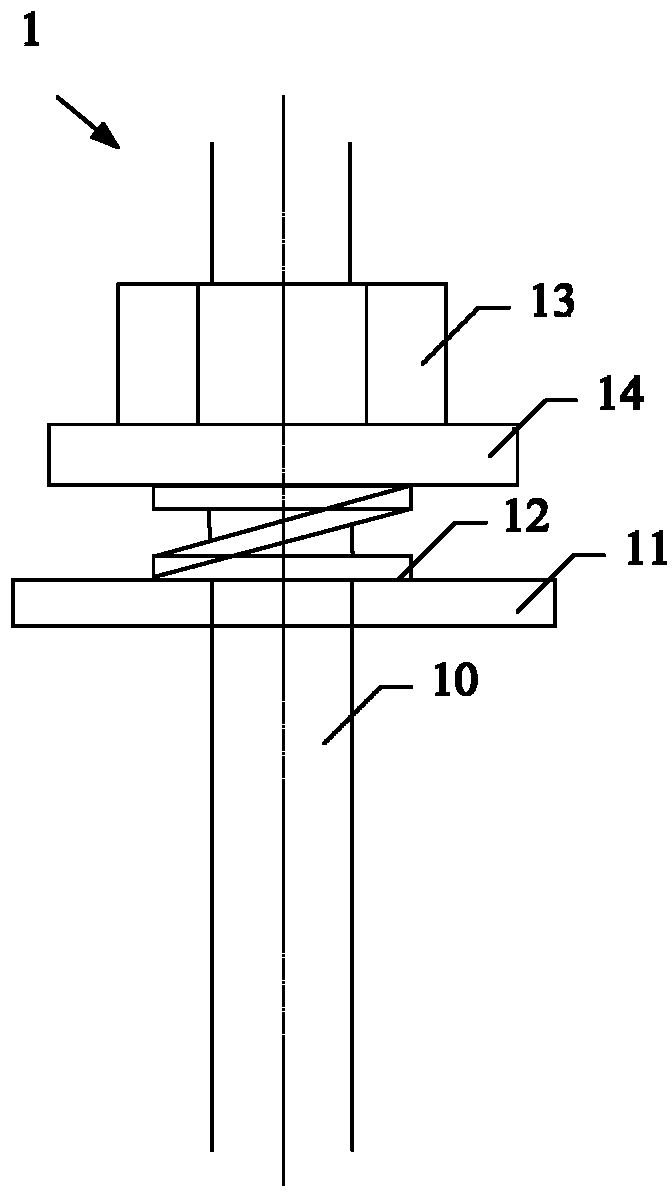

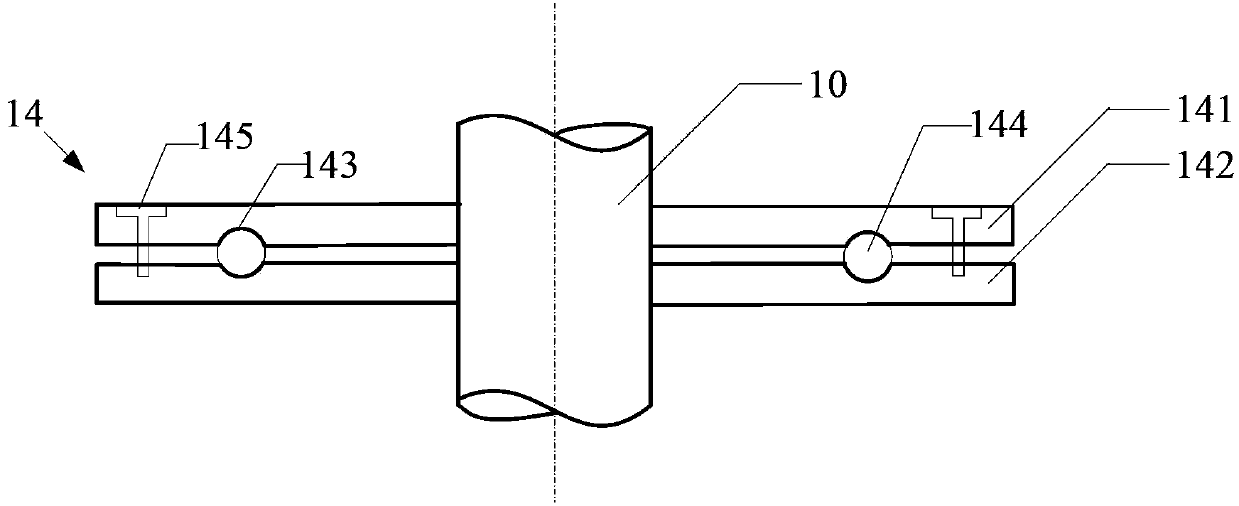

Testing tool system and testing method for LNG ship liquid cargo compartment three-dimensional board CM nodes

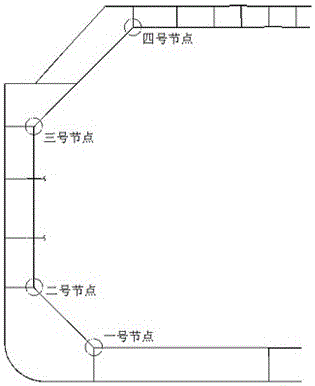

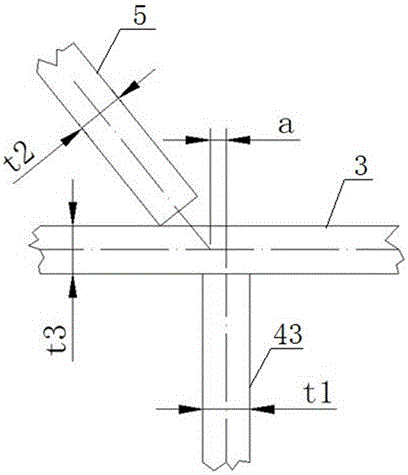

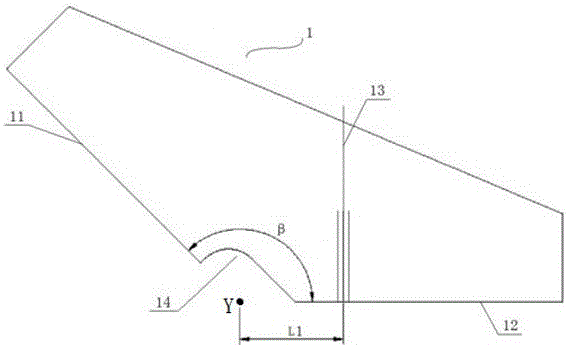

ActiveCN106679533AQuick assembly and loadingImprove build accuracyMechanical measuring arrangementsGreek letter alphaElectrical and Electronics engineering

The invention discloses a testing tool system for LNG ship liquid cargo compartment three-dimensional board CM nodes. The testing tool system comprises an inner clamping template and an outer clamping template. The inner clamping template is used for aligning the LNG ship liquid cargo compartment three-dimensional board CM node. The outer clamping template is used for verifying in a CM node verification stage after welding of the LNG ship liquid cargo compartment three-dimensional board CM node. The three-dimensional board comprises a transverse board, a vertical board and an oblique board. An included angle between the transverse board and the oblique board is alpha. A first reference line which is perpendicular with the transverse board is engraved on the transverse board. A second reference line which is perpendicular with the vertical board is engraved on the vertical board. According to the testing tool system, testing templates which matches the three-dimensional board are utilized. The testing templates comprise the inner clamping template for quick assembling and loading, thereby ensuring high precision and high stability in assembly. The testing templates further comprise the outer clamping template for after-welding verification. For ensuring high accuracy in final state measurement, the specialized outer clamping template is utilized, thereby truly testing the final deviation of each node.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

Connector system for securing an end portion of a steel structural member to a vertical cast concrete member

ActiveUS8209925B2Eliminating field weldingLow costBuilding roofsScaffold connectionsJoistSteel structures

A steel structural member such as a joist or beam is secured to a vertical cast concrete by a connector system including a fabricated steel receiver embedded within the wall. Embedded anchors are attached to the receiver which has front wall portions flush with the concrete wall and define a front opening. A support bracket has an attachment plate secured to the beam and a vertical plate which fits through the front opening within the receiver. The bracket is attached to the beam which is then elevated, and the vertical plate is inserted through the opening into the receiver. The beam and vertical plate are then shifted until opposite edge portions of the vertical plate are blocked by the front wall portions of the receiver. In the illustrated embodiments, the front opening and vertical plate are generally triangular, and the support bracket has a vertical or horizontal attachment plate.

Owner:CONNECT EZ

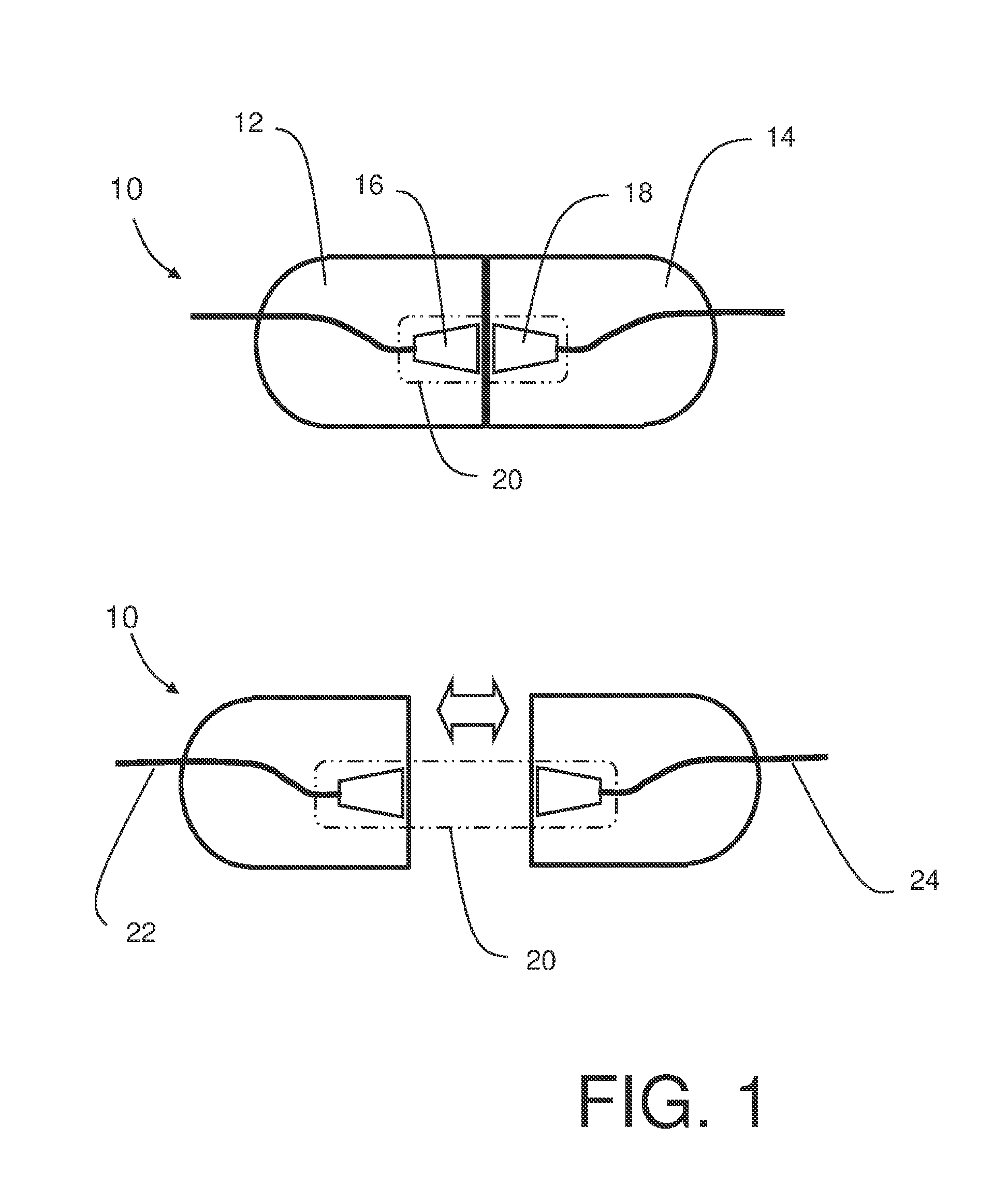

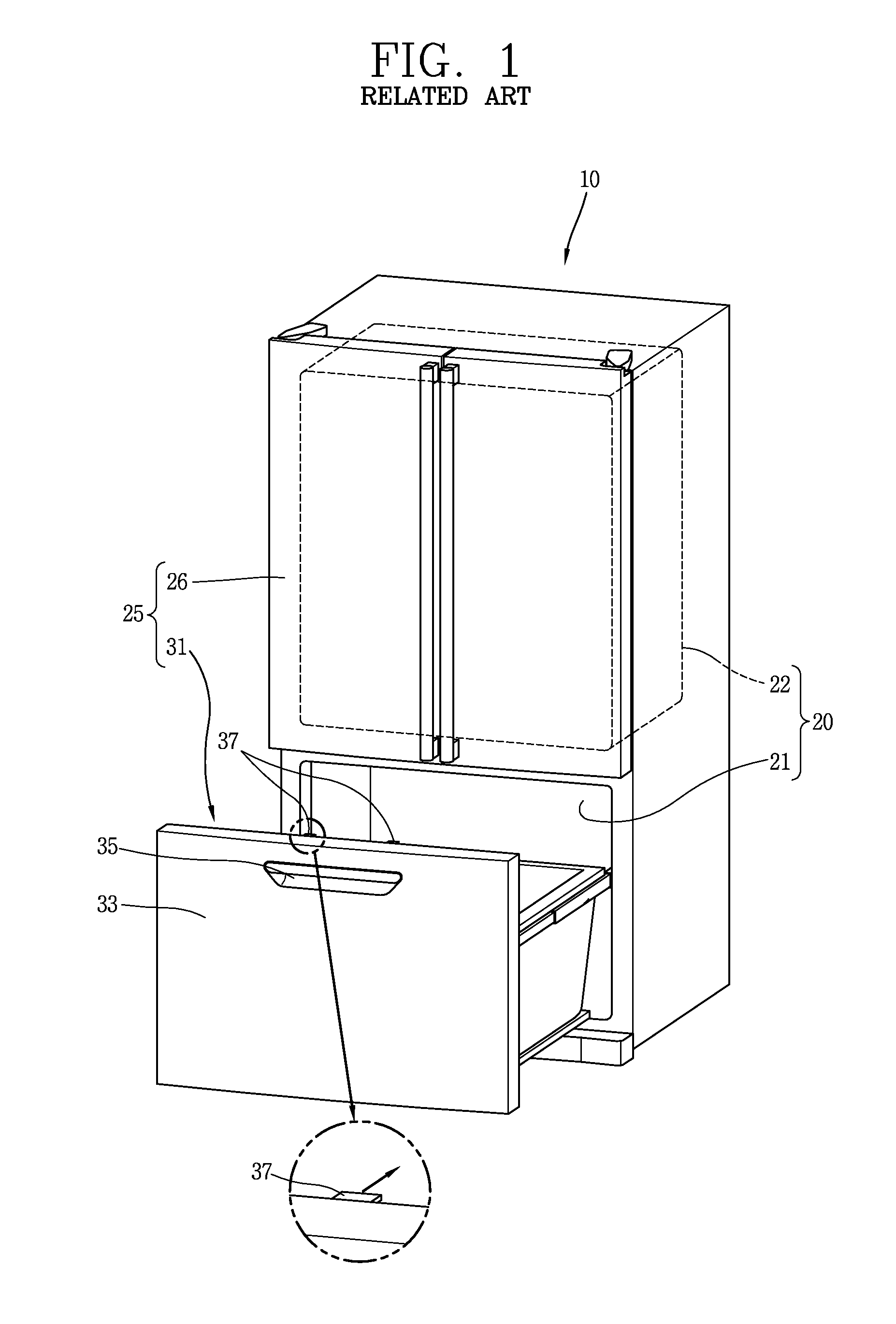

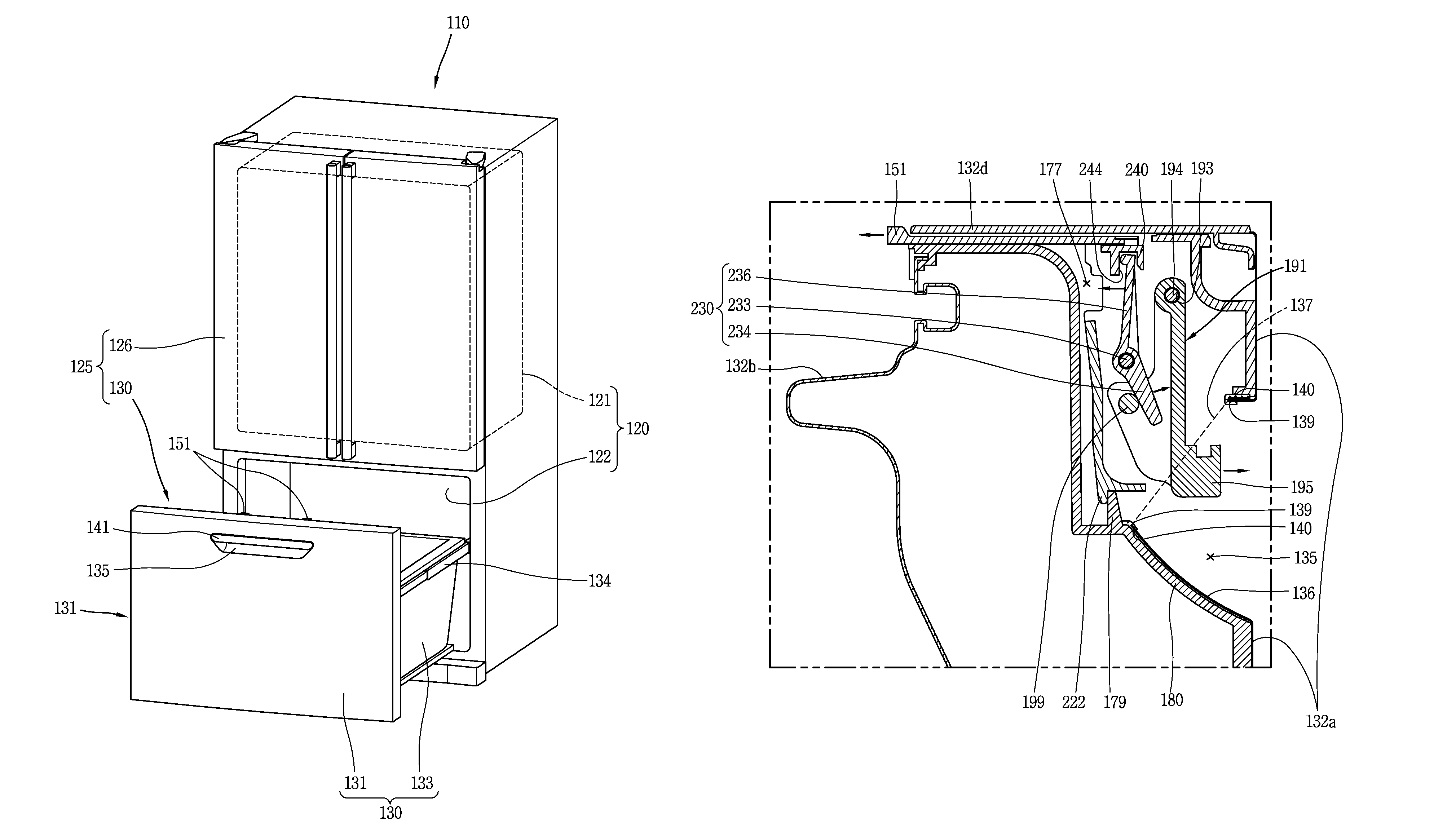

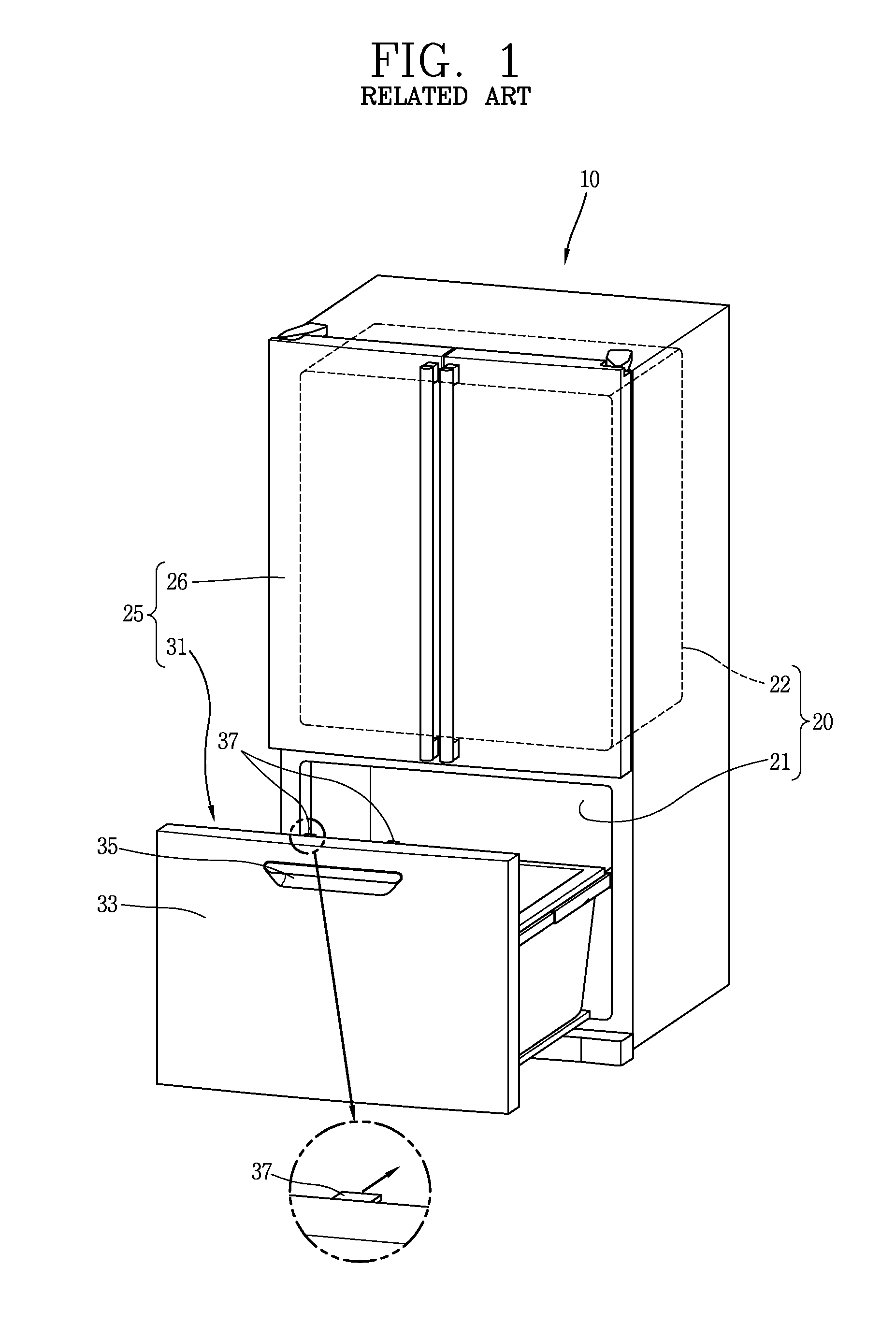

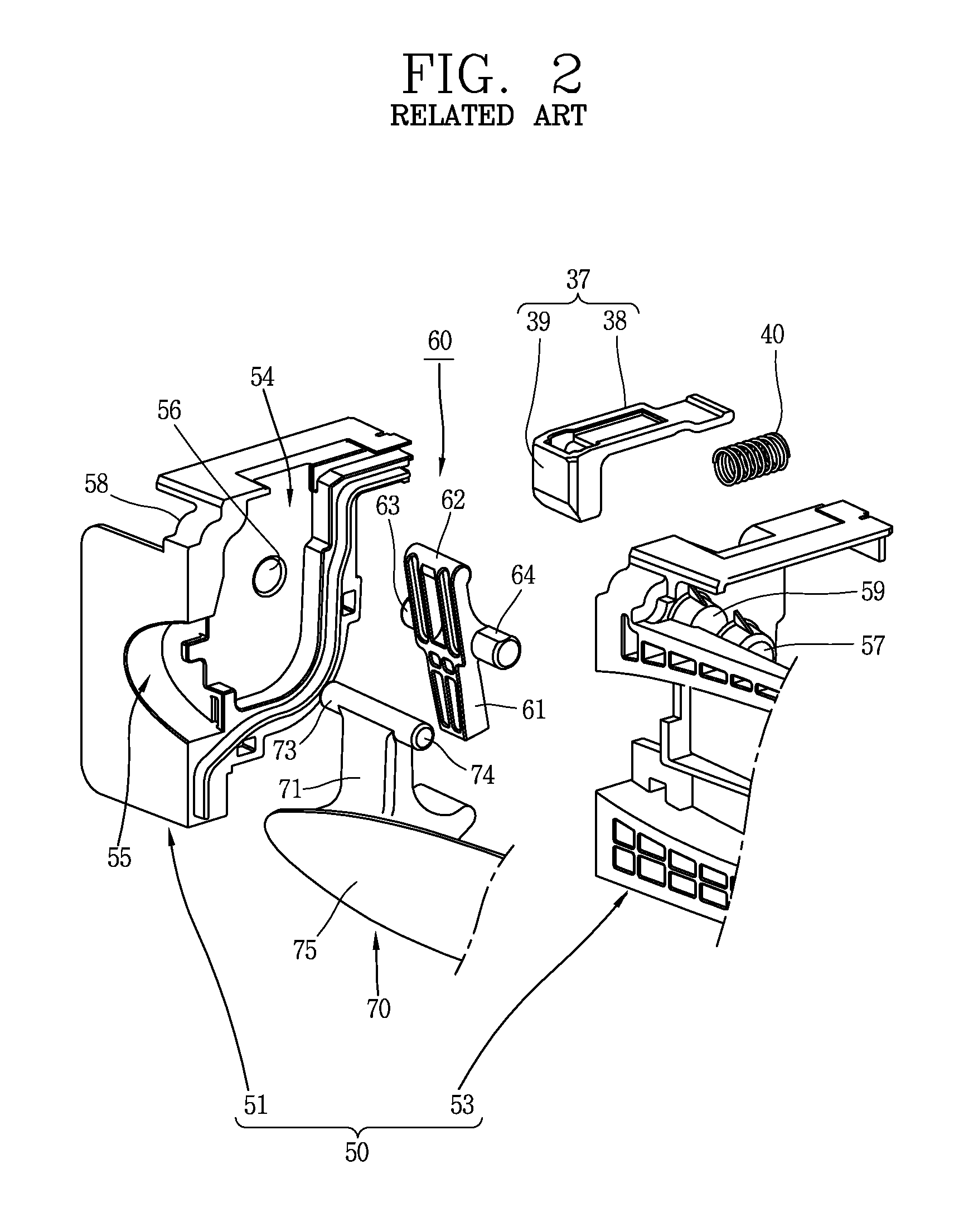

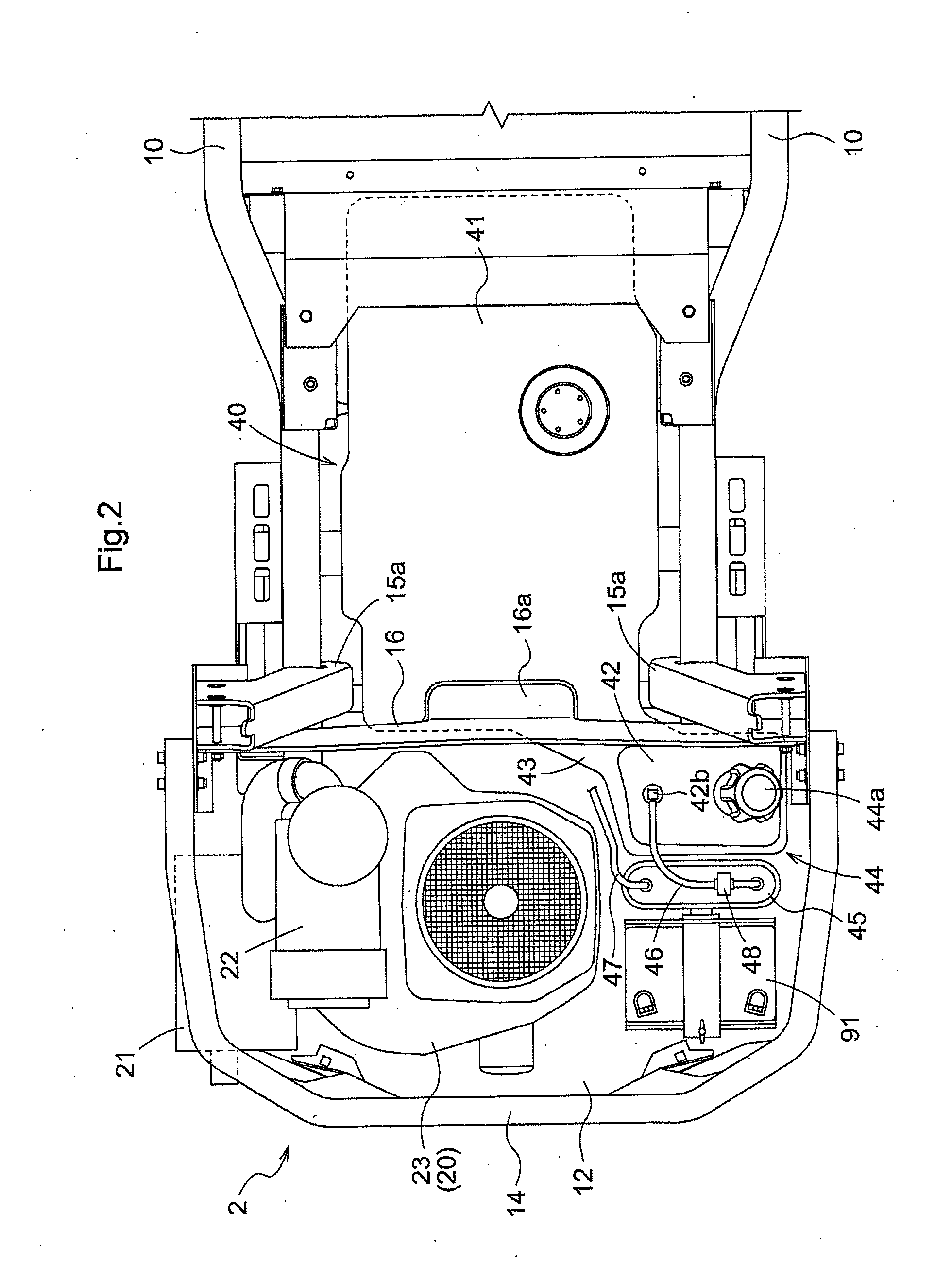

Refrigerator

ActiveUS20130270990A1Simple componentsIntuitive inspectionDomestic cooling apparatusLighting and heating apparatusEngineeringStore food

A refrigerator that includes a compartment to store foods, and a door to open and close the compartment. The door has a door main body, a door handle movably disposed on the door main body to actuate the door main body to be easily opened, a slider protruding toward the refrigerator main body in response to movement of the door handle, and a driving force transfer unit. The driving force transfer unit may be located between the door handle and slider to transfer a driving force, generated upon pulling the door handle, to the slider. The door further includes a pocket housing partially buried into the door main body and receiving therein the door handle. The slider and the driving force transfer unit may be individually detachable. This configuration facilitates opening of the refrigerator and inspection and replacement of components of the driving force transfer unit.

Owner:LG ELECTRONICS INC

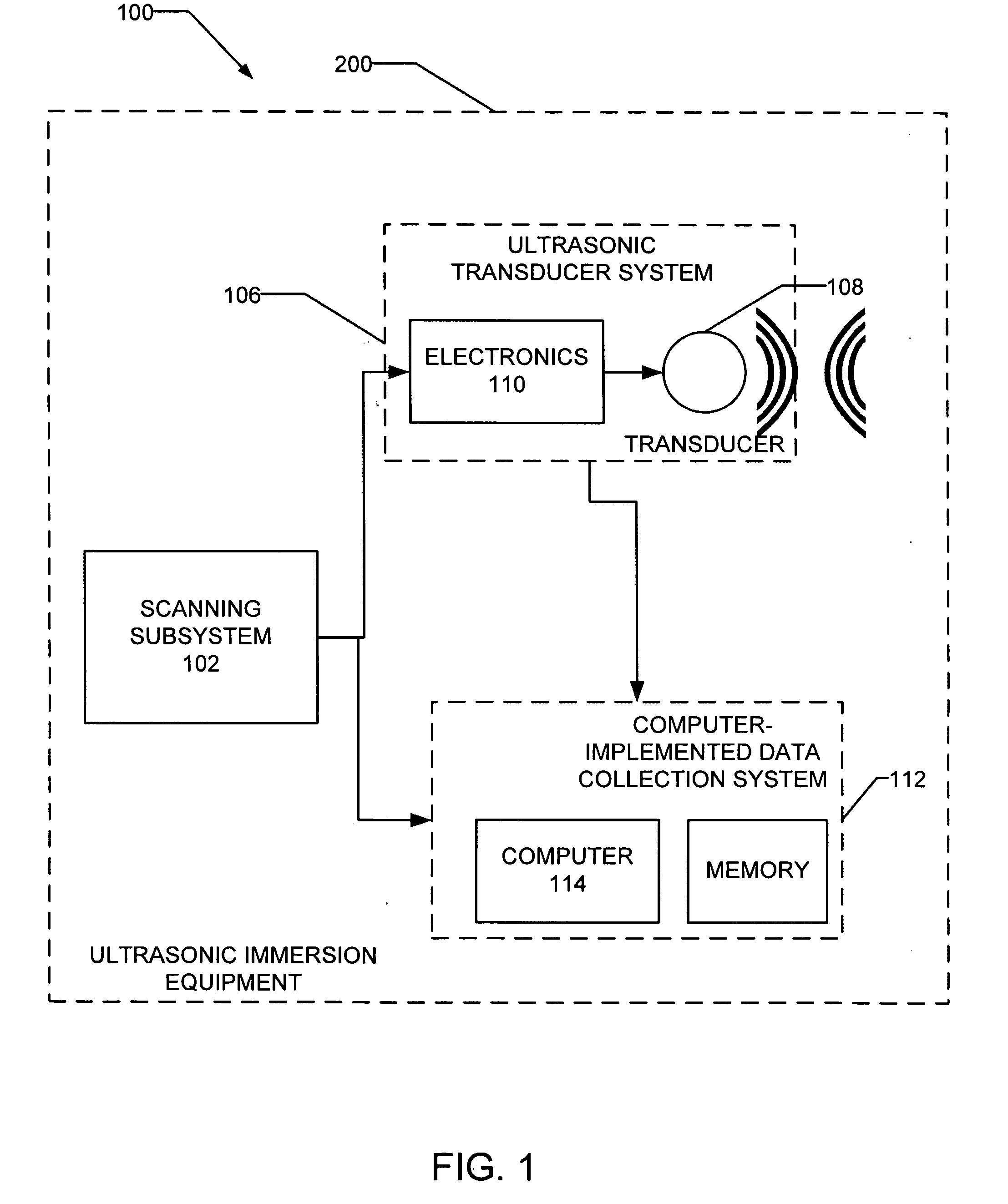

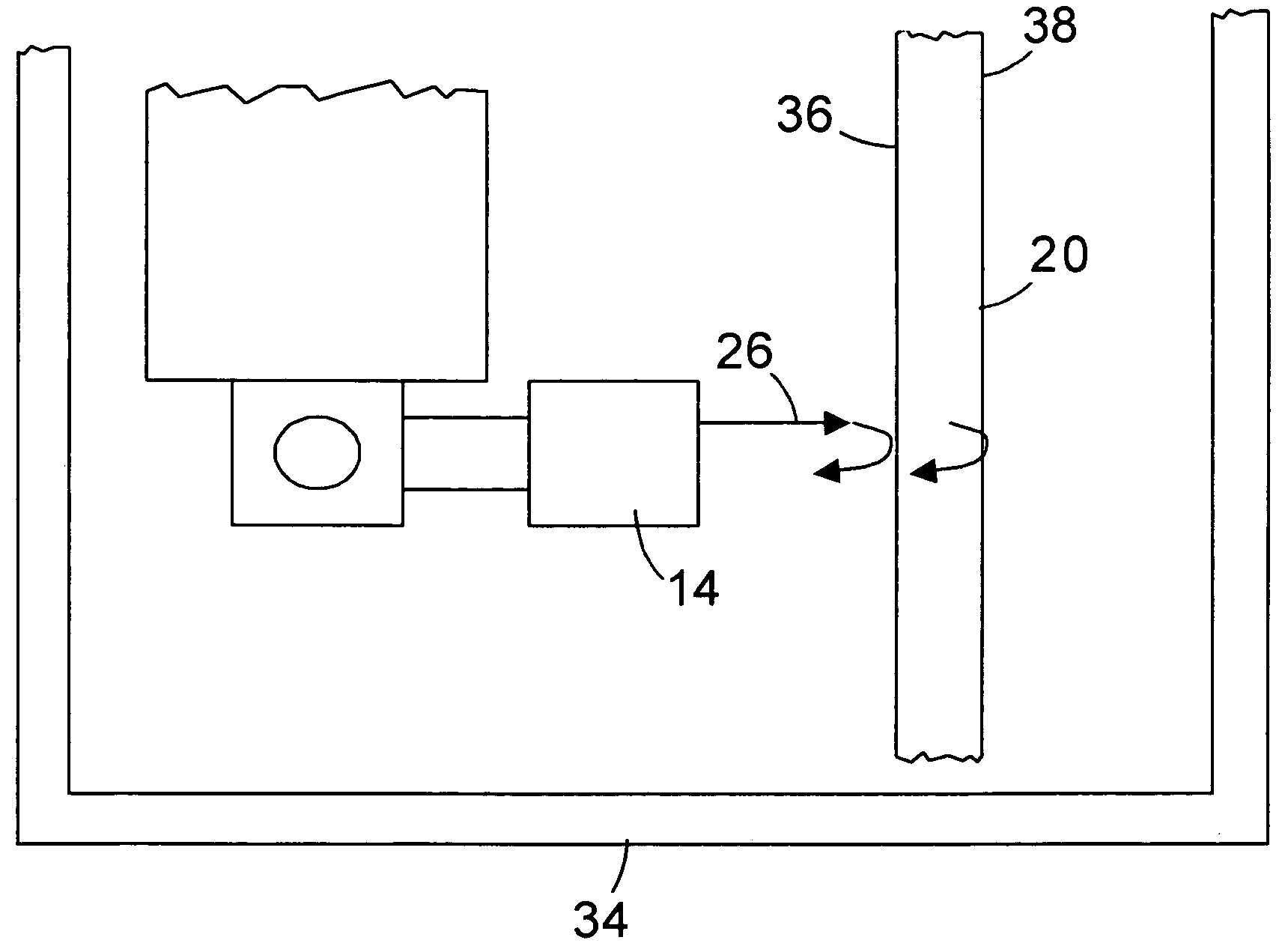

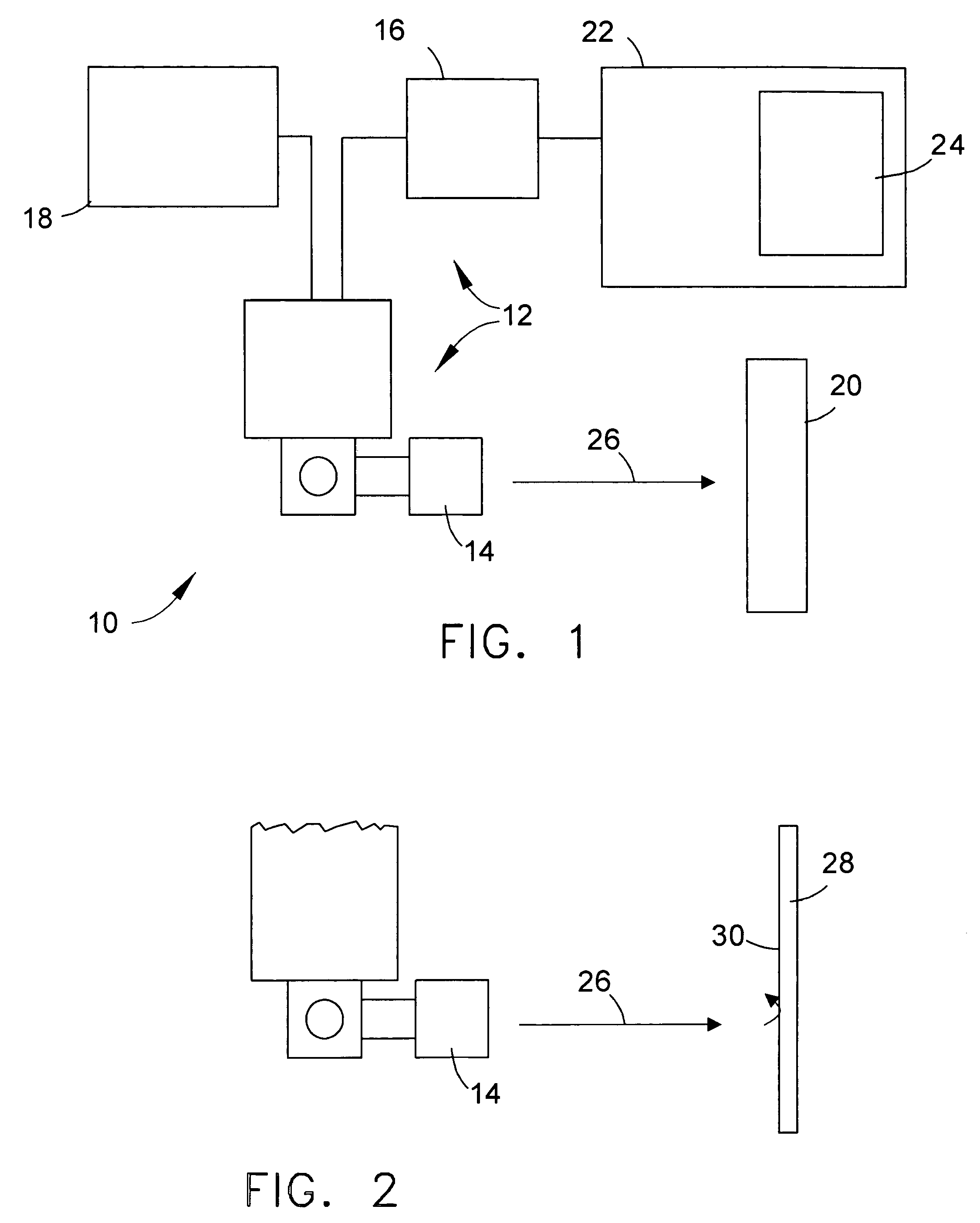

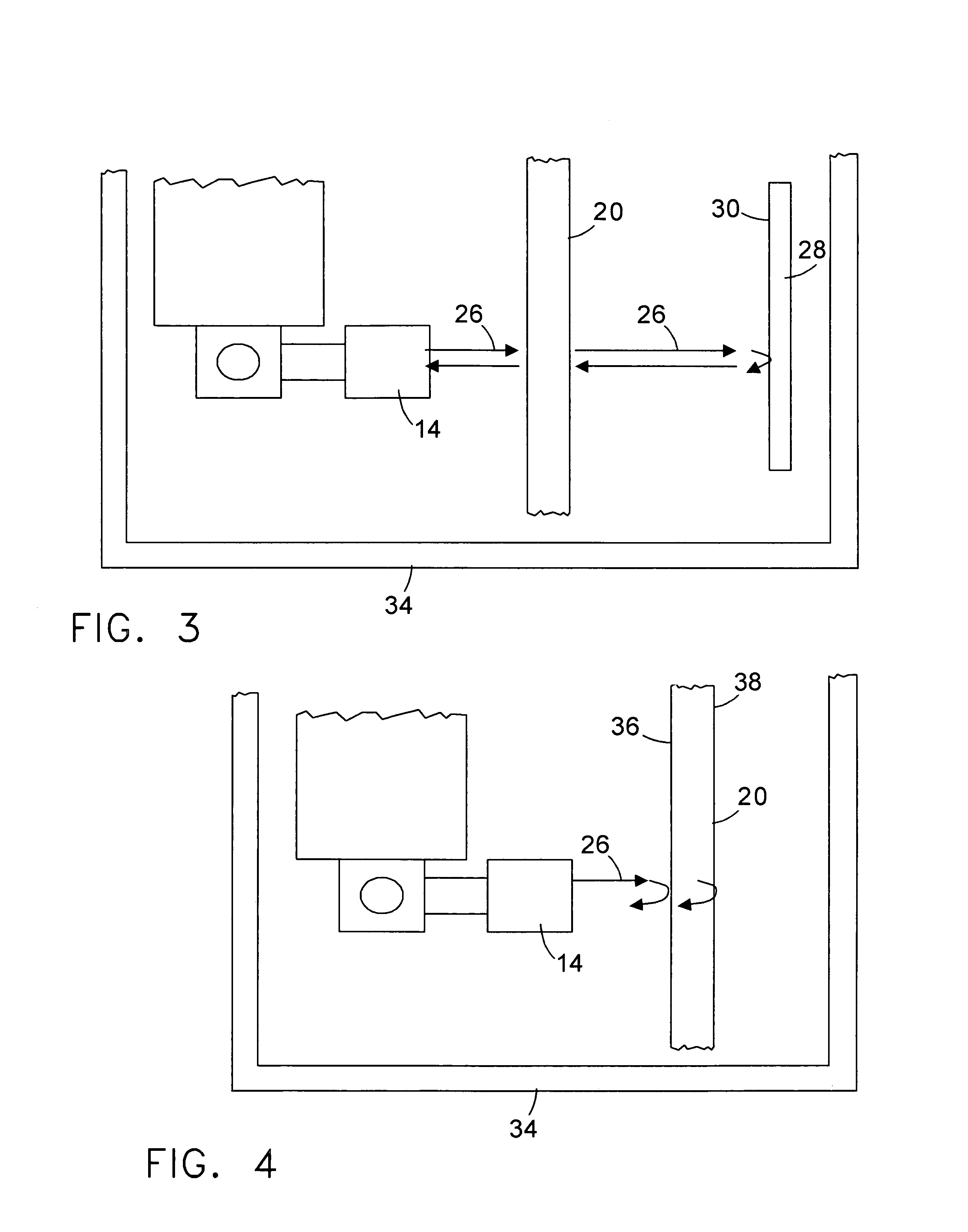

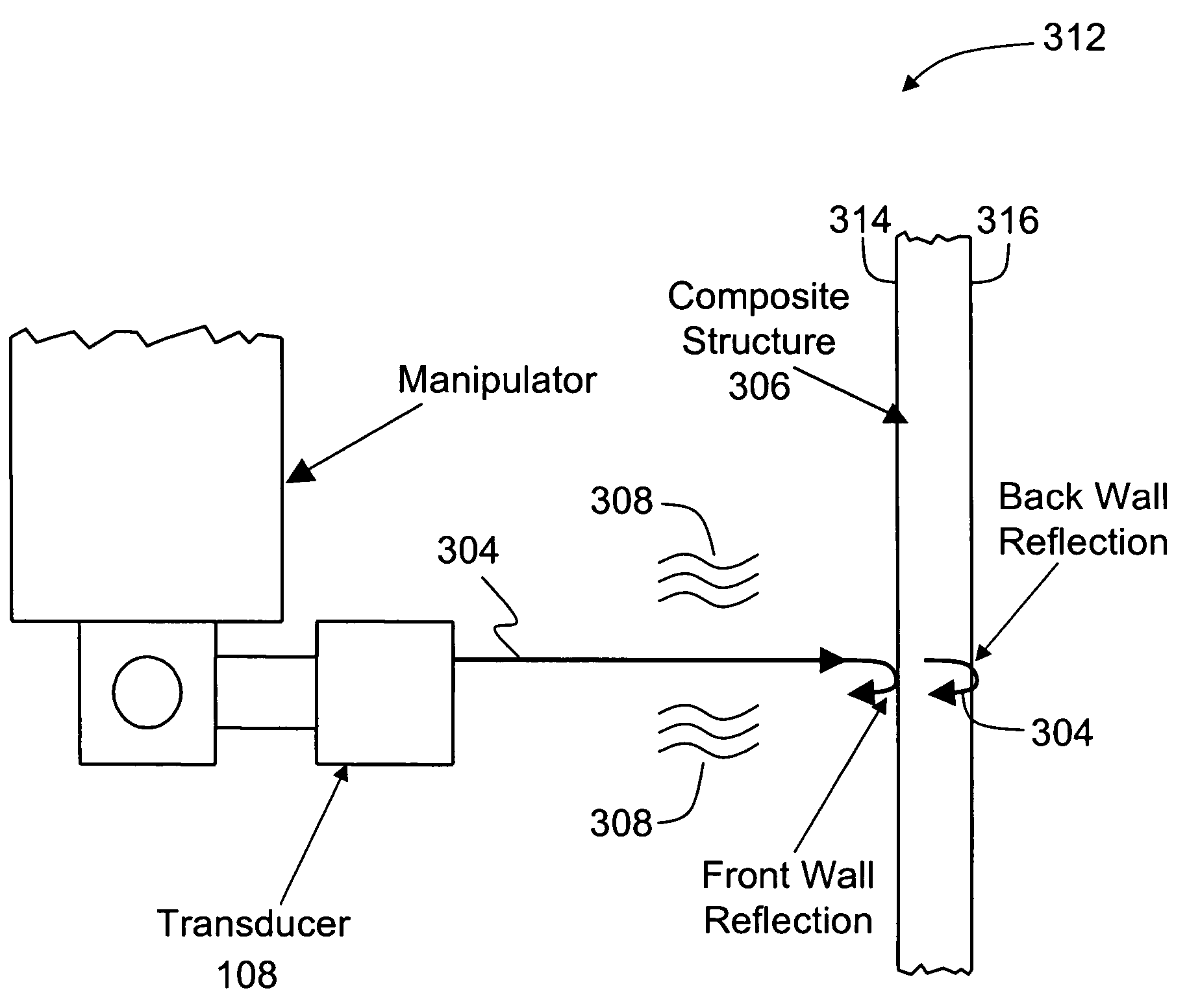

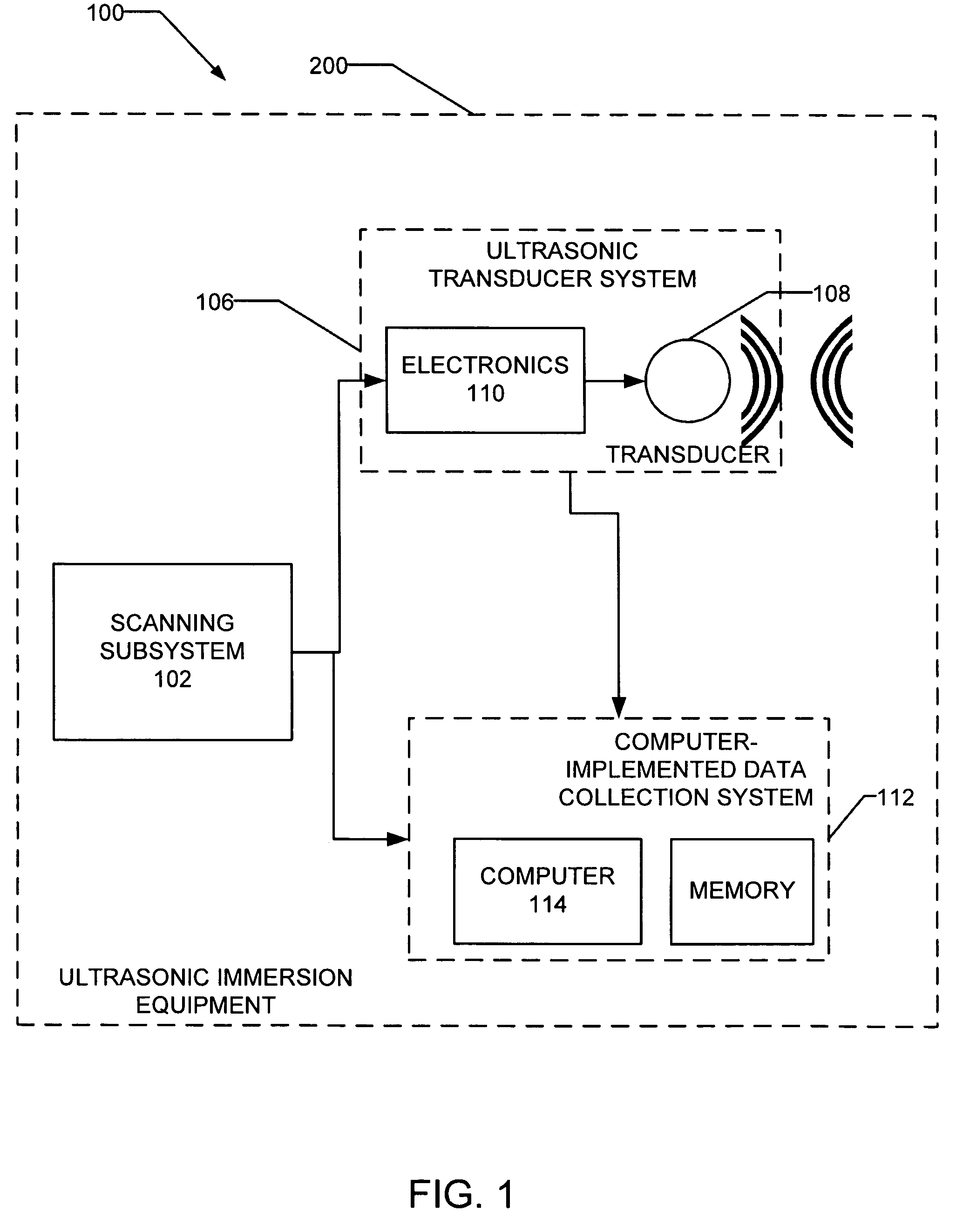

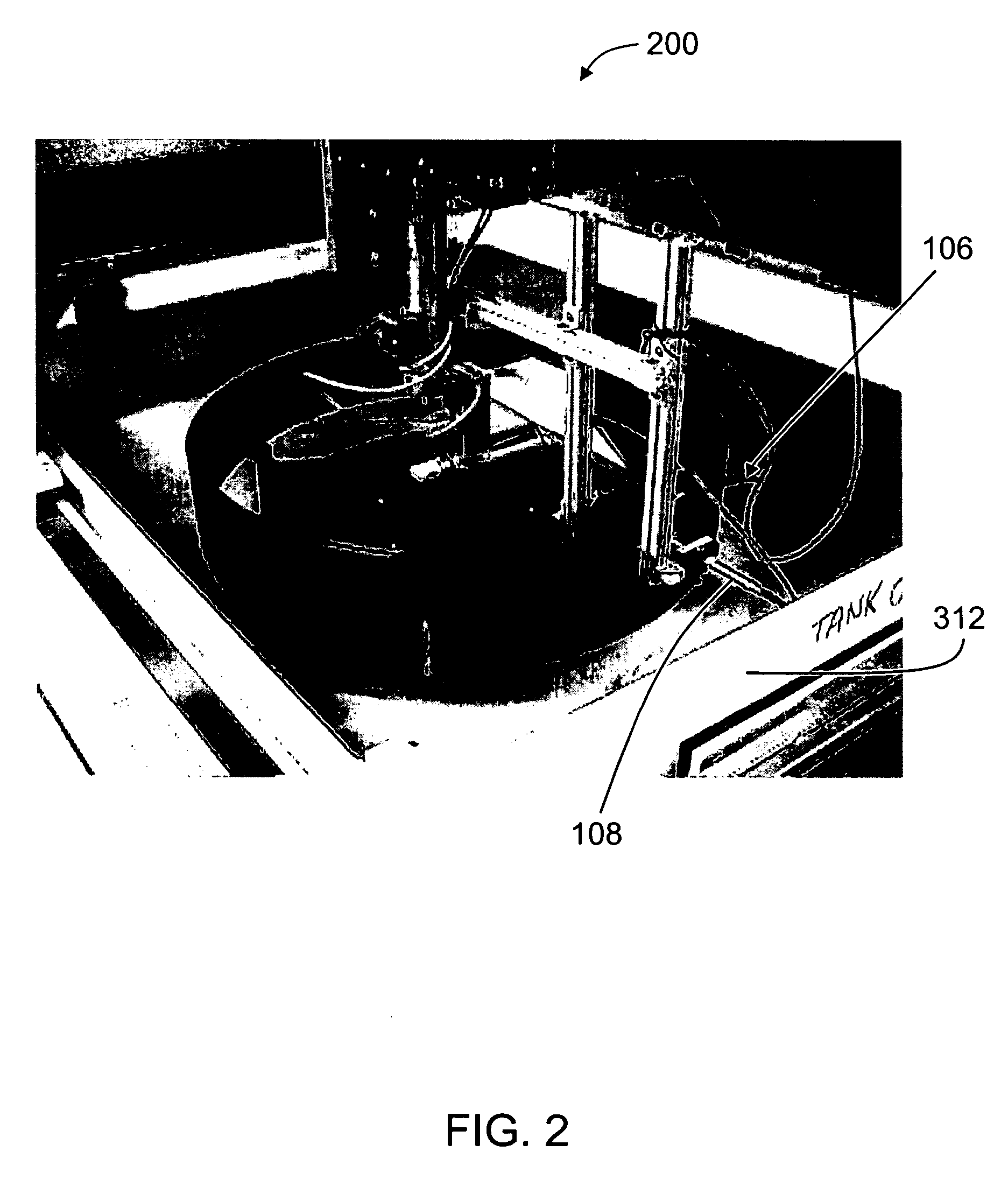

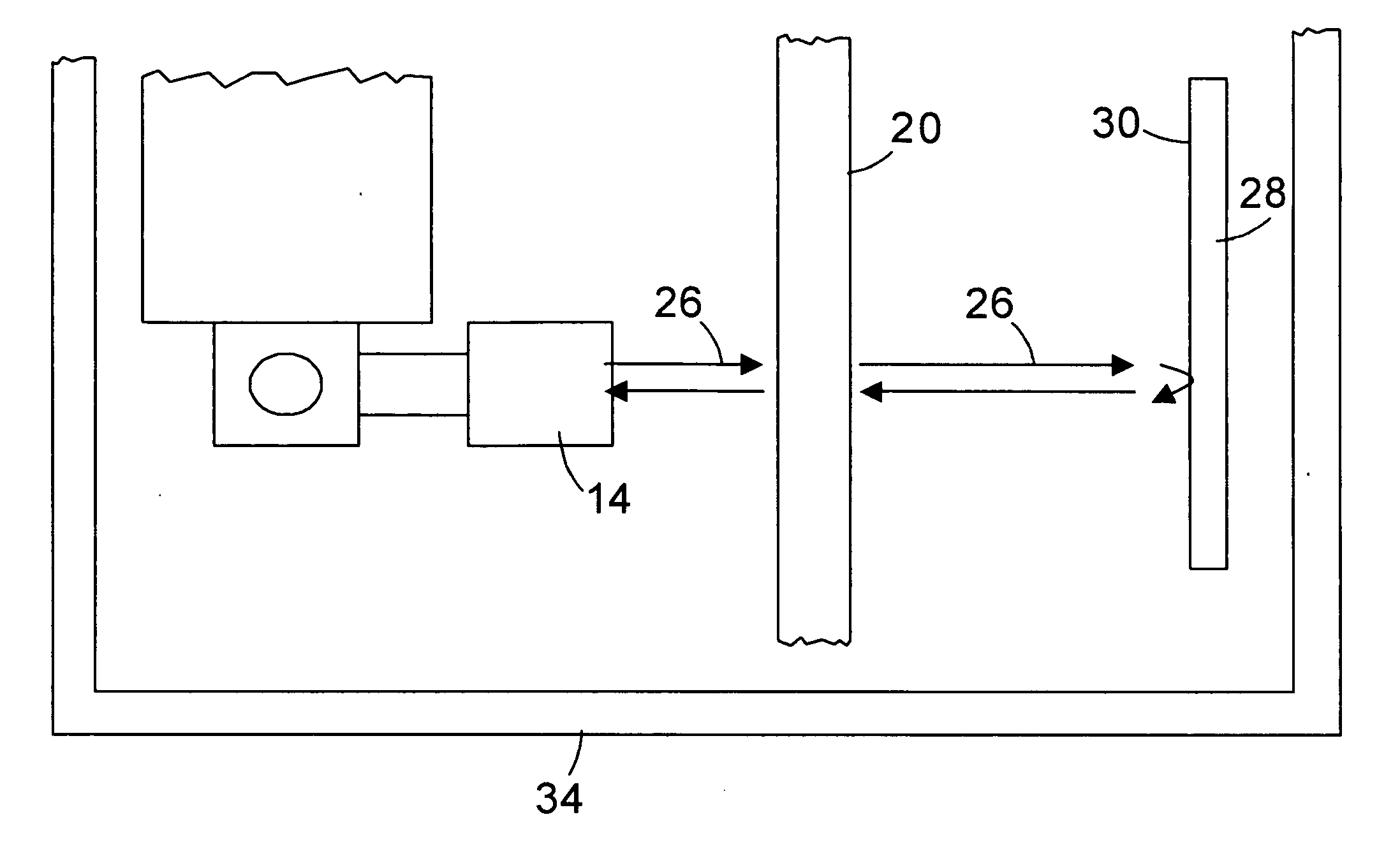

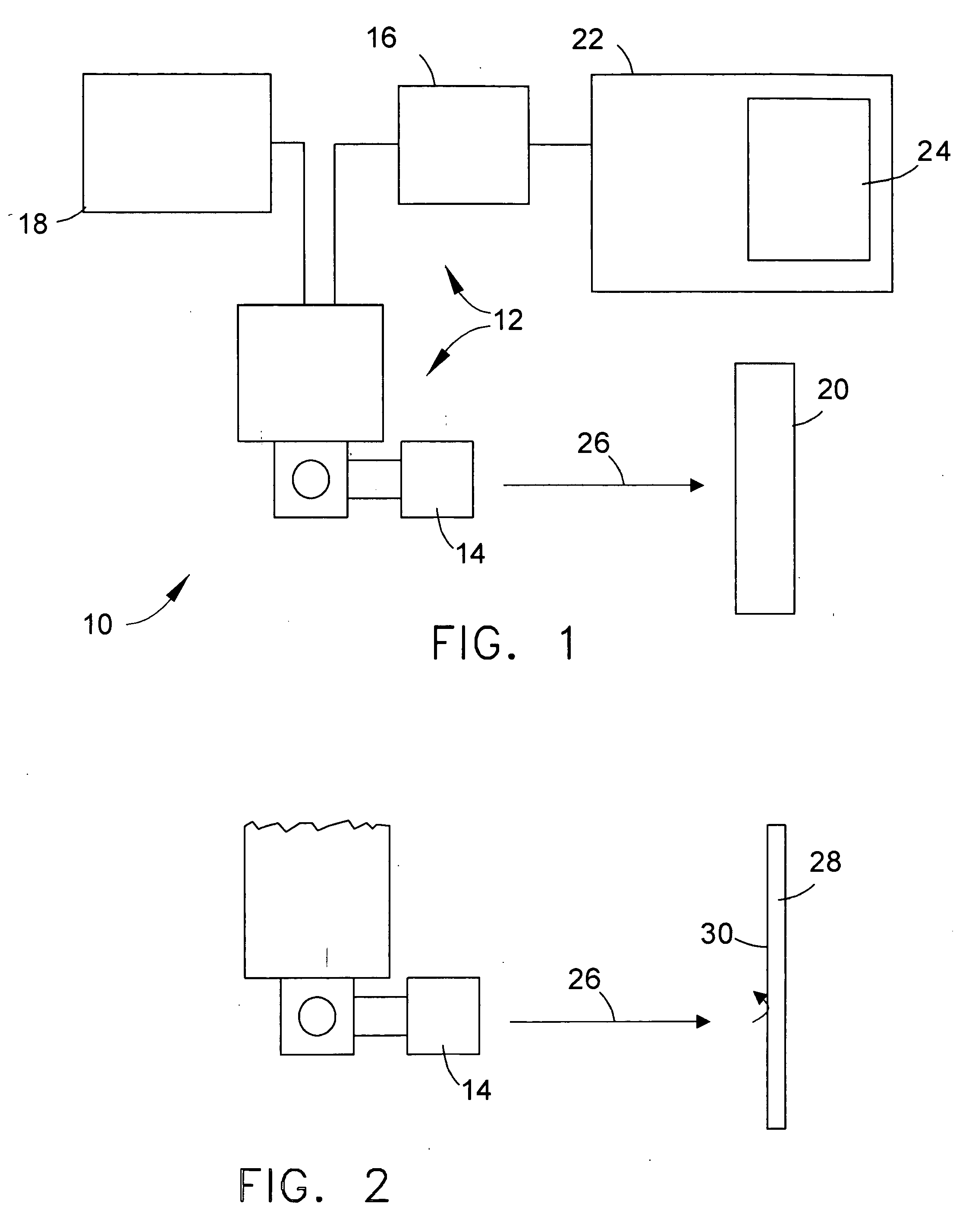

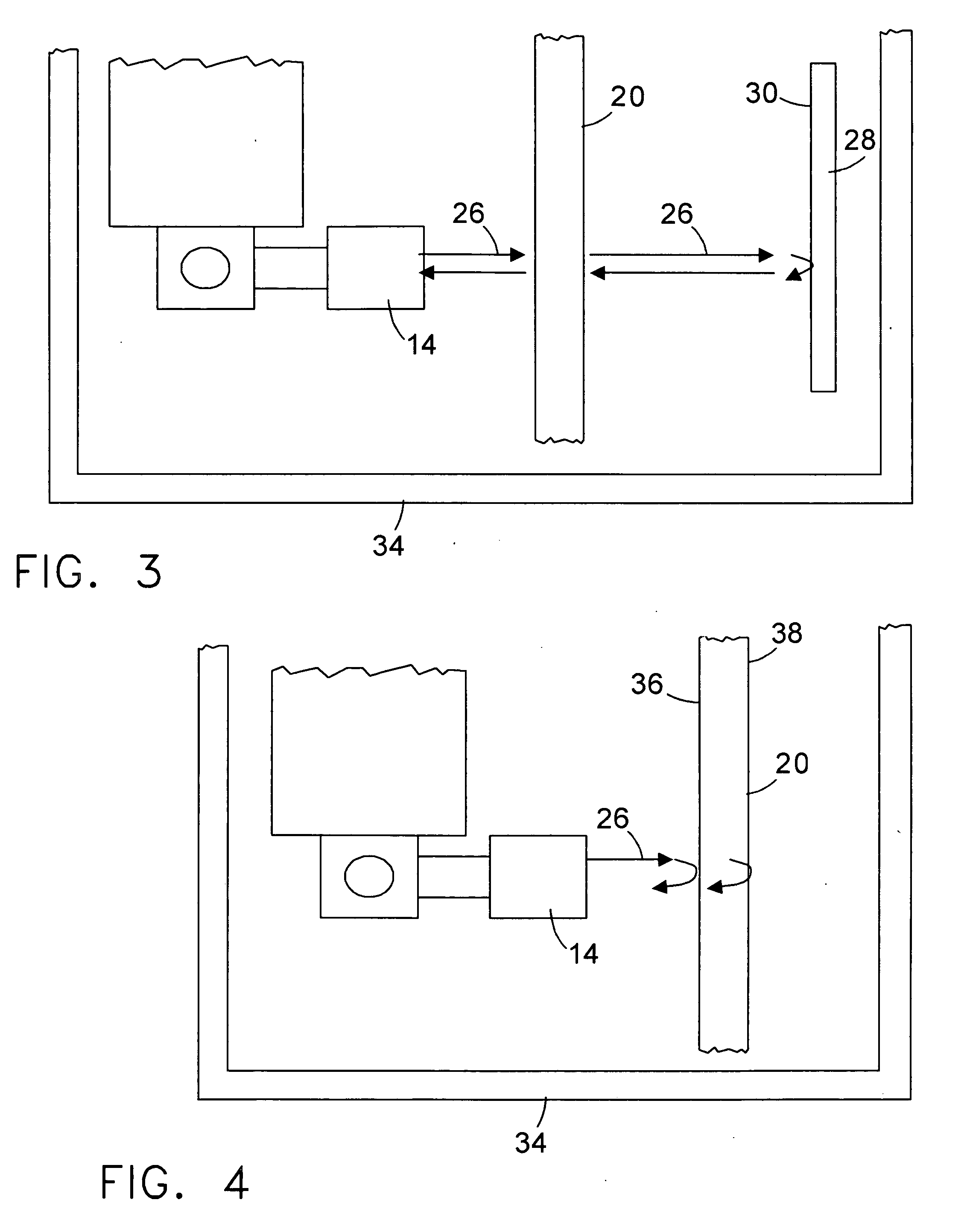

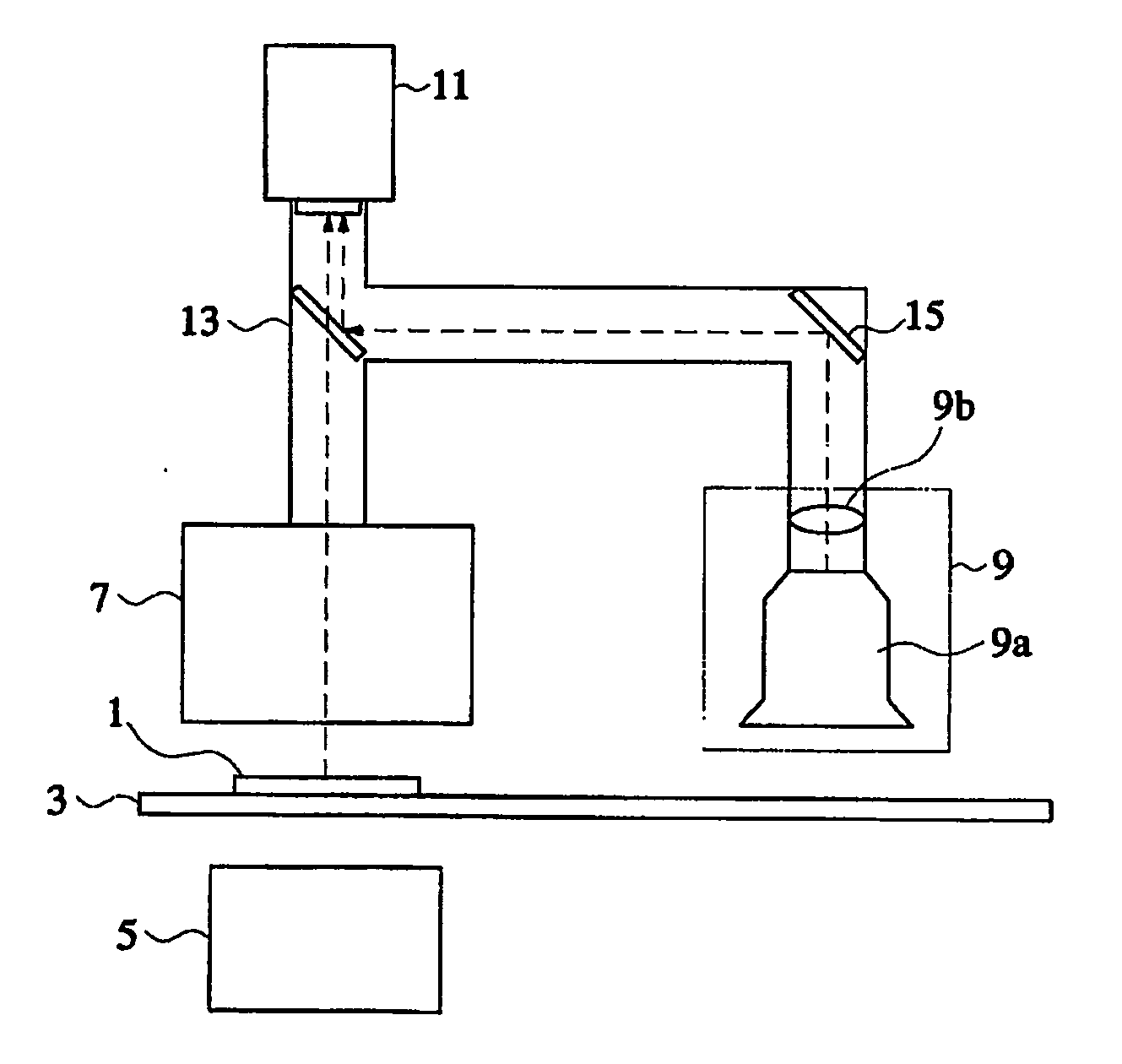

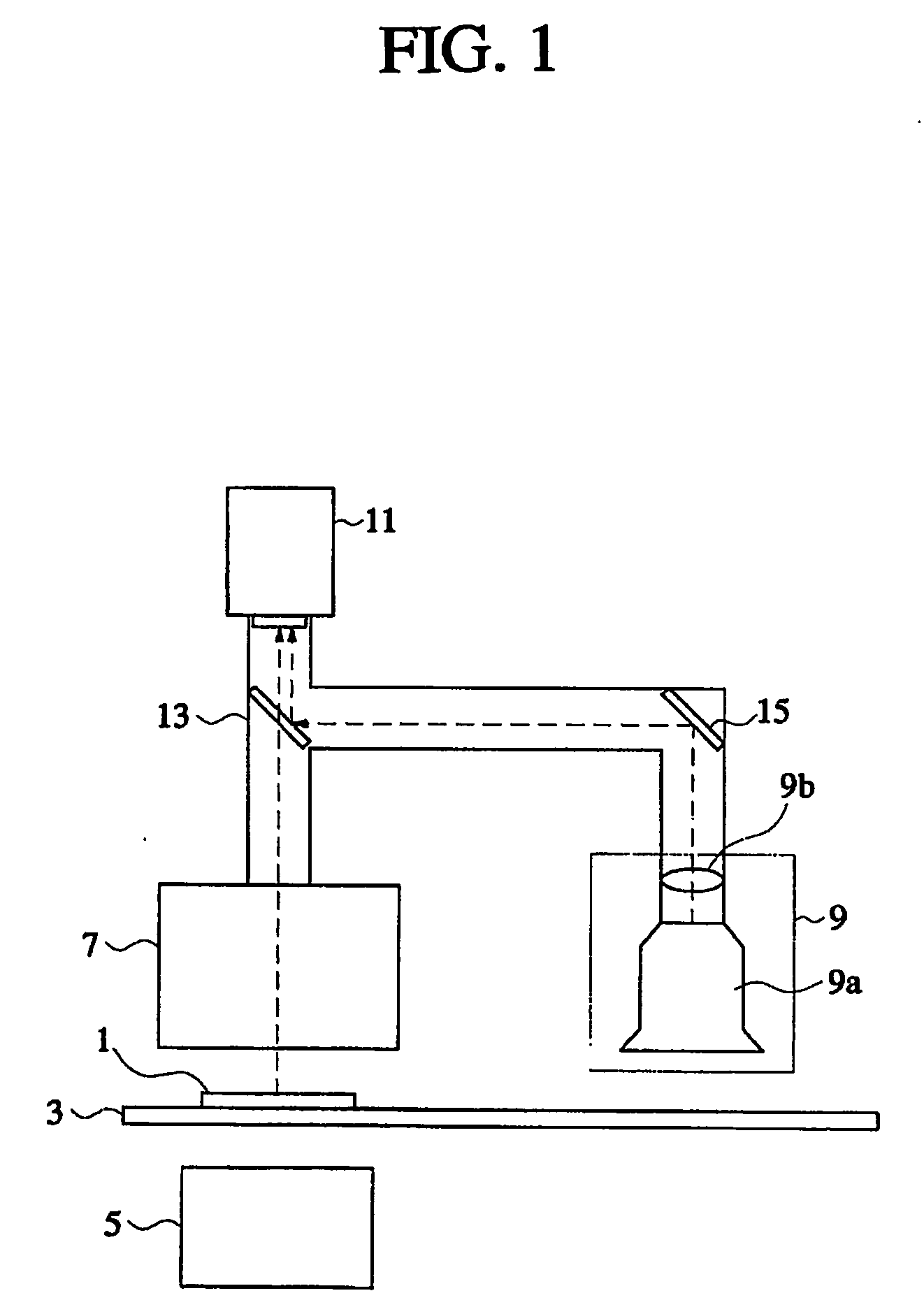

Methods and apparatus for porosity measurement

InactiveUS20070186655A1Easy CalibrationIntuitive inspectionAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesPorosityNon destructive

A method for non-destructively inspecting a composite structure with a single ultrasonic transducer includes determining a calibration amplitude of ultrasonic transmissions emitted by the single ultrasonic transducer to a reflector in a fluid-filled immersion tank and received back at the single ultrasonic transducer. The method also includes inserting the composite structure into the fluid-filled immersion tank between the reflector and the single ultrasonic transducer. In addition, the method includes scanning the composite structure with the single ultrasonic transducer to measure ultrasonic amplitudes for sound waves traveling through the composite structure, reflecting off the reflector plate and then traveling back through the structure to the single ultrasonic transducer. The measured ultrasonic amplitudes are corrected using the calibration amplitude and other measured transmission losses, and the corrected ultrasonic amplitudes are utilized to generate either or both a digital image showing porosity or a measurement of porosity of the composite structure.

Owner:GENERAL ELECTRIC CO

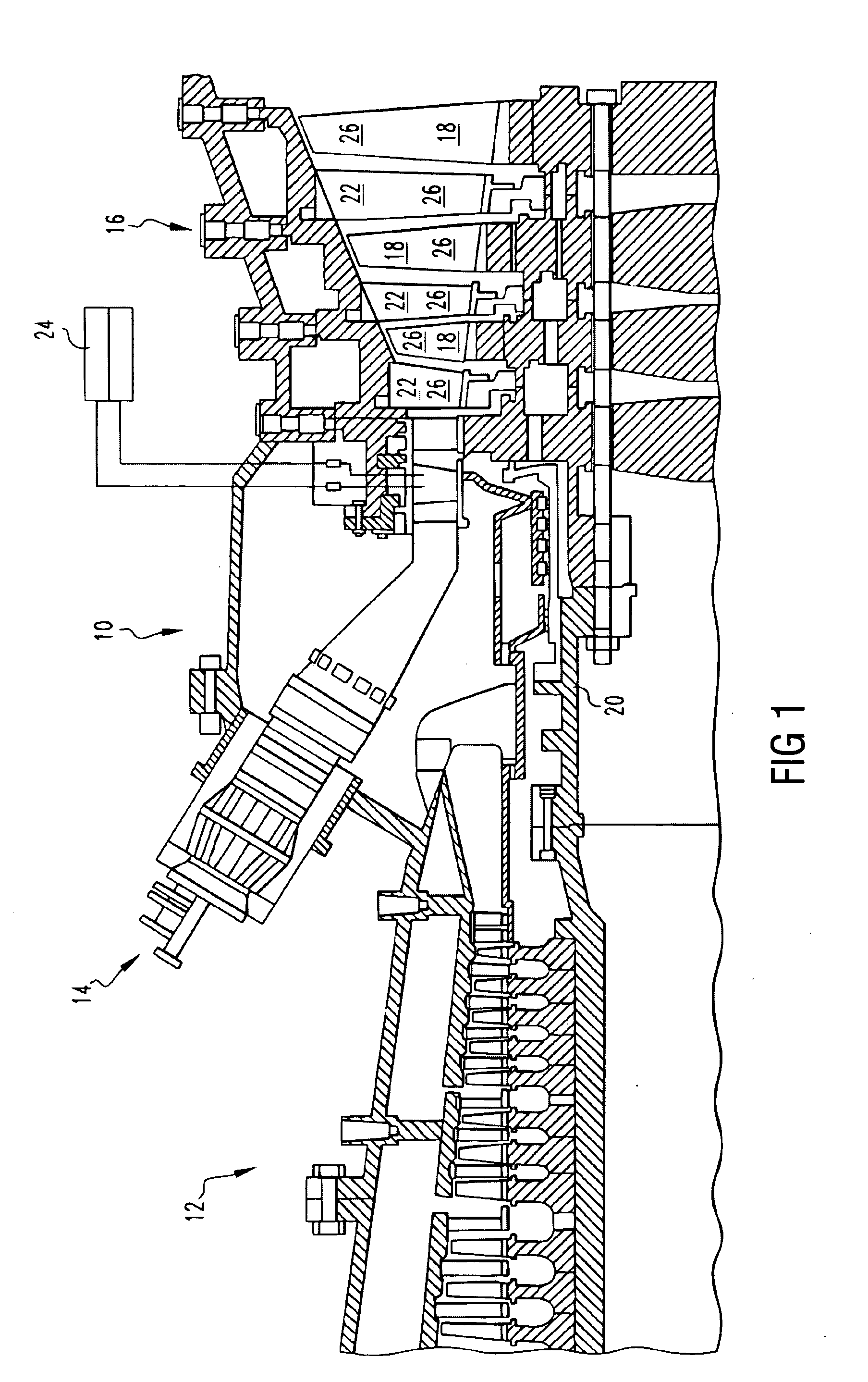

Optical monitoring of thermal barrier coatings

InactiveUS20050063450A1Intuitive inspectionSimplifying repair procedureTemperature measurement in motorsWeather/light/corrosion resistanceCombustionThermal barrier coating

A system, a method and a component using thermally stimulatable substances for the temperature measurement of thermal barrier coatings are provided. The a thermal barrier coating comprises a stimulatable substance as high-lighter and a substance to adhere the thermal stimulatable substance in the coating. The stimulatable substance having emission lines which vary in response to a temperature of a coated component. For example, the present invention can be used in combustion turbines or combustion machines.

Owner:SIEMENS AG

Connector system for securing an end portion of a steel structural member to a vertical cast concrete member

ActiveUS8209924B2Eliminating field weldingLow costBuilding roofsScaffold connectionsGusset plateJoist

A steel structural member such as a joist or beam is secured to a vertical cast concrete member or wall by a connector system including a fabricated steel receiver embedded within the wall. Embedded anchors are attached to the receiver which has front wall portions flush with the concrete wall and define a front opening. A support bracket has a horizontal plate attached to the beam and a vertical plate which fits through the front opening within the receiver. The bracket is attached to the beam which is then elevated, and the vertical plate is inserted through the opening into the receiver. The beam and vertical plate are then shifted until opposite edge portions of the vertical plate are blocked by the front wall portions of the receiver. In the illustrated embodiment, the front opening and vertical plate are generally triangular, and the support bracket has a welded reinforcing gusset.

Owner:CONNECT EZ

Nondestructive inspection method and system therefor

ActiveUS7086285B2Efficient use ofEasy CalibrationAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesPorosityFiber

A method and system for determining the fiber volume fraction of a composite structure. The system includes a unit for ultrasonically determining the porosity volume fraction in the article, and a unit for calculating the volume fraction of the fibrous reinforcement material in the article based on the porosity volume fraction in the article and the mass densities of the article and the fiber and matrix materials within the article. The method entails determining the mass density of the article, obtaining the mass densities of the fiber material and the matrix material, ultrasonically determining the porosity volume fraction in the article, and then calculating the volume fraction of the fibrous reinforcement material in the article based on the porosity volume fraction in the article, the mass density of the article, the mass density of the matrix material, and the mass density of the fiber material.

Owner:GENERAL ELECTRIC CO

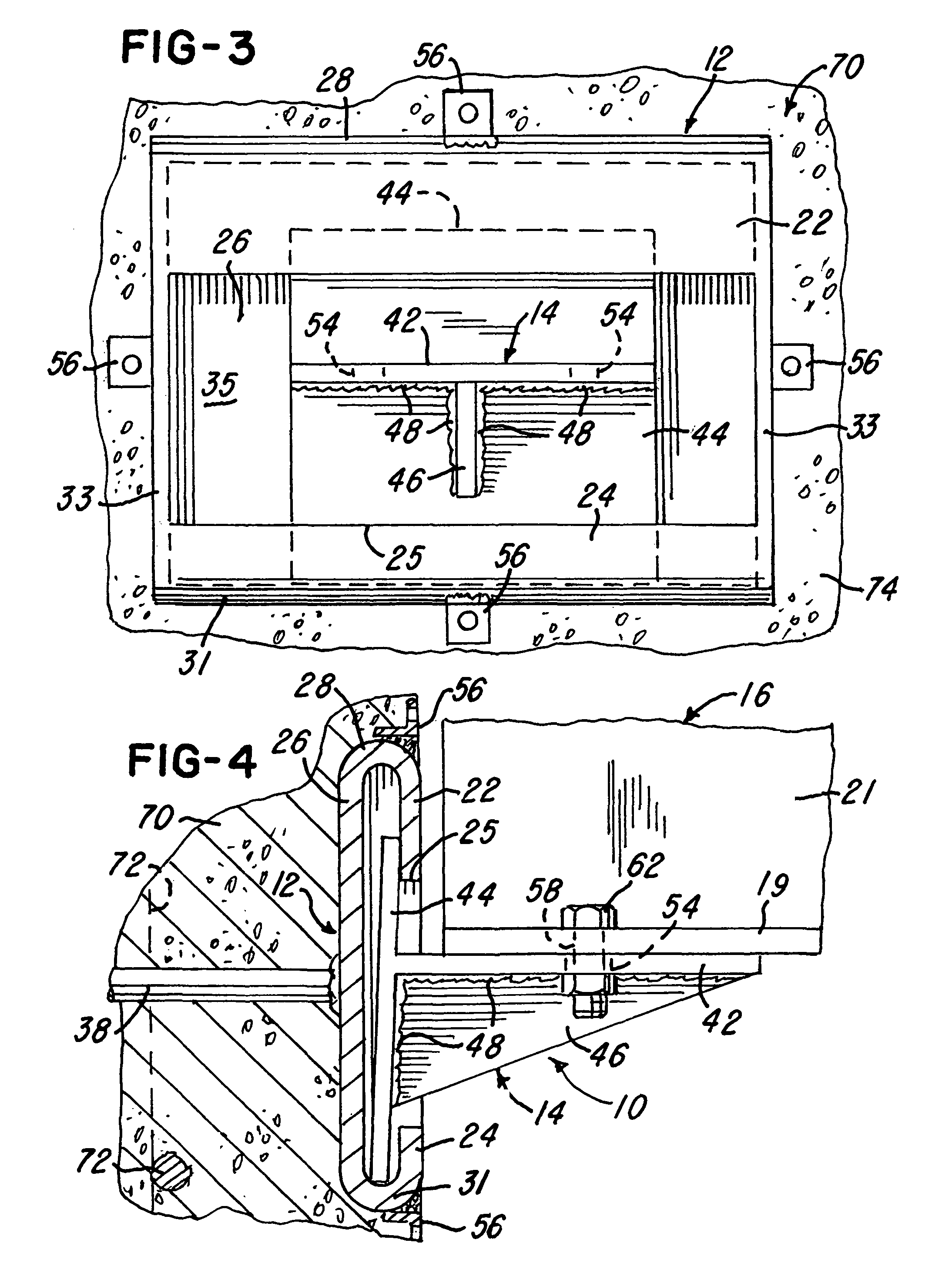

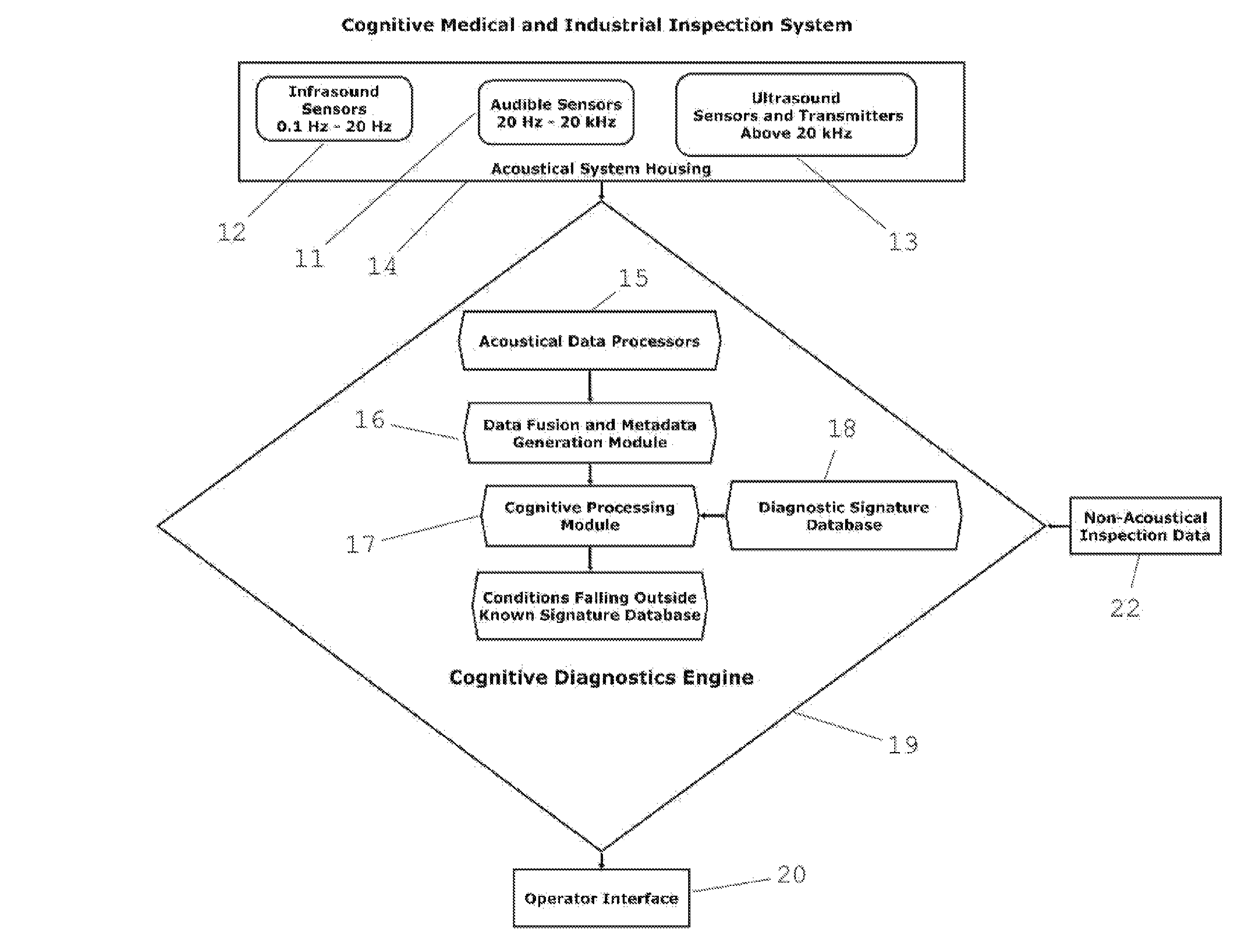

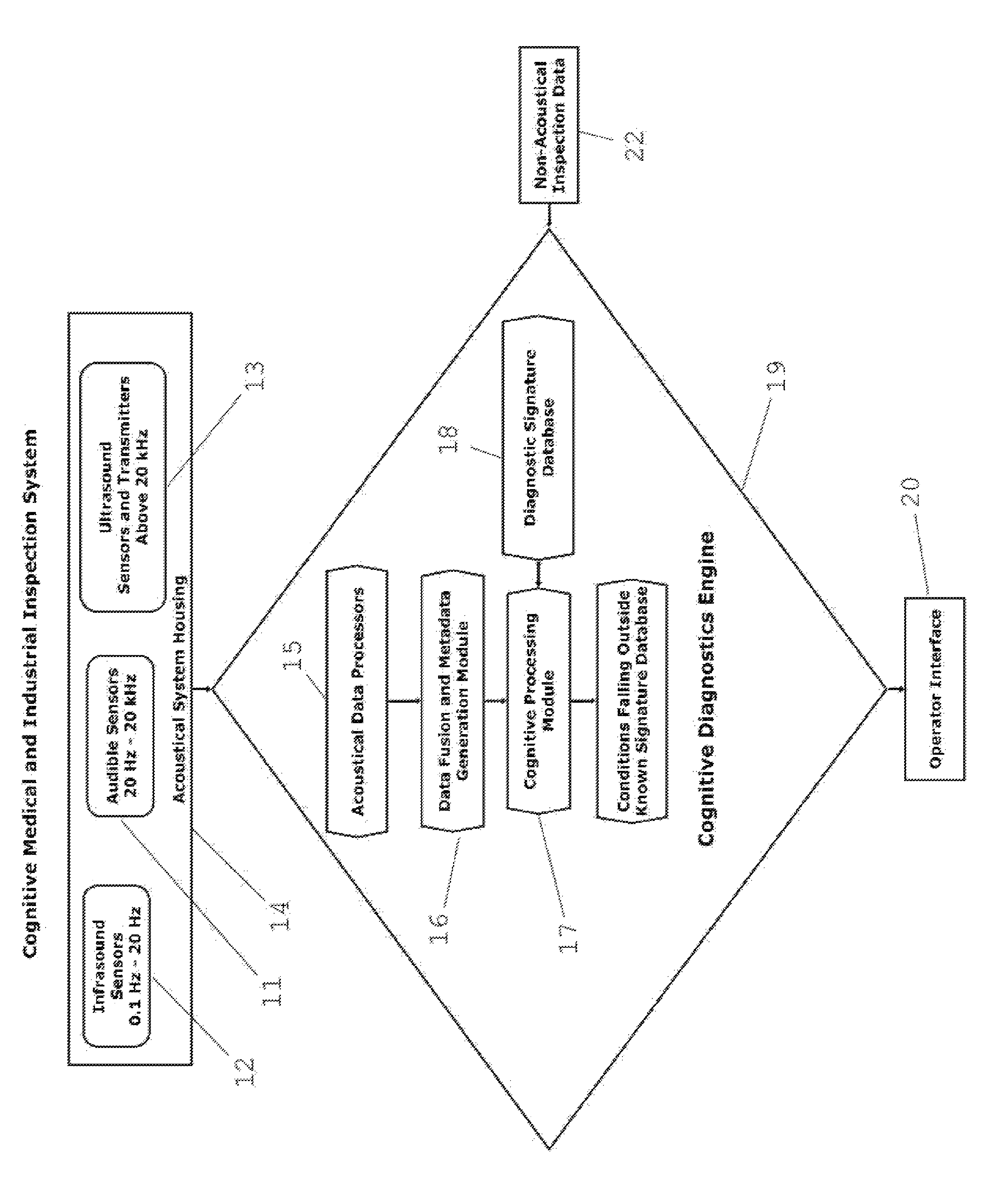

Cognitive medical and industrial inspection system and method

ActiveUS9349098B1Low costSimplifies initial inspectionMedical simulationUltrasonic/sonic/infrasonic diagnosticsGamma rayCompanion animal

The present invention relates to inspection of medical patients including, but not limited to, phonocardiography, auscultation and ultrasound medical imaging and other non-acoustical inspection techniques; and industrial non-destructive testing and evaluation of materials, structural components and machinery; and more particularly to the incorporation of cognitive artificial intelligence into an inspection system and method that utilizes cognitive mathematical techniques which emulate the cognitive processing abilities of the human brain including, but not limited to, symbolic cognitive architectures and inference process algebras, to analyze data collected from infrasound acoustical sensors (0.1 Hz-20 Hz), audible acoustical sensors (20 Hz to 20 kHz), ultrasound acoustical sensors and transmitters above 20 kHz, data collected from other non-acoustical inspection devices and systems including, but not limited to electrocardiography (EKG), computed-tomography (CT), single photon emission computed tomography (SPECT), positron emission tomography (PET), magnetic resonance imaging (MRI), electromagnetic testing (ET), magnetic particle inspection (MT or MPI), magnetic flux leakage testing (MFL), liquid penetrant, radiographic (x-ray and gamma ray), eddy-current testing, low coherence interferometry, and combinations thereof (i.e., multi-modality inspection data); fuse this data resulting in the generation of new metadata; and then utilize cognitive mathematical techniques to interpret this data against inspection signatures that characterize conditions being diagnosed. The present invention has the ability to also identify and anticipate abnormal conditions that fall outside known inspection signature patterns; and communicate the inspection results to an operator thereby simplifying the initial inspection and diagnosis for medical patients and industrial objects; minimizing false negative and false positive initial inspection results and lowering costs.

Owner:1619235 ONTARIO LTD

Methods and apparatus for porosity measurement

InactiveUS7389693B2Easy CalibrationIntuitive inspectionAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesNon destructivePorosity

Owner:GENERAL ELECTRIC CO

Connector system for securing an end portion of a steel structural member to a vertical cast concrete member

ActiveUS20110107716A1Eliminating field weldingReduces time and cost for makingBuilding roofsScaffold connectionsEngineeringJoist

A steel structural member such as a joist or beam is secured to a vertical cast concrete member or wall by a connector system including a fabricated steel receiver embedded within the wall. Embedded anchors are attached to the receiver which has front wall portions flush with the concrete wall and define a front opening. A support bracket has a horizontal plate attached to the beam and a vertical plate which fits through the front opening within the receiver. The bracket is attached to the beam which is then elevated, and the vertical plate is inserted through the opening into the receiver. The beam and vertical plate are then shifted until opposite edge portions of the vertical plate are blocked by the front wall portions of the receiver. In the illustrated embodiment, the front opening and vertical plate are generally triangular, and the support bracket has a welded reinforcing gusset.

Owner:CONNECT EZ

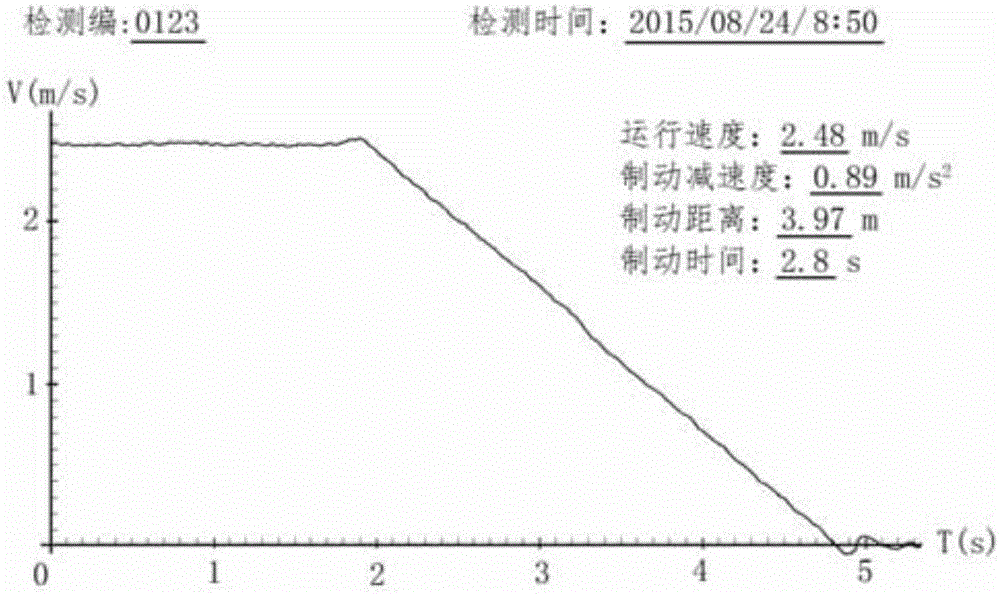

Elevator braking parameter detector

InactiveCN105136509AReduce volumeIntuitive inspectionStructural/machines measurementElevatorsComputer moduleDisplay device

An elevator braking parameter detector is formed by seven modules of an instrument housing, an acceleration sensor, a data processor, an SD card slot and SD card, a displayer, a power supply battery, a Micro-USB charging jack. Elevator cage motion information in the elevator braking process is collected by the acceleration sensor; and a speed-time curve graph and elevator braking parameters of elevator braking distance, elevator braking deceleration speed and elevator braking time and the like in the elevator braking process are obtained through analysis and calculation of the data processor, and the detection results are displayed and output through the displayer. The instrument is exquisite in structure and simple to detect and operate; setting of detection items and measurement data accords with elevator standard and industry habits; and through the arrangement of the SD card and the charging jack, compatibility is good.

Owner:TIANJIN HAOYA SCI & TECH DEV

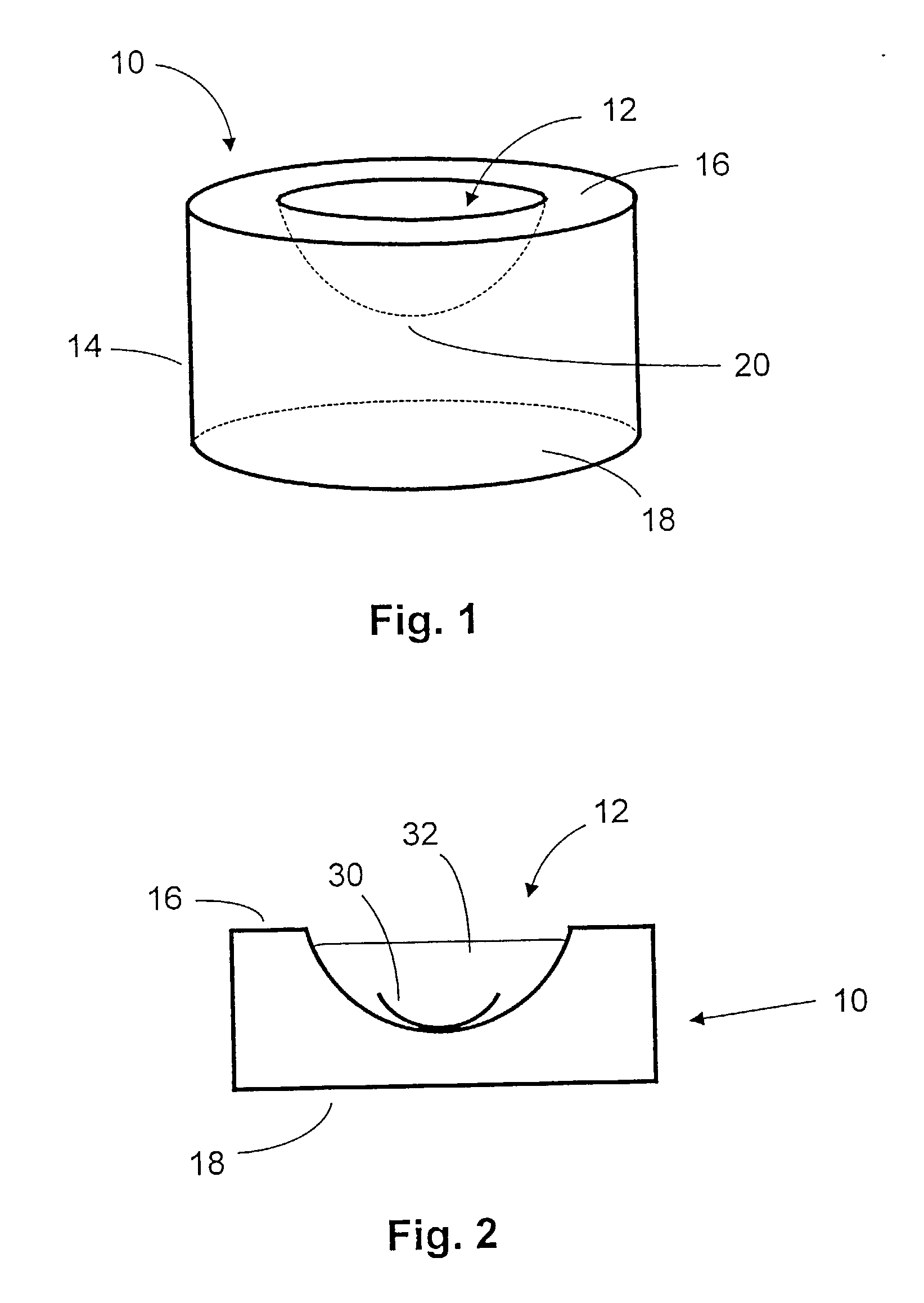

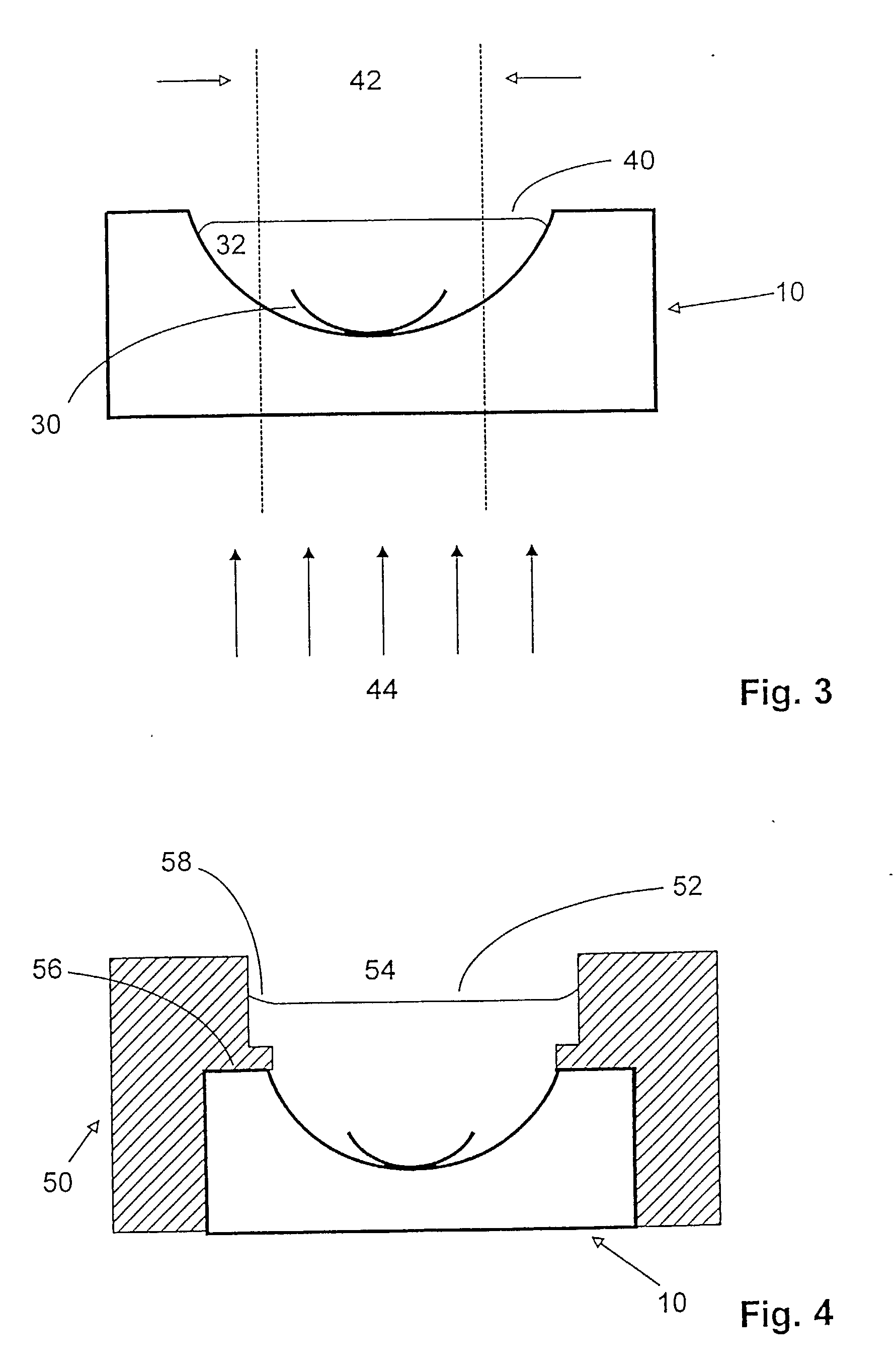

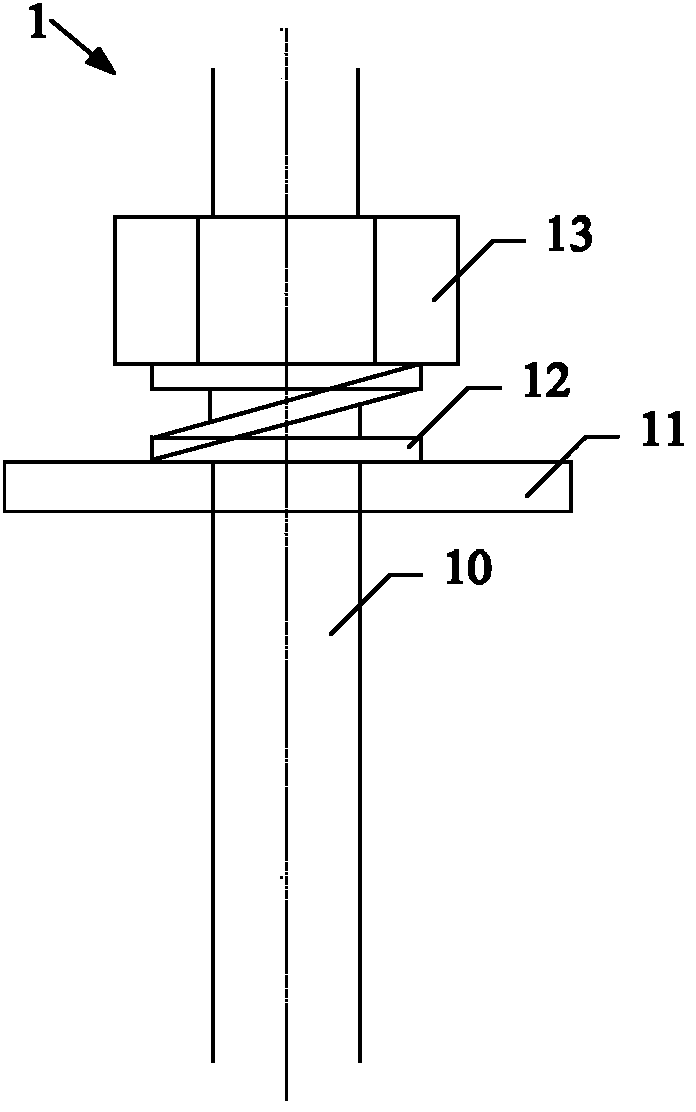

Wetcell device for inspection

InactiveUS20020196429A1Simple processSmall optical distortionUsing optical meansTesting optical propertiesEngineeringLens plate

The invention provides an inspection cell for inspecting an ophthalmic lens. The inspection cell is a solid block that has a bottom planar surface, a top surface, and an indentation in the top surface. The indentation is adapted to receive an ophthalmic lens. which is to be inspected. The invention additionally provides an inspection unit for an ophthalmic lens, which holds one or more of the inspection cells.

Owner:RUSSELL TODD ALDRIDGE +1

Anchor rod device

ActiveCN103422872AEasy to installIntuitive inspectionBulkheads/pilesAnchoring boltsEngineeringUltimate tensile strength

The invention provides an anchor rod device. The anchor rod device comprises an anchor rod, an anchor rod supporting plate, a spring and a nut, wherein the anchor rod is sequentially sleeved with the anchor rod supporting plate, the spring and the nut outward from the axial center of the anchor rod. When the nut is in the state that screwing is completed, the anchor rod supporting plate is tightly pressed into a palisade through the spring, wherein the anchor rod is inserted into the palisade. The yield strength of the spring is larger than or equal to the pre-tightening force borne by the anchor rod supporting plate when screwing of the nut is completed. According to the anchor rod device, whether the pre-tightening force is enough or not can be more intuitively tested so that the anchor rod can be more conveniently and rapidly installed.

Owner:HUAINAN MINING IND GRP

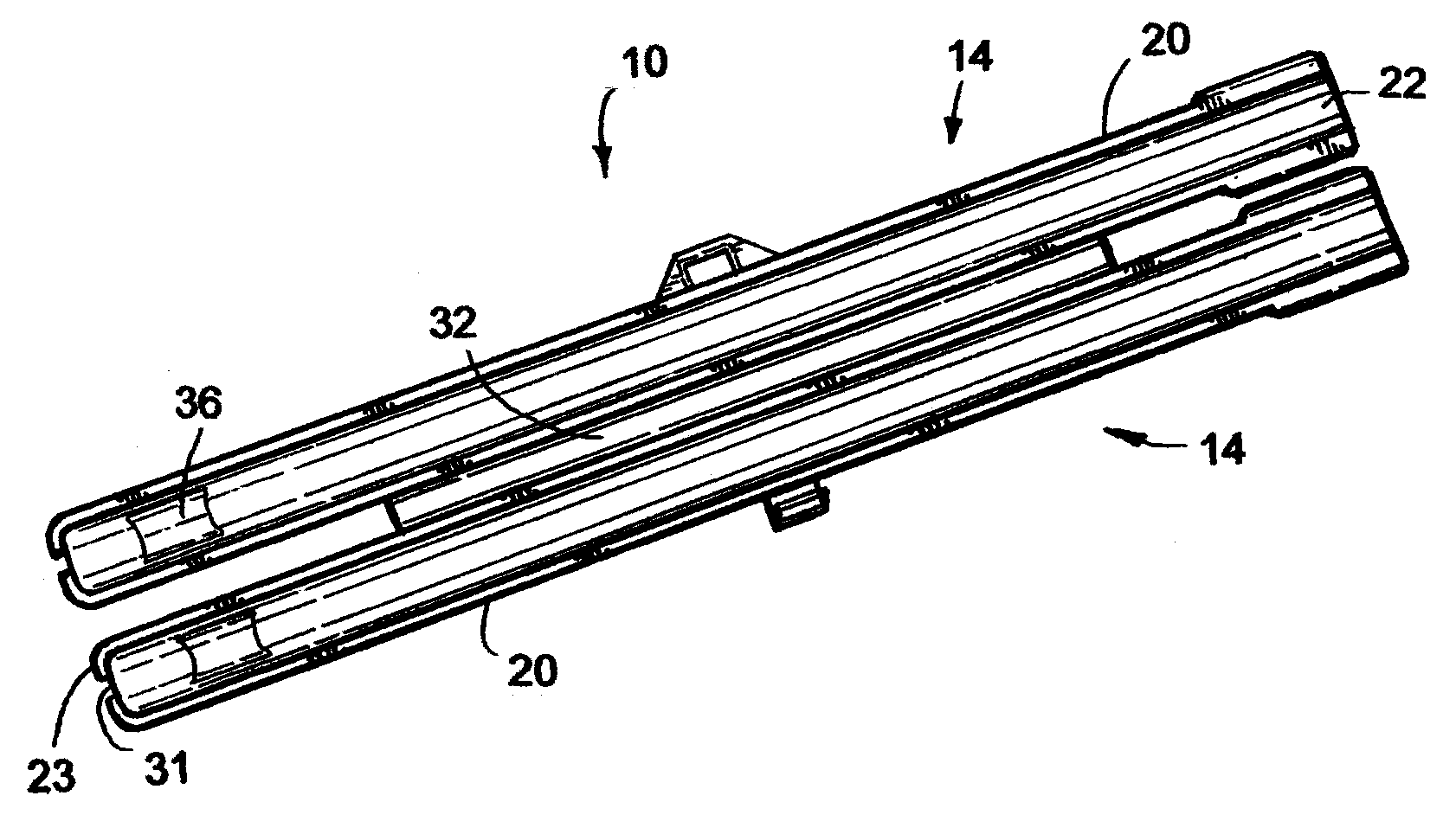

Aseptic thermometer storage case

InactiveUS20080232429A1Intuitive inspectionSave livesThermometer detailsThermometers using material expansion/contactionThermometerBody positions

The invention describes and claims an apparatus and method of maintaining cleanliness of the thermometer storage case. The apparatus is an improved elongated end-loading storage case for thermometers. The improvement comprises two or more elongated sections of the case. Each section comprises a connection edge, an insertion tip, and a distal tip. The elongated sections of the case are detachably connected to each other to form a thermometer storage case that opens up to reveal the inner surface of the case for easy inspection and cleaning. The case comprises a fastener for fixating the case in the assembled case body position. The method of cleaning the thermometer storage case comprises the steps of unfastening and opening the case, inspecting and sanitizing the inside surface of the case, and then reconnecting and fixating the elongated sections to form the thermometer storage case.

Owner:KNISHEVITSKIY ANNA

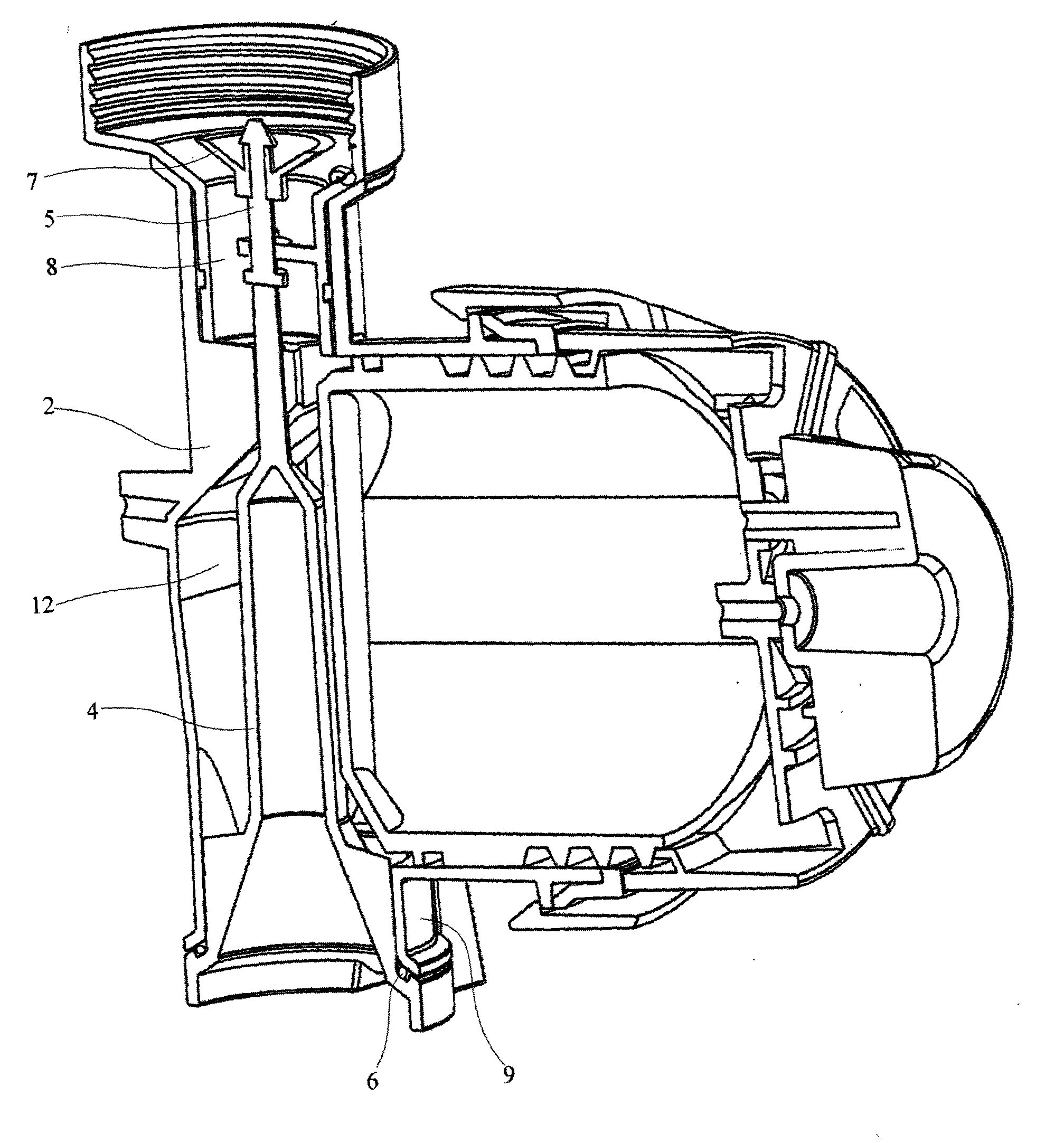

Valve body of a dosing device

ActiveUS20160015237A1Easy to replaceIntuitive inspectionOperating means/releasing devices for valvesCarpet cleanersBiomedical engineering

Owner:TTS CLEANING SRL

Nondestructive inspection method and system therefor

ActiveUS20060144149A1Readily applyEfficient use ofAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesNondestructive testingComposite structure

A method and system for determining the fiber volume fraction of a composite structure. The system includes a unit for ultrasonically determining the porosity volume fraction in the article, and a unit for calculating the volume fraction of the fibrous reinforcement material in the article based on the porosity volume fraction in the article and the mass densities of the article and the fiber and matrix materials within the article. The method entails determining the mass density of the article, obtaining the mass densities of the fiber material and the matrix material, ultrasonically determining the porosity volume fraction in the article, and then calculating the volume fraction of the fibrous reinforcement material in the article based on the porosity volume fraction in the article, the mass density of the article, the mass density of the matrix material, and the mass density of the fiber material.

Owner:GENERAL ELECTRIC CO

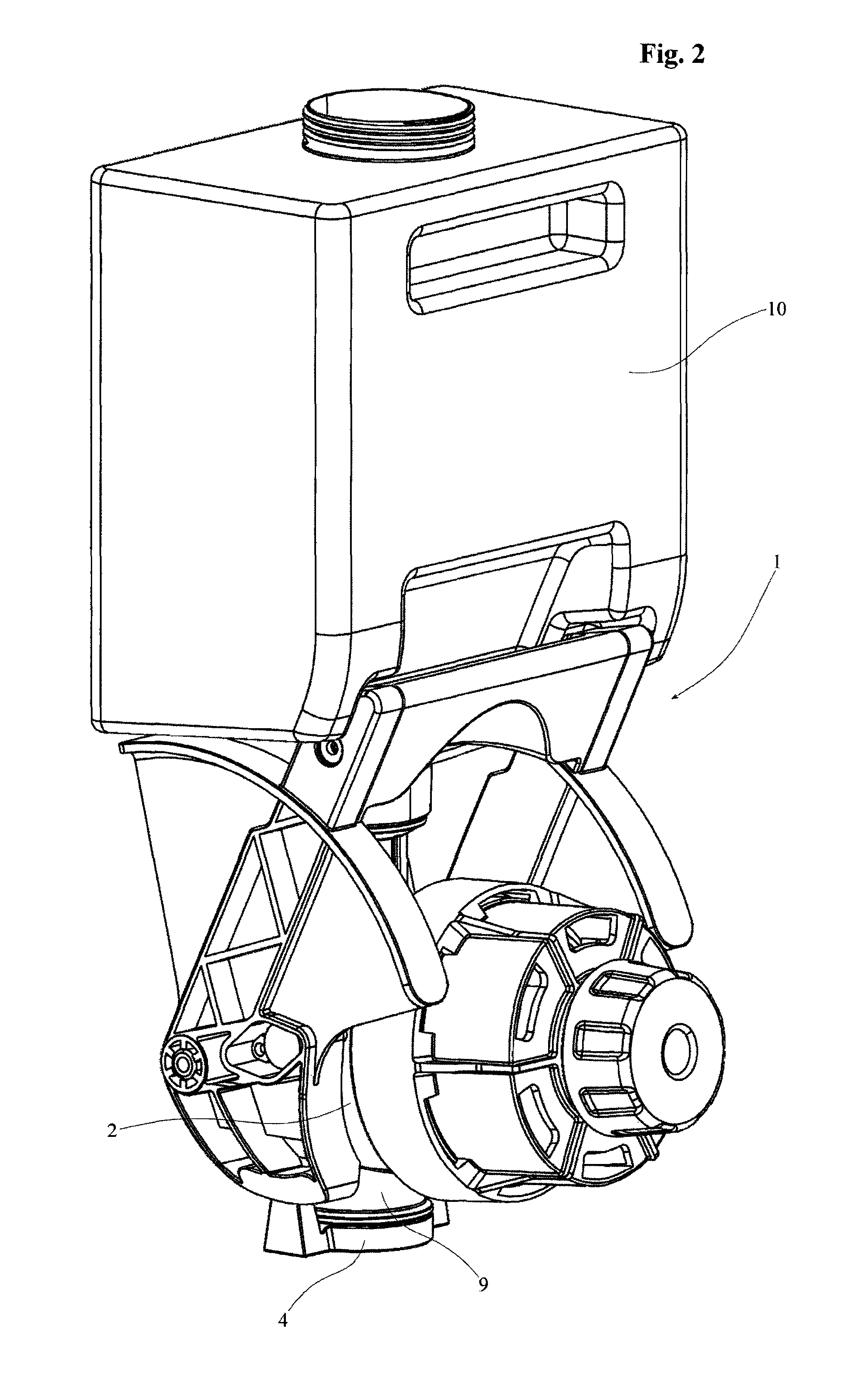

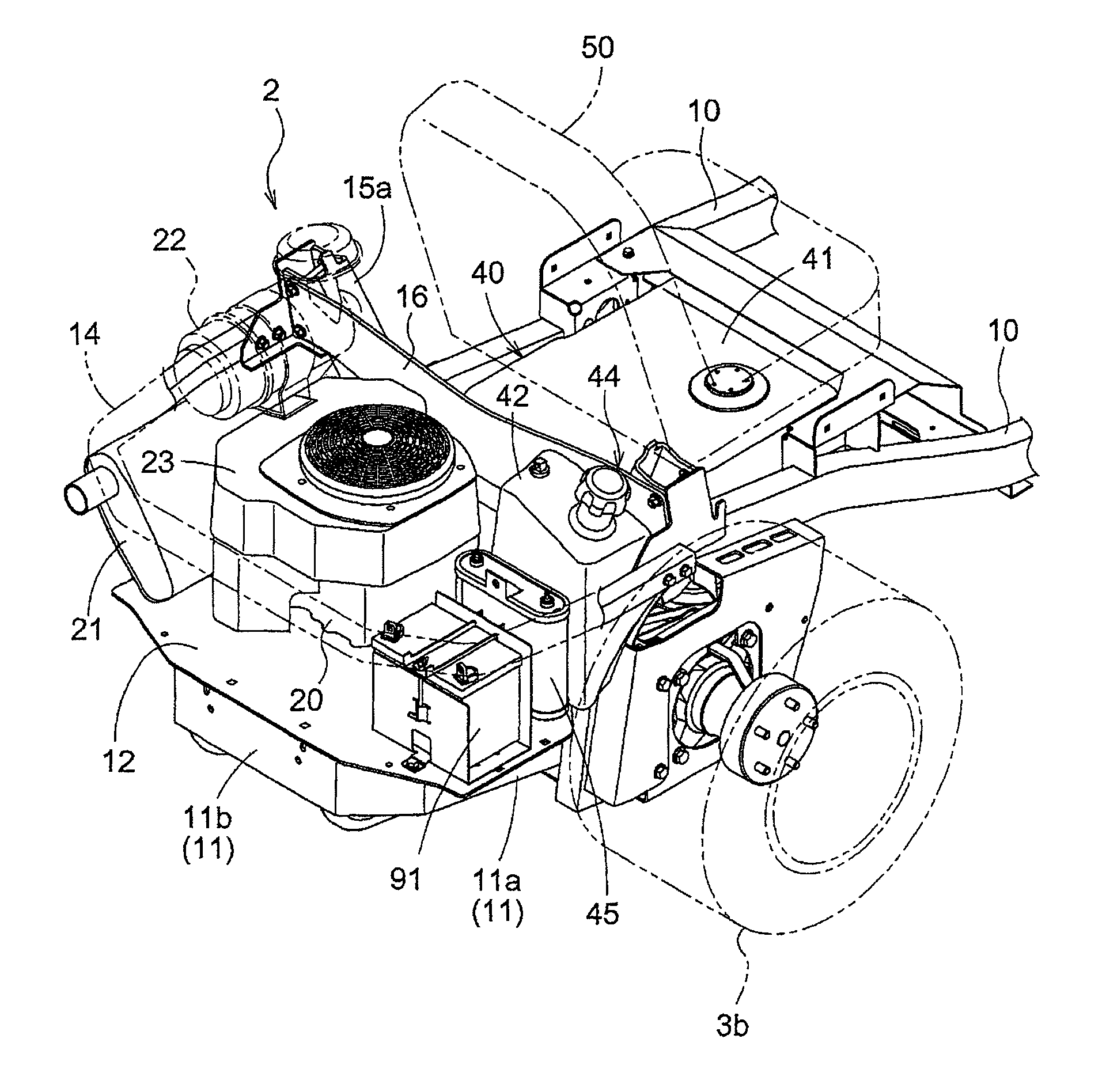

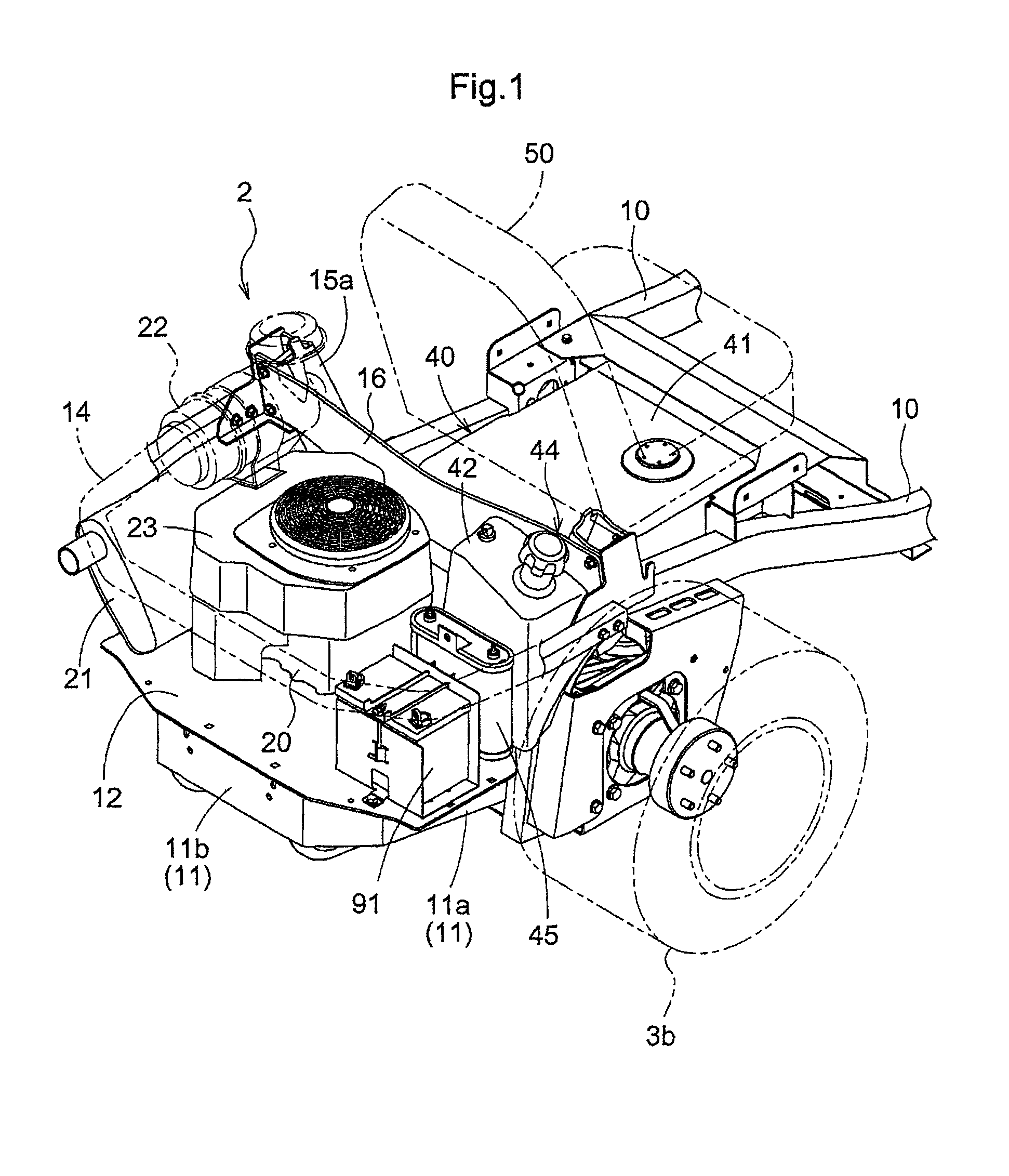

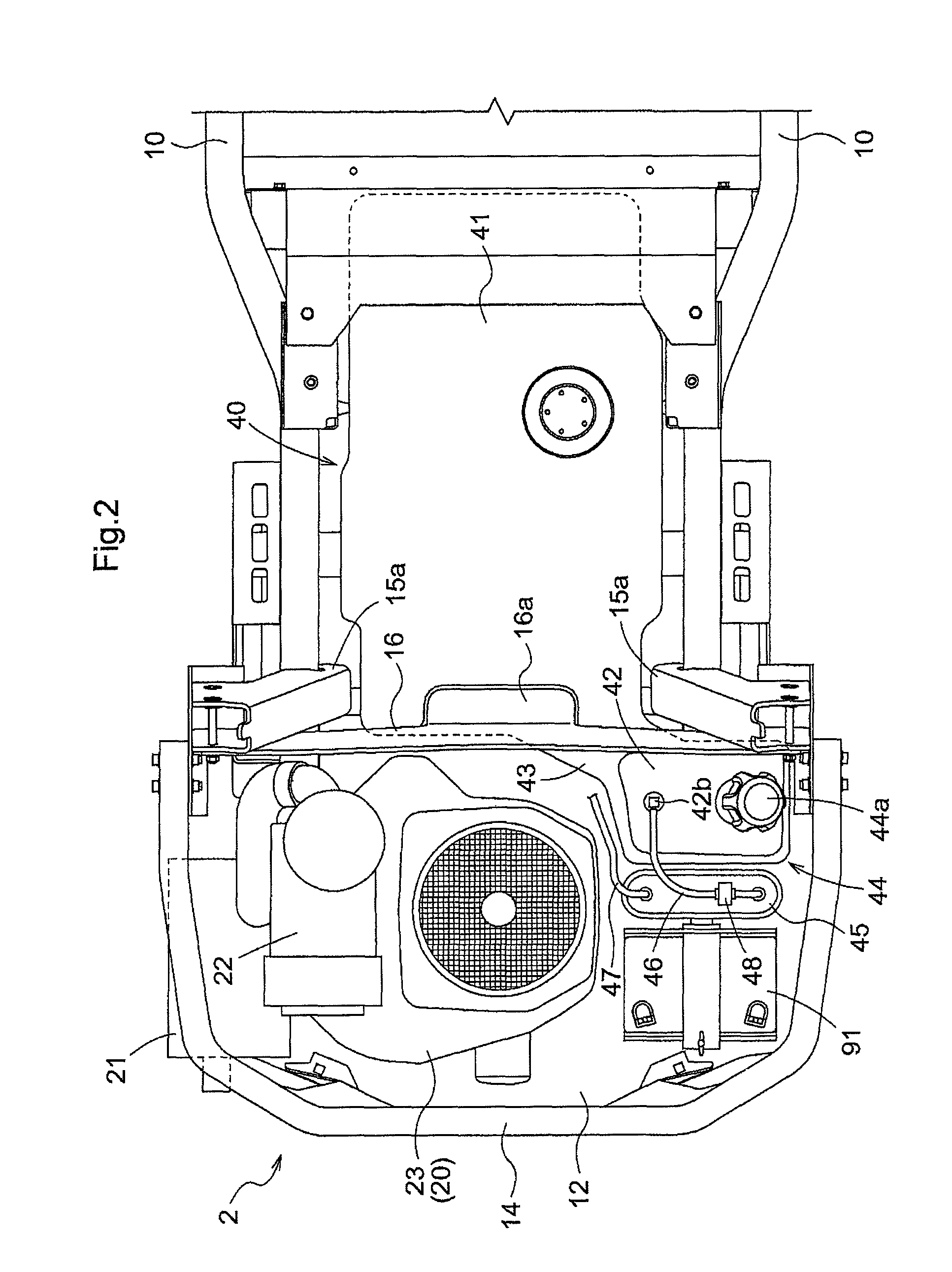

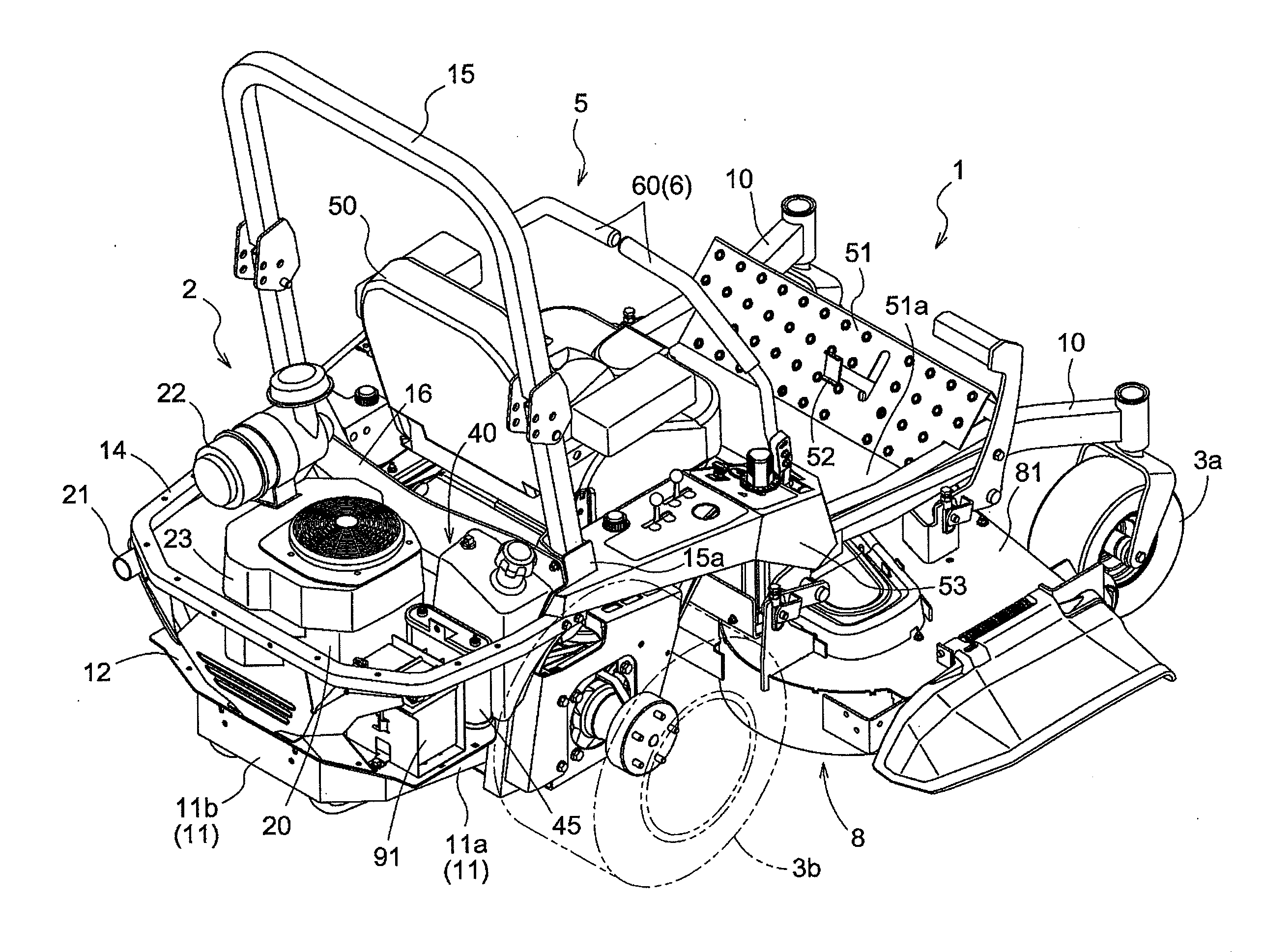

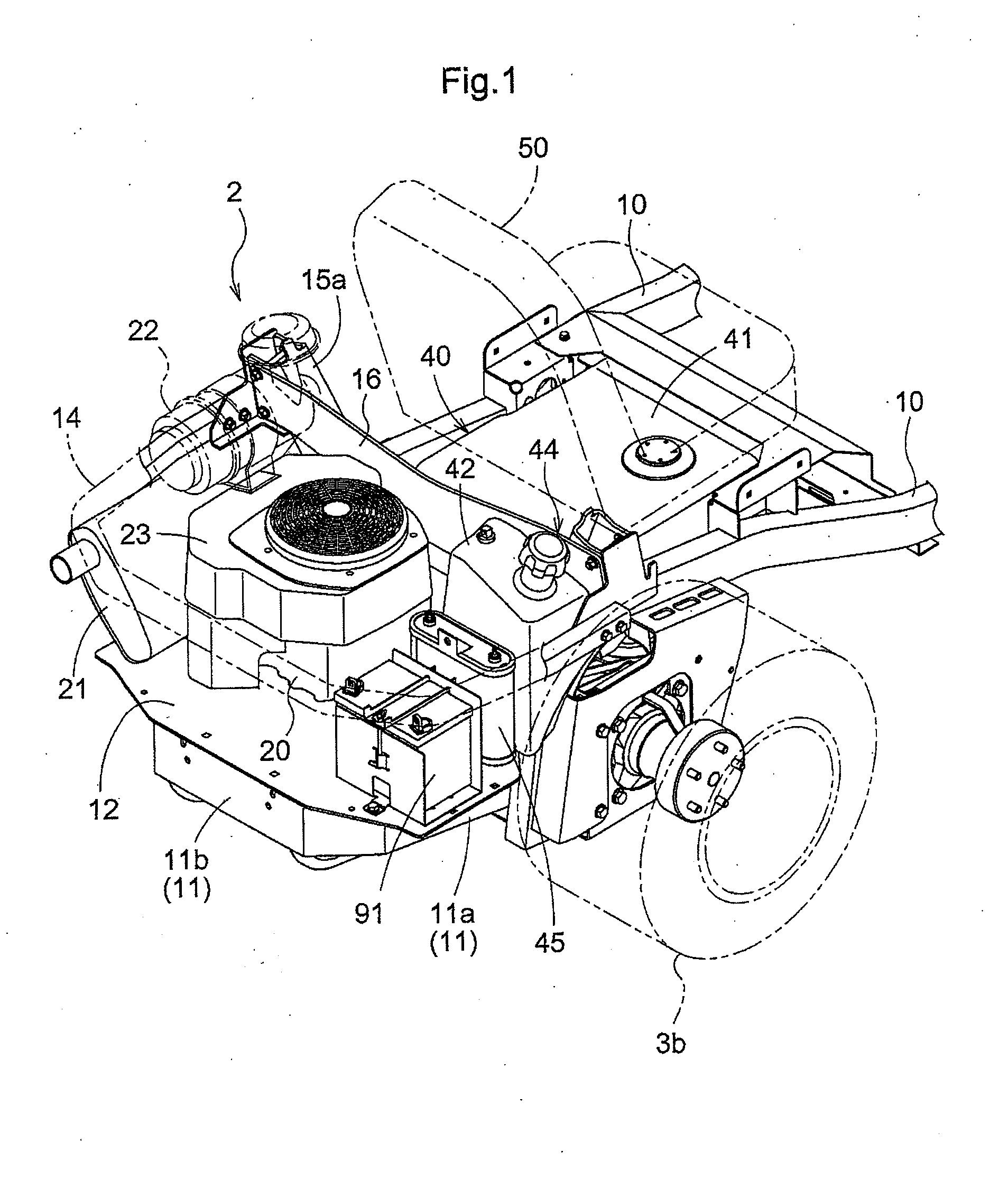

Work vehicle with engine mounted rearwardly

ActiveUS8690190B2Improving effective use of spaceIntuitive inspectionTank vehiclesUnderstructuresVehicle frameFuel tank

A work vehicle includes a vehicle frame extending between a right and left pair of rear wheels. An engine is mounted in a vertical position on a horizontal mounting surface defined in the vehicle frame in a peripheral area of the rear wheels in a central portion of a transverse direction of the vehicle. A fuel tank includes a main tank body mounted under a driver's seat and an auxiliary tank body mounted on the mounting surface on one lateral side of the engine in the transverse direction of the vehicle. A canister is mounted adjacent to the engine on one lateral side of the engine and rearwardly of and adjacent to the auxiliary fuel tank.

Owner:KUBOTA LTD

Pavement disease rapid inspection method based on mechanical indexes and artificial neural network

ActiveCN113177611AIntuitive inspectionFor quick inspectionMeasurement devicesCharacter and pattern recognitionTime informationData set

The invention relates to a pavement disease rapid inspection method based on mechanical indexes and an artificial neural network, and the method comprises the following steps: taking VMI values, vehicle speeds, vehicle elevation information and amplitudes on roads with different disease types in a vehicle driving process as a group of data, and forming an input data set by a plurality of groups of data; clustering the data in the input data set by using the SOM neural network, and outputting a corresponding clustering result; determining real disease classification level information corresponding to the acceleration characteristic information in each clustering center range according to the data in the clustering center range corresponding to the corresponding time information and latitude and longitude information, and establishing a sample disease database; and training a decision tree by using the established sample disease database, establishing a decision tree model, and performing disease classification and hierarchical decision on the damaged road. The method has the advantages of being short in detection period, low in cost, high in precision and not affected by subjective factors of people, and rapid recognition, classification, grading and positioning of pavement diseases are achieved.

Owner:HEBEI UNIV OF TECH

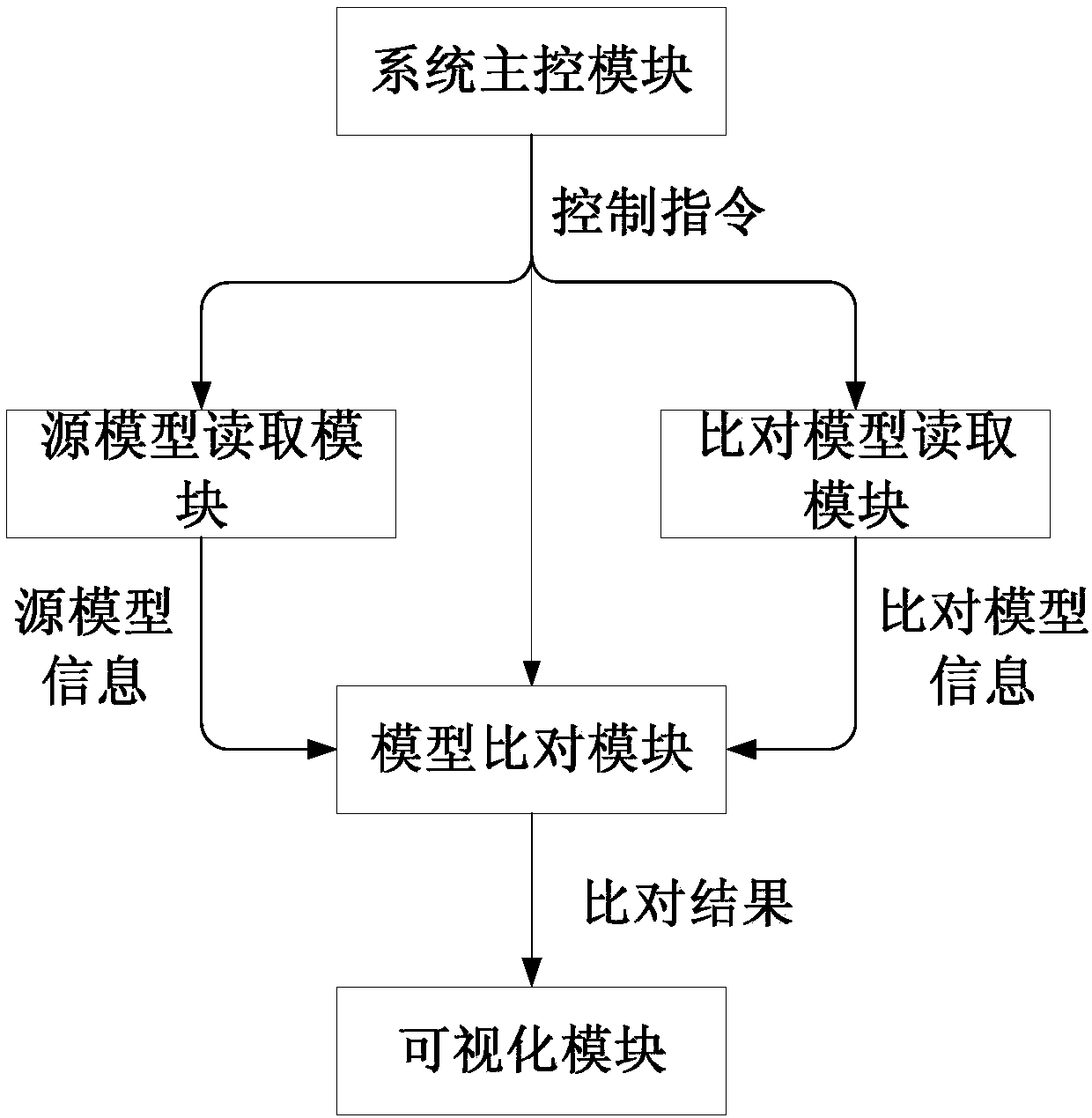

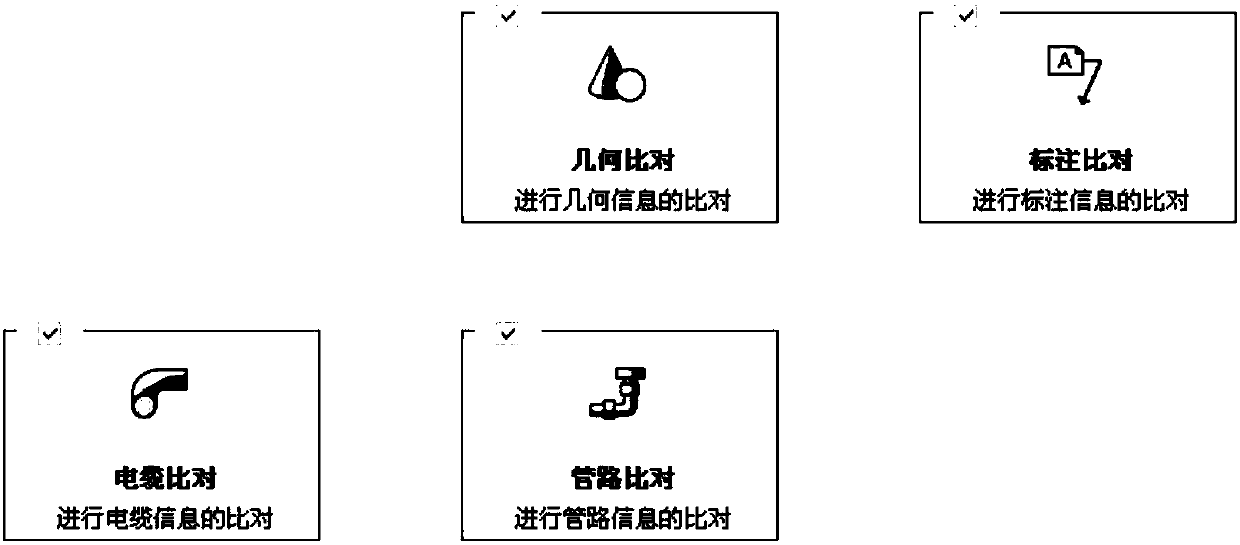

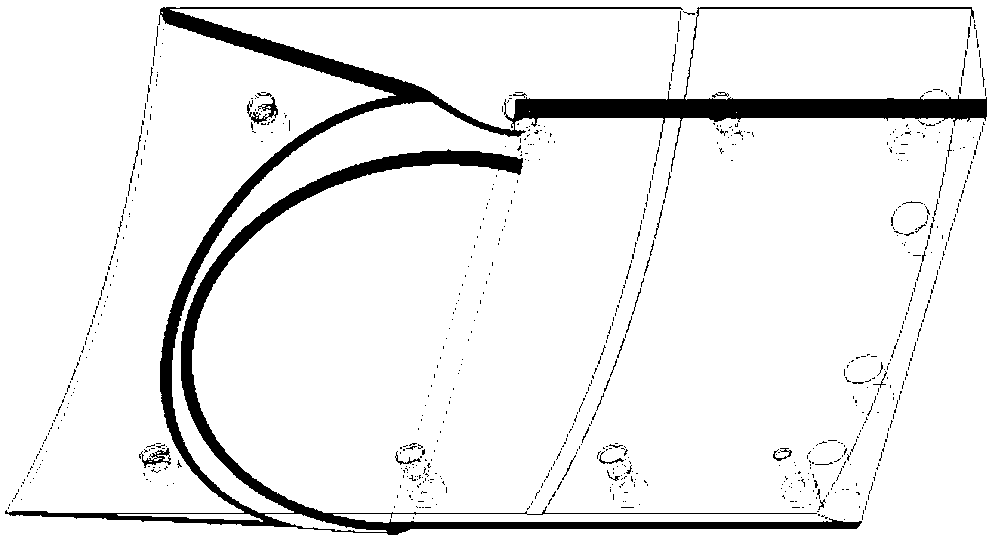

Three-dimensional-part-model version comparison system based on Creo software

InactiveCN107944101AImprove work efficiencyQuick comparisonDesign optimisation/simulationSpecial data processing applicationsInformation typeComputer module

The invention discloses a three-dimensional-part-model version comparison system based on Creo software. The system includes a system main-control module, a source-model reading module, a comparison-model reading module, a model comparison module and a visualization module. The system main-control module is used for providing comparison information types and source-model and comparison-model storage paths, and sending control instructions and the like. The source-model and comparison-model reading modules read corresponding information of a source model and a comparison model, and send the same to the model comparison module. The model comparison module adopts a method of traversal to compare the corresponding information of the source model and the comparison model piece by piece according to a comparison information type. The visualization module adopts row-by-row pairing lists or a manner of three-dimensional visualization to carry out result difference display according to the comparison information type. According to the system, comparison efficiency of different design versions of three-dimensional rocket part models is improved, manpower operation burdens and error probability in a traditional-manual-manner comparison process are reduced, and a product development cycle is shortened.

Owner:BEIJING INST OF ASTRONAUTICAL SYST ENG +1

Refrigerator

ActiveUS9506685B2Opening of the refrigerator door is facilitatedSimple componentsDomestic cooling apparatusLighting and heating apparatusStore foodEngineering

A refrigerator that includes a compartment to store foods, and a door to open and close the compartment. The door has a door main body, a door handle movably disposed on the door main body to actuate the door main body to be easily opened, a slider protruding toward the refrigerator main body in response to movement of the door handle, and a driving force transfer unit. The driving force transfer unit may be located between the door handle and slider to transfer a driving force, generated upon pulling the door handle, to the slider. The door further includes a pocket housing partially buried into the door main body and receiving therein the door handle. The slider and the driving force transfer unit may be individually detachable. This configuration facilitates opening of the refrigerator and inspection and replacement of components of the driving force transfer unit.

Owner:LG ELECTRONICS INC

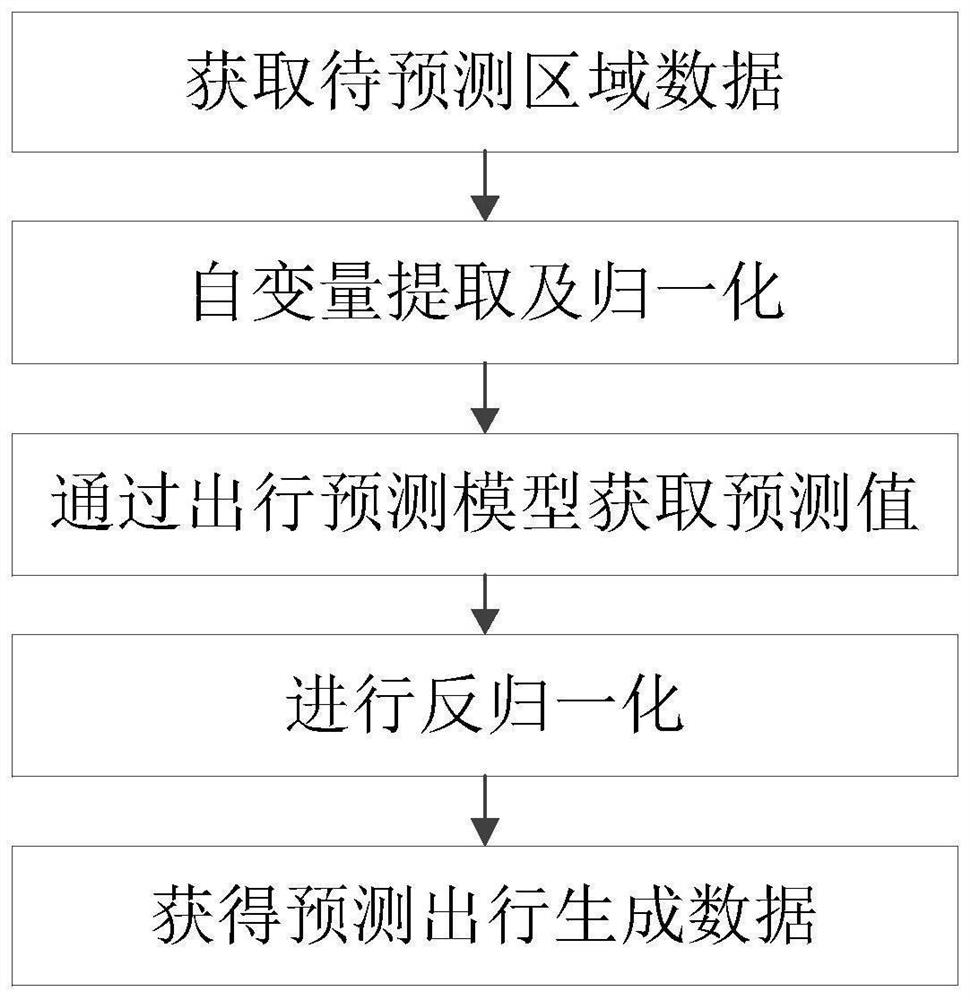

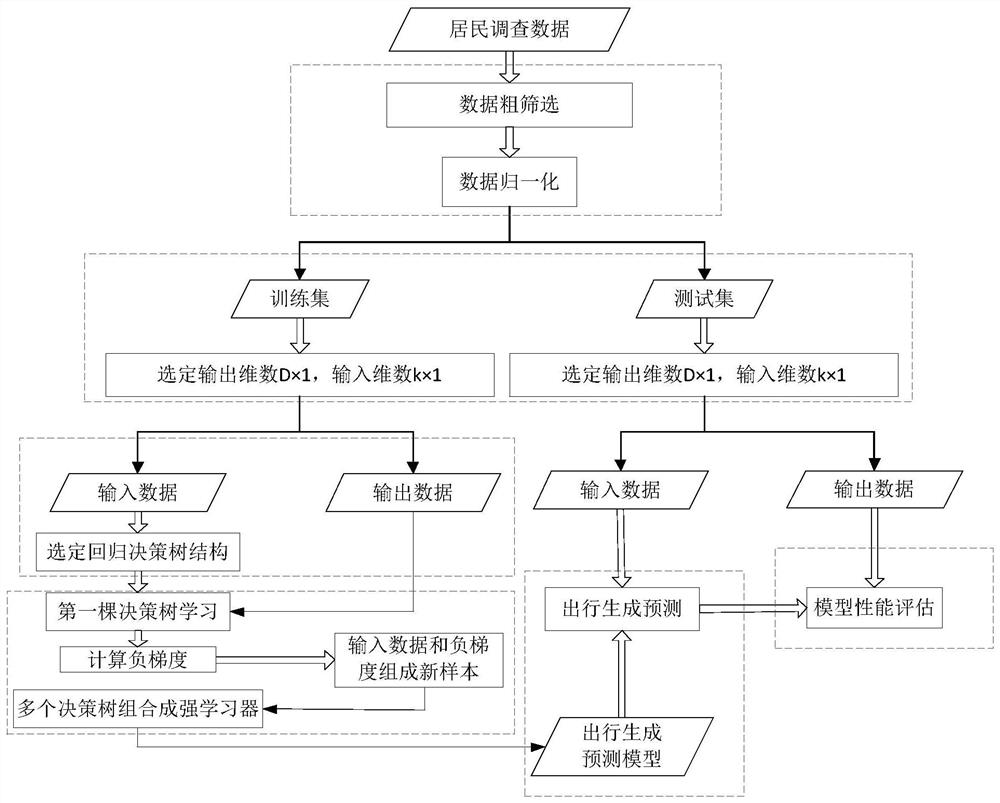

Travel generation prediction method, system and device based on gradient boosting decision tree

ActiveCN111784084AImprove accuracy and robustnessModel parameter verification process is simpleForecastingCharacter and pattern recognitionIndependent predictorPrediction methods

The invention belongs to the field of population travel generation and prediction, particularly relates to a travel generation and prediction method, system and device based on a gradient boosting decision tree, thereby solving problems that an existing travel generation method cannot truly reflect the nonlinear relationship between an input value and prediction, the model inspection calculation amount is large, and a result is not visual. The method comprises the steps: extracting independent variables of current travel generation data of each traffic cell in a to-be-predicted area, and performing normalization processing; obtaining a prediction value of each current traffic cell of the to-be-predicted area through a travel generation prediction model; and carrying out reverse normalization on the prediction values to obtain prediction travel generation data of each current traffic cell of the to-be-predicted area. According to the method, the nonlinear relation between original inputand output can be accurately reflected, the square error principle is used for searching the minimum division characteristic and division points, redundant variables are automatically ignored, the manual screening process of the variables is omitted, and high precision and robustness are achieved.

Owner:北京市城市规划设计研究院 +1

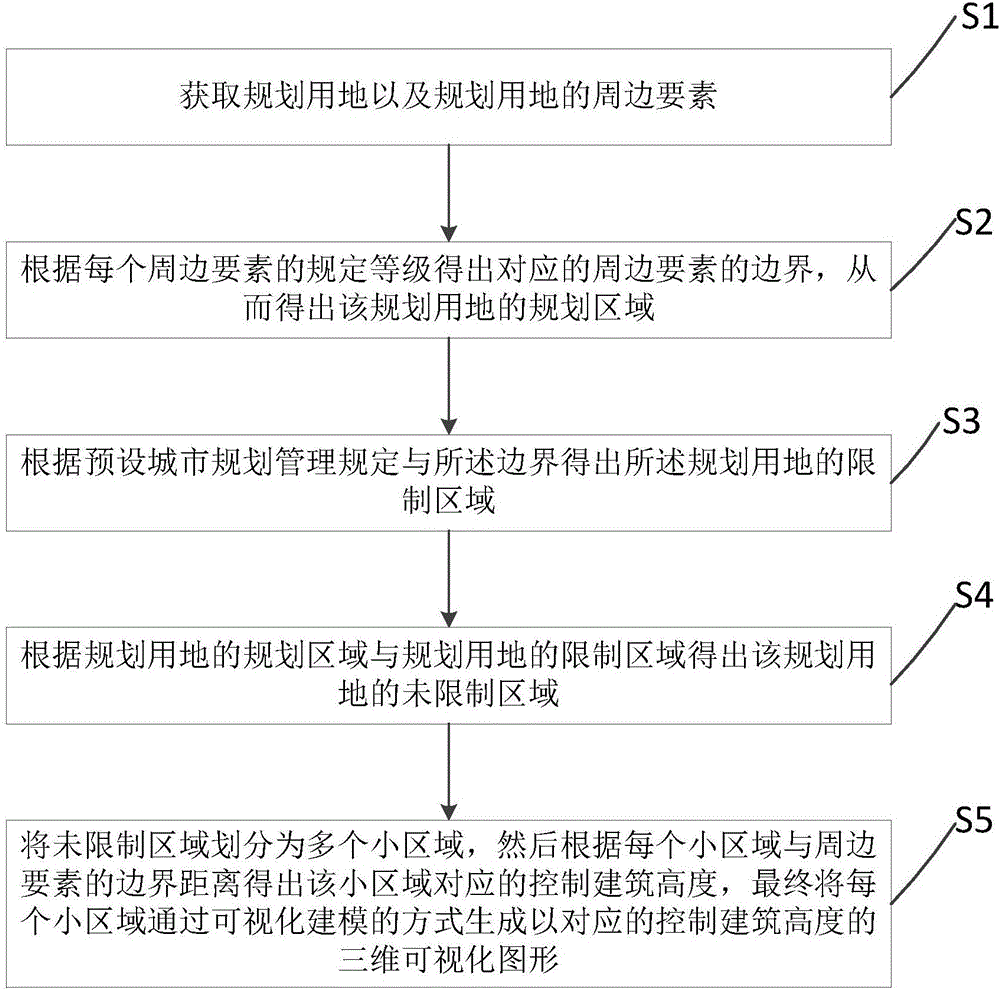

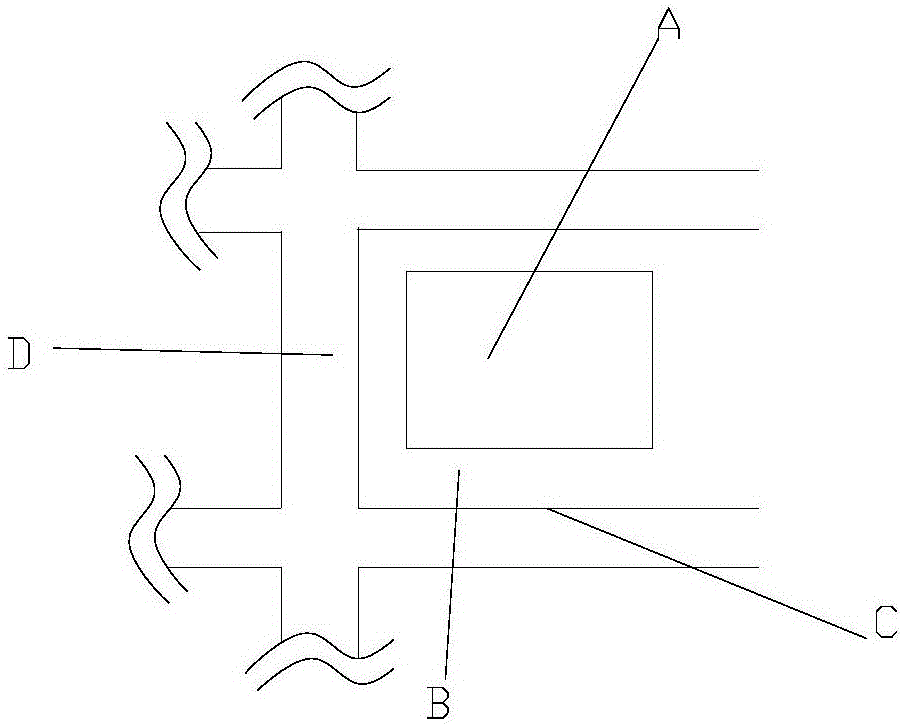

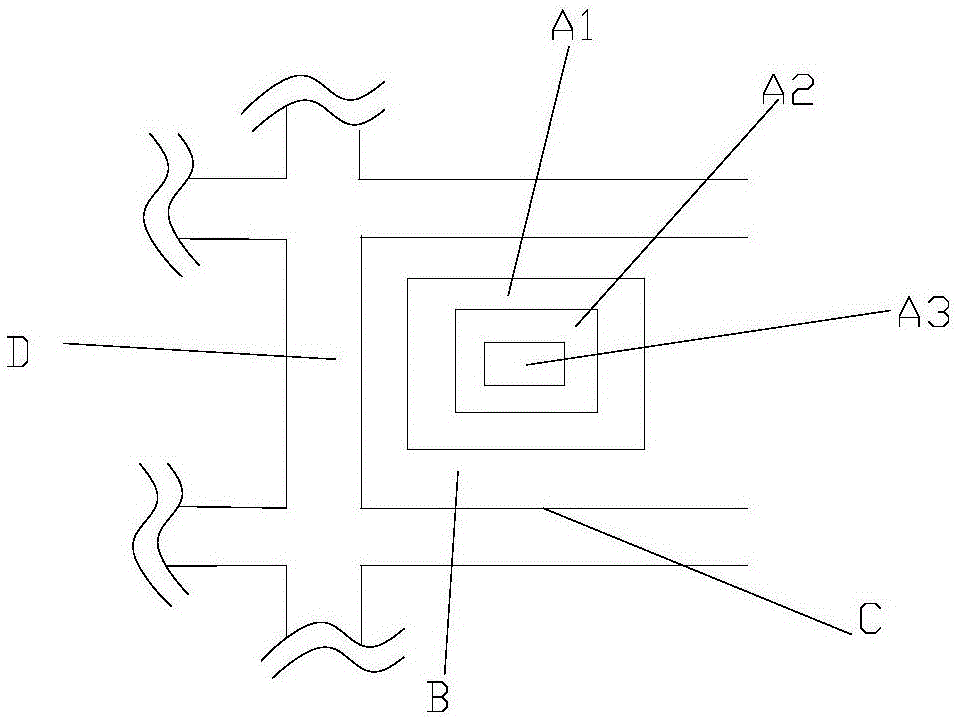

City planning management control processing method and system

The invention discloses a city planning management control processing method and system. The method comprises the steps of obtaining a planning land and all surrounding elements of the planning land; obtaining corresponding surrounding element boundaries according to regulations of the surrounding elements so as to obtain a planning region, a limited region and an unlimited region of the planning land; and dividing the unlimited region into a plurality of small regions, then obtaining corresponding controlled building heights of the small regions according to the distances between the small regions and the surrounding element boundaries, and finally generating three-dimensional visual graphs with the corresponding controlled building heights in a visual modeling mode by the small regions. According to the method and the system, the regions of the planning land are defined and are represented through the three-dimensional visual graphs, so that an existing building planning scheme can be checked very conveniently and intuitively.

Owner:GUANGZHOU YIDONG NETWORK TECH

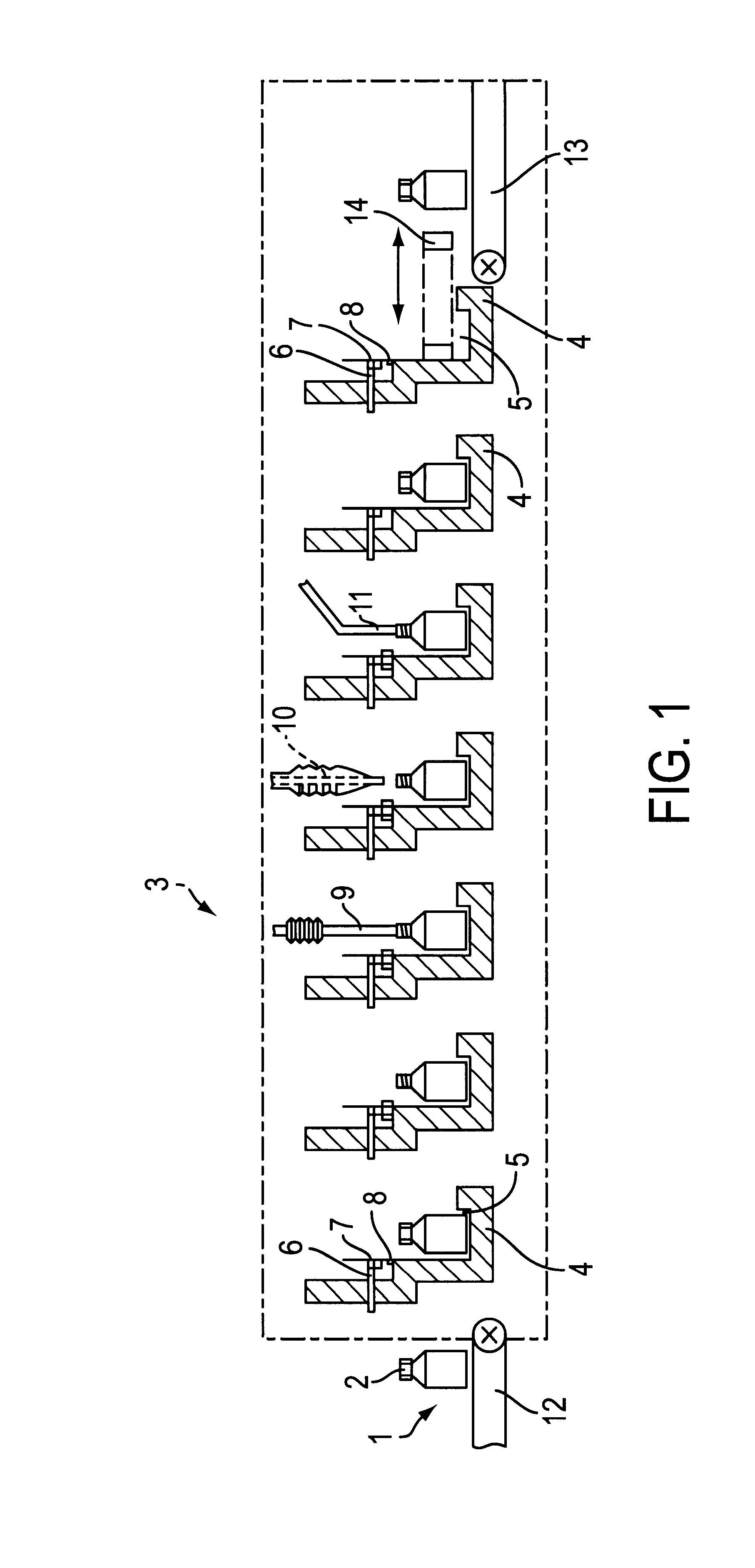

Printed circuit board inspection system combining x-ray inspection and visual inspection

ActiveUS20070104315A1Cost reductionSimplify inspection systemMaterial analysis by optical meansUsing wave/particle radiation meansX ray imagePrinted circuit board

A circuit board inspection system combining an X-RAY inspection and a visual inspection comprises a transfer unit (3) that lands an inspected object (1) safely thereon and transfers the inspected object (1) to a predetermined position; a light generating unit (5) that is installed below the transfer unit (3) and emits a light having a predetermined wavelength to the inspected object (1); a light amplifying unit (7) that is installed on the opposite side of the light generating unit (5) to convert and amplify a predetermined light that transmits the inspected object (1) into a visible light; an optical unit (9) that optically illuminates the inspected object (1) to create a visual image; and a camera (11) that receives an X-ray image amplified through the light amplifying unit (7) or a visual image by the optical unit (9) to obtain information.

Owner:MIRTEC

Work vehicle with engine mounted rearwardly

ActiveUS20130240283A1Improve efficiencyLarge capacityElectric propulsion mountingGas pressure propulsion mountingVehicle frameFuel tank

A work vehicle includes a vehicle frame extending between a right and left pair of rear wheels. An engine is mounted in a vertical position on a horizontal mounting surface defined in the vehicle frame in a peripheral area of the rear wheels in a central portion of a transverse direction of the vehicle. A fuel tank includes a main tank body mounted under a driver's seat and an auxiliary tank body mounted on the mounting surface on one lateral side of the engine in the transverse direction of the vehicle. A canister is mounted adjacent to the engine on one lateral side of the engine and rearwardly of and adjacent to the auxiliary fuel tank.

Owner:KUBOTA LTD

Pipeline laying construction method combining non-excavation jacking and liquid nitrogen horizontal freezing excavation laying

InactiveCN101749485AIncreased intensityRapid build-up of strengthPipe laying and repairUltimate tensile strengthSoil horizon

The invention relates to a pipeline laying construction method combining non-excavation jacking and liquid nitrogen horizontal freezing excavation laying. The invention is characterized in that liquid nitrogen horizontal freezing reinforcement is carried out in a receiving well area; a solidification area with certain soil layer strength is formed in an excavation area; and when the non-excavation jacking technology construction approaches the receiving well area, horizontal soil body excavating is carried out in the solidification area to lay pipe sections which are combined with the pipe sections jacked by the non-excavation jacking technology construction, thereby forming underground pipelines.

Owner:SHANGHAI MECHANIZED CONSTR GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com