Anchor rod device

A bolt and self-anchoring technology, which is applied to the installation of bolts, sheet pile walls, mining equipment, etc., can solve the problems of being unable to determine whether the pre-tightening force of the bolt is too large or insufficient, unable to measure the torque, and restricting the installation of the bolt.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

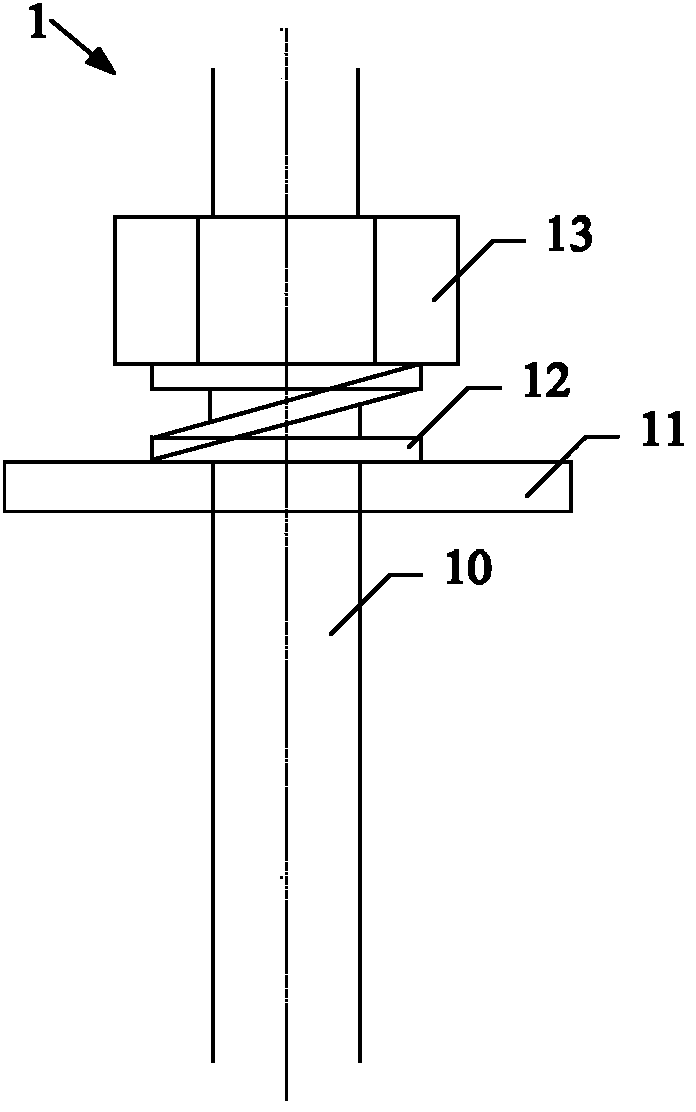

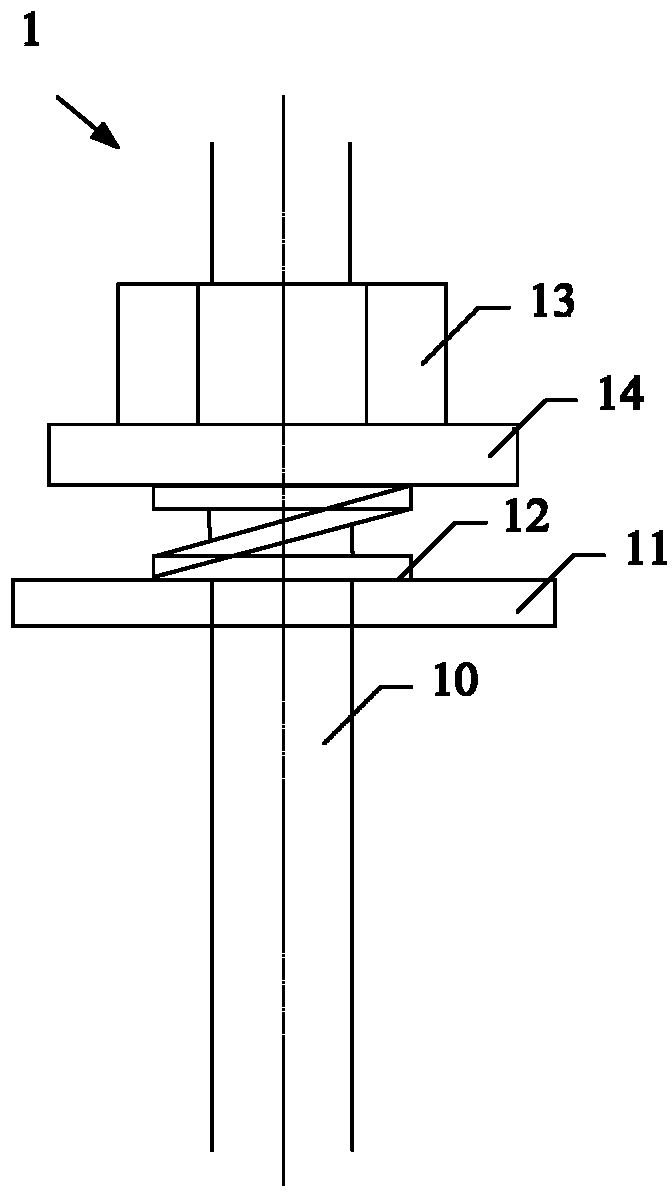

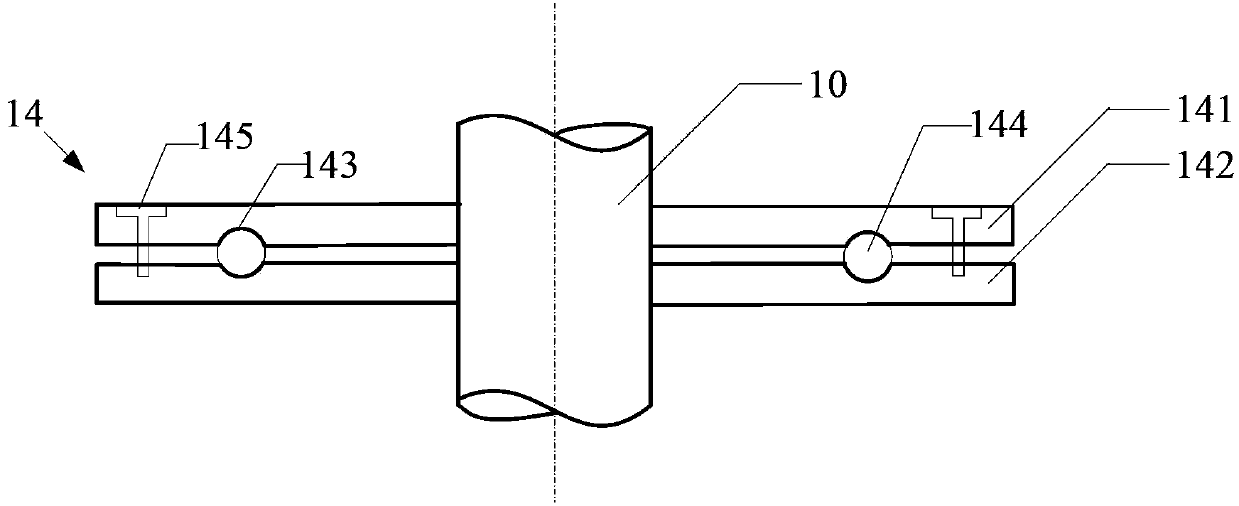

[0022] figure 1 A schematic structural view of the first embodiment of the anchor device provided by the present invention, such as figure 1 As shown, the bolt device 1 includes:

[0023] The anchor rod 10, and the anchor rod supporting plate 11, the spring 12 and the nut 13 are sequentially sleeved on the anchor rod from the axial center outward of the anchor rod.

[0024] By installing the anchor rod 10, the rock wall can be reinforced, mainly through the longitudinal tension of the rod body of the anchor rod 10, to overcome the shortcoming that the tensile capacity of the rock and soil body is far lower than the compressive capacity. On the surface, it can be seen as limiting the separation of rock and soil from the original body. Macroscopically, it can be seen as increasing the cohesion of rock and soil. From a mechanical point of view, it can be seen as improving the cohesion and internal friction angle of the surrounding rock mass.

[0025] It should be noted that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com