Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

96results about How to "Installed in place" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

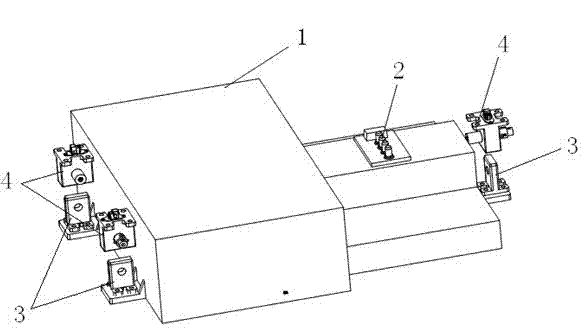

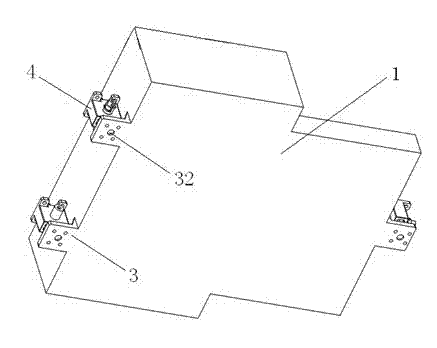

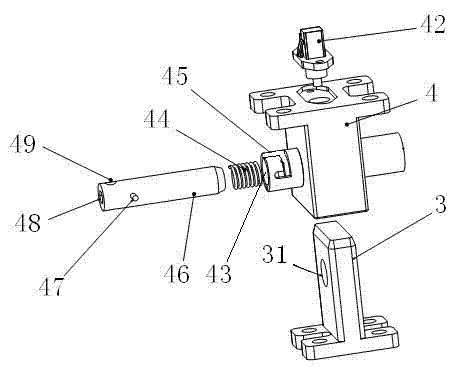

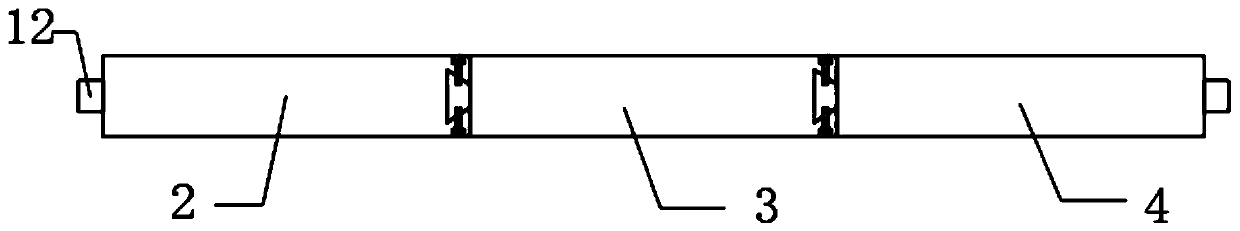

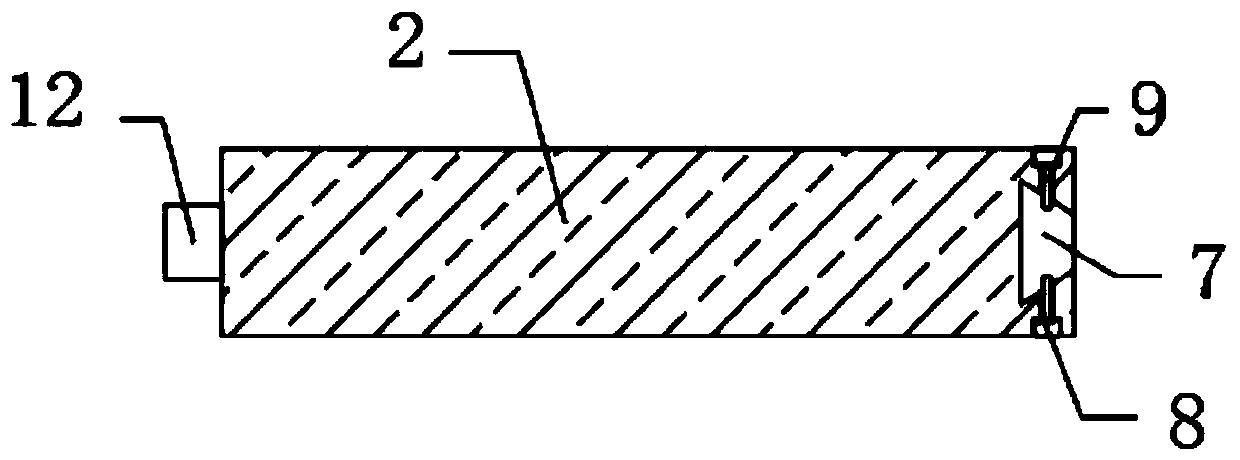

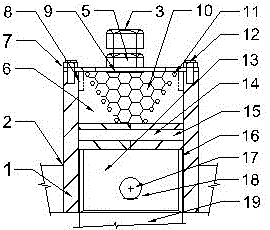

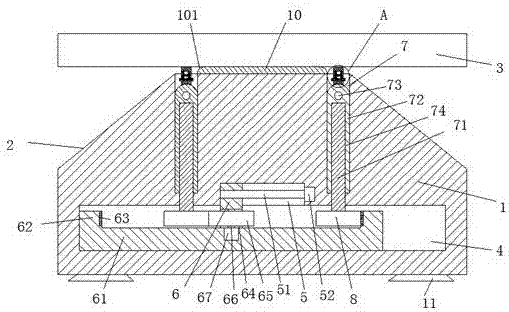

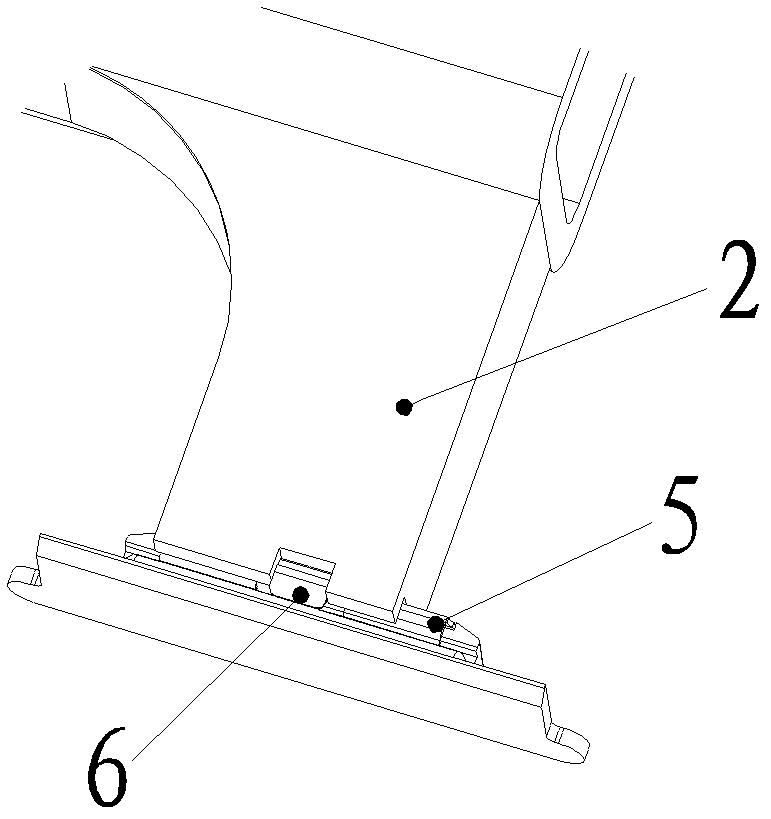

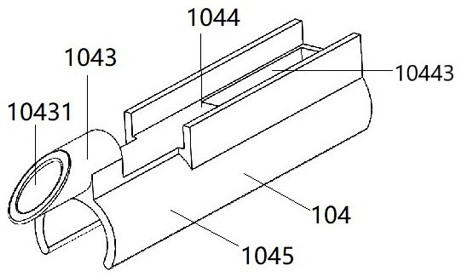

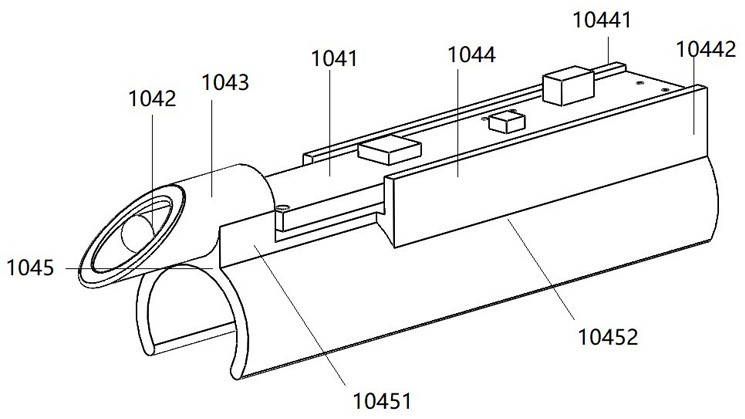

Mounting structure of battery of electric vehicle

ActiveCN102514471AGuaranteed reliabilityImprove installation efficiencyElectric propulsion mountingElectric vehicle charging technologyElectrical batteryEngineering

The invention aims to provide a mounting structure of a battery of an electric vehicle, wherein the battery of the electric vehicle can be replaced quickly and reliably by the aid of the mounting structure. The mounting structure of the battery of the electric vehicle comprises a battery jar and a connecting terminal mounted on the battery jar. The mounting structure is characterized in that mounting blocks are convexly disposed on the battery jar, the mounting structure of the battery further comprises mounting seats fixed to a vehicle body, the mounting seats are provided with positioning holes, the shape of each positioning hole matches with that of each mounting block, the mounting seat is provided with detection switches which are used for detecting in-place states of the mounting blocks, each detection switch is disposed at one end of the corresponding positioning hole, and the mounting seats are connected with the mounting blocks by hinge pins. The mounting structure of the battery of the electric vehicle realizes connection by the aid of the hinge pins, and is provided with guiding devices and the detection switches, accordingly, the battery can be positioned precisely, a connection state of the battery can be monitored in real time, and the mounting structure is simple in connection and extremely convenient in installation and detachment.

Owner:奇瑞新能源汽车股份有限公司

Automatic boxing device and method for canned products in gift box

Owner:HANGZHOU WAHAHA PRECISION MACHINERY

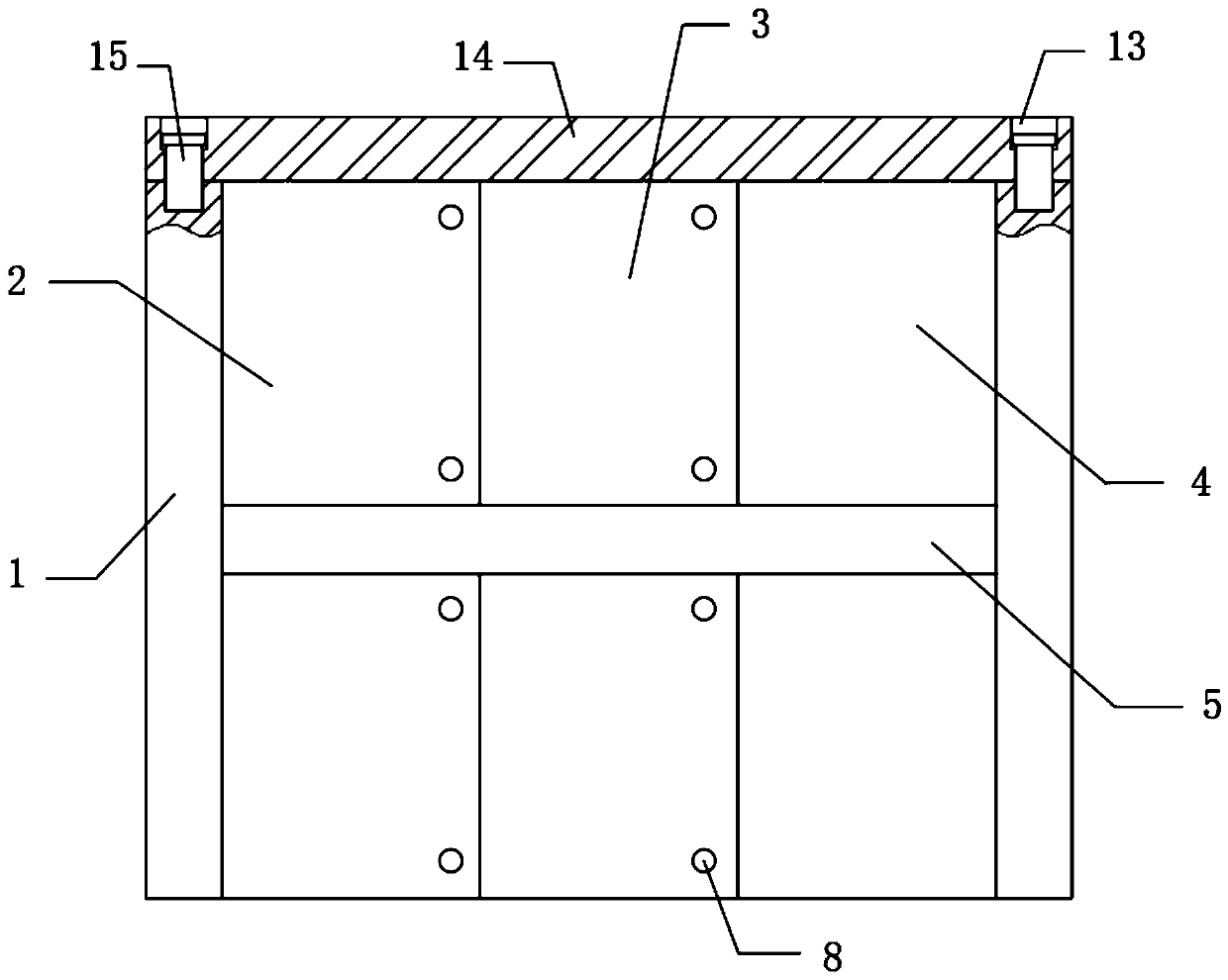

Energy-saving and environment-friendly fabricated wall and assembly method thereof

InactiveCN111236470AReduce areaReduce weightWallsHeat proofingStructural engineeringMechanical engineering

The invention discloses an energy-saving and environment-friendly fabricated wall and an assembly method thereof, and belongs to the field of fabricated buildings. The energy-saving and environment-friendly fabricated wall comprises two supporting columns, a plurality of groups of first wall bodies, second wall bodies and third wall bodies are arranged between the two supporting columns, and the first wall bodies, the second wall bodies and the third wall bodies are connected in a spliced mode, a partition plate is arranged between the two supporting columns and located between every two adjacent sets of the first wall bodies, the second wall bodies and the third wall bodies, inserting grooves are formed in one sides of the first wall bodies and one sides of the second wall bodies, and first inserting blocks matched with the inserting grooves are fixedly connected to one sides of the second wall bodies. Rapid installation of fabricated wall can be achieved, the area and the weight of asingle wall body are reduced, hoisting equipment is not needed, the installation cost is saved, positioning connection between the wall bodies is achieved through inserting connection of the inserting blocks and the inserting grooves, direct inserting can be achieved during installation, dislocation movement of the wall bodies is prevented, and in-place installation is ensured.

Owner:杜广锋

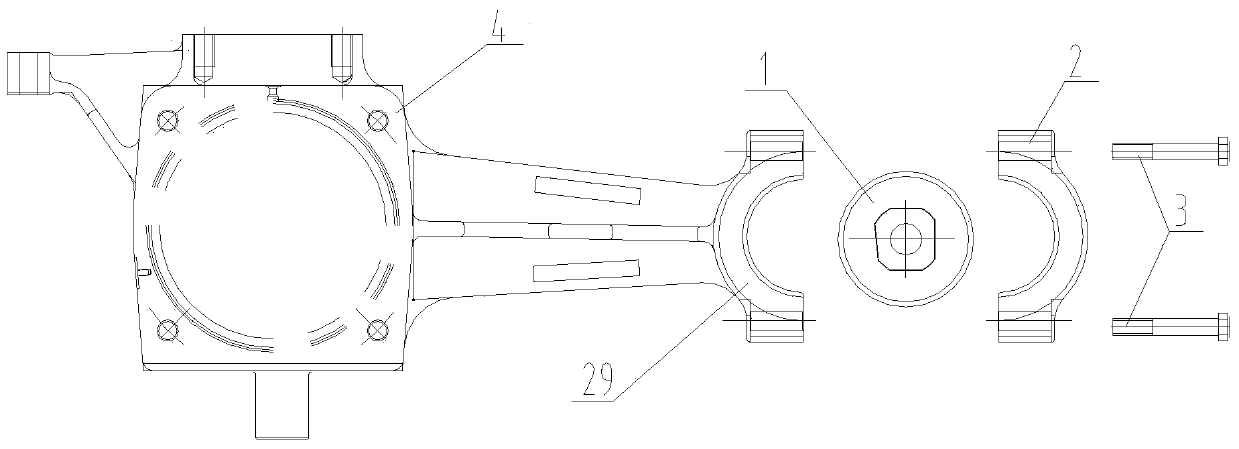

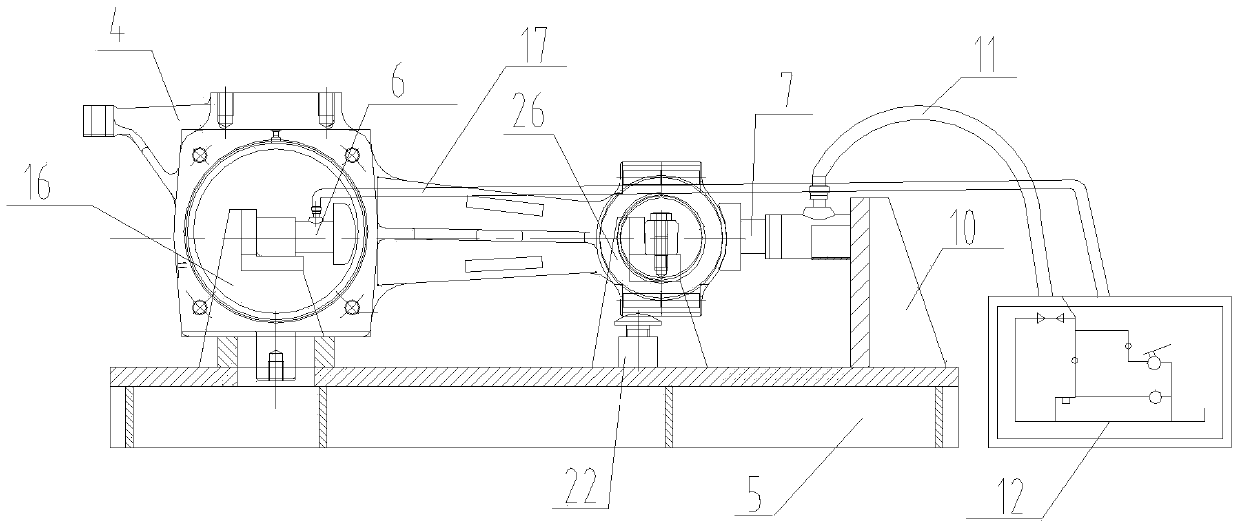

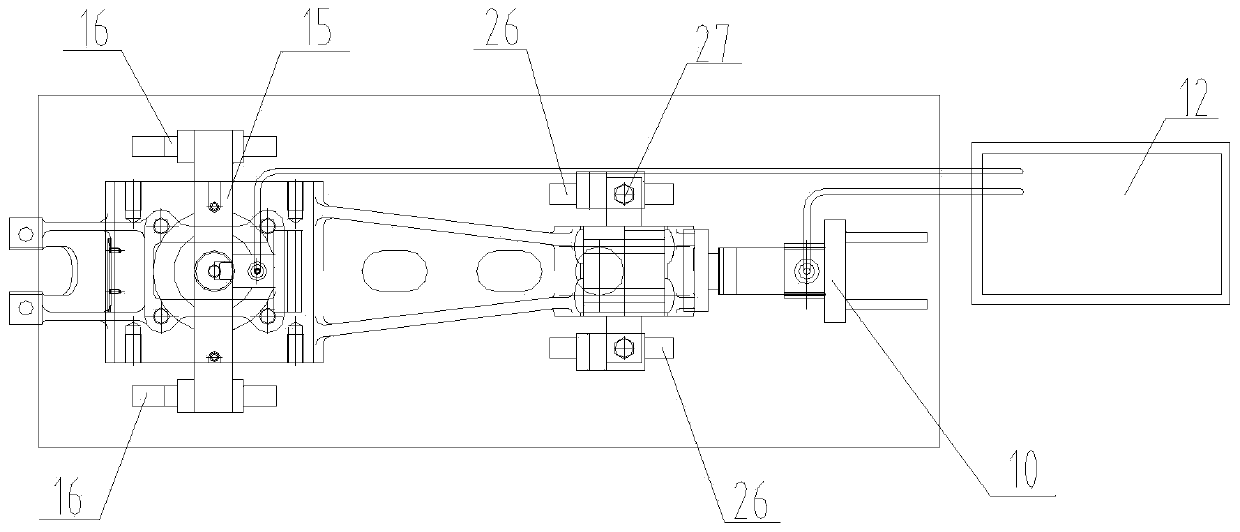

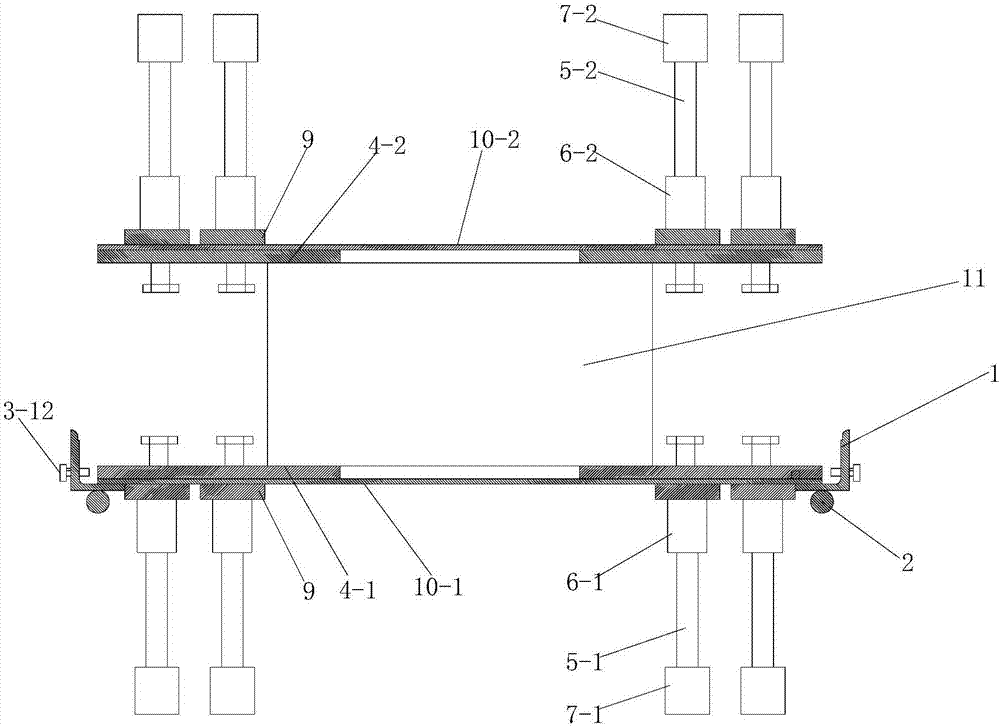

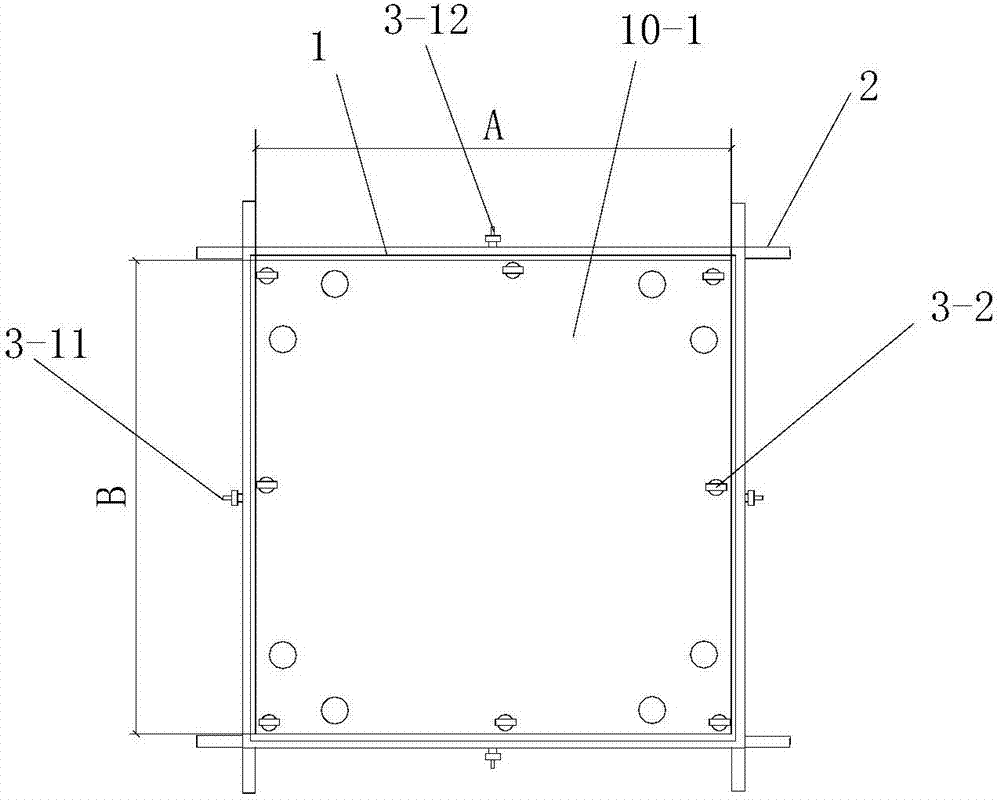

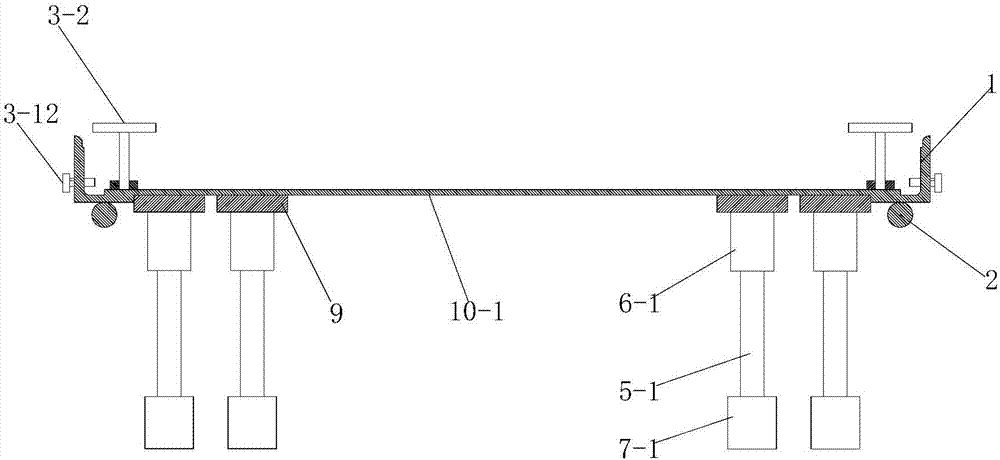

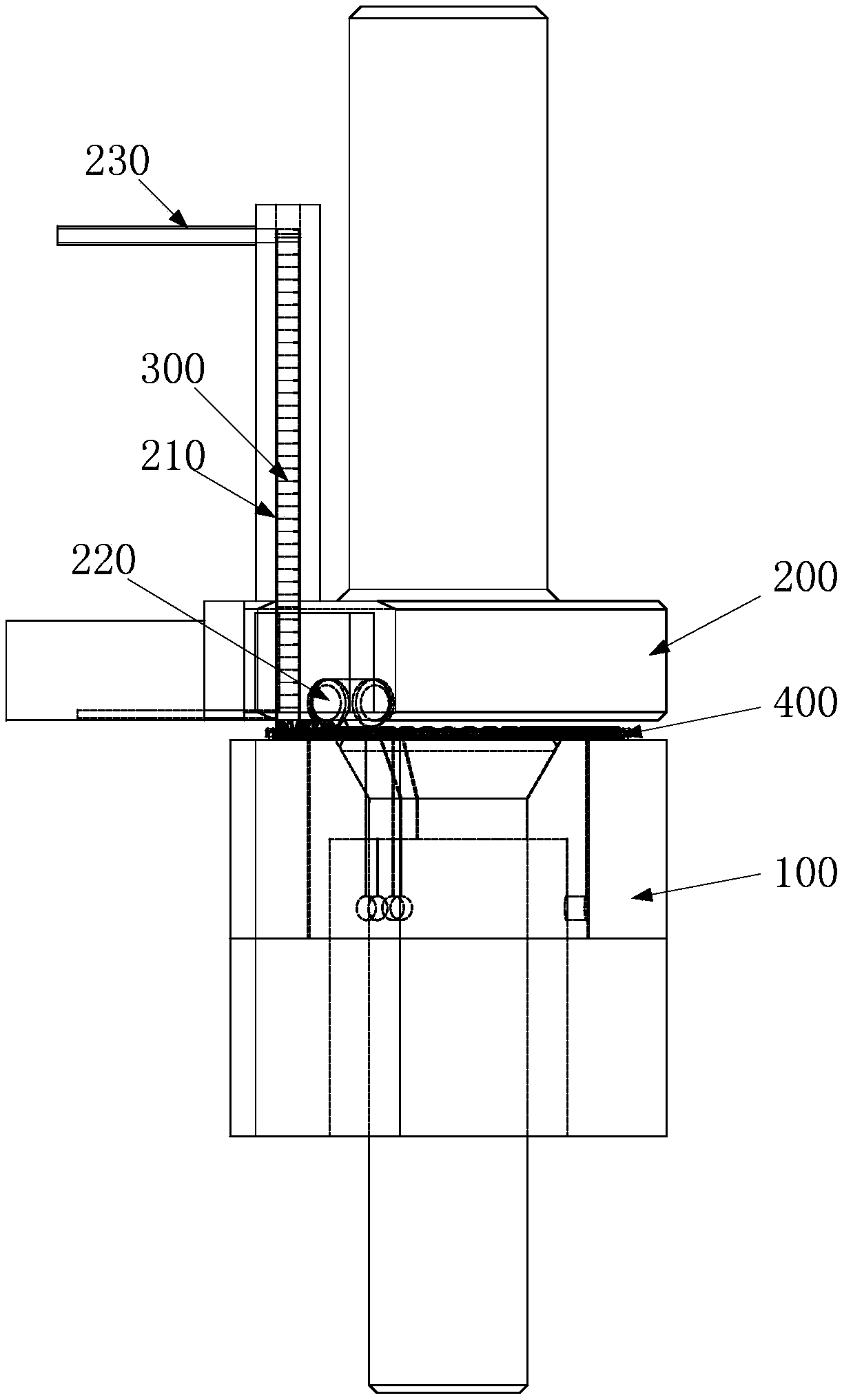

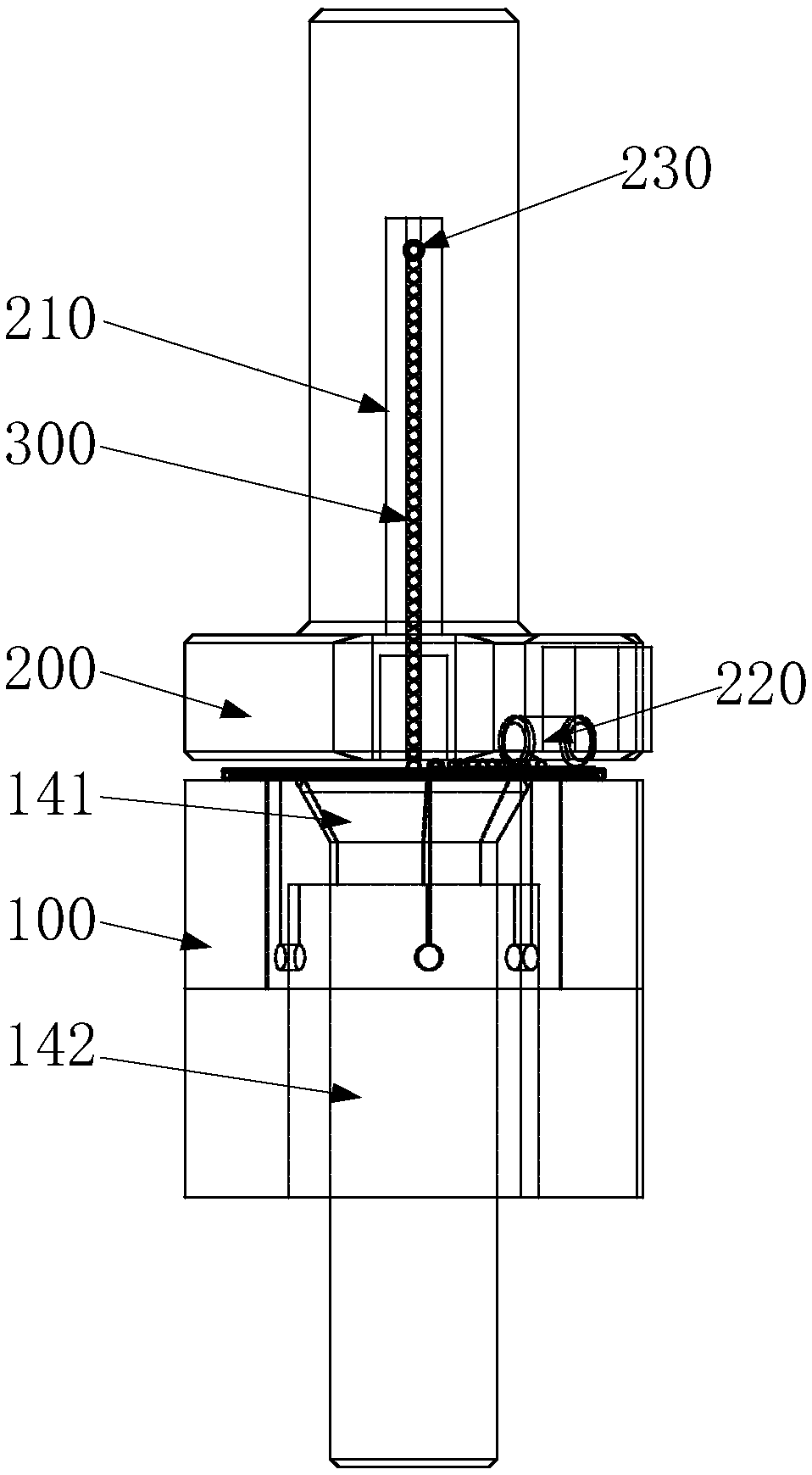

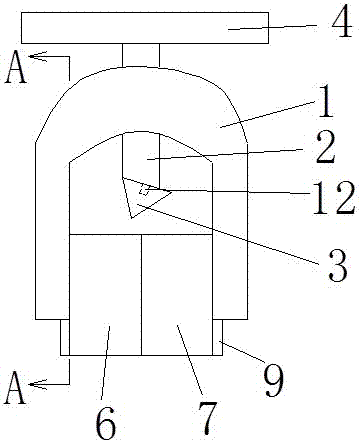

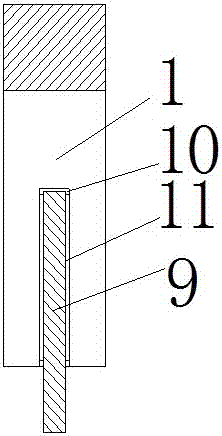

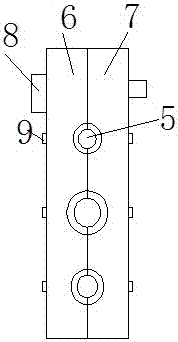

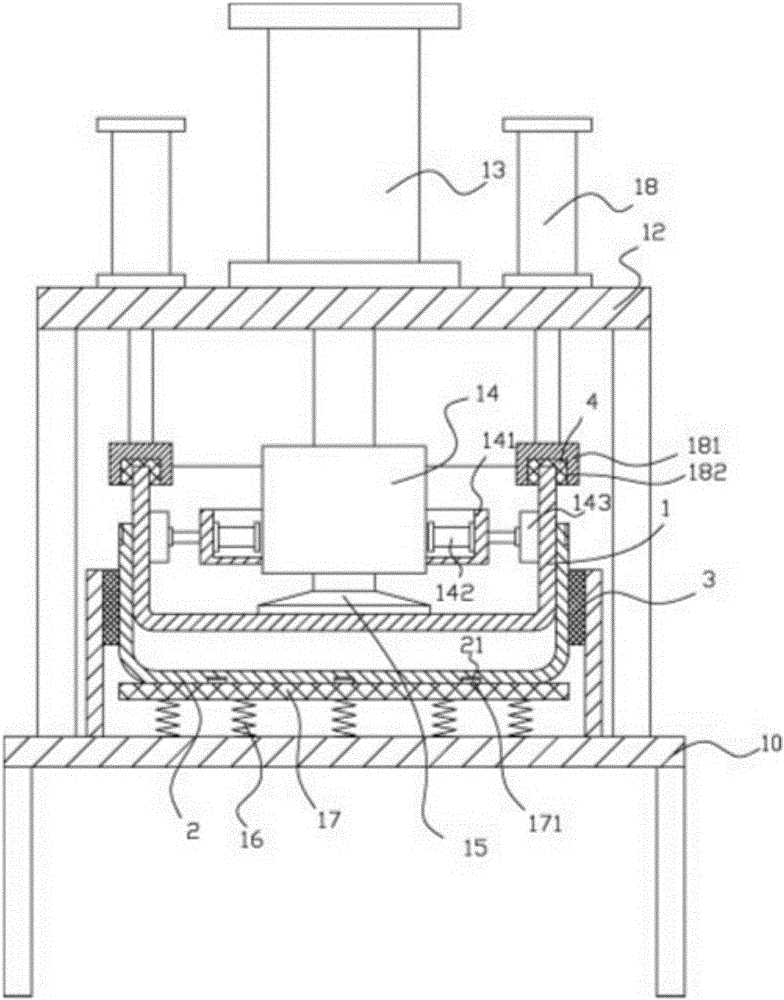

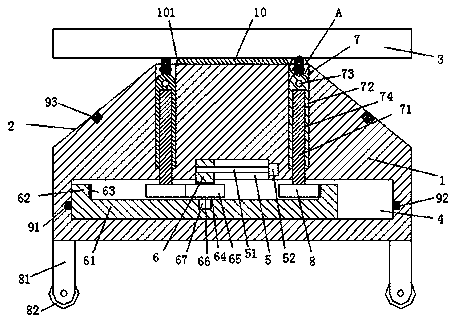

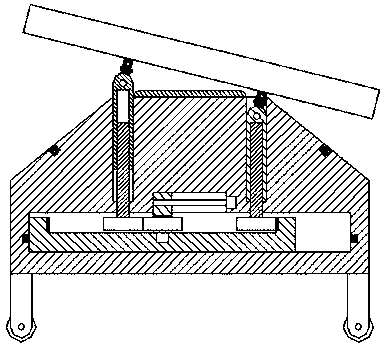

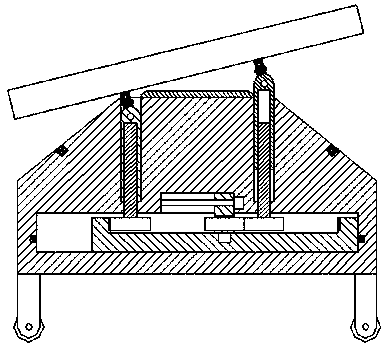

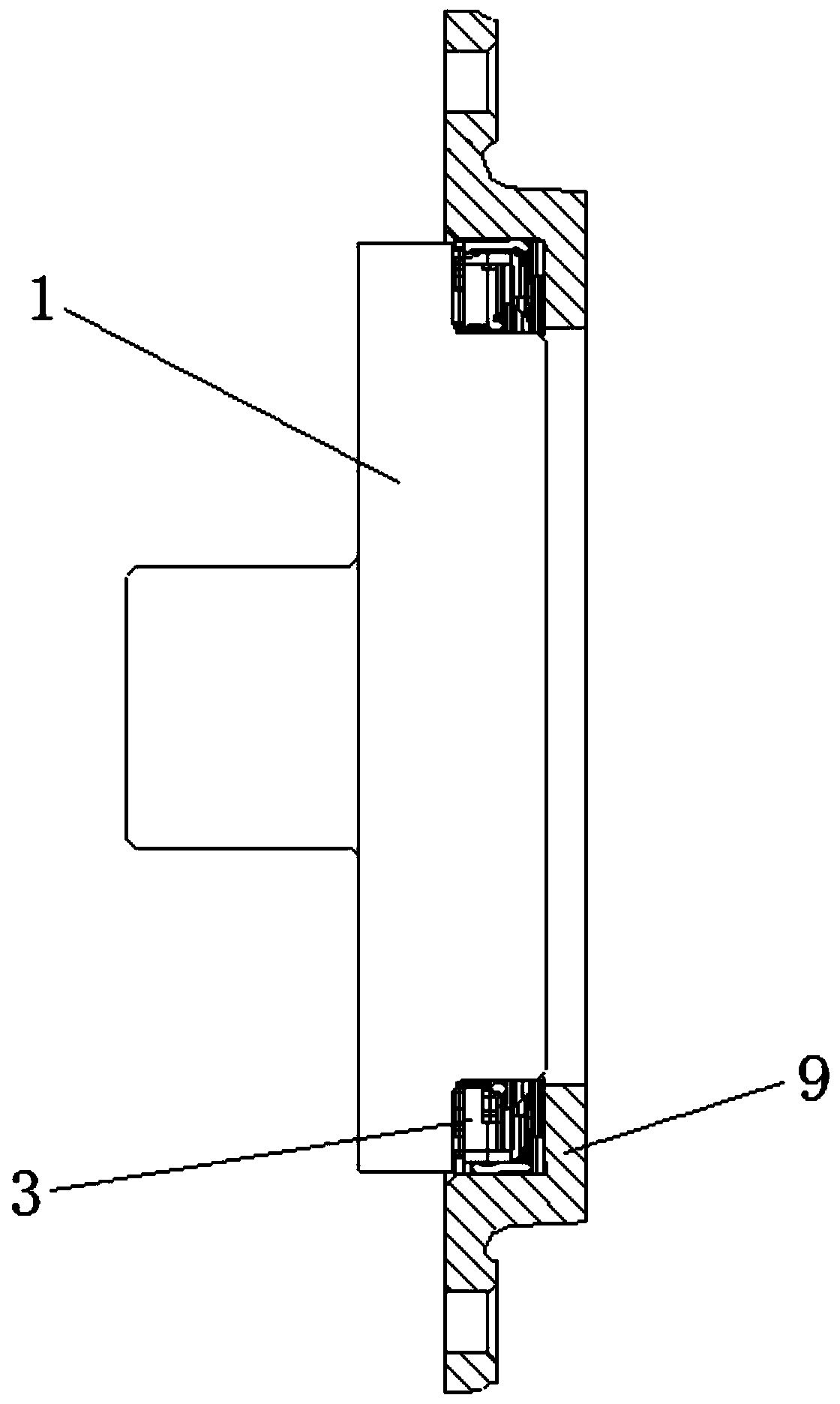

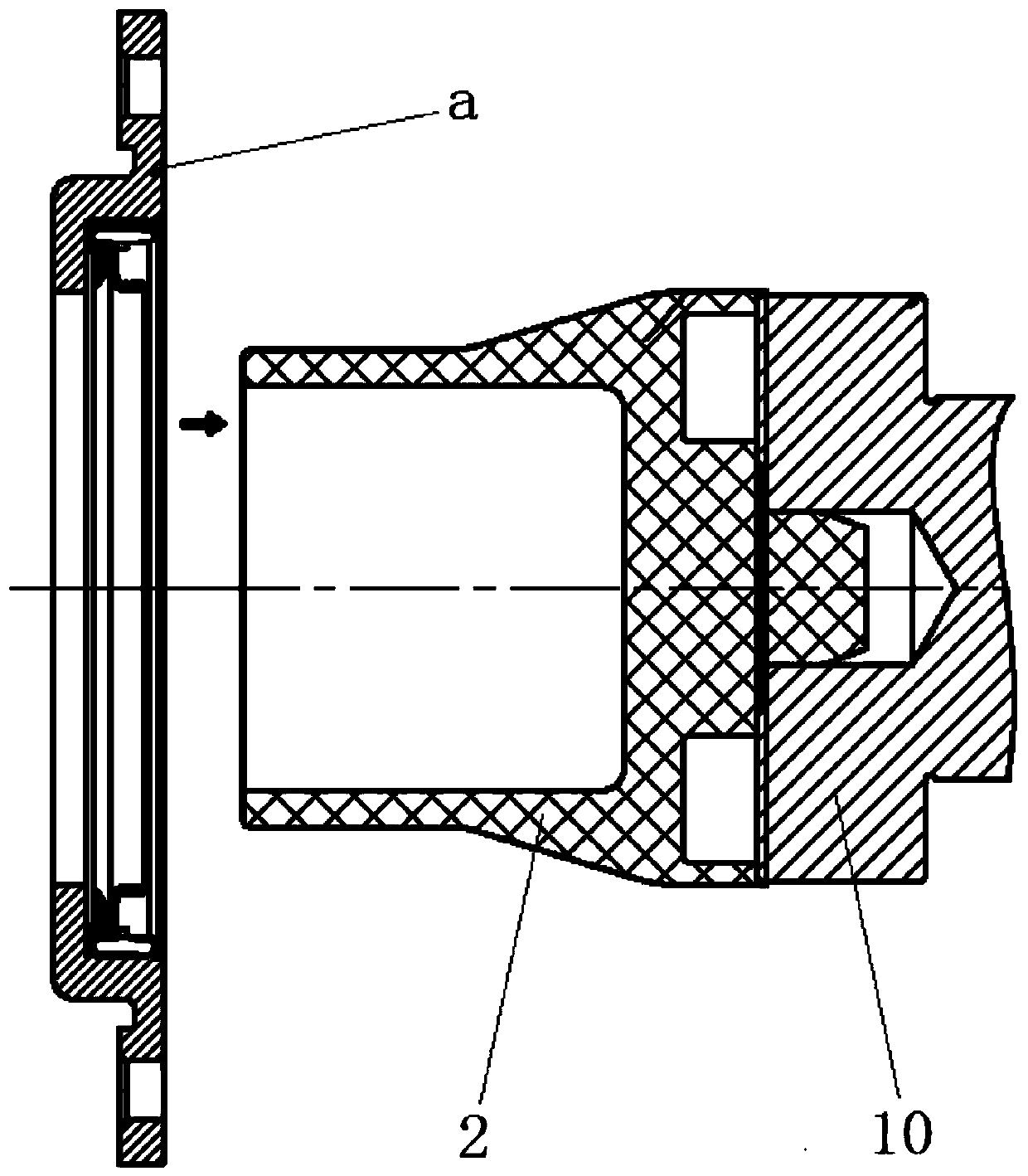

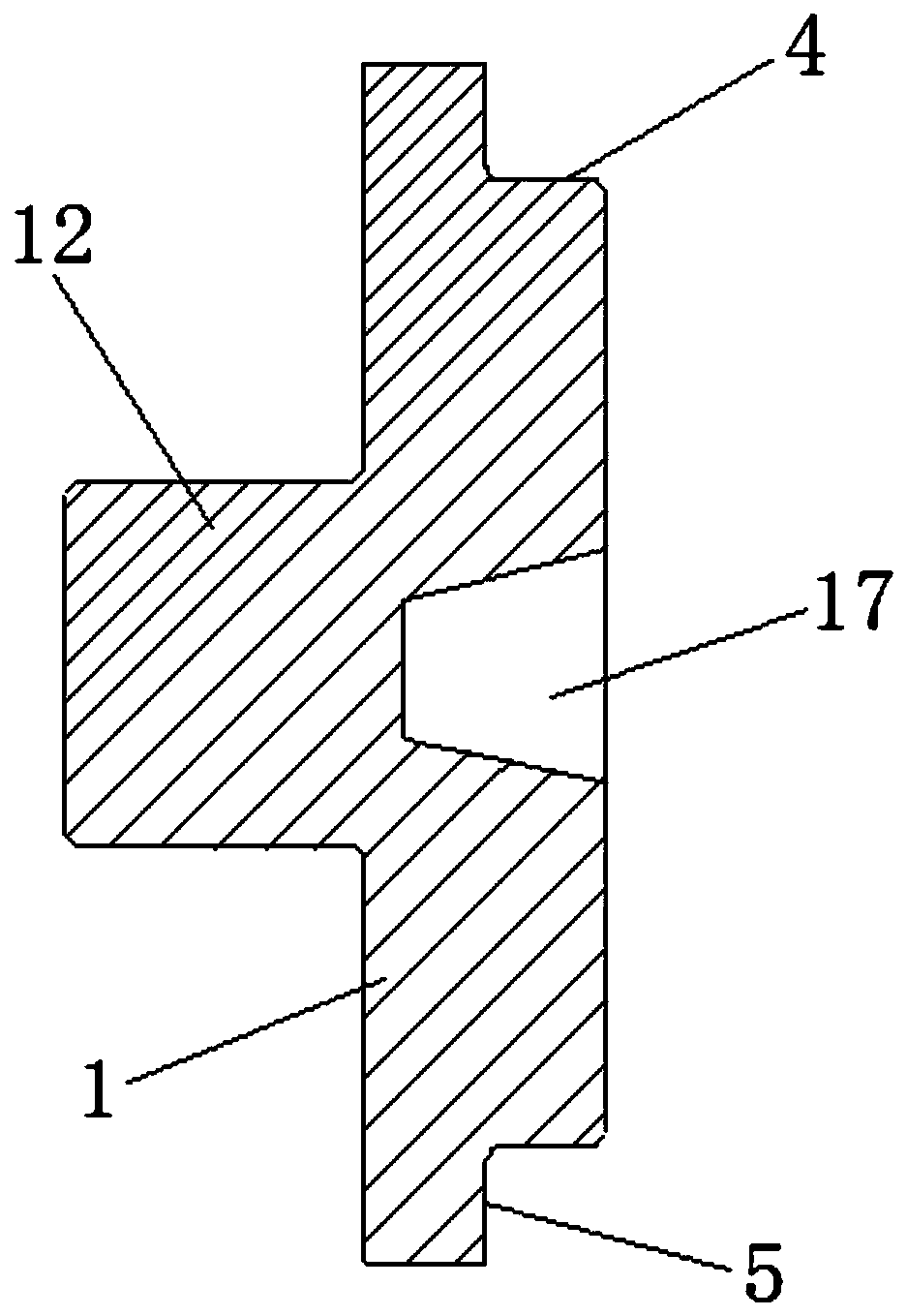

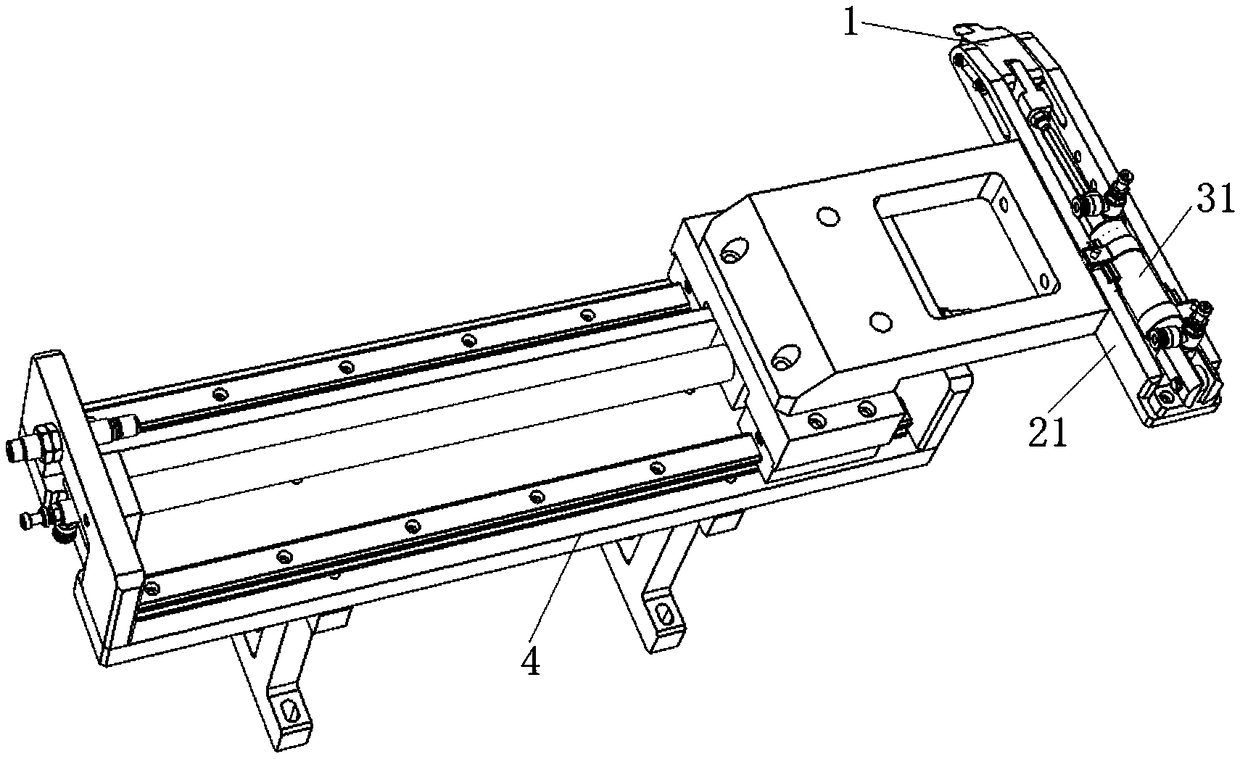

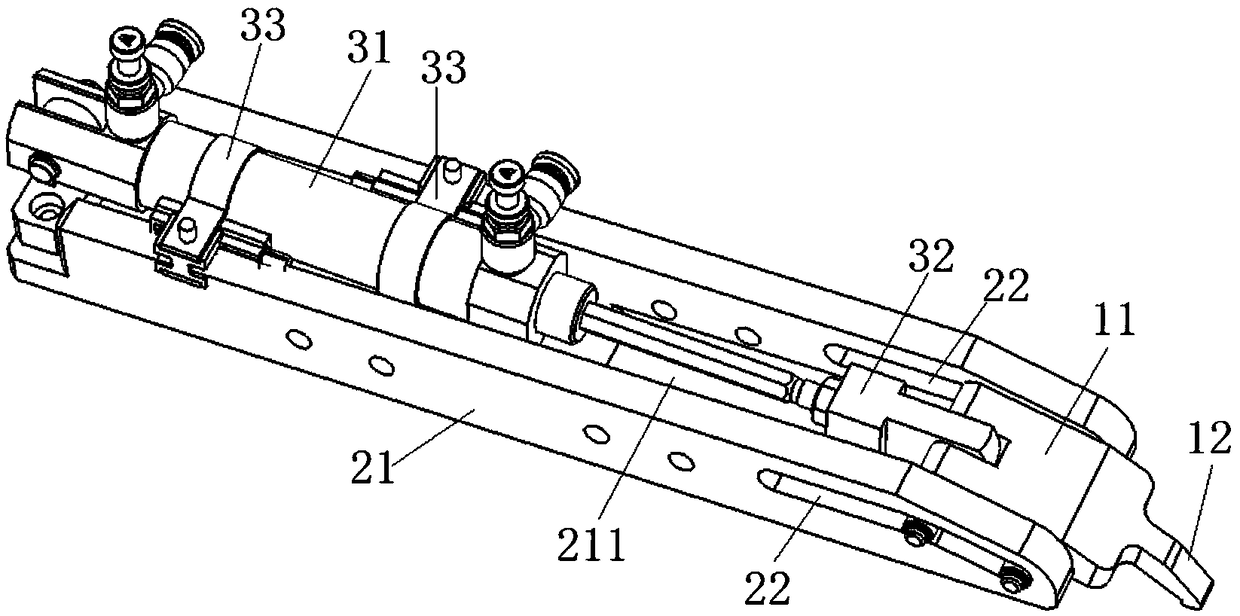

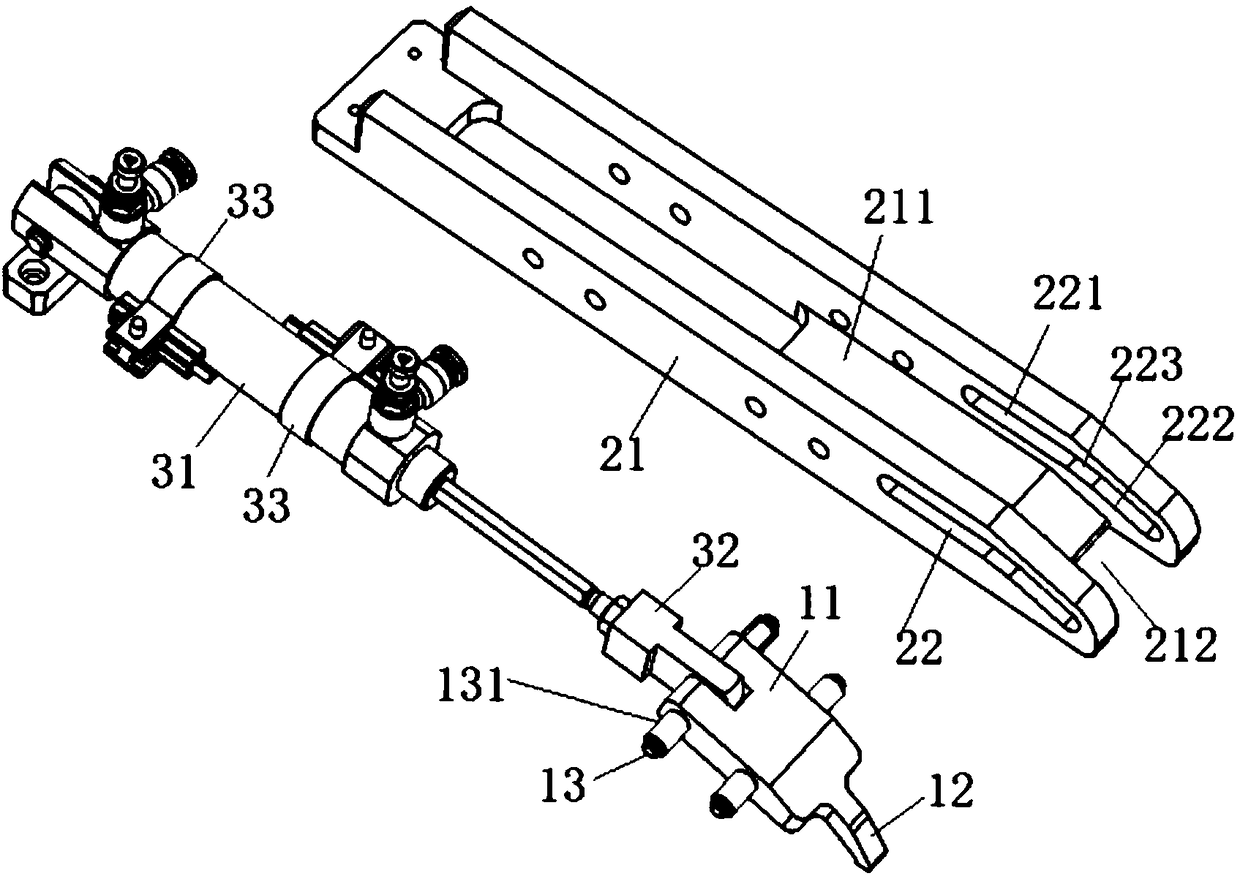

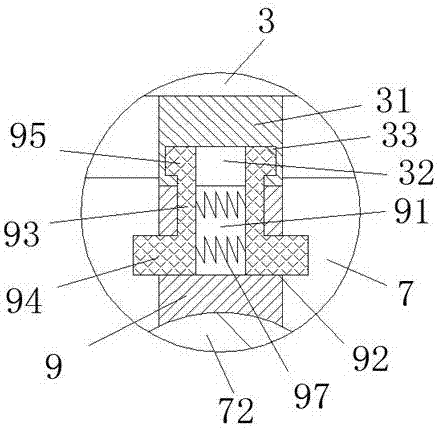

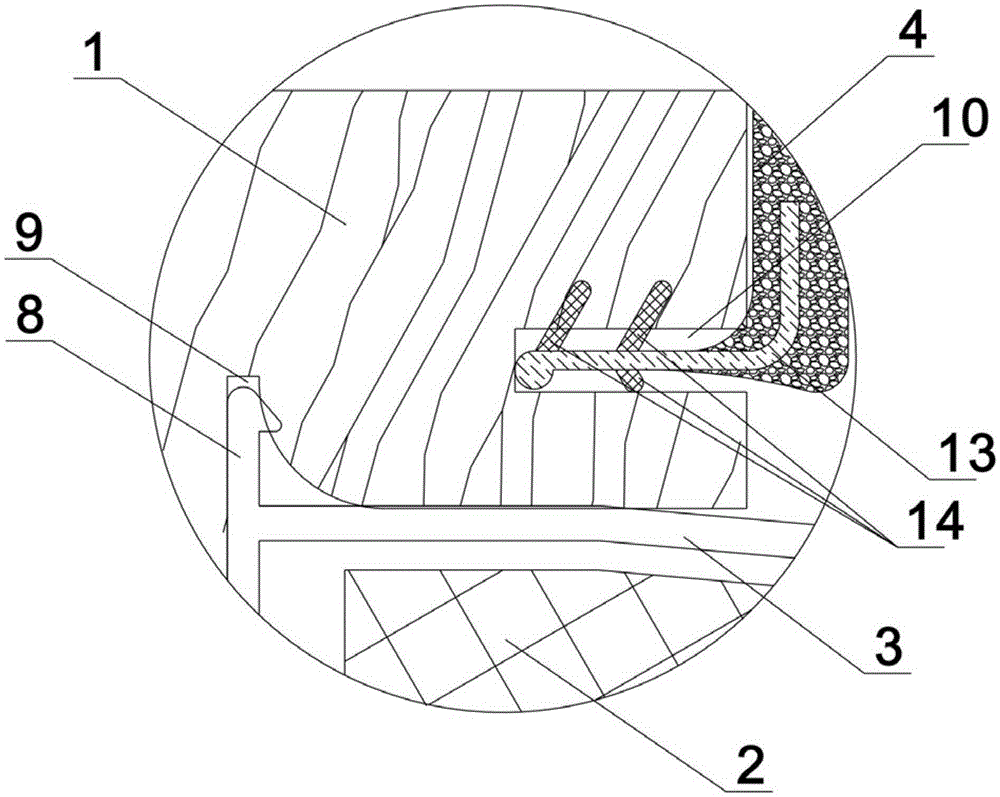

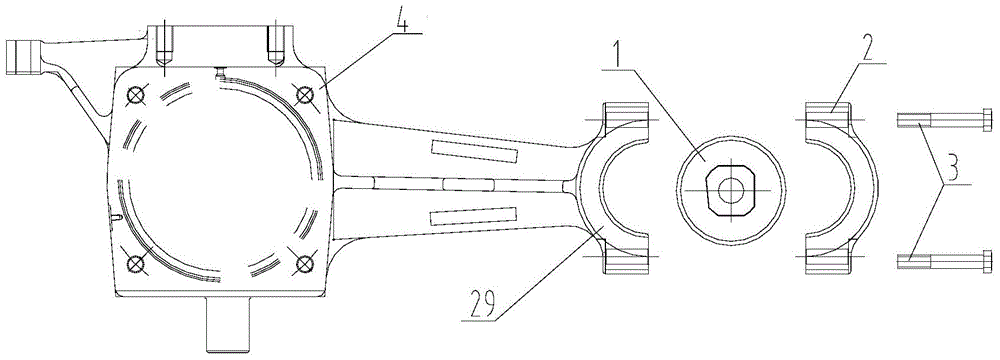

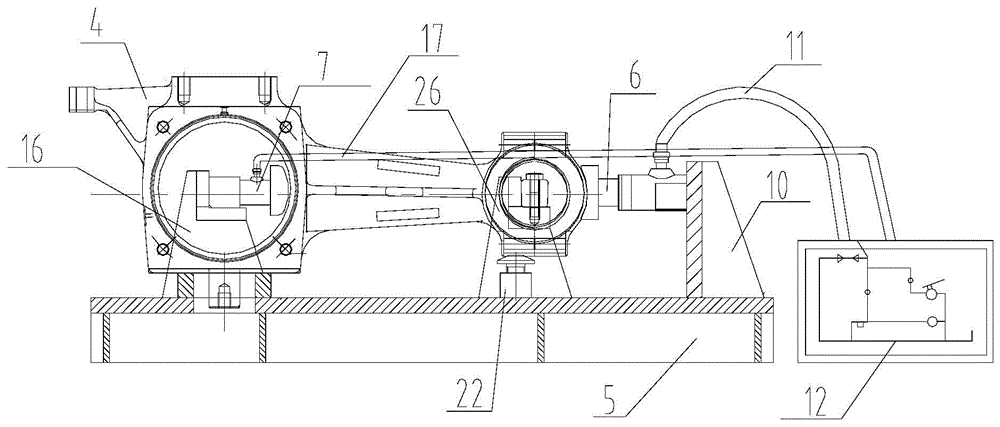

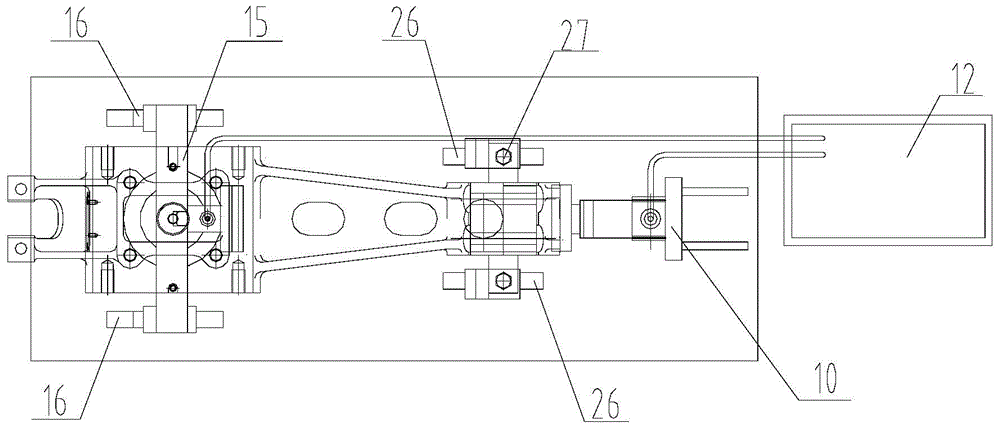

Railway vehicle jib-type axle box locating node assembling device

The invention relates to a railway vehicle jib-type axle box locating node assembling device. The railway vehicle jib-type axle box locating node assembling device comprises an axle box body, a locating node, a gland and bolts, and further comprises a press-fitting platform, a first abutting device and a second abutting device. The axle box body, the locating node, the first abutting device and the second abutting device are fixed onto the press-fitting platform, the first abutting device abuts against the gland from one side to enable the gland to abut against the end portion of the axle box body and the second abutting device abuts against the axle box body to provide back pressure when the axle box body is pressed onto the locating node. The railway vehicle jib-type axle box locating node assembling device is simple and convenient to operate and high in universality, effectively lowers the labor intensity for motor train unit jib-type axle box locating node assembling, improves the production efficiency and meanwhile guarantees the assembling quality.

Owner:CRRC QINGDAO SIFANG CO LTD +1

Tensile clamping and quick assembling and disassembling multipurpose clamp

ActiveCN106736658AFully and evenly lubricatedWork resistance is smallPositioning apparatusMaintainance and safety accessoriesMechanical engineering technologyEngineering

The invention discloses a tensile clamping and quick assembling and disassembling multipurpose clamp, and relates to the technical field of clamp machinery engineering. The tensile clamping and quick assembling and disassembling multipurpose clamp consists of five parts, namely an upper outer sleeve, water storage bins, wedge-shaped clamps, a blade and a lower outer sleeve, wherein the wedge-shaped clamps and tower-shaped springs which are assembled are arranged in the water storage bins of the upper and lower outer sleeves; spring cover plates are covered, and cover plate screws are tightened; tower-shaped sponge is placed in a water dropping hole; the lower outer sleeve is fixed in a square hole of a lower fixture body outer sleeve through two fixing bolts; two ends of the blade are respectively inserted into openings of the wedge-shaped clamps of the upper and lower outer sleeves; clamp chucks are fastened to blade clamping holes; under the action of the tower-shaped springs, the wedge-shaped clamps are set to clamp the blade, and mandril bolts are tightened, so as to fulfill the aim of tensioning and clamping the blade under the mutual action of the wedge-shaped clamps and the wedge-shaped surfaces in the upper and lower outer sleeves, and realize the tensile clamping function; during removal of the blade, the mandril bolts are screwed to the highest points, the upper outer sleeve and the blade are pressed at the same time, and the wedge-shaped clamps compress the tower-shaped springs to reach cover plate locating strips; the blade is rotated to enable the clamp chucks and the blade clamping holes to be separated, and the blade can be pulled out, thus fulfilling the aim of quick assembling and disassembling.

Owner:温智韬

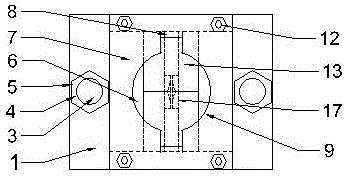

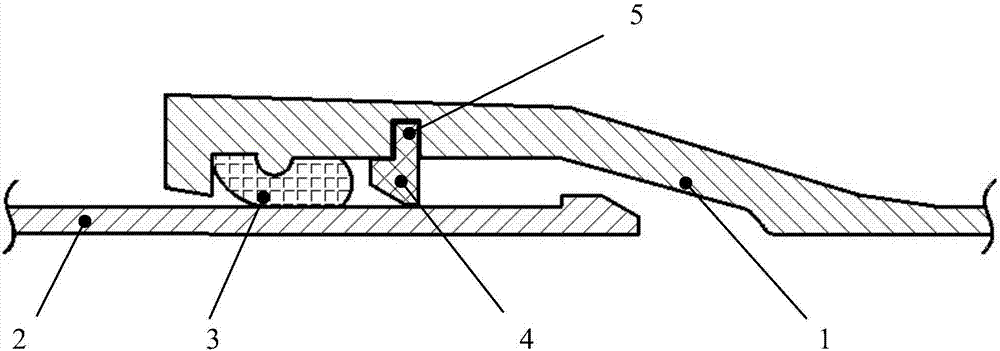

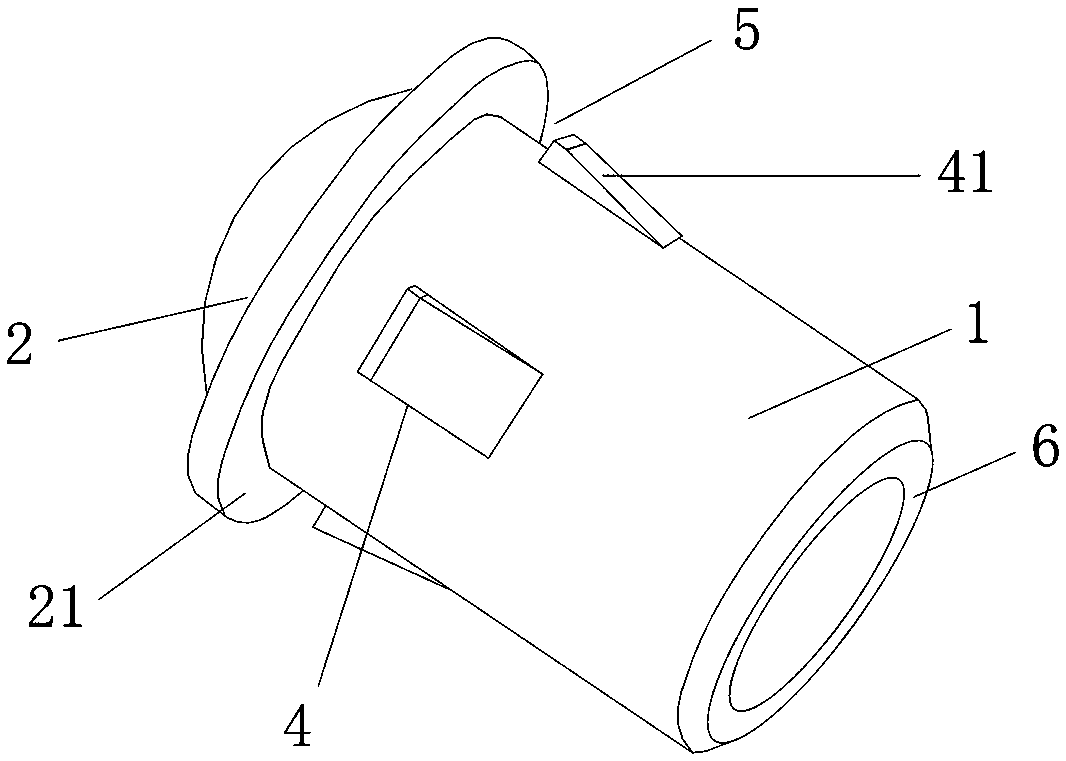

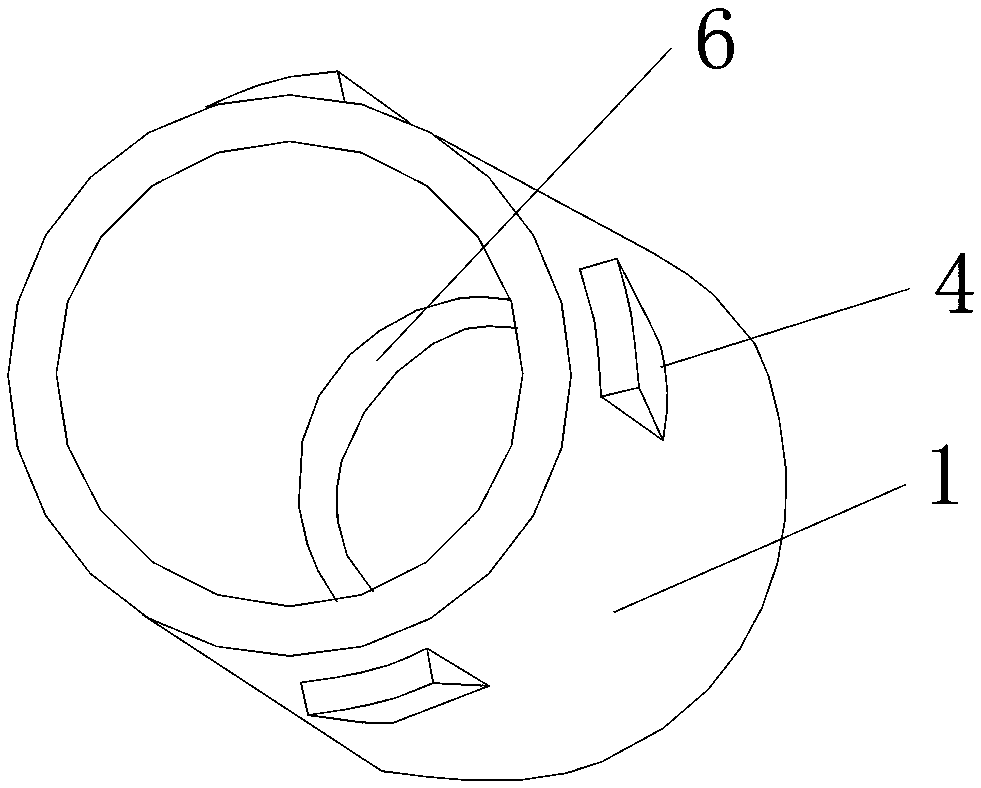

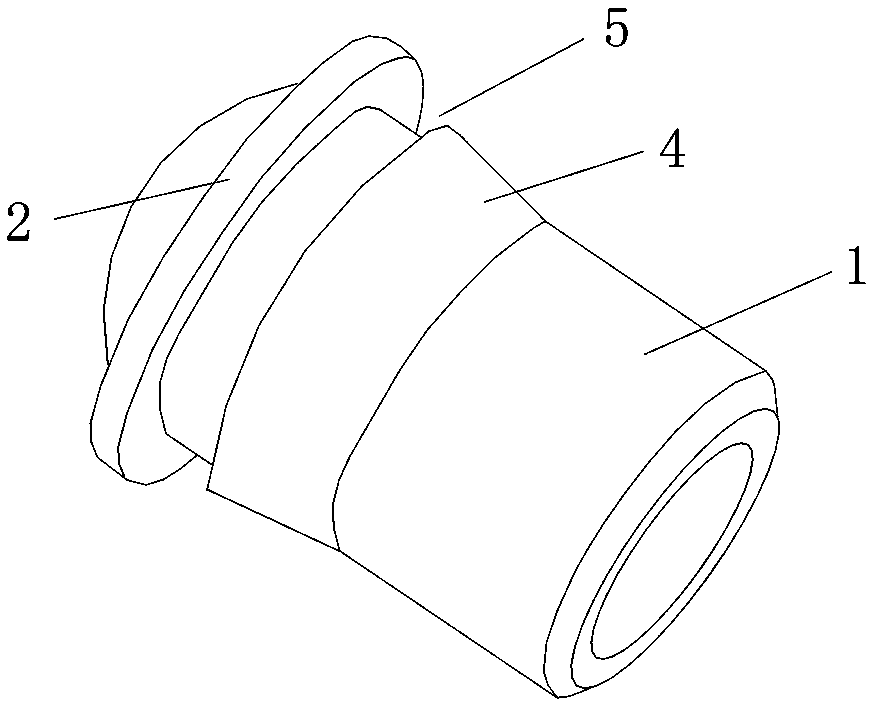

Socket and spigot joint pipeline anti-seismic connector

PendingCN106870850AIncreased lateral shear stiffnessEasy to processCouplingsEarthquake resistantBell mouth

The invention discloses a socket and spigot joint pipeline anti-seismic connector, and relates to a socket and spigot joint pipeline connector so as to improve the tensile bearing force of a buried pipeline connector, optimize the anti-seismic performance of the buried pipeline, effectively reduce the earthquake disaster at the position of the pipeline connector, prolong the service life of the pipeline connector, reduce the pipeline post-disaster repairing and maintaining cost. The connector comprises five parts including a pipeline bell mouth, a pipeline inserting port, a rubber ring, a metal limiting ring and a rubber gasket. The pipeline bell mouth is internally provided with an annular groove. A circle of ring-shaped protrusion is arranged at the tail end of an inserting port pipeline. One side of the tail end, close to the inserting port, of the protrusion part is provided with the gradient with the tilt angle ranging from 15 degrees to 45 degrees, and pipeline inserting port installation is convenient. The metal limiting ring is composed of three sets of arcs of 120 degrees, the cross section is in an L shape, and the part, protruding close to the outer side, of the metal limiting ring is used for installing and fixing the metal ring to the position of the groove of a bell mouth pipeline. After a single pipeline connector is pulled and deformed to the extreme, each pipeline can drive an adjacent pipeline to slide together, pipeline deformation is transmitted to an adjacent pipeline connector, and the capability of resisting large deformation of a soil body around the pipeline is achieved finally.

Owner:BEIJING UNIV OF TECH

Vibration isolation supporting seat and mounting construction method thereof

ActiveCN107386455AReasonable designLow input costProtective buildings/sheltersShock proofingEngineeringSteel bar

The invention discloses a vibration isolation supporting seat and a mounting construction method thereof. The vibration isolation supporting seat comprises a vibration isolation supporting seat body, and an adjusting die for adjusting the position of the vibration isolation supporting seat body, wherein the adjusting die comprises a rectangular side frame, a steel bar positioning frame for fixing a lower embedded plate, a transverse adjusting mechanism for adjusting the transverse position of the lower embedded plate, and a longitudinal adjusting mechanism for adjusting the longitudinal position of the lower embedded plate. The mounting construction method comprises the following steps: 1, mounting the adjusting die and the lower embedded component; 2, measuring and adjusting the position of the lower embedded plate; and 3, mounting the vibration isolation supporting seat body and an upper embedded plate. The method is simple in steps, and reasonable in design; a lower positioning steel pipe and the adjusting die are separated, so that the adjusting of the adjusting die to the position of the lower embedded plate is not influenced while the lower embedded part is positioned through the lower positioning steel pipe; in addition, the position accuracy of the lower embedded plate is ensured through a horizontal adjusting screw and a vertical adjusting screw, thus the vibration isolation supporting seat can be mounted in place, and as a result, the construction period is reduced; moreover, the operation is convenient.

Owner:SCEGC EQUIP INSTALLATION GRP COMPANY

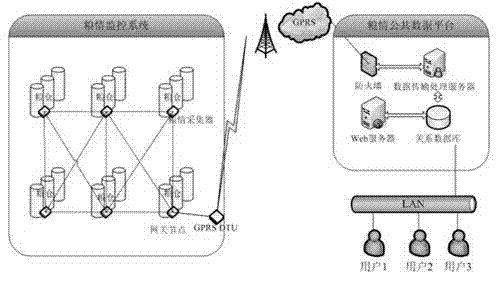

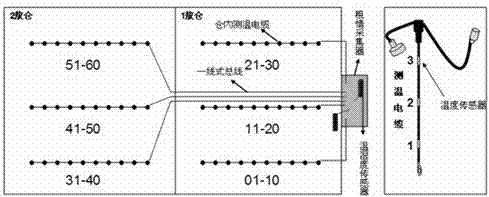

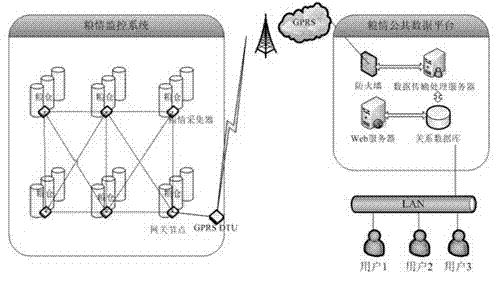

Grain condition monitoring system based on wireless Ad Hoc network

InactiveCN102607642AEasy to installInstalled in placeMeasurement devicesNetwork topologiesGeneral Packet Radio ServiceWireless mesh network

The invention provides grain condition monitoring system based on a wireless Ad Hoc network, which is high in efficiency and convenient for installation and maintenance. According to the system, grain condition data sensors are connected together in granaries through a one-line bus, and outside of the granaries, all granaries in a whole grain storage station are interconnected through a wireless sensor network with the Ad Hoc network and self-healing property. A gateway node in the wireless Ad Hoc network is provided with a GPRS (General Packet Radio Service) network interface or an LAN (local area network) interface which can be accessed to a VPN (Virtual Private Network) so as to collect grain condition data of a plurality of grain storage stations to a grain condition public data platform in a grain system.

Owner:ZTE VAST SKY INFORMATION TECH

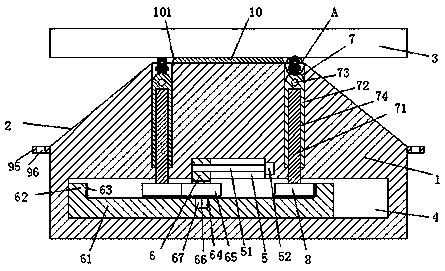

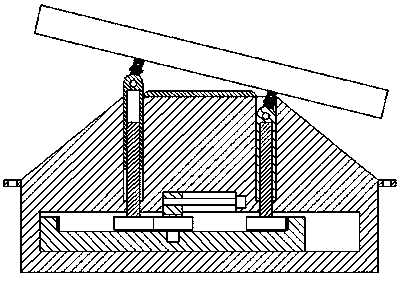

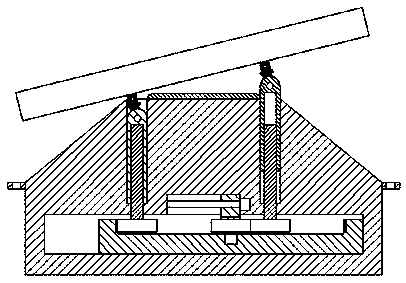

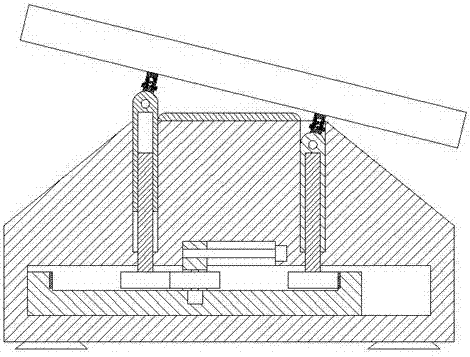

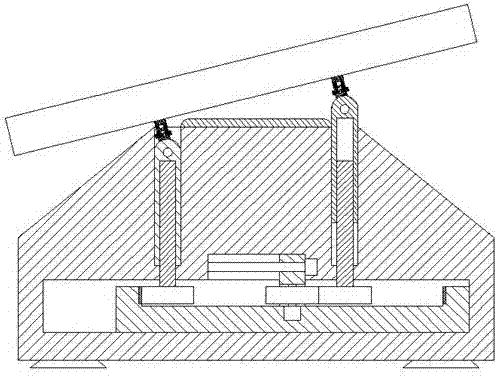

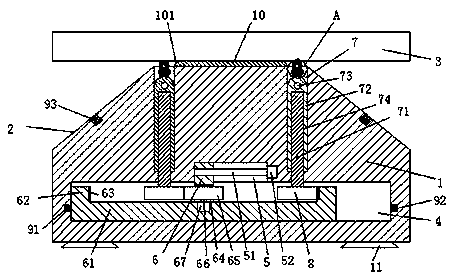

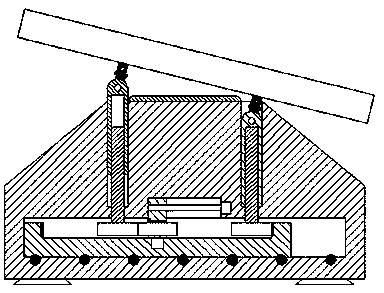

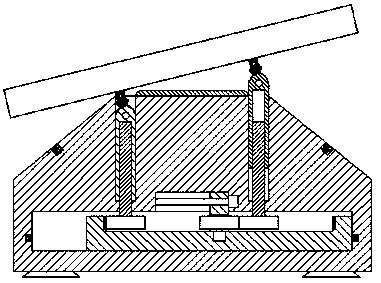

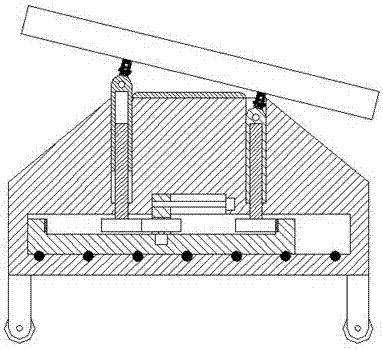

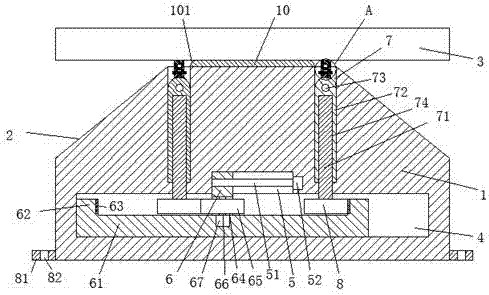

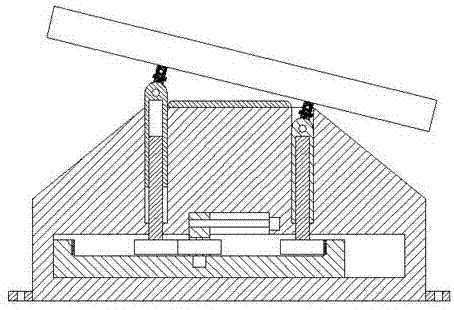

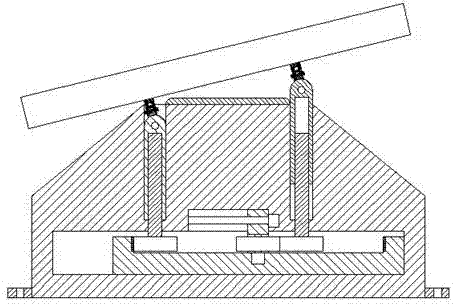

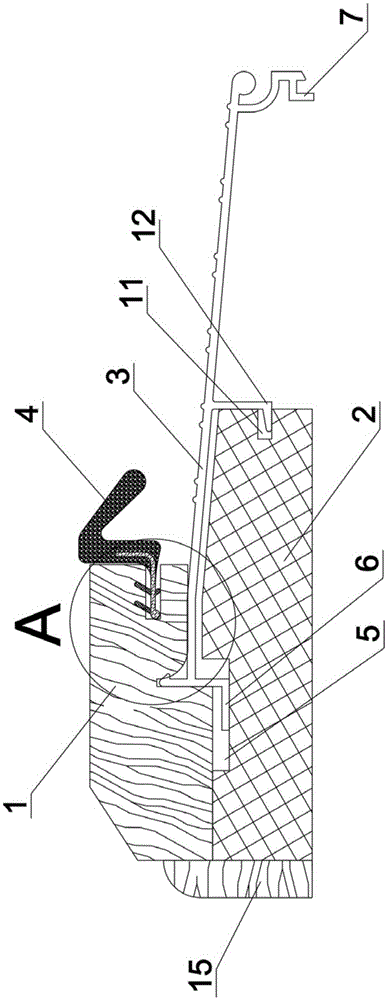

Improved solar photovoltaic panel installing device

InactiveCN108233835AImprove conversion efficiencyPromote absorptionPhotovoltaic supportsPhotovoltaic energy generationEngineeringSolar power

The invention discloses an improved solar photovoltaic panel installing device comprising a base and a solar photovoltaic panel which is installed on the base. The bottom part of the solar photovoltaic panel is provided with two fixed members which are symmetrically arranged in a left-and-right direction. The bottom part of each fixed member is provided with an inserting slot. The left and right end walls of the top part of the inserting slots are symmetrically provided with locking slots. The left and right ends of the base are provided with slope parts. The base is provided with a driving cavity. The middle of the top end wall of the driving cavity is provided with a slide slot. The left and right ends of the top part of the base are symmetrically provided with elevating slots which downwardly extend and are opposite to the fixed members. The structure is simple, the production cost is low, installation and disassembling of the solar photovoltaic panel are convenient and rapid, the installation stability of the solar photovoltaic panel is great, elevating and inclination setting operation of the solar photovoltaic panel is convenient and operation of the whole device is safe andreliable so that the solar conversion efficiency can be greatly increased and the present use requirements of solar power generation can be met.

Owner:广州迅速光电科技有限公司

Installation method for short mandrel continuous casting rolls adopting interference fit

The invention provides an installation method for short mandrel continuous casting rolls adopting interference fit. Since the installation between roller sleeves and mandrels of the short mandrel continuous casting rolls adopts interference fit, the assembly is realized by utilizing the principle of thermal expansion and cold contraction of materials, namely the roller sleeves are assembled with the mandrels at normal temperature after being heated to a set temperature, or the roller sleeves are assembled with the cooled mandrels after being heated to the set temperature, so that the requirement on interference fit of the short mandrel continuous casting rolls can be realized. The installation method is suitable for installation of the short mandrel continuous casting rolls.

Owner:SINOSTEEL XIAN MACHINERY

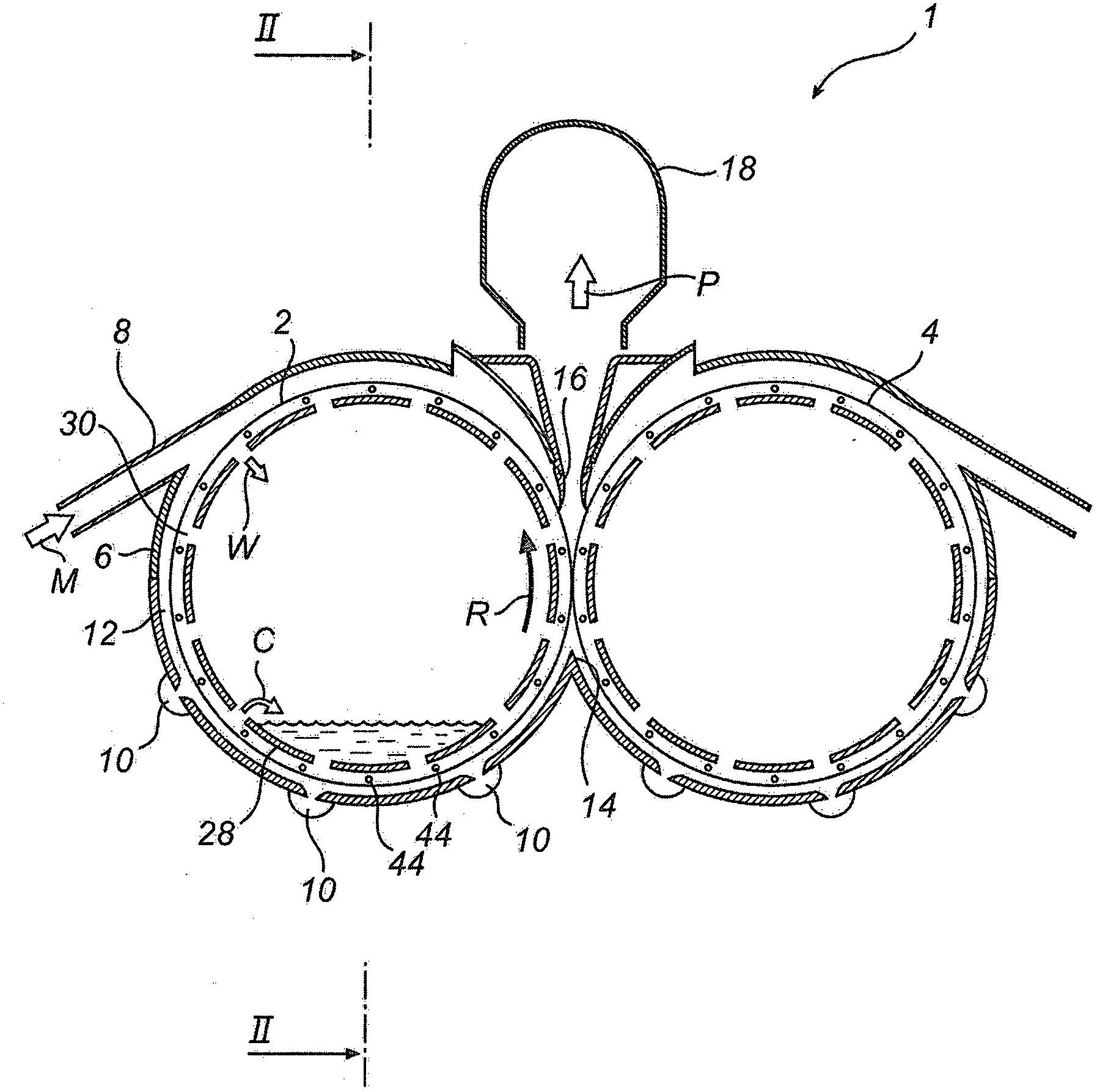

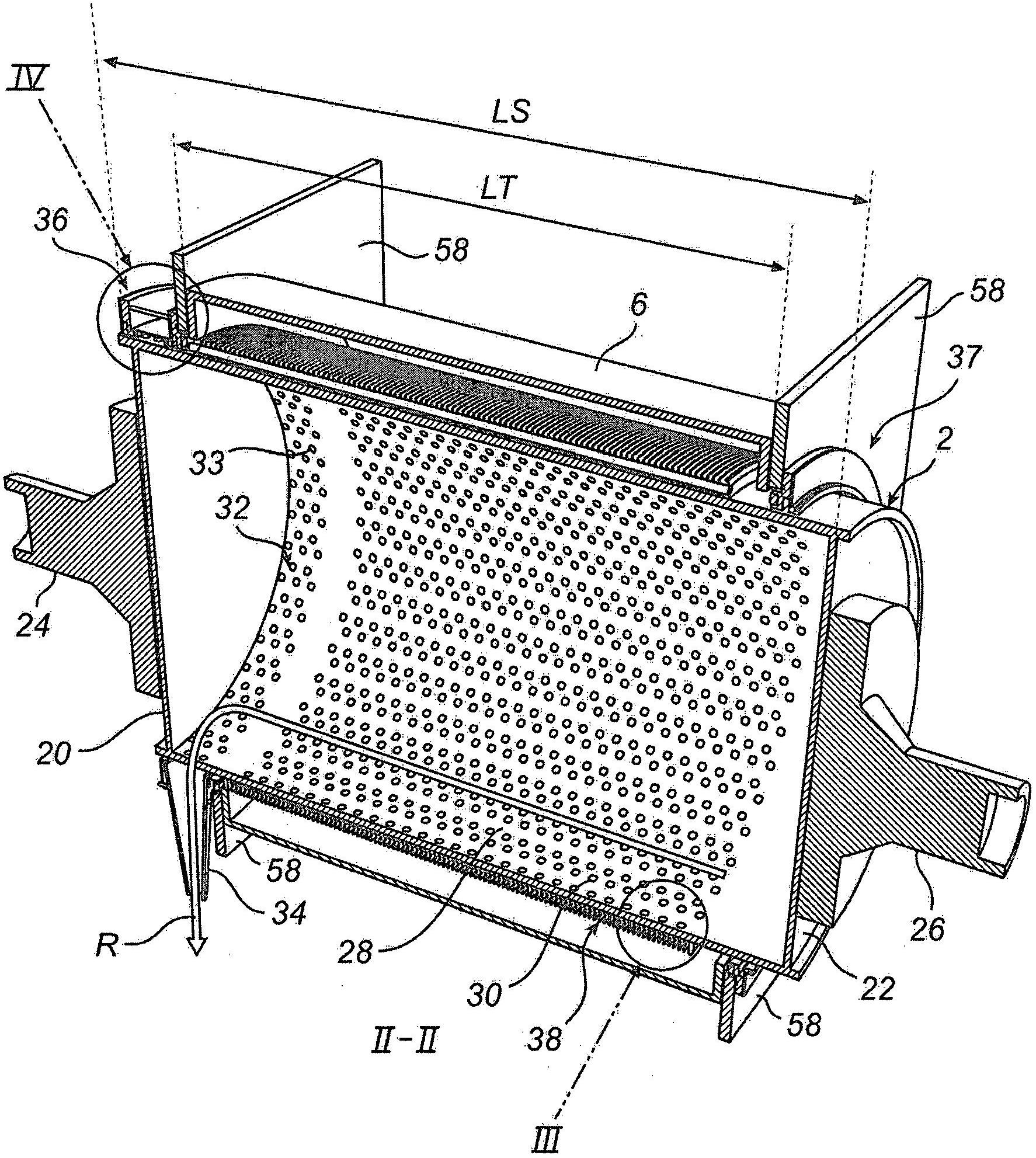

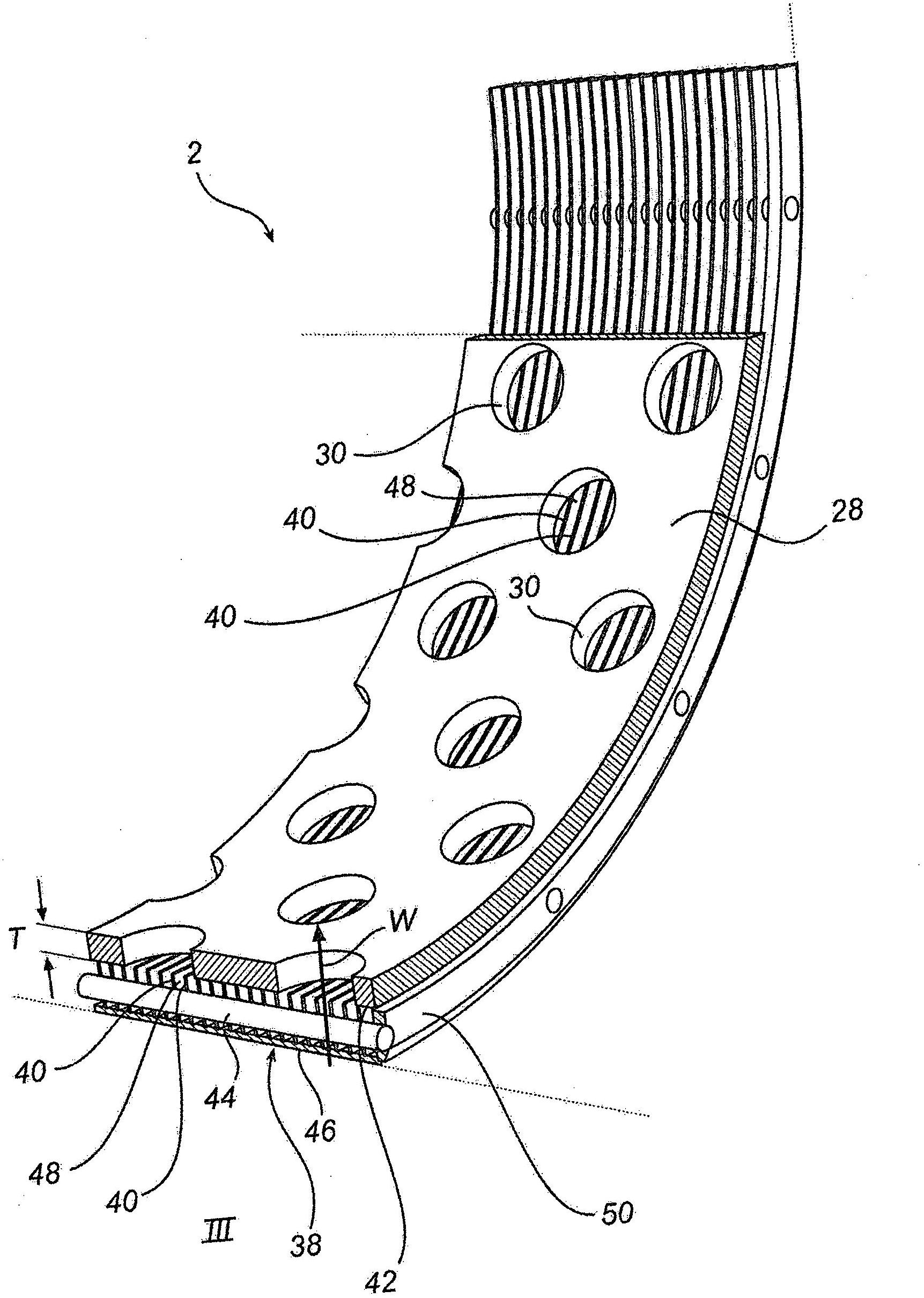

Arrangement for sealing a press

A sealing arrangement (36) for a press (1 ) comprises a first sealing ring (54), in which a replaceable first sealing strip (76) is fixed, said first sealing strip (76) being arranged to slide towards the dewatering drum (2) while it rotates, and a second sealing ring (54) arranged at an axial distance from the first sealing ring (52), in which second sealing ring (54) a replaceable second sealing strip (92) is fixed, said second sealing strip being arranged to slide against the dewatering drum (2) while it rotates.Both the first and the second sealing rings (52, 54) are fixed in a common holding device (58) that is located at the first sealing ring (52). The second sealing ring (54) is fixed in the holding device (58) by means of at least one spacer element (102). At least a part (60, 62) of the first sealing ring (52) is detachable from the holding device (58) for being made to slide along said at least one spacer element (102) in order to allow replacing the first sealing strip (76).

Owner:ANDRITZ AG

Monitoring probe device

ActiveCN107172403AExpand the scope of monitoringImprove stabilityClosed circuit television systemsStands/trestlesEngineering

The invention discloses a monitoring probe device. The monitoring probe device comprises a bracket and a monitoring probe arranged on the bracket. Two fixed piles are oppositely arranged at the bottom of the monitoring probe on left and right sides. A latch groove is arranged at the bottom of each fixed pile. Locking grooves are oppositely arranged in left and right ends of the top of each latch groove respectively. A suction pad is fixedly arranged at the bottom of the bracket. Beveled parts are arranged on right and left ends of the bracket. A groove is arranged in the bracket. A slide groove is arranged at the center of the top end of the groove. Lifting grooves which extend downwardly and are opposed to the fixed piles are oppositely arranged on left and right ends of the top of the bracket. According to the invention, the monitoring probe device has the advantages of simple structure, low cost, convenient and quick monitoring probe installation and removal, stable monitoring probe installation, safe and reliable operation and greatly increased monitoring scope, and meets the use need of the existing monitoring probe.

Owner:NANJING SHENYE INTELLIGENT SYST ENG

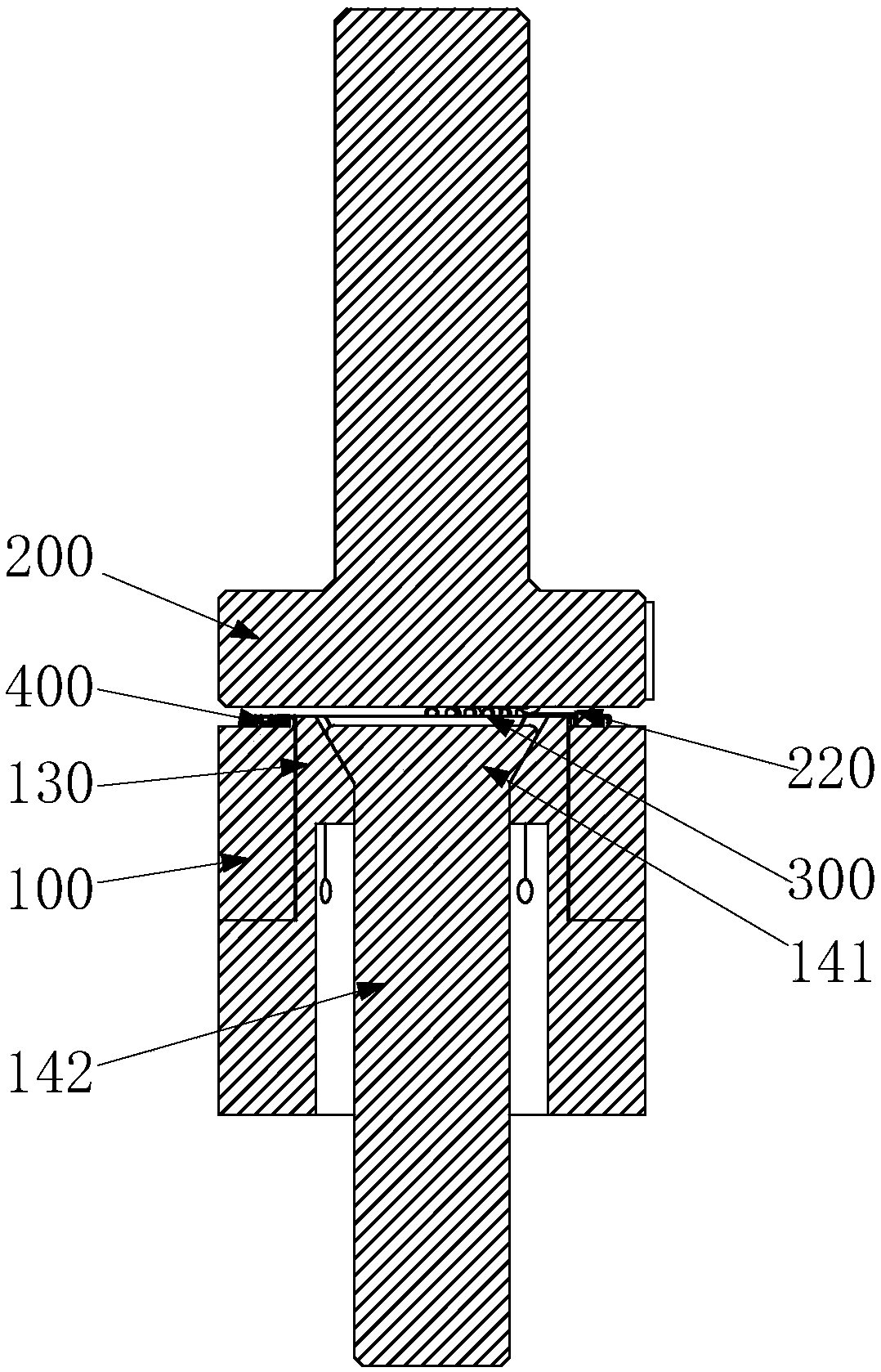

Bearing needle mounting device and planar thrust bearing needle mounting system

PendingCN108825668AInstalled in placeNo risk of damageShaftsBearing componentsNeedle positionThrust bearing

The invention provides a bearing needle mounting device and a planar thrust bearing needle mounting system and relates to the technical field of bearing assembly, and aims to solve the problems that bearing needle mounting efficiency is low and a holder during the mounting process is liable to be damaged. The bearing needle mounting device comprises a holder positioning device, a roller needle positioning device and a driving device, wherein the holder positioning device is used for keep the end surface of the holder face to the roller needle positioning device; the roller needle positioning device includes at least one roller needle accommodating channel, of which the outlet is faced to the position of a roller needle mounting station on the holder fixed on the holder positioning device;at least one press roller is installed rotationally on the roller needle positioning device and is located above the position of the roller needle mounting station; the driving device drives the holder positioning device to rotate axially and move linearly. The bearing needle mounting device is used for mounting a needle onto a bearing and is high in efficiency, and can avoid the risk of damage ofthe holder due to knock.

Owner:SUZHOU XINHAO BEARING

Pipe expander

InactiveCN107127265AEasy to adjustImprove efficiencyMetal-working feeding devicesPositioning devicesEngineeringIntermediate pressure

The invention discloses a pipe expander, which includes a clamp, a bow frame, a top pressure screw, a pipe expansion cone and a handle. The bow frame is installed on both sides of the fixture, and a top pressure screw is installed on the bow frame. Cone head, the upper end of the top pressure screw protrudes from the bow frame to connect with the handle, a row of middle holes for clamping the metal pipe is set in the middle of the fixture, and a fine-tuning mechanism is set at the connection between the bow frame and the fixture for fine-tuning the top of the bow frame The concentricity of the pressure screw and the middle hole. The pipe expander of the present invention uses the top pressure screw to press and expand the cone to expand the metal pipe clamped in the center hole. In order to adjust the position of the pipe expander, the concentricity between the top pressure screw and the middle hole is ensured. Set the fine-tuning mechanism at the connection between the bow frame and the fixture. Before processing, first press the expander cone to the upper edge of the metal pipe to correct the concentricity of the top pressure screw and the middle hole. When there is a deviation, adjust the fine-tuning mechanism until The top pressure screw is concentric with the middle hole.

Owner:句容新禾五金电器有限公司

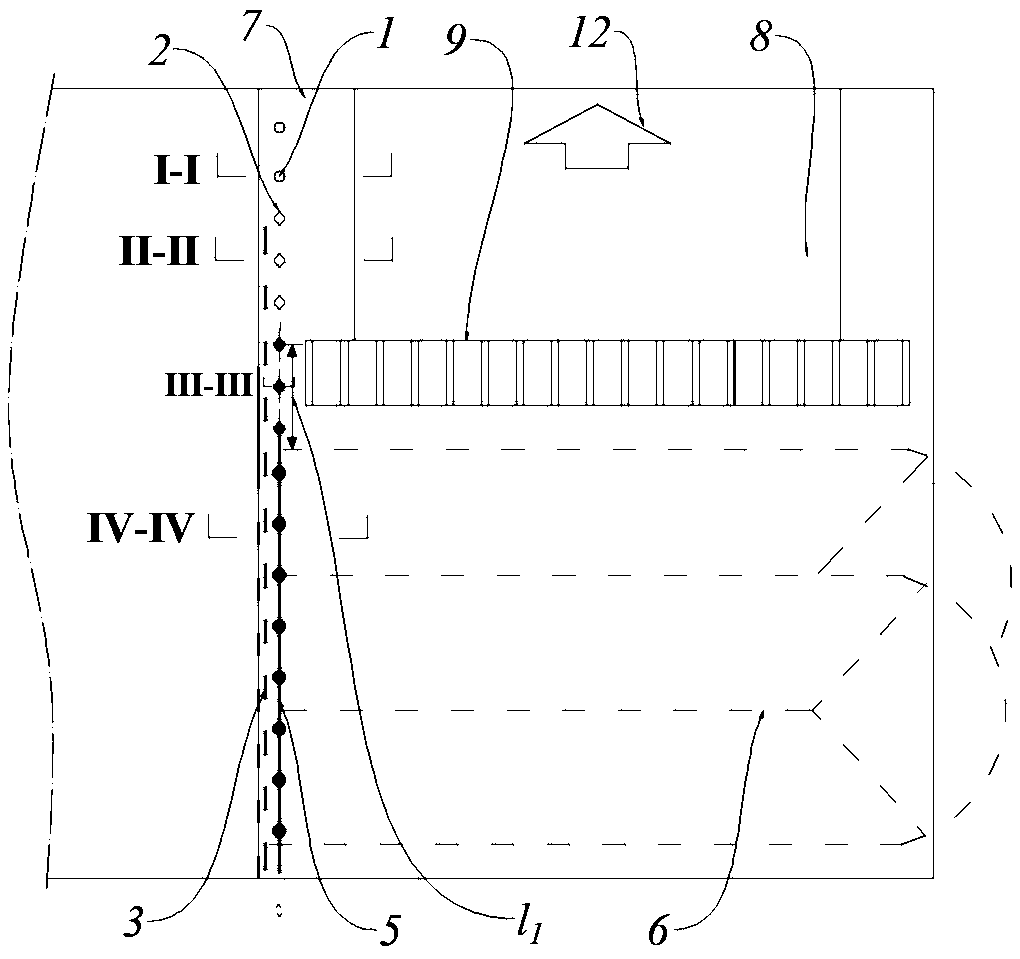

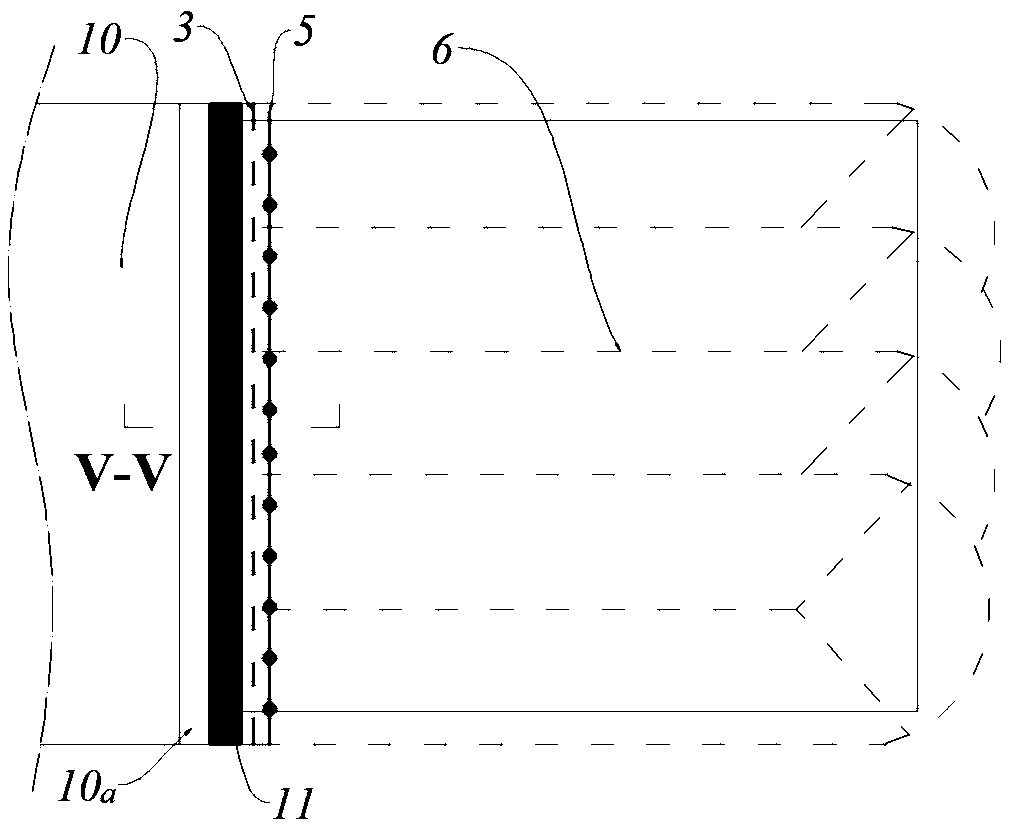

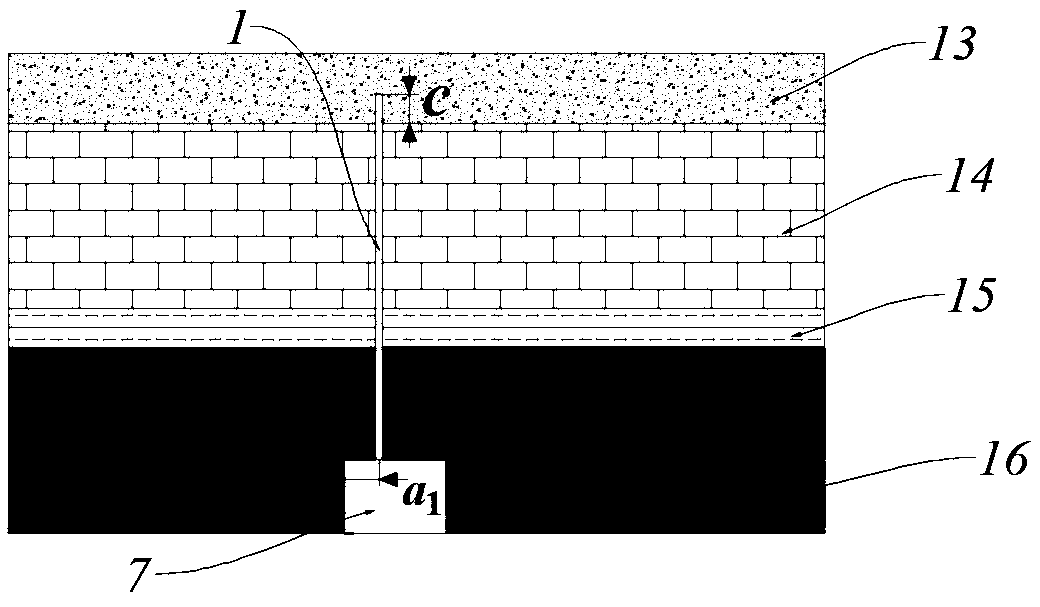

Construction method for stable top plate-coal pillar structure along empty coal roadway through fully-mechanized caving

ActiveCN111364995AEasy to achieve fracture cuttingAvoid areaUnderground miningSurface miningCantilevered beamMining engineering

The invention relates to a construction method for a stable top plate-coal pillar structure along an empty coal roadway through fully-mechanized caving. The stable top plate-coal pillar structure comprises a tensile anchor cable, a circular truncated cone type baffle disc, a Z-shaped locking tray, a special-shaped quadrilateral tray, a groove cap, a mounting rod, an expanding agent and a hole sealing agent, wherein expanding and fracturing boreholes are formed in a top plate, near a non-stoping roadside, of a mining roadway, slits are cut on the two sides of the boreholes, the tensile anchor cable, the expanding gent, the hole sealing agent and the circular truncated cone type baffle disc are installed in the boreholes, thick top coal is cut on the non-stoping roadside, a locking anchor cable and the Z-shaped locking tray are installed after the slits, and after the fracturing boreholes enter a goaf, the tensile stress on the upper side of a base top at the side region of a working face is remarkably increased, the expansion force of the expanding agent enables a basic top to substantially break along the fracturing boreholes, roadway driving along the goaf is carried out on an adjacent side coal body, a coal pillar side shoulder socket stabilizing anchor is installed on the adjacent side coal body, and the roadway top plate and a coal pillar are located under the protection ofa stable structure of a base top cantilever beam, so that the top plate-coal pillar structure along the empty coal roadway through fully-mechanized caving is constructed, and the method has importantand wide application value.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Automobile glass tool for mounting metal clip

The invention relates to an automobile glass tool for a mounting metal clip. The tool consists of a handle and a mounting head which is arranged at the front end of the handle, wherein the mounting head consists of a central cylindrical magnet and peripheral notch-shaped chucks; the metal clip is directly attracted to the mounting head by the cylindrical magnet; and the metal clip is positioned by the peripheral notch-shaped chucks. Compared with the prior art, the automobile glass tool has the advantages of high efficiency and convenience in use, and the labor intensity of workers is reduced.

Owner:SHANGHAI FUYAO BUS GLASS

Angle-adjustable monitoring probe device

The invention discloses an angle-adjustable monitoring probe device. The angle-adjustable monitoring probe device comprises a bracket and a monitoring probe installed on the bracket. Two fixing pilesare oppositely arranged at the bottom of the monitoring probe left and right, and the bottom of each fixing pile is provided with an insertion pin groove. Locking grooves are oppositely formed in theleft end and the right end of the top of each insertion pin groove separately. A suction pad is fixedly installed at the bottom of the bracket. Slope parts are arranged at the left end and the right end of the bracket. A vacant groove is formed in the bracket. A sliding groove is formed in the center of the top end of the vacant groove. Lifting grooves which extend downwards and are opposite to the fixing piles are oppositely formed in the left end and the right end of the top of the bracket. The angle-adjustable monitoring probe device is simple in structure and low in production cost, and the monitoring probe can be mounted and dismounted conveniently and rapidly. Moreover, the mounting stability of the monitoring probe is good, the whole device can operate safely and reliably, the monitoring range is greatly widened and the using requirements of an existing monitoring probe are met.

Owner:广西梧州四海建筑工程有限责任公司

Working method of multi-cylinder fixed cosmetic container liner installation mechanism

InactiveCN107433443AImprove installation efficiencyGood effectMetal working apparatusMechanical engineeringEngineering

Owner:裘名金

Bridge equipment convenient to use

The invention discloses bridge equipment convenient to use. The bridge equipment comprises an underframe and a working table face mounted on the underframe. Two fastening pieces are arranged at the bottom of the working table face in a bilateral symmetry mode, and an inserting hole is formed in the bottom of each fastening piece. Locking holes are formed in the left ends and the right ends of thetops of the inserting holes in a symmetrical mode correspondingly. Vertical columns are fixedly mounted on the periphery of the bottom of the underframe, and universal wheels are arranged at the bottoms of the vertical columns. Oblique parts are arranged at the left end and the right end of the underframe, and a driving cavity is formed in the underframe. A sliding cavity is formed in the middle end of the top end of the driving cavity. According to the bridge equipment, the structure is simple, the production cost is low, mounting and dismounting of the working table face are convenient and quick, the mounting stability of the working table face is good, and lifting tilting arrangement operation of the working table face is convenient; and the whole device is safe and reliable in operation, the workpiece unloading efficiency is greatly improved, and the use demand of an existing workpiece machining table is met.

Owner:广东龙城建筑工程有限公司

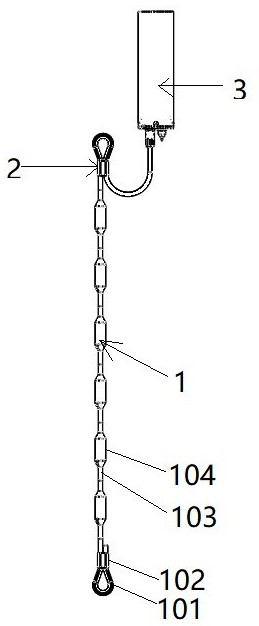

Temperature chain and method of use thereof

ActiveCN114705322AMiniaturizationEasy to transportThermometer detailsOpen water surveyControl cellProcess engineering

The invention discloses a temperature chain and a use method thereof, and the temperature chain comprises a measurement unit which is used for monitoring a marine environment, a control unit which is used for controlling the measurement unit and processing marine environment data, and a connection unit which is used for fixing the measurement unit on the control unit. The measuring unit comprises a first heart-shaped ring, a first Kevlar rope, a temperature chain cable and a temperature measuring mechanism, and the connecting unit comprises a watertight cable, a second heart-shaped ring and a second Kevlar rope, wherein the second heart-shaped ring and the second Kevlar rope are used for reducing local stress of the watertight cable. The control unit comprises a control cabin end cover, a control cabin body, a master control board used for receiving and analyzing the measuring unit, a watertight connecting piece and a power source, the temperature measuring mechanism is miniaturized and integrated, the temperature measuring mechanism is supported on the temperature chain cable through the supporting structure, the measuring precision is guaranteed, and meanwhile the temperature measuring mechanism is supported on the temperature chain cable through the watertight connecting piece. And the transportation, laying and recycling convenience of the temperature chain is greatly improved.

Owner:海南浙江大学研究院

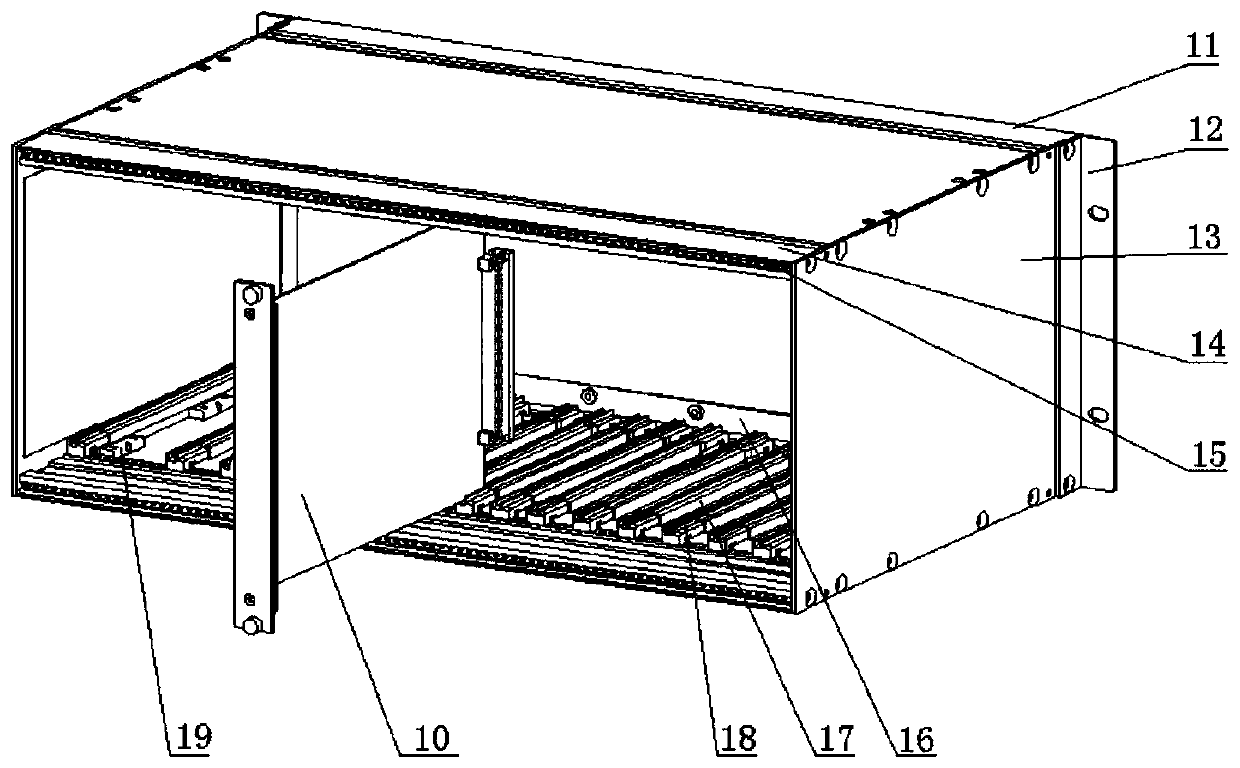

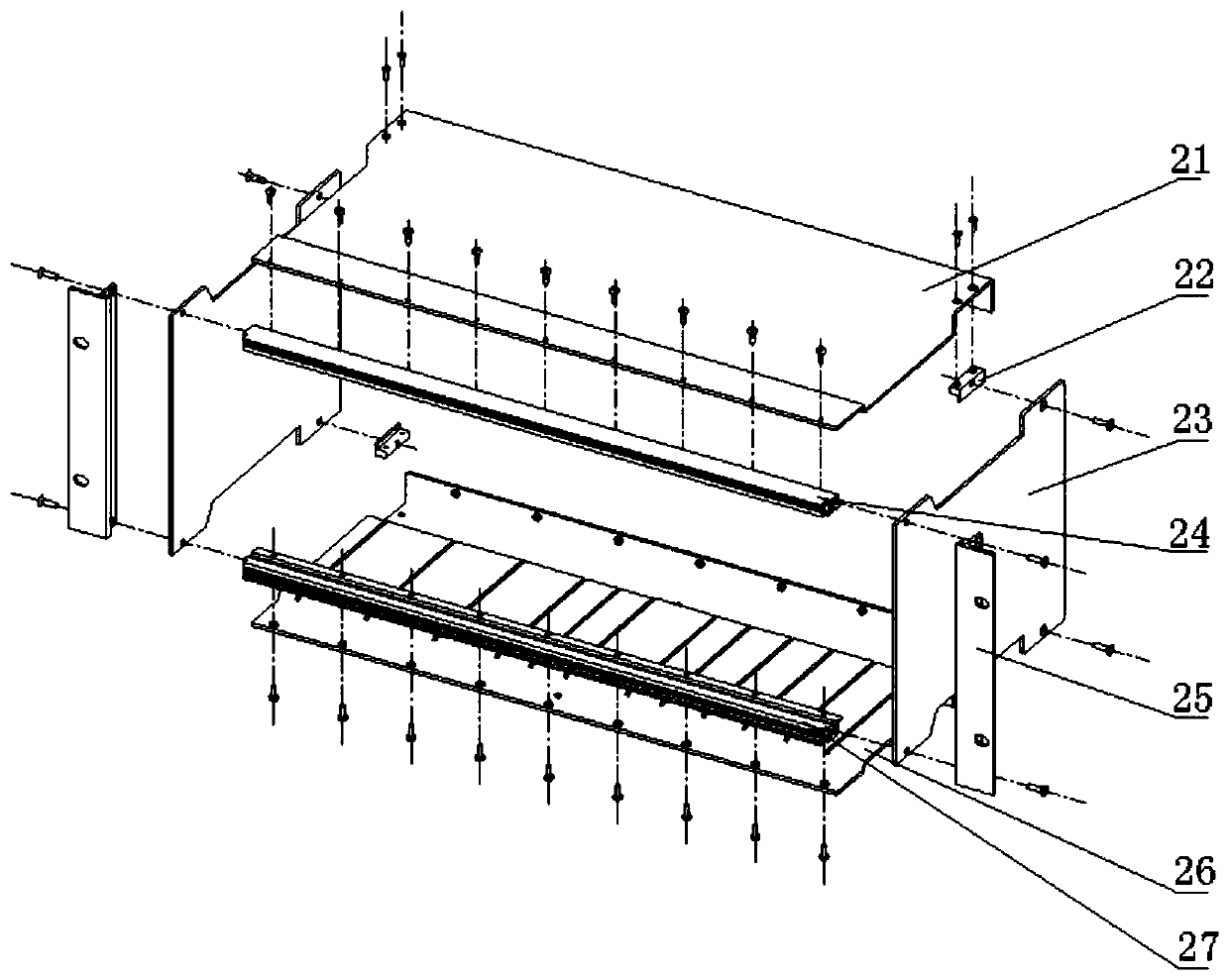

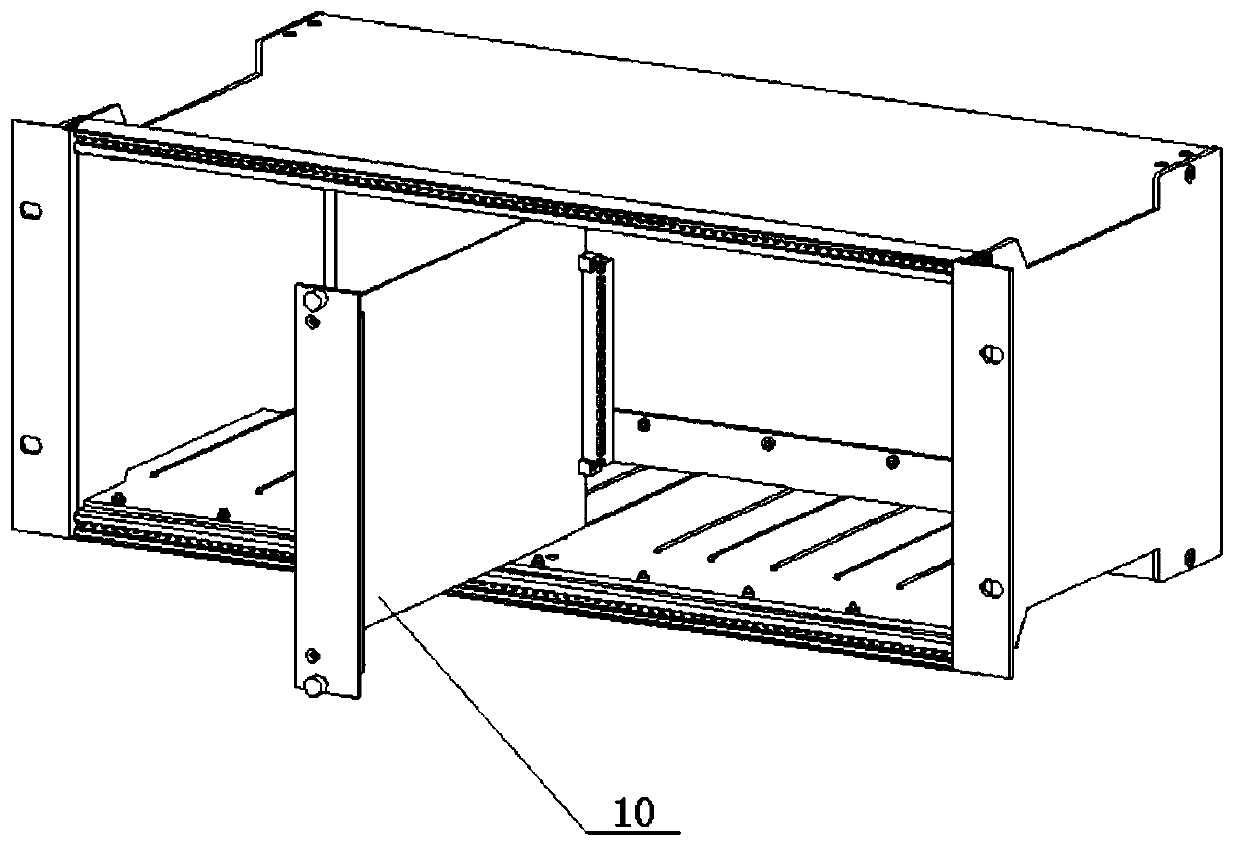

Electronic equipment subrack and assembling method thereof

ActiveCN110996600AReduce typesReduce in quantityAssembly machinesPrinted circuit board receptaclesHemt circuitsStructural engineering

The invention relates to an electronic equipment subrack. The electronic equipment subrack is characterized in that when an upper guide rail plate and a lower guide rail plate are horizontally placed,the projection top view is rectangular, the subrack comprises a middle section of convex flat plate and a section of bent vertical plate positioned at the edge, and more than two guide rail grooves vertical to the vertical plate are formed in the convex flat plate; riveting nuts used for installing a circuit mother board are arranged on the bent vertical plate, and via holes used for installing parts are formed on the plane adjacent to the vertical plate and the plane away from the vertical plate; the side plates, a cross beam and the fixing lugs are provided with the connecting holes matchedwith the via holes of the upper guide rail plate and the lower guide rail plate respectively, nut holes are formed in the length direction of the cross beam and the two ends of the cross beam, and nut holes are formed in the two adjacent planes perpendicular to each other of a cover plate fixing block. The invention further relates to an assembling method of the electronic equipment subrack. Theelectronic equipment subrack has the obvious advantages of being small in number of parts, few in variety and low in manufacturing difficulty and being easy to assemble.

Owner:INTEGRATED ELECTRONICS SYST LAB

Engine crankshaft oil seal press-fitting tool and method

PendingCN111267038AMeet sealing requirementsEasy to slip inMetal-working hand toolsControl theoryMechanical engineering

The invention discloses an engine crankshaft oil seal press-fitting tool, belongs to the field of crankshaft press-fitting, and solves the problem that traditional crankshaft oil seal press-fitting ishigh in labor intensity and low in efficiency. The engine crankshaft oil seal press-fitting tool comprises a pressure head and a positioning sleeve arranged in a split manner, wherein a mounting basefor mounting a crankshaft oil seal is arranged at one end of the pressure head; a press-fitting surface is formed between the mounting base and the pressure head; a guiding annular surface, an oblique annular surface and a positioning annular surface are sequentially arranged on the outer surface of the positioning sleeve in the axial direction of the positioning sleeve; the diameter of the guiding annular surface is less than the internal diameter of the axle hole of an oil seal seat; the diameter of the positioning annular surface is matched with the diameter of a crankshaft large head; anda positioning shaft matched with the axle hole of the crankshaft large head is arranged in the center of the positioning sleeve on one side of the positioning annular surface. The invention further discloses an engine crankshaft oil seal press-fitting method. The engine crankshaft oil seal press-fitting tool and method can effectively lower the labor intensity and improve the working efficiency while meeting the oil seal sealing requirement.

Owner:广西玉柴船电动力有限公司

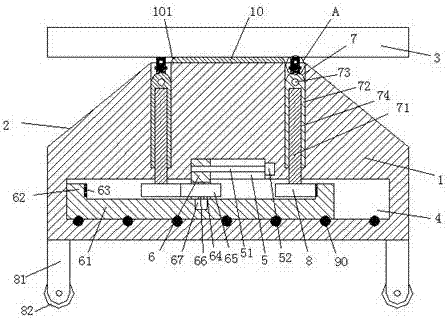

Compression device and installation structure of small arm casting and reducer synchronous wheel assembly

PendingCN109128761ASmall footprintGuaranteed accuracyProgramme-controlled manipulatorMetal working apparatusReduction driveCompression device

The invention discloses a compression device and an installation structure of a small arm casting and a reducer synchronous wheel assembly. The compression device comprises moving transforming parts and a pressure head, the moving transforming parts are provided with guiding faces extending horizontally, the pressure head is driven by a first driver and can be slidably arranged on the guiding faces, and the pressure head is guided by the guiding faces and transforms from initial horizontal motion into motion with at least motion components in the vertical direction. The installation structureincludes the compression device and a manipulator. Under the action of the vertical motion components, the pressure head moves downward and exerts downward compressive force on to-be-compressed parts,the space occupied by the compression device in the vertical direction is reduced, thus the compression device and the vertical operating manipulator can operate synchronously above the to-be-compressed parts, and the accuracy of assembling of the to-be-compressed parts and other parts is ensured.

Owner:SUZHOU RS TECH

Convenient-to-use bridge equipment

Owner:义乌市雄发尔机械设备有限公司

Traffic sign on luminescent road and lamp bead lens for traffic sign

The invention discloses a lamp bead lens for a traffic sign on a luminescent road. The lamp bead lens comprises a mounting rod and a lens. The lens is fixed onto the head end of the mounting rod, a luminescent lamp bead can be inserted into the hollow mounting rod from the tail end of the mounting rod, the diameter of the lens is larger than that of the mounting rod, and a circle of protruded guide restraint portions is arranged on the circumferential surface of the mounting rod, so that a circle of clamping space can be formed between the lens and the guide restraint portions; each guide restraint portion is provided with a guide oblique plane which is upwardly oblique towards the direction of the lens; the mounting rod can be inserted into mounting holes of a traffic signboard from the front surface of the traffic signboard during mounting, and the guide oblique planes can be gradually squeezed by the traffic signboard to deform, and then are ultimately fed into the clamping space tobe clamped and restrained. The invention further discloses the traffic sign on the luminescent road. The lamp bead lens and the traffic sign have the advantages of simple and compact structure, convenience and speediness in mounting, low manufacturing cost and high safety.

Owner:HUNAN XIANGXU TRAFFIC & LIGHTING HI TECH CO LTD

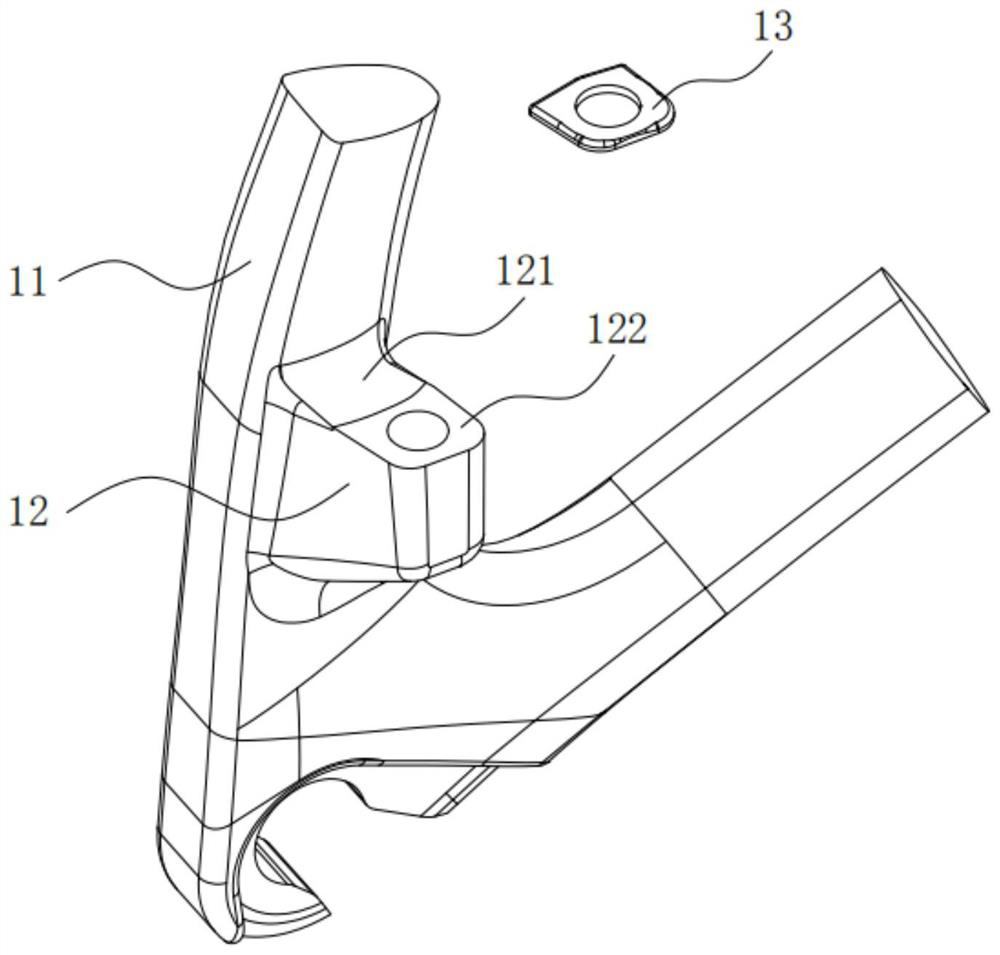

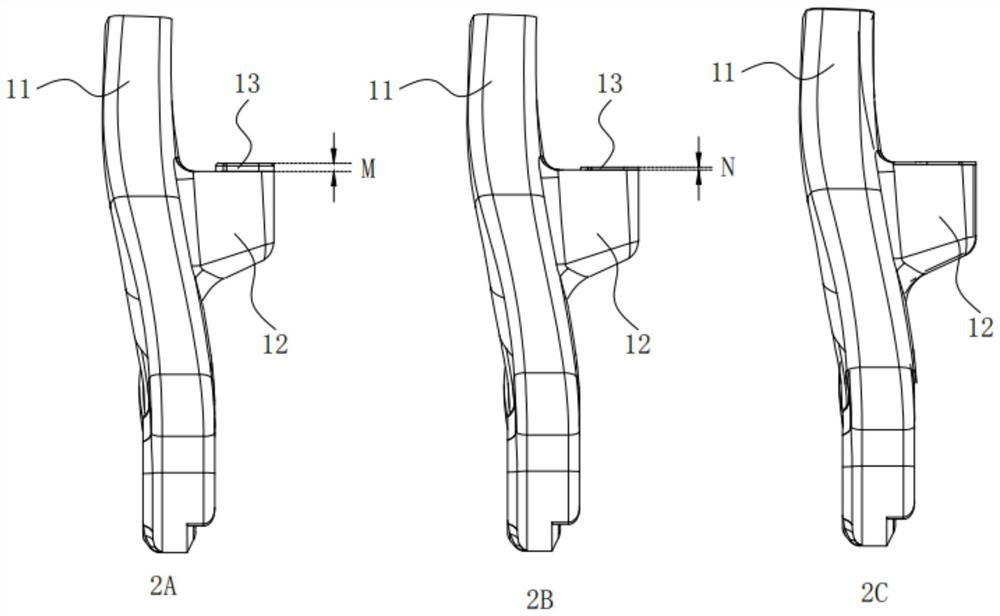

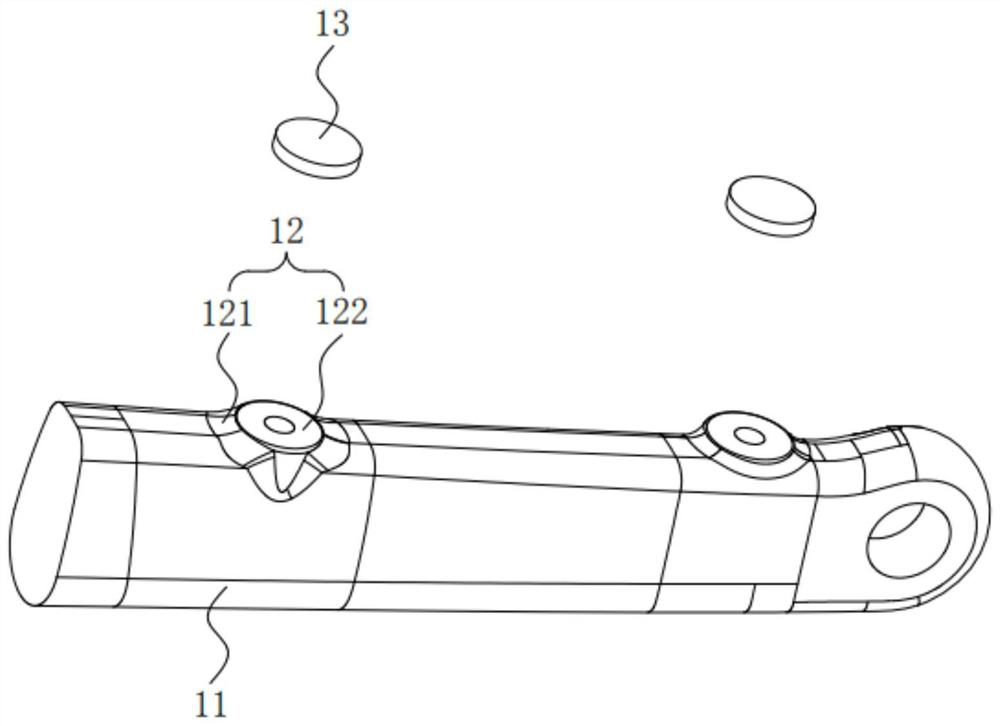

Carbon fiber bicycle processing method and carbon fiber bicycle

ActiveCN112498554AGuaranteed appearance qualityAvoid damageSteering deviceCycle framesDisc brakeStructural engineering

The invention belongs to the technical field of bicycle machining, and discloses a carbon fiber bicycle machining method and a carbon fiber bicycle. The carbon fiber bicycle comprises a bearing body,the bearing body comprises a supporting body, a protruding block and an embedded part, the protruding block is arranged on one side of the supporting body, and the embedded part is arranged on the protruding block. The machining method comprises the steps that the top face of the protruding block is divided into a coating area and a disc brake area; one end of the embedded part is arranged in thedisc brake area in a protruding mode, and the protruding thickness of the embedded part is a first preset thickness M; the protruding top surface of the embedded part is machined, so that the protruding thickness of the embedded part is reduced to a second preset thickness N; and the periphery of the supporting body, the side face of the protruding block and the coating area are sprayed with paint. By means of the method, when a brake system is installed, the brake system can be prevented from damaging the paint layer on the surface of the bearing body, and the appearance quality of the carbonfiber bicycle is guaranteed.

Owner:TEN TECH COMPOSITE TECH CORP

Landscape LED lamp device

InactiveCN107314290AEasy to glideEasy to replaceMechanical apparatusLighting support devicesEngineeringLED lamp

The invention discloses a landscape LED lamp device. The landscape LED lamp device comprises a base and a LED lamp mounted on the base. Two fasteners are symmetrically arranged at the bottom of the LED lamp left and right. An insertion cavity is formed in the bottom of each fastener. Lock cavities are symmetrically formed in the left end and the right end of the top of each insertion cavity. The left end and the right end of the base are provided with inclined parts. Setting plates are fixedly mounted at the positions, located at the lower ends of the inclined parts, of the left end and the right end of the base. Setting holes penetrating up and down are formed in the setting plates. A driving cavity is formed in the base. A sliding cavity is formed in the middle of the top end of the driving cavity. The landscape LED lamp device is simple in structure and low in production cost, the LED lamp is convenient and rapid to mount and dismount and good in mounting stability, operation is convenient due to the lifting inclined arrangement of the LED lamp, the whole device is safe and reliable in operation, the illumination angle of the LED lamp is greatly increased, and the application demands of existing landscape LED lamps are met.

Owner:深圳永呈实业有限公司

Doorsill assembly

The invention relates to the technical field of house decoration, in particular to a doorsill assembly. The doorsill assembly comprises a doorsill, a cushion block, an extending block and a sealing strip. A groove is formed in the upper surface of the cushion block, a fixing leg is arranged on the side, connected with the doorsill, of the extending block, a clamping block is arranged on the lower surface of the other side of the extending block, a buckle is arranged on the upper surface of the extending block in an upward extending mode, a bayonet is formed in the part, corresponding to the buckle, on the lower surface of the doorsill, the buckle is clamped into the bayonet, the fixing leg is arranged in the groove and located between the lower surface of the doorsill and the bottom face of the groove, an open groove is formed in the right side face of the doorsill, one side of the sealing strip is arranged in the open groove, and other side of the sealing strip is exposed out of the open groove and located above the extending block. The doorsill assembly is simple in structure, convenient to install, firm and durable.

Owner:USA WORLDWIDE DOOR COMPONENTS PINGHU CO LTD

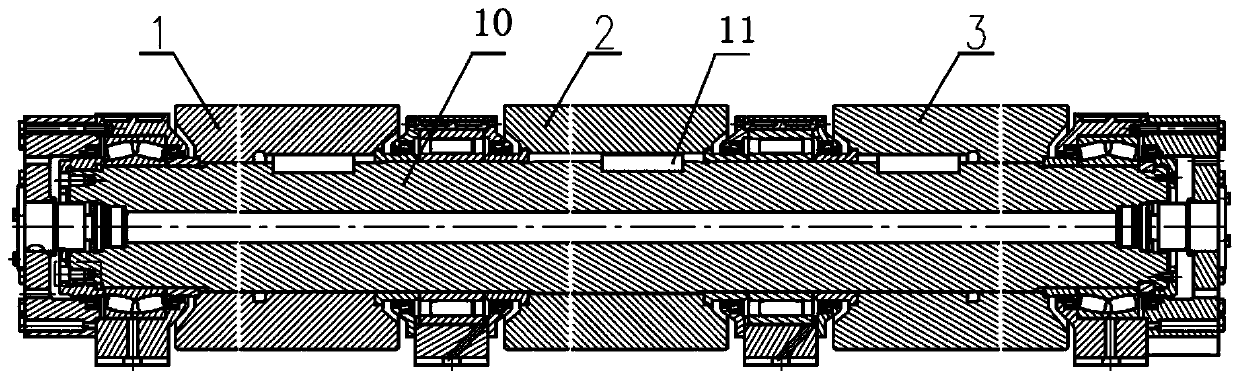

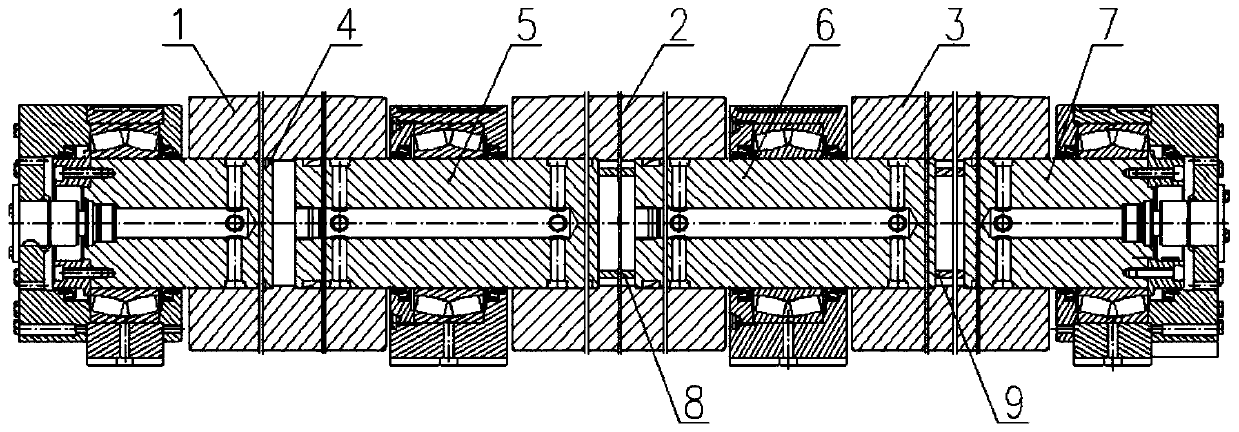

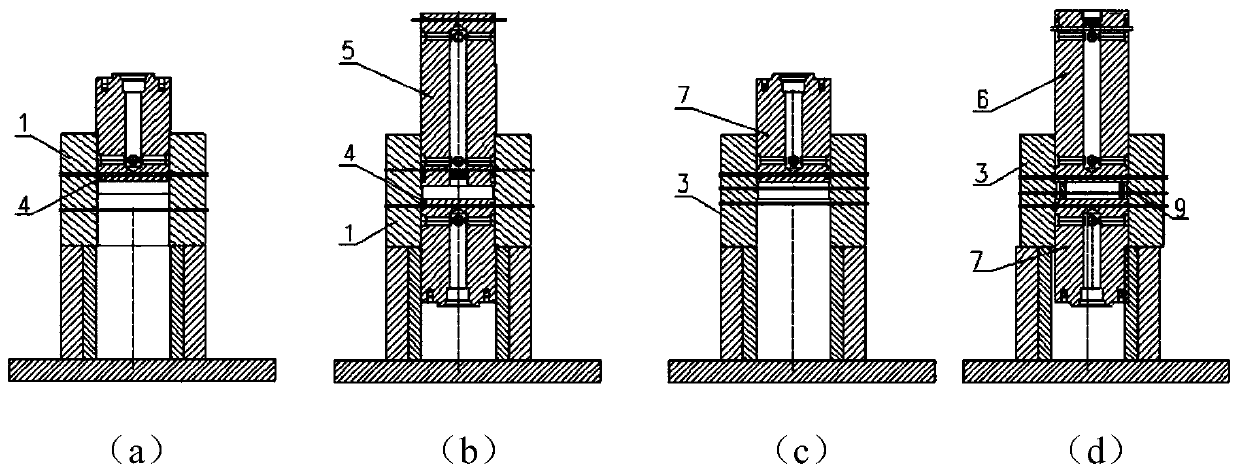

A rail vehicle pivoting arm type axle box positioning node assembly device

ActiveCN103624541BOvercome reboundInstalled in placeAssembly machinesUltimate tensile strengthBack pressure

The invention relates to a railway vehicle jib-type axle box locating node assembling device. The railway vehicle jib-type axle box locating node assembling device comprises an axle box body, a locating node, a gland and bolts, and further comprises a press-fitting platform, a first abutting device and a second abutting device. The axle box body, the locating node, the first abutting device and the second abutting device are fixed onto the press-fitting platform, the first abutting device abuts against the gland from one side to enable the gland to abut against the end portion of the axle box body and the second abutting device abuts against the axle box body to provide back pressure when the axle box body is pressed onto the locating node. The railway vehicle jib-type axle box locating node assembling device is simple and convenient to operate and high in universality, effectively lowers the labor intensity for motor train unit jib-type axle box locating node assembling, improves the production efficiency and meanwhile guarantees the assembling quality.

Owner:CRRC QINGDAO SIFANG CO LTD +1

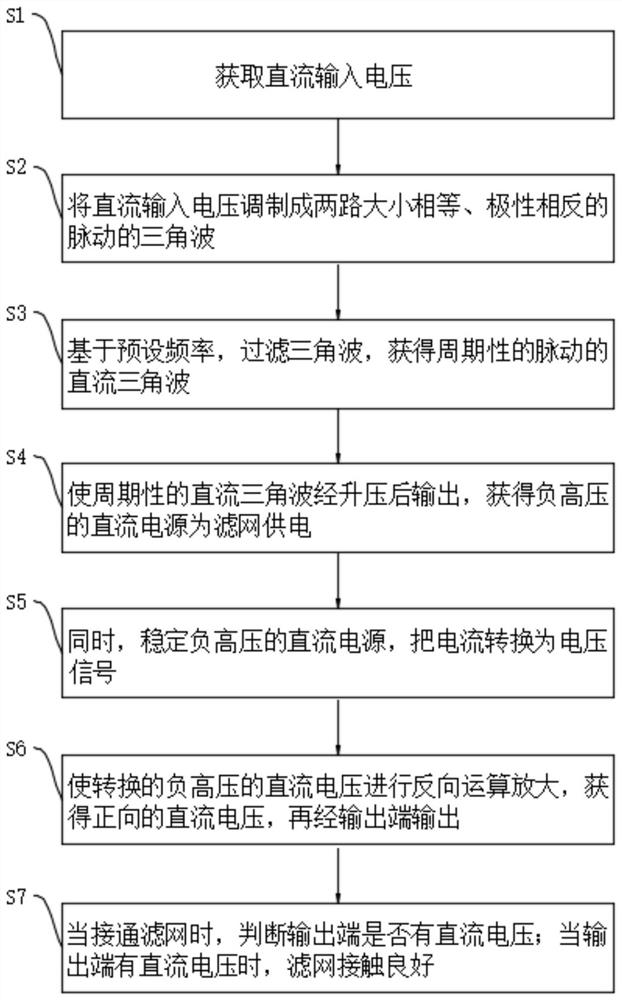

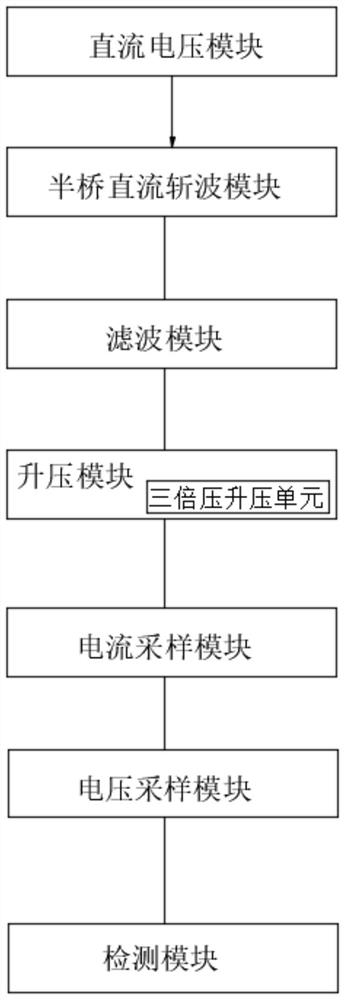

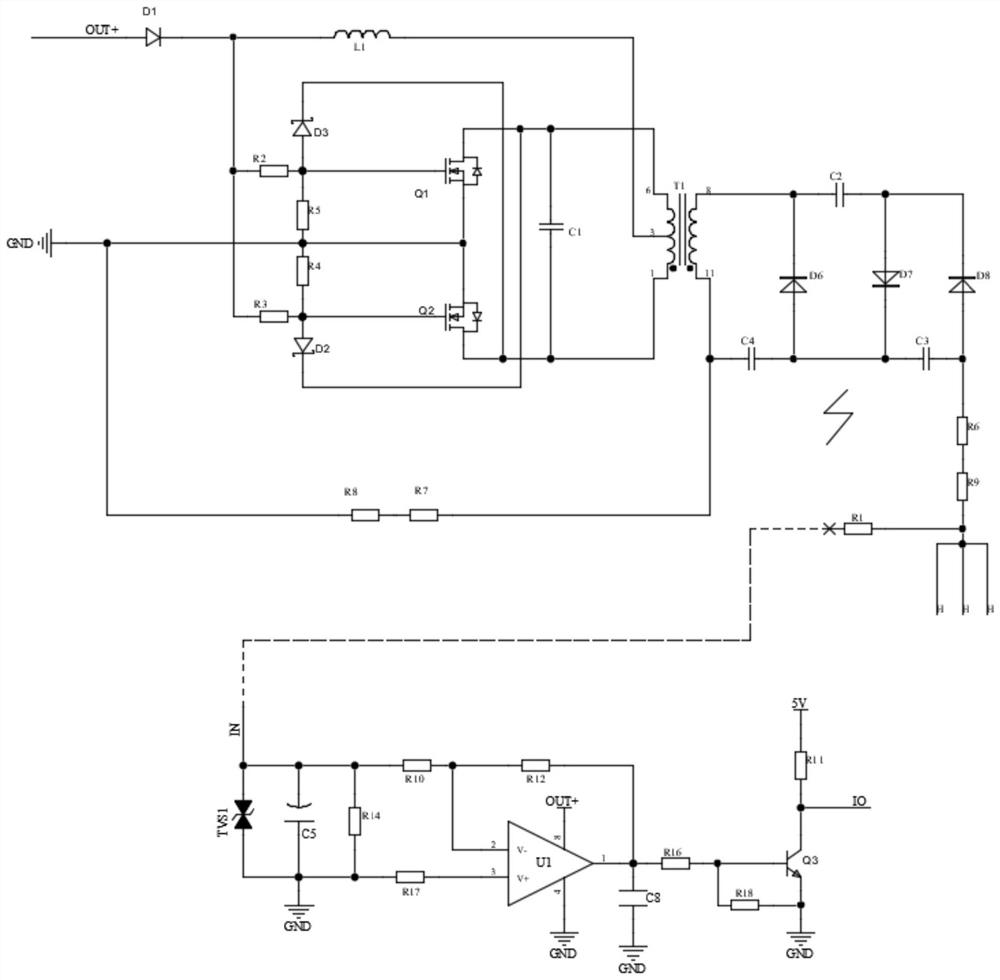

Method and device for detecting good contact of filter screen

PendingCN113835045AIncrease contactGood purification effectAc-dc conversion without reversalCurrent/voltage measurementDC - Direct currentDc current

The invention relates to the technical field of purification, in particular to a method and a device for detecting whether a filter screen is in good contact or not. The method comprises the steps of: acquiring negative-high-voltage direct current on the filter screen, and converting a direct current into a voltage signal; subjecting the voltage signal to reverse operational amplification to obtain forward direct-current voltage, and outputting the forward direct-current voltage through the output end; when the filter screen is switched on, acquiring the output voltage of the output end to judge whether the output end has direct current voltage or not; when the output end has direct-current voltage, indicating that the filter screen is in good contact. The problem that in the actual use process of the purifier based on electrostatic dust collection, a user cannot perceive whether the filter screen is in good contact or not, and consequently the purification effect of the purifier is weakened or even does not exist is solved. The method and the device has the effect that the purifying effect of the purifier is good.

Owner:SHUNDE APOLLO AIR CLEANER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com