Arrangement for sealing a press

A technology for sealing devices and presses, which is applied in presses, separation methods, filtration and separation, etc., and can solve problems such as difficulty in replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

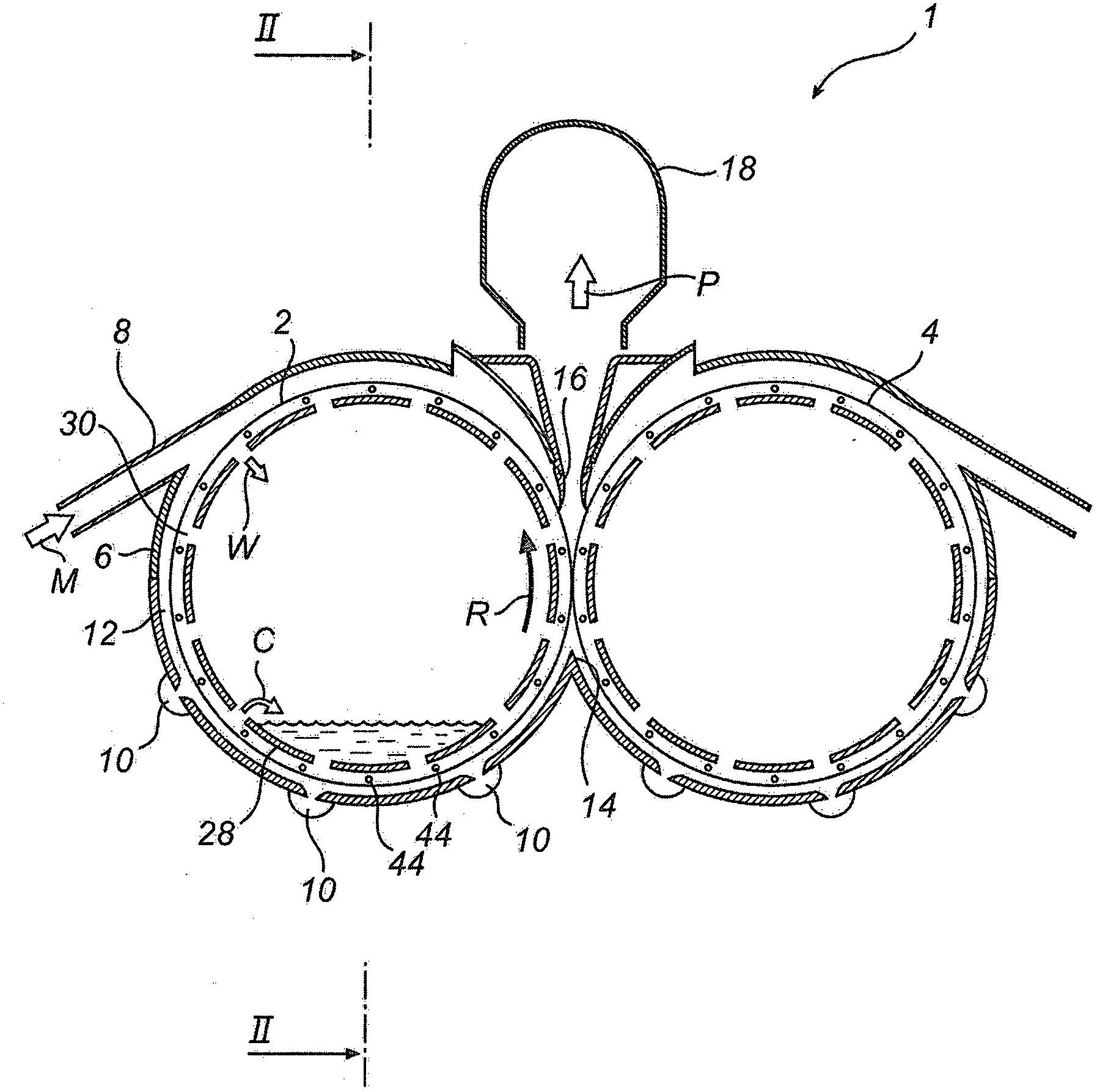

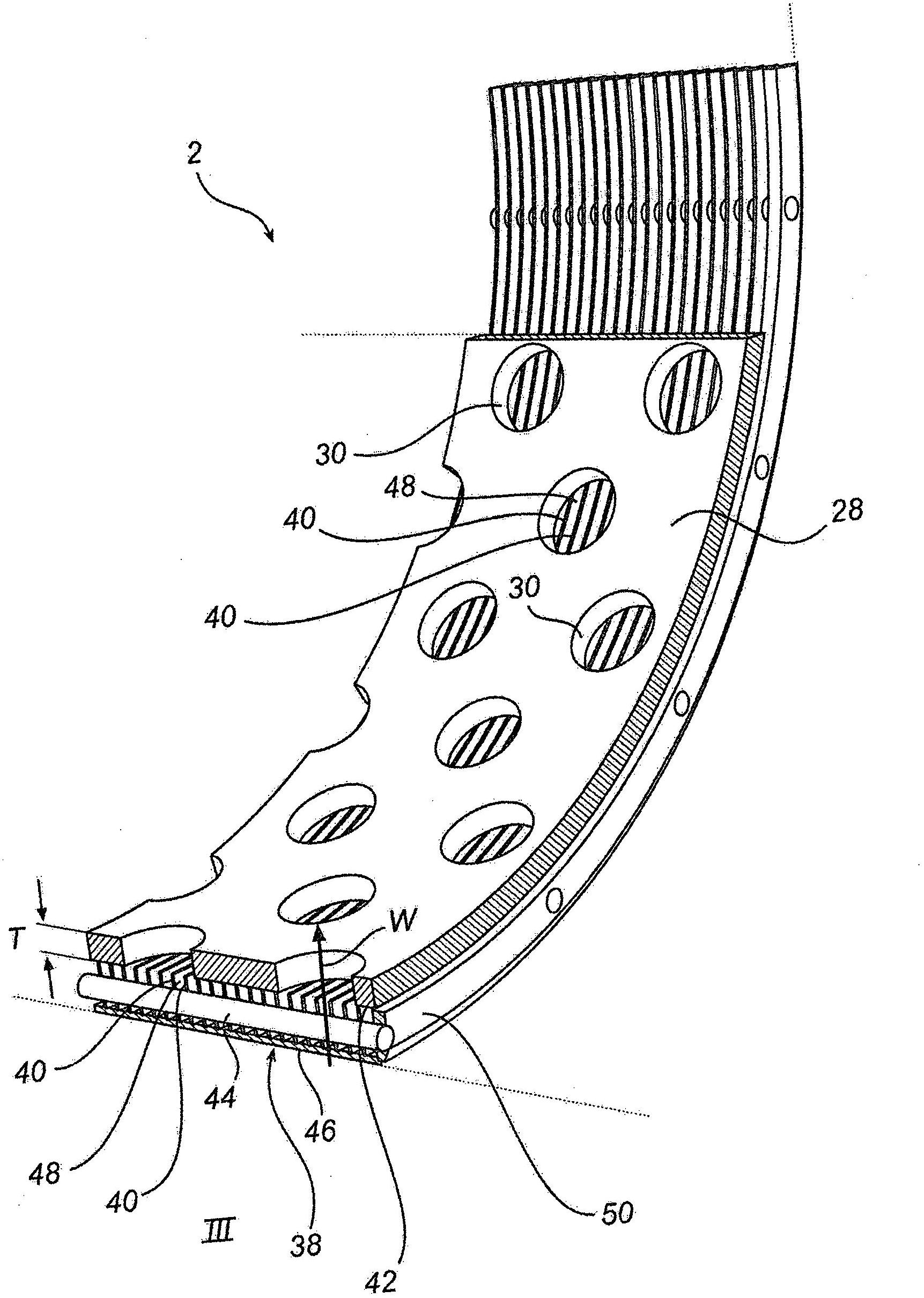

[0029] figure 1 A dewatering plant in the form of a press 1 is shown seen from the side and in section for dewatering a liquid suspension of solid biological material, eg cellulose pulp. The press 1 has a first dewatering drum 2 and a second dewatering drum 4 . like figure 1 As shown by the arrow R in , the dehydration drum 2 is arranged to rotate counterclockwise. The dewatering drum 4 is arranged to rotate in the opposite direction, that is, clockwise, but, hereinafter, even if the second dewatering drum 4 is mirror-symmetrical with respect to the first dewatering drum 2, the dewatering drum 4 is also similar in structure and function to the dewatering drum 2, so it will not The dewatering drum 4 is described again in more detail.

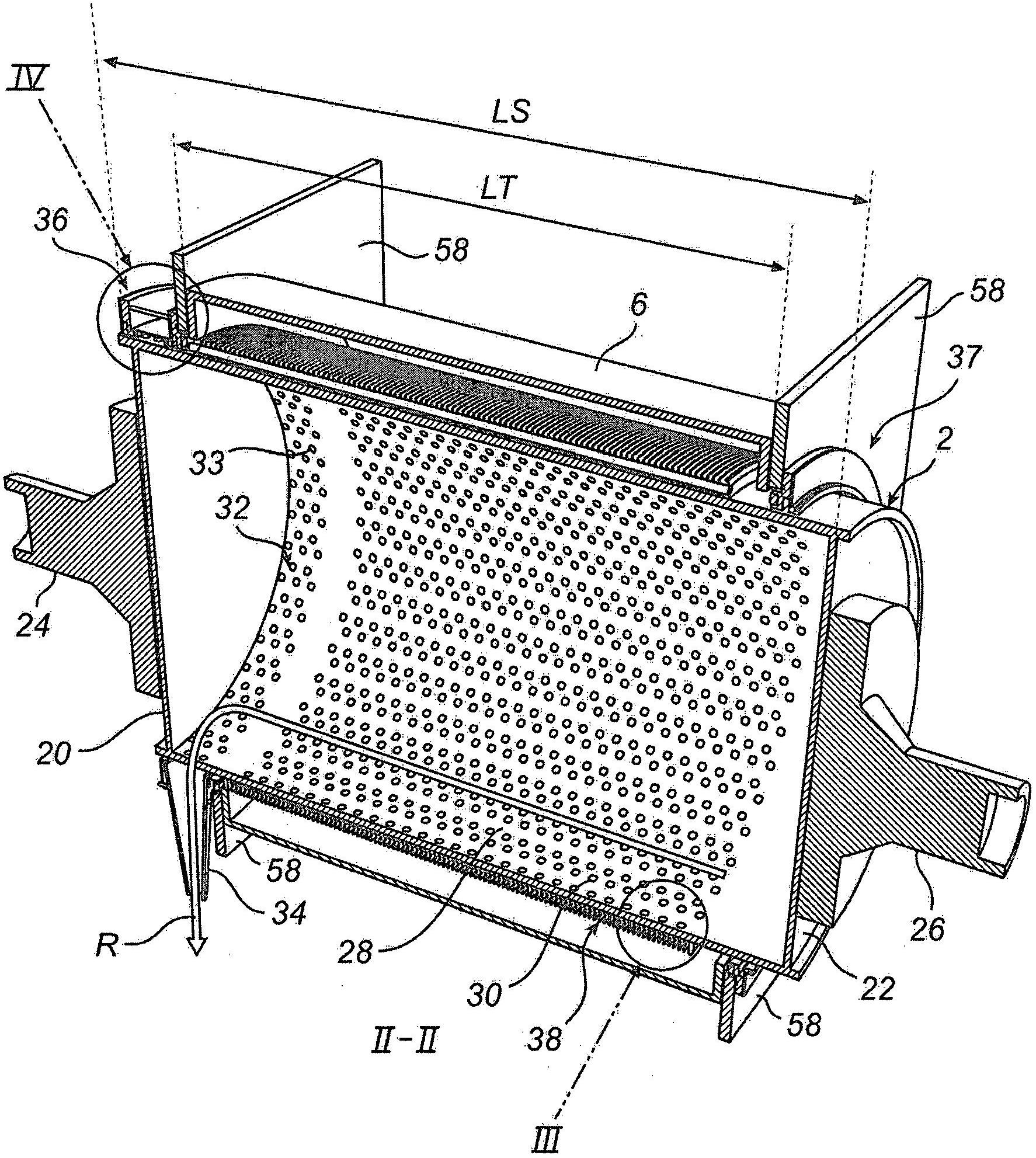

[0030] The press 1 also comprises pressing means in the form of a barrel 6 inside which the first dewatering drum 2 is arranged to rotate. The barrel 6 has an inlet 8 on one side of it for a liquid suspension of cellulose pulp, ie a dry solid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com