Engine crankshaft oil seal press-fitting tool and method

A technology for press-fitting tooling and engine, applied in the field of crankshaft oil seal press-fitting, can solve the problems of high labor intensity, difficult to meet the needs of rapid development of enterprises, low work efficiency, etc., to reduce labor intensity, meet oil seal sealing requirements, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

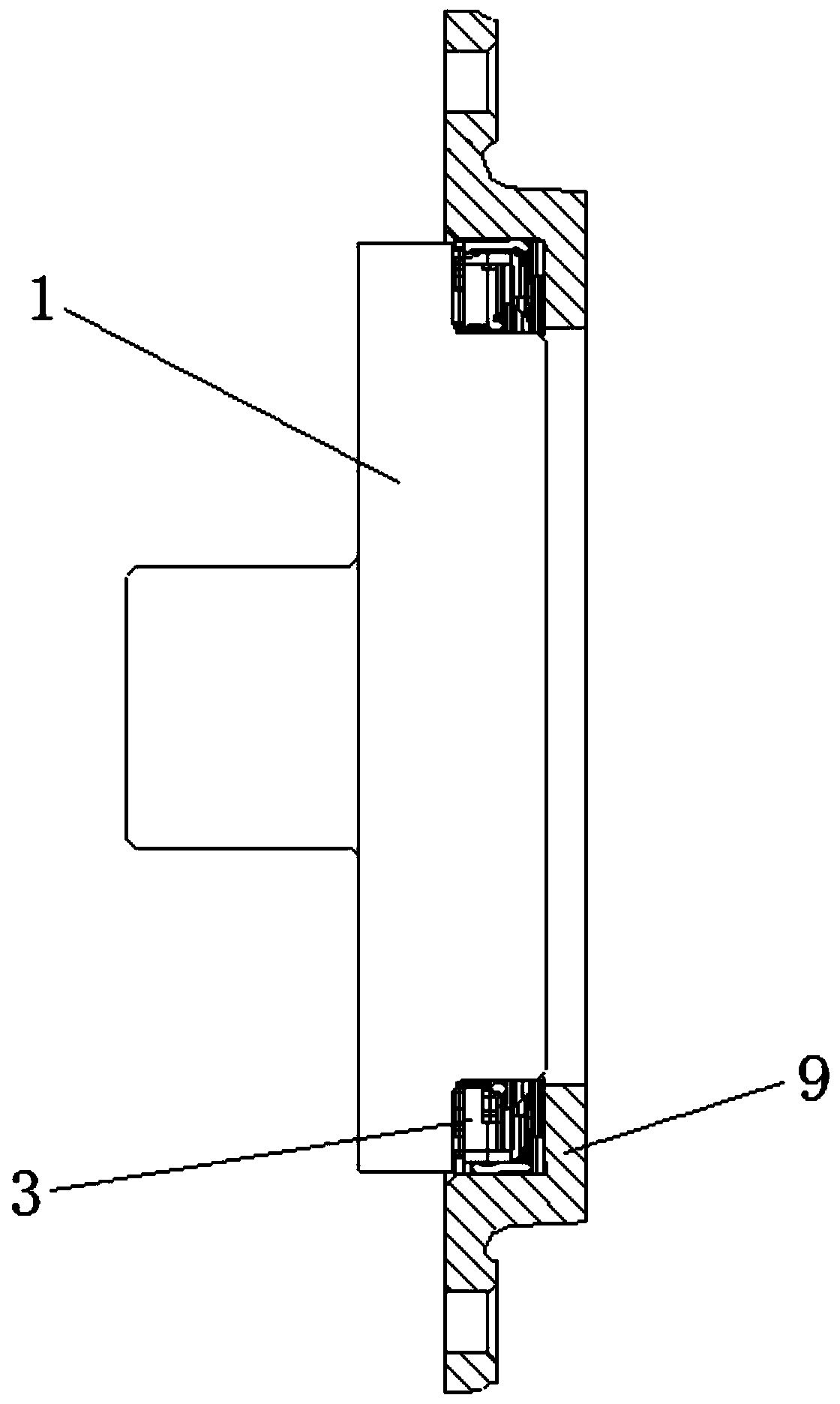

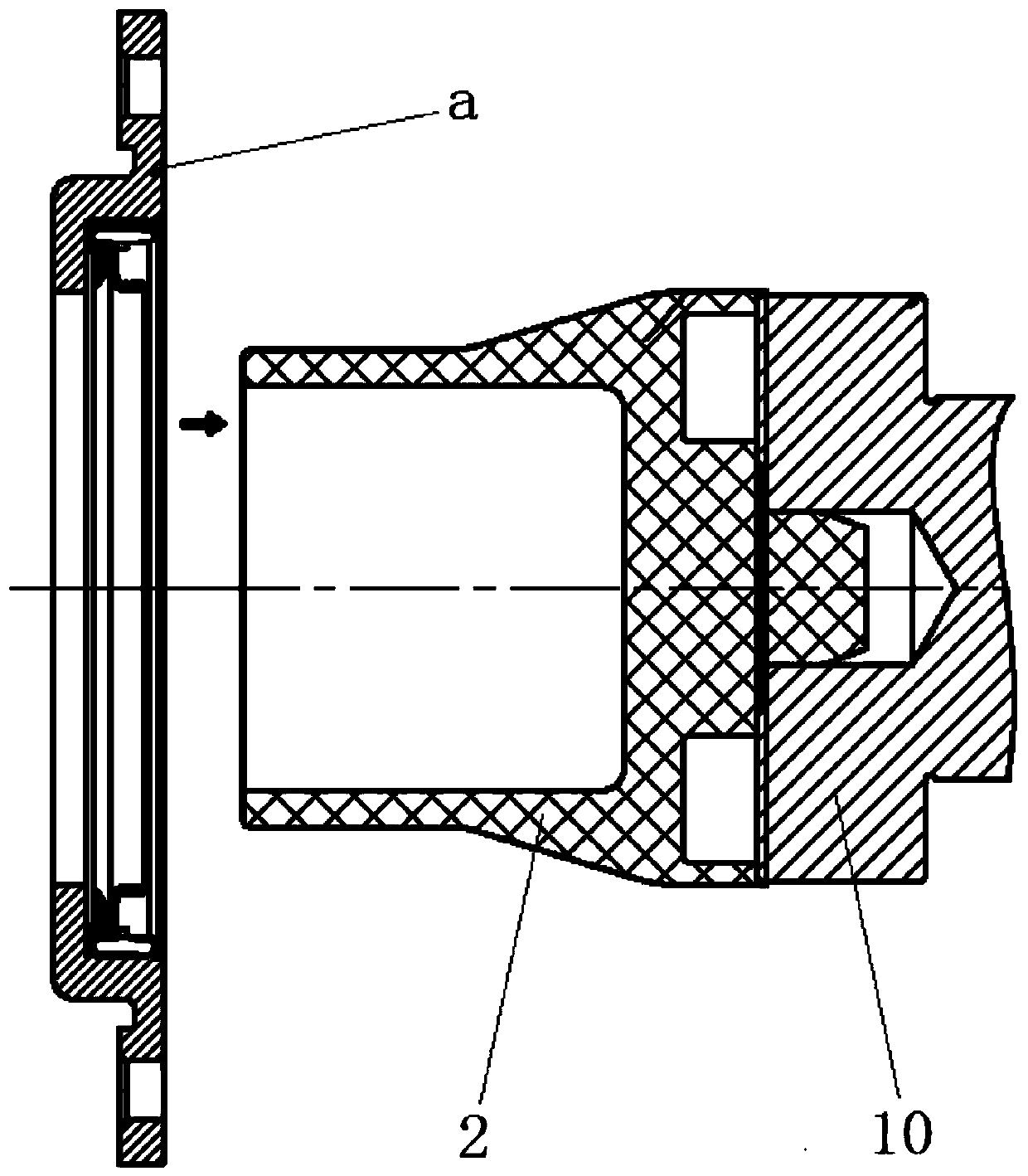

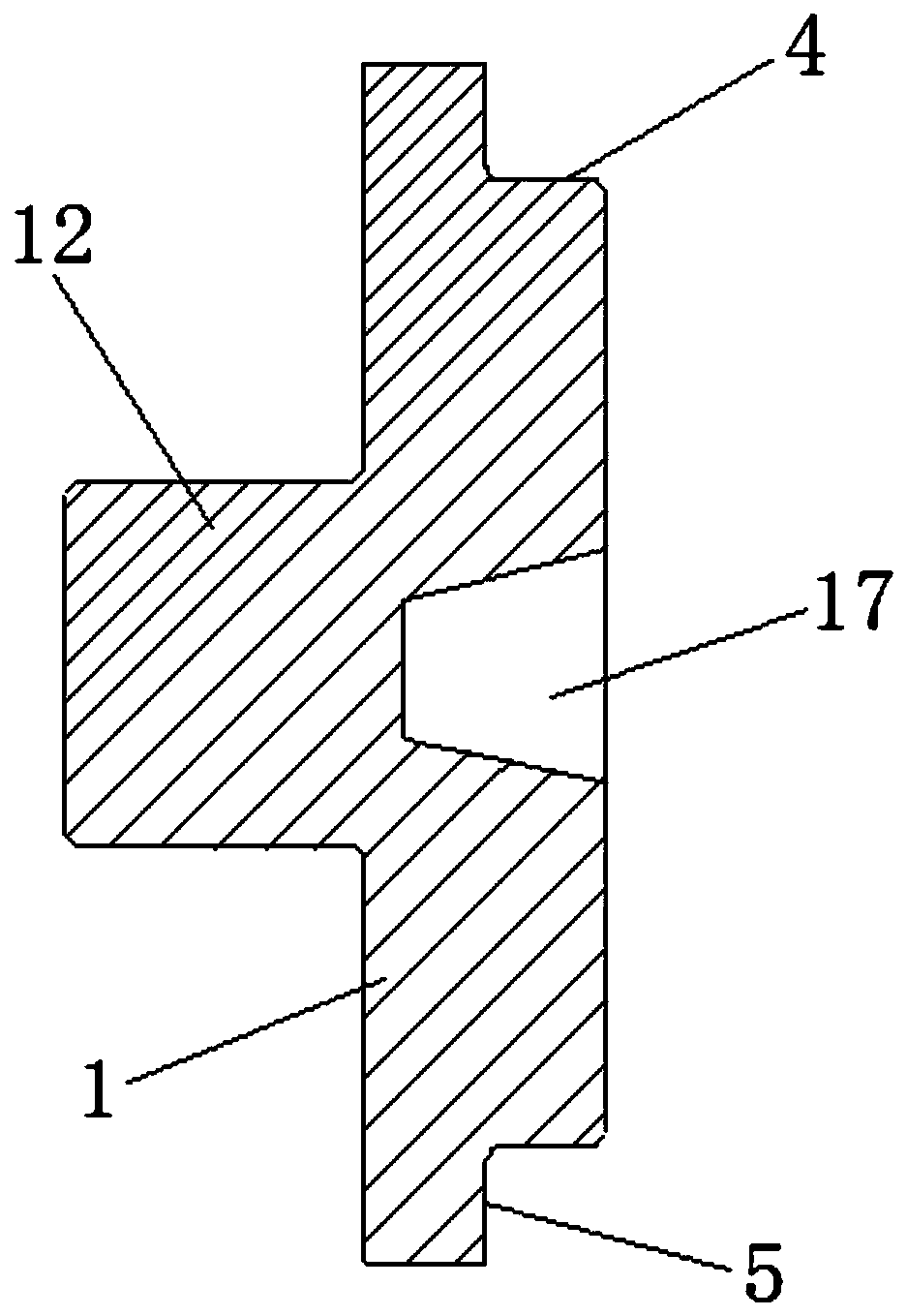

[0026] refer to Figure 1-5 , an engine crankshaft oil seal press-fitting tooling of the present invention, including a split-type indenter 1 and a positioning sleeve 2, one end of the indenter 1 is provided with a mounting seat 4 for installing the crankshaft oil seal 3, and the mounting seat 4 and the pressure A press-fit surface 5 is formed between the heads 1, and the crankshaft oil seal is pushed by using the press-fit surface. The mounting seat 4 and the pressure head 1 are integrally formed and arranged coaxially; The guide ring surface 6, the inclined ring surface 7 and the positioning ring surface 8 are arranged in sequence, wherein the diameter of the guide ring surface 6 is smaller than the inner diameter of the shaft hole of the oil seal seat 9, and the diameter of the positioning ring surface 8 is adapted to the diameter of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com