Installation method for short mandrel continuous casting rolls adopting interference fit

An installation method and technology for continuous casting rolls, applied in the field of continuous casting roll processing, can solve problems such as unfavorable installation of short mandrel continuous casting rolls, unfavorable continuous casting rolls, etc., and achieve mass production, save assembly time, and save installation time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below with reference to the accompanying drawings, which is an explanation rather than a limitation of the present invention.

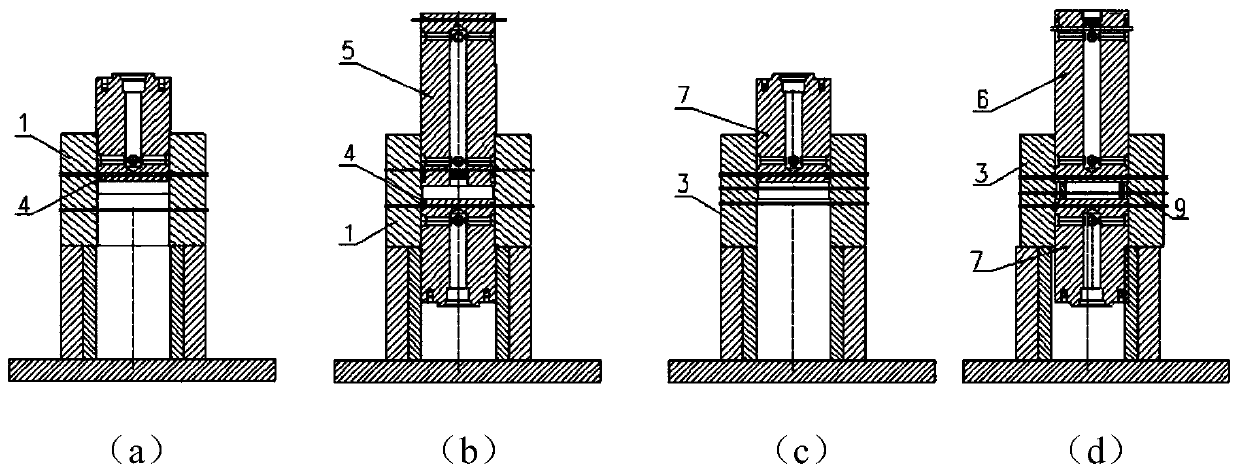

[0037] The installation between the roller sleeve and the mandrel of the short mandrel continuous casting roll to be installed in the present invention is an interference assembly, and the interference is between 0.41 and 0.45mm, so the installation should be realized by the principle of thermal expansion and contraction of materials Assembling, each step of the assembly adopts vertical installation.

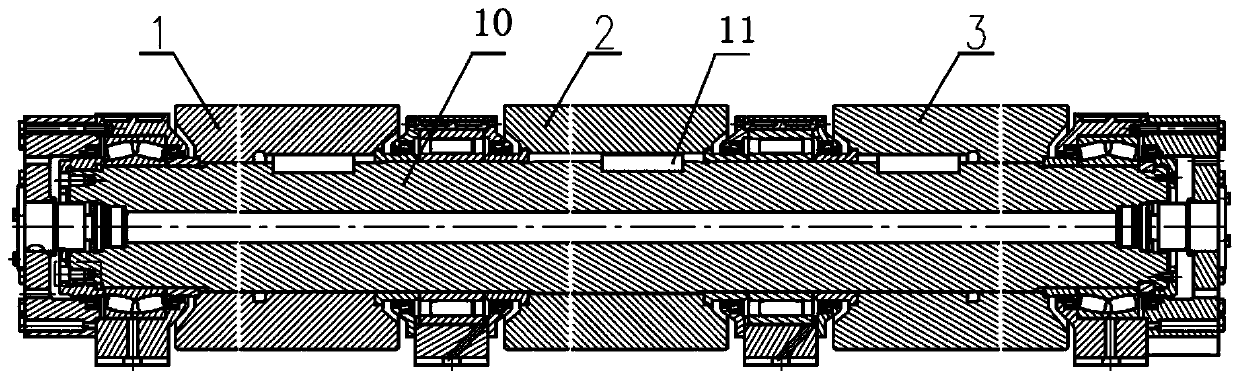

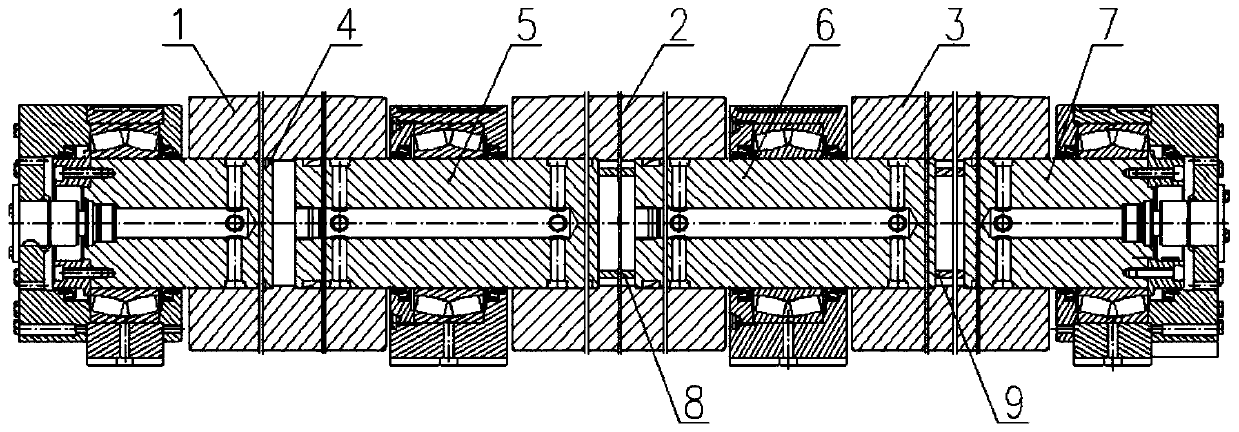

[0038] The structure of the short mandrel continuous casting roll is as figure 2 As shown, including the first roller sleeve 1, the second roller sleeve 2, the third roller sleeve 3, the first mandrel 4, the second mandrel 5, the third mandrel 6, the fourth mandrel 7, the first water guide The sleeve 8, the second water guide sleeve 9, the first set of bearing assembly, the second set of beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com