Machine tool for product assembling

A technology of a mother machine and a product, applied in the field of automation equipment for product assembly, can solve problems such as poor versatility, and achieve the effects of low production cost, automation, and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

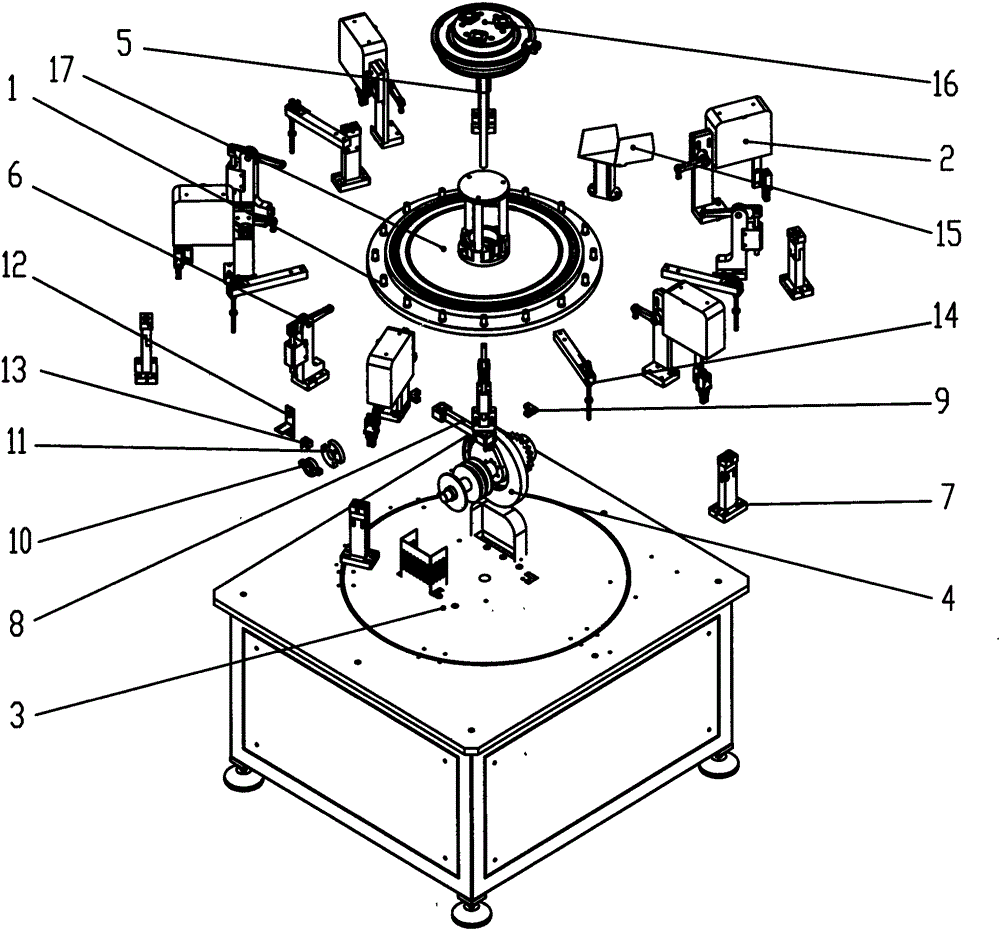

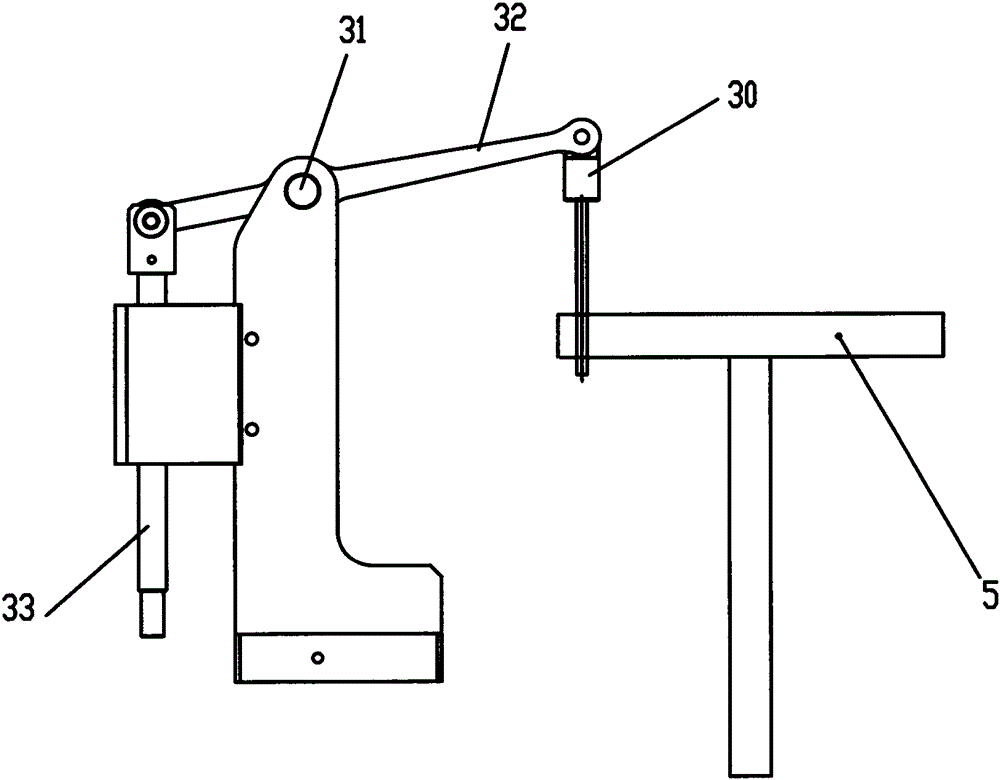

[0017] A mother machine for product assembly, including a frame 3, a discharge hopper 15 is installed on the upper part of the frame 3, a reducer is installed inside the frame 3, an indexing mechanism 1, an indexing piece 11, and a sensor plate are horizontally installed on the upper part of the frame 3 12 and sensor 13, the described speed reducer is connected with the lifting disc assembly 5 through the cam assembly 4, and the first indexing plate 11, the second indexing plate 10 and the indexing top plate 17 are installed on the indexing mechanism 1, and the indexing The top plate 17 is connected with the manipulator assembly 2, the riveting assembly 6 and the detection assembly 14, the lifting plate assembly 5 is provided with the lifting top plate 16, the lower part is connected with the directional arm assembly 8, and the lifting plate assembly 5 and the manipulator assembly 2 are installed. There are connectors 20, connecting rods 21, sector gears 22 and rotary gears 23,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com