Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Increased flow cross section" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

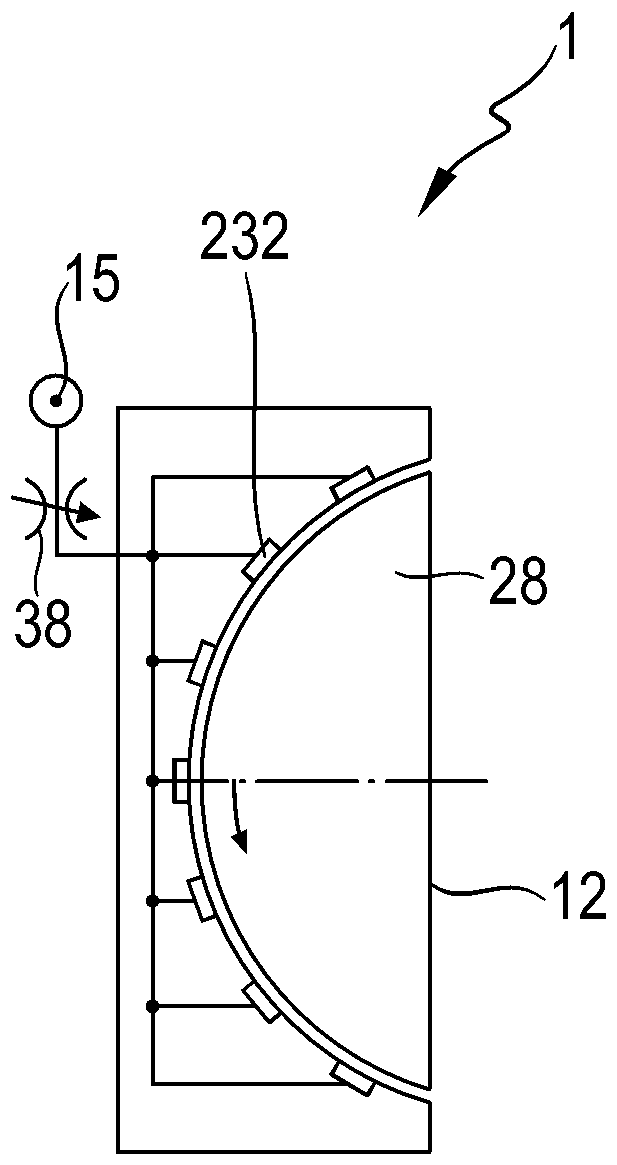

Hydrostatic Axial Piston Machine

ActiveCN106481526ALow running costIncrease volumetric efficiencyPump controlReciprocating piston enginesEngineeringMechanical engineering

A hydrostatic axial piston machine defines an adjustable displacement volume and includes a housing, a cylinder drum, a plurality of working pistons, a pivot cradle, and a plain bearing. The working pistons are received in the cylinder drum so as to be axially displaceable, and are supported on a sliding surface of the pivot cradle. The pivot cradle is configured to adjust the displacement volume, and is pivotably mounted on the plain bearing. The plain bearing is fixed with respect to the housing. The hydrostatic axial piston machine is configured to form at least one first hydrostatic relief pressure field between the plain bearing and the pivot cradle.

Owner:ROBERT BOSCH GMBH

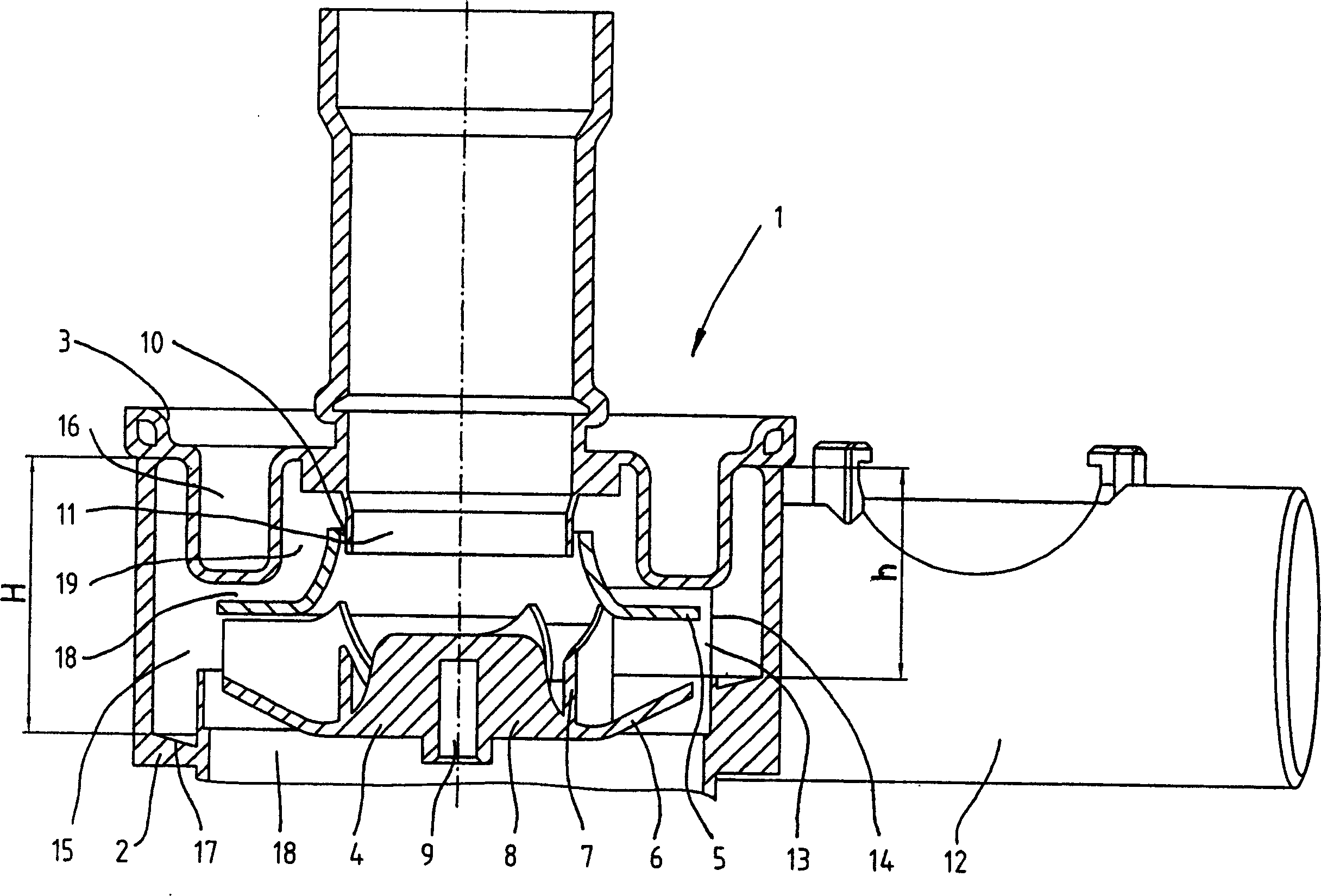

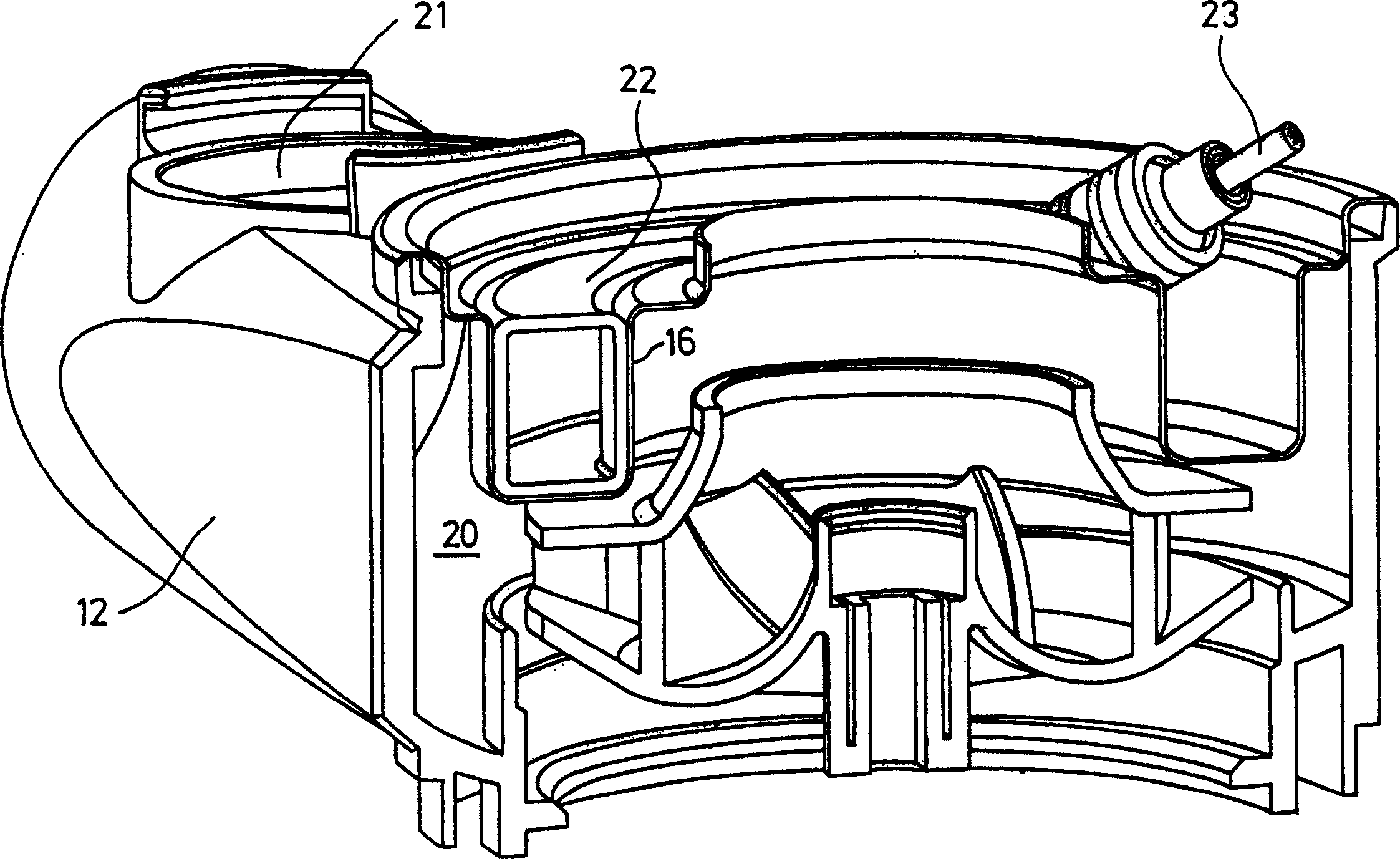

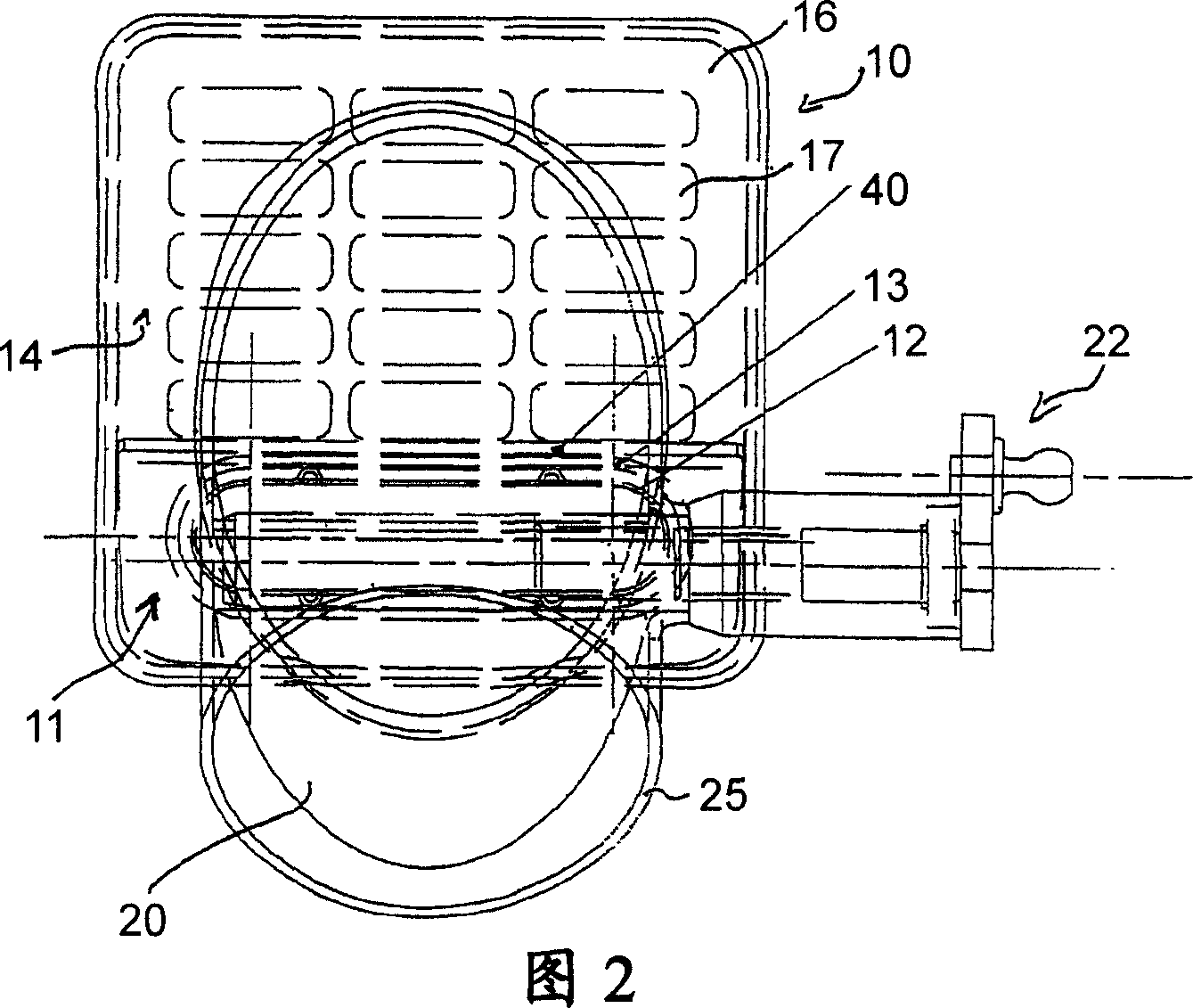

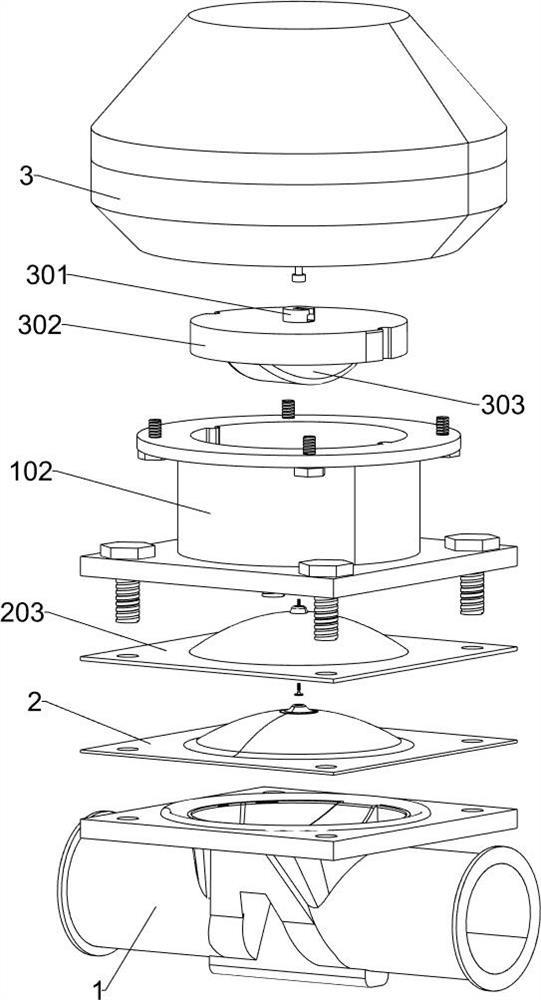

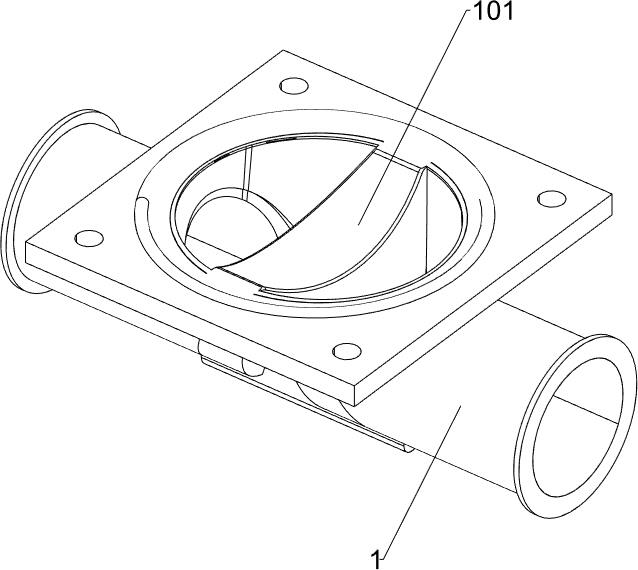

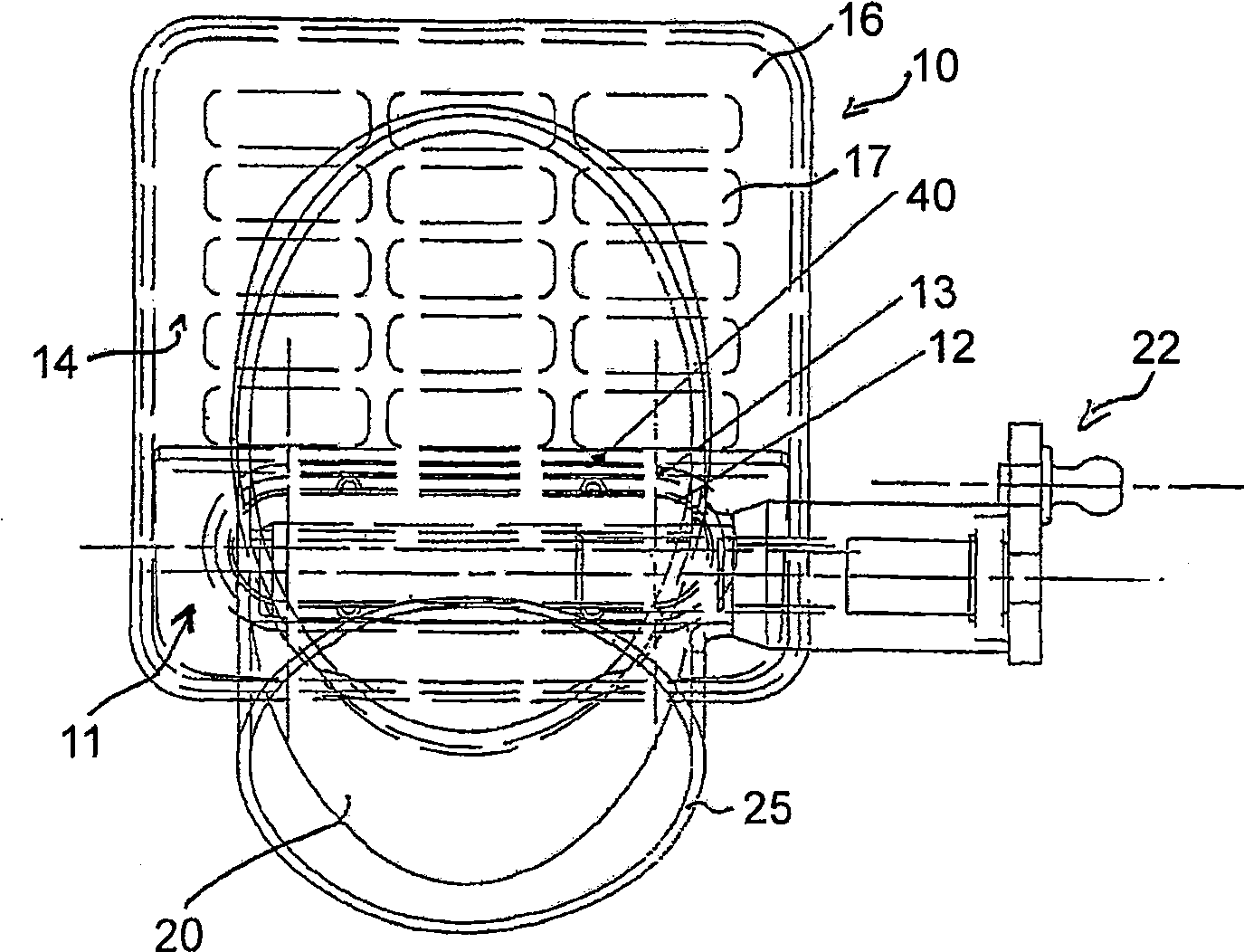

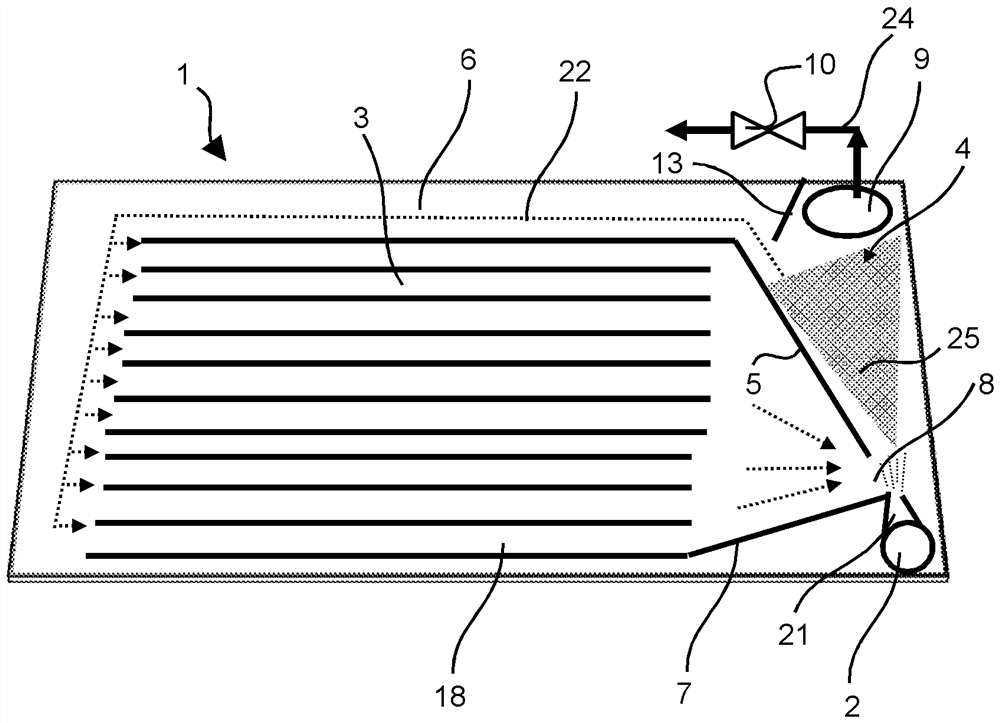

Centrifugal pump

InactiveCN1727696AImprove flow conditionsImprove efficiencyTableware washing/rinsing machine detailsPump componentsCentrifugal pumpEngineering

The invention relates to a centrifugal pump (1), in particular to a centrifugal pump for household appliances, such as washing machines or dishwashers, which comprises a pump housing (2) having an axial inlet (11), an outlet (12) and a heating element, wherein the pump housing (2) incorporates a rotatably mounted impeller (4) and a flow channel (15) enveloping the impeller (4) and heating element. The centrifugal pump (1) according to the invention is intended to have improved efficiency. This is achieved by having the flow cross-section of the flow channel (15) increase along the periphery toward the outlet (12).

Owner:AWECO APPLIANCE SYST

Exhaust gas diffuser of gas turbine

InactiveCN102844527AShorten the lengthSmall sizePower plant exhaust arrangementsEngine manufactureEngineeringGas turbines

Owner:SIEMENS AG

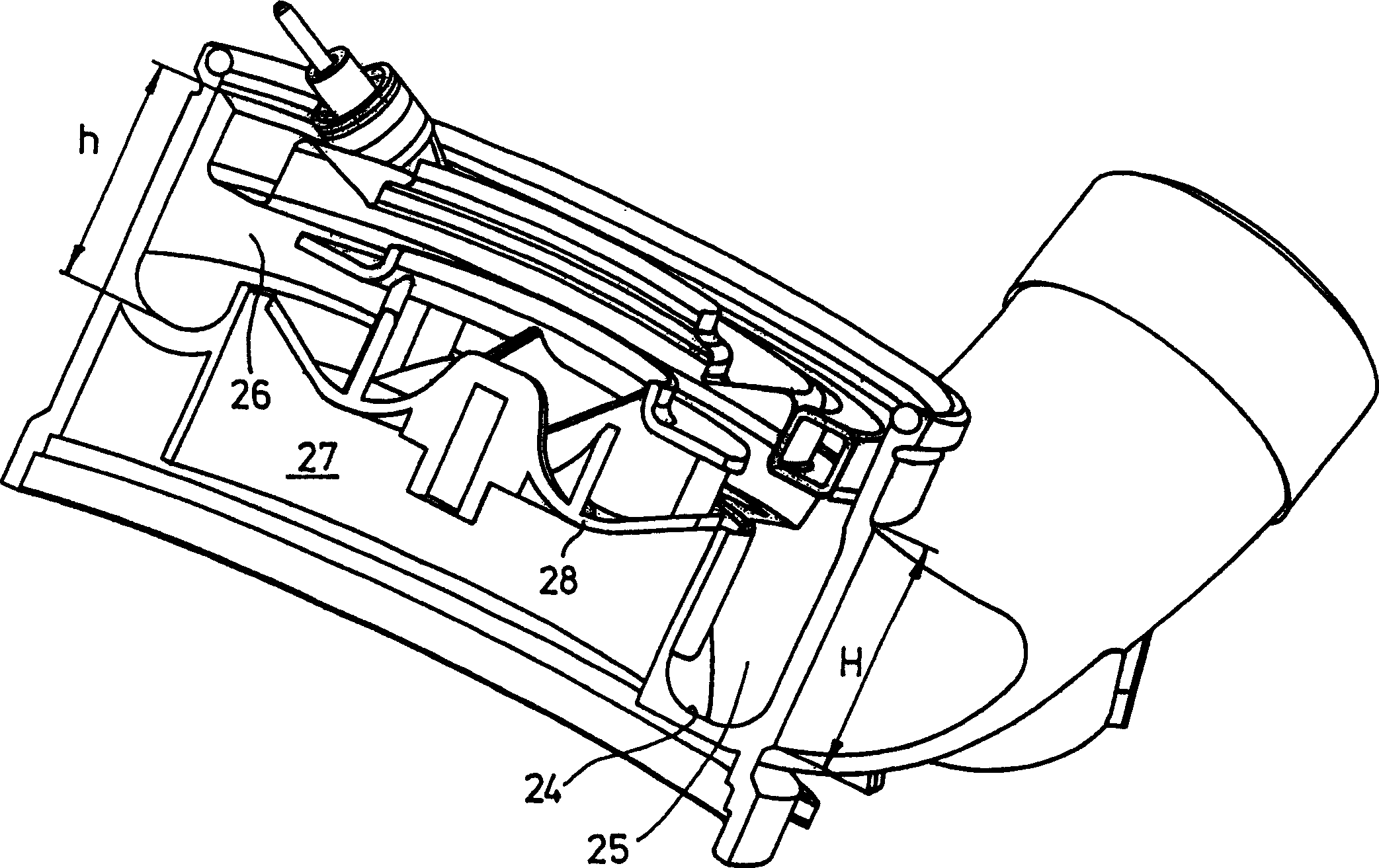

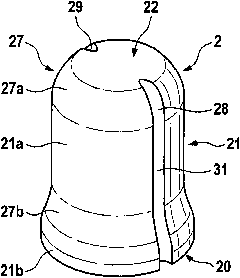

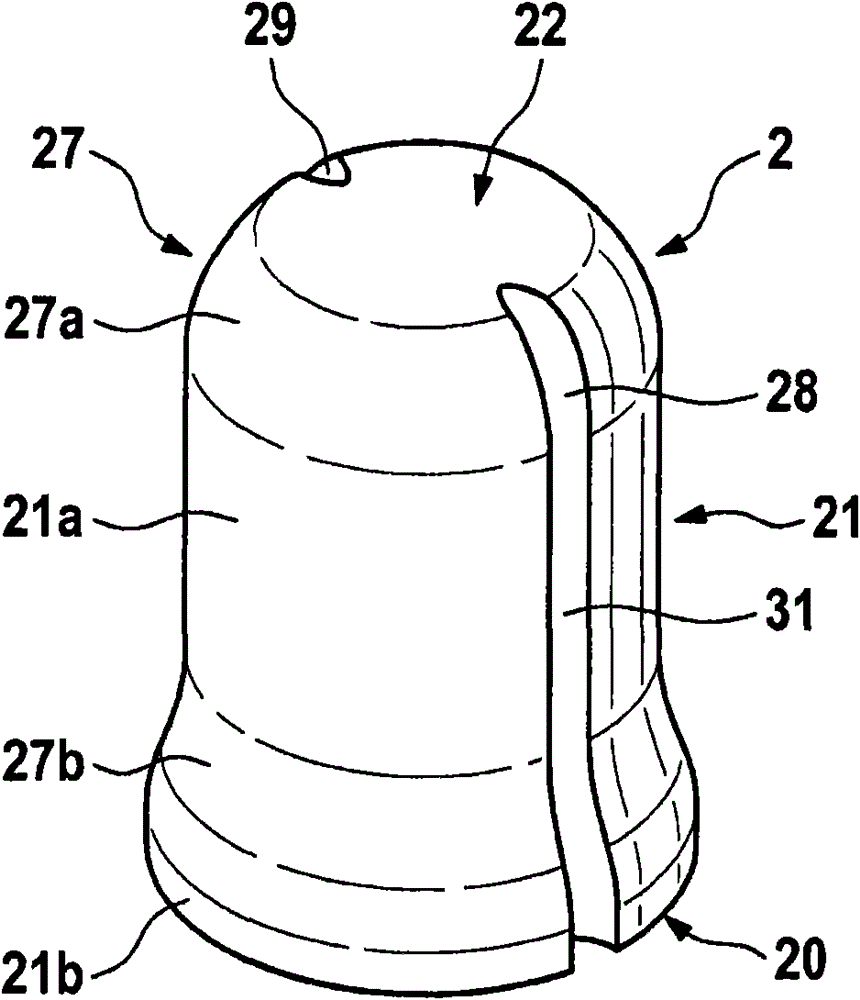

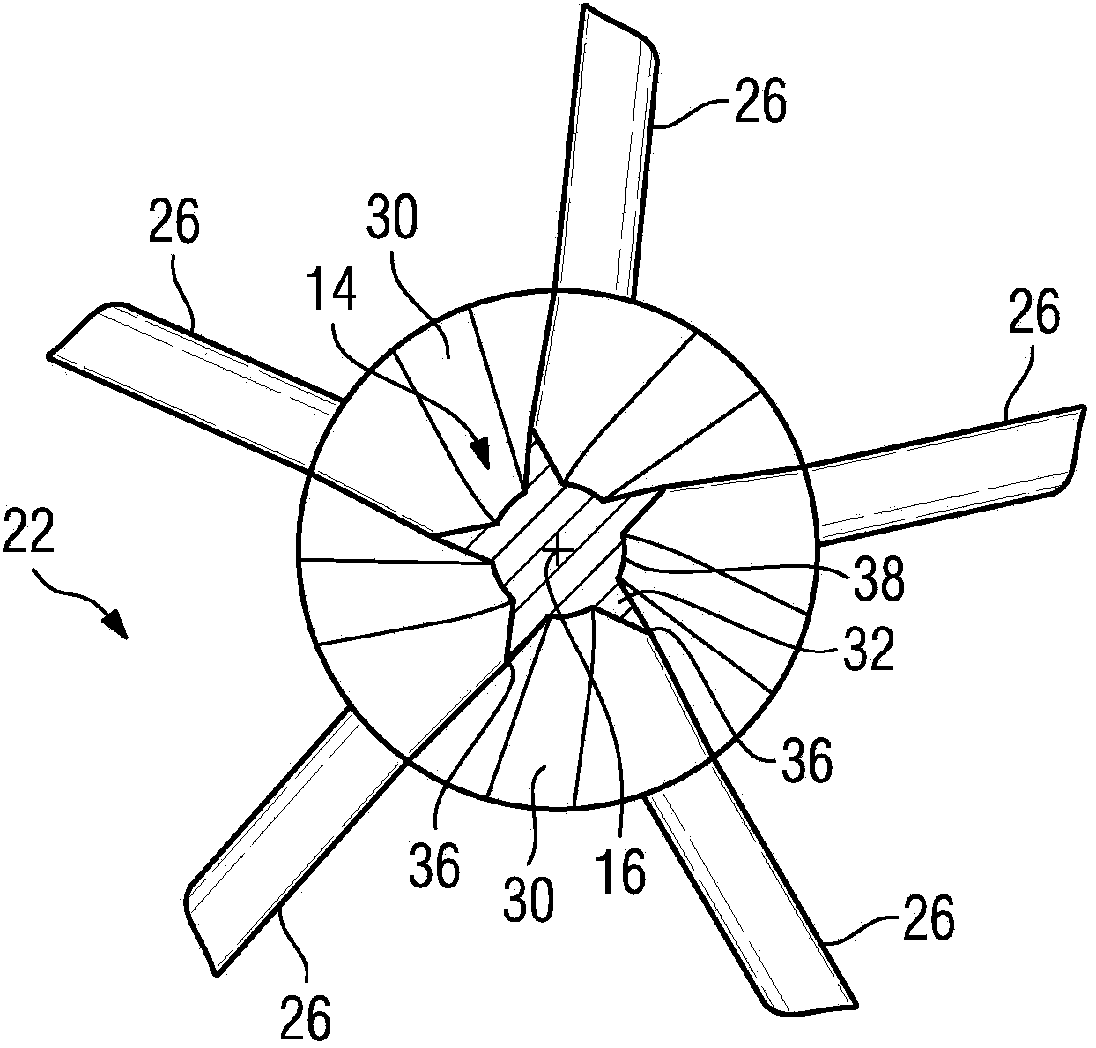

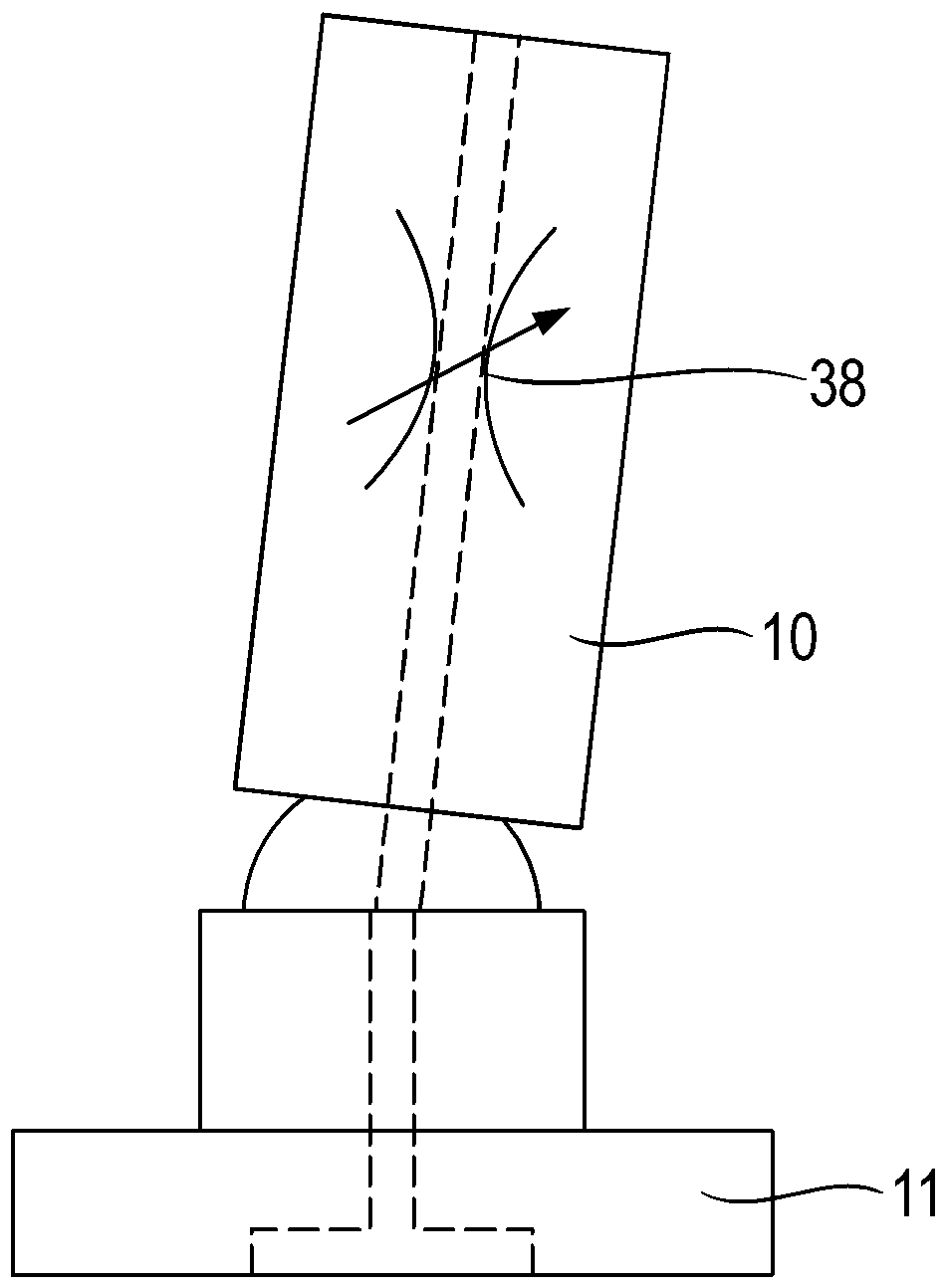

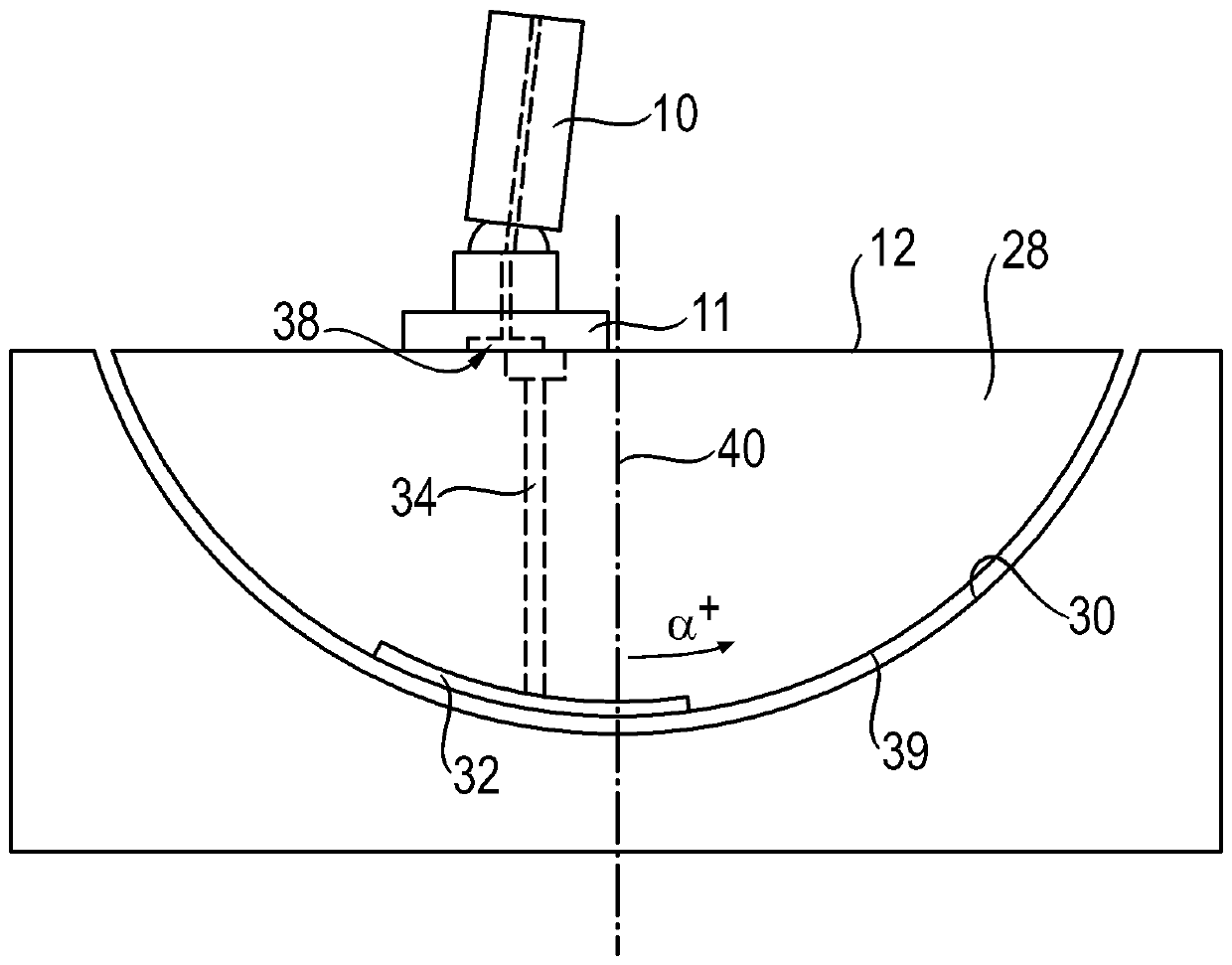

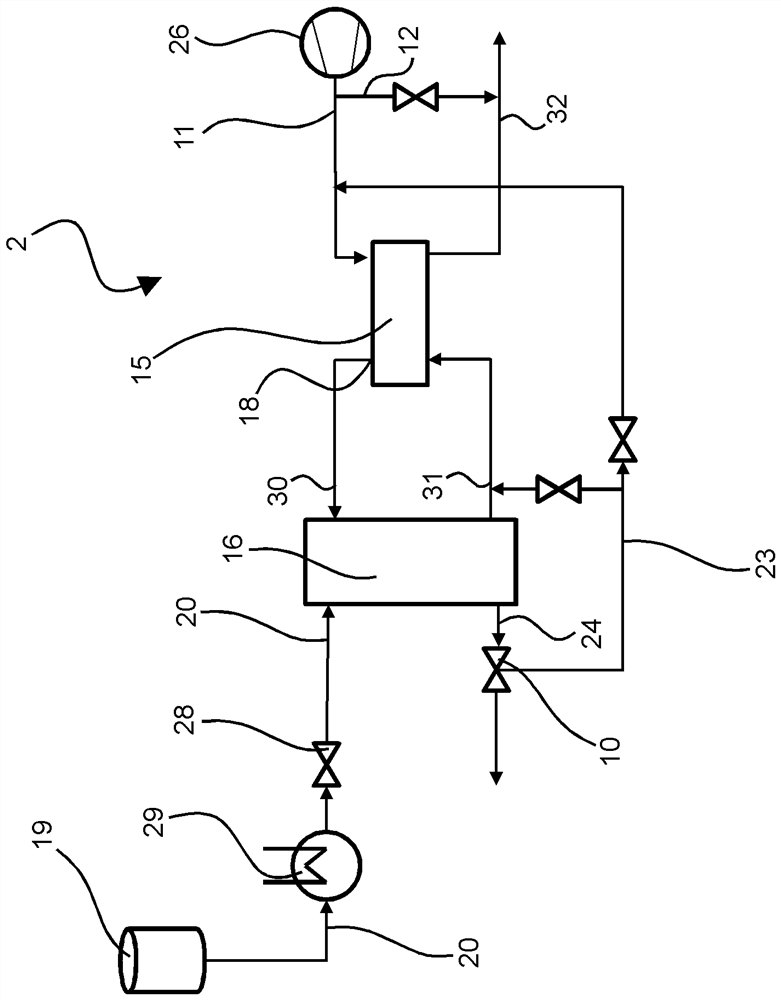

Method and device for producing a container filled with filling medium

ActiveCN106103044AEasy to understandRapid coolingDomestic articlesLiquid materialLiquid stateEngineering

The invention relates to a method for producing a container (2) filled with a liquid filling medium, wherein a preform (1) made of a thermoplastic material is stretched after thermal conditioning by means of a stretching rod (11) and is transformed into the container (2) in an inflation process, wherein the inflation process comprises a pre-blowing phase, in which a fluid at a first pressure level is used for inflation, and a main blowing phase, in which a fluid at a second pressure level higher than the first pressure level is used for inflation. The invention is characterised in that the fluid used in the pre-blowing phase is a blowing gas, and that the fluid used in the main blowing phase is the filling medium. The invention further relates to a device for carrying out a method according to the invention.

Owner:KHS GMBH

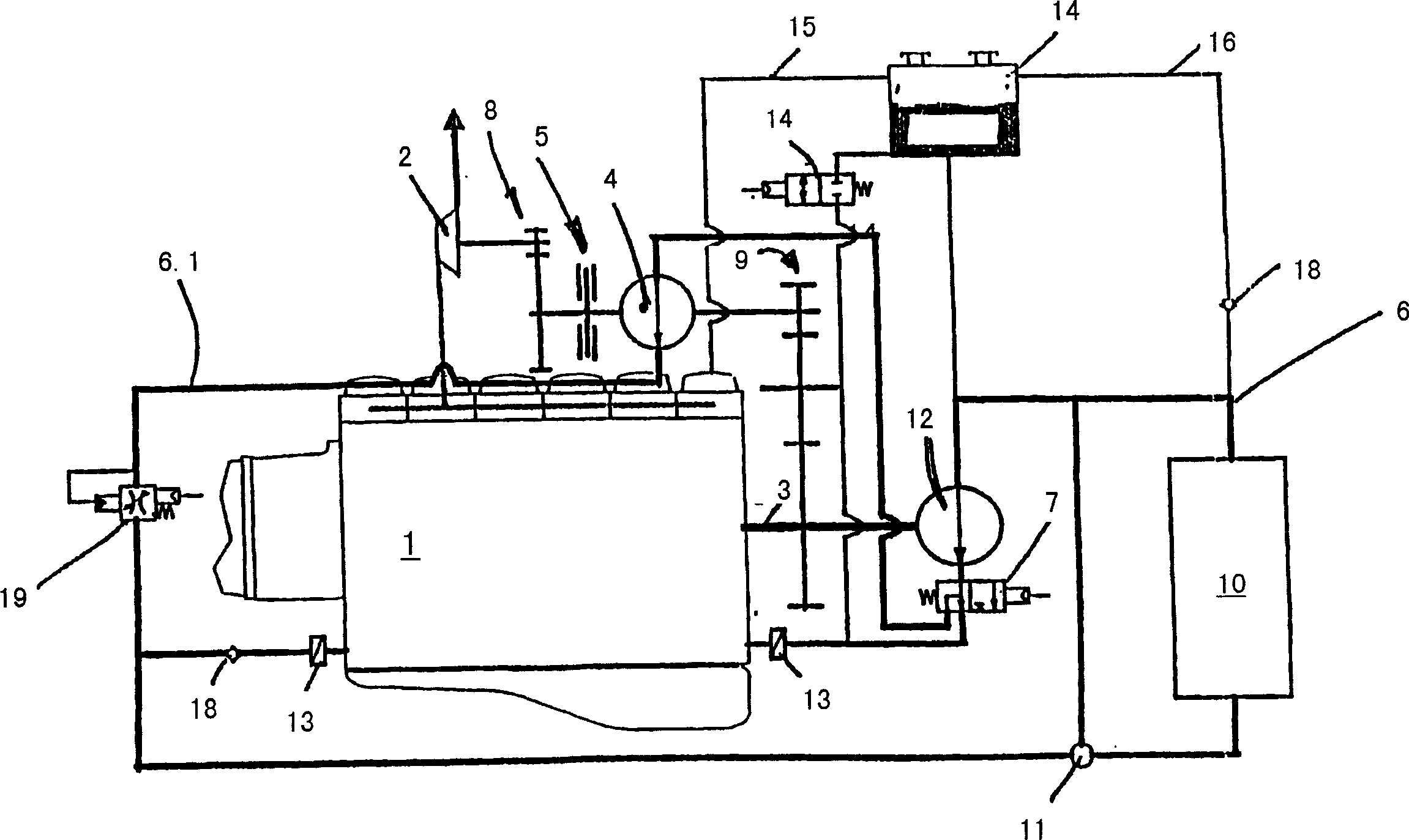

Drive train with exhaust gas utilisation and control method

InactiveCN1898463AImprove driving comfort performanceContinuous load conditionInternal combustion piston enginesDrive wheelCoupling

The invention relates to a power train comprising: an internal combustion engine; an exhaust gas utilization turbine arranged in the exhaust gas flow of the internal combustion engine; a crankshaft driven by the internal combustion engine; Connected so that the crankshaft can be driven by the exhaust gas utilization turbine; the hydraulic coupling has a driving wheel and a driven wheel, which form a working chamber with each other, which can be filled with a working medium for torque transmission; the driving wheel and the exhaust gas utilization turbine form a transmission connection; the driven wheel forms a transmission connection with the crankshaft; the relative rotational movement of the driving wheel can be mechanically braked and locked, so that the fluid coupling obtains the function of a hydraulic speed reducer; according to the power transmission system of the present invention The characteristic feature is that a control device is provided, which causes the working chamber of the fluid coupling to be emptied in a targeted manner to a predetermined filling level before and / or while the driving wheel is braked.

Owner:VOITH TURBO GMBH & CO KG

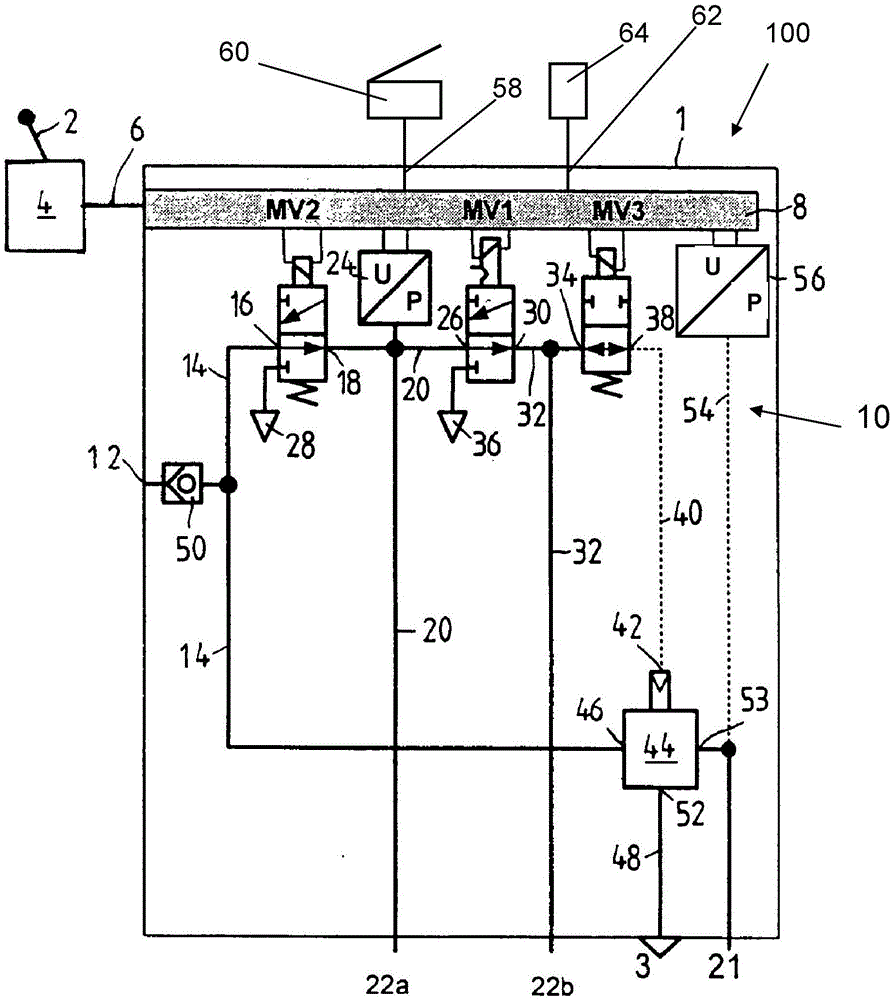

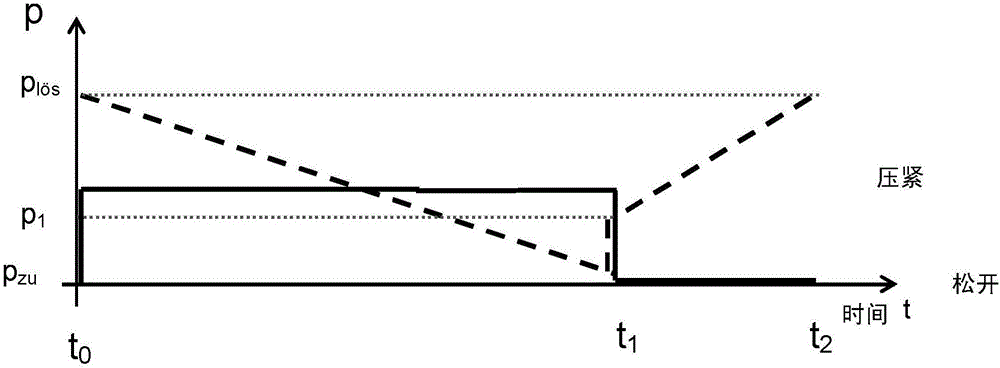

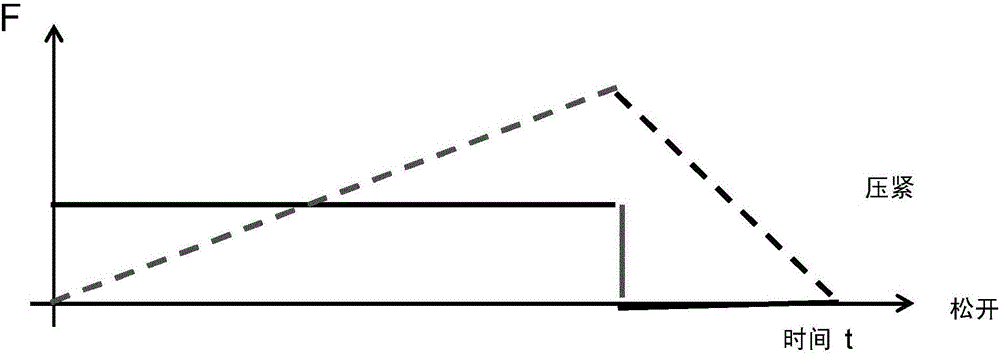

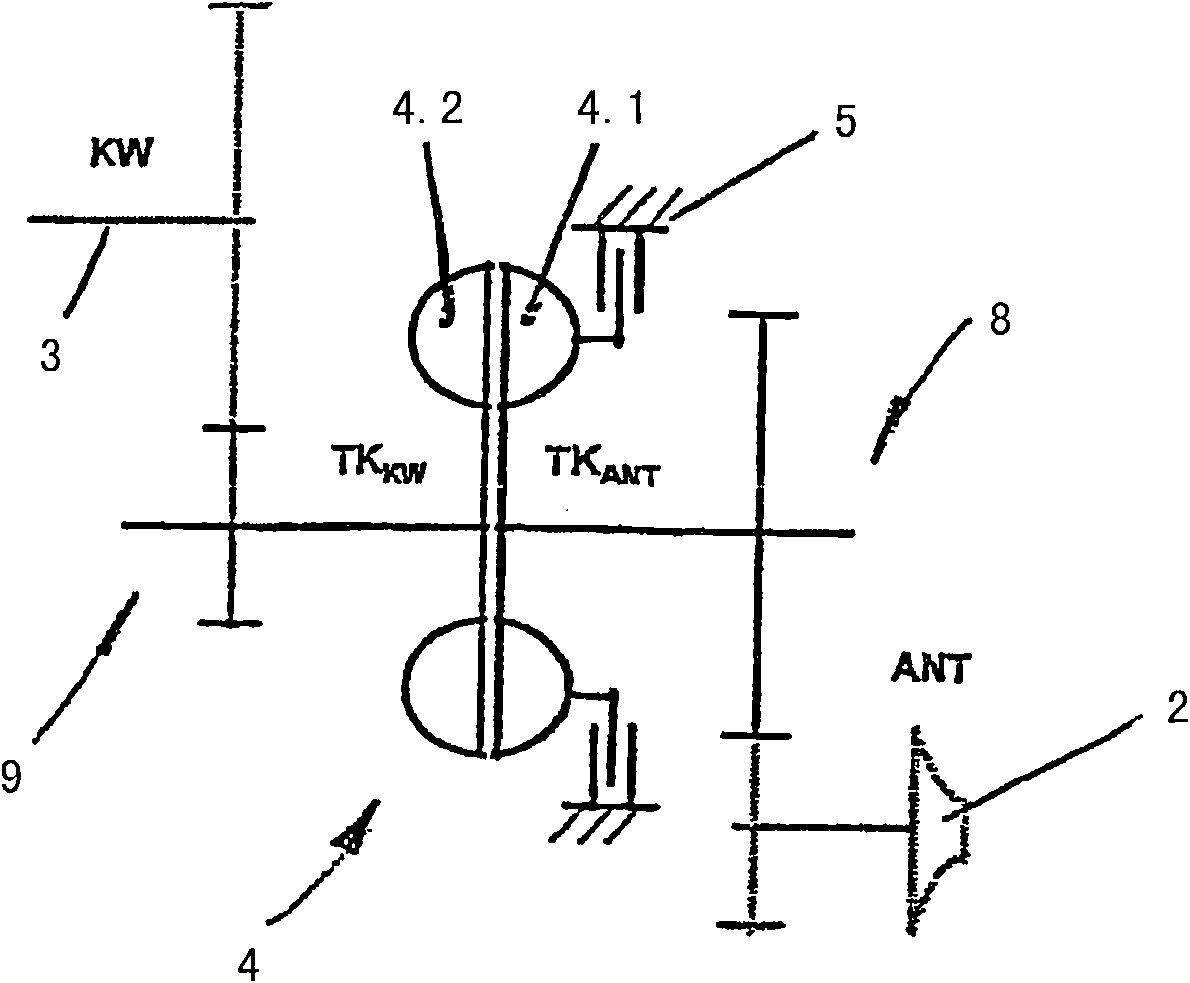

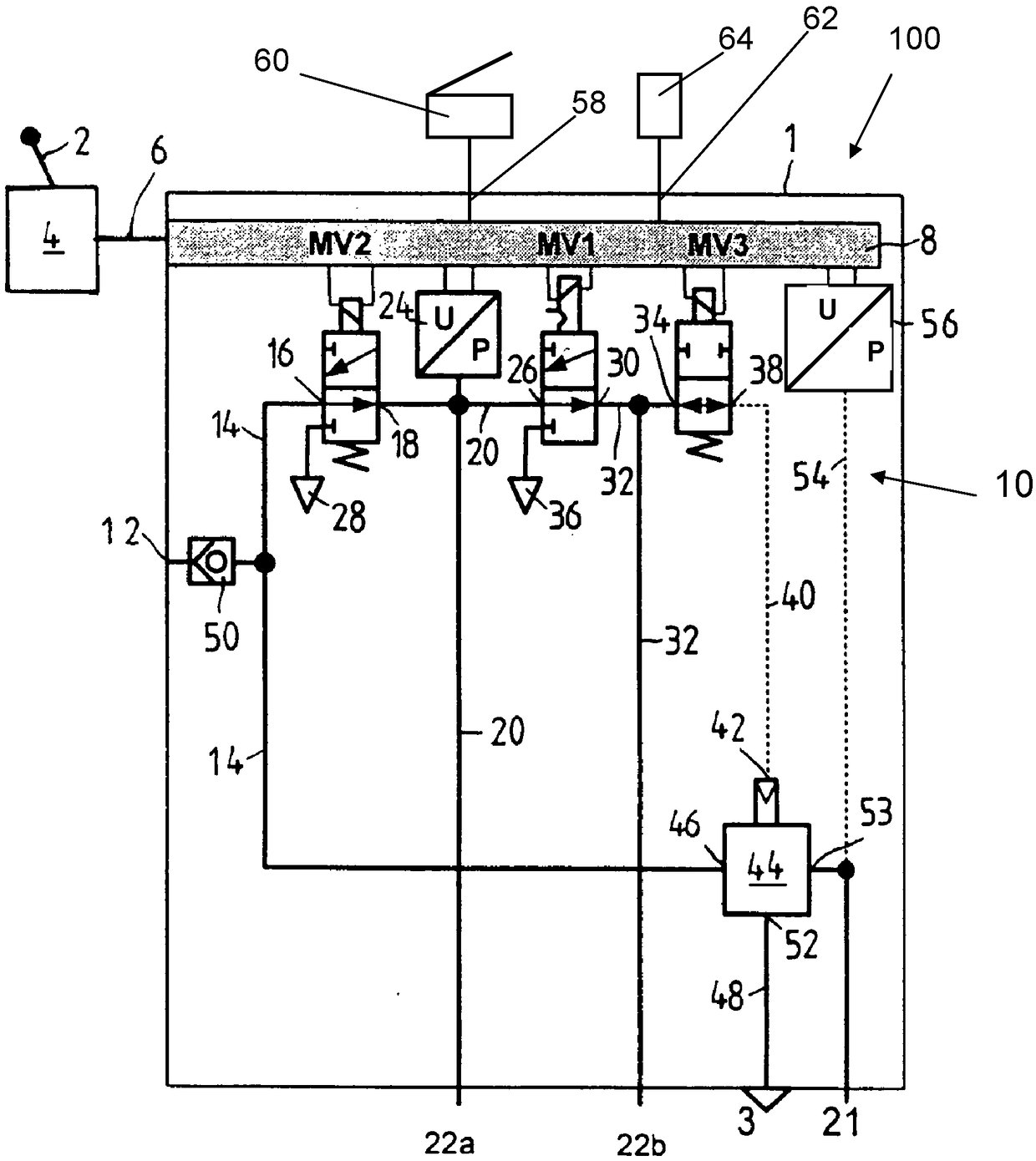

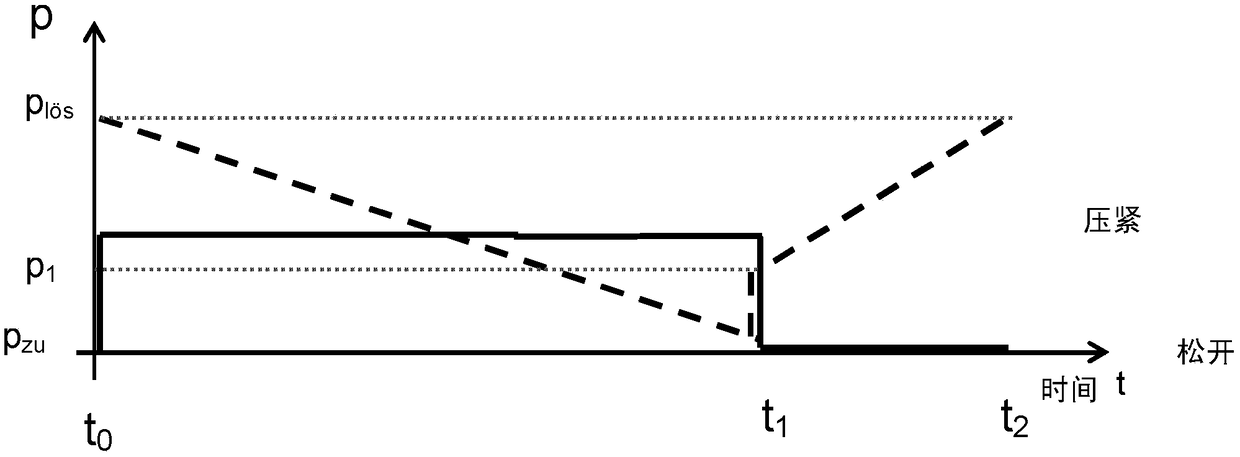

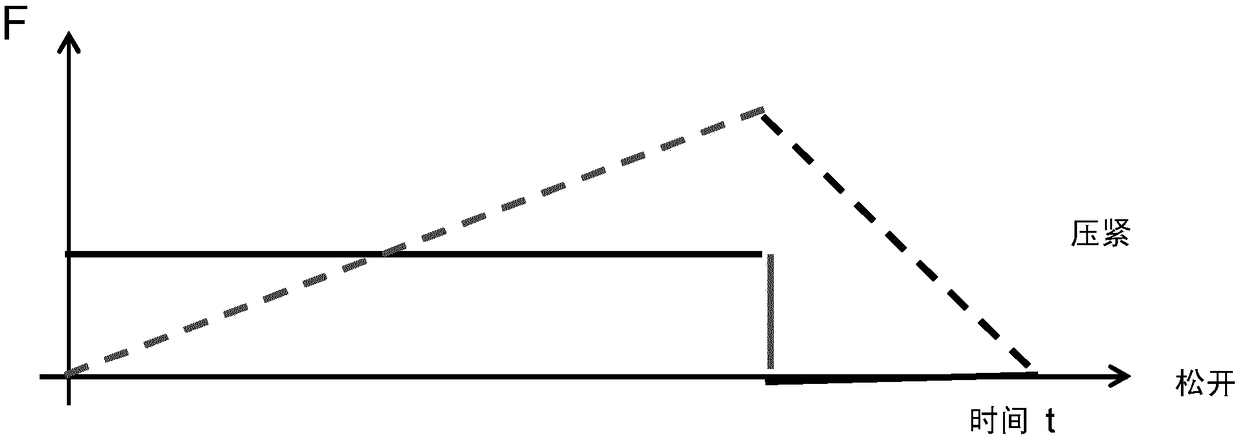

Electropneumatic spring brake device of a motor vehicle with an abrupt pressure increase when releasing the brake

ActiveCN106414194AIncreased flow cross sectionAdjust the flow cross sectionFluid braking transmissionApplication and release valvesElectricityElectronic controller

The invention relates to an electropneumatic spring brake device (1) of a motor vehicle, including means for generating electric brake actuation signals that represents at least the "brake application" state and the "brake release" state; an electronic controller (8) which receives the brake actuation signals; an electropneumatic valve device (10) which is controlled by the electronic controller (8) dependent on the actuation signals; and at least one pneumatically actuated spring brake cylinder. The electropneumatic valve device (10) aerates the at least one spring brake cylinder by connecting to a compressed air supply (12) or de-aerates the spring brake cylinder by connecting to a pressure sink (3). A maximally aerated state, which can be brought about by the electronic controller (8), of the electropneumatic valve device (10) is produced in that the electropneumatic valve device (10) releases a maximum flow cross-section between the compressed air supply (12) and the at least one spring brake cylinder. According to the invention, the electronic controller (8) is designed to keep the electropneumatic valve device (10) in the maximally aerated state when switching from the "brake application" state to the "brake release" state while the vehicle is traveling until the pressure in the at least one spring brake cylinder is abruptly increased from a starting pressure value lying below a first gradient to a relatively higher first pressure value which still lies below a brake release pressure that fully releases the spring brake cylinder, and after the first pressure value has been reached, the electropneumatic valve device is switched to a state in which the pressure in the at least one spring brake pressure cylinder is increased from the first pressure value lying below a second gradient that is smaller than the first gradient to a second pressure value that is higher than the first pressure value in order to assume a partial release position or a full release position.

Owner:KNORR-BREMSE SYST FUER NUTZFAHRZEUGE GMBH

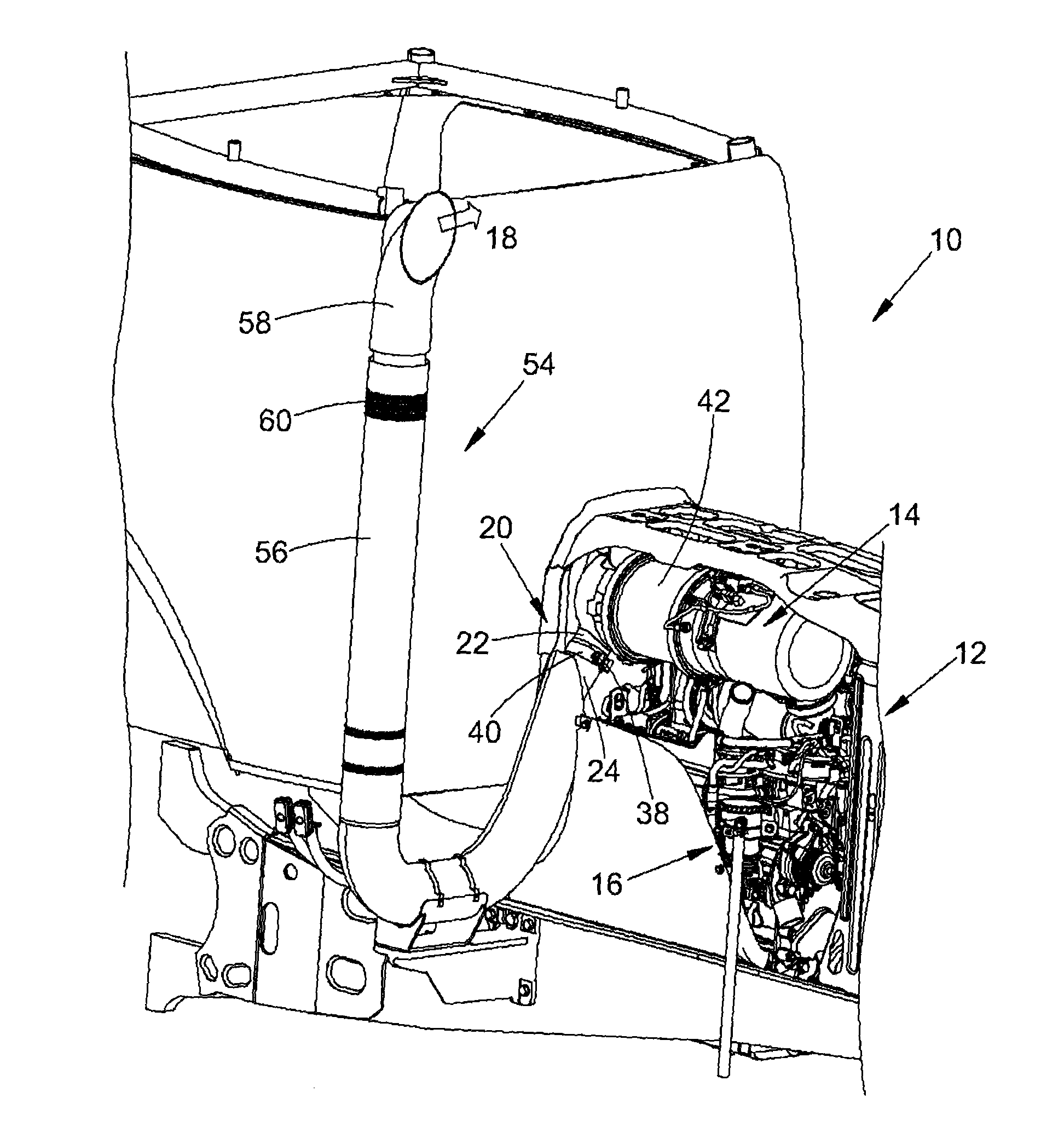

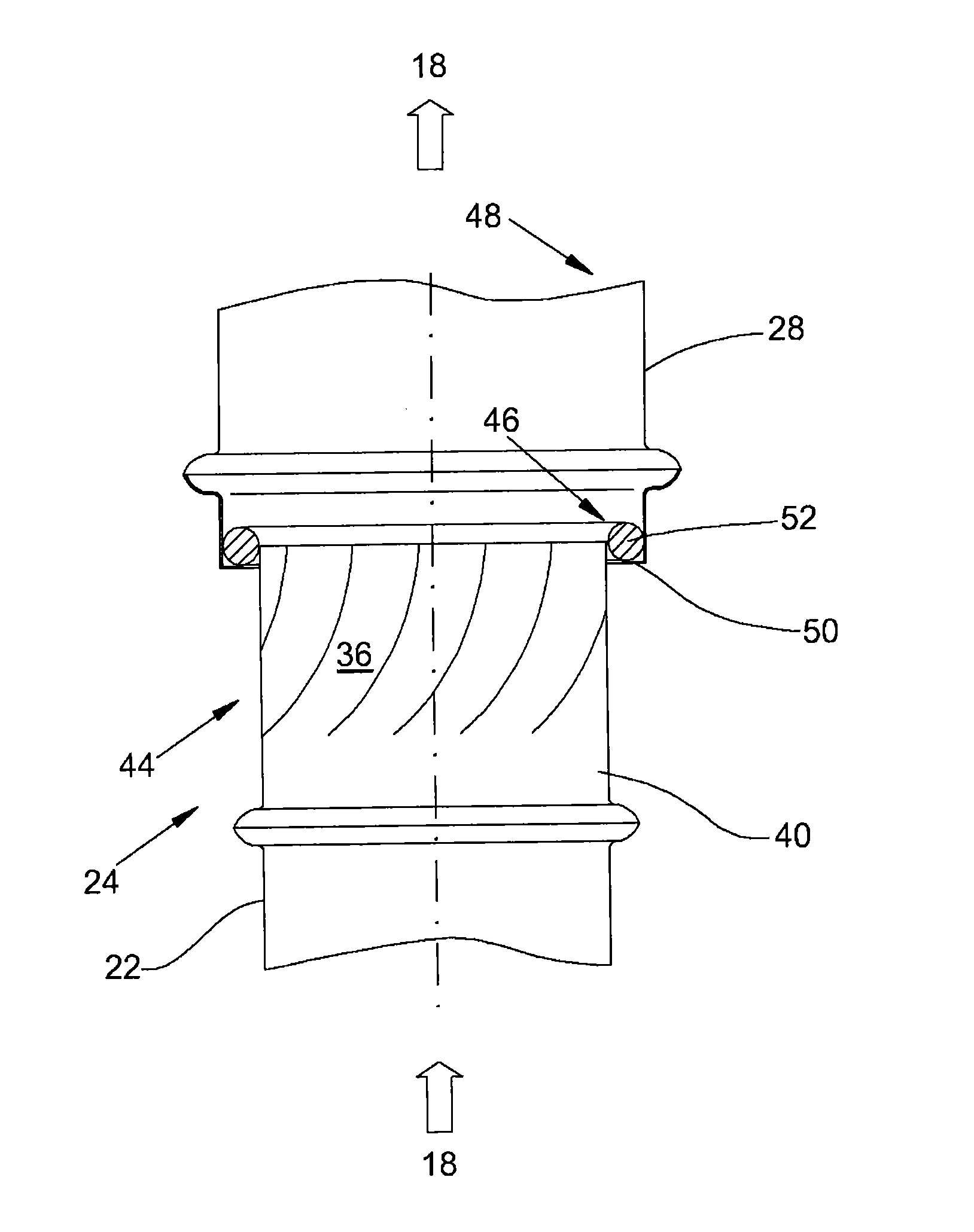

Device for cooling an exhaust gas stream

InactiveCN102052134AIncreased flow cross sectionUnimpeded passageExhaust apparatusSilencing apparatusExhaust gasNozzle

An assembly for cooling an exhaust gas stream includes an outlet nozzle capable of being loaded by the exhaust gas stream. The outlet nozzle projects into an open end of an adjacent exhaust gas pipe so that a reduced pressure relative to the surrounding environment is produced in a suction region between the outlet nozzle and the exhaust gas pipe by flow of exhaust gas. Adjusting members vary the flow cross section of the outlet nozzle.

Owner:DEERE & CO

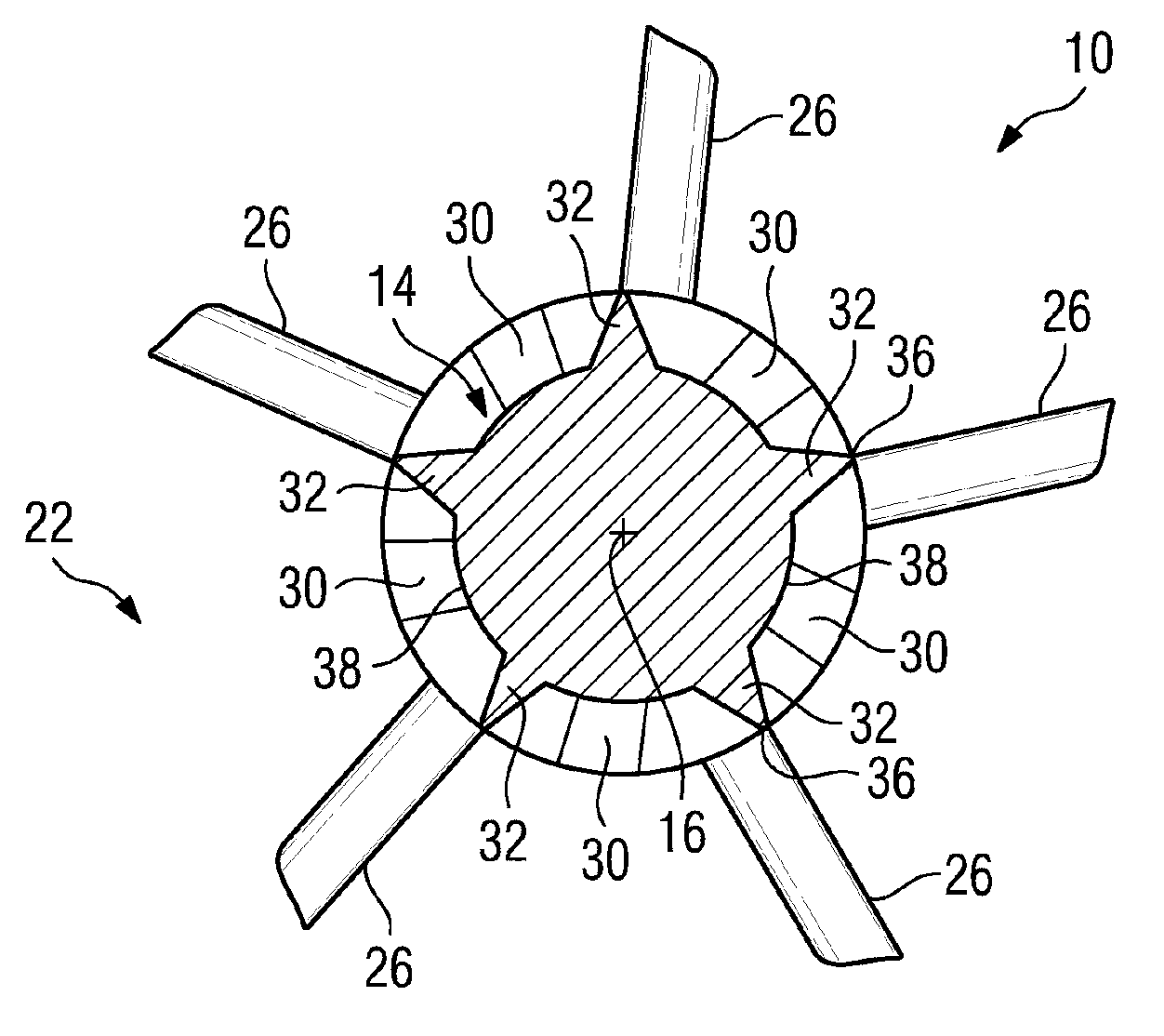

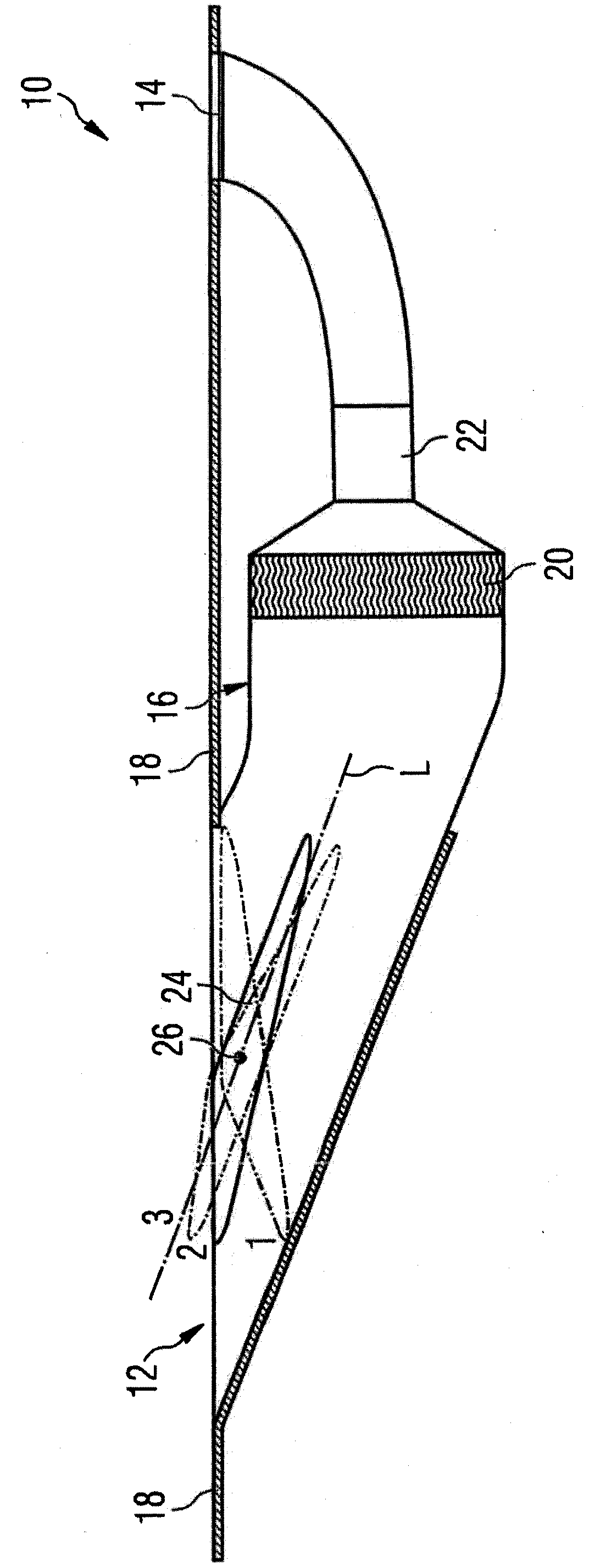

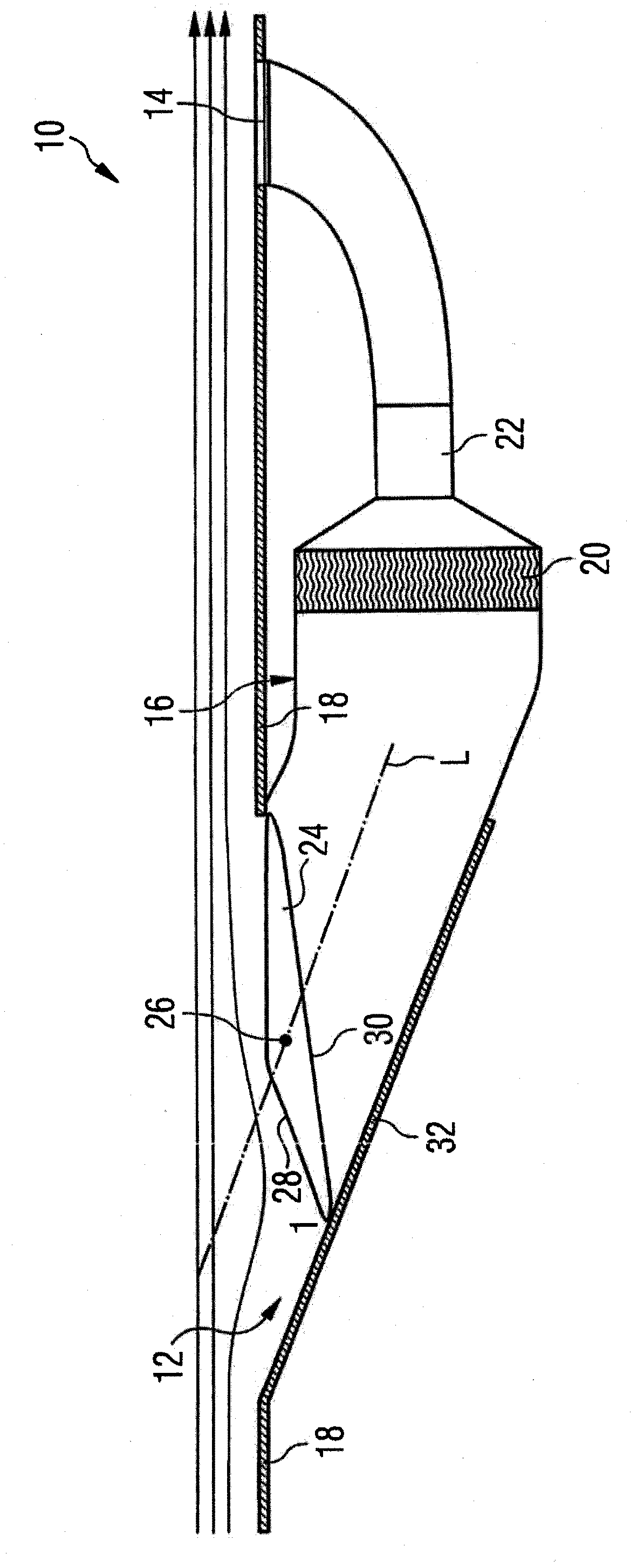

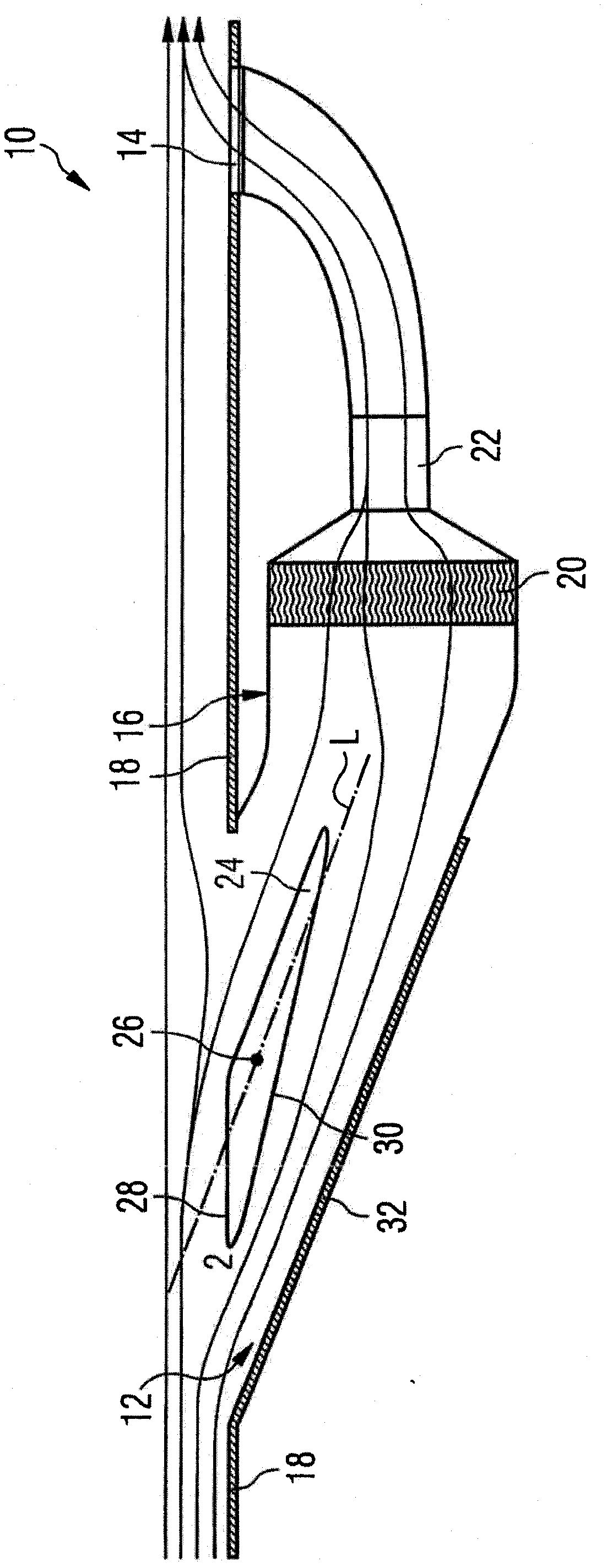

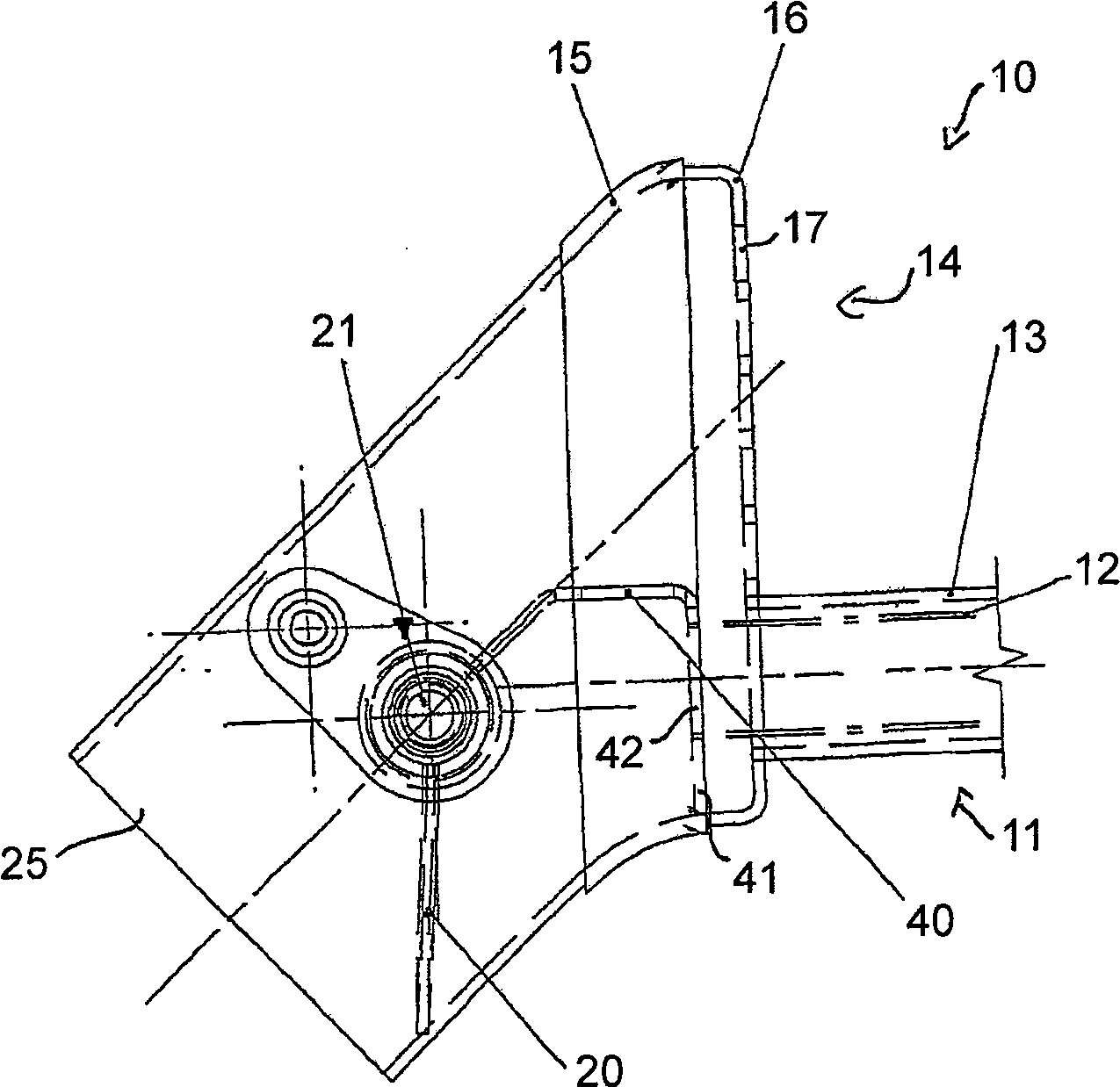

Air duct for supplying ambient air in an aircraft

ActiveCN102105358AReduce consumptionReduce designNACA type air intakesAir-treatment apparatus arrangementsAerospace engineering

The invention relates to an air duct (10) for supplying ambient air in an aircraft, comprising an air inlet (12), a duct channel section (16) extending downstream of the air inlet (12) and an air conveying device (22) which is adapted to convey ambient air through the air inlet (12) and the duct channel section (16). A flow control flap (24) closes the air inlet (12) in a first position, releases a first flow cross-section of the air inlet (12) in a second position and releases a second flow cross-section of the air inlet (12), which is larger than the first flow cross-section, in a third position.; The flow control flap (24) is designed and arranged in such a manner that a first surface section (28) of the flow control flap (24) is oriented substantially parallel to an aircraft shell section (18) surrounding the air inlet (12) in the area of the air inlet (12) in the second position of the flow control flap (24) and that the first surface section (28) of the flow control flap (24) is oriented at an angle with respect to the aircraft shell section (18) surrounding the air inlet (12) in an area of the air inlet (12) in the third position of the flow control flap (14).

Owner:AIRBUS OPERATIONS GMBH

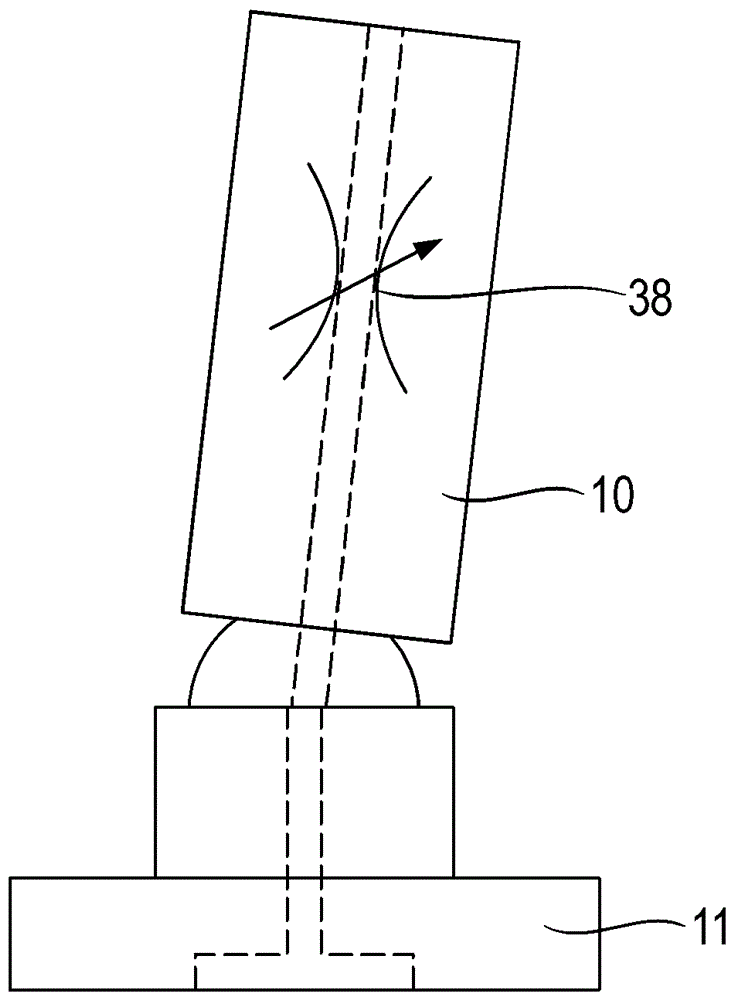

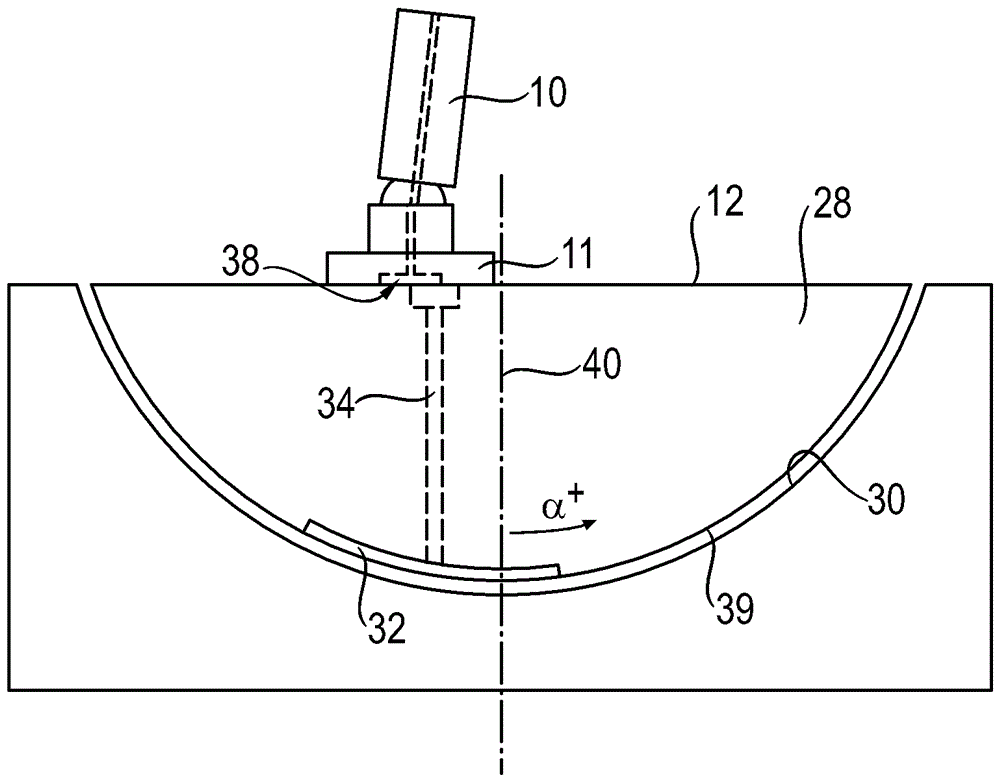

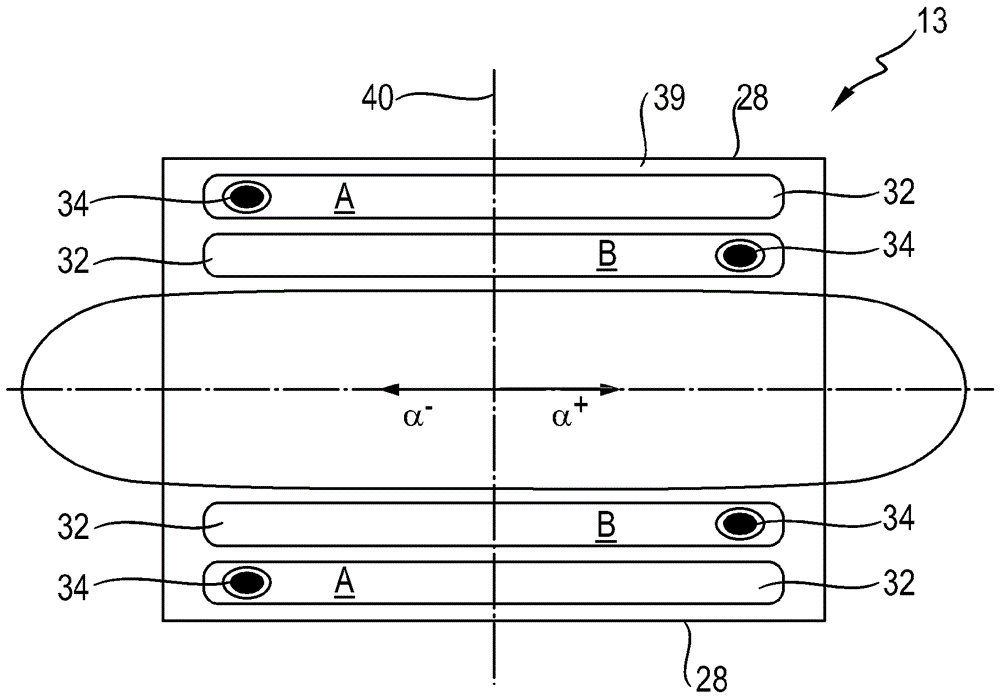

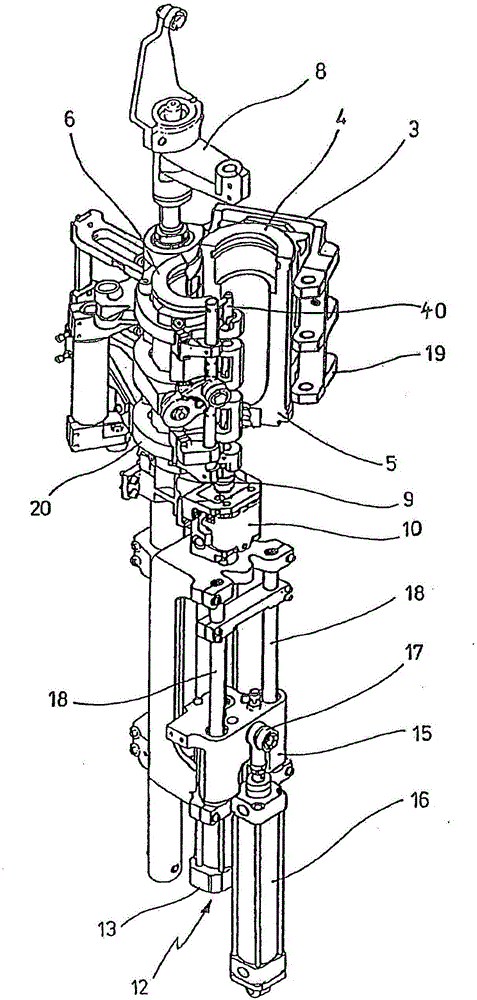

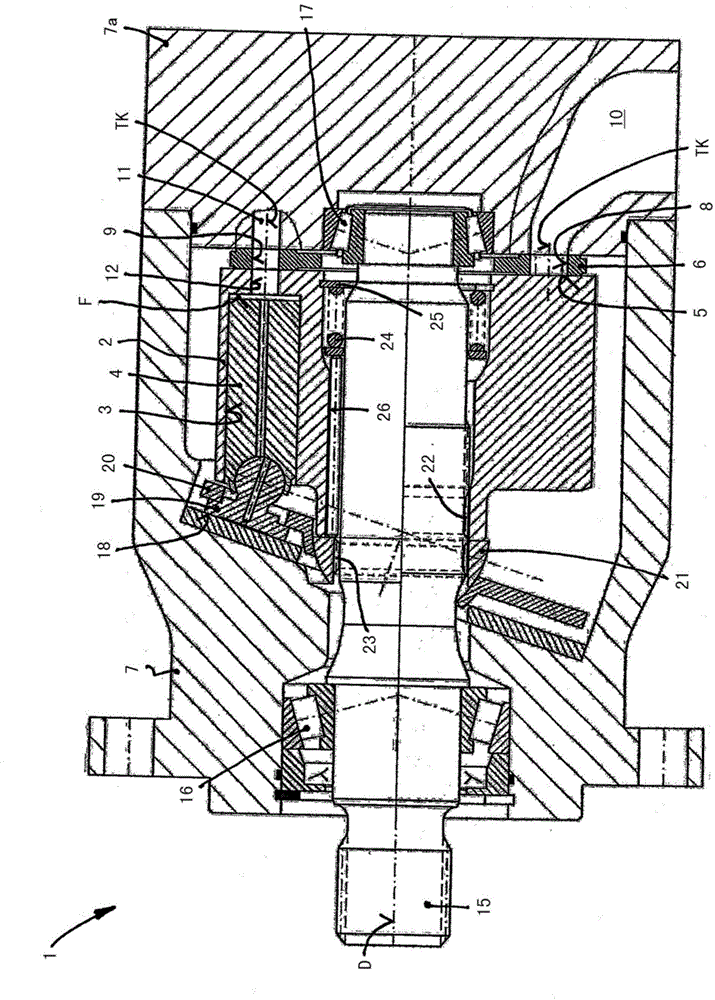

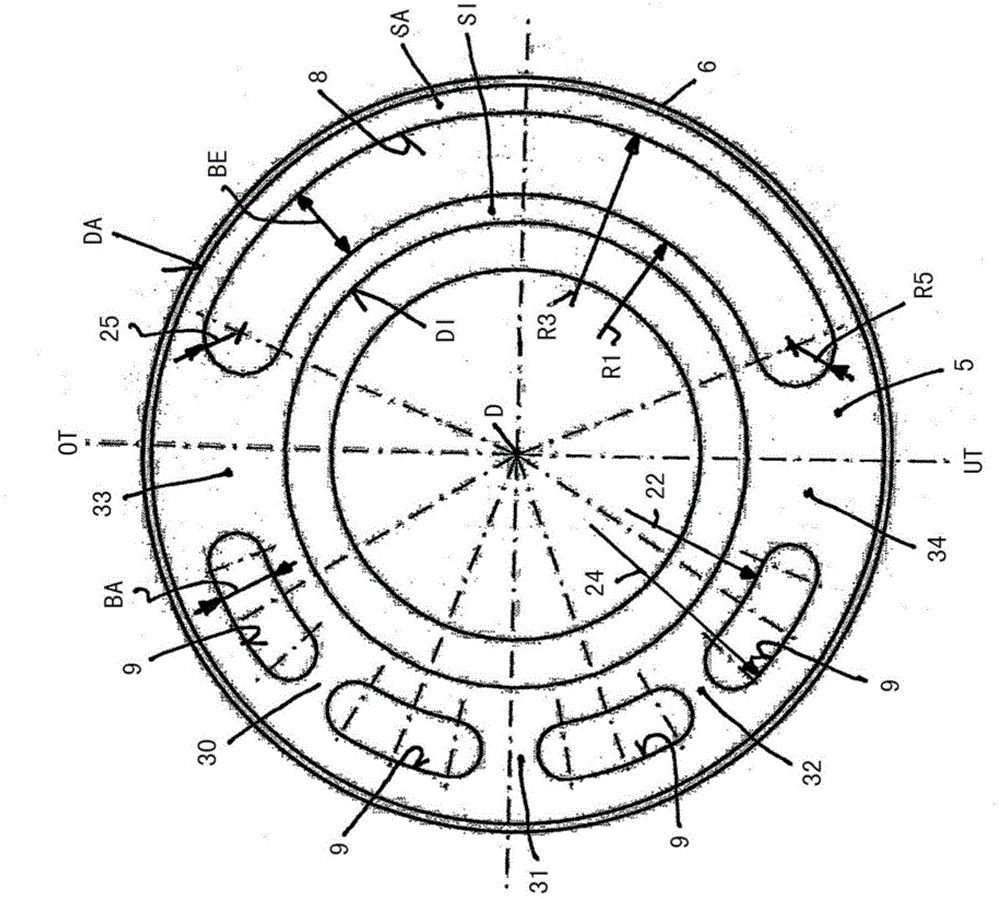

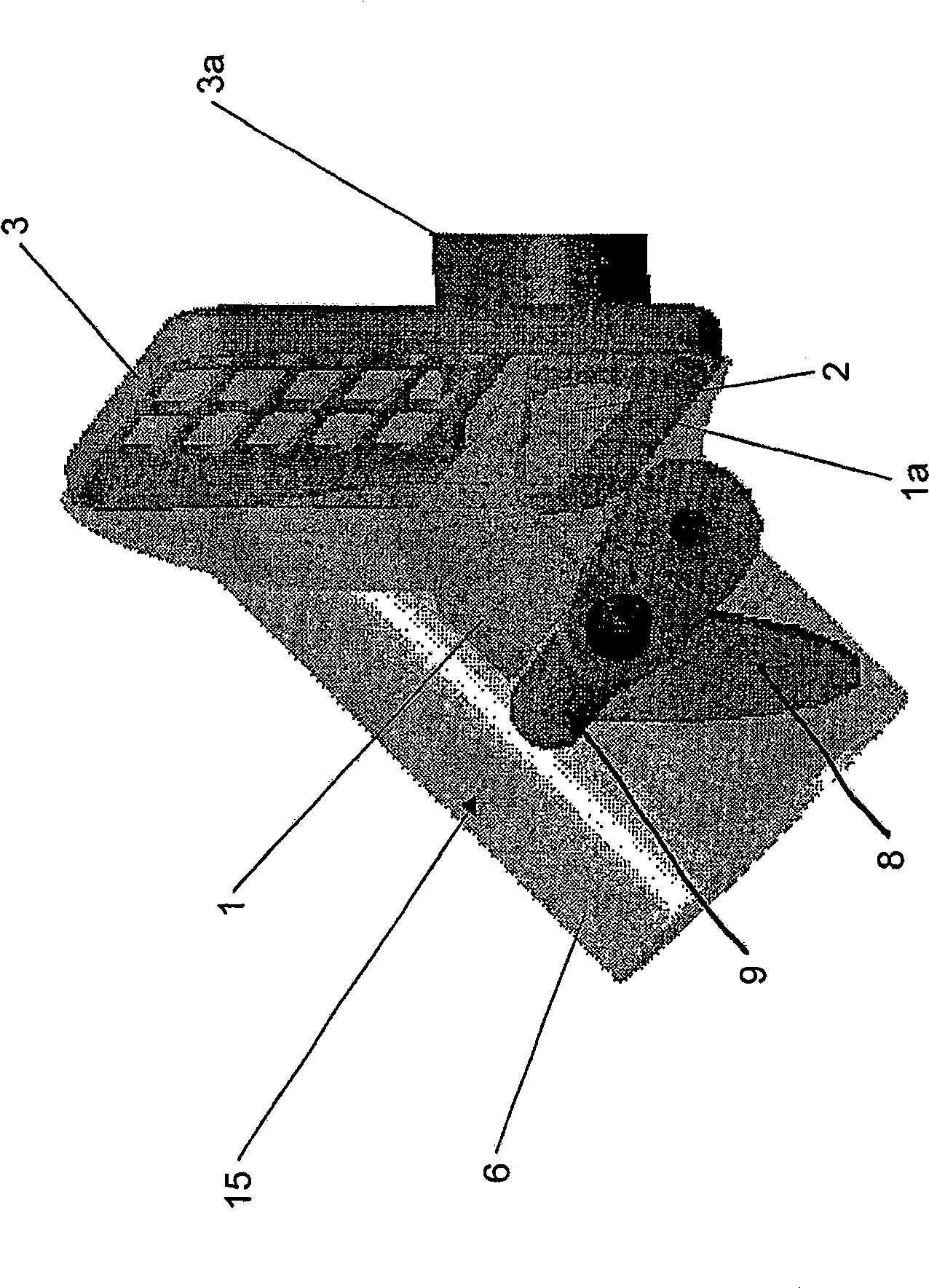

Hydrostatic axial piston engine

ActiveCN104454421AReduced seal bridging areaPrevent removalStarters with fluid-driven auxillary enginesReciprocating piston enginesEngineeringKidney

The invention relates to a hydrostatic axial piston machine with a cylinder barrel and a control surface. A kidney-shaped input connector and a kidney-shaped output connector are configured in a control base. An exhaust chamber is connected with the input connector and the output connector alternately when the cylinder barrel rotates. The hydrostatic axial piston machine may operate as a pump and a motor. When the cylinder barrel is driven in the operation of the pump, the axial piston machine inhales a pressure medium with the input connector and conveys the pressure medium to the output connector. In the operation of the motor, the axial piston machine is driven by the pressure medium supplied by the input connector. The area of a sealing bridging portion is decreased in the area of the input connector on the control surface configured on the control base in order that hydrostatic unloading force is reduced when pressure is applied to the input connector. Therefore, in the operation of the motor, the pressing force of a pressure spring operatively connected with the cylinder barrel and / or pressed cylinder pressure retains pressure of the cylinder barrel on the control surface. Additionally or alternatively, the end portion of the kidney-shaped input connector has a transition contour flattened against a circular arc at a radially outer region.

Owner:LINDE HYDRAULICS

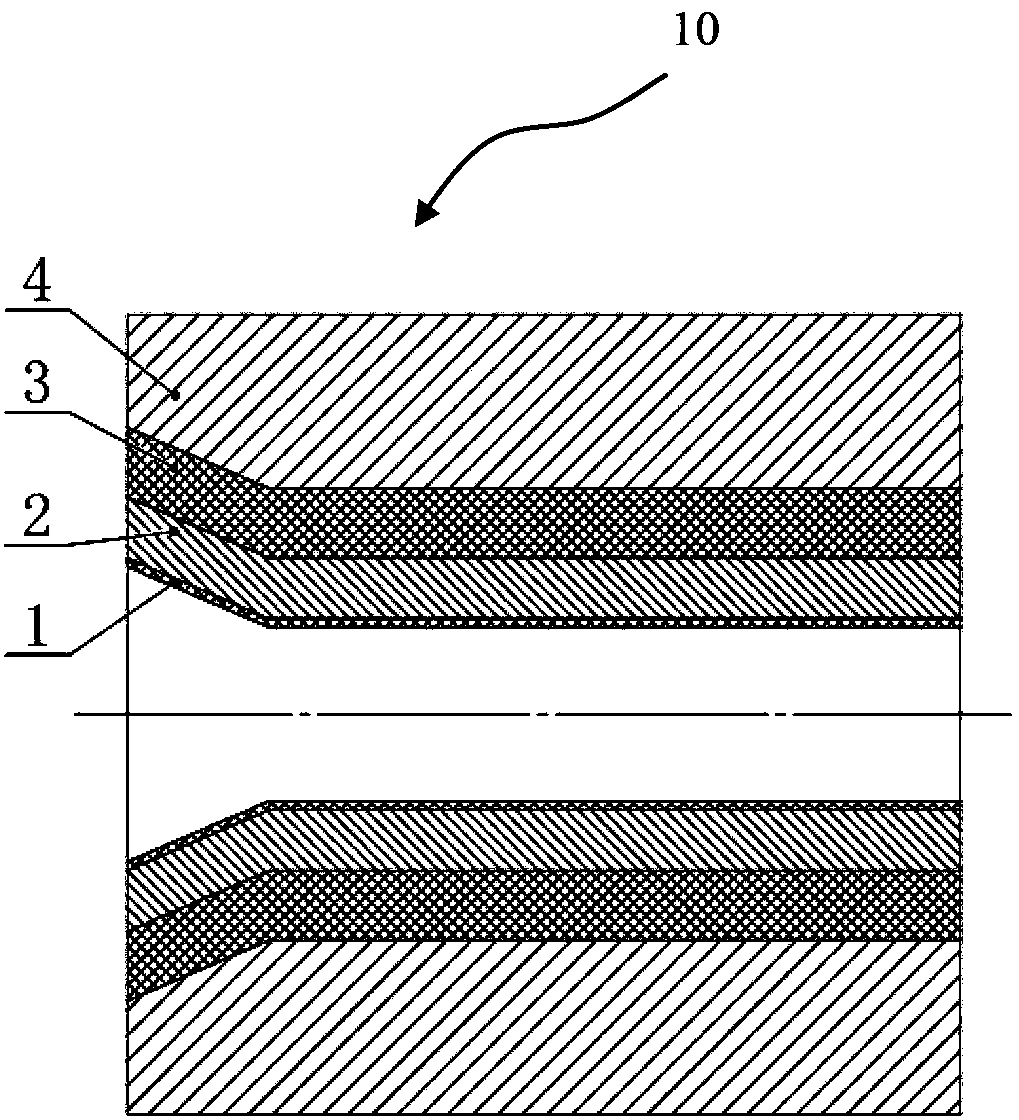

Nozzle for sandblast fracturing

ActiveCN104213883AIncreased flow cross-sectionChange intensityFluid removalUltimate tensile strengthMaterial Perforation

The invention discloses a nozzle for sandblast fracturing. The nozzle for sandblast fracturing comprises a nozzle body and a reinforcing layer arranged on the inner surface of the nozzle body, wherein the reinforcing layer comprises multiple abrasion-resistant layers with different degrees of abrasion resistance, the abrasion-resistant layers include the first ceramic layer which is directly adjacent to the nozzle body, the alloy steel layer which is adjacent to the first ceramic layer and a second ceramic layer which is adjacent to the alloy steel layer, and the abrasion resistance of the second ceramic layer is higher than the abrasion resistance of the alloy steel layer. According to the nozzle for sandblast fracturing, the nozzle can be abraded properly during sandblast perforation, the strength of the nozzle can not be reduced seriously, and the discharge capacity can be improved during fracturing.

Owner:CHINA PETROLEUM & CHEM CORP +1

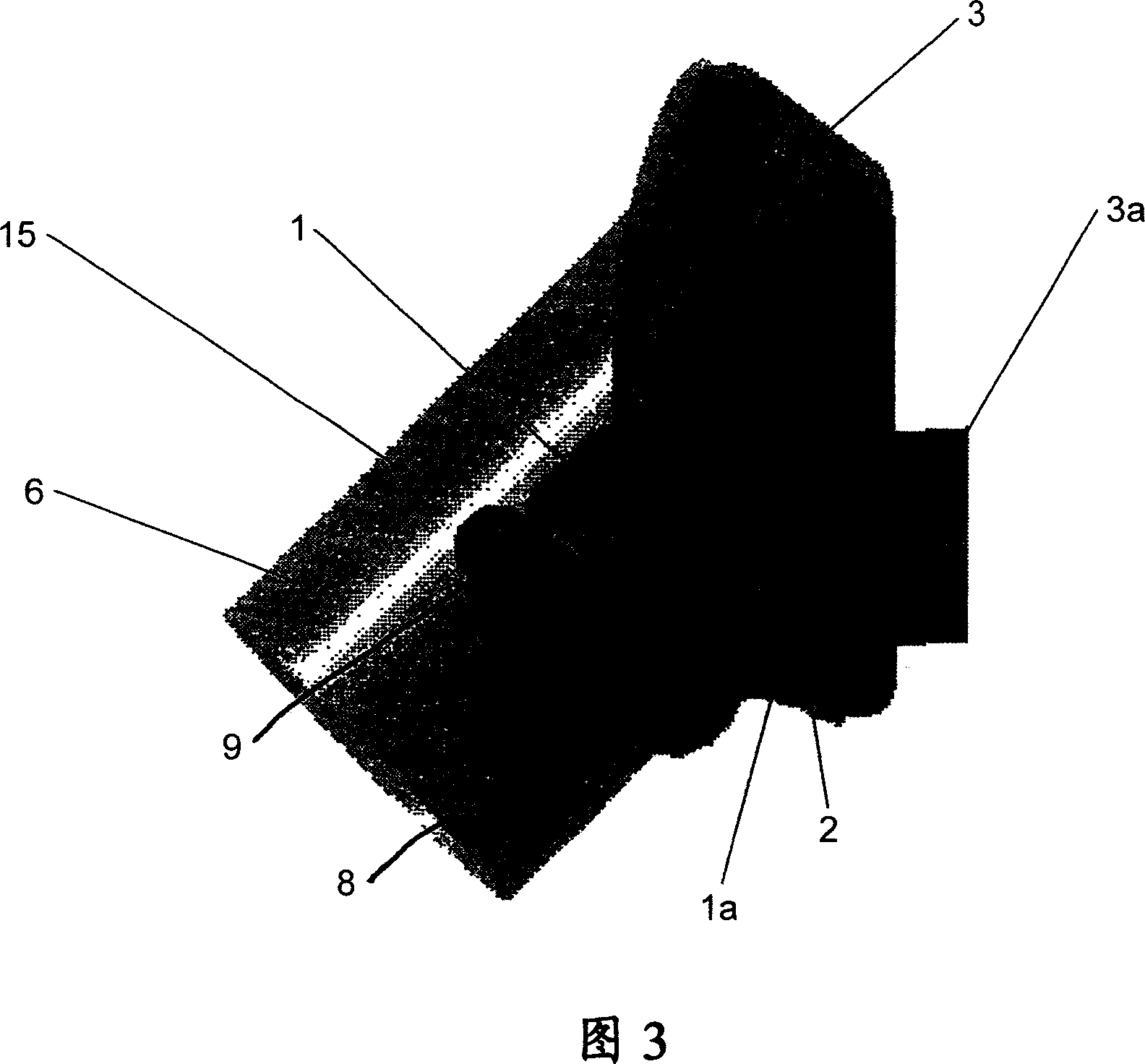

Cylinder, in particular for a motor vehicle hydraulic brake system

ActiveCN100443338CIncreased flow cross sectionEasy to moveEngine sealsPiston ringsEngineeringExternal Lip

The invention relates to a cylinder, in particular for a motor vehicle hydraulic brake systems comprising at least one case (2) provided with a plunger piston (3) movable therein, at least one angular sealing collar (5) arranged in the snap ring groove (4) of the case (2), an internal lip (6) dynamically applied to the plunger piston (3) by a first sealing surface (8), an external lip (7) statically applied to the bottom of the snap ring groove (4) by a second sealing surface (9) and the back of the collar (17). Said invention is characterised in that the back of the collar (17) is not flat and is provided with at least one peripheral-sealing surface (18, 24).

Owner:CONTINENTAL AUTOMOTIVE TECH GMBH

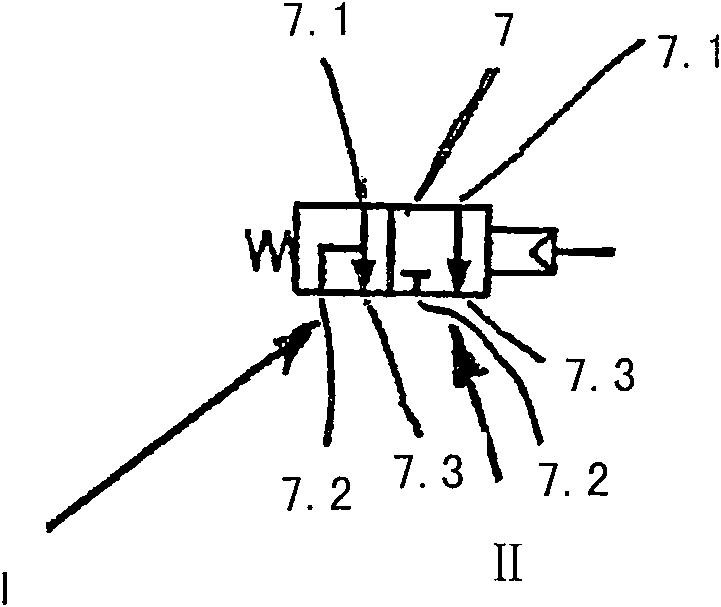

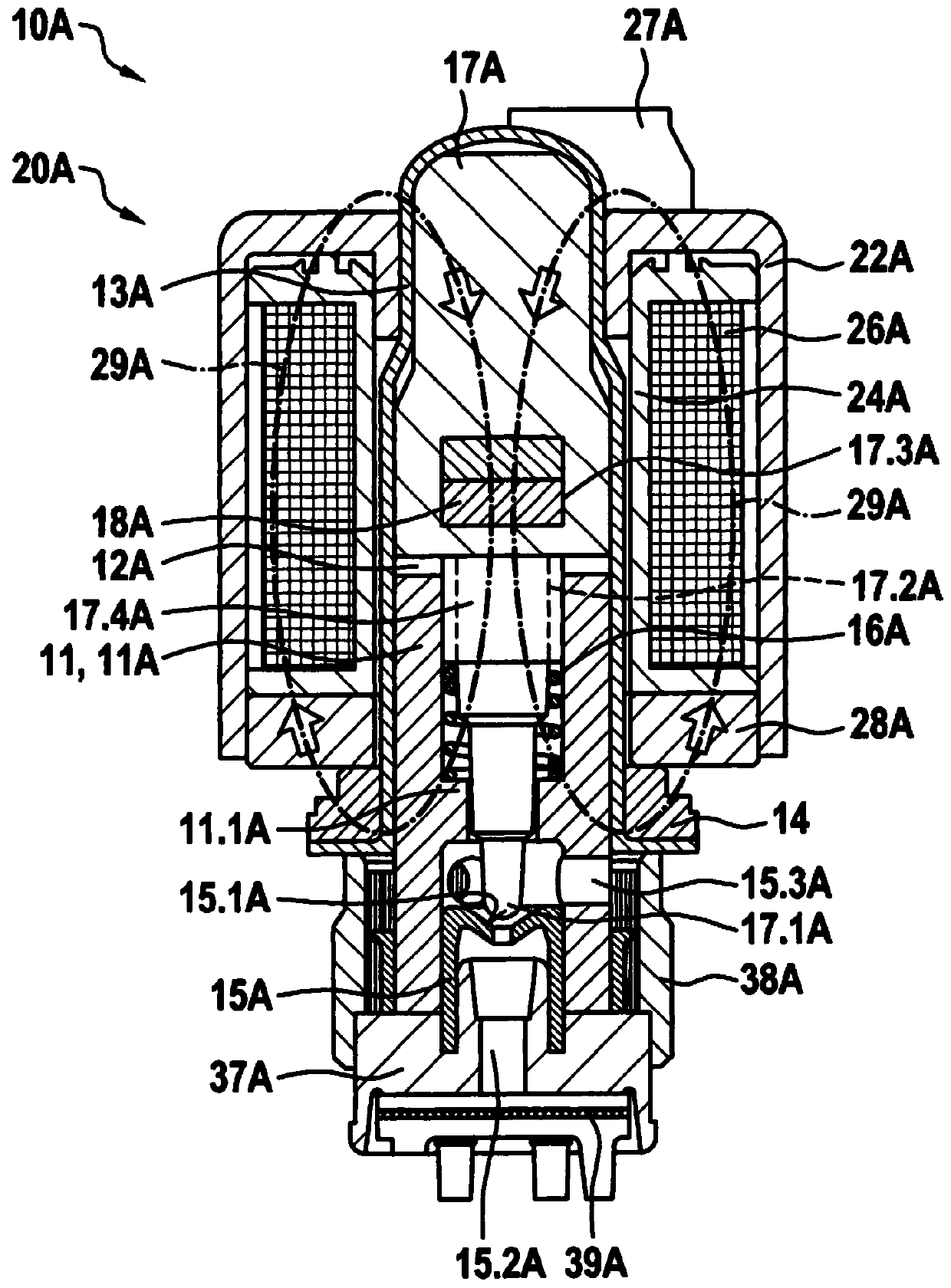

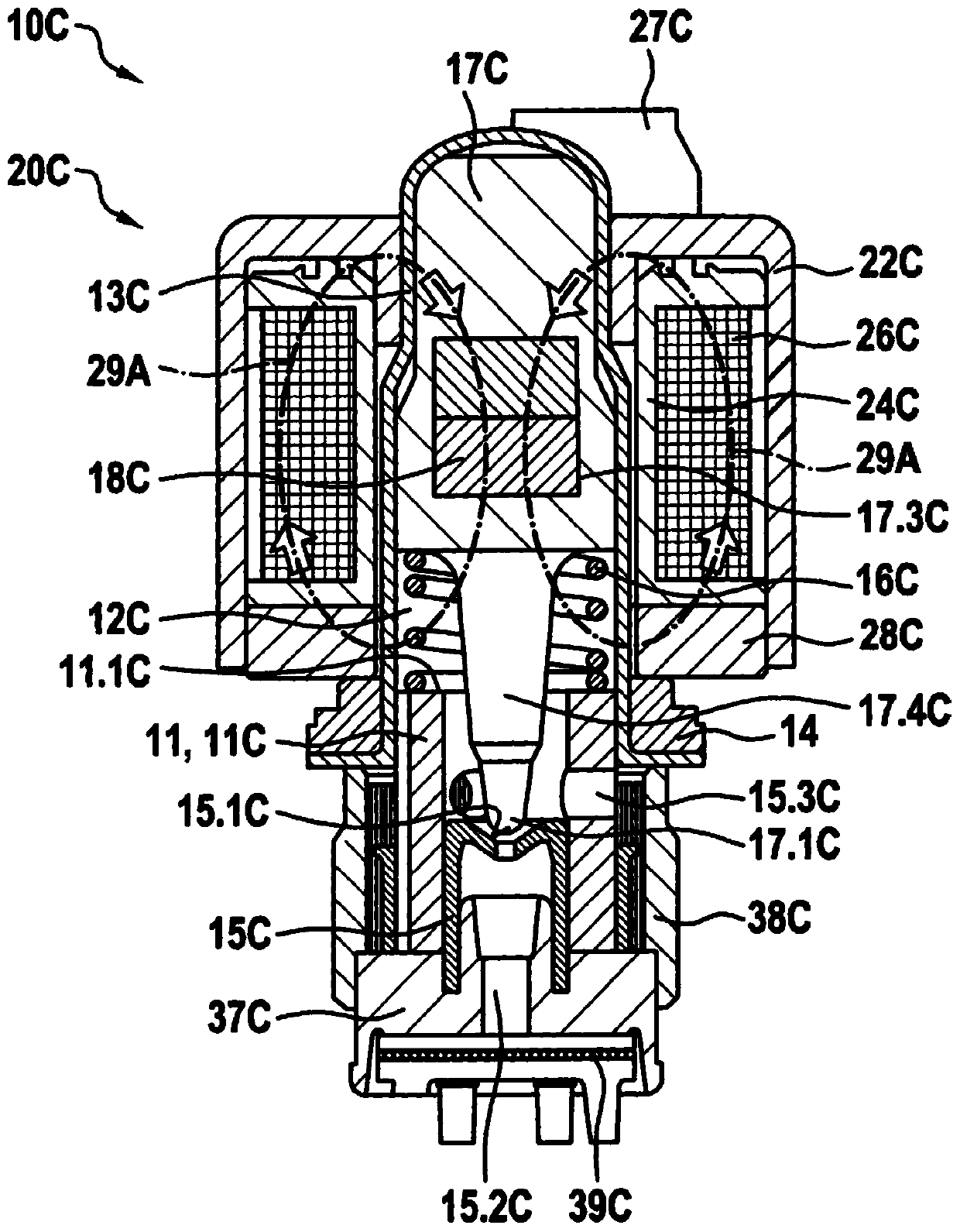

Adjustable magnetic valve

ActiveCN108930832AReduce weightIncrease the magnetic field strengthOperating means/releasing devices for valvesApplication and release valvesMagnetic tension forceMagnetic valve

The invention relates to an adjustable magnetic valve (10A) which includes a magnet assembly (20A) and a guide sleeve (13A) in which a static component (11) is arranged fixedly and a valve armature (17A) is arranged so as to be axially displaceable therein. The magnet assembly (20A) is pushed onto the static component (11) and the guide sleeve (13A). The static component (11) forms an axial stop for the valve armature (17A), which either forces a closing element (17.1A) into a valve seat (15.1A) or lifts the closing element from the valve seat (15.1A) depending on the direction in which the valve armature is driven. The valve armature (17A) and the static component (11) are each formed as plastic components. The valve armature (17A) has a magnet receptacle (17.3A) that receives a permanentmagnet (18A) which is polarized in terms of its movement direction such that the permanent magnet (18A) is arranged within the magnet assembly (20A) regardless of the armature stroke.

Owner:ROBERT BOSCH GMBH

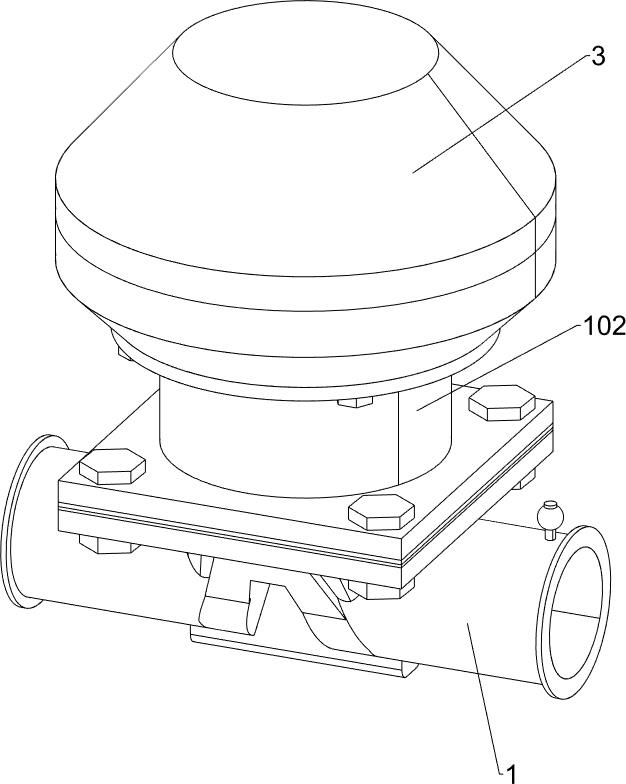

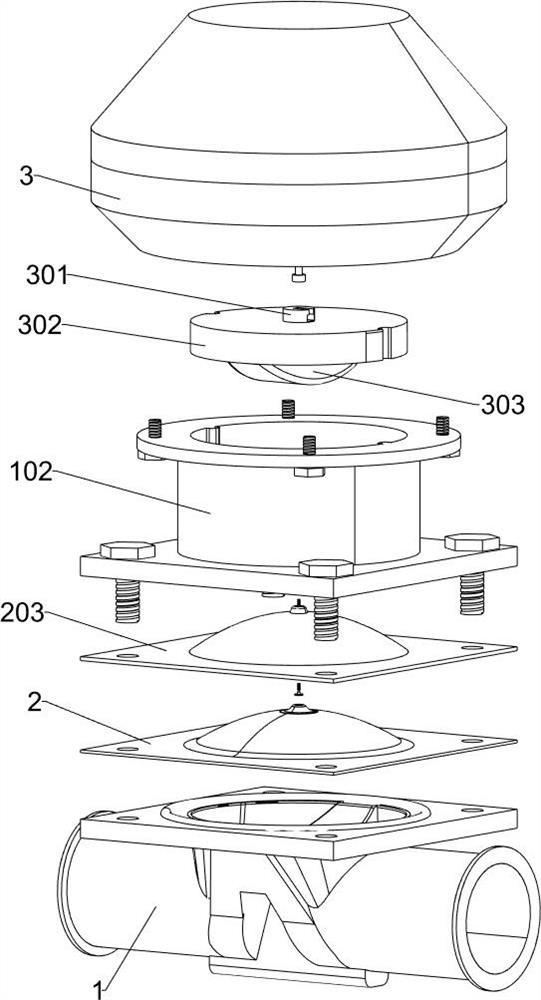

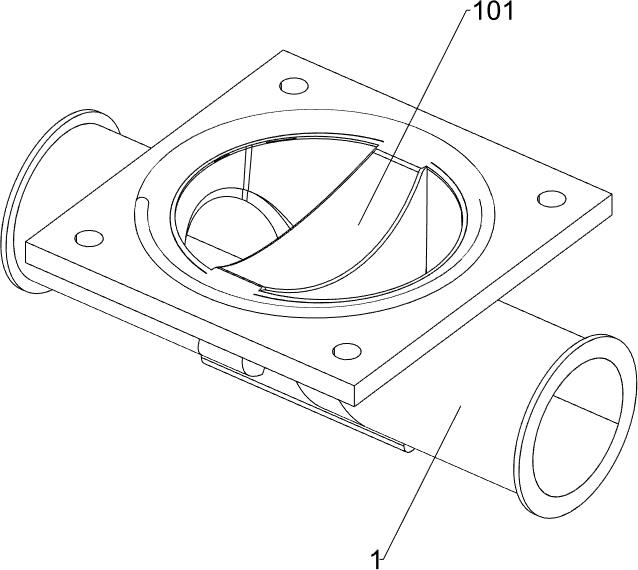

A Pneumatic Diaphragm Valve Intelligent Control System and Method Based on the Internet of Things

ActiveCN113757411BIncreased flow cross-sectionImprove adhesionDiaphragm valvesOperating means/releasing devices for valvesSimulationThe Internet

Owner:NANJING DAOLONG BIOTECHNOLOGY CO LTD

Heat exchanger in particular for exhaust coolers on internal combustion engines

InactiveCN1950592AUniform thermal expansionAchieve vertical circulationInternal combustion piston enginesExhaust apparatusCombustionExternal combustion engine

The invention relates to a heat exchanger (10), in particular for an exhaust gas cooler of an internal combustion engine. The object of the invention is to achieve a separation of the carrier medium into two partial flows as free as possible of flow leakage by means of a suitable design of the partition ( 40 ). A heat exchanger (10) which can be used as an exhaust gas cooler of an internal combustion engine has a heat exchange line (14) and a bypass line (11), wherein in the flow line (25) the A switching valve (20) is provided upstream, which separates the carrier medium flowing into the heat exchange line and the bypass line. In order to maintain separation between the partial flow through the bypass line (11) and the partial flow through the heat exchange line (14), a partition (40) is provided which, according to the invention, extends from the switching valve (20) to the beginning of the bypass pipe (11).

Owner:贝洱公司

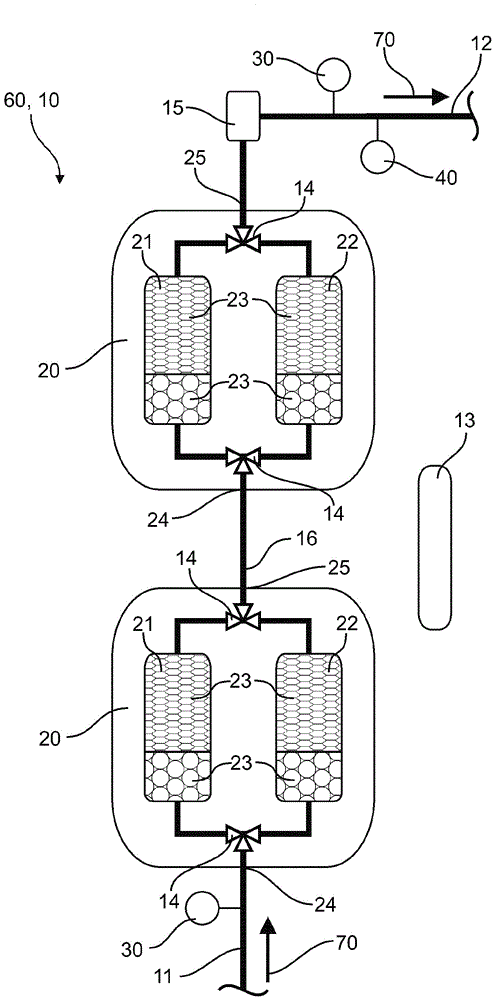

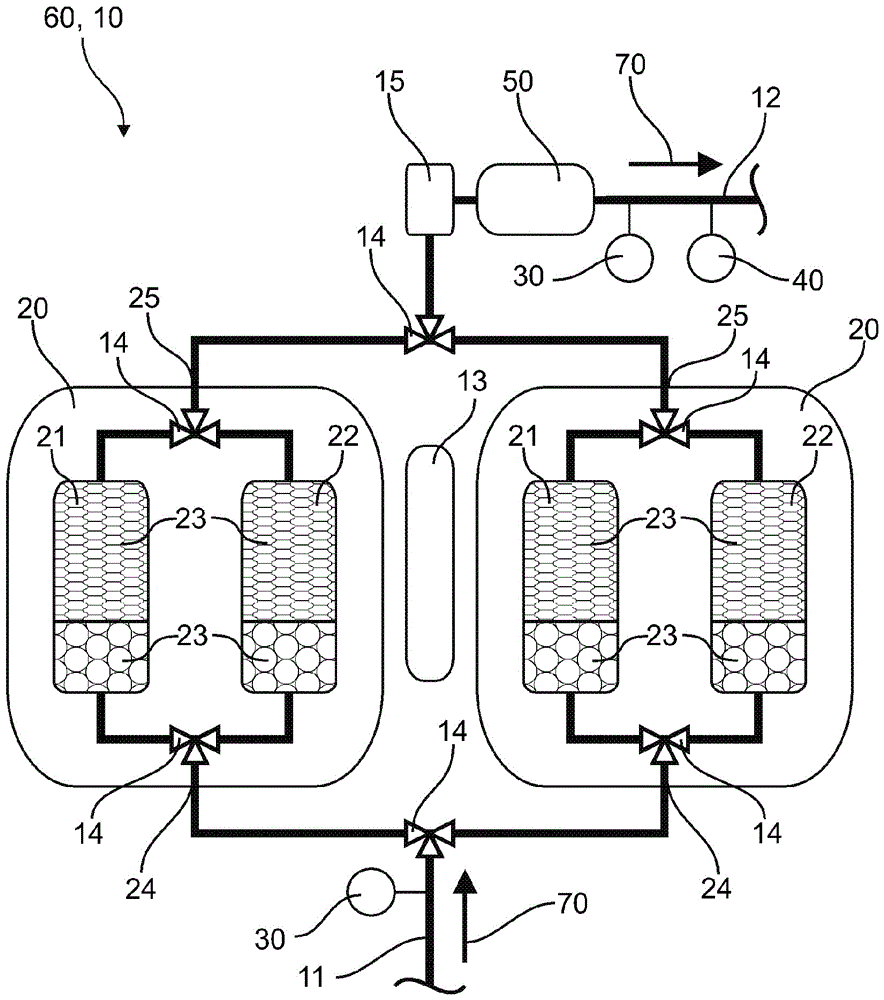

Method for operating an air-drying device for drying air, air-drying device for drying air as well as compressed air system

ActiveCN106345240AQuality impactIncreased flow cross sectionGas treatmentDispersed particle separationEnvironmental engineeringCompressed air

A method for operating an air-drying device (10) and air-drying device (10) are provided. The air-drying device (10) has at least one absorption device (20) with a first absorption section (21), a second absorption section (22), an air feed line (11), an air removal line and an analysis unit (13). The first absorption section (21) and the second absorption section (22) can be used alternating to dry air (70). The air feed line (11) feeds air (70) to be dried and is connected to an inlet opening (24) of the absorption device (20) in a fluid-communicating manner. The air removal line (12) removes dried air (70) and is connected to an outlet opening (25) of the absorption device (20) in a fluid-communicating manner. A compressed air system (60) for providing compressed air (70) has such an air-drying device (10).

Owner:DRAGERWERK AG

Solenoid valve for controlling a fluid

ActiveCN102192362AImprove featuresGood conditionOperating means/releasing devices for valvesValve housingsLateral regionSolenoid valve

A solenoid valve for controlling a fluid includes an armature having a base region, a lateral region and a head region. The solenoid valve includes a valve member connected to the armature. The solenoid valve further includes an armature casing component in which the armature is positioned. A flow path is formed between the armature and the armature casing component, the flow path extending from a lower armature space to an upper armature space and back to the lower armature space. A junction region is arranged between the head region and the lateral region. The junction region has at least one groove formed therein to facilitate an overflow between the lateral region and the head region.

Owner:ROBERT BOSCH GMBH

Solenoid valves for fluid control

ActiveCN102192362BImprove featuresGood conditionOperating means/releasing devices for valvesValve housingsSolenoid valveLateral region

A solenoid valve for controlling a fluid includes an armature having a base region, a lateral region and a head region. The solenoid valve includes a valve member connected to the armature. The solenoid valve further includes an armature casing component in which the armature is positioned. A flow path is formed between the armature and the armature casing component, the flow path extending from a lower armature space to an upper armature space and back to the lower armature space. A junction region is arranged between the head region and the lateral region. The junction region has at least one groove formed therein to facilitate an overflow between the lateral region and the head region.

Owner:ROBERT BOSCH GMBH

Gas turbine and exhaust gas diffuser thereof

InactiveCN102844527BShorten the lengthSmall sizePower plant exhaust arrangementsEngine manufactureEngineeringMechanics

Owner:SIEMENS AG

Drive power train with exhaust gas utilisation and control method

InactiveCN100580232CImprove driving comfort performanceContinuous load conditionInternal combustion piston enginesEngine controllersFluid couplingDrivetrain

The invention relates to a drive train, comprising an internal combustion engine, an exhaust gas turbine, arranged in the exhaust system of the internal combustion engine, a crankshaft, driven by the internal combustion engine, switchably connected by means of a hydrodynamic coupling to the exhaust turbine with a drive direction such that the crankshaft is driven by the turbine, said hydrodynamic coupling comprising a primary rotor and a secondary rotor which together form a working chamber which may be filled with a working medium for torque transmission, the primary rotor being in driven connection to the exhaust turbine. The primary rotor may be mechanically braked and locked with relation to a rotational movement such that the hydrodynamic coupling assumes a hydrodynamic retarding function. Said drivetrain according to the invention is characterised in that a controller is provided which, before and / or during a braking of the primary rotor, empties the working chamber of the hydrodynamic coupling to a given level.

Owner:VOITH TURBO GMBH & CO KG

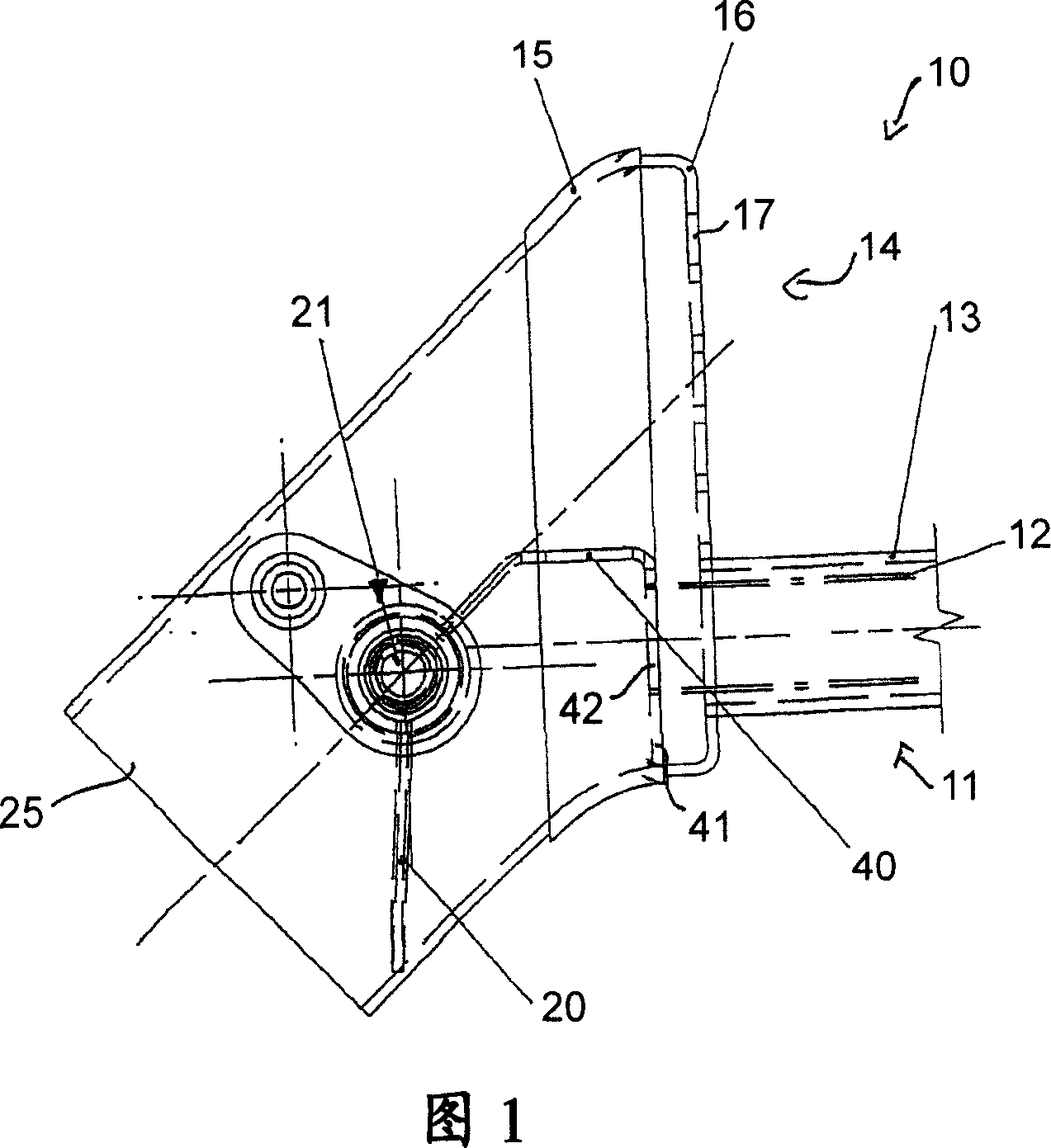

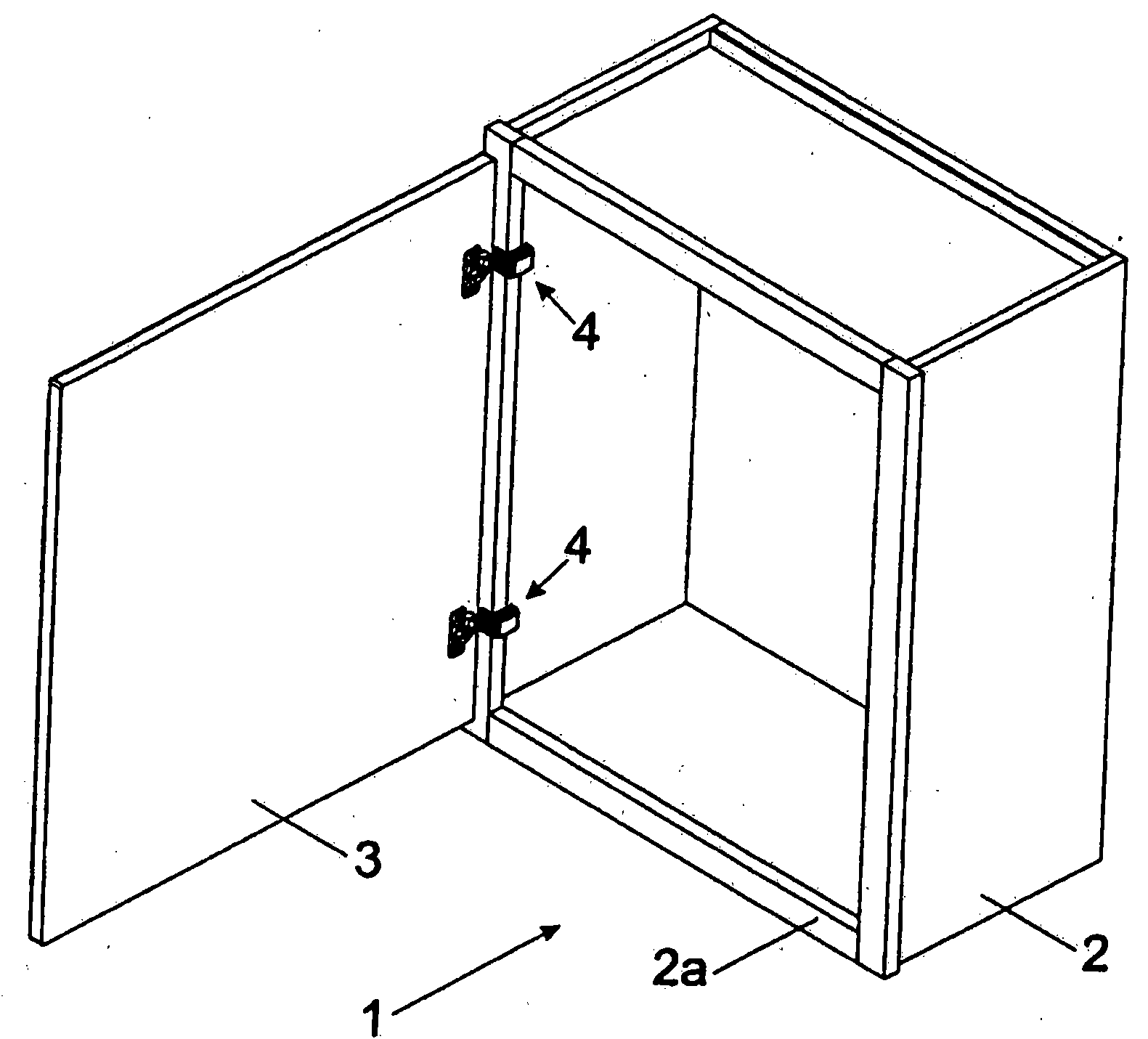

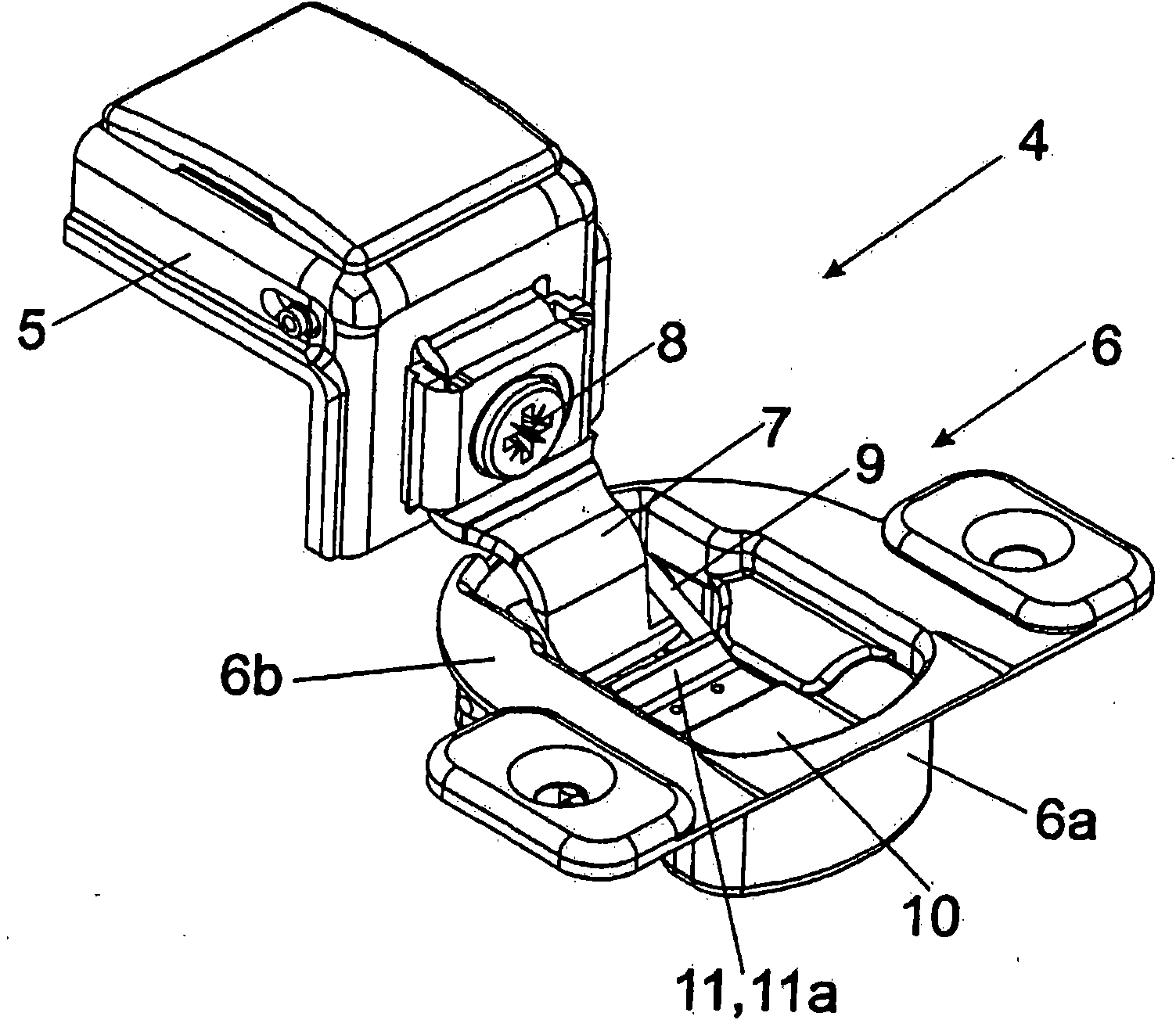

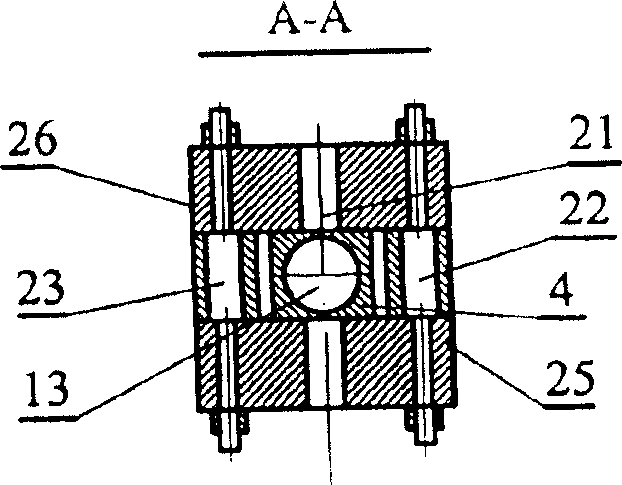

Furniture hinge

ActiveCN101845923BChange volumeShorten the lengthBuilding braking devicesWing accessoriesEngineeringPiston

The invention relates to a furniture hinge (4), including: at least two positioning members (5, 6) which are hinged and fixed on furniture members (2, 3); a buffer device (10) for buffering the relative movement of at least two positioning members, wherein the buffer device has a first fluid chamber (16) and a second fluid chamber (21) which are filled by buffer fluids; a channel (19) for connecting two fluid chambers; a piston (16a) inserting into the first fluid chamber in two fluid chambers and changing the volume of the first fluid chamber (16); and a device (25) arranged in the second fluid chamber, deforming or moving through inlet and outlet of the buffer fluid into / from the second fluid chamber to chamber the volume of the second fluid chamber, wherein at least one connection sheet (20) having at least one port (20a) is arranged behind the channel (19) along a flowing direction set in a buffer process, and the buffer fluids can flow in the second fluid chamber through the port.

Owner:JULIUS BLUM GMBH

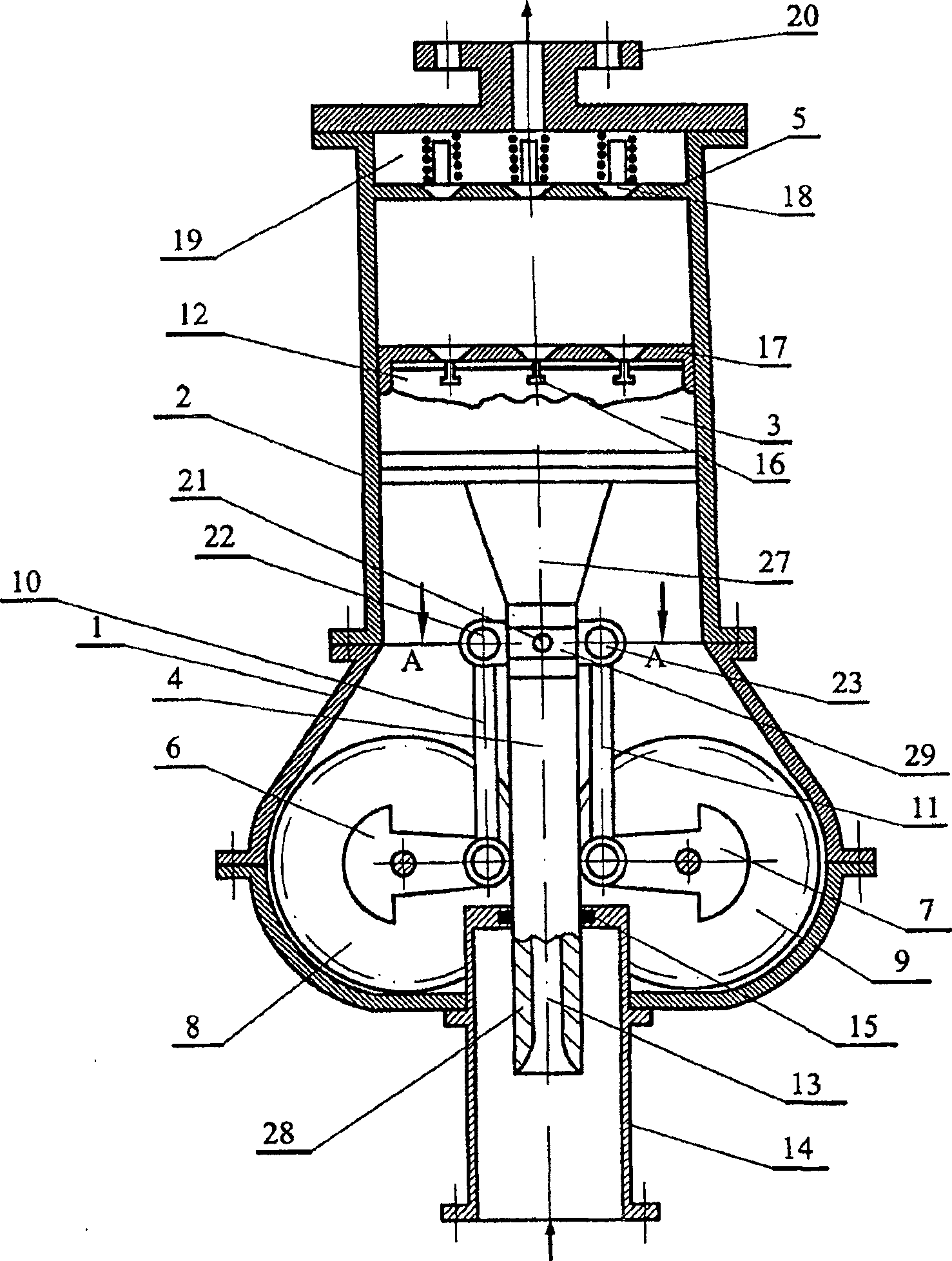

Piston machine

InactiveCN1910340ASmall volumeIncreased volumetric productivityPositive displacement pump componentsValve drivesCrankcaseMechanical engineering

A machine proposed for use in energy producing industry as an engine, a pump and a compressor. The machine has a crankcase 1, a cylinder 2, and a piston 3 and a piston rod 4, two crankshafts 6 and 7 rotating in opposite directions. An inner hollow 12 of the piston communicates with a throughgoing axial passage 13 of the piston rod 4 located in the crankcase with the possibility of a reciprocating movement in a suction pipe 14; wherein the passage 13 of the piston rod is formed with a diffusor 27 from the side of the hollow 12 of the piston 3 and with a confusor 28 from the side of the suction pipe 14. Pumping valves 18 are arranged on the cover 5 of the cylinder, and suction valves 16 are arranged on the front wall of the piston; wherein the piston rod 16 and the connecting rods 10 and 11 of the crankshaft 6 and 7 are hingedly connected with a traverse 29. The invention provides a reduction of a waste space and reduction of hydraulic losses.

Owner:MICHAELLA K CORP

Indirectly heated fluidized bed dryer

InactiveCN102224388BSpeed up the flowReduce dustDrying solid materials with heatFluidised bed heat exchangersFluidized bed dryingProcess engineering

The invention relates to an indirectly heated fluidized bed dryer (1) for drying moist fine-grained bulk material. The fluidized bed dryer (1) comprises a housing (2) with an aerated bottom (6), heat exchanger inners extending above the aerated bottom (6) and at least one (6) The lower discharge device for the dried loose material. The fluidized bed dryer (1) according to the invention is characterized in that the available flow cross section of the housing (2) in the region of the heat exchanger inserts is constant over the entire height of the heat exchanger inserts in the cross section of the housing The case increases in the flow direction of the fluidized medium. Inadmissible expansion of the steady-state fluidized bed is reliably prevented in this way.

Owner:RWE POWER AKTIENGESELSCHAFT

Piston machine

InactiveCN100489274CIncreased volumetric productivityReduce hydraulic lossPositive displacement pump componentsValve drivesCylinder headCrankcase

A machine recommended for use in the energy generation industry as an engine, pump and compressor. The machine has a crankcase 1 , a cylinder 2 with a piston 3 and a piston rod 4 , two crankshafts 6 and 7 rotating in opposite directions. The internal cavity 12 of the piston communicates with the through axial passage 13 of the piston rod 4, which is arranged in the crankcase and has the possibility of reciprocating movement in the suction pipe 14; A diffuser 27 is formed on the side of the cavity 12 and a stirrer 28 is formed from the side of the suction tube 14 . The pumping valve 18 is arranged on the head 5 of the cylinder, the suction valve 16 is arranged on the front wall of the piston; wherein the piston rod 16 and the connecting rods 10 and 11 of the crankshafts 6 and 7 are hingedly connected with the beam 29 . The present invention provides a reduction in wasted space and a reduction in hydraulic losses.

Owner:MICHAELLA K CORP

hydrostatic axial piston machine

ActiveCN106481526BLow costIncreased flow cross-sectionPump controlReciprocating piston enginesEngineeringMechanical engineering

A hydrostatic axial piston machine defines an adjustable displacement volume and includes a housing, a cylinder drum, a plurality of working pistons, a pivot cradle, and a plain bearing. The working pistons are received in the cylinder drum so as to be axially displaceable, and are supported on a sliding surface of the pivot cradle. The pivot cradle is configured to adjust the displacement volume, and is pivotably mounted on the plain bearing. The plain bearing is fixed with respect to the housing. The hydrostatic axial piston machine is configured to form at least one first hydrostatic relief pressure field between the plain bearing and the pivot cradle.

Owner:ROBERT BOSCH GMBH

Refrigerator with an air duct

ActiveCN105393072AWell formedQuick assemblyLighting and heating apparatusCooling fluid circulationEngineeringMechanical engineering

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

Pneumatic diaphragm valve intelligent control system and method based on Internet of Things

ActiveCN113757411AIncreased flow cross-sectionImprove adhesionDiaphragm valvesOperating means/releasing devices for valvesIntelligent control systemInternet of Things

The invention relates to the field of diaphragm valve intelligent control, in particular to a pneumatic diaphragm valve intelligent control system and method based on the Internet of Things. The pneumatic diaphragm valve intelligent control system based on the internet of things is large in circulation amount, long in service life, relatively stable in sealing retentivity and convenient for replacing parts in advance. A pneumatic diaphragm valve intelligent control system based on the internet of things comprises a valve body, a valve cover and a diaphragm assembly, wherein the valve body is in bolted connection with the valve cover, a flow sensor is arranged at the fluid outflow end of the valve body, a flow module is arranged on the flow sensor, the flow sensor is electrically connected with the flow module, and the diaphragm assembly is arranged between the valve body and the valve cover. The flow cross section of fluid is increased through the design of the arc-shaped groove in the valve body, the adhesive force between the valve body and the diaphragm is increased and the service life of the valve body is prolonged through the design of the connecting piece, so that problems generated during fluid filling are displayed through the field control panel, and the service lives of parts are reminded.

Owner:南京道隆生物科技有限公司

Heat exchanger in particular for exhaust coolers on internal combustion engines

InactiveCN100543280CImprove isolationPrevent leakageInternal combustion piston enginesExhaust apparatusCombustionExternal combustion engine

The invention relates to a heat exchanger (10), in particular a heat exchanger for an exhaust gas cooler of an internal combustion engine. The object of the present invention is to achieve a separation of the carrier medium into two partial flows with as little flow leakage as possible by means of a suitable structure of the partition ( 40 ). The heat exchanger ( 10 ) can be used as an exhaust gas cooler for an internal combustion engine, the heat exchanger having a heat exchange line ( 14 ) and a bypass line ( 11 ), wherein, in the flow line ( 25 ), in the heat exchanger A switching valve (20) is provided upstream, which separates the carrier medium flowing into the heat exchange conduit and the bypass conduit. In order to maintain the separation between the split flow through the bypass duct (11) and the split flow through the heat exchange duct (14), a partition (40) is provided, which according to the invention extends from the switching valve (20) all the way to the beginning of the bypass pipe (11).

Owner:贝洱公司

Motor vehicle electropneumatic spring energy storage brake with a jumpy pressure rise when the brake is released

ActiveCN106414194BIncreased flow cross sectionAdjust the flow cross sectionFluid braking transmissionApplication and release valvesPressure riseElectricity

The invention relates to an electro-pneumatic spring energy storage brake device (1) for a motor vehicle, comprising means for generating an electric brake operating signal (the electric brake operating signal represents at least "brake applied" and "brake applied"). device, the electronic control device (8) receiving the brake operation signal, the electropneumatic valve device (10) controlled by the control electronic device (8) according to the operation signal, and at least one pneumatically operated spring storage An energy braking cylinder, wherein the electro-pneumatic valve device (10) is connected to a compressed air source (12) to inflate the at least one spring energy storage brake cylinder or ventilated by connecting to a pressure relief port (3) , and wherein there is a maximum inflation state of the electropneumatic valve device (10) that can be caused by the electronic control device (8), in which state the electropneumatic valve device (10) opens at the compression The largest flow cross-section between the air source (12) and the at least one spring-charged cylinder. It is provided according to the invention that the electronic control unit (8) is configured such that the solenoid valve unit (10) is activated by the The electronic control unit (8) is controlled in the maximum charging state for a long time in this way until the pressure in at least one spring storage brake cylinder starts from the output pressure value with a first gradient and jumps to a level higher than that At a first pressure value that is higher, but still below the brake release pressure for fully releasing the spring-loaded brake cylinder, and is controlled in a state after reaching the first pressure value, In this state, starting from a first pressure value, the pressure in at least one spring accumulator brake cylinder is increased with a second gradient, which is smaller than the first gradient, to At a second pressure value higher than the first pressure value.

Owner:KNORR-BREMSE SYST FUER NUTZFAHRZEUGE GMBH

Flux field plate

PendingCN112204784AEfficient separationAvoid enteringDispersed particle filtrationFuel cellsFuel cellsLiquid water

Owner:AUDI AG +1

adjustable solenoid valve

ActiveCN108930832BReduced flow cross sectionIncrease the current intensityOperating means/releasing devices for valvesApplication and release valvesMagnetic tension forceSolenoid valve

The invention relates to an adjustable solenoid valve (10A) having a magnet assembly (20A) and a guide sleeve (13A) in which a non-movable part (11) is fixedly arranged and a valve armature (17A) is axially displaceable arranged in the guide sleeve, wherein the magnet assembly (20A) is pushed onto the immovable part (11) and the guide sleeve (13A), wherein the said non-movable part (11) forms an axial stop for said valve armature (17A), wherein said valve armature (17A) can be driven by a magnetic force generated by an energized magnet assembly (20A), And pressing the blocking element (17.1A) into the valve seat (15.1A) during the movement in the blocking direction; and lifting the blocking element from the valve seat (15.1A) during the movement in the opening direction. In this case, the valve armature (17A) and the immovable part (11) are each formed as a plastic component, wherein the valve armature (17A) is in its second position facing the immovable part (11). At one end face there is a magnet housing (17.3A) which accommodates a permanent magnet (18A) polarized along its direction of motion so that the permanent magnet (18A) is arranged on the Inside the magnet assembly (20A).

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com