Heat exchanger in particular for exhaust coolers on internal combustion engines

A heat exchanger and inner tube technology, applied in the field of heat exchangers, can solve problems such as flow leakage and achieve the effect of thermal expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

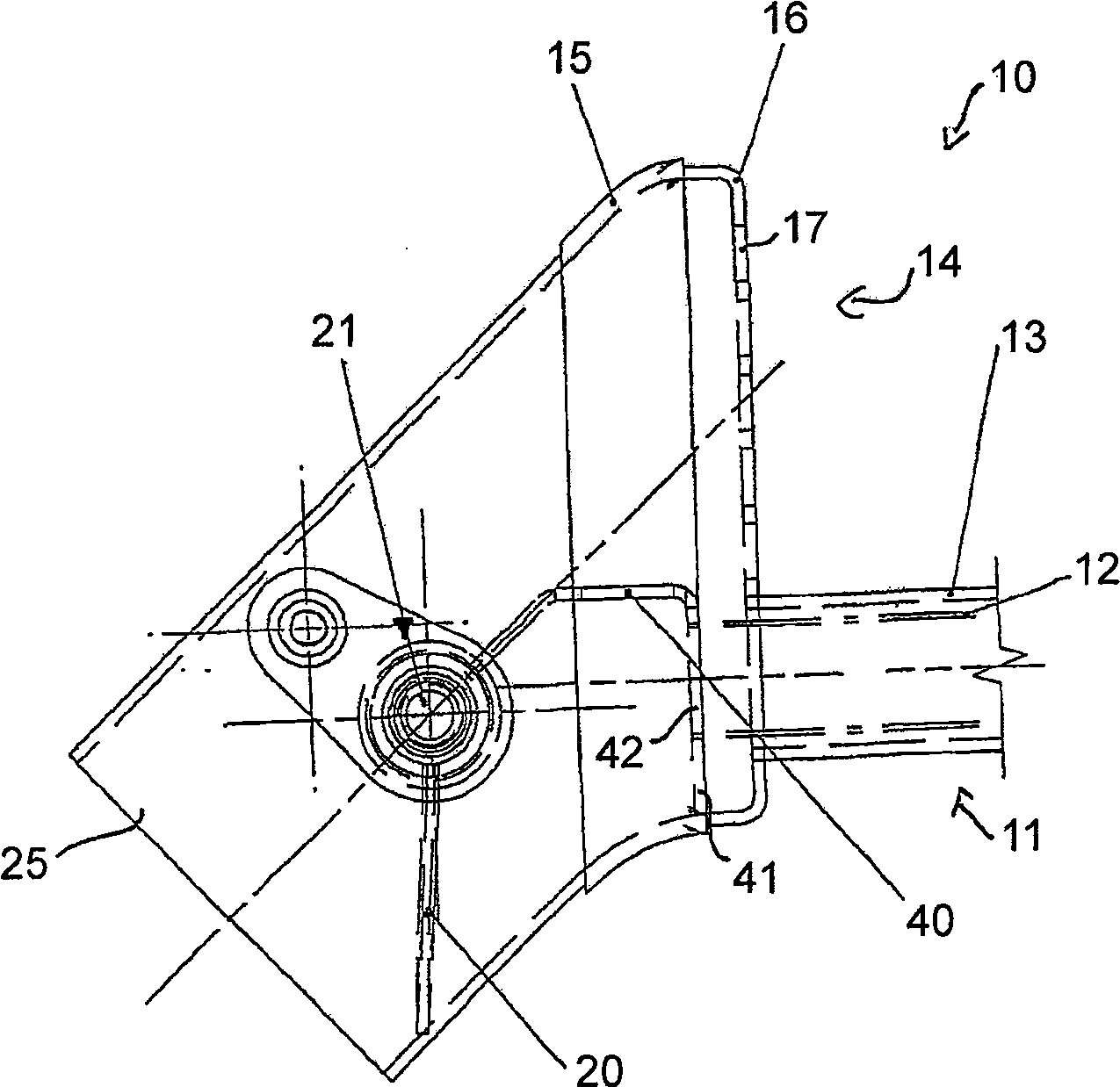

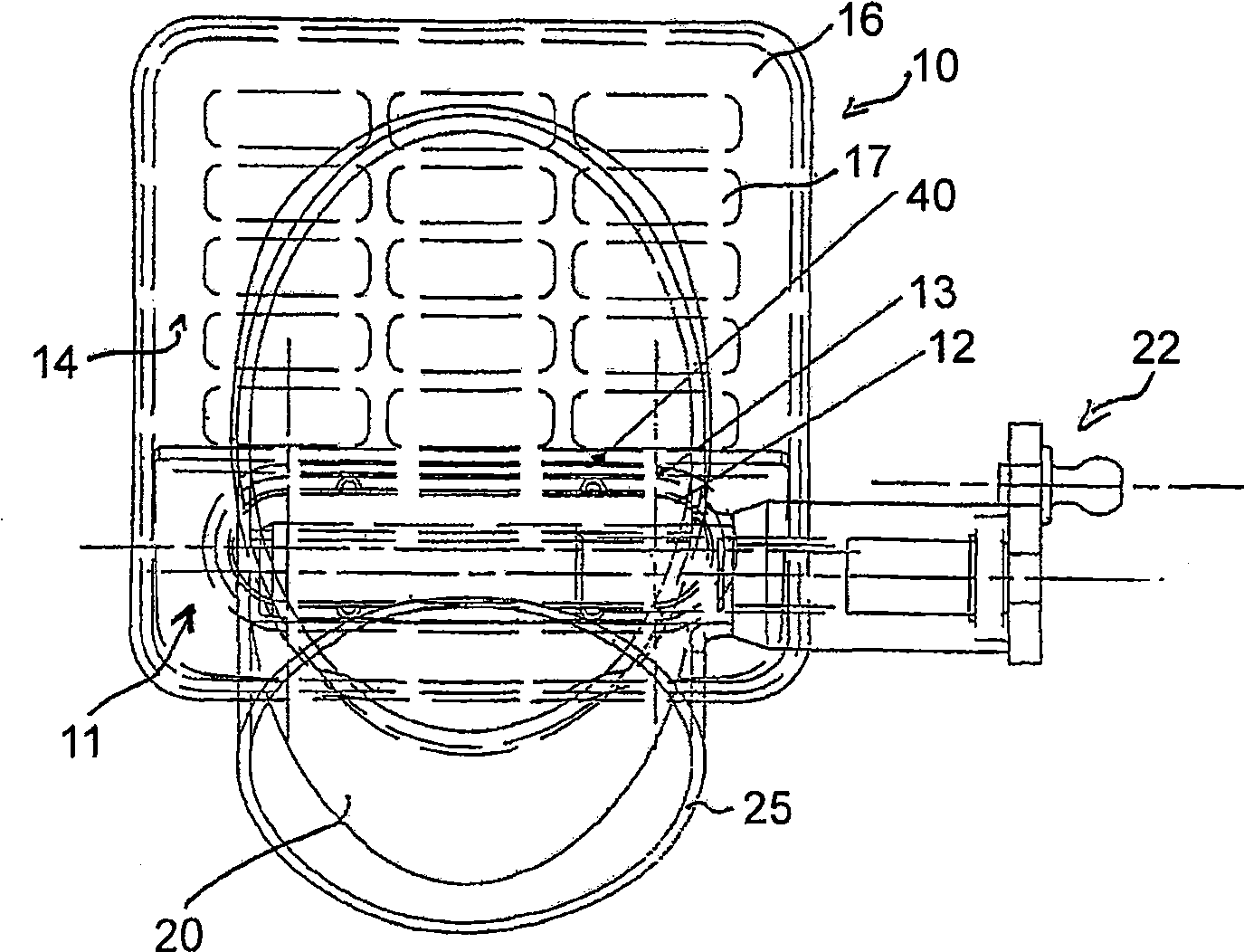

[0023] figure 1 and 2 A longitudinal and transverse section through the heat exchanger 10 is shown in the flow guide of the carrier medium in the inflow region. The heat exchanger 10 is designed as a double pipe, one of the two pipes forming the bypass pipe 11 and the other pipe forming the heat exchange pipe 14 . The heat exchange lines 14 are designed to exchange energy between the carrier medium and the heat exchange medium formed in the region of the heat exchange lines 14 (exchanging energy to the carrier medium) and thus to heat or cool the carrier medium. In the exemplary embodiment shown, the heat exchanger is used for an exhaust gas cooler of an internal combustion engine, in which the carrier medium is formed by the exhaust gas flow and correspondingly supplied with cooling water as heat exchange medium. The heat of the carrier medium - exhaust gas is transferred to the heat exchange medium - water and reduces the temperature of the exhaust gas stream.

[0024] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com