Solenoid valves for fluid control

A technology for controlling fluids and solenoid valves, applied in the field of solenoid valves, can solve problems such as electromagnetic function damage of solenoid valves, achieve the effects of improving flow conditions, reducing pressure and flow speed, improving electromagnetic characteristic curves and hydraulic damping conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

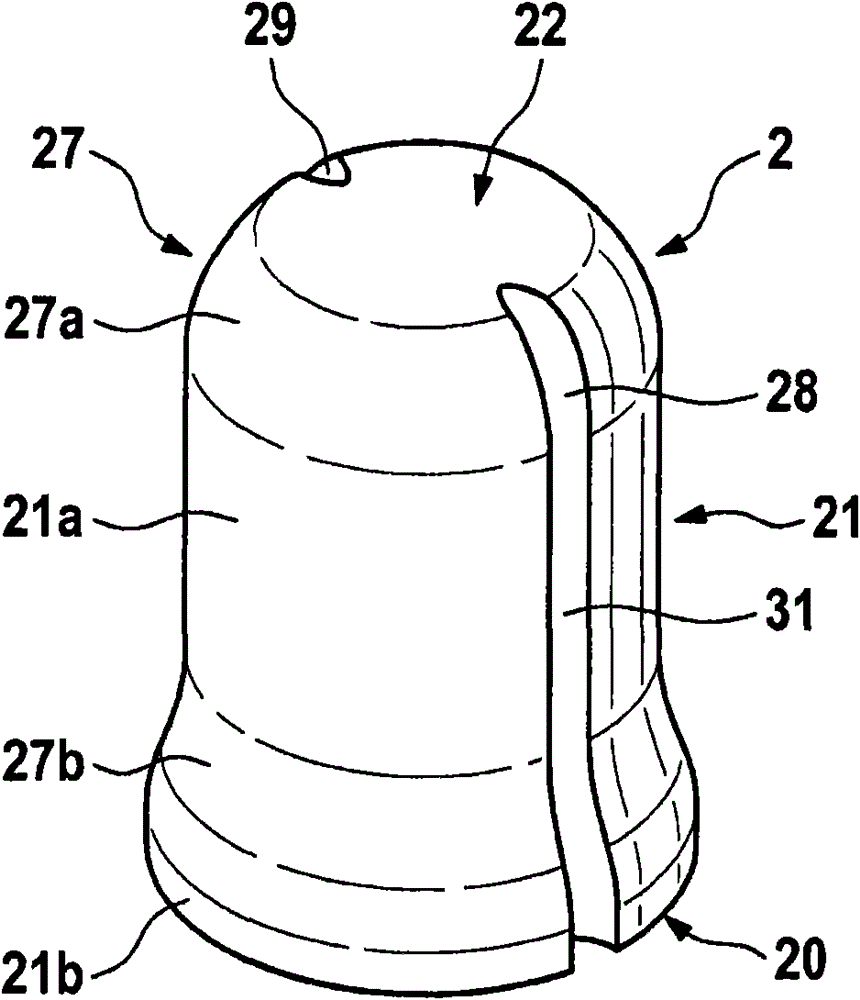

[0018] Next refer to figure 1 and figure 2 The solenoid valve for controlling fluid according to the first preferred embodiment of the present invention will be described in detail.

[0019] figure 1 A schematic sectional view of an armature 2 of a solenoid valve 1 for controlling a fluid according to a first embodiment of the present invention is shown.

[0020] as by figure 1 It can be seen that the armature comprises a bottom region 20 , a side region 21 and a top region 22 and is connected to the valve element 3 of the solenoid valve 1 at the bottom region 20 . The armature 2 is accommodated in a pot-shaped armature housing part 23 . A flow path 26 is formed between the armature 2 and the armature housing part 23 . The flow sequences in the flow path 26 are marked with arrows P1 , P2 and P3 and run from the lower armature chamber 24 to the upper armature chamber 25 and back to the lower armature chamber 24 . Between the top region 22 and the side region 21 of the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com