Drive power train with exhaust gas utilisation and control method

A technology of power train and exhaust gas, applied in the direction of engine control, combustion engine, machine/engine, etc., can solve the problems of unfavorable weight and high cost, and achieve the effect of improving driving comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

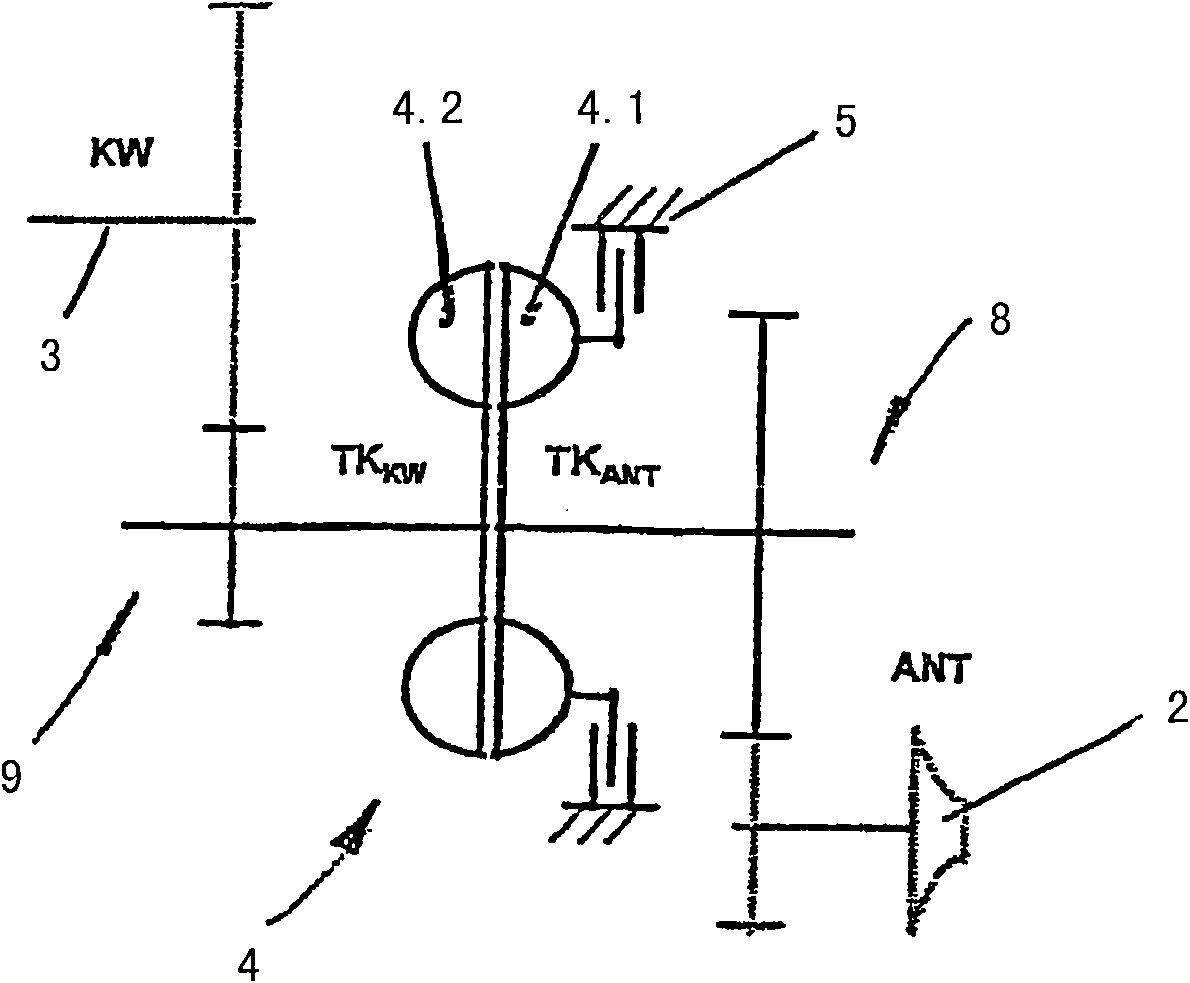

[0024] figure 1 The drive connection between an exhaust gas utilization turbine 2 and a crankshaft 3 of an internal combustion engine (not shown) according to an exemplary embodiment of the invention can be seen in FIG. The driven shaft of the exhaust gas utilization turbine is connected via a first transmission 8 to the drive wheel 4 . 1 of the hydrodynamic coupling 4 . The crankshaft 3 is connected to the driven wheel 4.2 of the hydrodynamic coupling 4 via a second transmission 9 . Accordingly, when the working chamber of the turbo coupling 4 is filled, preferably completely filled, torque or rotational power is transmitted from the exhaust gas utilization turbine 2 to the crankshaft 3 .

[0025] In order to generate a braking torque, the drive wheel 4 . 1 of the turbo coupling 4 can be braked and mechanically locked by means of the multi-plate clutch 5 . In this embodiment, the locking has two functions: first, the fluid coupling 4 is used as a reducer, that is, the crank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com