Motor vehicle electropneumatic spring energy storage brake with a jumpy pressure rise when the brake is released

An energy storage braking, motor vehicle technology, applied in the direction of braking transmission, braking action starting device, hydraulic braking transmission, etc., can solve problems such as unfavorable dynamics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

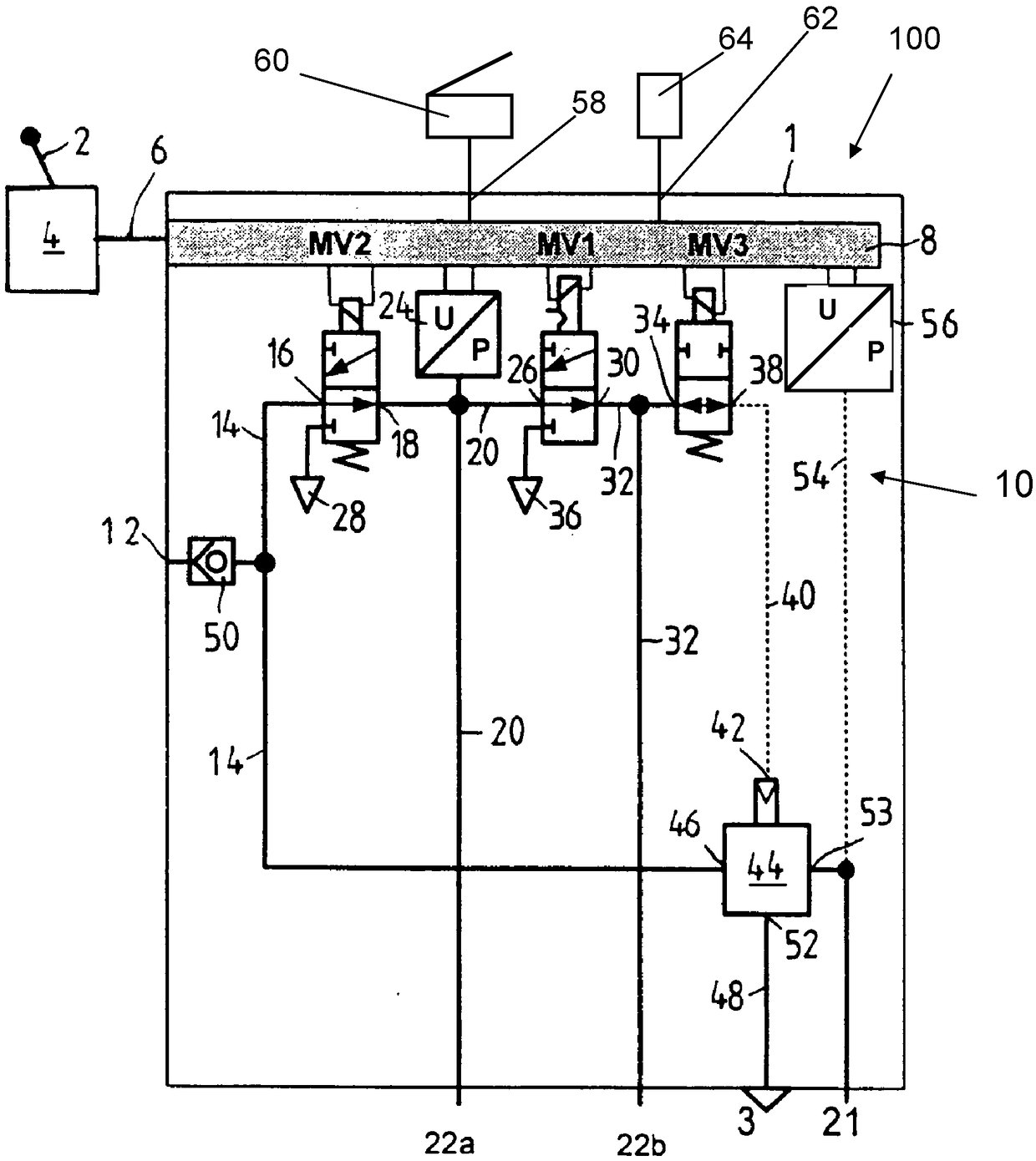

[0047] The electro-pneumatic parking brake device 100 figure 1 The preferred embodiment shown in is part of a brake device of a pressure medium operated, for example an electrically operated tractor-trailer combination, and is arranged in the tractor. This particularly relates to an electronically regulated braking system (EBS).

[0048] The electro-pneumatic parking brake device 100 includes a parking brake module 1 symbolically shown by a box and a parking brake signal transmitter 4, which is manually operated, for example, by a brake operating mechanism Here, for example, it is adjusted via the operating lever 2, and the parking brake signal transmitter controls the electronic control device 8 of the parking brake module 1 through the electronic signal wire 6 with electrical operating signals.

[0049] Preferably, the electronic control device 8 is integrated into the parking brake module 1. In addition, a solenoid valve device 10 that can be controlled by the control device 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com