hydrostatic axial piston machine

A technology of axial piston machine and hydrostatic force, which is applied to reciprocating piston engines, liquid displacement machinery, mechanical equipment, etc., can solve the problems of reducing the efficiency of axial piston machines, achieve precise adjustment, and reduce leakage losses Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

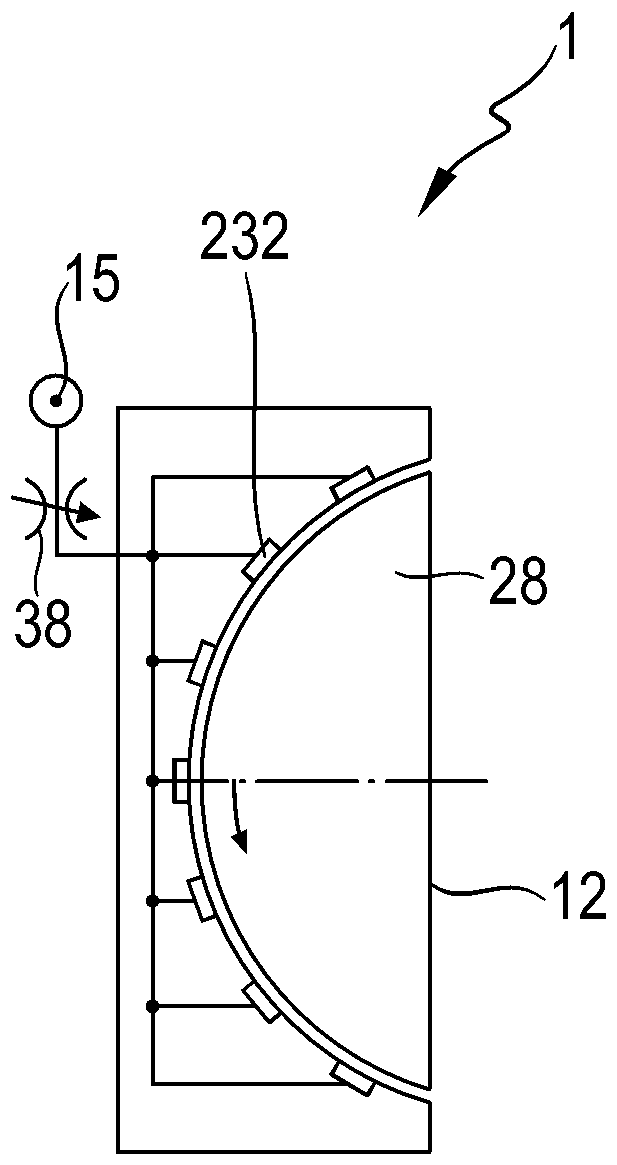

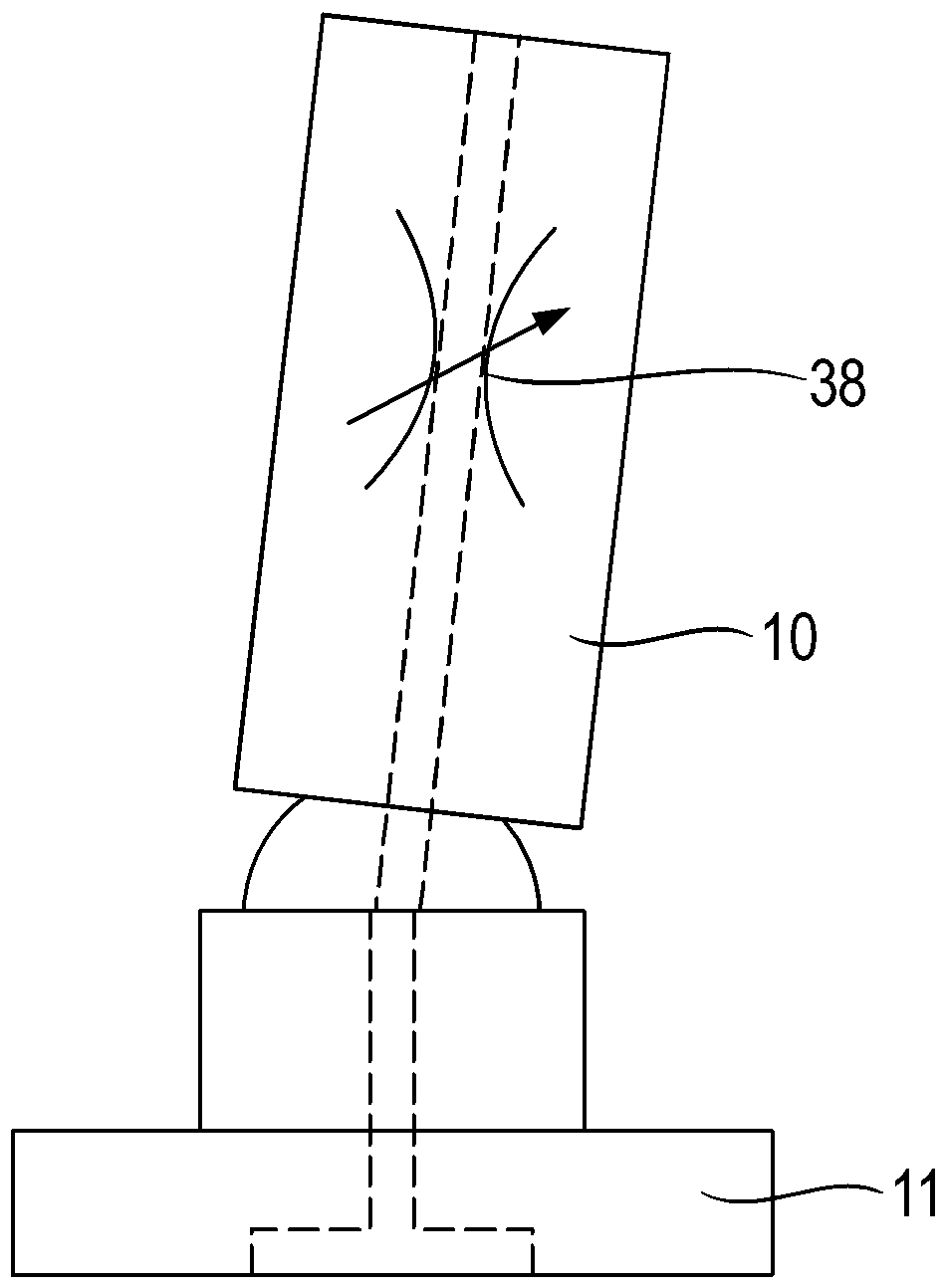

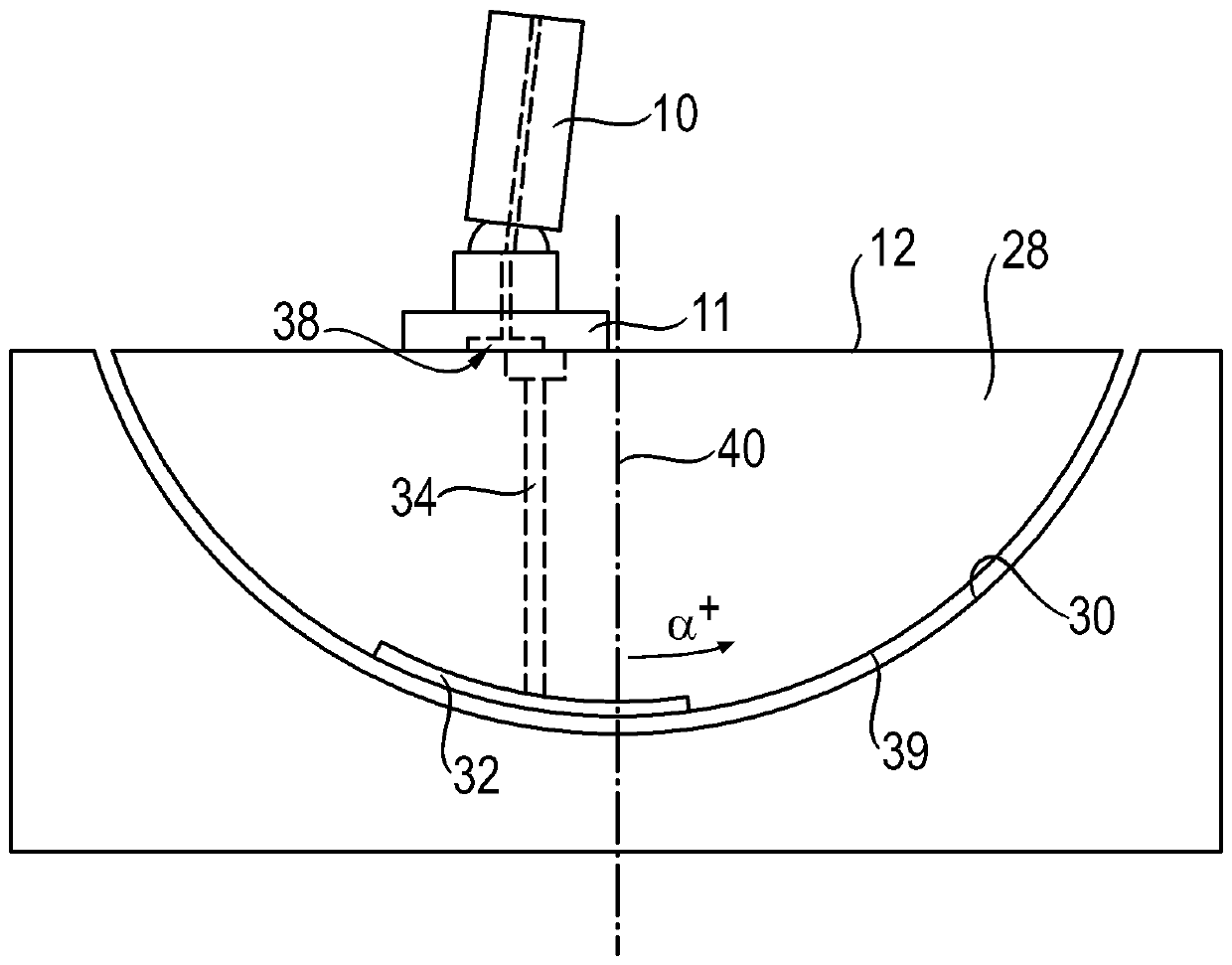

[0050] figure 1 A hydrostatic axial piston machine 1 is shown in longitudinal section. In the exemplary embodiment shown, this axial piston machine is designed as a hydraulic pump and therefore has a firmly assigned high-pressure connection HD and a firmly arranged low-pressure connection ND, which are formed on the housing cover 2 and at the figure 1 is not displayed. The drive shaft 4 is driven in rotation about the axis of rotation 3 and carries a cylinder 6 , in which a plurality of cylinder bores 8 arranged distributed over the circumference are provided, in which corresponding working cylinders are guided along the axial direction. Piston 10. The working pistons 10 are supported slidingly on sliding surfaces 12 of the pivoting cradle 13 via sliding shoes 11 . The last-mentioned cradle does not rotate, but can be adjusted in its inclination via the adjusting cylinder 14 of the adjusting device. In this way, the swivel angle α and thus the displacement volume of the ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com