Nozzle for sandblast fracturing

A nozzle and fracturing technology, which is applied in the field of formation fracturing devices, can solve the problems that the displacement of fracturing construction cannot be increased and affect the effect of fracturing reconstruction, and achieve the effects of improving production stimulation effect and high wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

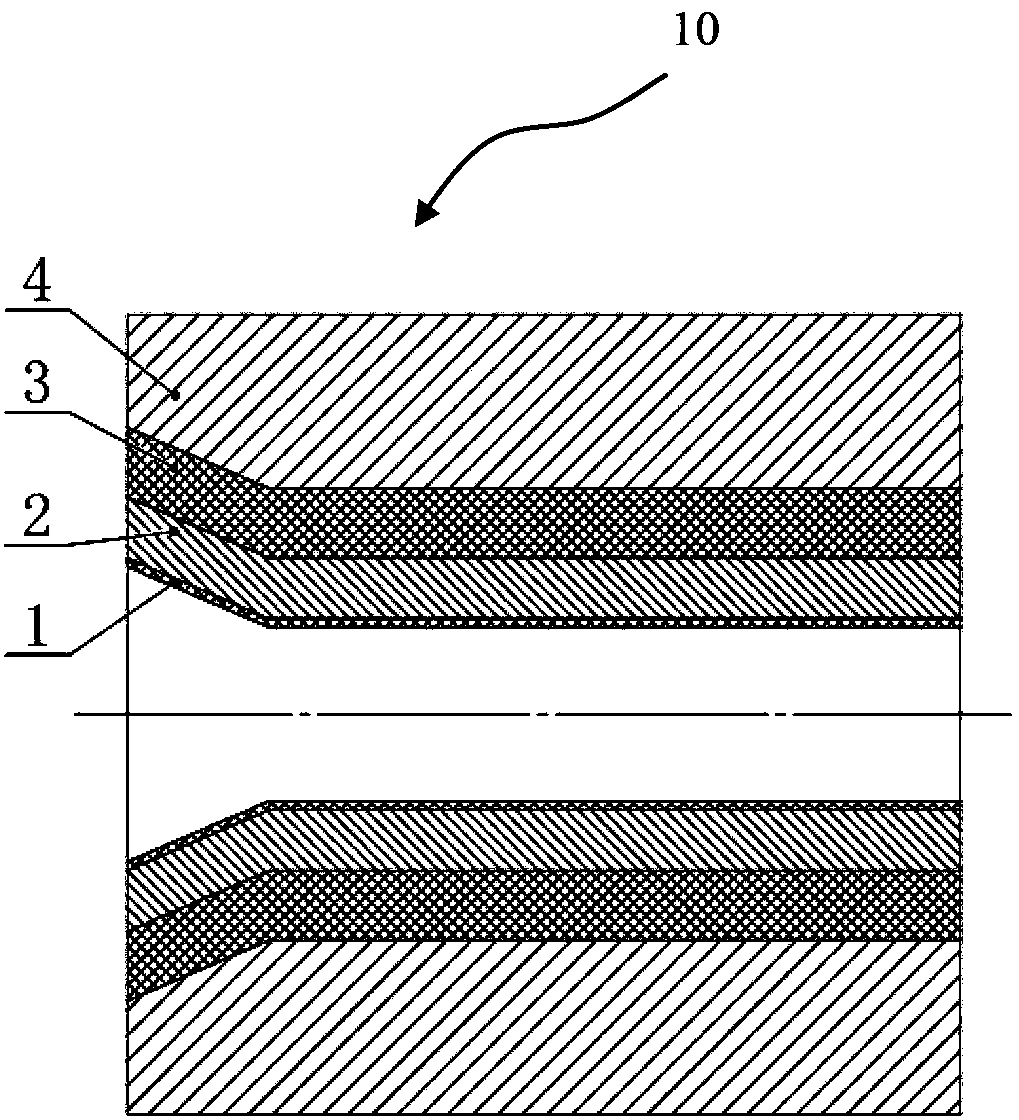

[0019] figure 1 The structure of a nozzle 10 for sandblasting fracturing (hereinafter referred to as nozzle 10 ) according to the present invention is schematically shown. The nozzle 10 includes a nozzle body 4 and a reinforcing layer arranged on the inner surface of the nozzle body 4 . exist figure 1 In the illustrated embodiment, the reinforcing layer comprises a first ceramic layer 3 directly adjacent to the nozzle body 4, an alloy steel layer 2 adjacent to the first ceramic layer 3 and a second ceramic layer adjacent to the alloy steel layer 2 1. During the fracturing construction process, part or even all of the reinforcement layer will be gradually worn away, so that the flow area of the nozzle 10 will increase, and the production stimulation effect of hydraulic sandblasting fracturing will be improved. A connection structure is also provided on the outer surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com