Drive train with exhaust gas utilisation and control method

A technology for power transmission and exhaust gas, which is applied in the field of power transmission, can solve the problems of unfavorable weight and high cost, and achieve the effect of improving driving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

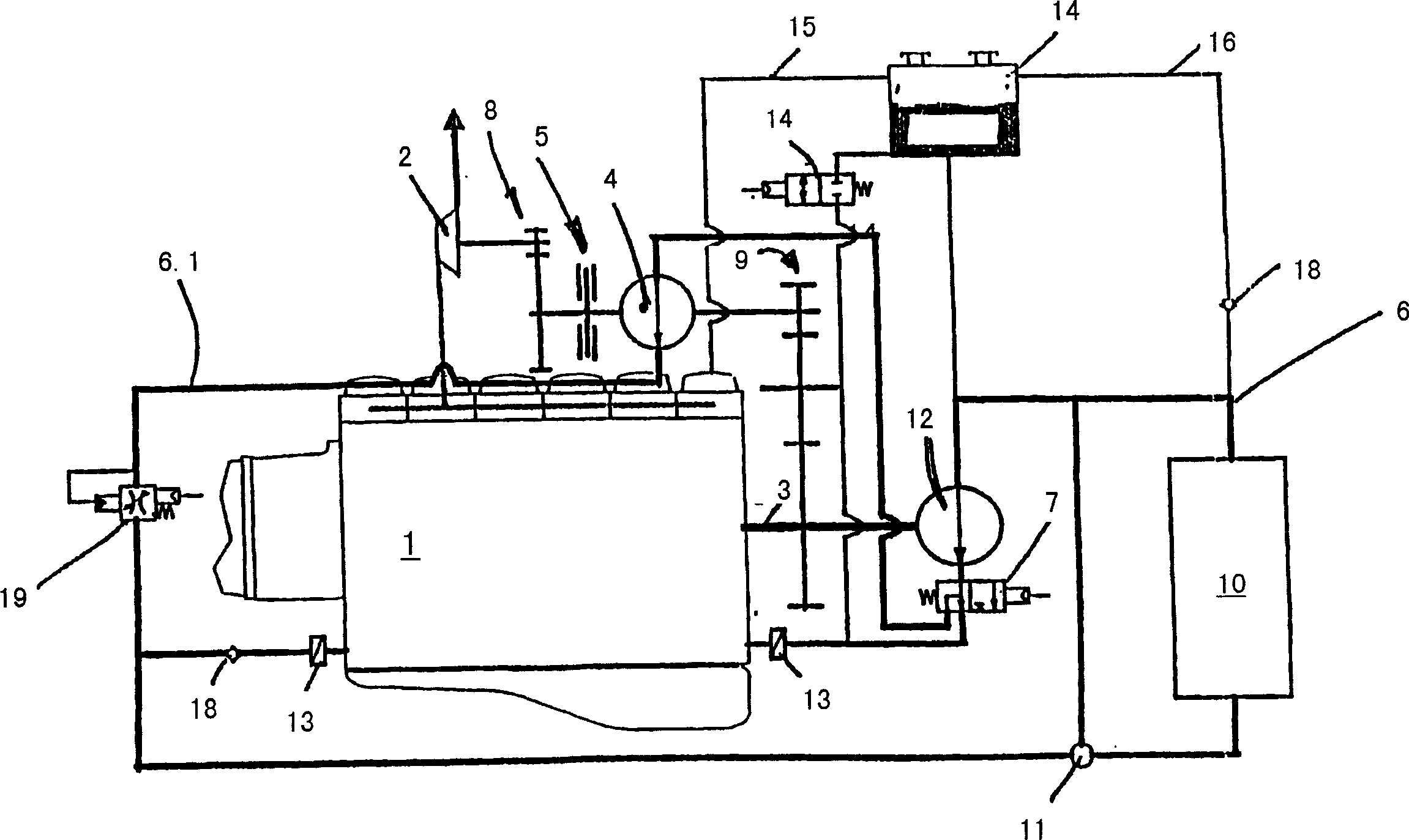

[0022] figure 1 The drive connection between an exhaust gas utilization turbine 2 and a crankshaft 3 of an internal combustion engine, not shown, can be seen in the . The driven shaft of the exhaust gas utilization turbine is connected via a first transmission 8 to the drive wheel 4.1 of the hydrodynamic coupling 4 . The crankshaft 3 is connected to the driven wheel 4 . 2 of the hydrodynamic coupling 4 via a second transmission 9 . Correspondingly, when the working chamber of the hydrodynamic coupling 4 is filled, preferably completely filled, torque or rotational power will be transmitted from the exhaust gas utilization turbine 2 to the crankshaft 3 .

[0023] In order to generate the braking torque, the driving wheel 4 . 1 of the hydrodynamic coupling 4 can be braked and mechanically locked by means of the disc clutch 5 . In the present embodiment, the locking has two effects: firstly the hydrodynamic coupling 4 is used as a retarder, ie the crankshaft 3 then drives the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com