Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Increase the anti-seepage pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

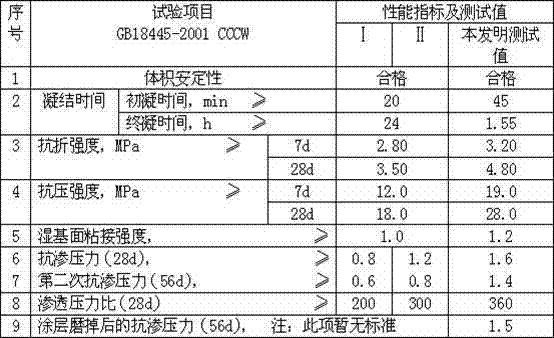

Inorganic powder capillary crystalline waterproof coating material

InactiveCN101362867AImprove impermeabilityImprove permeabilityAntifouling/underwater paintsPaints with biocidesWater reducerQuartz

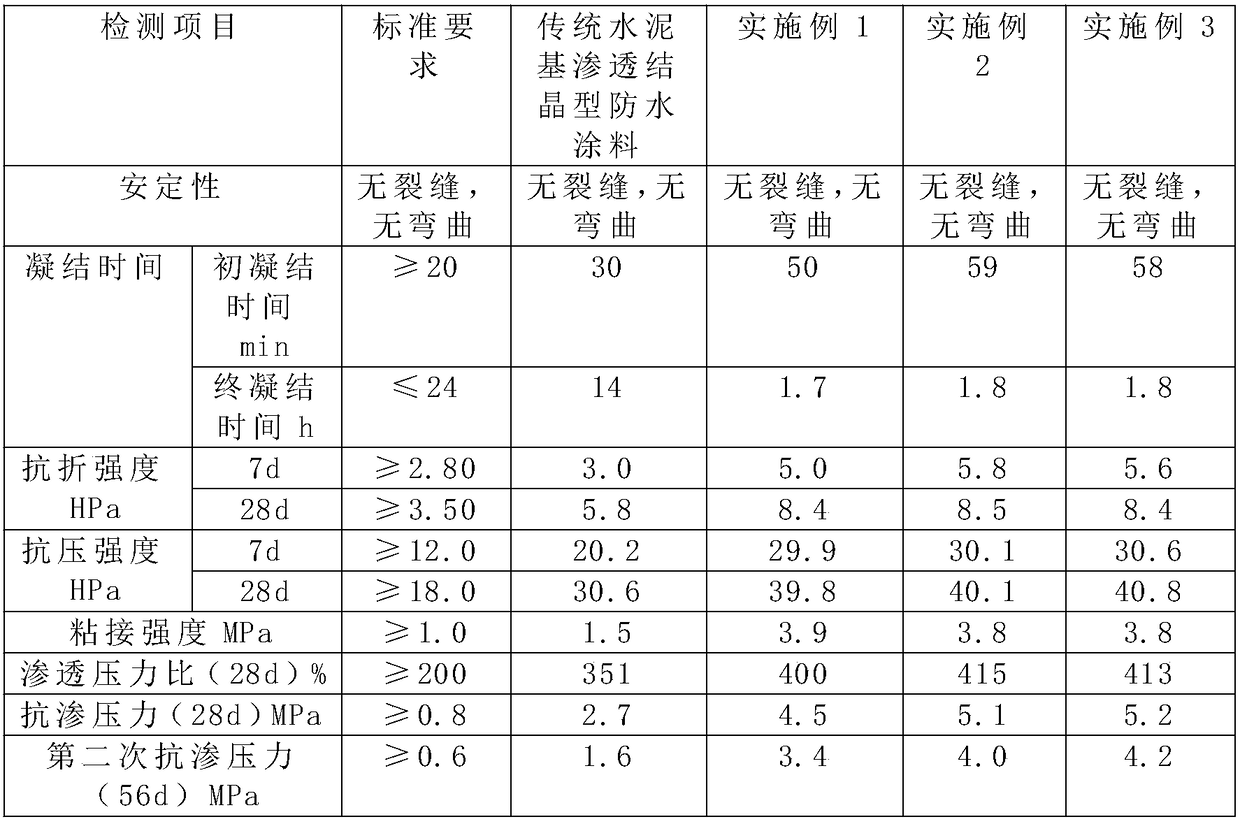

The invention discloses an inorganic powder infiltration crystalline water-proof material which consists of 45 to 55 portions of 600#silicate cement, 20 to 25 portions of ultra-thin quartz sands, 25 to 30 portions of master batches, 1 to 5 portions of effective retarding water reducers and 1 to 5 portions of macromolecular tougheners and is manufactured by feeding the materials into a stirrer to be uniformly stirred. The inorganic powder infiltration crystalline water-proof material is characterized by having the advantages of secondary anti-permeability capacity, durable water-proof performance, high sticking performance, acid resistance and alkali matter resistance; besides, the inorganic powder infiltration crystalline water-proof material have the capacity of growing an insoluble crystal in the pores and the micro cracks of a concrete substrate to plug the pores and the micro cracks, thereby improving the anti-permeability capacity of the concrete and achieving the goals of anti-permeability and anti-leakage. The inorganic powder infiltration crystalline water-proof material can be broadly applied to the water-proof projects of railways, roads, ports and docks, culverts, dams and pools as well as large underground projects.

Owner:天津市耀新科技发展有限公司

Self-crystallized polymer cement-based waterproof coating, and preparation method thereof

The invention relates to a self-crystallized polymer cement-based waterproof coating, and a preparation method thereof. The polymer cement-based waterproof coating is composed of liquid materials and powder materials according to a weight ratio of 1 : 2-3, wherein the liquid materials comprise 93-96 parts of a polymer emulsion, 2-3 parts of a waterproof agent, 1-3 parts of a plasticizing agent and 1-2 parts of a defoaming agent; and the power materials comprise 30-45 parts of a hydraulic cementing material, 40-55 parts of quartz sand, 10-20 parts of mineral fibers, 3-5 parts of plant active protein, 1-2 parts of a surfactant, 0.5-1 part of a cross-linking agent and 0.5-1 part of a crystallizing agent. The mineral fibers with high length-diameter ratio are selected as a network structure of the waterproof coating. The liquid materials and the powder materials with stable performance are obtained by performing shear dispersion plasticization and waterproof modification on the liquid materials and diffusion mixing the powder materials; and the crystallizing agent dispersed in the network structure swells in water to achieve an auto-repairing function for cracks of the waterproof layer.

Owner:XIAMEN HOLSIN ENG TECH CO LTD

Cement-base osmotic crystalline waterproof material and its production process

The invention discloses a cement base osmotic crystallizing waterproof material and its producing process, including the following components in weight percent: ordinary Portland cement 35%-55%, calcium carbonate 5%-20%, silca sand 25%-50%, osmotic crystallizing active mother material 1%-5%, methyl cellulose MHEC15000PFR 0.05% -0.2%, methyl cellulose MHEC20000PFR 0.05%-0.2%, BaiErLe 4330-3 0-2.5%, and encrypted microsilicon, and the producing process includes in turn: screening, mixing, feeding, blending, checking, and packaging and storing. And the waterproof material forms crystallized waterproof protective layers in the micropores of the cement base to stop exudation of water, and the waterproofing and ant moistureproofing effects are permanent and the adhesion of the waterproof material onto the surfaces of the concrete poured in advance, and the performance is stable and the strength is high.

Owner:李凌伟

Impermeable moisture-proof pre-stirring mortar and production method thereof

InactiveCN106242419AExcellent infiltration and crystallizationImprove crack resistanceCelluloseCrack resistance

The present invention relates to an impermeable moisture-proof pre-stirring mortar and a production method thereof, wherein the raw materials comprise, by weight, 40-55 parts of an aggregate, 40-50 parts of superfine 52.5 portland cement, 3-5 parts of high activity permeable crystallization master batch, 5-15 parts of nanometer calcium carbonate, 0.2-0.8 part of a water reducing agent, 0.5-2 parts of a coagulation promoting enhancer, 1-3 parts of redispersible latex powder, 0.1-0.4 part of cellulose ether, 0.02-0.05 part of an anti-foaming agent, 0.2-0.5 part of polypropylene fibers, and 0.1-0.3 part of zinc stearate. According to the present invention, the slurry obtained by stirring the impermeable moisture-proof pre-stirring mortar according to a proper water to material ratio has advantages of cracking resistance, penetrating crystallization, moisture resistance, impermeability and excellent hydrophobicity, and can be used in the fields of building basements, pools, toilets, inner and outer walls, and the like.

Owner:张珏

High-performance corrosion-resistant dry-mixed waterproof mortar

The invention discloses high-performance corrosion-resistant dry-mixed waterproof mortar. The high-performance corrosion-resistant dry-mixed waterproof mortar is prepared from the following raw materials in parts by weight: 60-70 parts of cement, 35-45 parts of mineral powder, 10-30 parts of coal ash, 300-500 parts of regenerated fine aggregates and 5-10 parts of a compounded additive, wherein the compounded additive is prepared from the following raw materials in parts by weight: 40-60 parts of coal ash, 5-7 parts of a water repellent, 40-50 parts of an expanding agent, 2-5 parts of an air-entraining and water-reducing agent, 2-4 parts of anti-crack short fiber and 2-10 parts of a water-retaining thickening agent. By virtue of a dry-mixing form, the high-performance corrosion-resistant dry-mixed waterproof mortar is convenient to use, and the sulfate corrosion can be effectively prevented.

Owner:潍坊德霖建材科技有限公司

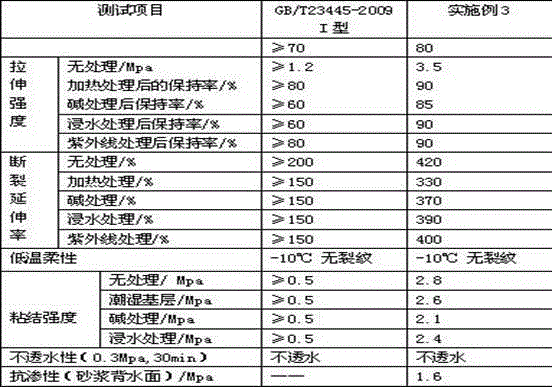

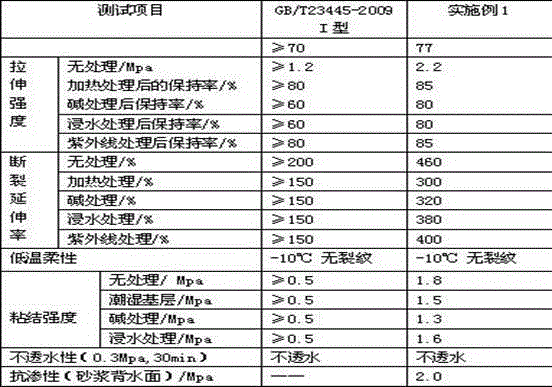

Self-healing type non-self-adhesive modified asphalt waterproof coiled material and preparation method thereof

ActiveCN104312174AEasy to produceGood physical propertiesBuilding insulationsSelf-healingBituminous waterproofing

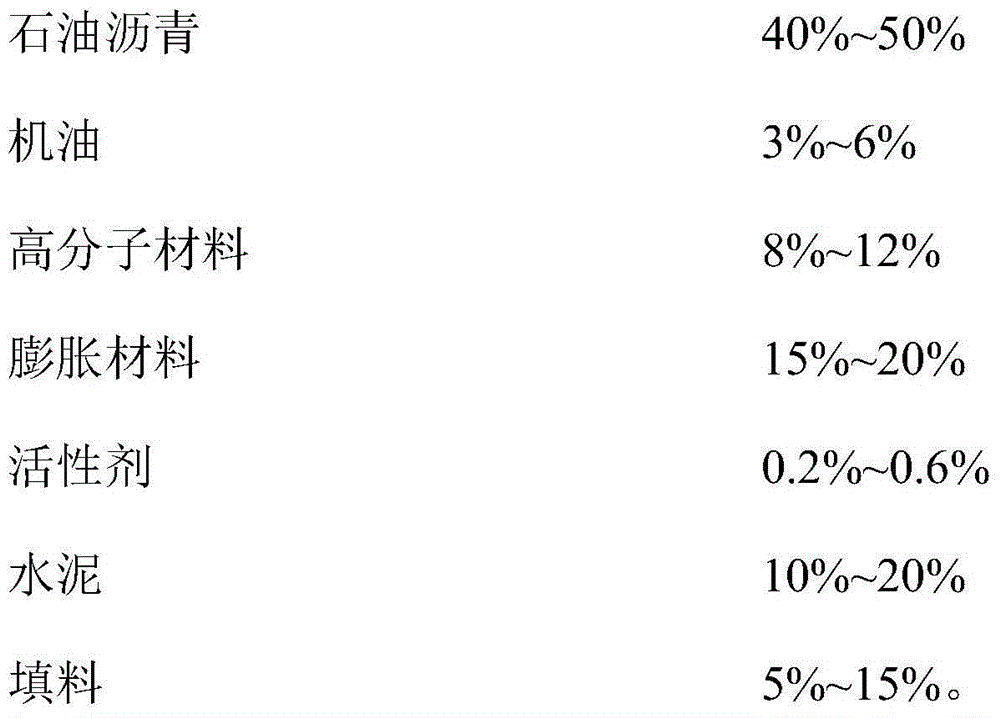

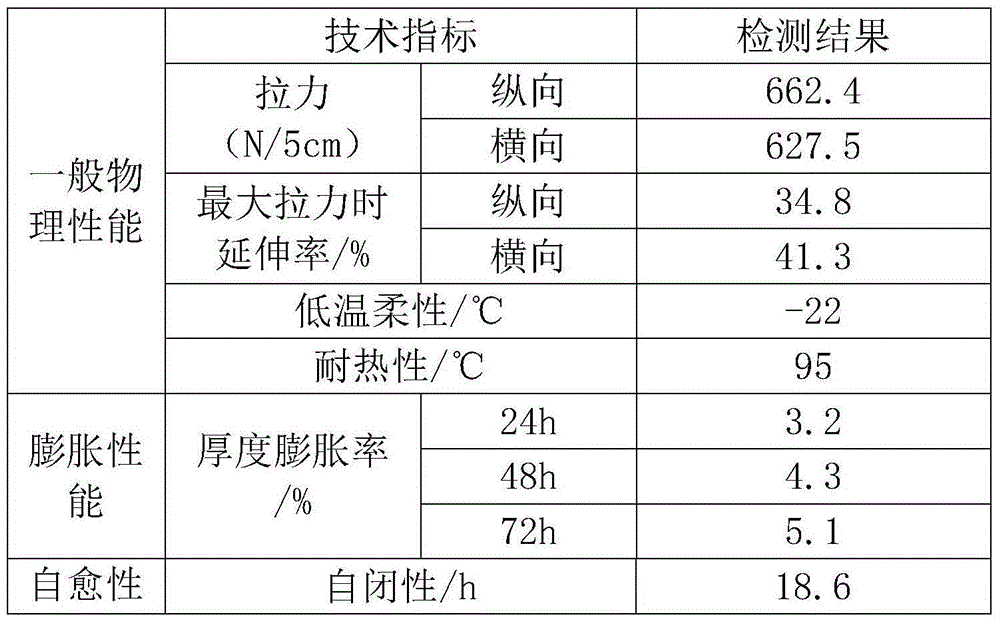

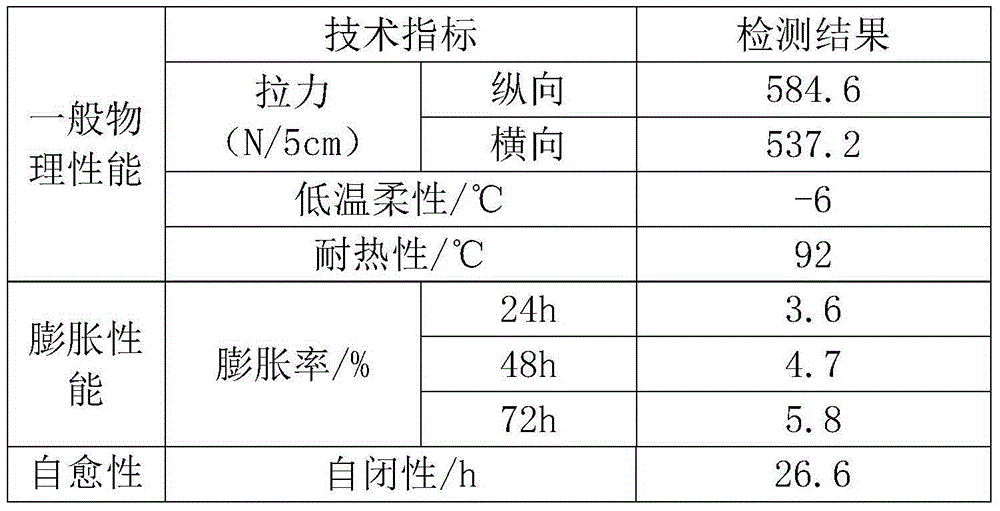

The invention discloses a self-healing type non-self-adhesive modified asphalt waterproof coiled material which is characterized by consisting of a modified asphalt coating material, a tire body and an isolation material, wherein the modified asphalt coating material consists of the following components in percentage by mass: 40-50% of petroleum asphalt, 3-6% of machine oil, 8-12% of high polymer material, 15-20% of expanding material, 0.2-0.6% of active agent, 10-20% of cement and 5-15% of filler. During preparation, the coating material is uniformly mixed and then is coated on the tire body, and then the tire body is covered with the isolation material to obtain the self-healing type non-self-adhesive modified asphalt waterproof coiled material. By virtue of tests performed according to relevant national or industrial test methods, the waterproof coiled material disclosed by the invention has good mechanical properties and excellent self-healing performance.

Owner:苏州市姑苏新型建材有限公司

Green and environment-friendly building mortar and production method thereof

The invention relates to green and environment-friendly building mortar and a production method thereof. The building mortar is prepared from, by weight, 60-70 parts of aggregates, 55-60 parts of sulphoaluminate cement clinker, 6-8 parts of high-activity infiltration crystalline masterbatch, 16-20 parts of nano calcium carbonate, 1.2-1.6 parts of water reducing agent, 3-5 parts of coagulation accelerating enhancer, 0.06-0.08 part of compound activator, 4-6 parts of redispersible latex powder, 0.5-0.8 part of cellulose ether, 0.08-0.12 part of defoamer, 0.6-0.8 part of polypropylene fiber and 0.4-0.6 part of zinc stearate. After the green and environment-friendly building mortar is stirred according to the appropriate ratio of water to material, the mortar is good in crack resistance, infiltration crystalline, corrosion resistance, permeability resistance and hydrophobicity and suitable for the fields of building basements, pools, toilets, inner walls, outer walls and the like.

Owner:秦文雄

Impervious early strength organosilicon waterproof agent and preparation process thereof

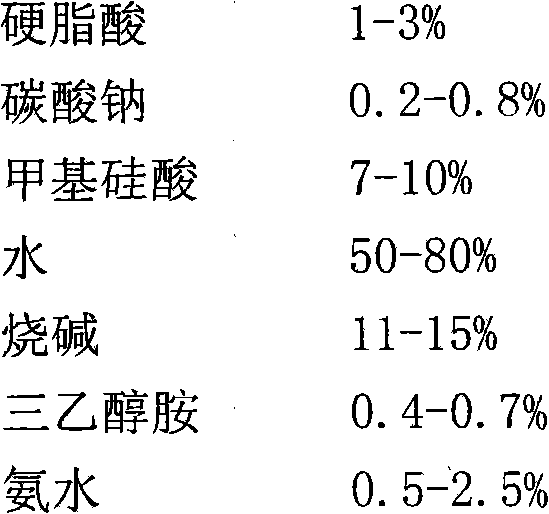

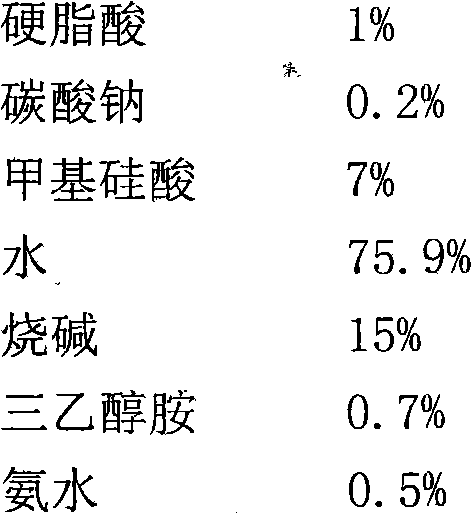

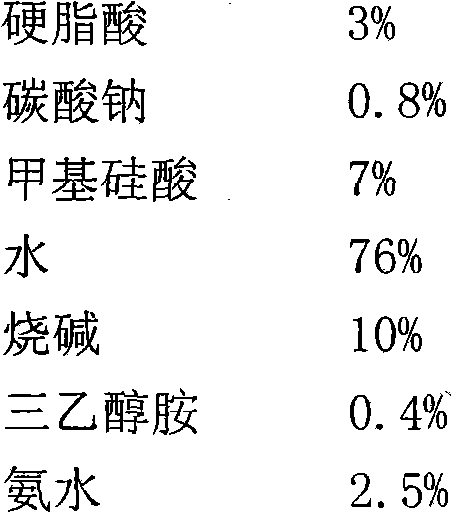

The invention relates to an impervious early strength organosilicon waterproof agent and a preparation process thereof. The impervious early strength organosilicon waterproof agent comprises the following raw materials in percentage by weight: 1 to 3 percent of stearic acid, 0.2 to 0.8 percent of sodium carbonate, 7 to 10 percent of methyl silicic acid, 50 to 80 percent of water, 11 to 15 percentof sodium hydroxide, 0.4 to 0.7 percent of triethanolamine and 0.5 to 2.5 percent of ammonia water. Due to the addition of the stearic acid, the methyl silicic acid and the sodium hydroxide which serve as main raw materials and the triethanolamine serving as an auxiliary material, the waterproof agent enhances the early strength and plasticization of concrete and mortar and improves the performance of weather resistance and impermeability pressure further, and has the characteristic of convenience for construction simultaneously. The waterproof agent can be sprayed on surfaces of buildings directly, and also can be used for stirring the concrete and the mortar for water prevention. The composition and the construction of the waterproof agent meet requirements of national environmentally-friendly standards. The preparation process of the waterproof agent comprises simple operating steps, so the large-scale production is convenient, and the waterproof agent can be widely used for the waterproof construction of the surfaces of the buildings, projects, basements, tunnels and water ponds.

Owner:陈磊 +1

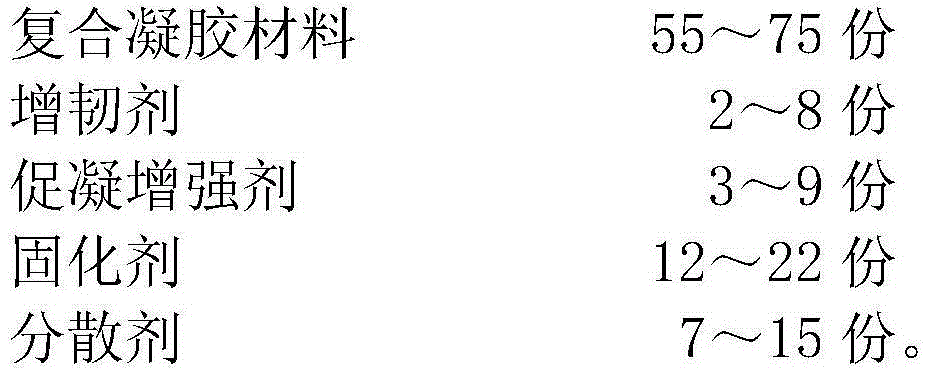

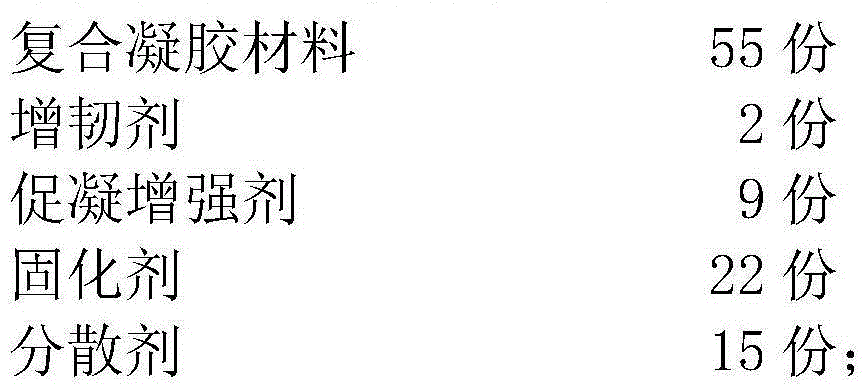

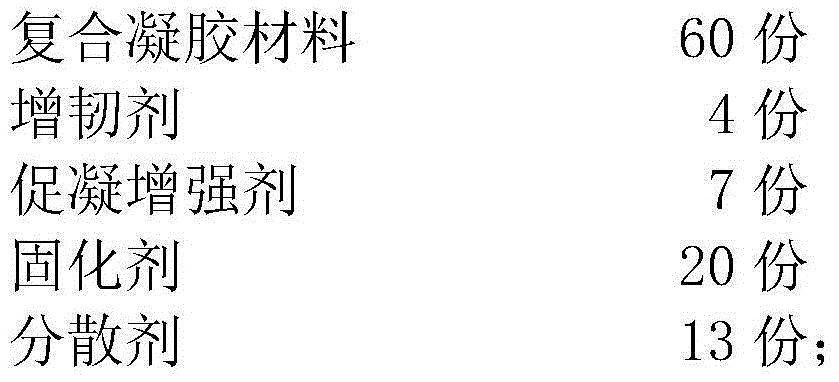

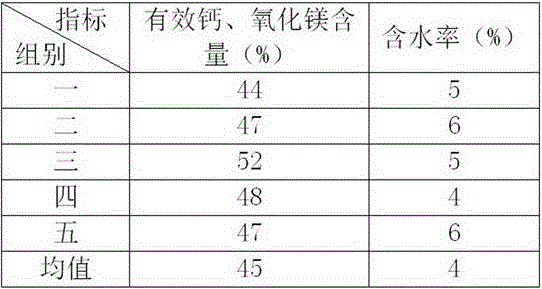

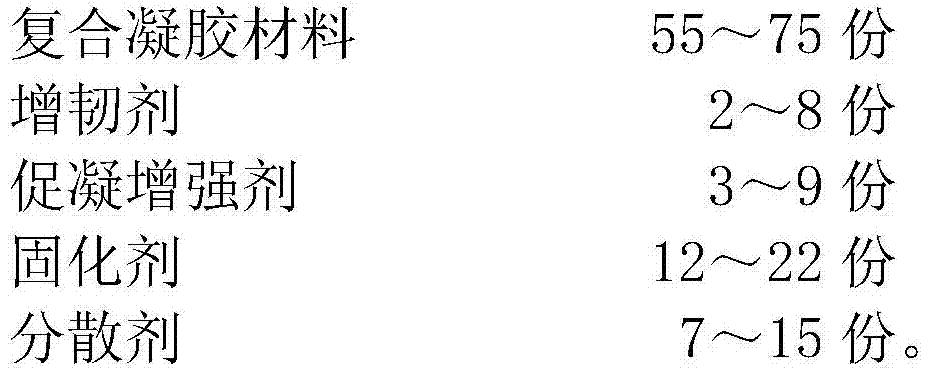

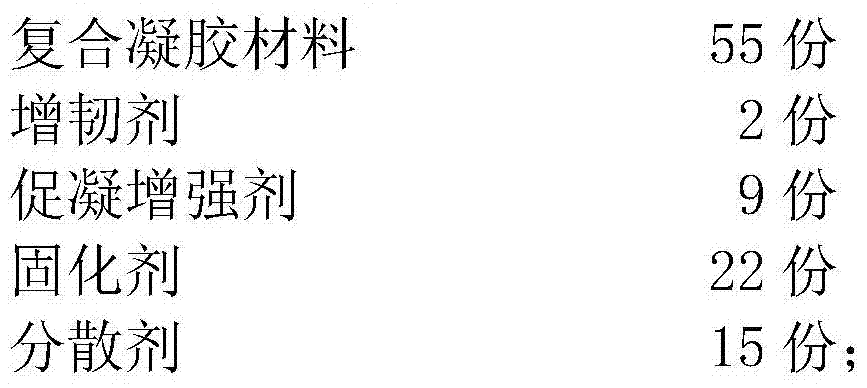

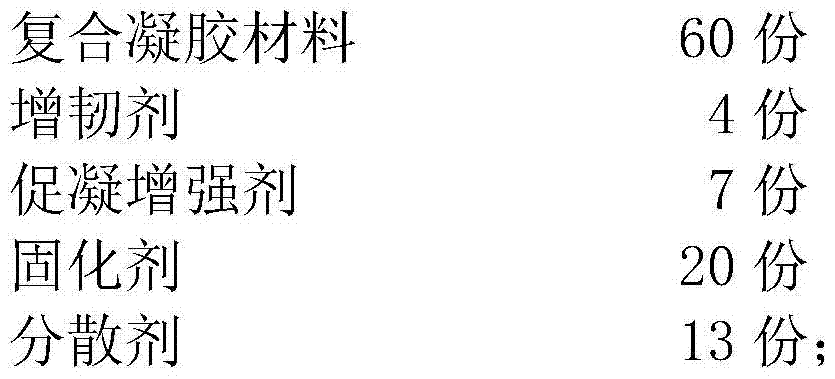

Compound plugging agent

ActiveCN104987017AWide temperature rangeImprove temperature and pressure resistanceMaterials scienceRaw material

The invention relates to the technical field of building materials, in particular to a compound plugging agent, which is prepared from the following raw materials in parts by weight: 55 to 75 parts of composite gel material, 2 to 8 parts of flexibilizer, 3 to 9 parts of coagulating enhancer, 12 to 22 parts of curing agent and 7 to 5 parts of dispersant. The compound plugging agent provided by the invention has rigidness and flexibility, has the effects of transforming and filling, simultaneously, has the effects of bridging and transforming and filling, the use amount of plugging materials is greatly reduced and the cost is lowered.

Owner:GUILIN HEXIN WATERPROOF DECORATION MATERIAL

Seepage-resistant cement

The invention relates to seepage-resistant cement prepared from raw materials of, by weight: 5-8% of fluorine-containing polyacrylate emulsion powder with fluorine content of 1-3%, 2-3% of rosin with a specification of 100-200 meshes, 3-5% of sodium silicate, 3-5% of calcium hydroxide, 1-2% of alum, 1-2% of sodium dodecyl sulfate, 10-15% of phosphoaluminate cement, and balance of Portland cement. The cement provided by the invention is advantaged in high seepage resistance and high binding strength. With the cement, seepage resistance of cement mortar can be substantially improved, and bending strength and compressive strength of the cement mortar are improved.

Owner:博元建设集团股份有限公司

Environment-friendly masonry mortar and production method thereof

The invention relates to environment-friendly masonry mortar and a production method thereof. The environment-friendly masonry mortar is produced from, by weight, 38-42 parts of lime factory waste, 42-46 parts of sulphate aluminium cement clinker, 10-20 parts of steel slag micro powder, 10-12 parts of high-activity capillary crystalline master batches, 12-14 parts of nano calcium carbonate, 1.0-1.2 parts of water reducer, 3-5 parts of coagulating enhancer, 0.12-0.14 part of compound activator, 5-7 parts of redispersible powder, 1.2-1.4 parts of cellulose ether, 0.16-0.18 part of antifoaming agent, 1.5-1.7 parts of polypropylene fibers and 0.8-1.2 parts of zinc stearate. According to the environment-friendly masonry mortar, the mortar stirred according to the proper water-material ratio has excellent cracking resistance, capillary crystalline, corrosion resistance, seepage resistance and hydrophobicity, and is suitable for the fields of building basements, pools, toilets, inner and outer walls and the like.

Owner:秦文雄

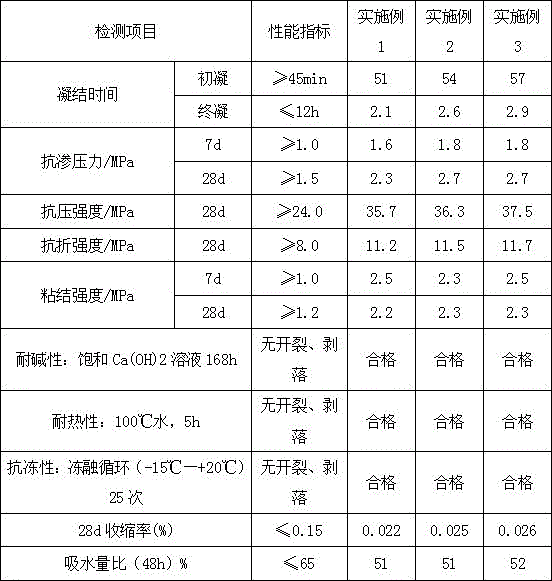

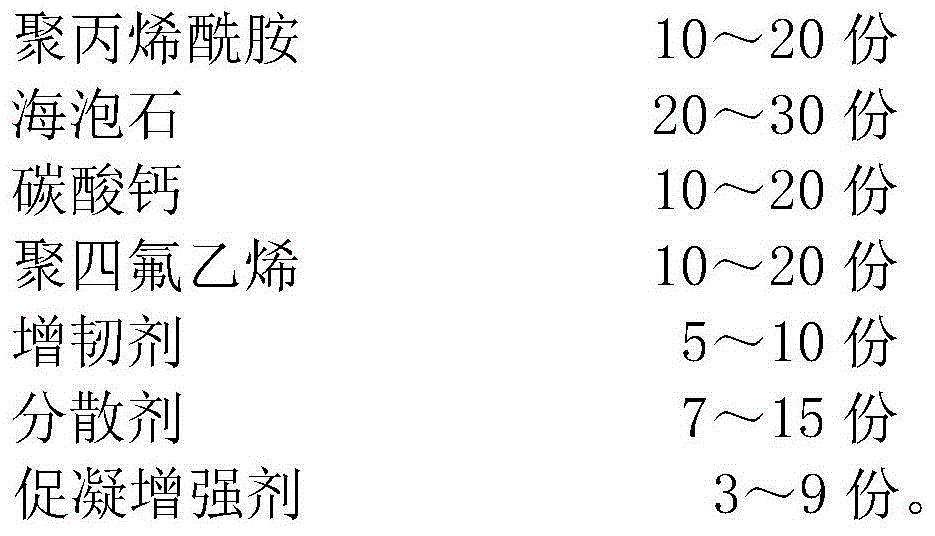

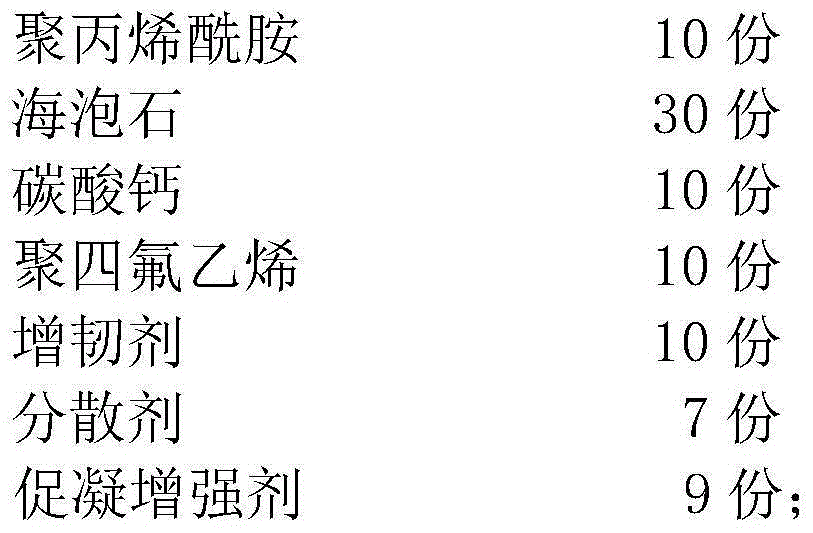

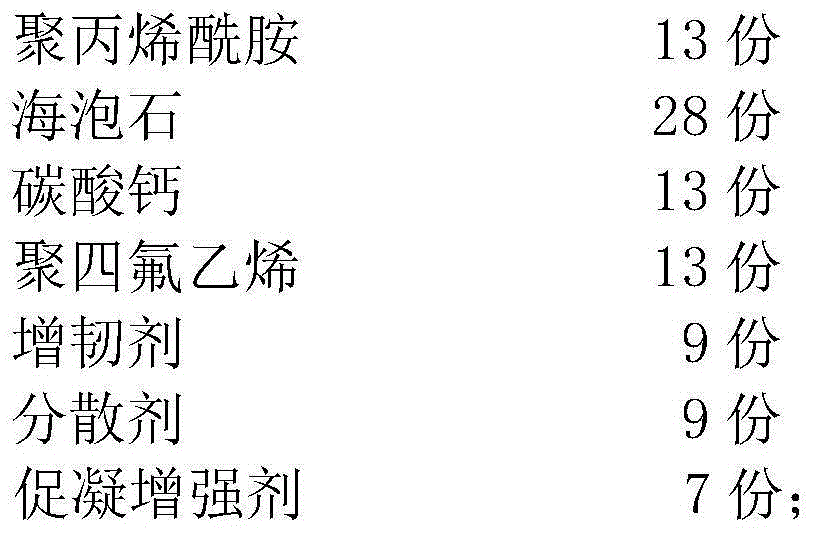

Expansion-controllable plugging agent

The invention relates to the technical field of a plugging agent, especially to an expansion-controllable plugging agent. The expansion-controllable plugging agent is prepared from the following raw materials, by weight, 60-80 parts of polyacrylamide, 10-20 parts of meerschaum, 10-20 parts of teflon, 5-10 parts of a flexibilizer, 7-15 parts of a dispersant and 3-9 parts of a coagulant enhancer. The expansion-controllable plugging agent can control expansion speed, has good deformability and adaptability, can reduce permeability of a plugged zone, enhance strength of the plugged zone and raise pressure-bearing capacity of the plugged zone, is low-cost, is non-toxic, harmless and pollution-free, and is green and environmentally friendly.

Owner:GUILIN HEXIN WATERPROOF DECORATION MATERIAL

Special mixed cement for on-site preparation of concrete as well as preparation method and application

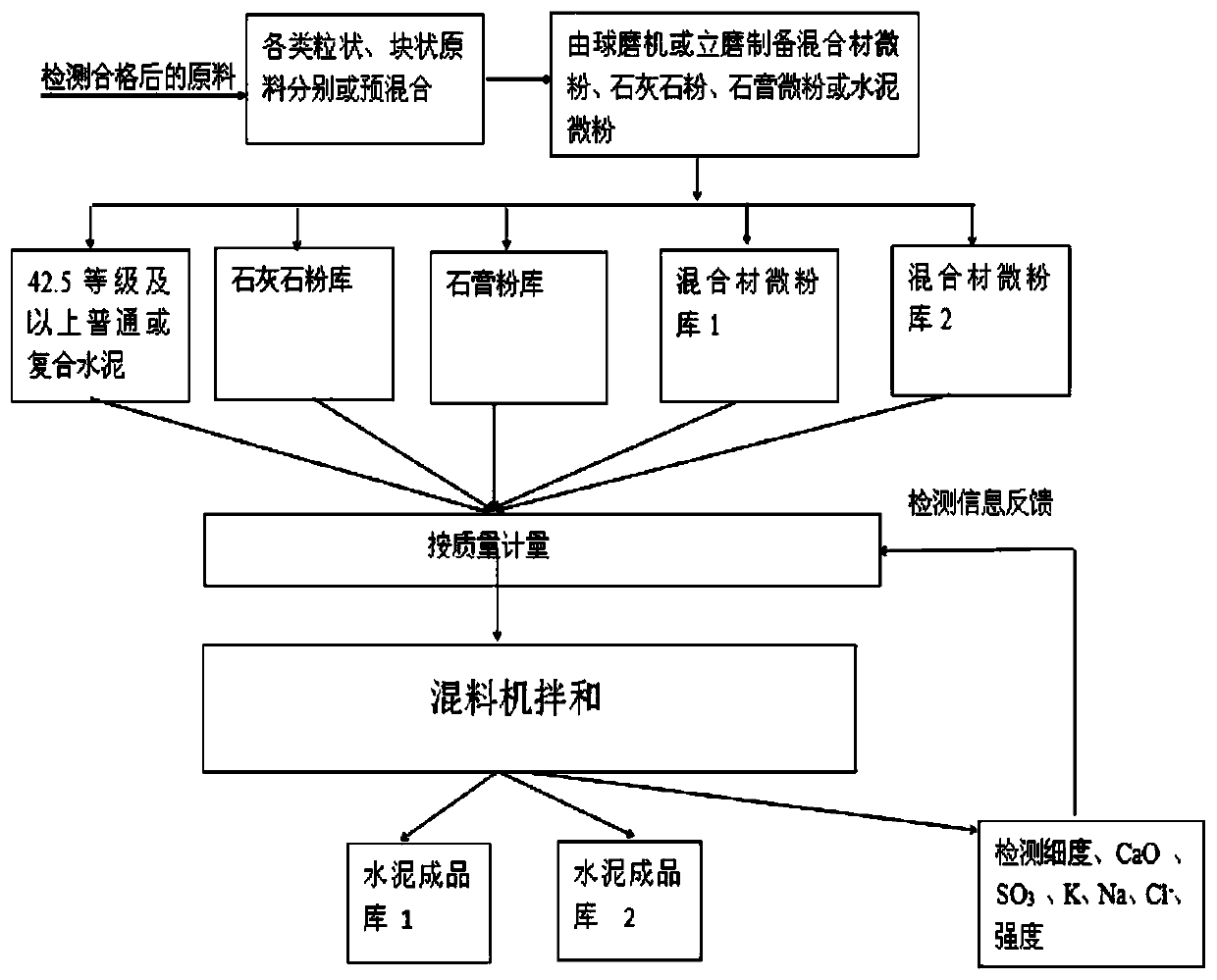

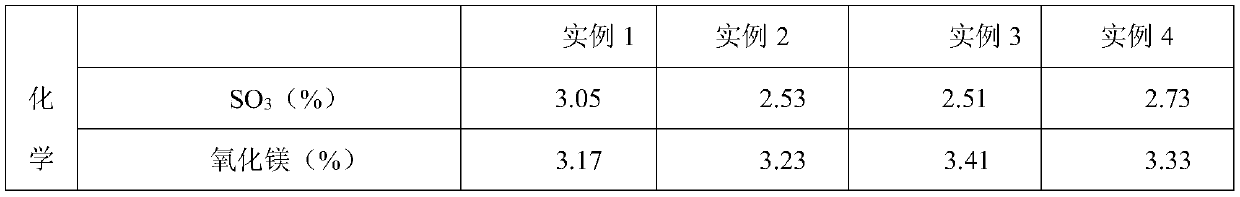

The invention relates to the field of cement and concrete. The invention discloses special mixed cement for on-site preparation of concrete as well as a preparation method and application. Except formixing and grinding cement clinker and other raw materials, the mixed cement is prepared from the following components in percentage by mass: 60%-80% of general Portland cement of the 42.5 grade or above, 3.0%-6.0% of gypsum, 5%-15% of limestone, 2%-29% of an admixture and 0.5%-3.0% of a functional additive. The general Portland cement with the grade of 42.5 or above meets the requirements of GB175, and parameters of the general Portland cement are controlled such that the mass ratio of the micro powder less than or equal to 3 [mu]m is less than or equal to 10%, the one-day compressive strength is less than or equal to 12 MPa, the 3-day compressive strength is more than or equal to 20 MPa, the 28-day compressive strength is more than or equal to 45 MPa, the water consumption of the standard consistency of the cement paste is less than or equal to 28%, the alkali content is less than 0.6% in terms of 0.658 K2O + Na2O, and the chloride ion content is less than 0.06%. The raw materials are wide in source, the mixed cement can be directly used for preparing or premixing concrete on site, no admixture or functional additive needs to be added again, crack resistance, workability and themechanical property of the concrete are improved, and construction operation is simplified.

Owner:程菲 +1

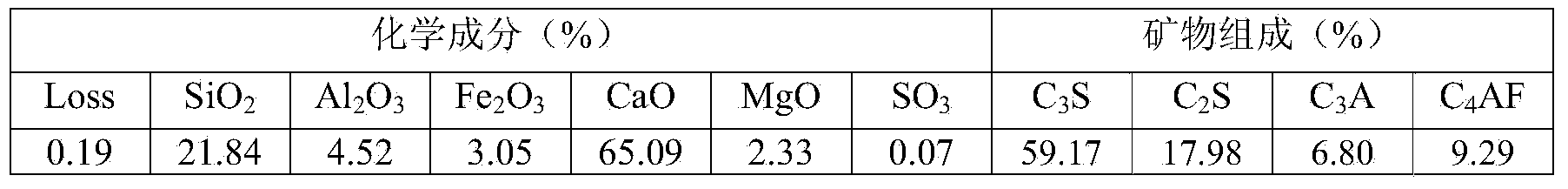

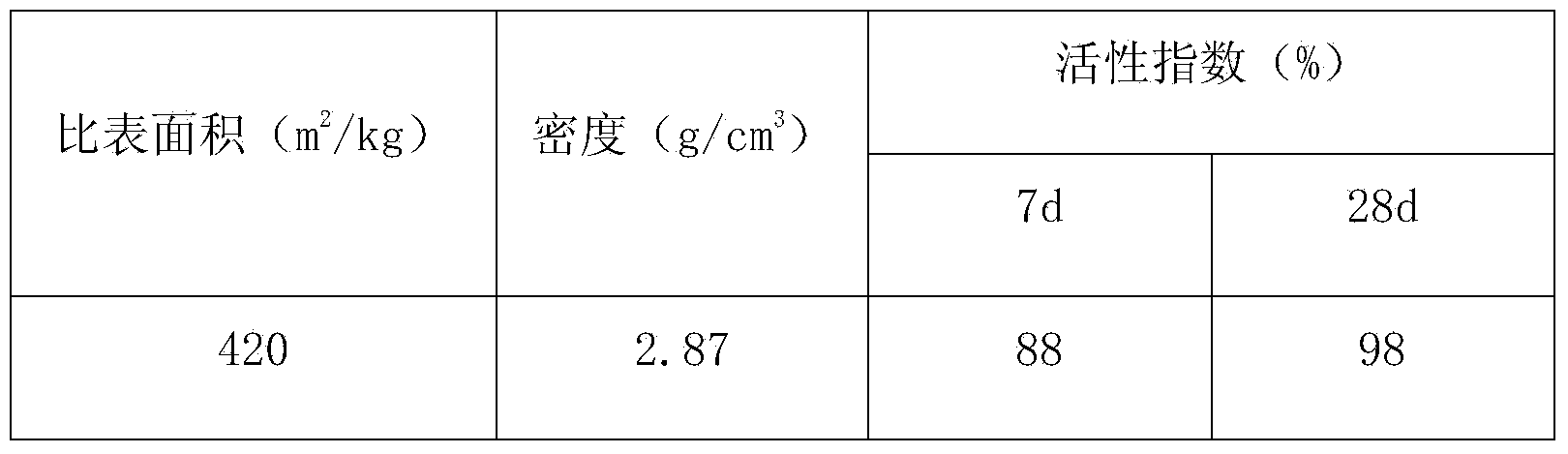

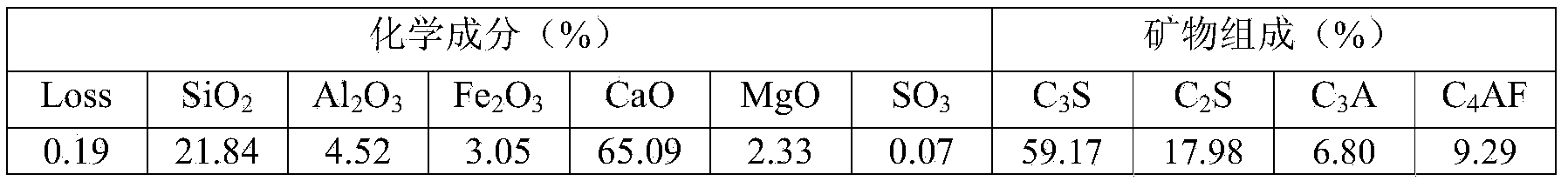

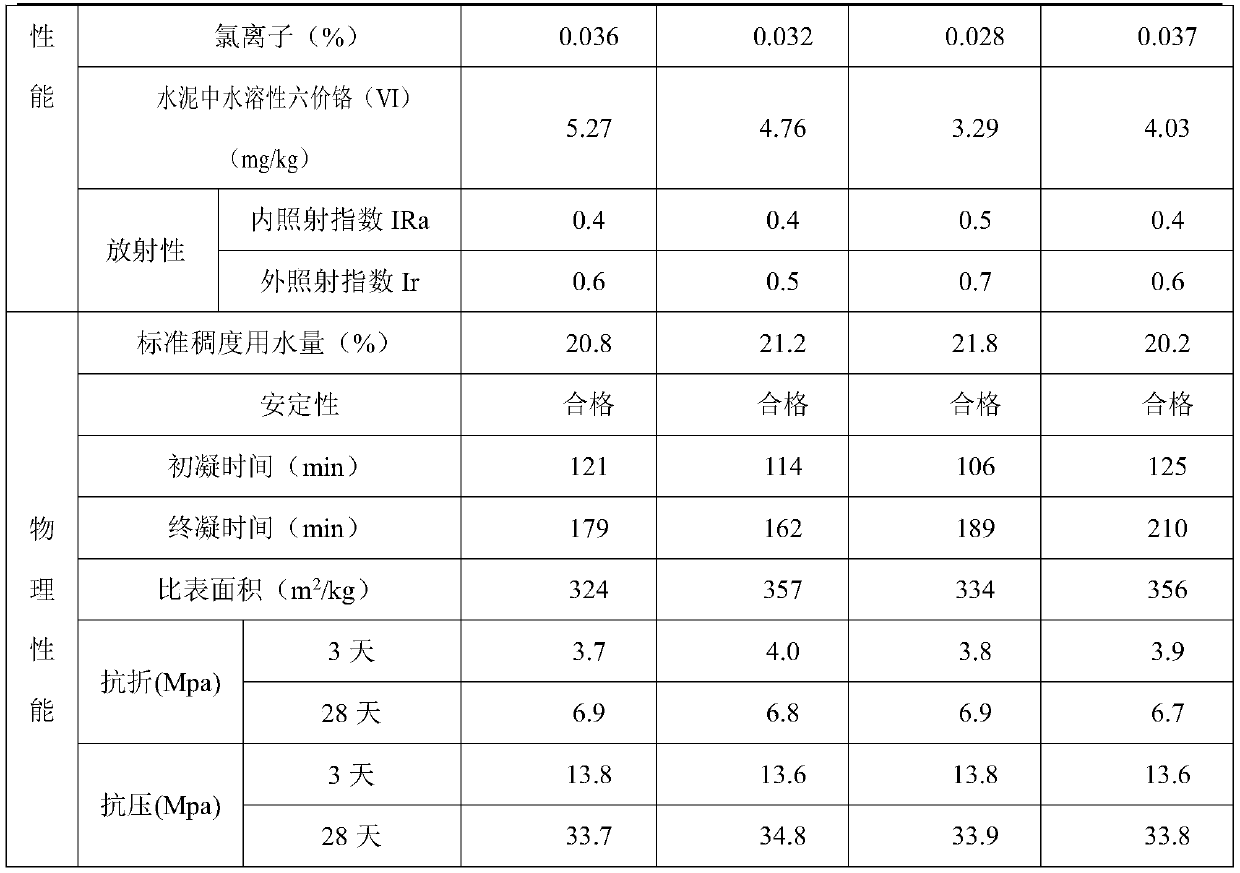

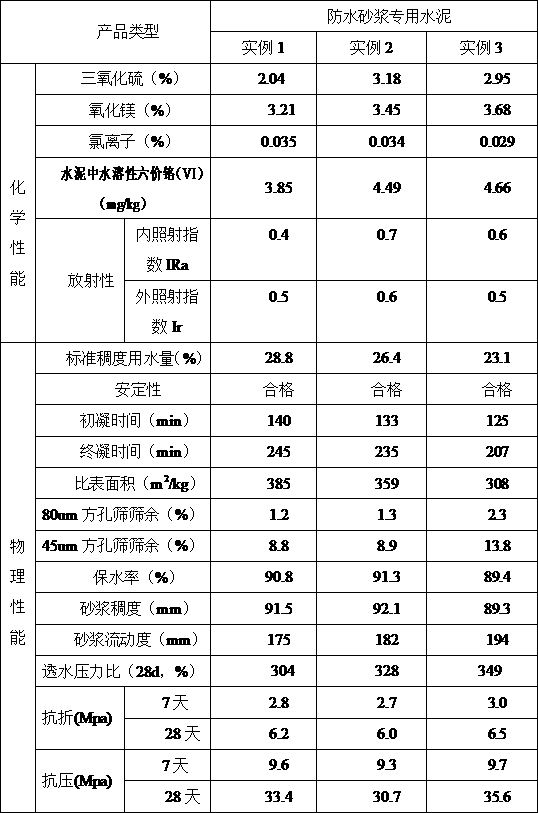

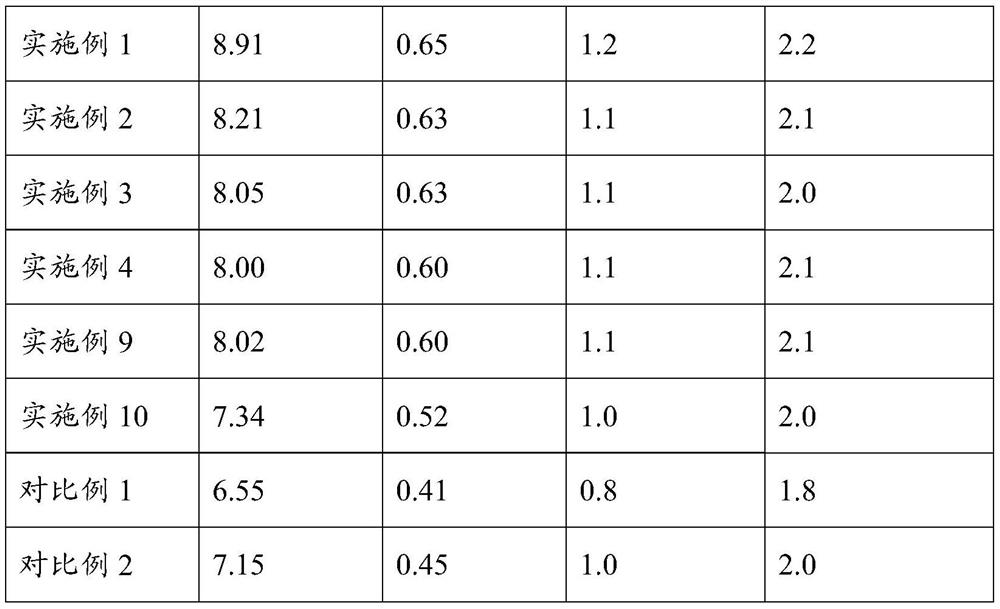

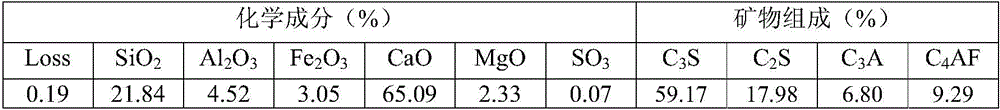

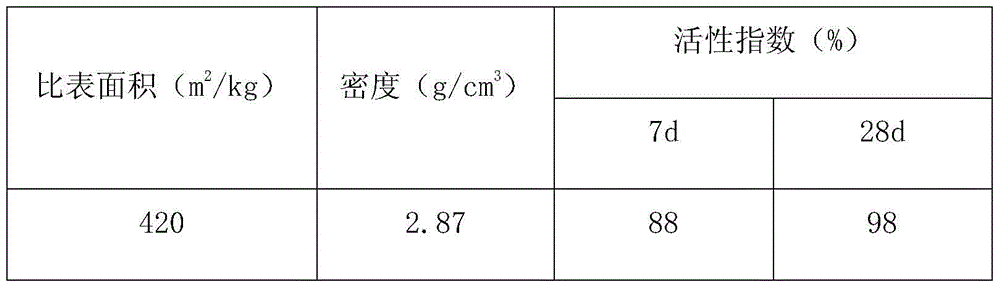

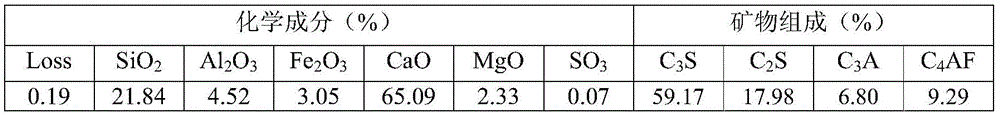

Cement special for waterproof mortar and preparation method thereof

ActiveCN109809720ATake advantage ofPromoting energy saving, consumption reduction, emission reduction and waste utilizationCement productionSlagMixed materials

The invention discloses cement special for waterproof mortar. The cement is prepared from the following raw materials: clinker, gypsum, limestone, a grinding aid and a modifying component, and furtherfrom one or more active or nonactive mixed materials comprising granulated blast furnace slag, slag powder, cinerite and flyash. And other residues are allowed to be mixed in to replace active mixedmaterials. The invention also discloses a preparation method of the cement special for waterproof mortar, and the raw materials have a lot of sources; in terms of the problem that temperature of cement is high and thus difficult for being mixed with the modifying component in an existing cement production technology, a cement cooling method and a cement cooling device are combined; in the design,a secondary batching, stirring and homogenizing system is adopted, so that technological conditions for adding the modifying component and preparing various mortar are achieved; when mortar is stirred, no admixture is added, so that the homogeneous problem of a gelatinizing material system in the mortar is alleviated and various performance and construction efficiency of the mortar are improved.

Owner:王紫娴 +1

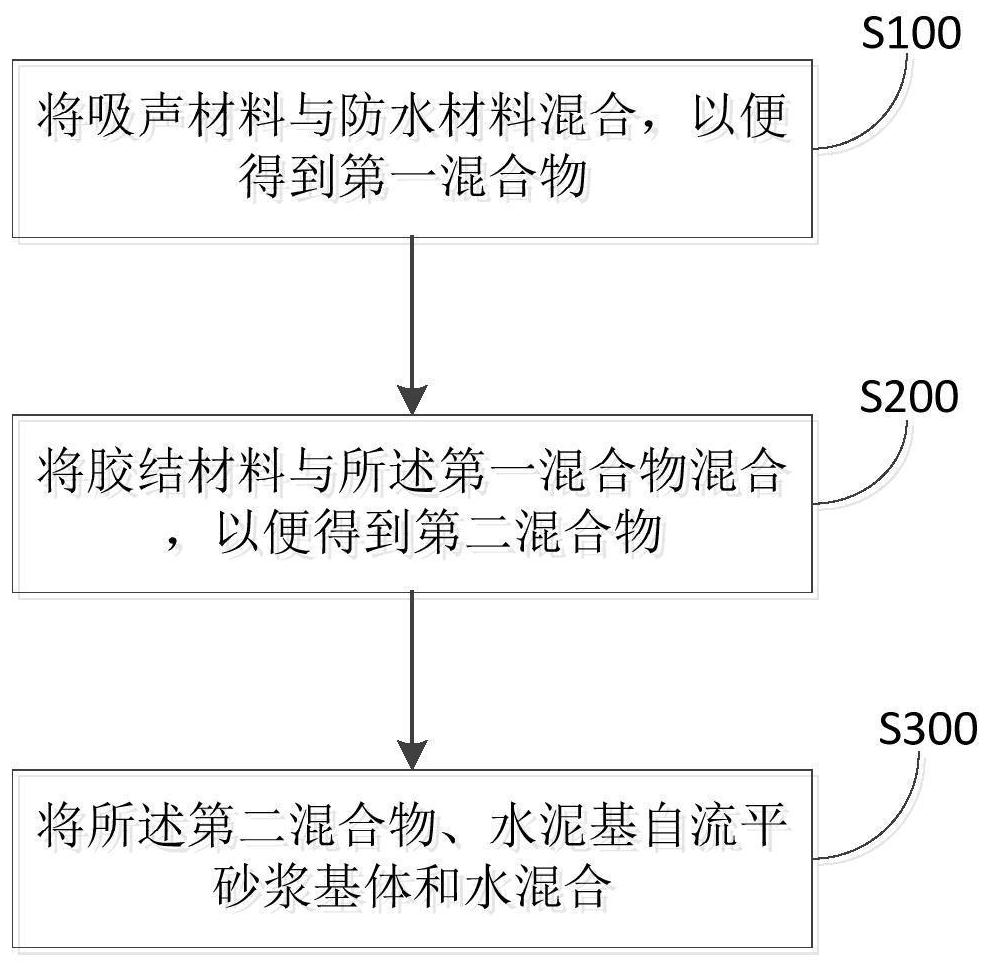

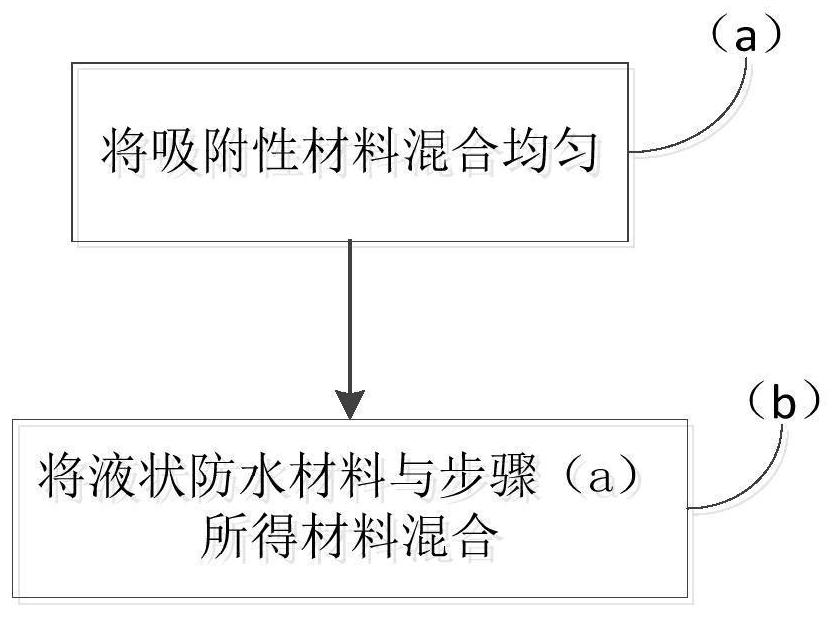

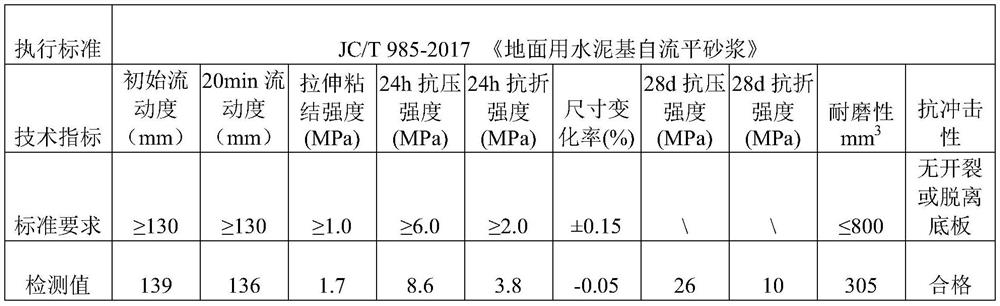

Cement-based self-leveling mortar and preparation method thereof

InactiveCN112010624AImprove hydrophobicityIncrease the anti-seepage pressureMechanical engineeringChemistry

The invention discloses cement-based self-leveling mortar and a preparation method thereof. The cement-based self-leveling mortar is prepared from a cement-based self-leveling mortar matrix and a mixture with sound insulation and waterproof functions, wherein the mixture with the sound insulation and waterproof functions comprises a sound absorption material, a waterproof material and a cementingmaterial. According to the invention, three important characteristics including water resistance, sound insulation performance and self-leveling performance are perfectly fused together, and performance conflicts in respective raw material performances are effectively solved, so the self-leveling mortar with excellent performance and sound insulation and water resistance functions is obtained.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

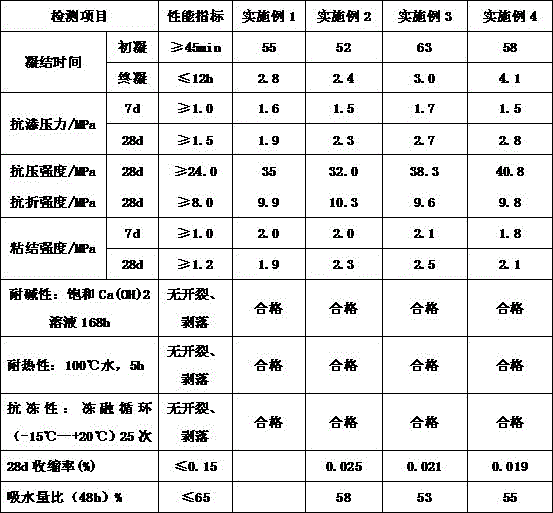

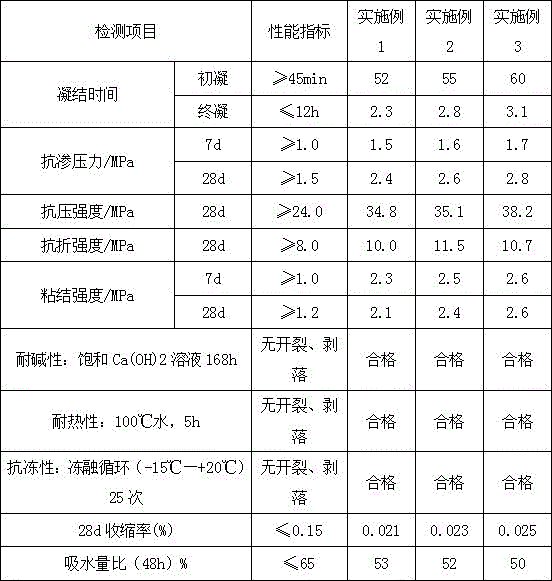

High-anti-permeability cement-based repair material for tunnel engineering and preparation method thereof

The invention belongs to the technical field of building materials, and particularly relates to a high-anti-permeability cement-based repair material for tunnel engineering. The repair material consists of portland cement, coal ash, silica fume, steel slag powder, rock powder, tailing sand, quartz sand, attapulgite, acrylate emulsion, cellulose ether, polyacrylamide, PVA fibers, PET fibers, a polycarboxylic acid water reducer and a defoaming agent. The repair material has the characteristics of easy construction, good working performance, good water retention performance, high compressive strength, high anti-permeability level, high toughness and adhesion, excellent durability and the like; and the repair material can be suitable for construction initial protection or engineering later maintenance and repair of lining concrete in the tunnel engineering.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

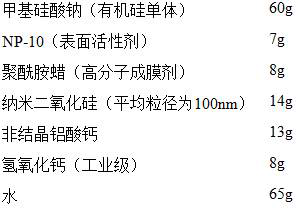

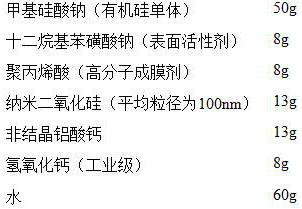

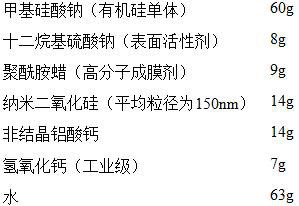

Water-based capillary crystalline waterproofing agent

The invention discloses a water-based capillary crystalline waterproofing agent. The agent is characterized by being prepared from the following components in parts by mass: 40-60 parts of an organicsilicon monomer, 6-9 parts of a surfactant, 6-9 parts of a polymer film-forming agent, 10-15 parts of nano silicon dioxide, 10-15 parts of amorphous calcium aluminate, 6-9 parts of calcium hydroxide and 50-70 parts of water. The waterproof agent has very strong permeability and can permeate below the surface layer of concrete by 3-8 cm, formed eutectic always grows along capillary pores of the concrete, all pores of the concrete are blocked, the compactness of the concrete can be enhanced, the strength and hardness of a concrete base material can also be enhanced, and the waterproof effect with the same service life as the concrete is achieved, according to the invention, the plasticization of concrete and mortar can be improved, and the weathering resistance, shrinkage resistance and impermeable pressure of concrete are further improved,construction is easy, and cost is low.

Owner:湖南加美乐素新材料股份有限公司

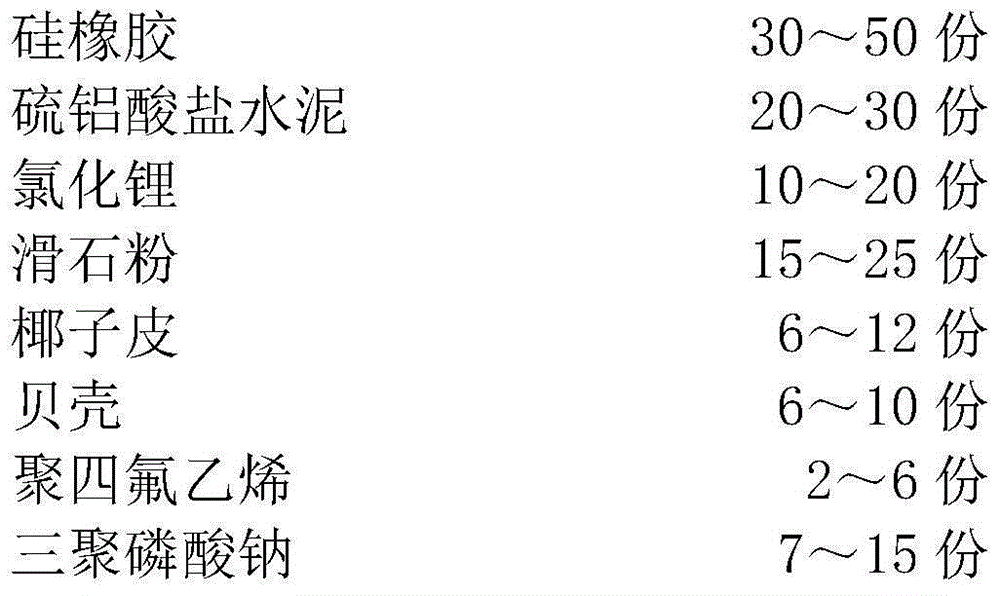

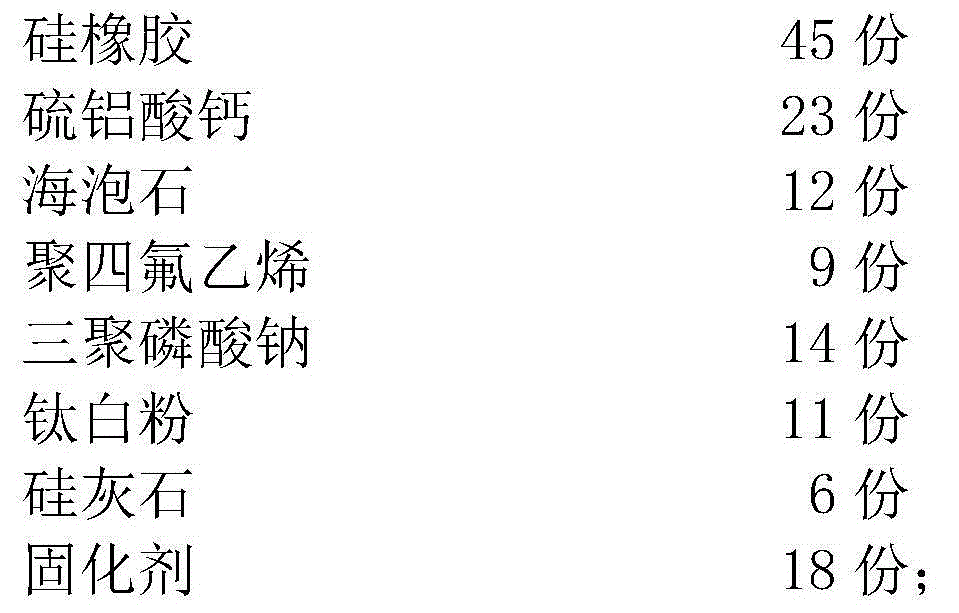

High-elasticity waterproof plugging agent

InactiveCN105038742AGood flexibilityHigh compression resilienceDrilling compositionLithium chlorideMethyl cellulose

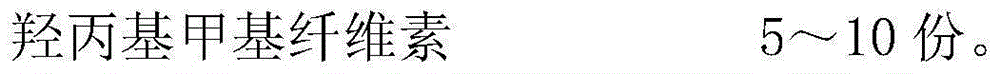

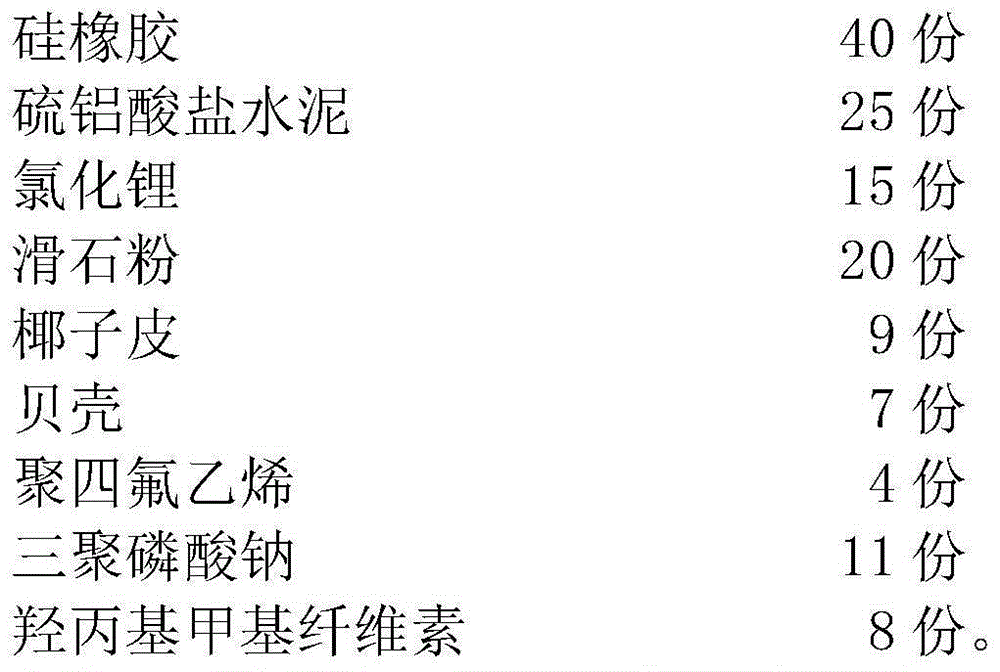

The invention relates to the technical field of plugging agents, particularly a high-elasticity waterproof plugging agent. The high-elasticity waterproof plugging agent is prepared from the following raw materials in parts by weight: 30-50 parts of silicon rubber, 20-30 parts of sulfoaluminate cement, 10-20 parts of lithium chloride, 15-25 parts of talcum powder, 6-12 parts of coconut root-barks, 6-10 parts of shells, 2-6 parts of polytetrafluoroethylene, 7-15 parts of sodium tripolyphosphate and 5-10 parts of hydroxypropyl methyl cellulose. The high-elasticity waterproof plugging agent provided by the invention has high compression elasticity, and is remarkable and efficient in plugging effect and strong in leakage layer lingering property, and a plugging layer is high in loading capacity within a short time, good in flowability and elastic and variable in shaped under pressure.

Owner:GUILIN HEXIN WATERPROOF DECORATION MATERIAL

Water seepage prevention cement

InactiveCN104671727AImprove water repellencyReduce the probability of gapsAluminateDodecylsulfonic acid

The invention relates to water seepage prevention cement which is prepared from the following raw materials in percentage by weight: 5%-8% of fluorine-containing polyacrylate latex powder, 2%-3% of rosin of 100-200 meshes, 3%-5% of sodium silicate, 3%-5% of calcium hydroxide, 1%-2% of alums, 1%-2% of sodium dodecyl sulfate, 10%-15% of sulphate aluminum cement and the balance of silicate cement, wherein the fluorine content of the fluorine-containing polyacrylate latex powder is 1%-3%. The water seepage prevention cement prepared by the invention has water seepage prevention function.

Owner:李永前

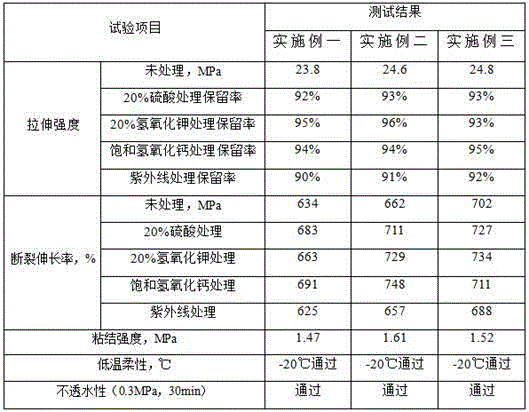

Plugging agent special for building roof crack

ActiveCN104927751AIncrease the anti-seepage pressureImprove adhesionNon-macromolecular adhesive additivesOther chemical processesUltravioletWollastonite

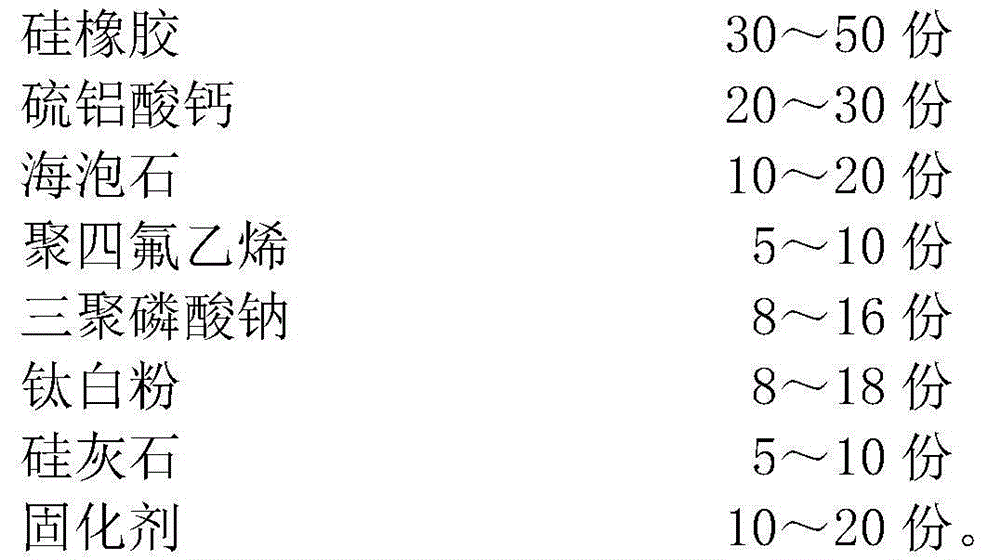

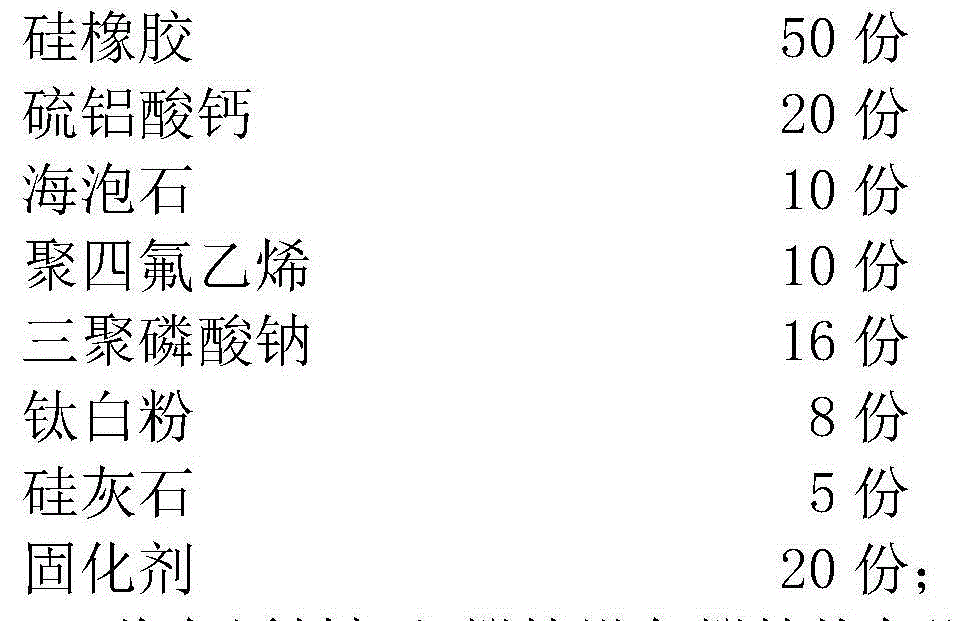

The invention relates to the technical field of plugging agents, in particular to a plugging agent special for a building roof crack. The plugging agent comprises, by weight, the raw materials of 30-50 parts of silicone rubber, 20-30 parts of calcium sulphoaluminate, 10-20 parts of sepiolite, 5-10 parts of Teflon, 8-16 parts of sodium tripolyphosphate, 8-18 parts of titanium dioxide, 5-10 parts of wollastonite and 10-20 parts of curing agent. The plugging agent special for the building roof crack can both be used on the upstream face and the downstream face, impermeability pressure is high, cementation power is high, anti-cracking effect is good, the plugging agent and a base body are combined into a whole, ultraviolet resistance and aging resistance are achieved, waterproof performance is obvious, and waterproof performance, permeability resistance and quick plugging are achieved.

Owner:广西普士高防水工程技术有限公司

Inorganic waterproof coating

The invention discloses an inorganic waterproof coating. The inorganic waterproof coating is prepared by conveying the following raw materials to a stirrer to be stirred uniformly: 45-55 parts of 800# Portland cement, 20-25 part of extra-fine quartz sand, 25-30 parts of master batch, and 1-5 parts of an efficient coagulation-delaying type water reducing agent. The inorganic waterproof coating has the characteristics of having secondary seepage resistance, long-lasting waterproof performance, strong bonding, acid corrosion resistance and alkaline corrosion resistance, can grow insoluble crystals in capillary pores and microcracks in the concrete matrix to block the capillary pore passages and microcracks, in order to improve the concrete seepage resistance and reach the purposes of seepage resistance and leakage proofing. The inorganic waterproof coating can be widely applied to waterproof projects for metros, roads, ports, culverts, dams, pools and large-scale underground projects.

Owner:天津市耀新科技发展有限公司

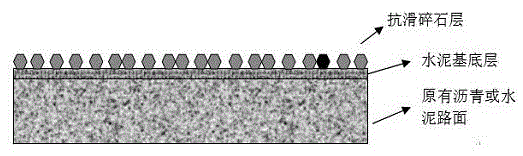

Cement-base colored microsurface and construction method thereof

The invention discloses a cement-base colored microsurface, belonging to the technical field of road engineering. The microsurface pavement comprises a cement-base layer, wherein the cement-base layer comprises the following components in parts by mass: 100 parts of cement, 150-170 parts of colored quartz sand, 50 parts of water, 7 parts of waterproofing agent and 10 parts of pigment; and the cement-base layer also comprises 0.1 vol% of polyvinyl alcohol fiber and a right amount of modifier. The modifier is composed of a water-based epoxy resin (the mass ratio of the water-based epoxy resin to the cement is (8-12):100) and a curing agent (the mass ratio of the curing agent to the water-based epoxy resin is 1.3:1), or hydroxy cellulose (the mass ratio of the hydroxy cellulose to the water is 3:100), or a water-based organic silicon resin (the mass ratio of the water-based organic silicon resin to the cement is 2.5:100). The color of the colored quartz sand has the same color system as the color of the pigment. The invention also discloses a construction method of the cement-base colored microsurface. The cement-base colored microsurface has the advantages of higher water resistance, higher crack resistance, higher wear resistance, higher color distinction degree and high color durability, and is easy for construction.

Owner:SOUTHEAST UNIV

A compound plugging agent

ActiveCN104987017BWide temperature rangeImprove temperature and pressure resistanceLost circulationMaterials science

The invention relates to the technical field of building materials, in particular to a composite plugging agent, which is made of the following raw materials in parts by weight: 55-75 parts of composite gel material, 2-8 parts of toughening agent, and 3-9 parts of coagulation accelerator 12-22 parts of curing agent, 7-15 parts of dispersant. The composite plugging agent of the present invention has both rigidity and flexibility, can play the roles of deformation and filling, bridging and deformation filling at the same time, greatly reduces the amount of plugging materials and reduces the cost.

Owner:GUILIN HEXIN WATERPROOF DECORATION MATERIAL

High impermeability cement-based repair material for tunnel engineering and preparation method thereof

The invention belongs to the technical field of building materials, and specifically relates to a high-impermeability cement-based repair material for tunnel engineering, which is composed of Portland cement, fly ash, silica fume, steel slag powder, rock powder, tailings sand, quartz sand, Attapulgite, acrylate emulsion, cellulose ether, polyacrylamide, PVA fiber, PET fiber, polycarboxylate water reducer and defoamer. The invention has the characteristics of easy construction, good workability, good water retention, high compressive strength, high impermeability grade, high toughness, cohesiveness and excellent durability; the product of the invention can be applied to the construction of lining concrete in tunnel engineering Initial protection or post-project maintenance and repair.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

Cement-based penetrable crystallized waterproof paint, preparation method and construction method thereof

The invention relates to a cement-based penetrable crystallized waterproof paint, a preparation method and a construction method thereof. The cement-based penetrable crystallized waterproof paint is prepared from the following raw materials in percentage by weight: 65 to 70 percent of cement, 3 to 10 percent of modified bentonite, 2 to 5 percent of modified sodium silicate, 1 to 5 percent of diffusant, 0.5 to 1 percent of penetrant, 2 to 10 percent of wollastonite and 15 to 25 percent of quartz sand. The waterproof paint can recover minute cracks on concrete interfaces and inhibit the water seepage and damp of base interfaces effectively. In addition, the waterproof paint is high in capacity of freezing resistance, high-temperature resistance, chloridion resistance and acid and alkali resistance, and has a long waterproof effect. According to the cement-based penetrable crystallized waterproof paint, leveling layers on the concrete interfaces are saved, and protective layers are savedafter the concrete interfaces are coated, so the waterproof construction is simple. The cement-based penetrable crystallized waterproof paint is suitable for constructional engineering such as underground engineering, subway tunnels, civil air-defense construction, water ponds, oil sumps, sewage tanks, barns, bathrooms, roof squares, parking platforms, high-grade roadways and the like, and is used for processing defects of cracks, honeycomb pitted surfaces and the like of the concrete interfaces.

Owner:姜哲 +1

A kind of transparent water-based waterproof paint for building and preparation method thereof

ActiveCN103614063BThe composition formula is reasonableSimilar refractive indexPolyurea/polyurethane coatingsWater basedUltraviolet

The invention discloses a transparent waterborne waterproof coating for a building and a preparation method thereof. The transparent waterborne waterproof coating comprises the following components in percentage by mass: 70-80% of water soluble high polymer material, 0.8-1.6% of coalescing agent, 0.8-1.6% of accelerant, 0.5-1.0% of nano material, 0.02-0.06% of penetrating agent, 0.3-0.8% of ultraviolet absorbent, 0.5-1.2% of thickening agent, 0.1-0.3% of defoaming agent and the balance of water. The coating disclosed by the invention is pollution resistant, good in weather fastness, excellent in physical and mechanical properties, acid and alkali resistance and waterproof performance, and good in transparency, and the coating does not cover the bottom, so that the coating can maintain the appearance and feature of the building when in use; and meanwhile, the coating is simple to prepare, environment-friendly, free of pollution and convenient to use and can be both spray coated and crush coated, so that the coating can be widely applied to water resistance of building periphery or exterior wall so as to provide long-term waterproof protection for the building.

Owner:苏州市姑苏新型建材有限公司

Graphene repairing waterproof paint for concrete crack

ActiveCN108129098AImprove performanceIncrease the anti-seepage pressurePortland cementFilling materials

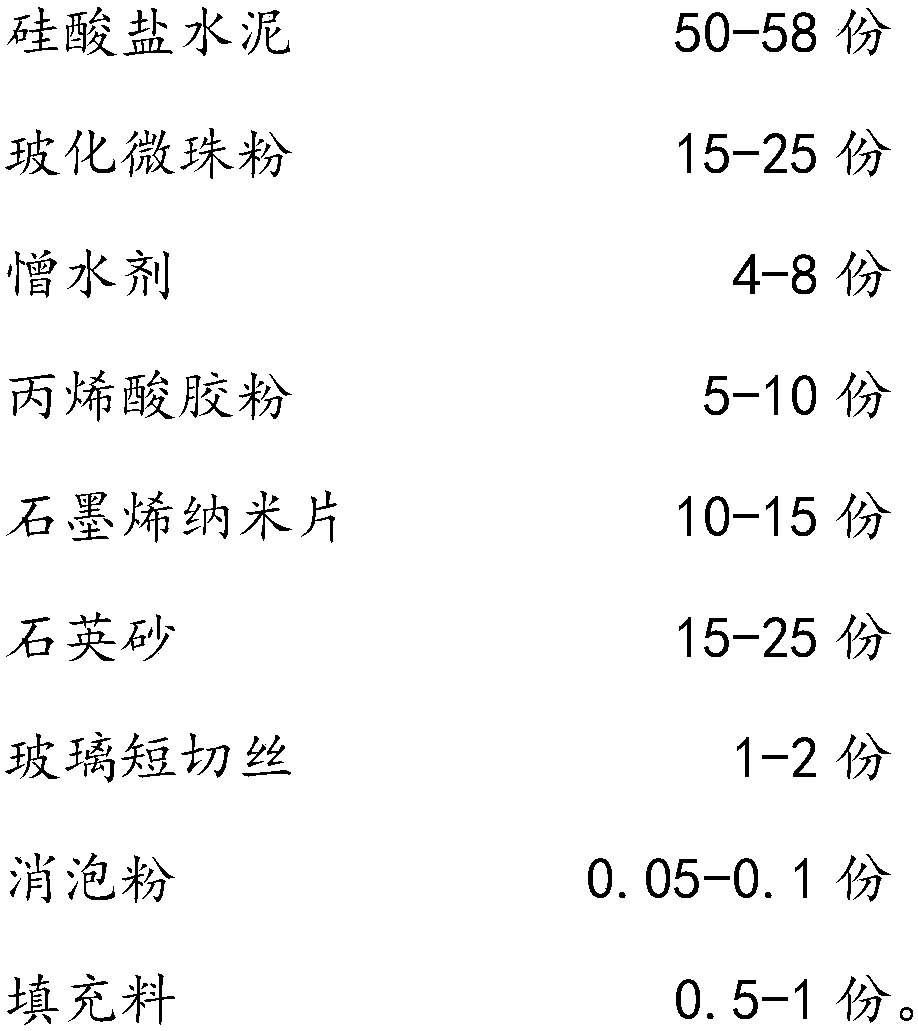

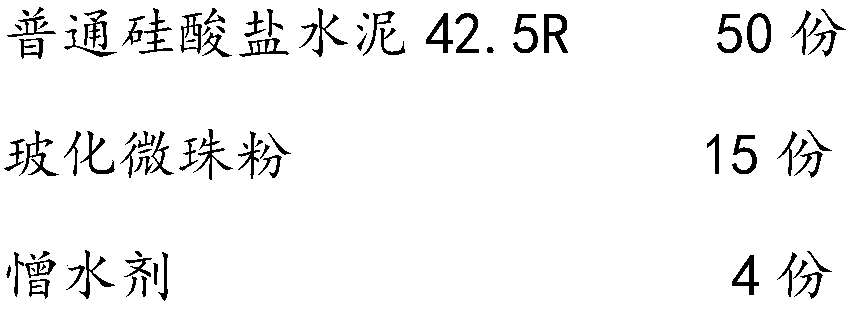

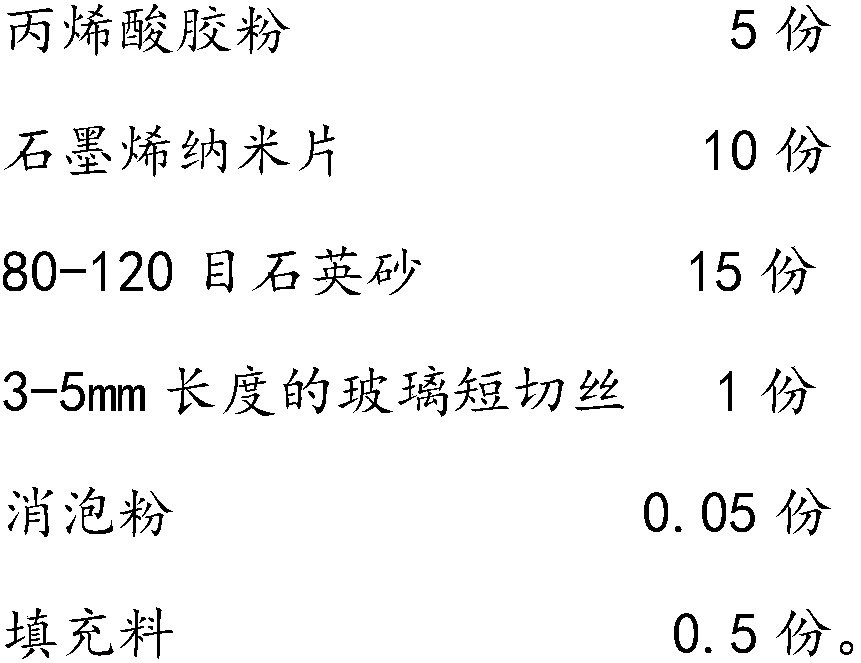

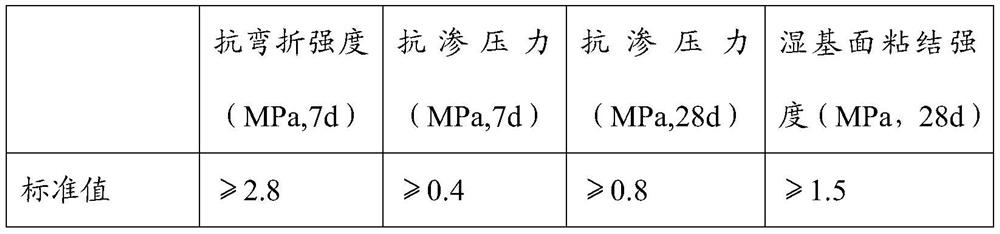

The invention discloses graphene repairing waterproof paint for a concrete crack. The graphene repairing waterproof paint is prepared from the following components in parts by weight: 50 to 58 parts of portland cement, 15 to 25 parts of vitrified micro bead powder, 4 to 8 parts of water repellent, 5 to 10 parts of acrylic latex powder, 10 to 15 parts of graphene nanosheet, 15 to 25 parts of quartzsand, 1 to 2 parts of glass chopped silk, 0.05 to 0.1 part of antifoaming powder and 0.5 to 1 part of filling material. Relative to existing repairing waterproof paint for the concrete crack, the graphene repairing waterproof paint is enhanced in performance.

Owner:XIAMEN LIKASAM WATERPROOF ENG

A kind of environment-friendly waterproof plugging material and its preparation method and application

The invention belongs to the technical field of building construction, and particularly relates to an environmentally friendly waterproof leakage stopping material and a preparation method thereof. The environmentally friendly waterproof leakage stopping material is prepared from the following raw materials in parts by weight: 50-100 parts of silicate, 10-35 parts of aluminate, 10-40 parts of redispersible rubber powder, 0.5-15 part of quartz sand, 5-20 parts of calcined gypsum powder, 1-10 parts of a retarder and 1-10 parts of an additive. The waterproof leakage stopping material which is prepared by the provided formula and the preparation method is environmentally friendly and toxic-free, and is high in bending resistance, high in impermeability pressure, high in wet base surface bonding strength and high in acid resistance.

Owner:吴广义

A high-performance corrosion-resistant dry-mixed waterproof mortar

The invention discloses high-performance corrosion-resistant dry-mixed waterproof mortar. The high-performance corrosion-resistant dry-mixed waterproof mortar is prepared from the following raw materials in parts by weight: 60-70 parts of cement, 35-45 parts of mineral powder, 10-30 parts of coal ash, 300-500 parts of regenerated fine aggregates and 5-10 parts of a compounded additive, wherein the compounded additive is prepared from the following raw materials in parts by weight: 40-60 parts of coal ash, 5-7 parts of a water repellent, 40-50 parts of an expanding agent, 2-5 parts of an air-entraining and water-reducing agent, 2-4 parts of anti-crack short fiber and 2-10 parts of a water-retaining thickening agent. By virtue of a dry-mixing form, the high-performance corrosion-resistant dry-mixed waterproof mortar is convenient to use, and the sulfate corrosion can be effectively prevented.

Owner:潍坊德霖建材科技有限公司

A kind of anion water waterproof coating and preparation method thereof

The invention specifically relates to an anionic water-based waterproof paint and a preparation method thereof, belonging to the field of waterproof paints for buildings. According to the invention, the anionic water-based waterproof paint is dissolved in water, then the dissolved paint is directly brushed onto the surface of cement mortar, and an aqua immediately penetrates into the structure of the cement mortar; when cement comes across water, cations are ionized and react with anions in the dissolved paint to produce a crystal insoluble in water to block capillary channels of the cement mortar, so compaction, impervious and waterproof effects are obtained; and the concentration of an activator can be increased, cracks do not occur after painting of the paint, and a technical blank in the world is filled in.

Owner:滨州市良友防水材料有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com