Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Increase lump coal rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

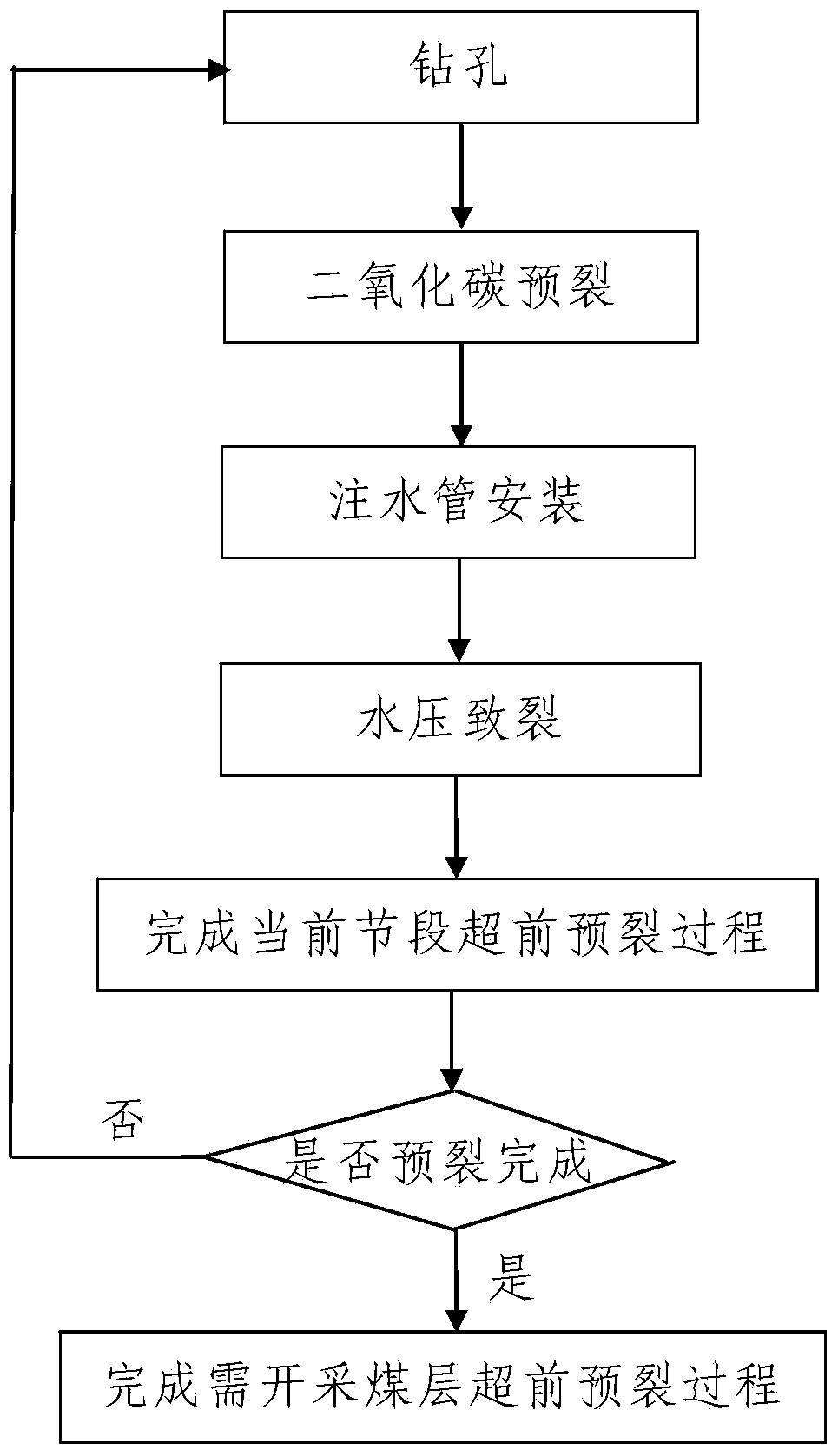

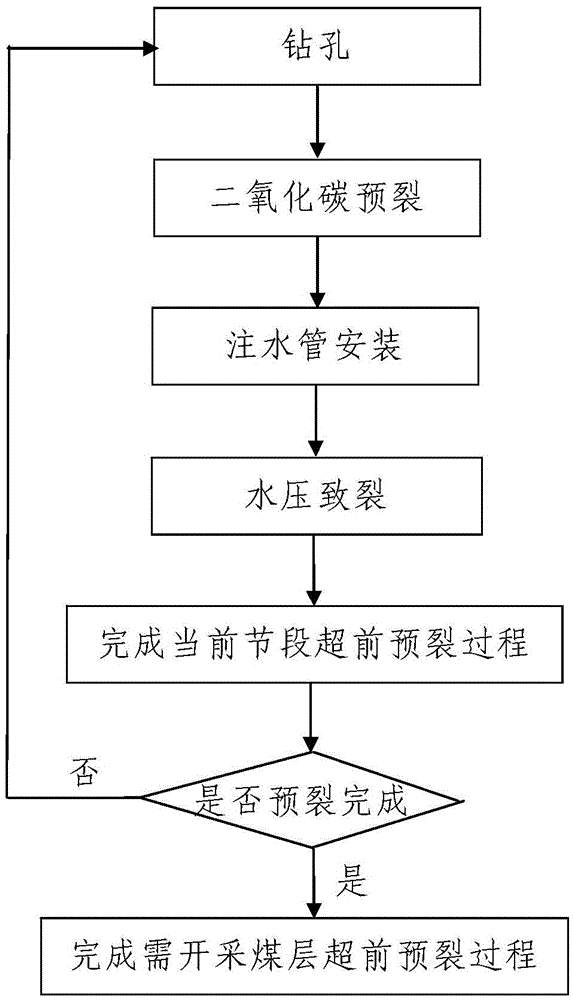

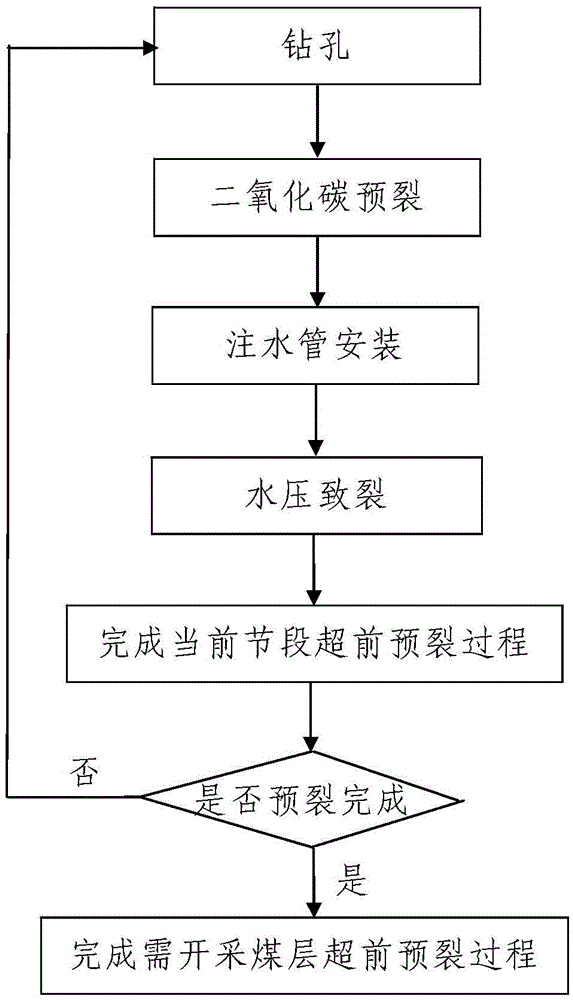

Advanced pre-splitting method for lump coal mining

ActiveCN103924956AThe method steps are simpleReasonable design and simple operationUnderground miningFluid removalHydraulic fracturingHigh pressure water

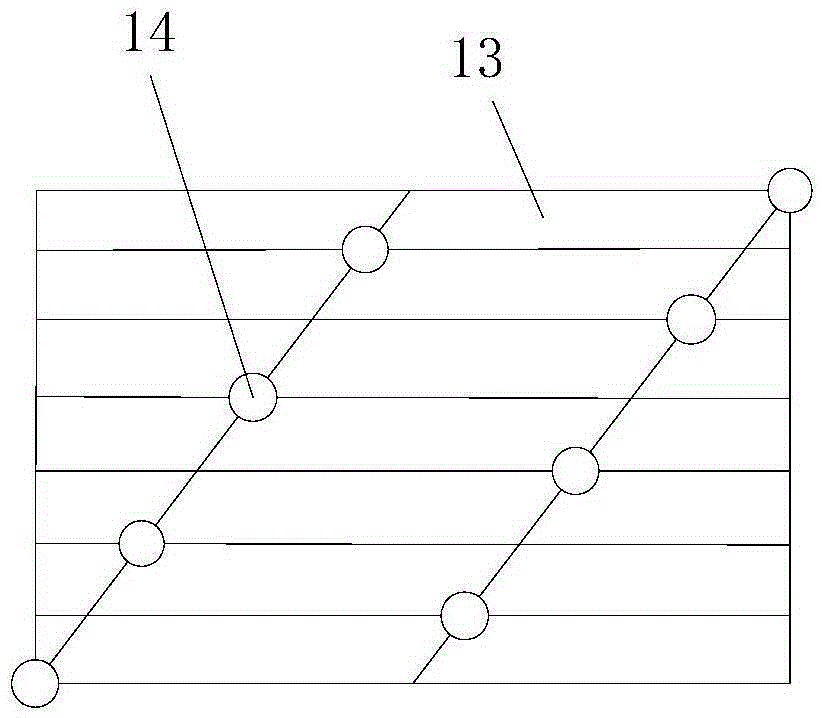

The invention discloses an advanced pre-splitting method for lump coal mining. The method with carbon dioxide pre-splitting and hydraulic fracturing combined is adopted, advanced pre-splitting of a working face is carried out on a coal layer needing mining in a multi-segmental mode from near to far in the advancing direction of the coal layer working face. The advanced pre-splitting method for every segment comprises the first step of hole drilling, wherein pre-splitting drill holes are drilled in the current pre-split segment; the second step of carbon dioxide pre-splitting, wherein a carbon dioxide pre-splitting device is installed in each drilled pre-splitting drill hole, the drill holes are sealed, and then pre-splitting is initiated; the third step of installation water injection pipes, wherein each pre-splitting drill hole is internally provided with one high pressure water injection pipe, and the holes are sealed; the fourth step of hydraulic fracturing, wherein water is injected into the pre-splitting drill holes through the high pressure water injection pipes to carry out hydraulic fracturing. According to the method, steps are simple, design is reasonable, the method is easy to implement and good in use effect, the problems that an existing deep hole blasting pre-splitting method is not safe, serious in pollution, high in investment cost, poor in use effect and the like are effectively solved, and the lump coal rate of a fully mechanized coal mining face is improved effectively.

Owner:XIAN UNIV OF SCI & TECH

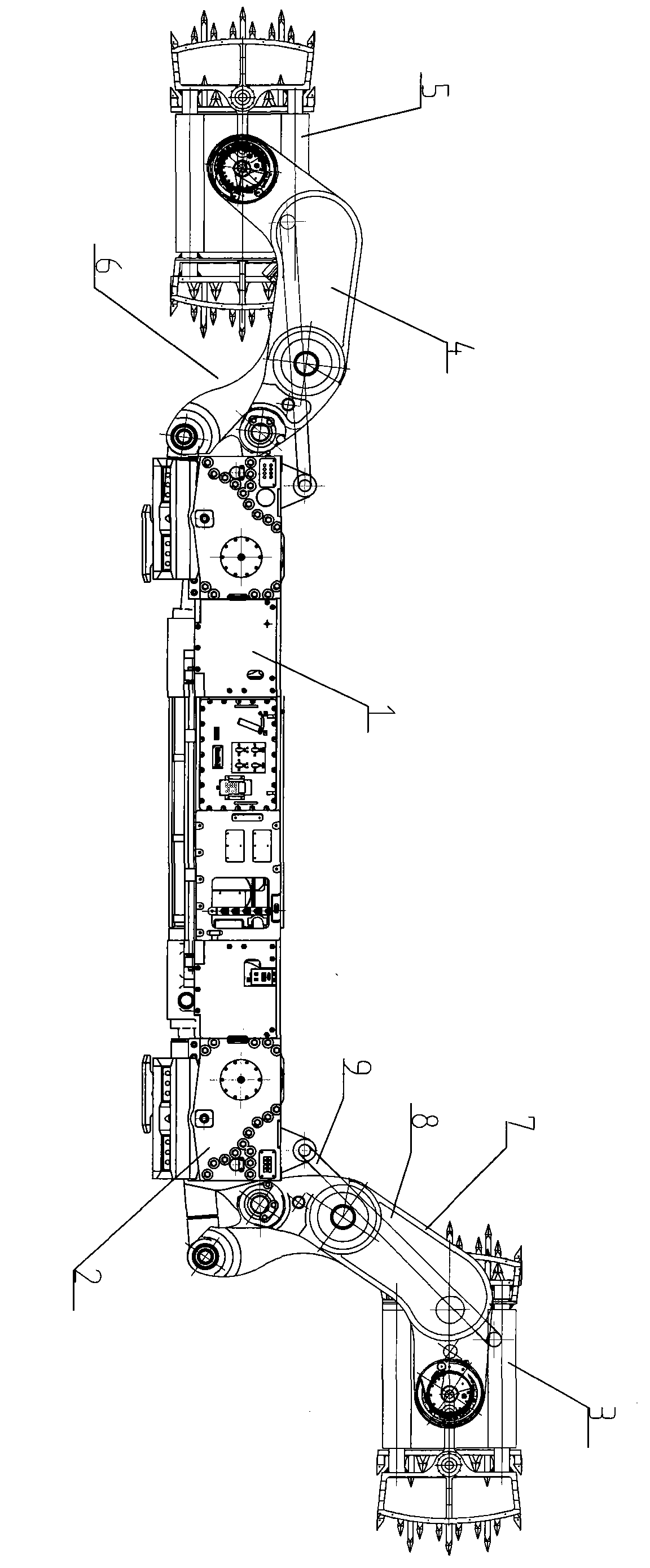

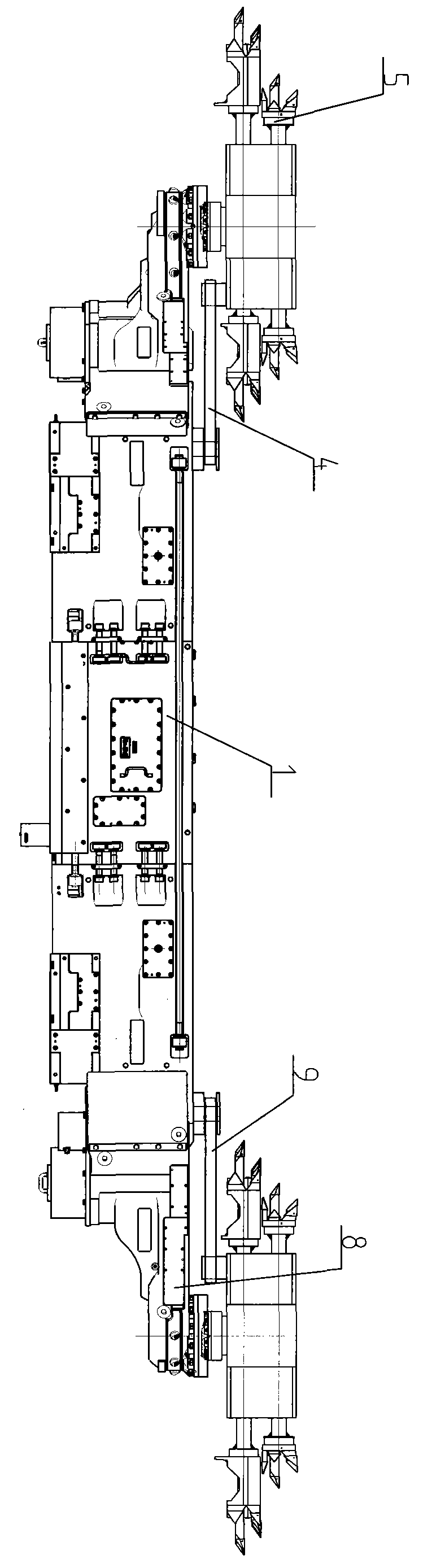

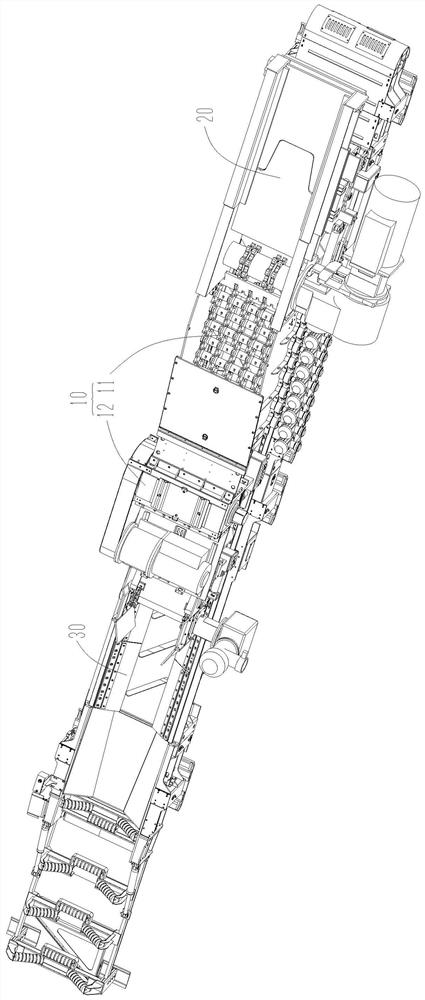

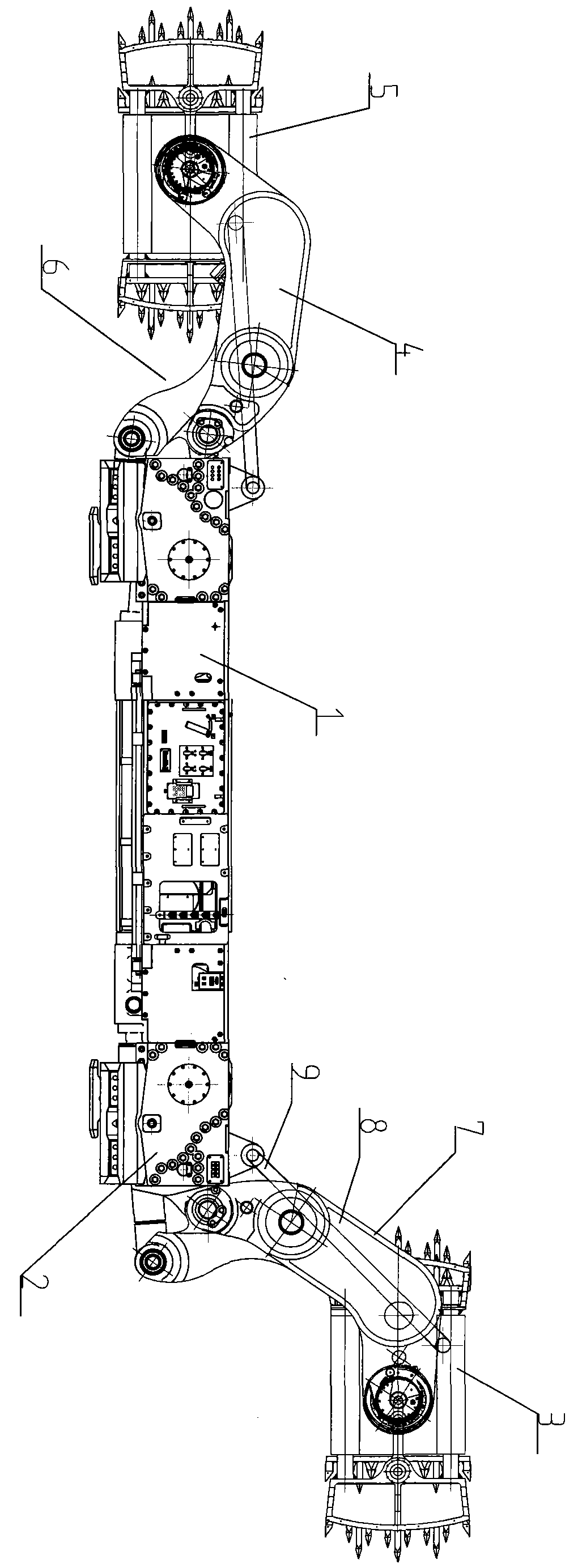

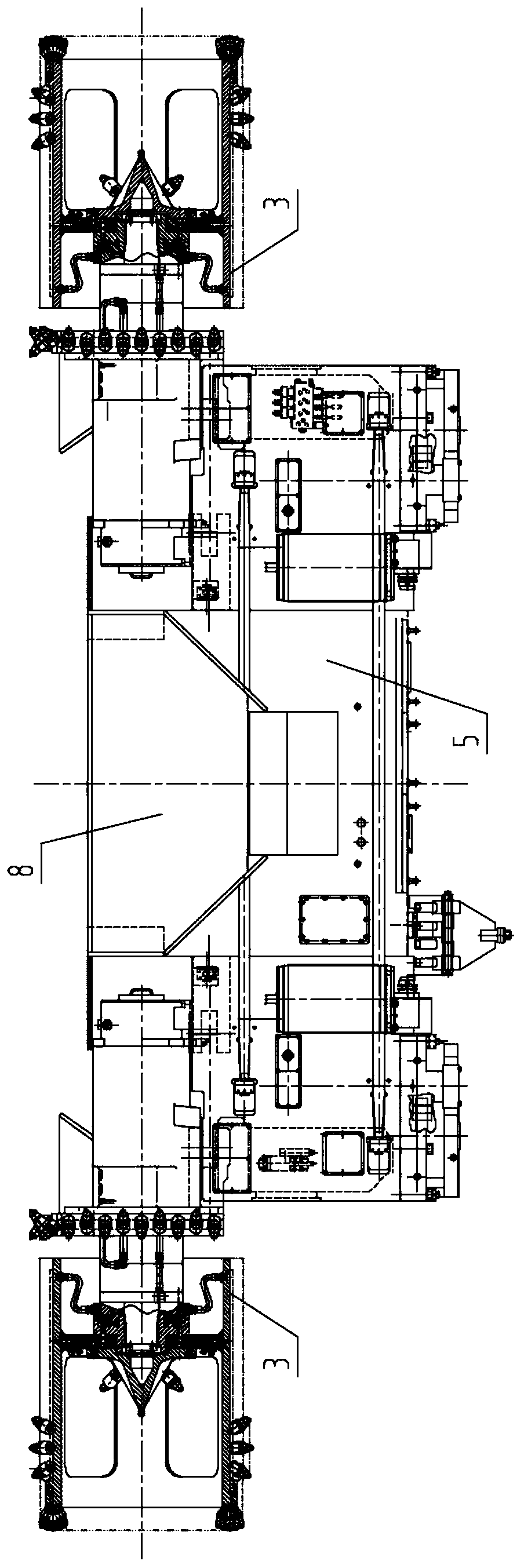

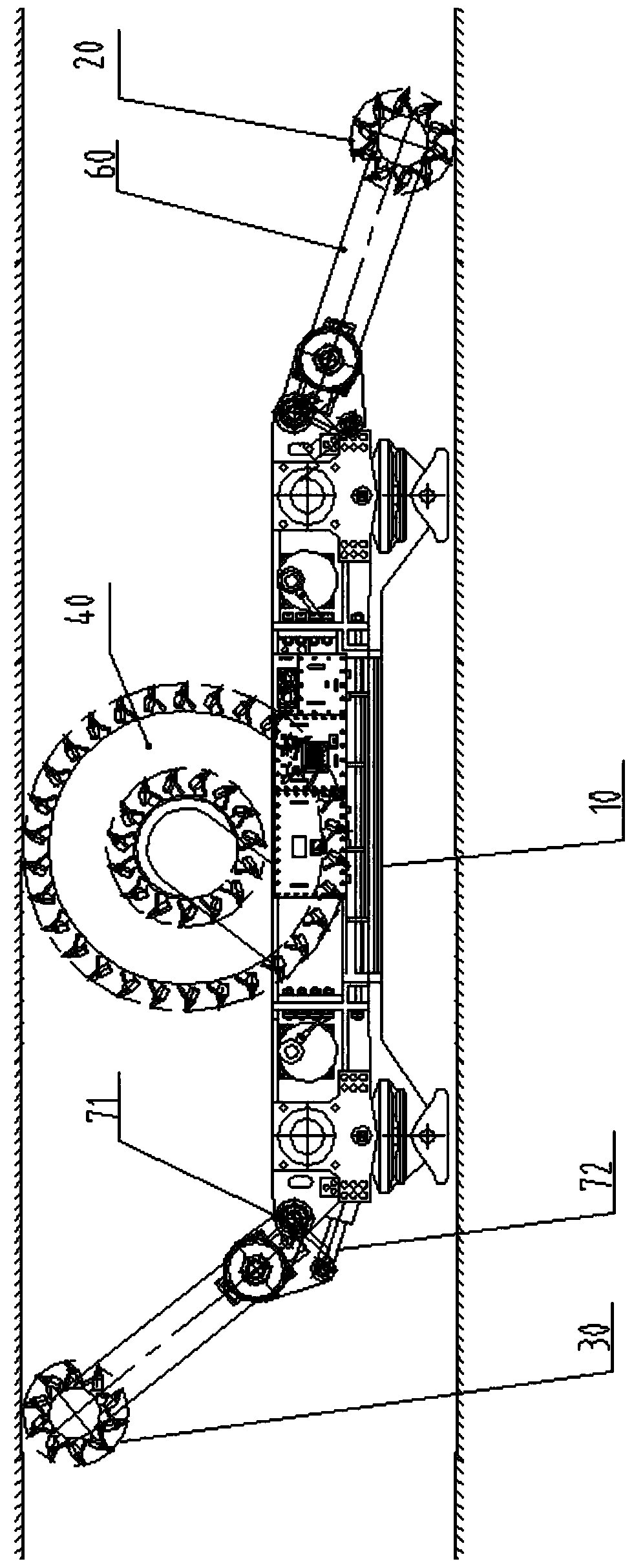

Mining machine with rocker arm provided with coal-passing space

ActiveCN103498671AReduce frictional resistanceLess wearing partsDriving meansCutting machinesMachineRocker arm

The invention provides a mining machine with a rocker arm provided with coal-passing space, which comprises a machine body and a walking portion, and is characterized in that the mining machine with a rocker arm provided with coal-passing space also comprises a rocker arm, and cutting heads; the walking portion is disposed at the lower part of the machine body; the cutting heads are disposed at two ends of the machine body; the rocker arm is a rhomboid rocker arm or a single rocker arm; one end of the rocker arm is connected with the machine body, and the other end of the rocker arm is connected with the cutting heads; the rocker arm arches upwards to form the coal-passing space; the rocker arm is provided with the coal-passing space, which well solves the problem that coal falling by impact of a cutting head near a machine body of a reciprocating impact mining machine can not be conveyed out due to no coal-passing space between a straight rocker arm and a scraper conveyer, gives full play to advantages of high coal mining rate, high efficiency, energy saving, and environmental protection for reciprocating impact mining machines.

Owner:刘素华

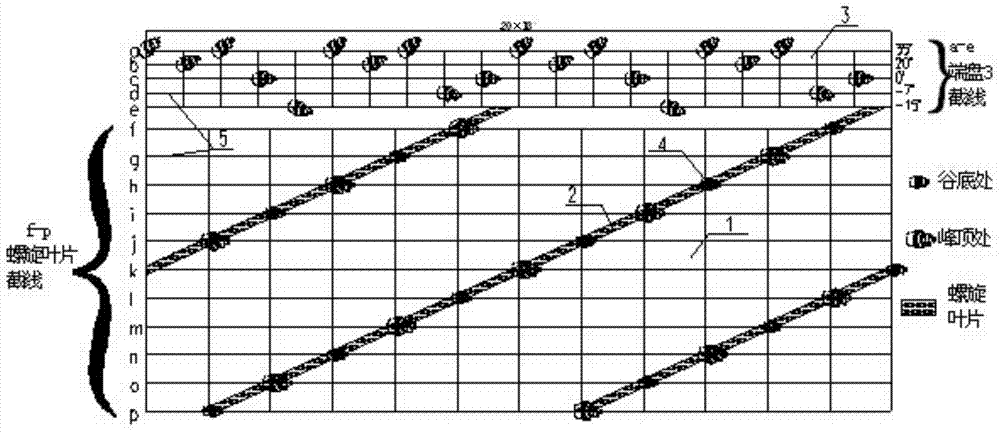

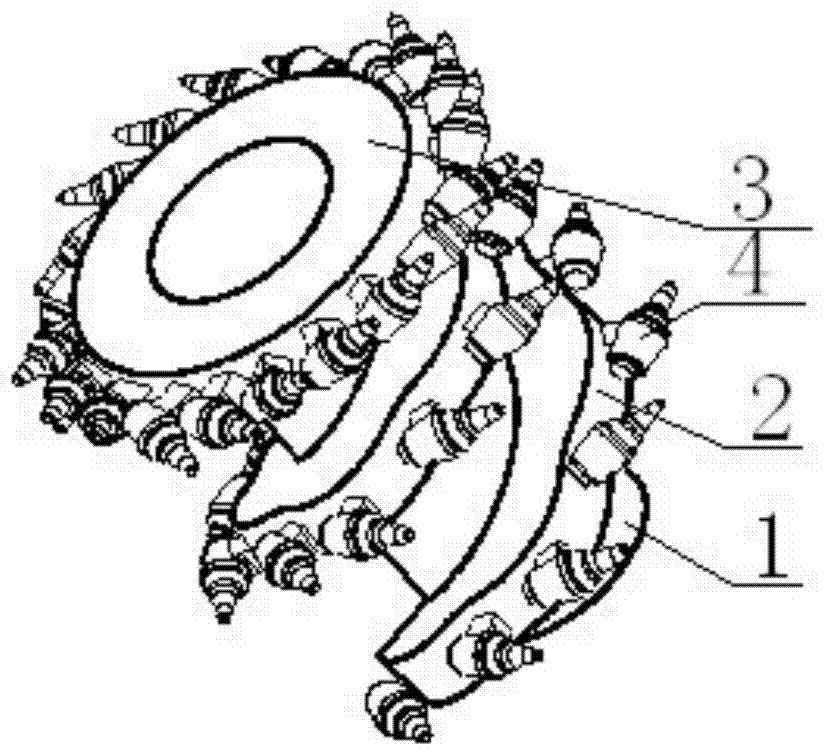

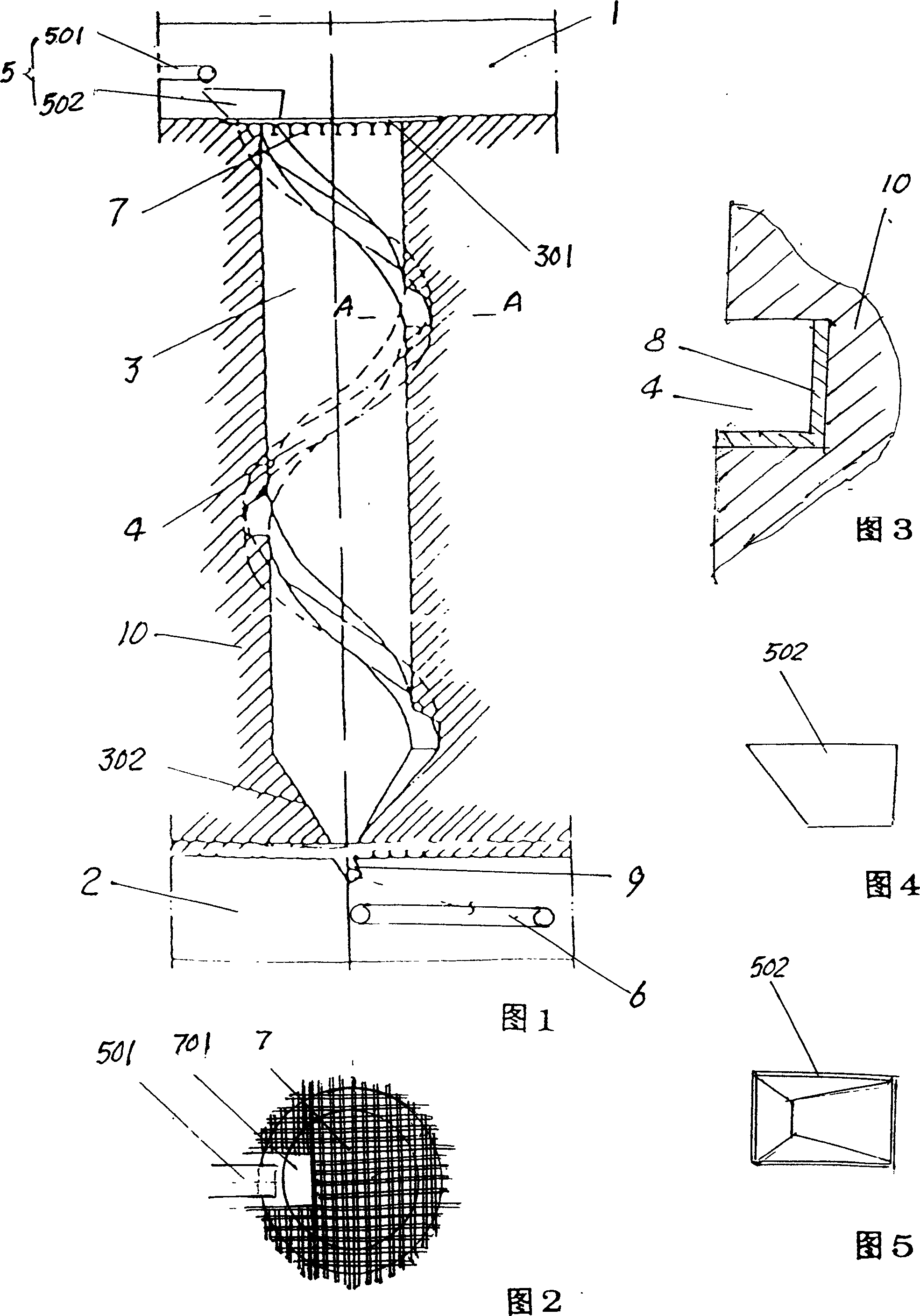

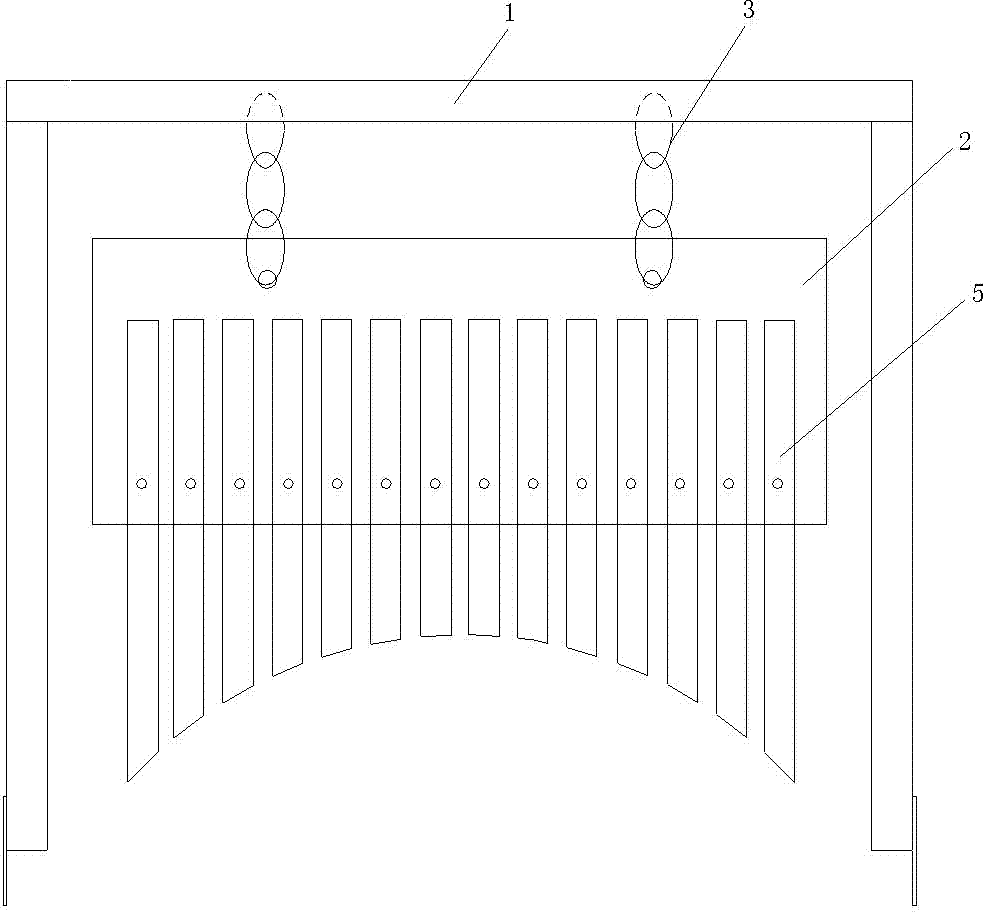

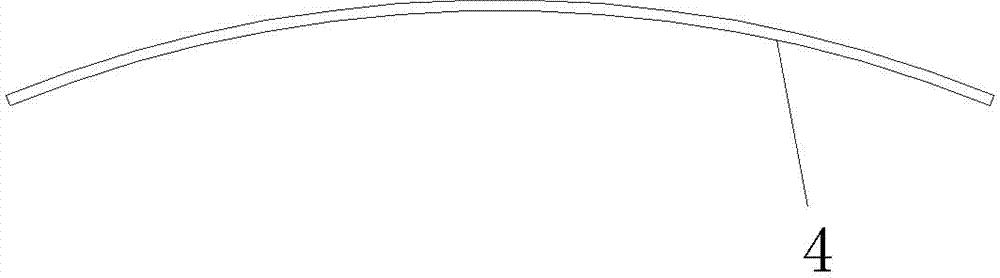

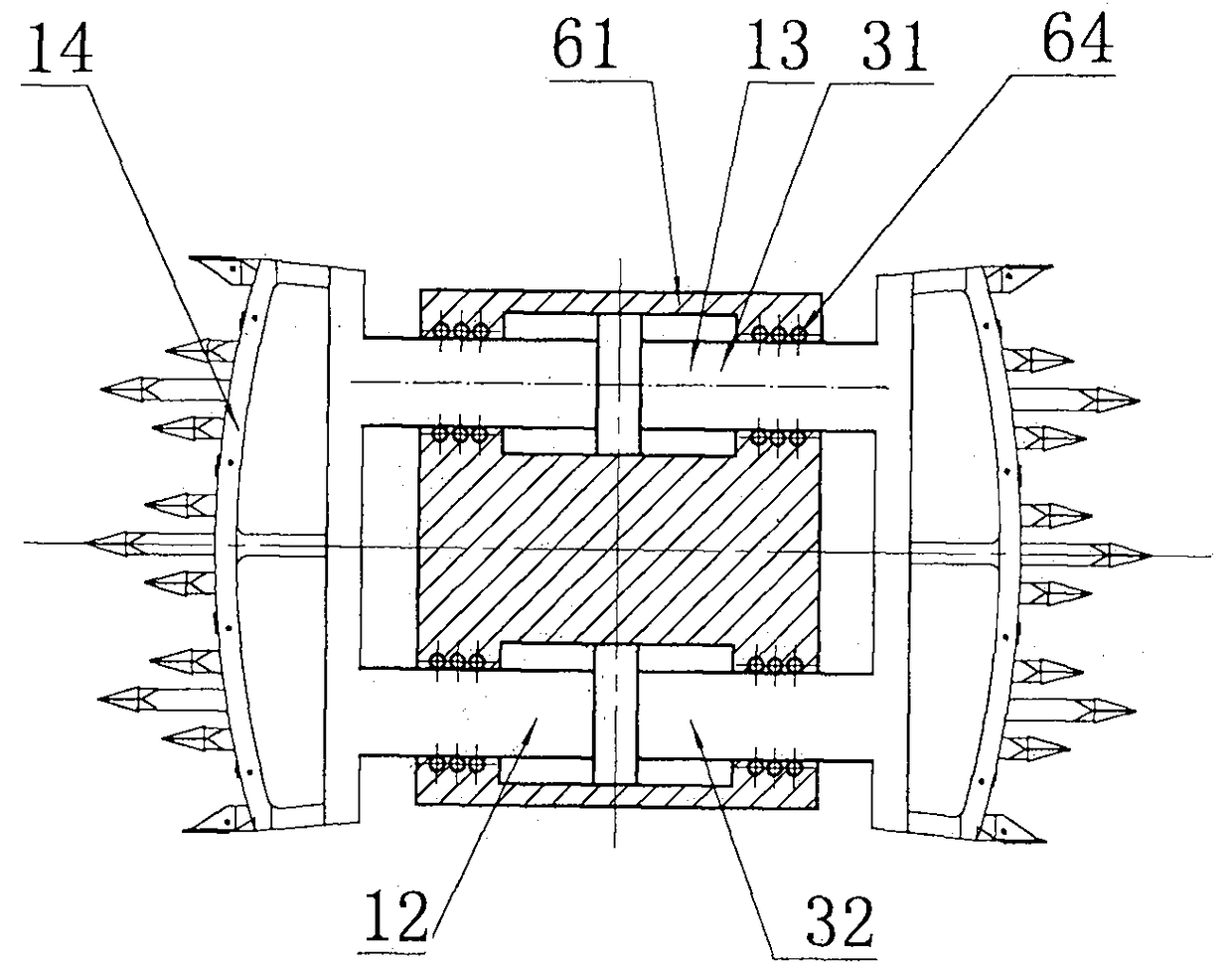

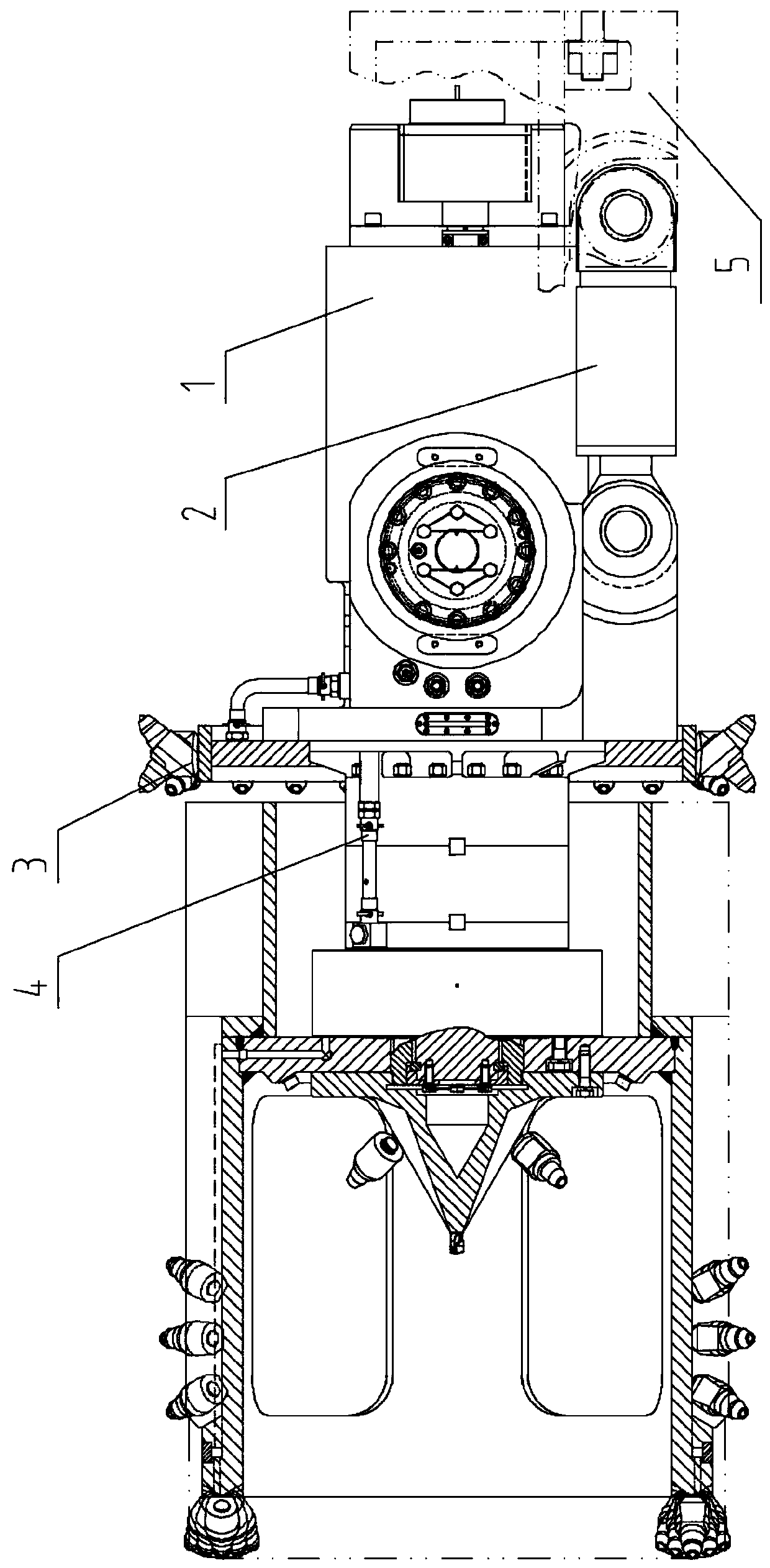

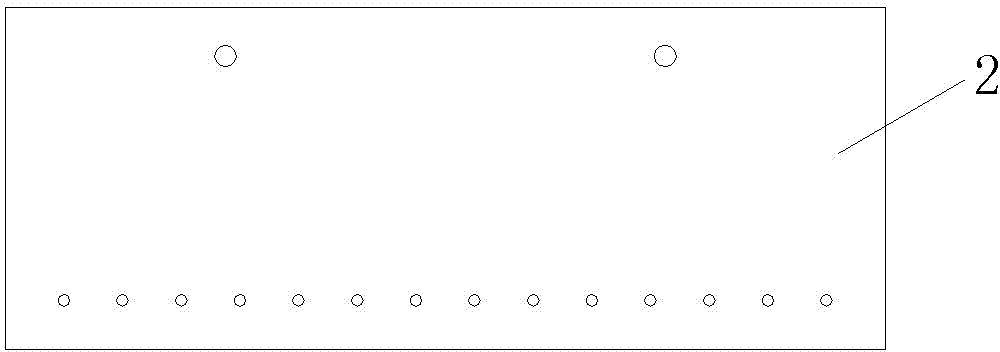

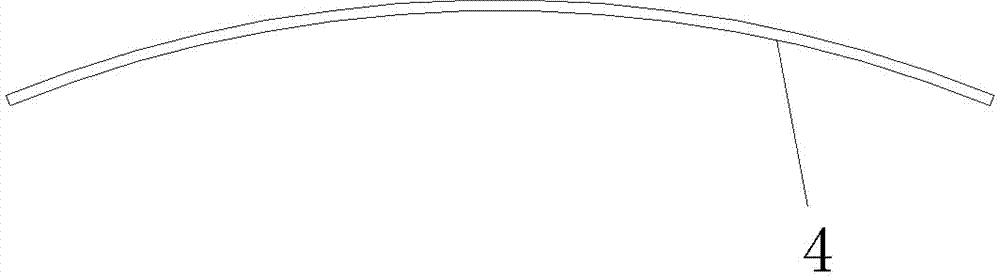

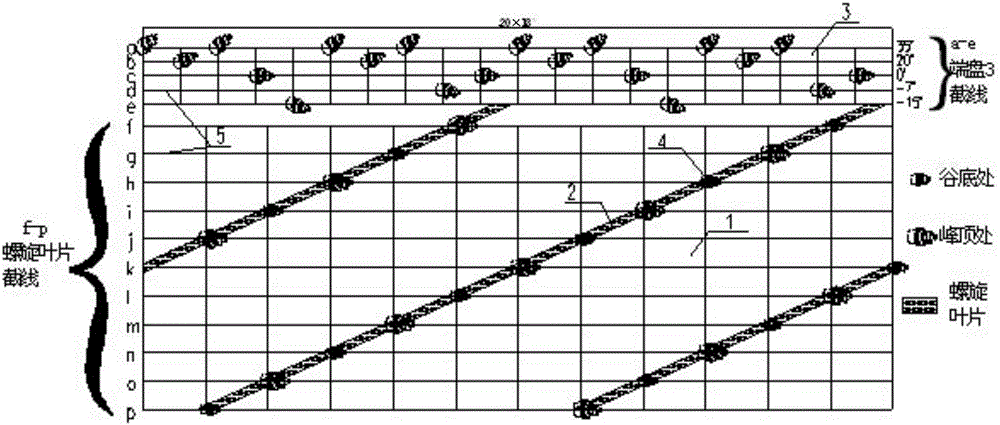

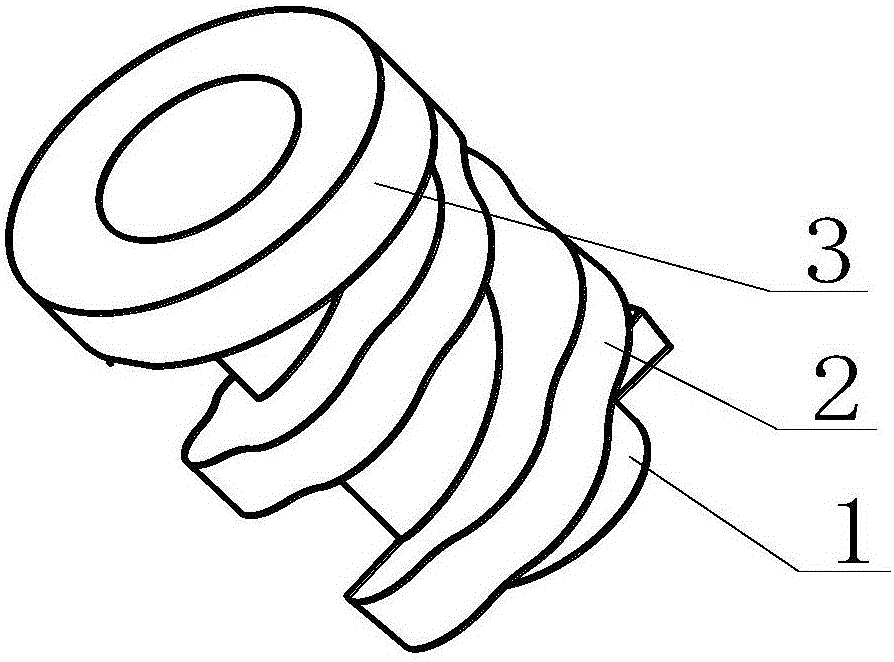

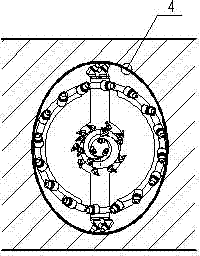

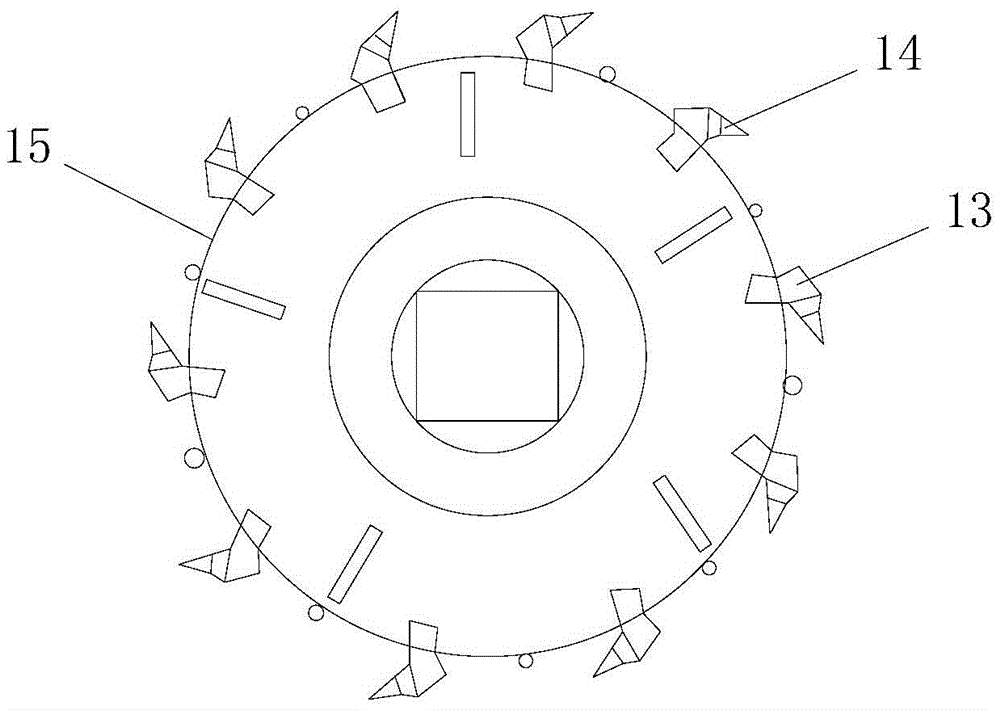

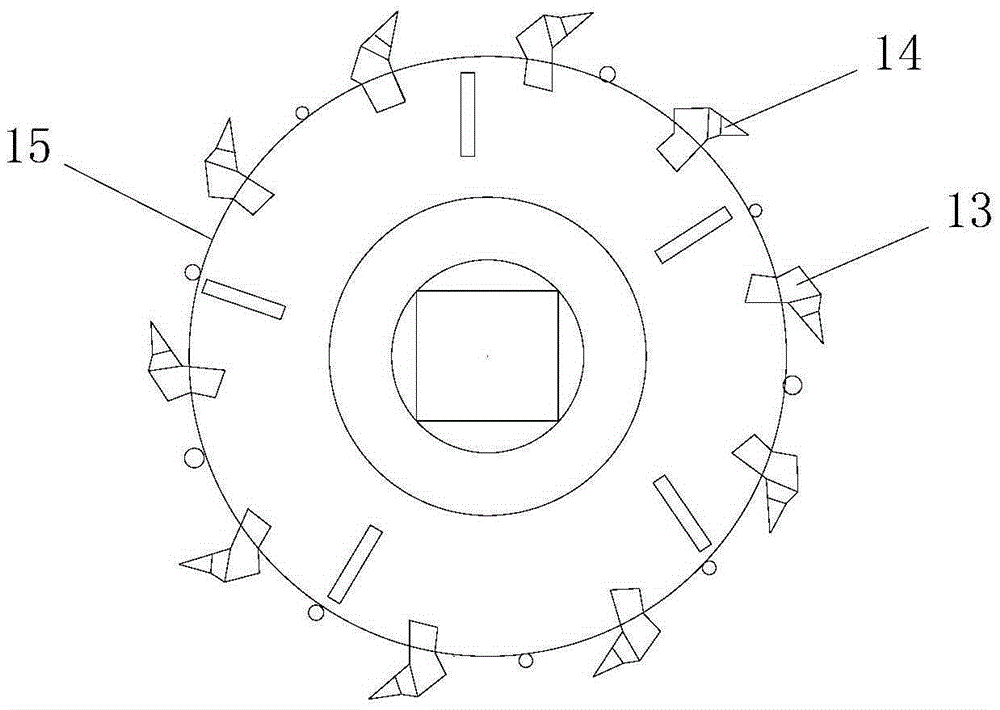

Wavy helical blade roller

ActiveCN104747188AAvoid stress concentrationReduce the specific energy consumption of cuttingCutting machinesHelical bladeEngineering

The invention discloses a wavy helical blade roller which is suitable for a roller type mining machine. The wavy helical blade roller comprises a cylinder hub, helical blades, an end plate and pickaxe-type cutting teeth, wherein the cylinder hub is cylindrical; the end plate is welded on the head part of the cylinder hub; two helical blades are welded on the cylinder hub to form a double-end roller; the pickaxe-type cutting teeth are mounted on the end plate and the helical blade. The outer edges of the helical blades are wavy; on the same cutting line, a crest of one of the helical blade corresponds to a valley bottom of the other one of the helical blades to ensure that the total cutting thicknesses of the cutting lines are same; the pickaxe-type cutting teeth are sequentially mounted on the crest and at the valley bottom of the helical blades to realize different mounting height. The roller is high in coal breaking efficiency, high in lump coal rate, simple in structure and convenient to mount and operate.

Owner:CHINA UNIV OF MINING & TECH

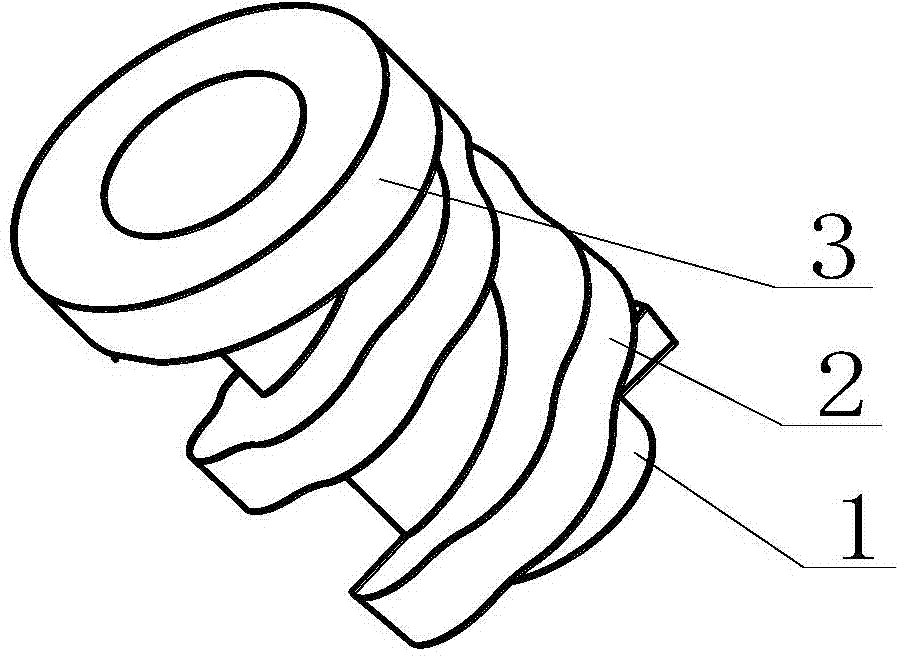

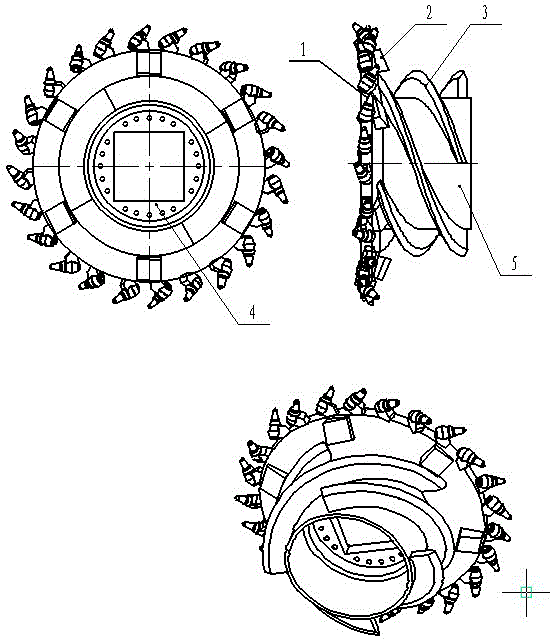

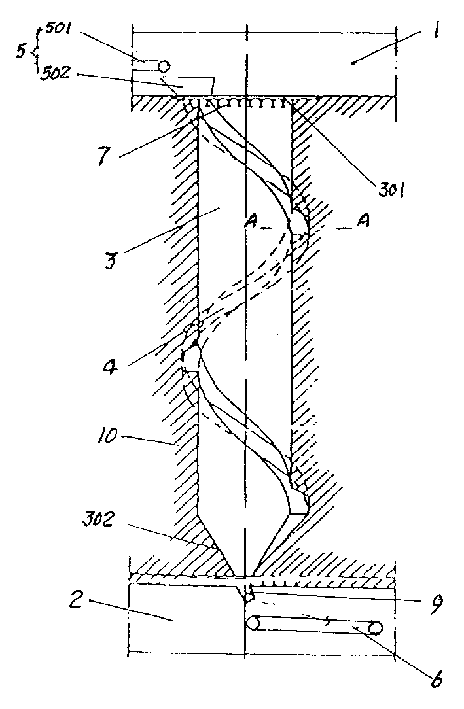

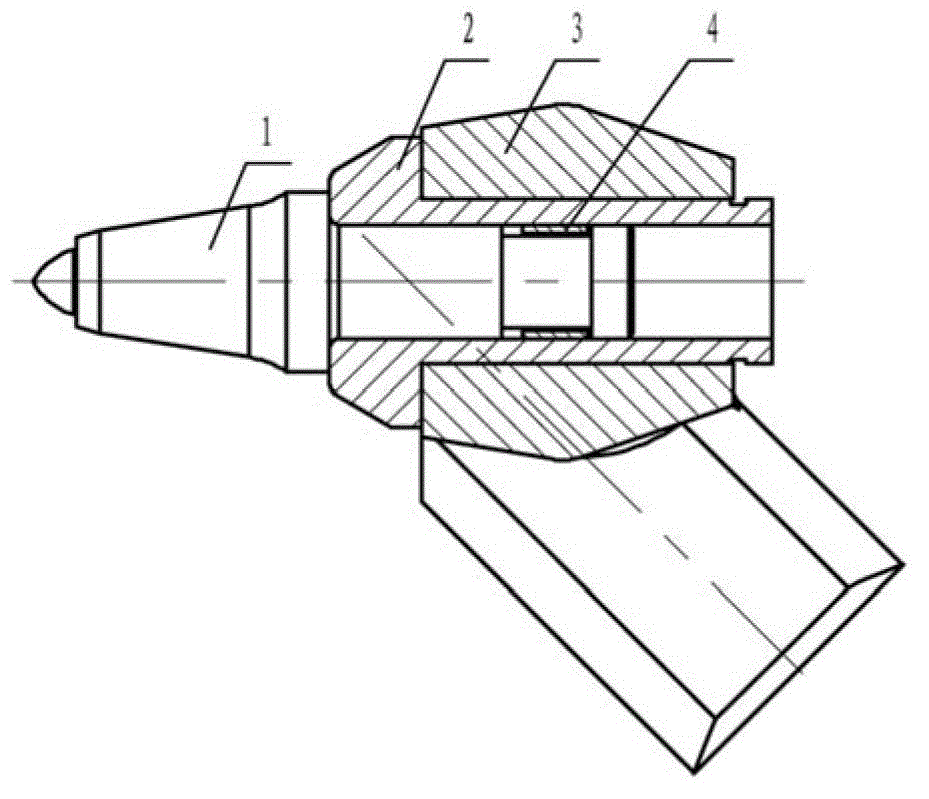

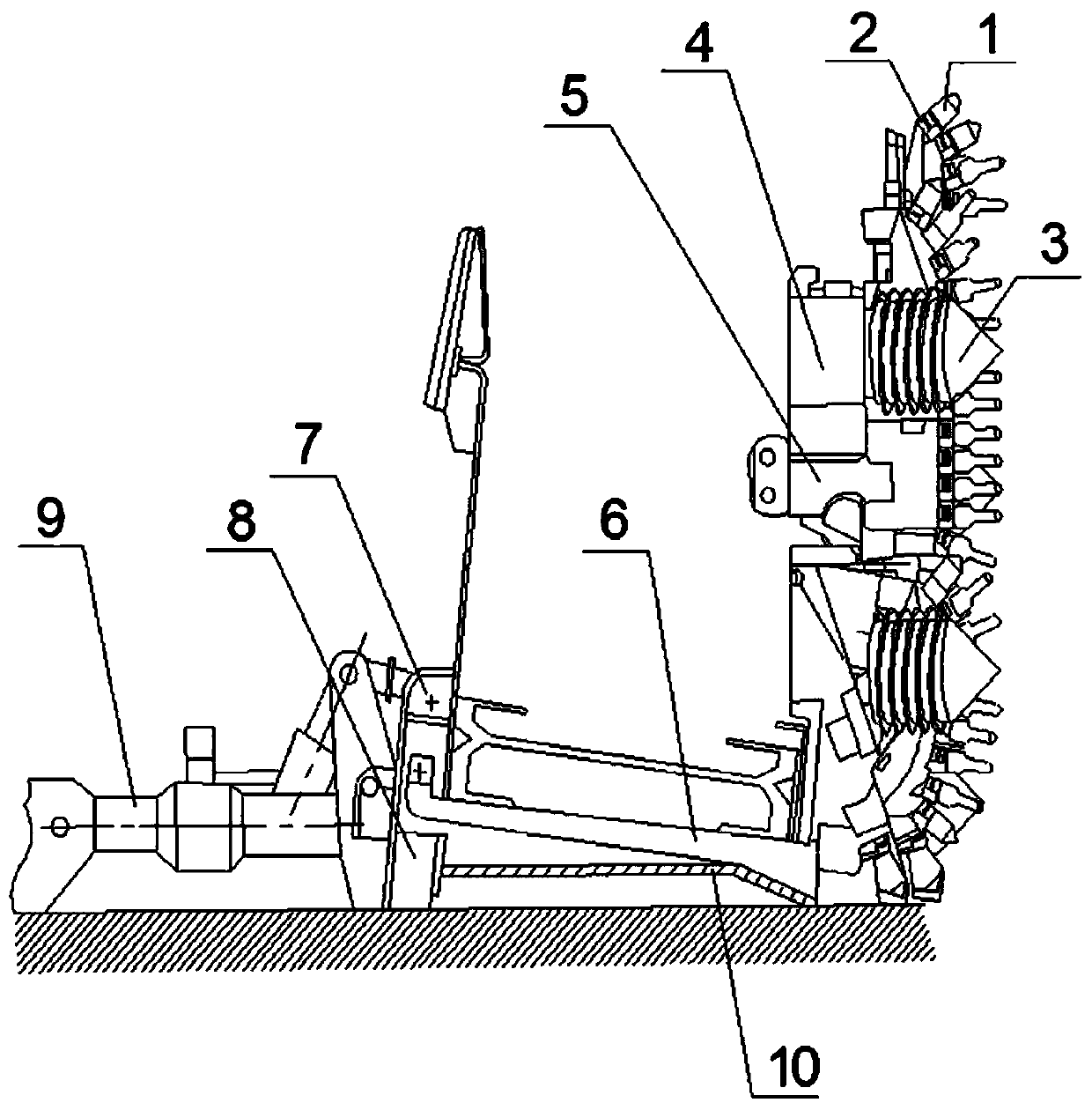

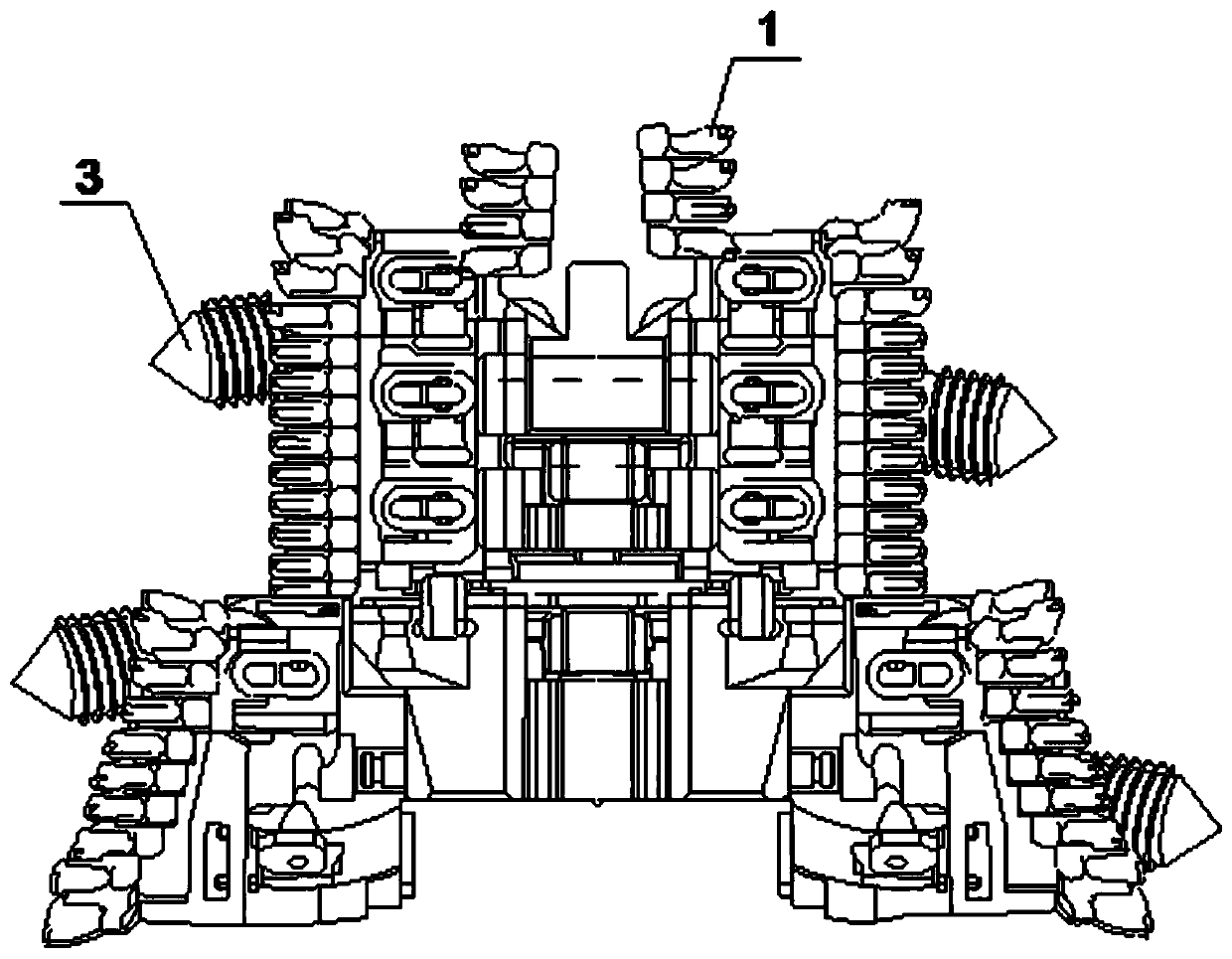

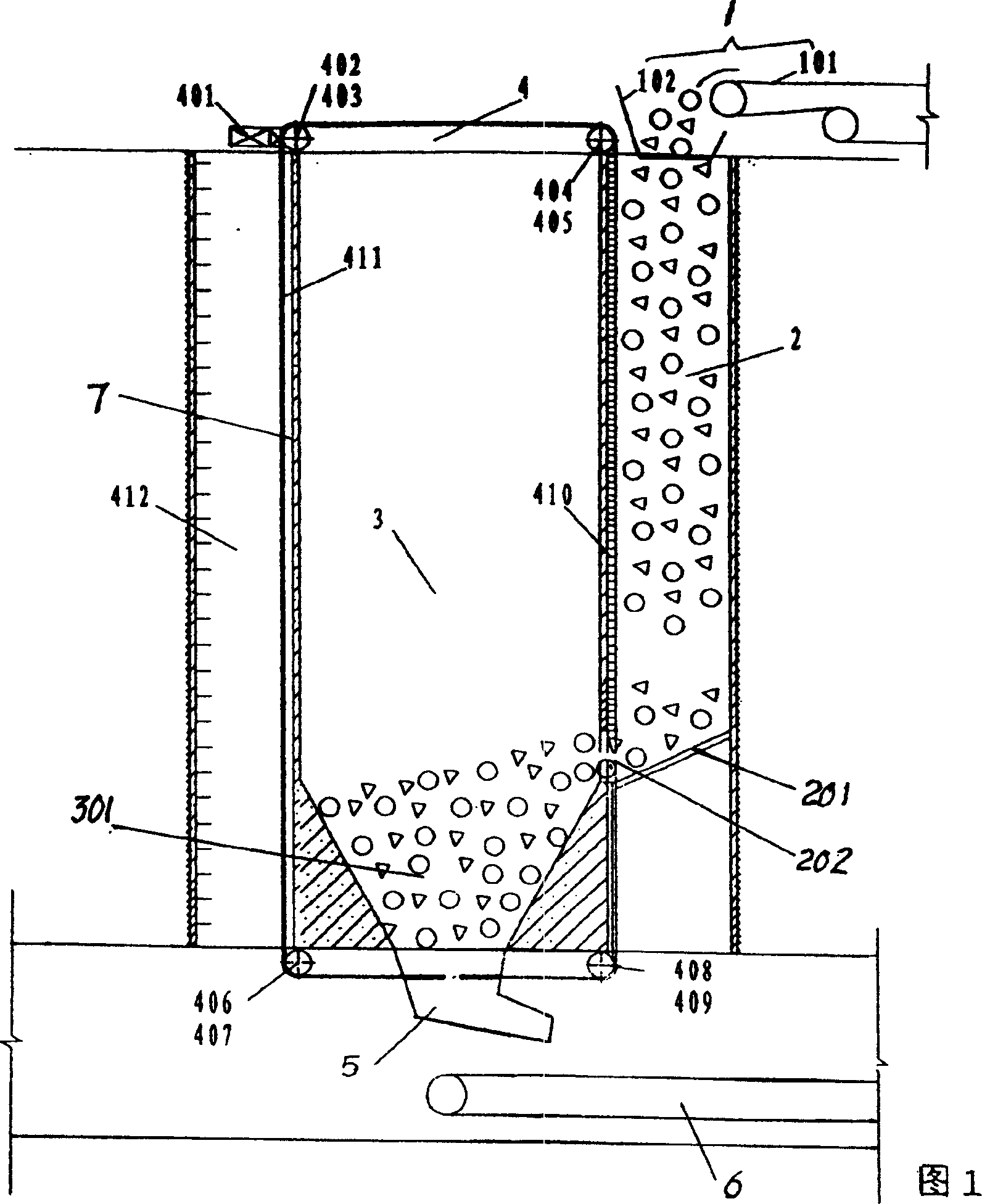

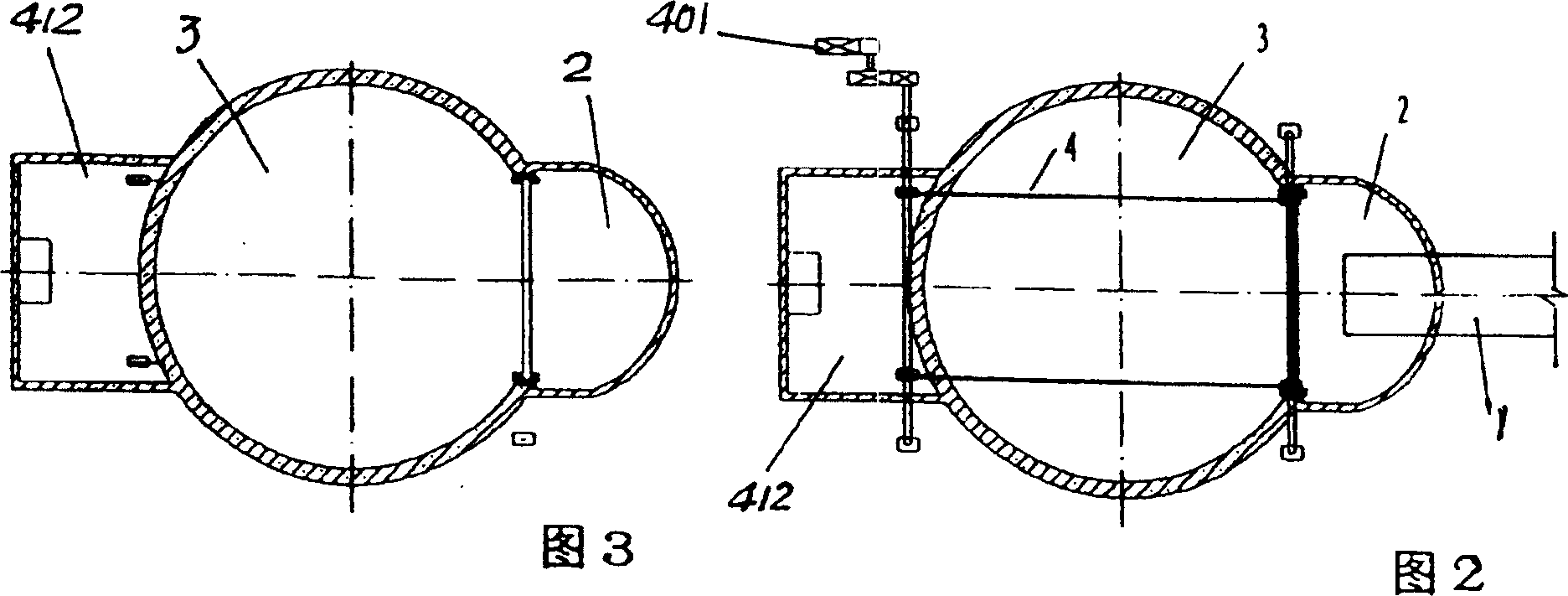

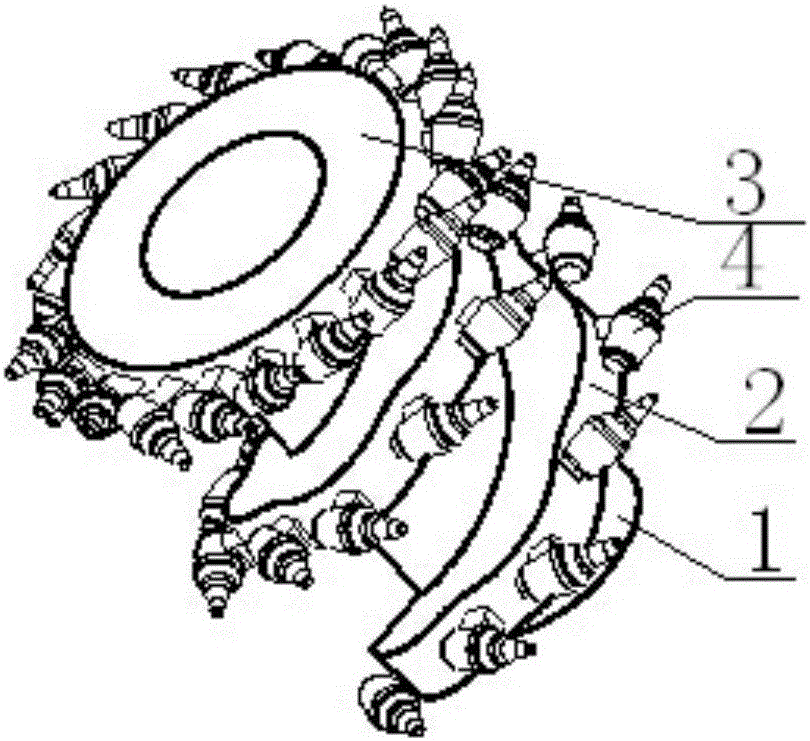

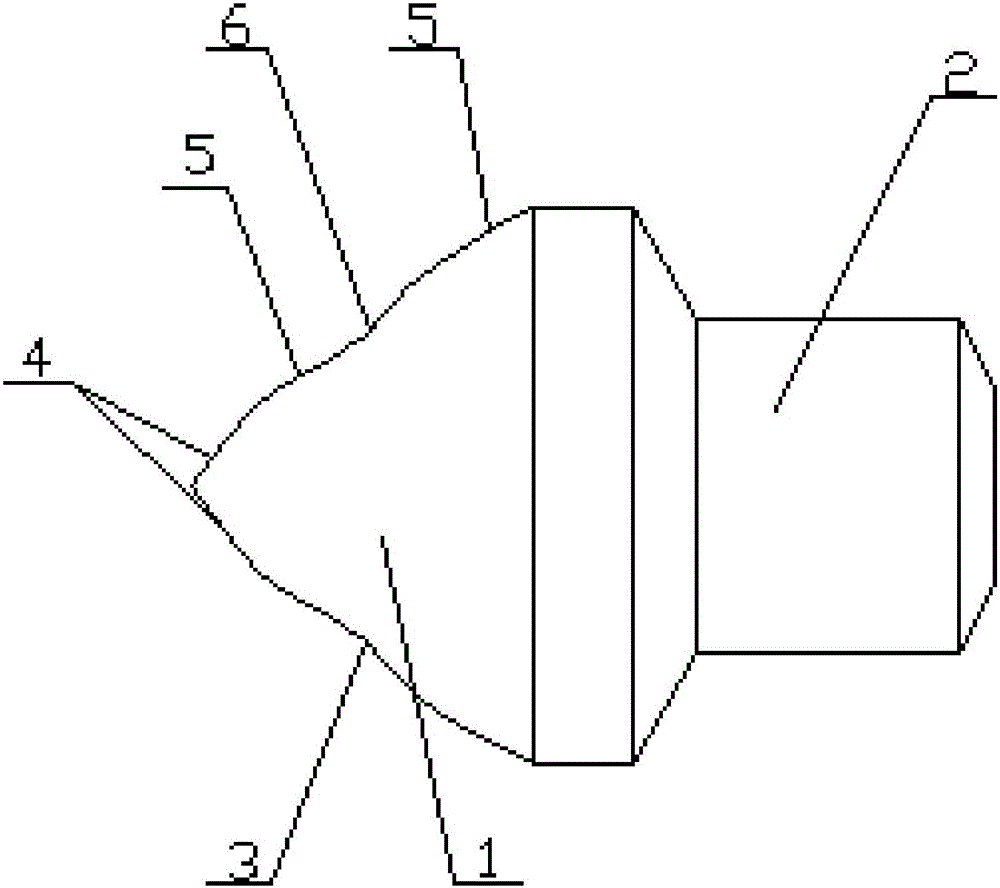

Semi-wedge type roller

The invention relates to a semi-wedge type roller applied in coal cutter of coal mining equipment. In order to improve the block coal rate, a novel coal cutting theory and structure are adopted. The semi-wedge type roller is different from the conventional rollers mainly in three parts: the cutting disc (1), the wedge block (2), and the spiral blade (3). The cutting disc (1) is similar to the end plate in the conventional rollers and is used to dig a groove on the coal wall. The external surface of the wedge block (2) is a spacial inclined plane, the wedge block (2) is inserted into the groove as the coal cutter is moving forward, and the coal on the external side of the groove is cut off through the movement of the coal cutter and the rotation of the roller. The external edge of the spiral blade is in a shape angle shape and is not provided with any cutting pick, the spiral blade (3) is mainly used to store coals, and when the coals are not cut off, the sharp angle of the external edge of the spiral blade (3) will cut off the coals to assist the coal cutting.

Owner:郑涛

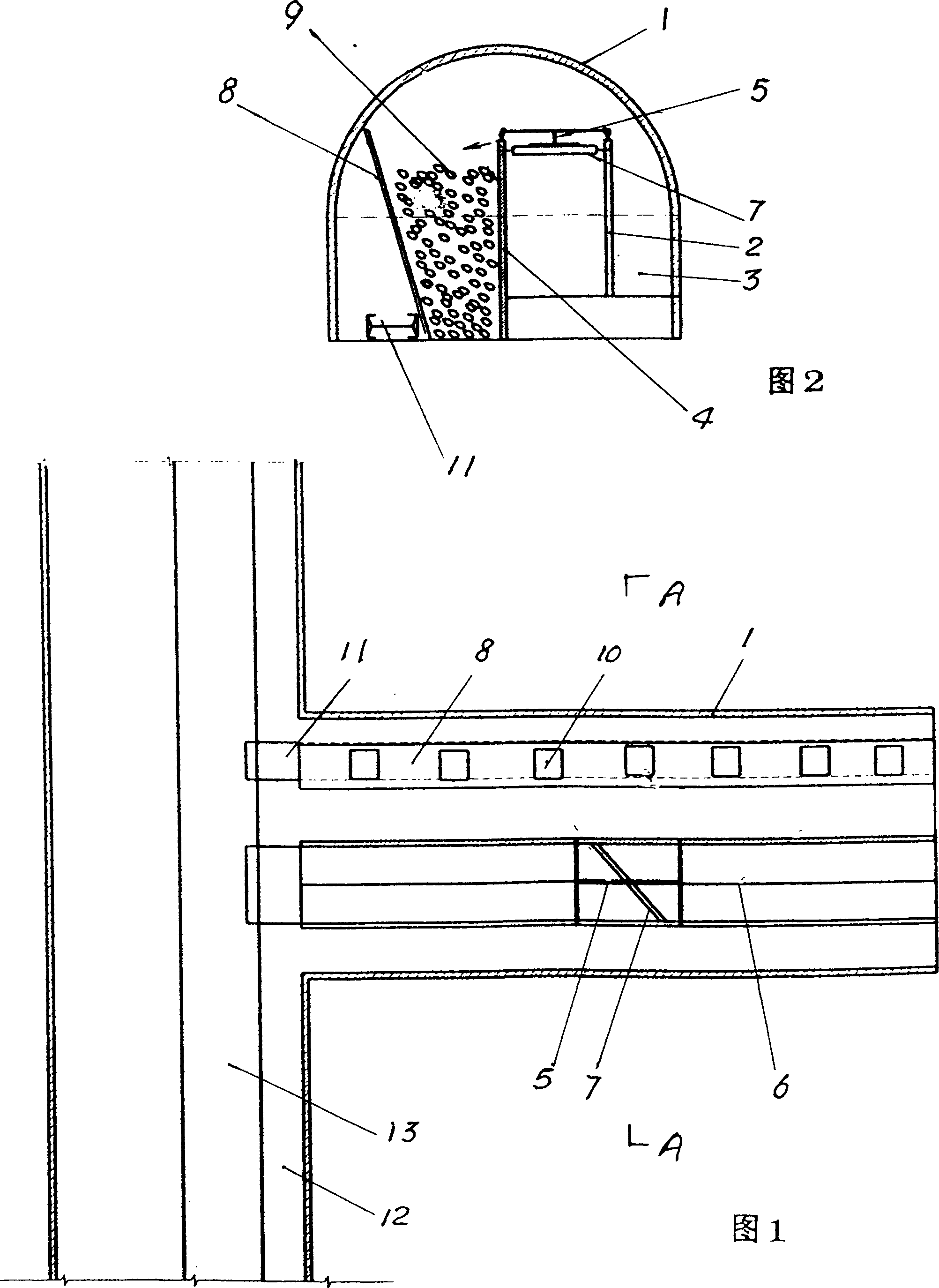

Underground drift coal bunker

InactiveCN1465849ASave engineeringEasy constructionMining devicesUnderground transportEngineeringBelt machine

The present invention relates to an underground driftway bunker, including coal scatter, running larry, belt machine and scraper conveyor, in the tunnel whose upper portion of the cross-section is made into the form of round arch, between one side wall of the tunnel and belt frame a footway is set, and on the belt frame and track rail of middle partition wall the coal scatter and running larry are set, said larry is connected with pull steel rope, under the coal scatter the belt machine is set, and between the inner side of the partition wall and outside of inward inclined partition in the tunnel the coal bunker whose upper portion is wide and lower portion is narrow can be formed. Said invention can raise block coal rate and its construction is simple.

Owner:河南神火煤电股份有限公司

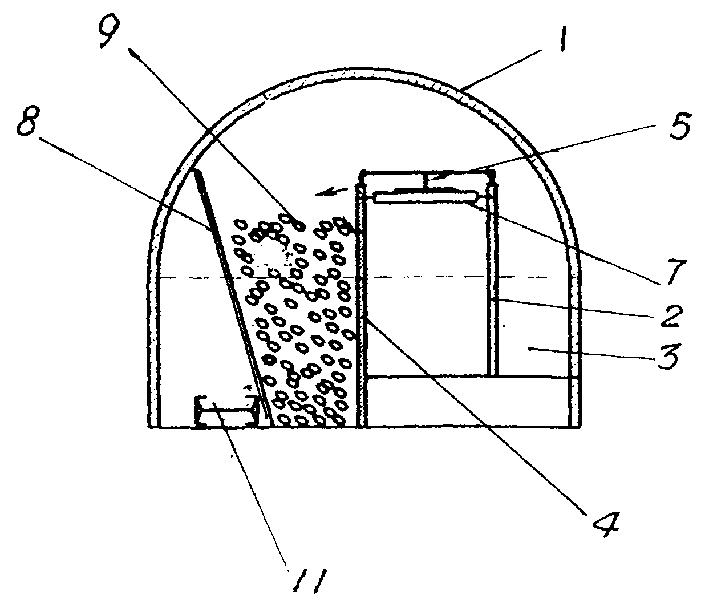

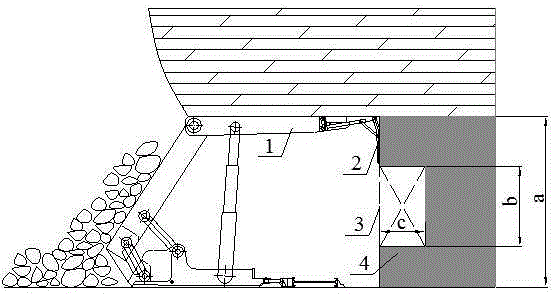

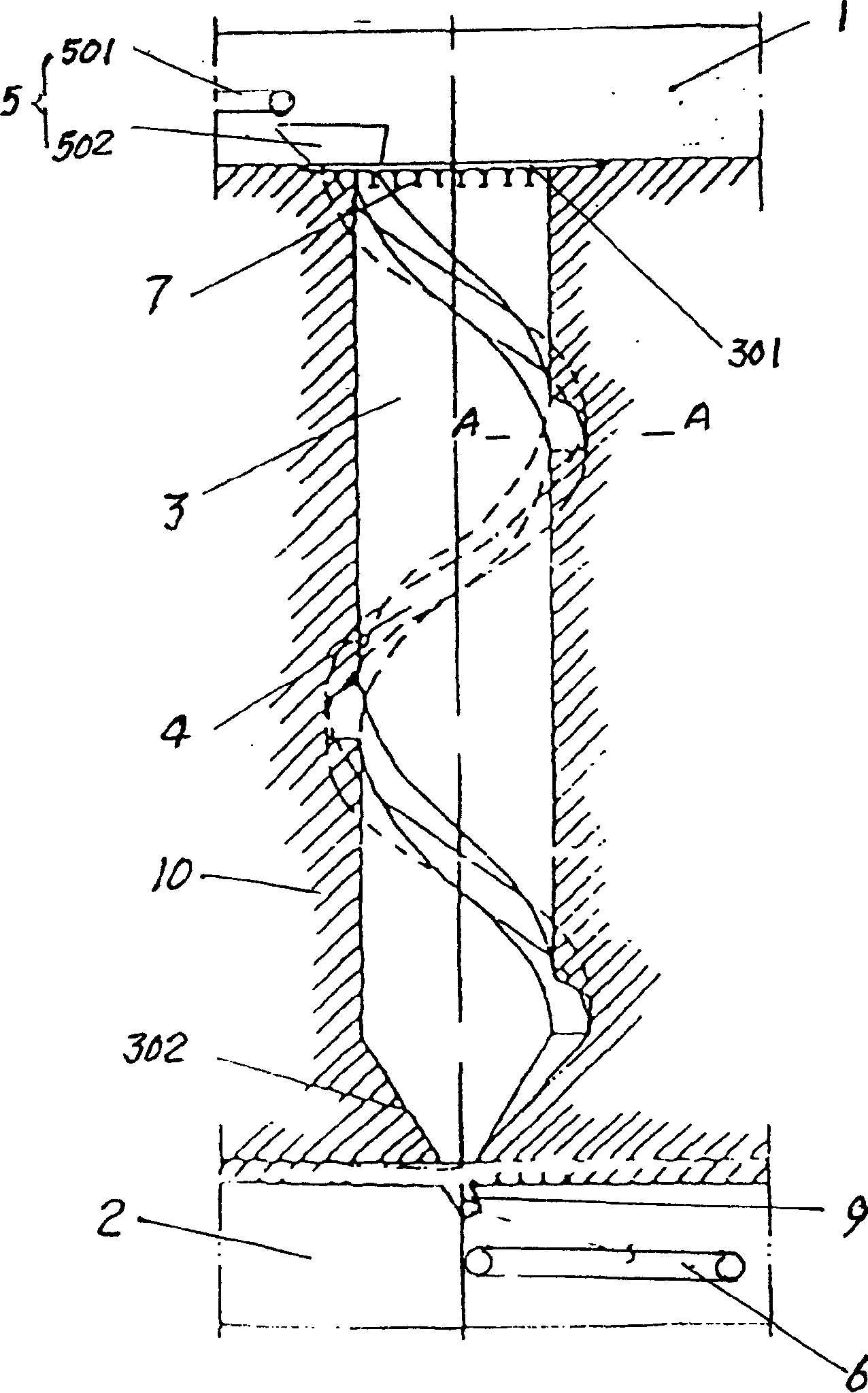

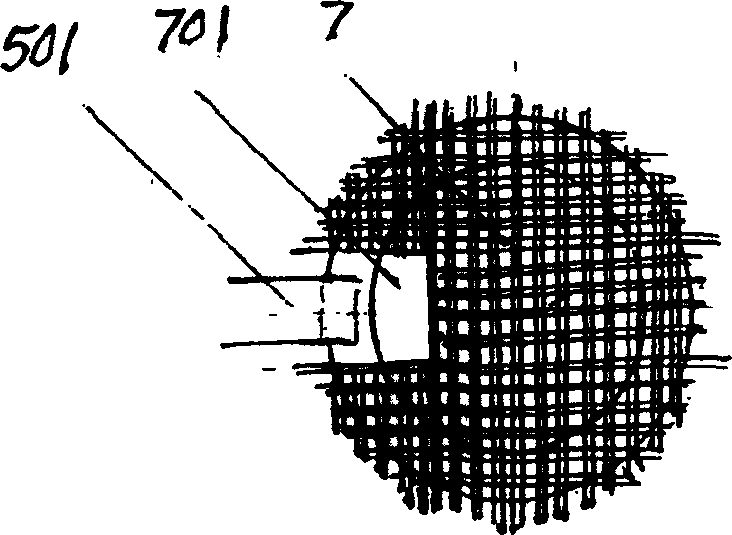

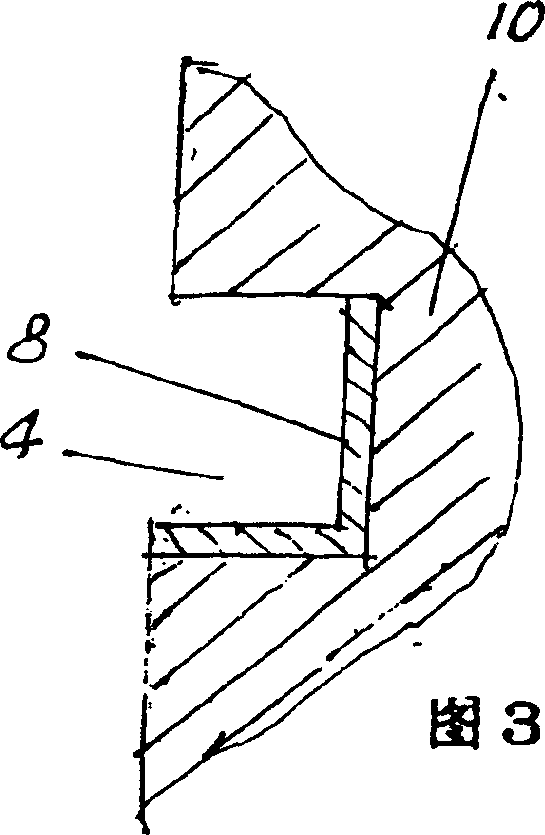

Rock screw breaking-resisting coal bunker

InactiveCN1465515AIncrease lump coal rateAvoid disadvantagesLoading/unloadingChutesEngineeringBunker

The present invention relates to a rock helical groove anti-breaking bunker, including inlet guide device and coal-feeding machine, on the rock between upper tunnel and lower tunnel a vertical cylindrical bunker body is cut, and the upper circular hole of said bunker body is equipped with a sealing grate with inlet, and the lower end of said bunker body is equipped with a reduced cone hole whose bottom outlet is equipped with coal-feeding machine, said coal-feeding machine is equipped with helical groove cut into the inner wall of the cylindrical rock bunker body, and the upper end of the helical groove is connected with the inlet of the sealing grate. Said invention has good effect for preventing coal block from being broken, and its coal block breaking rate is low.

Owner:张光建

Water cutting falling coal mining method and water cutting falling coal mining machine

InactiveCN103089256AEasy to useImprove economySlitting machinesCutting machinesMining engineeringWater jet cutter

The invention belongs to a coal mining method and a coal mining machine, and concretely relates to a water cutting falling coal mining method and a water cutting falling coal mining machine. A coal seam is cut and coal falls when and / or after the machine adopts a water jet cutting device to transversely cut a coal wall, and the machine body moves on to drive the water jet cutting device and a water jet falling device to realize continuous coal mining. Compared with machines for realizing present coal mining methods, the water cutting falling coal mining machine has the advantages of high lump coal rate, realization of regular shapes of coal obtained after cutting, improvement of the use values and the economic values of raw coal, energy saving, low energy consumption, less dust, compact structure, use convenience, material saving, no need of the adjustment of the machine body, realization of the continuous coal mining through adjusting the right and wrong directions of the machine body, omitting of coal mining support equipment, and saving of the coal mining equipment investment, and can be used as a drilling machine to complete the drilling of roadways and dig out various chambers and roadways; no sparks and high safety are realized through adopting a water jet to cut coal; and mist spraying, water spraying and cooling devices used in mechanical coal mining are omitted when water jet cutting is adopted, so the structure of the machine is simplified, the failure rate is low, and the maintenance amount is less.

Owner:刘素华

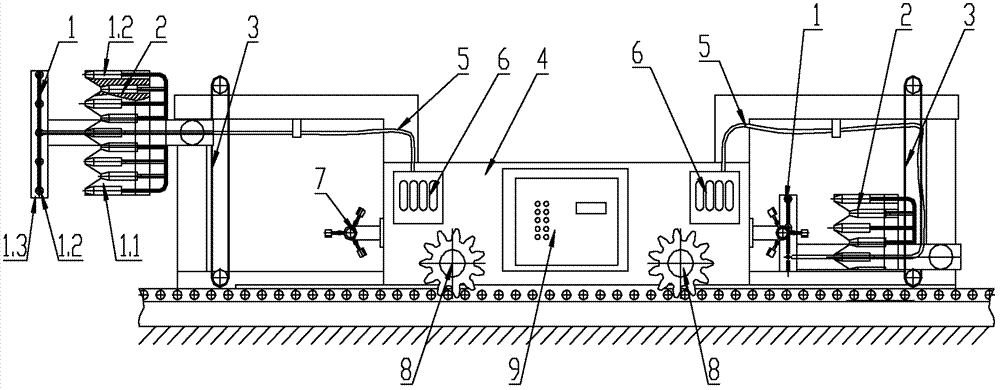

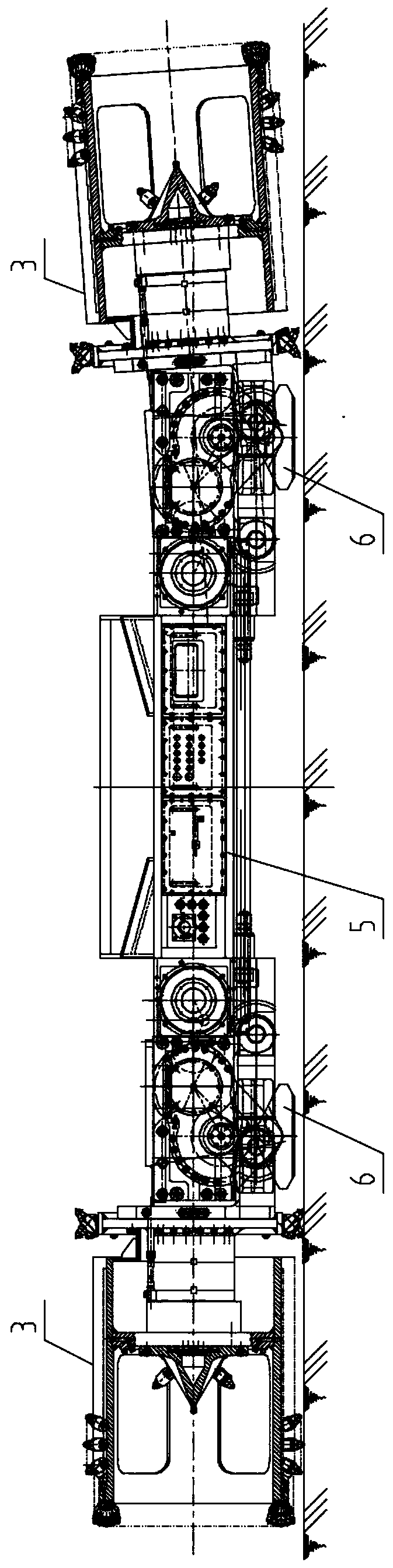

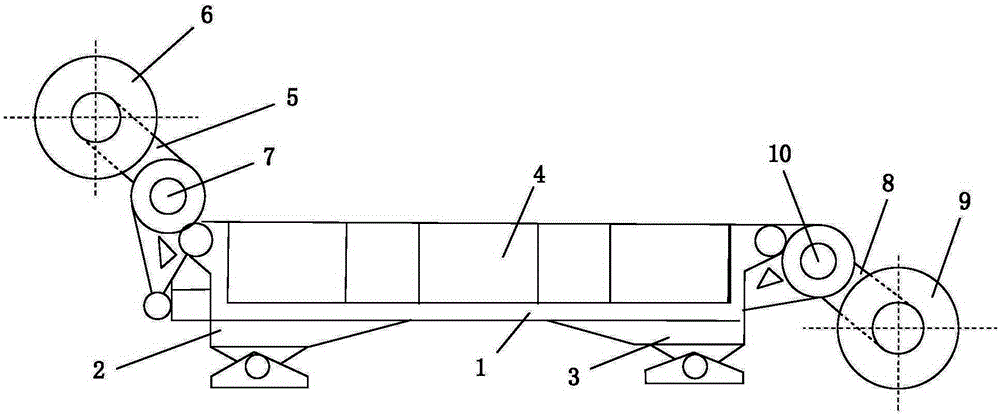

Gate roadway loader raw coal transporting and crushing system for underground coal mining

ActiveCN106311389ARealize extrusion crushingIncrease lump coal rateGrain treatmentsMechanical conveyorsMechanical engineeringCoal mining

A gate roadway loader raw coal transporting and crushing system for underground coal mining comprises a scraper conveyer, a gate roadway loader and a belt conveyer which are sequentially connected end to end from right to left. A supporting connection piece and a roll crushing mill are arranged between the unloading end of the gate roadway loader and the self-advancing tail of the belt conveyer. A movable connection piece is arranged between the roll crushing mill and the self-advancing tail of the belt conveyer. According to the gate roadway loader raw coal transporting and crushing system for underground coal mining, the roll crushing mill and the gate roadway loader synchronously move at the self-advancing tail of the belt conveyer through the supporting connection piece and the movable connection piece; and not only can the gate roadway loader and the roll crushing mill move at the self-advancing tail of the belt conveyer, but also the position between the roll crushing mill and the unloading end is fixed relatively, and squeezing and crushing of materials are achieved.

Owner:NINGXIA TIANDI BENNIU IND GRP

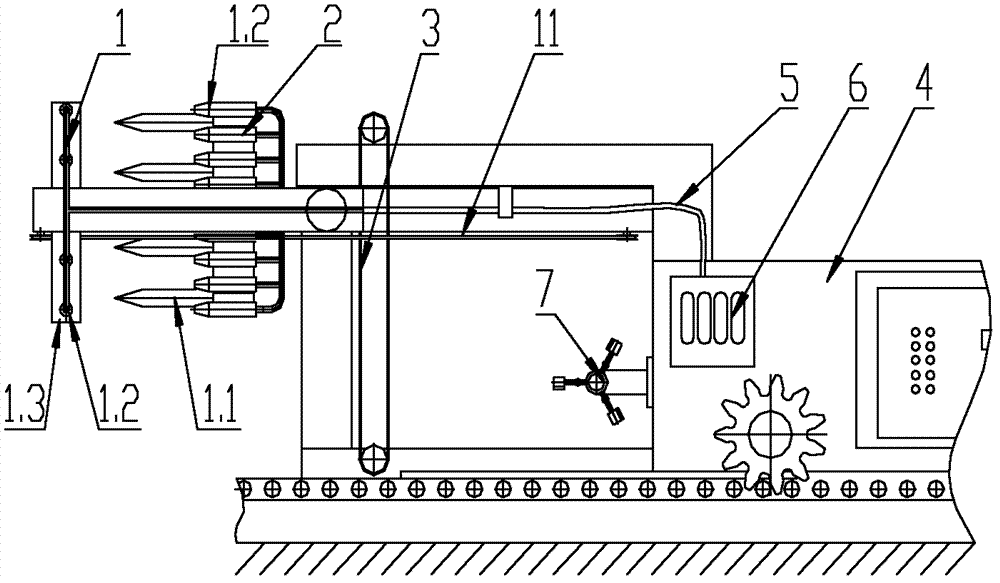

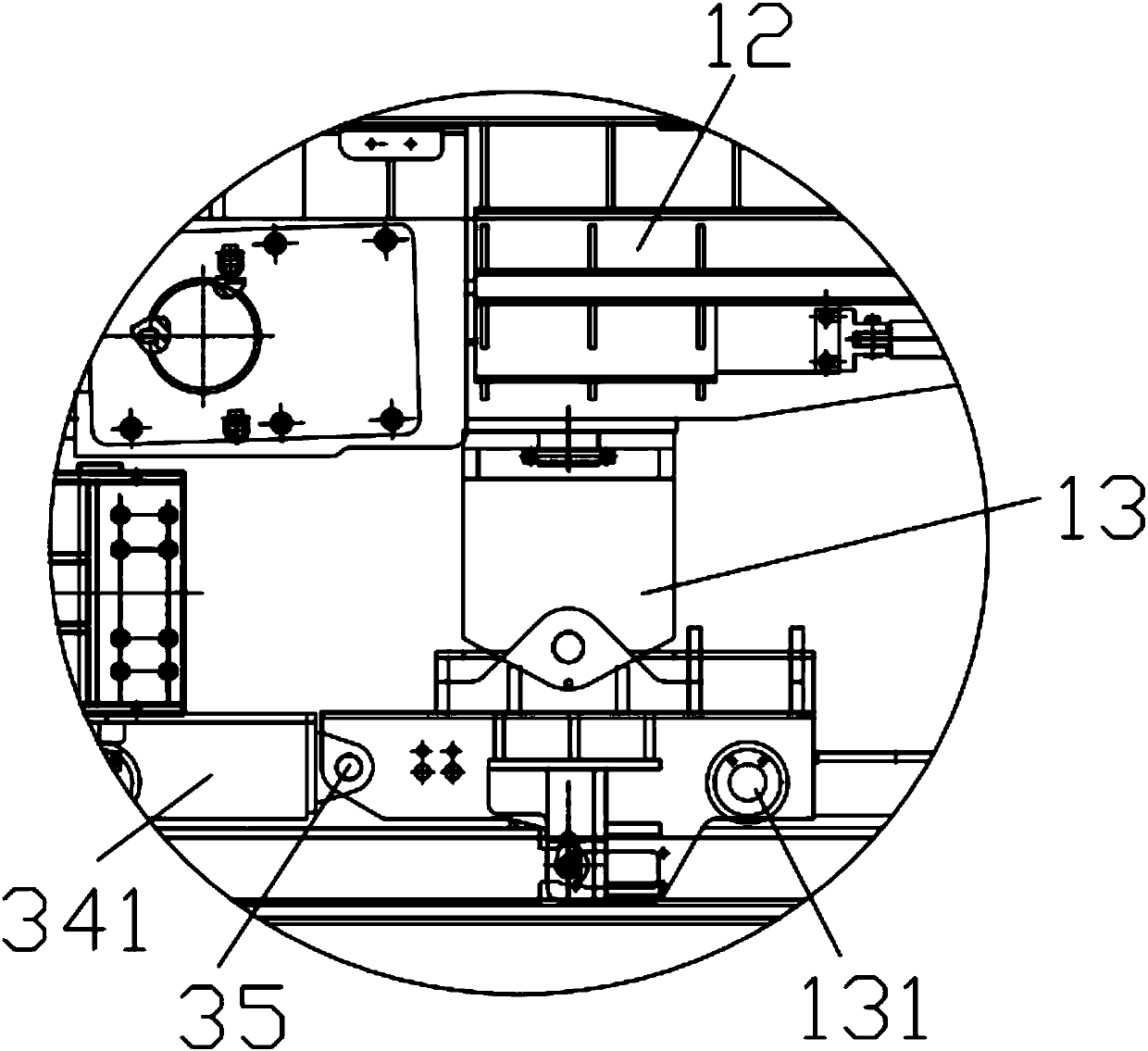

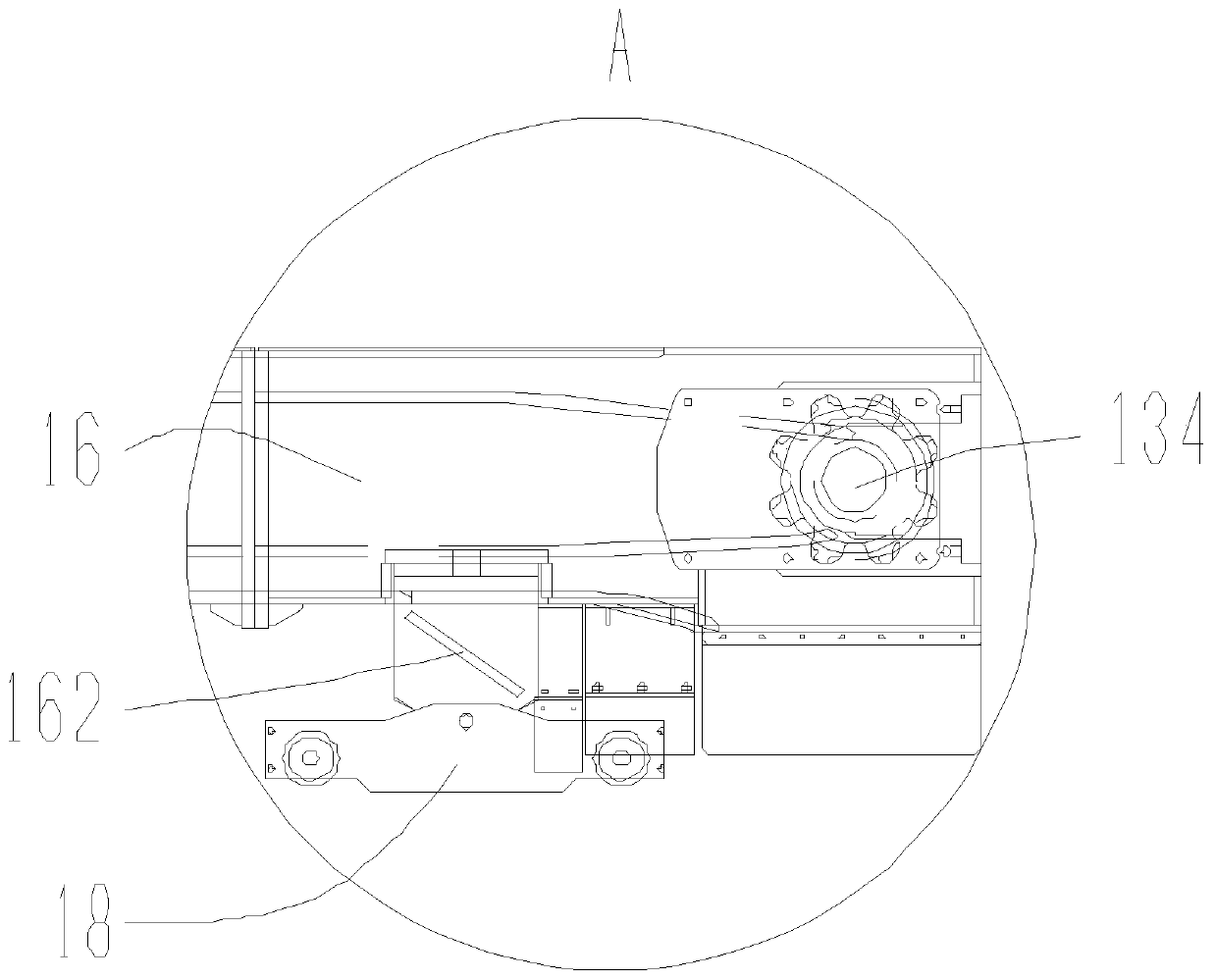

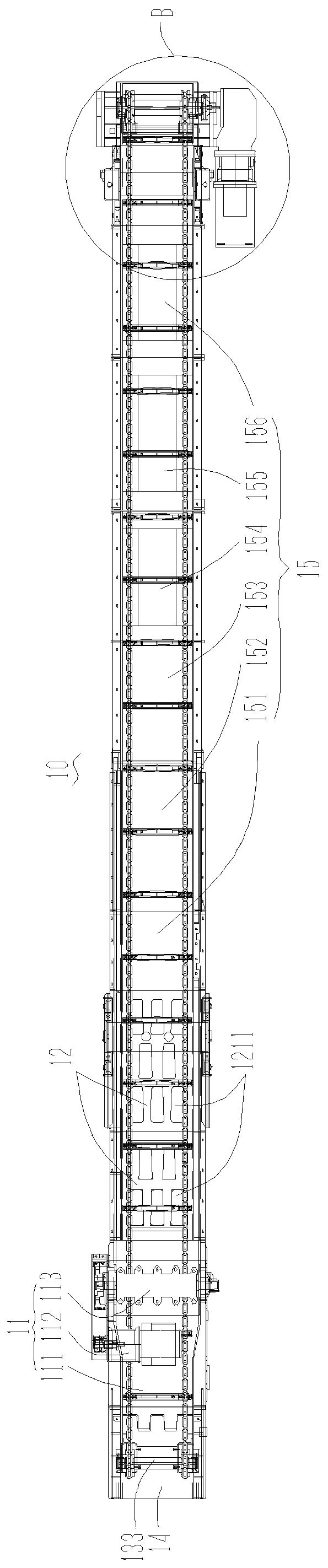

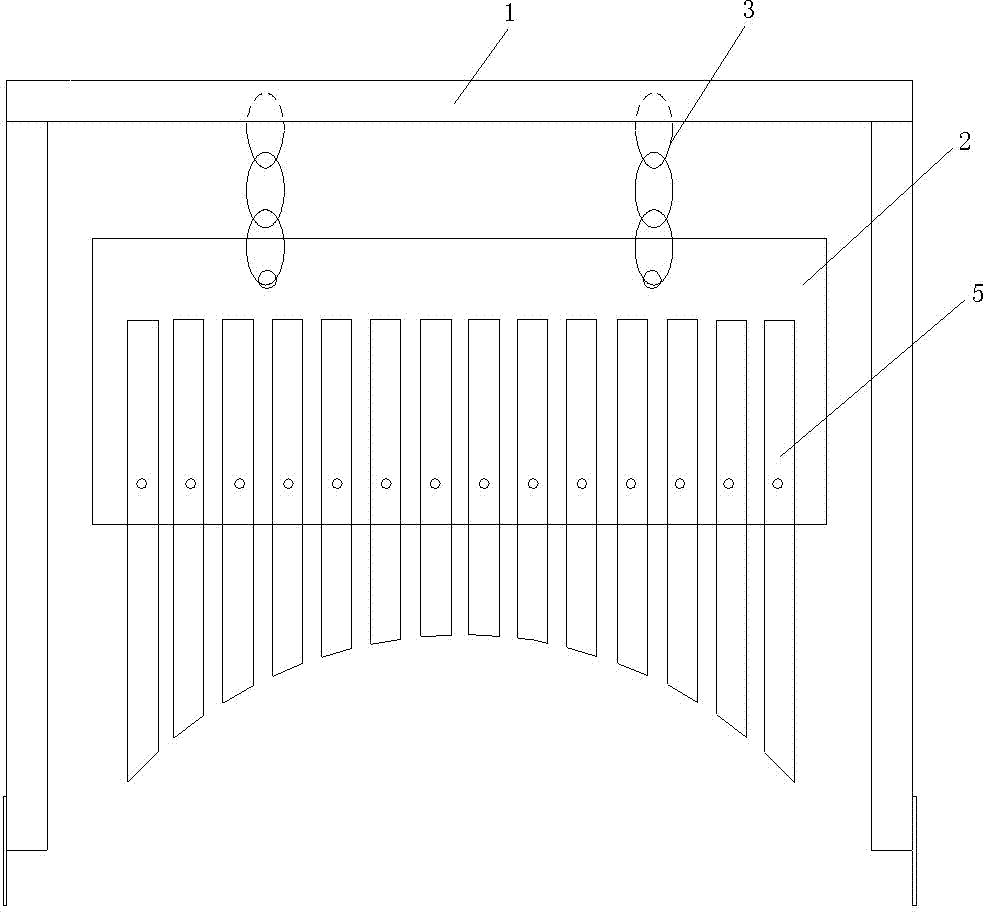

Gate road rolling shaft type sieving, crushing and transferring device

PendingCN111744654ANo secondary shear fracture occursWith screening functionSievingConveyorsProcess engineeringTransfer mechanism

The invention provides a gate road rolling shaft type sieving, crushing and transferring device and relates to the technical field of conveying equipment for coal mine underground mining. The gate road rolling shaft type sieving, crushing and transferring device is connected with a machine head of a reversed loader and a machine tail of a belt machine. The gate road rolling shaft type sieving, crushing and transferring device comprises a sieving device and a crushing device. The sieving device and the crushing device are located right above the machine tail of the belt machine and located on the end portion of the machine head of the reversed loader. The machine head of the reversed loader, the sieving device and the crushing device are sequentially connected. The crushing device comprisesa scraping plate chain assembly, a gate body and a scraping plate chain power portion. The crushing device is provided with a transferring mechanism. Raw coal is autonomously transferred and crushedthrough the crushing device. The sieving device is directly arranged right above the machine tail of the belt machine. Small patches of raw coal obtained after sieving directly pass through the sieving device and fall on the machine tail of the belt machine to be conveyed away without passing through the reversed loader longitudinally. A scraping plate of the reversed loader does not touch the small patches of raw coal obtained after sieving completely. The situation that the small patches of raw coal is shorn and crushed for a second time is avoided. While having a sieving function, the lumpcoal rate can be improved relatively.

Owner:NINGXIA TIANDI BENNIU IND GRP +1

Intelligent burst coal mining method

InactiveCN104929640AImprove high efficiencyReduce manual labor intensityUnderground miningSurface miningEngineeringUltimate tensile strength

The invention relates to the technical field of coal mining, in particular to an intelligent burst coal mining method. An intelligent drill carriage is adopted for positioning and hole drilling. A mechanical arm of an intelligent mechanical charging device is adopted for automatic positioning and charging, automatic hole sealing is achieved, an explosive charge is ignited for bursting according to the hole size, position, depth, inclination angle and coal cracking sequence in the bursting method, the burst coal body cracks and is not thrown out, large loosened coal blocks are formed, the block coal rate reaches more than 30%, an automatic coal collection device is adopted for coal loading after the coal blocks are formed, and finally an intelligent dust suppression system capable of adjusting the dust collection strength according to the coal dust amount percent is adopted for suppressing dust. According to the technical scheme, the labor intensity is low, the coal mining and the block coal rate are high, the coal dust amount is low, and the requirement for effective and safe coal mining is met.

Owner:LIAONING TECHNICAL UNIVERSITY

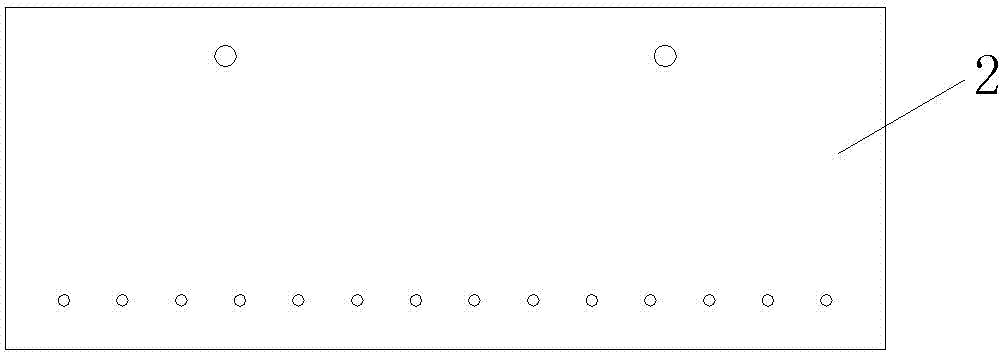

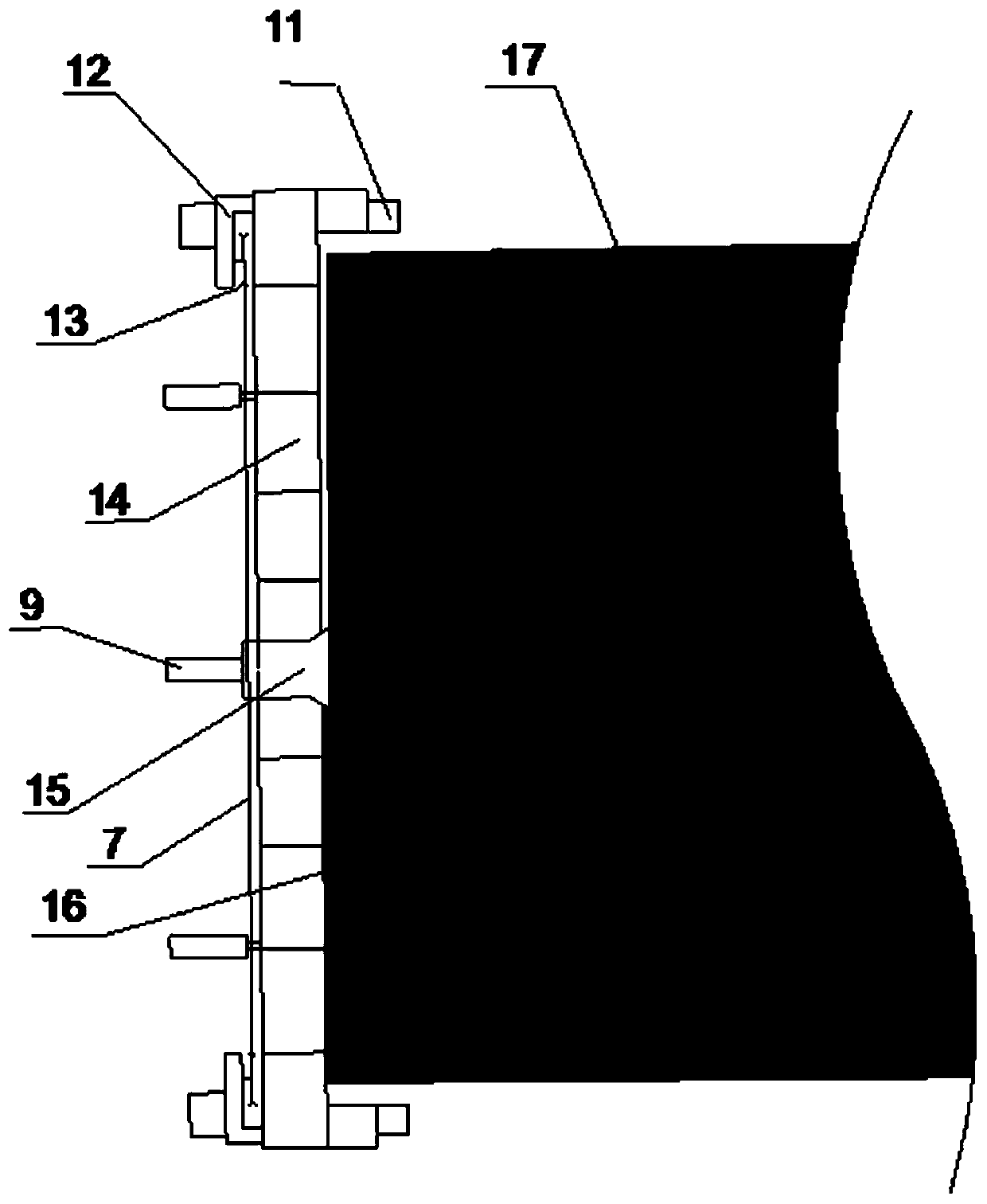

Coal leakage preventive device of belt conveyor

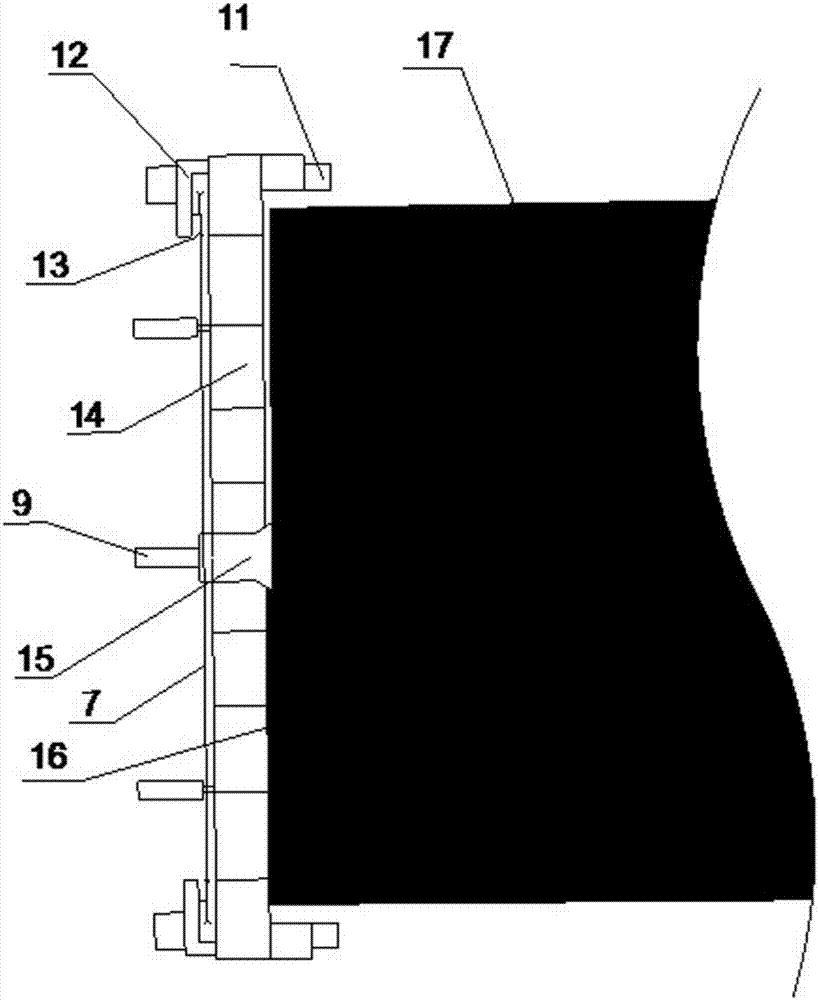

InactiveCN103046954BShorten speedReduce the stress areaEarth drilling and miningUnderground transportCoal briquetteCoal

The invention relates to the technical field of coal mine equipment, particularly to a coal leakage preventive device of a belt conveyor. The coal leakage preventive device comprises a coal stop board arranged above a belt and used for stopping coal briquettes, and the coal stop board is provided with a concave camber surface with the opening facing the direction of the coal briquettes and used for reducing the speed of the coal briquettes. Compared with the prior art, the opening of the concave camber surface of the coal stop board faces the direction of the coal briquettes, when the coal briquettes bump against the concave camber surface, not only speeds of the coal briquettes are reduced, but also stressed areas of the coal briquettes are reduced, the possibility that the coal briquettes are crashed is reduced, and therefore the lump coal rate of the coal briquettes can be improved.

Owner:永煤集团股份有限公司新桥煤矿

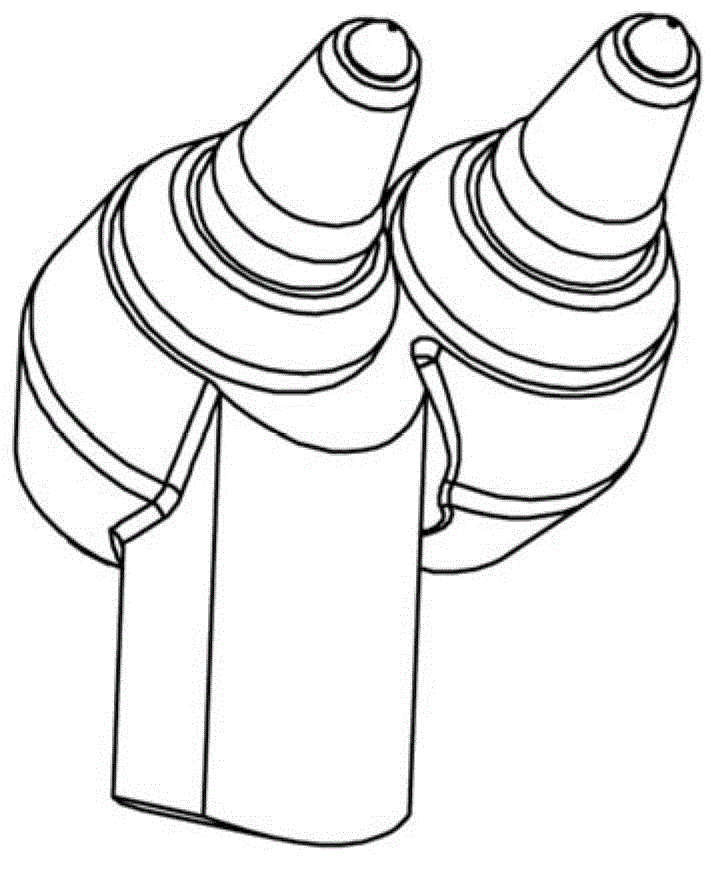

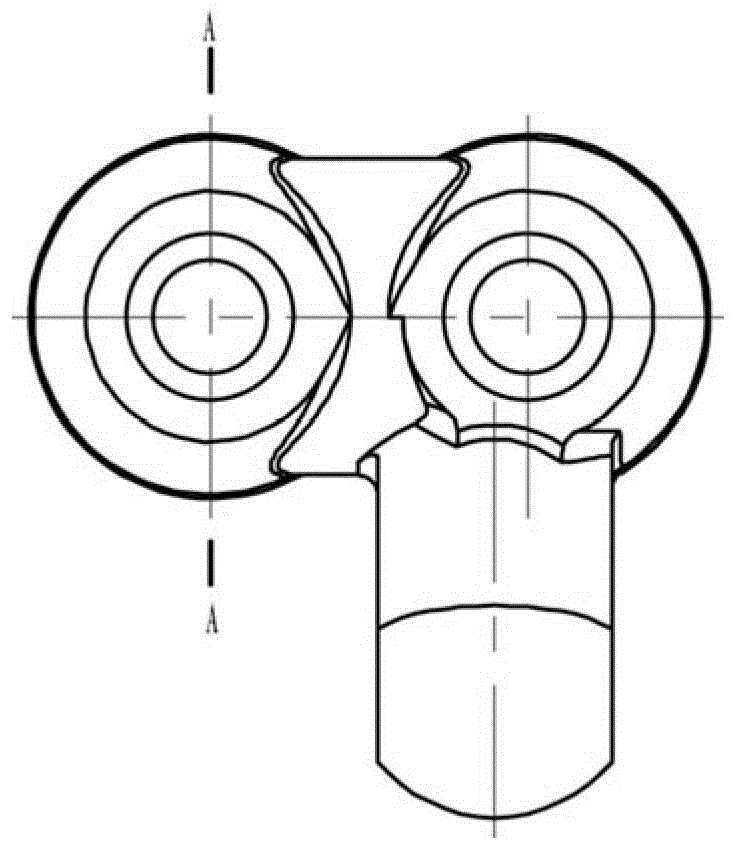

Duplex pickaxe type cutting tooth holder of drum shearer

InactiveCN103334752AReduce the number of picksQuality improvementCutting machinesSpiral bladeEngineering

The invention relates to the field of coal-cutting machinery, and particularly relates to a duplex pickaxe type cutting tooth holder of a drum shearer. The lump coal rate, the powdered coal quantity, the cutting tooth specific energy consumption and the like are influenced by a geometric construction and a spatial arrangement of an existing pickaxe type cutting tooth holder. The invention provides a novel tooth holder, which is capable of being simultaneously provided with two pickaxe type cutting teeth and can be arranged in a parallel, outwards inclining or inwards inclining manner along a spiral blade, and is directly welded on a spiral drum through a tail handle according to a certain principle. Under the condition that structure parameters and cutting tooth quantities are same, the quantity of cutting teeth distributed on the blade of the spiral drum can be reduced so that the unit area of the cutting teeth acting on the coal petrography is large. The duplex pickaxe type cutting tooth holder has the beneficial effects that the coal petrography is crushed by adopting the pickaxe type cutting teeth of the duplex pickaxe type cutting tooth holder, a gap between every two adjacent cutting teeth can be increased to ensure that the coal cutting capacity is enhanced and the unit area of the cutting teeth acting on the coal petrography can be increased, the grinding force on the contact surface is reduced, the lump coal rate is increased, the powdered coal quantity is reduced, and the unit cutting energy consumption is lowered.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

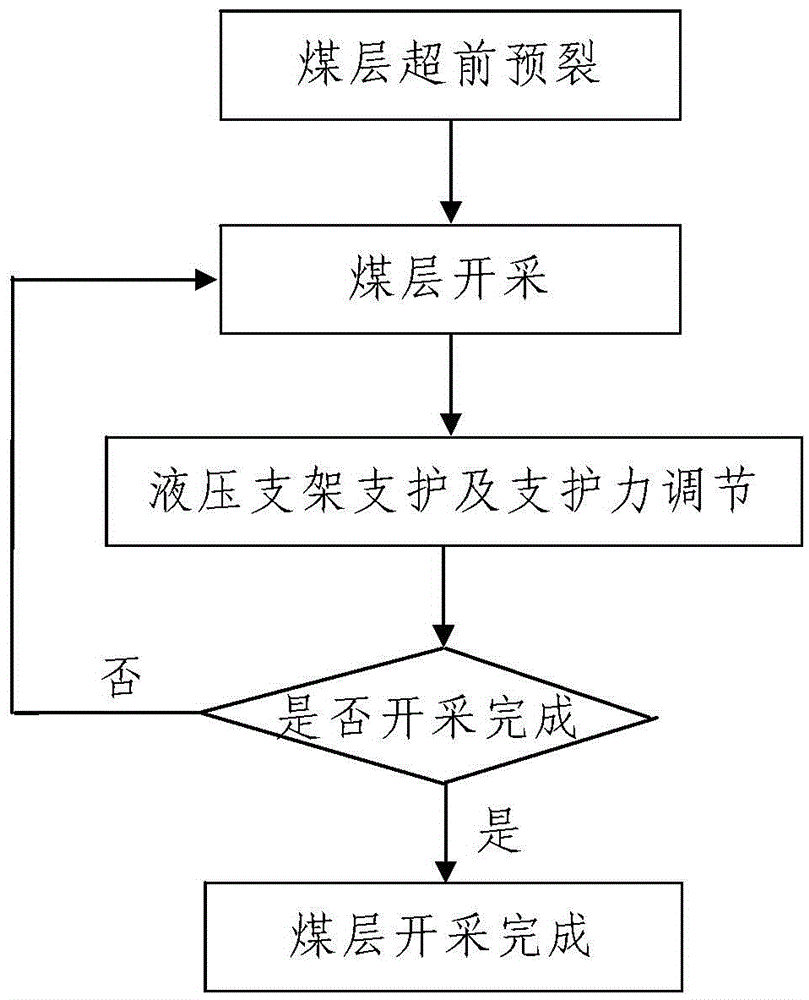

A kind of lump coal mining adopts advanced pre-splitting method

ActiveCN103924956BThe method steps are simpleReasonable design and simple operationUnderground miningFluid removalHydraulic fracturingHigh pressure water

The invention discloses an advanced pre-splitting method for lump coal mining. The method with carbon dioxide pre-splitting and hydraulic fracturing combined is adopted, advanced pre-splitting of a working face is carried out on a coal layer needing mining in a multi-segmental mode from near to far in the advancing direction of the coal layer working face. The advanced pre-splitting method for every segment comprises the first step of hole drilling, wherein pre-splitting drill holes are drilled in the current pre-split segment; the second step of carbon dioxide pre-splitting, wherein a carbon dioxide pre-splitting device is installed in each drilled pre-splitting drill hole, the drill holes are sealed, and then pre-splitting is initiated; the third step of installation water injection pipes, wherein each pre-splitting drill hole is internally provided with one high pressure water injection pipe, and the holes are sealed; the fourth step of hydraulic fracturing, wherein water is injected into the pre-splitting drill holes through the high pressure water injection pipes to carry out hydraulic fracturing. According to the method, steps are simple, design is reasonable, the method is easy to implement and good in use effect, the problems that an existing deep hole blasting pre-splitting method is not safe, serious in pollution, high in investment cost, poor in use effect and the like are effectively solved, and the lump coal rate of a fully mechanized coal mining face is improved effectively.

Owner:XIAN UNIV OF SCI & TECH

Raw coal transportation and crushing system for coal mine underground workers

ActiveCN106311389BRealize extrusion crushingIncrease lump coal rateGrain treatmentsMechanical conveyorsTransport systemEngineering

A gate roadway loader raw coal transporting and crushing system for underground coal mining comprises a scraper conveyer, a gate roadway loader and a belt conveyer which are sequentially connected end to end from right to left. A supporting connection piece and a roll crushing mill are arranged between the unloading end of the gate roadway loader and the self-advancing tail of the belt conveyer. A movable connection piece is arranged between the roll crushing mill and the self-advancing tail of the belt conveyer. According to the gate roadway loader raw coal transporting and crushing system for underground coal mining, the roll crushing mill and the gate roadway loader synchronously move at the self-advancing tail of the belt conveyer through the supporting connection piece and the movable connection piece; and not only can the gate roadway loader and the roll crushing mill move at the self-advancing tail of the belt conveyer, but also the position between the roll crushing mill and the unloading end is fixed relatively, and squeezing and crushing of materials are achieved.

Owner:NINGXIA TIANDI BENNIU IND GRP

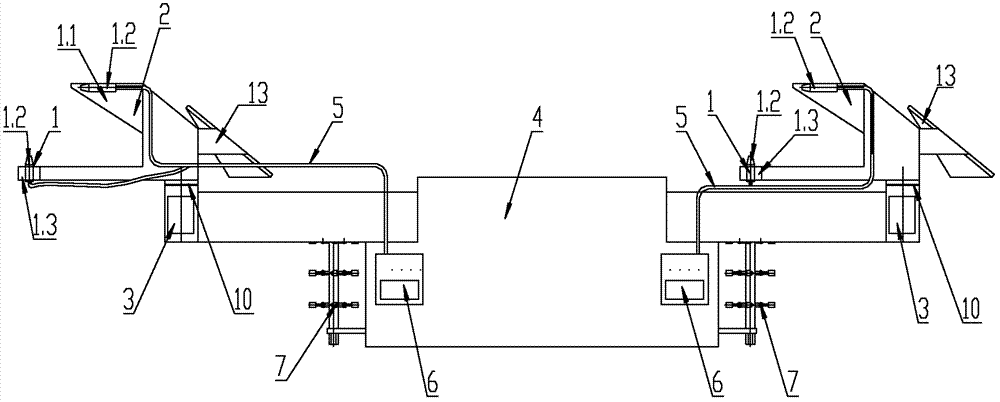

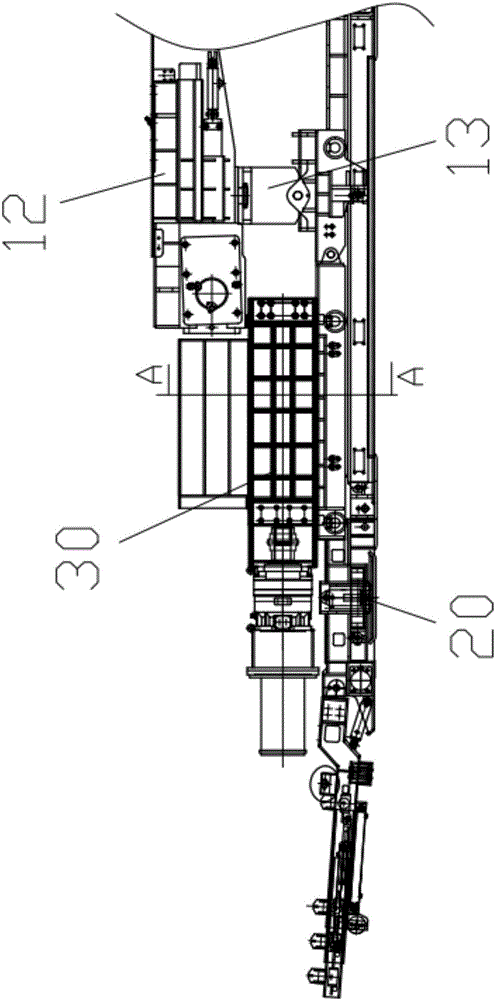

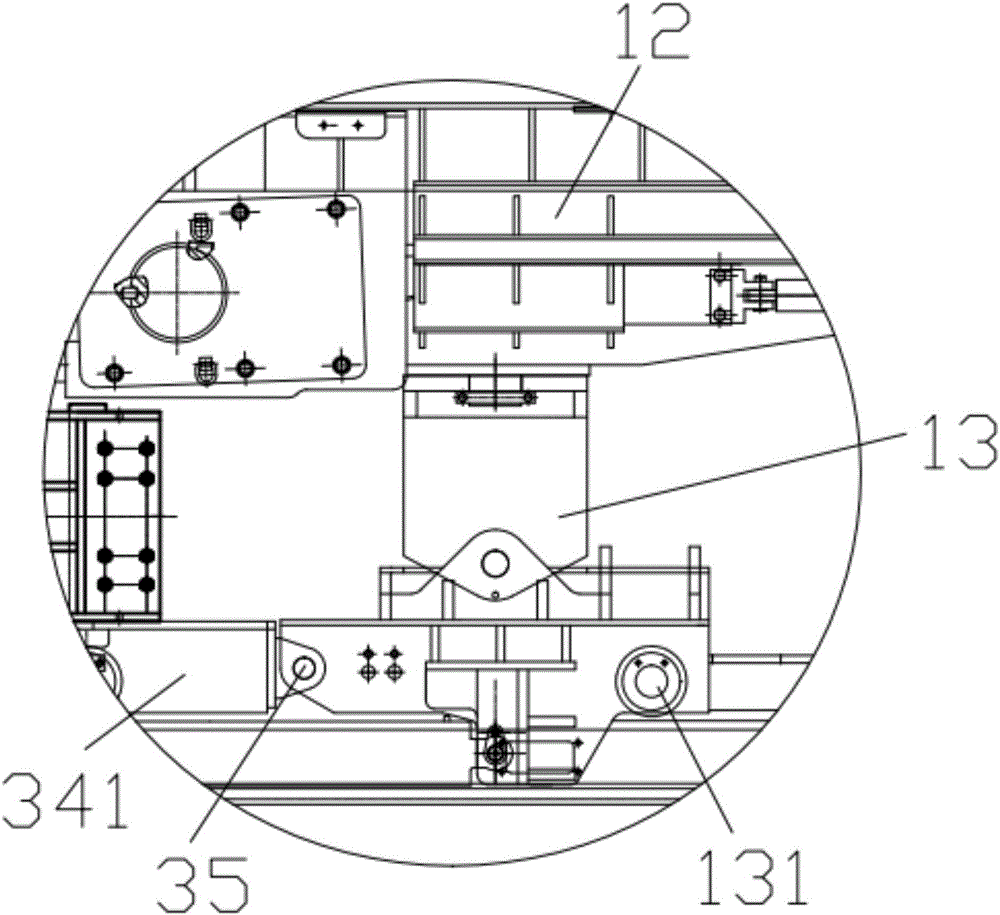

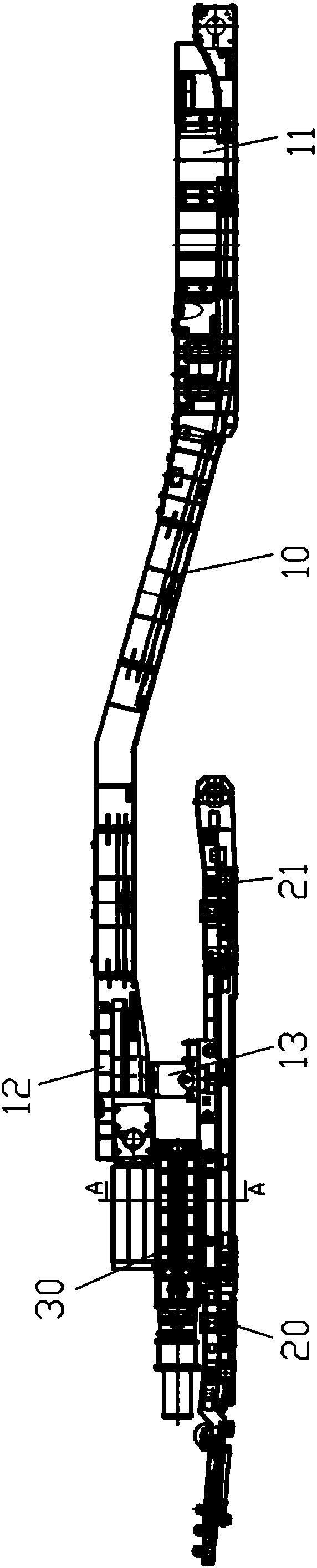

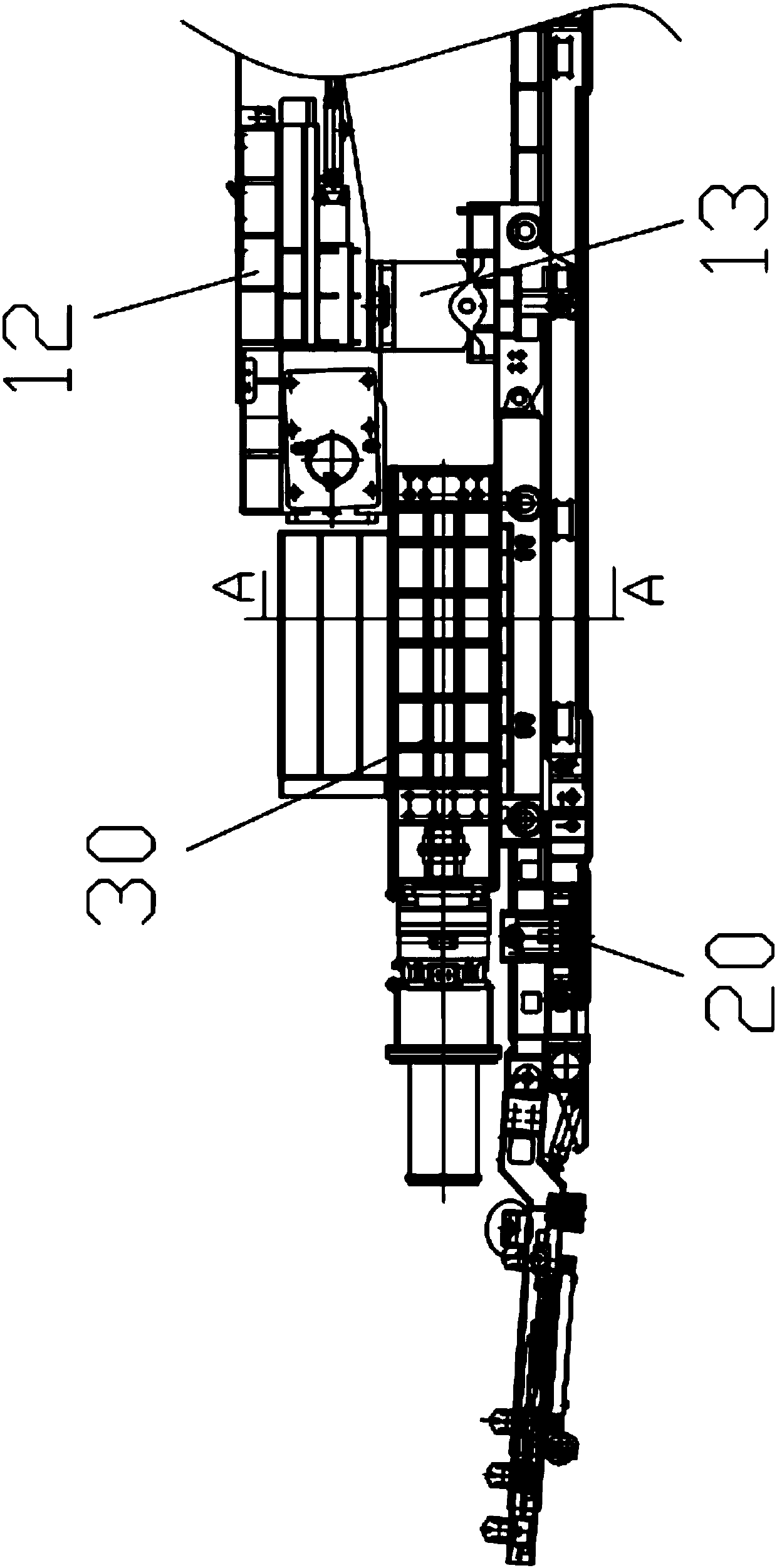

Crossheading bidirectional transporting, screening, crushing and transloading system

The invention relates to a crossheading bidirectional transporting, screening, crushing and transloading system and relates to the technical field of transloading machines. The crossheading bidirectional transporting, screening, crushing and transloading system comprises a crushing device, a screening device and a bidirectional transporting device. The crushing device and the screening device arearranged a landing section and are connected. The screening device is a screening groove and comprises a screening middle plate and a screening bottom plate. The screening middle plate is located on the upper part of the screening bottom plate, and screening holes are formed in the screening middle plate. The bidirectional transporting direction of the bidirectional transporting device is matchedwith arranging positions of the crushing device and the screening device, so that raw coal on the crossheading transloading machine is screened and crushed successively and transported to a belt conveyor. The length of a suspended section is reduced greatly while the lump coal rate is improved, so that the length of a self-moving tail of the belt conveyor is further reduced. The crossheading bidirectional transporting, screening, crushing and transloading system is matched with a complex environment under a coal mine, so that it is ensured that the device is shifted relatively smoothly, problems as a result of too long self-moving tail of the belt are further avoided, and safety accidents are reduced.

Owner:NINGXIA TIANDI BENNIU IND GRP +2

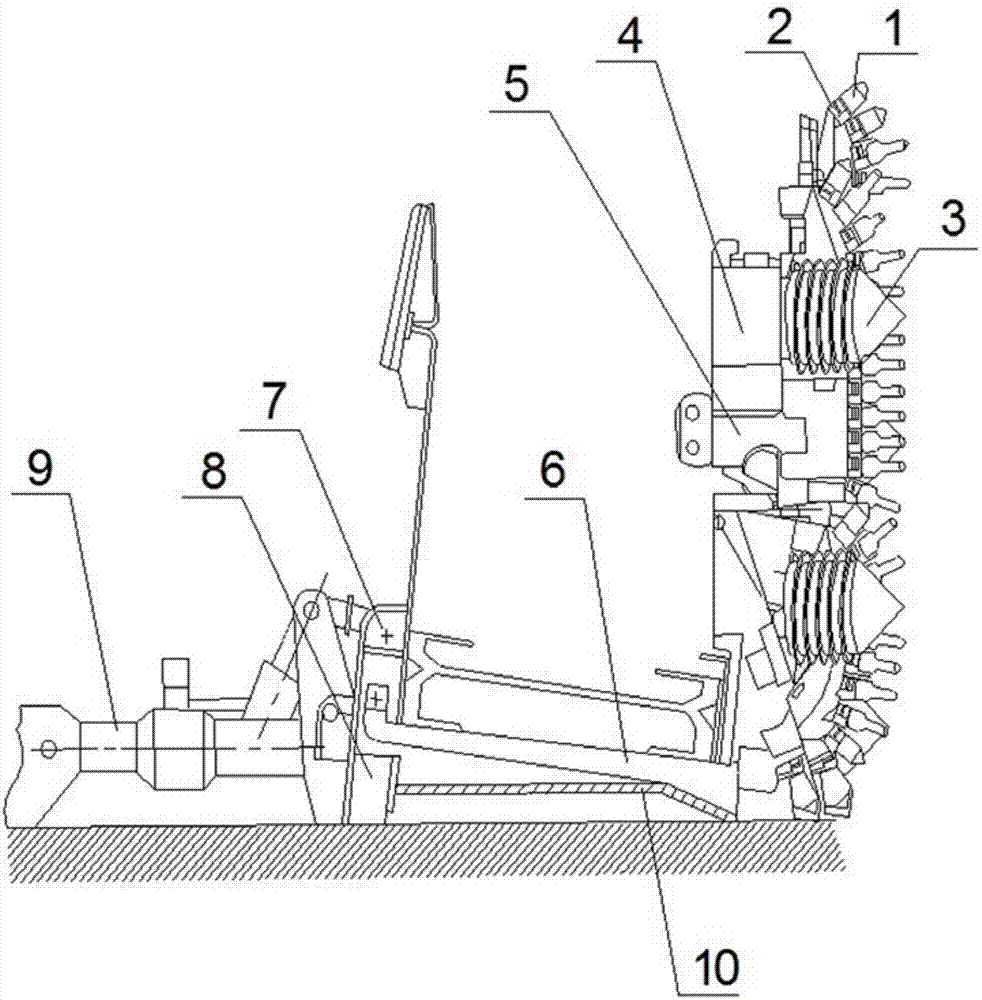

Drilling and planing coal mining machine plow head

The invention provides a drilling and plowing type coal winning machine plow head which comprises a coal plowing device; the coal plowing device is composed of a plane cutter, cutter seats, a planing body which has an asymmetric structure and a coal drilling device; the cutter seats on the left and right sides are arranged in a staggering manner; the coal drilling device is composed of four explosion-proof motors and four conical drills; the explosion-proof motors are arranged in the planing body; the output ends of the explosion-proof motors are directly connected with the conical drills respectively; and the conical drills are arranged on the left and right sides of the planing body in the staggering manner. The drilling and plowing type coal winning machine plow head can effectively lower the coal plowing difficulty, greatly improves the coal plowing efficiency, can effectively solve the problem of mining thin coal seams with large hardness and no joint development, greatly improves the mining efficiency of the thin coal seams and is wide in application range.

Owner:CHINA UNIV OF MINING & TECH

The rocker arm is equipped with a coal-passing space mining machine

ActiveCN103498671BIncrease material rateImprove efficiencyDriving meansCutting machinesFuselageRocker arm

The invention provides a mining machine with a rocker arm provided with coal-passing space, which comprises a machine body and a walking portion, and is characterized in that the mining machine with a rocker arm provided with coal-passing space also comprises a rocker arm, and cutting heads; the walking portion is disposed at the lower part of the machine body; the cutting heads are disposed at two ends of the machine body; the rocker arm is a rhomboid rocker arm or a single rocker arm; one end of the rocker arm is connected with the machine body, and the other end of the rocker arm is connected with the cutting heads; the rocker arm arches upwards to form the coal-passing space; the rocker arm is provided with the coal-passing space, which well solves the problem that coal falling by impact of a cutting head near a machine body of a reciprocating impact mining machine can not be conveyed out due to no coal-passing space between a straight rocker arm and a scraper conveyer, gives full play to advantages of high coal mining rate, high efficiency, energy saving, and environmental protection for reciprocating impact mining machines.

Owner:刘素华

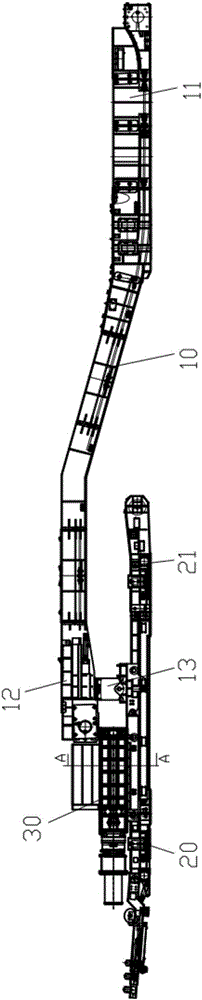

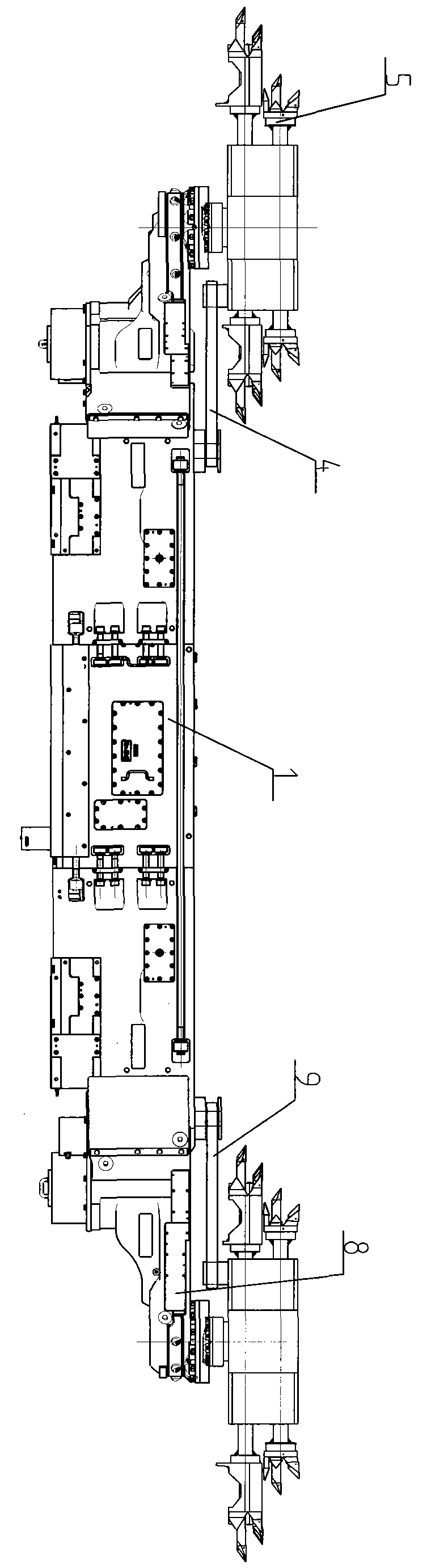

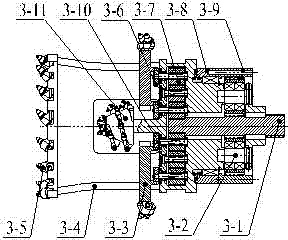

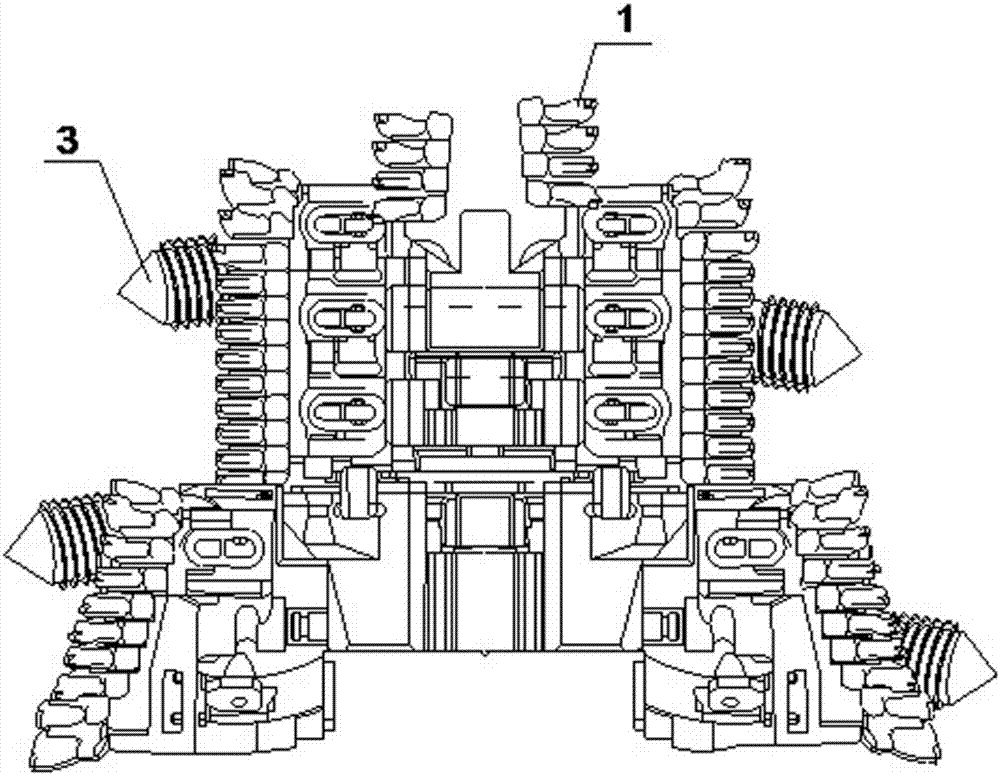

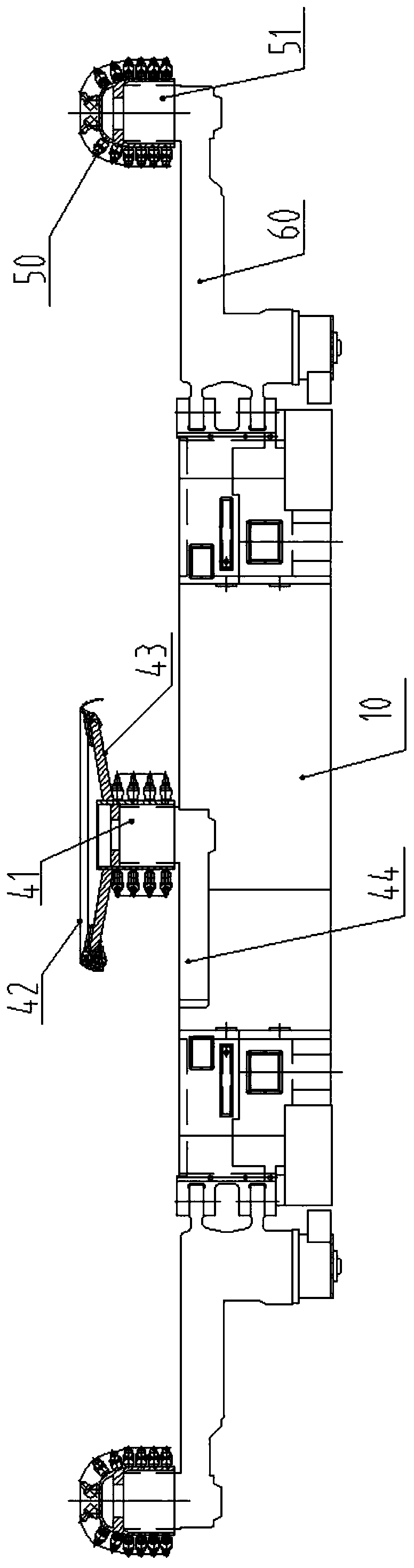

Drilling and planing part of thin coal seam drilling and planing combined coal mining machine

The invention discloses a drilling and planing part of a thin coal seam drilling and planing combined coal mining machine. Two sets are symmetrically arranged front and back relative to a coal miningmachine fixing box, the two sets of thin coal seam drilling and planing combined coal mining machine drilling and planing parts are installed on the front portion and the rear portion of the coal mining machine fixing box through drilling and planing box shells respectively, each drilling and planing part of the thin coal seam drilling and planing combined coal mining machine comprises a transmission device and a drilling and planing coal mining device, and each drilling and planing coal mining device comprises a hollow drilling part, a crushing drilling part and a coal planing disc part. Thedrilling and planing part of the thin coal seam drilling and planing combined coal mining machine adopts two-stage planetary reduction transmission, and the modes of high-speed stage planetary carrierfloating and low-speed stage sun wheel shaft floating are adopted in the two-stage planetary reduction transmission process, so that the drilling and planing combined coal mining machine is compact in structure, small in size, large in transmission ratio and stable in operation; the mode that drilling and planing combined coal mining is conducted through the drilling and planing coal mining device is adopted, the thin coal seam mining production efficiency can be improved on the premise that the machine body length is effectively shortened, the coal loading effect is improved, the lump coal rate is increased, and the drilling and planing part of the thin coal seam drilling and planing combined coal mining machine is particularly suitable for thin coal seam mining.

Owner:JIANGSU ZHONGJI MINE EQUIP

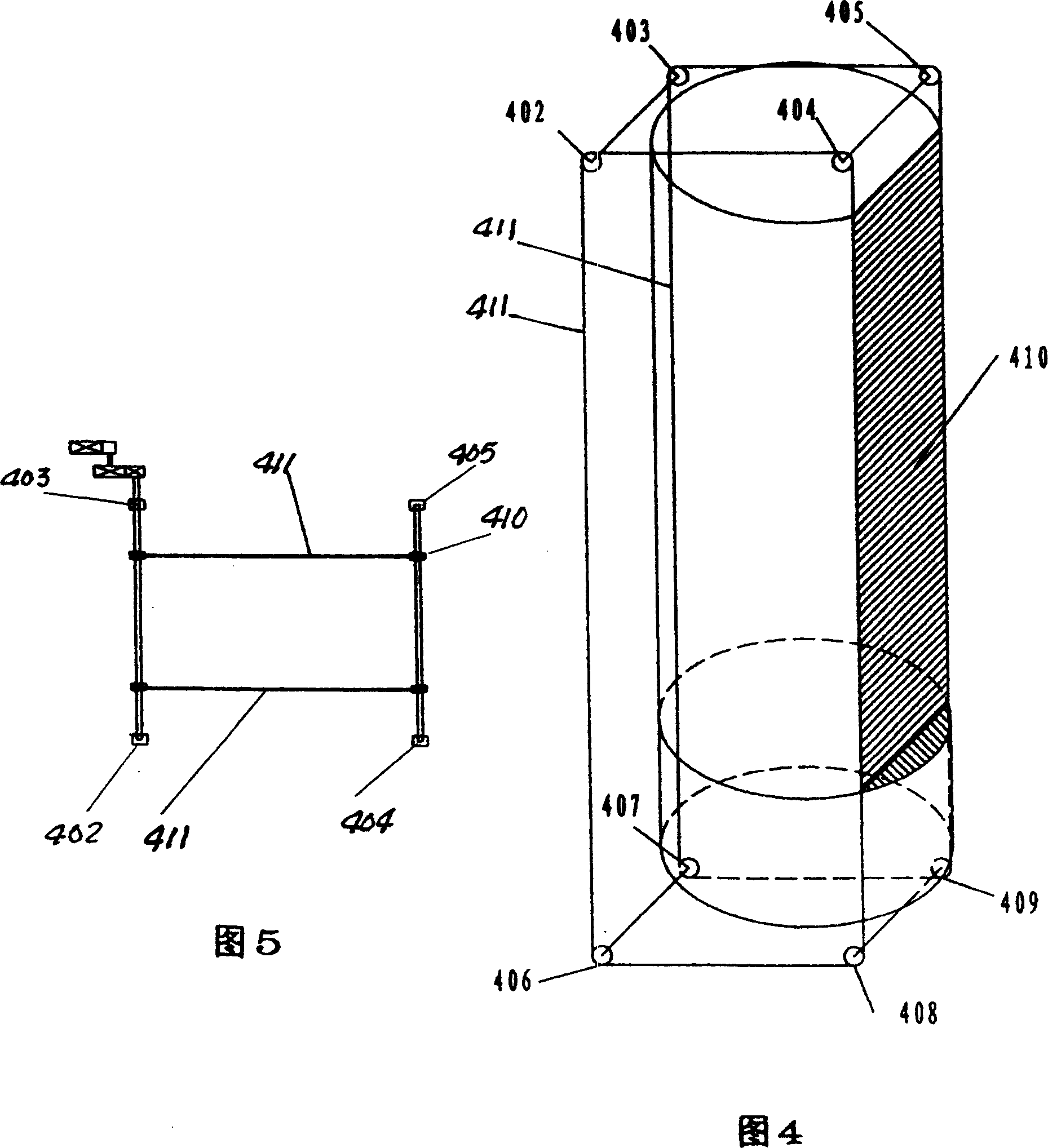

Breaking-resistant vertical storehouse

The present invention relates to a mother and son type anti-breaking vertical bunker, including power system, conveyer, coal-feeding machine, and its bunker body is formed from mother bunker, son bunker and screen-returning chamber, and the upper portion of the son bunker is equipped with bunker-feeding device, and the lower portion of the son bunker is equipped with an oblique bottom, and the tail endof the oblique bottom is communicated with inlet of mother bunker, and the lower outlet of the bottom chamber of mother bunker is connected with coal-feeding machine. Said invention also provides the structure of the gate screen equipment, it utilizes the combination of mother bunker, son bunker and gate screen to attain the goal of preventing block coal from being broken.

Owner:HENAN SUNHO COAL & POWER CO LTD

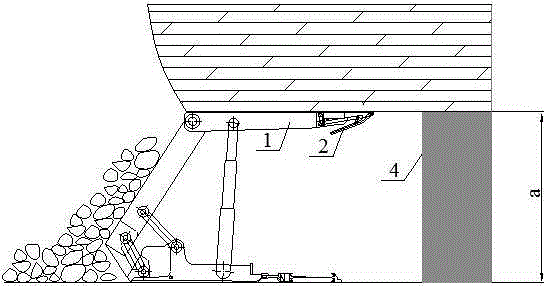

Rapid Coal Mining Technology in Fully Mechanized Mining Face with Large Mining Height

A large-mining-height fully-mechanized-face fast coal mining technology is suitable for large-mining-height fully-mechanized-face fast coal mining with a roof of a coal seam higher than medium hard level and firmness coefficient of the coal seam more than 1.0. Coal is first cut in the middle part of the coal seam, a front roller of a coal mining machine is then used for cutting top coal, a rear roller of the coal mining machine is used for cutting bottom coal, and simultaneously a hydraulic support of a coal cutting achieving part is moved, after the hydraulic support is moved, a face guard of the hydraulic support is opened to enable the face guard to be tightly attached to a coal wall. Every cycle operation goes on sequentially in a cycling mode according to the working procedures, the middle part of the coal seam is cut first, and the top coal at the upper part depends on the face guard to support so that wall caving of the coal wall and roof fall of the end face can be effectively prevented. Due to the fact that a coal cutting height is reduced, coal cutting speed is remarkably improved, and simultaneously coal of large sizes cannot be produced. Therefore, the large-mining-height fully-mechanized-face fast coal mining technology fundamentally resolves the problem that large-mining-height fully-mechanized-face large-sized coal hinders working-face coal cutting, coal charging and coal carrying, removes potential dangers of manually breaking large-sized coal, and is simple in technological operation, safe, reliable and high in efficiency.

Owner:CHINA UNIV OF MINING & TECH

Rock screw breaking-resisting coal bunker

InactiveCN1233541CIncrease lump coal rateAvoid disadvantagesLoading/unloadingChutesBunkerEngineering

A rock spiral anti-breaking coal bunker, including an inlet diversion device, a coal feeder, a vertical cylindrical bin body is set on the rock between the upper and lower roadways, and the upper round hole of the bin body is provided with a belt inlet hole The lower end of the bin body is provided with a tapered hole, and the outlet at the bottom of the taper hole is equipped with a coal feeder. The coal feeder is excavated on the inner wall of the cylindrical rock of the bin body with a spiral concave inward. Groove, the upper part of the spiral groove communicates with the entrance of the sealing grate mounted on the round hole, the lower part of the spiral groove leads to the entrance of the coal feeder, and an inlet guide device is installed in the upper roadway. The invention has a good effect of preventing coal from being broken, has a low breaking rate, and has the function of preventing blockage of a circular vertical bin.

Owner:张光建

Coal leakage preventive device of belt conveyor

InactiveCN103046954AShorten speedReduce the stress areaEarth drilling and miningUnderground transportCoal briquetteCoal

The invention relates to the technical field of coal mine equipment, particularly to a coal leakage preventive device of a belt conveyor. The coal leakage preventive device comprises a coal stop board arranged above a belt and used for stopping coal briquettes, and the coal stop board is provided with a concave camber surface with the opening facing the direction of the coal briquettes and used for reducing the speed of the coal briquettes. Compared with the prior art, the opening of the concave camber surface of the coal stop board faces the direction of the coal briquettes, when the coal briquettes bump against the concave camber surface, not only speeds of the coal briquettes are reduced, but also stressed areas of the coal briquettes are reduced, the possibility that the coal briquettes are crashed is reduced, and therefore the lump coal rate of the coal briquettes can be improved.

Owner:永煤集团股份有限公司新桥煤矿

Wave spiral blade roller

ActiveCN104747188BAvoid stress concentrationReduce the specific energy consumption of cuttingCutting machinesSpiral bladeEngineering

An undulant spiral blade roller is disclosed. The roller is suitable for a roller type mining machine and includes a cylinder hub (1), spiral blades (2), an end plate (3) and pick-shaped teeth (4). The cylinder hub (1) is cylindrical, the head of the cylinder hub (1) is welded with the end plate (3), the cylinder hub (1) is welded with two spiral blades (2) to form a double-end roller, and the pick-shaped teeth (4) are arranged and mounted on the end plate (3) and the spiral blades (2). The outer edges of the spiral blades (2) are undulated, and the crest of one spiral blade corresponds to the valley of another spiral blade in the same cutting line to make the total cutting thickness of each cutting line equal. The pick-shaped cutting teeth (4) are sequentially arranged and mounted at the crests and the valleys of the spiral blades to achieve different mounting height. The roller is high in coal-breaking efficiency and lump coal rate, simple in structure and convenient to mount and operate.

Owner:CHINA UNIV OF MINING & TECH

Anti-falling alloy cutter head

InactiveCN105003262AImprove wear resistanceExtended service lifeCutting machinesWave shapeWear resistant

The invention discloses an anti-falling alloy cutter head, which comprises a work section and a connecting section, wherein two parts including a wave-shaped curve surface section and a cone surface top end are processed on the work section; a diamond layer is arranged on the cone surface top end; and the diamond layer and the wave-shaped curve surface section are in smooth transition connection. The anti-falling alloy cutter head has the advantages that the design is reasonable; the structure is simple; the problem of hard alloy falling is solved; the hardness, the strength and the wear-resistant performance of the alloy cutter head are greatly improved; and the service life of the alloy cutter head is prolonged.

Owner:安徽省皖江机电设备制造有限公司

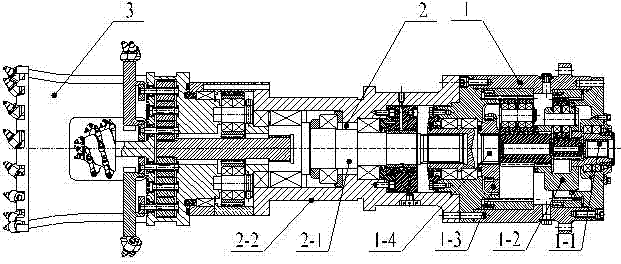

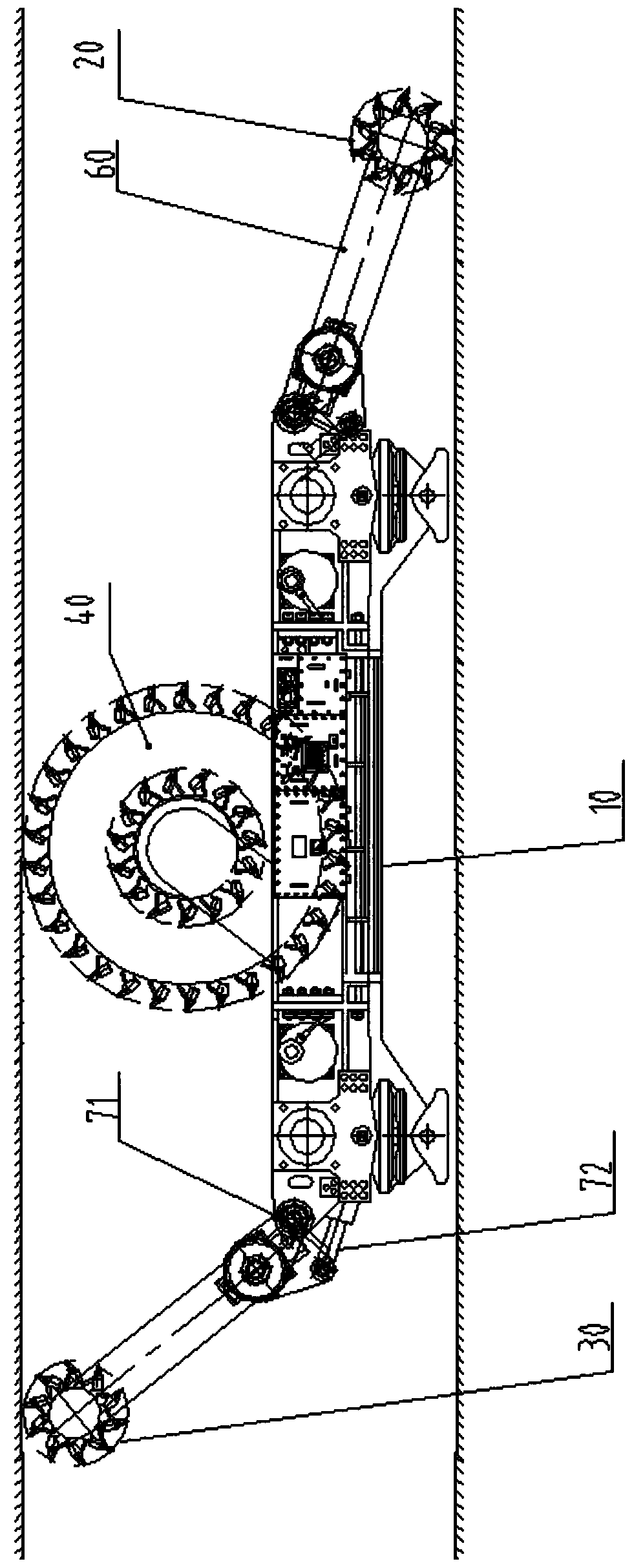

Rotary-digging type coal mining machine and development machine cutting part

InactiveCN102536227BIncrease lump coal rateReduce energy consumptionCutting machinesReduction driveTransmitted power

A rotary-digging type coal mining machine and development machine cutting part comprises a speed reducer, a cutting arm and a cutting head. The speed reducer comprises a two-level planet mechanism, a coupling band and a speed reducer output shaft. The cutting arm comprises a cutting arm main shaft and a cutting arm shell. The cutting head comprises a screw hole drill, cutting teeth, a reamer, an eccentric disc, a pinion, a cutting head main shaft, a bearing block, a planet wheel assembly and an annular gear, wherein the front end of the screw hole drill and the top end of the reamer are welded with the cutting teeth. During work, a motor transmits power to the cutting arm main shaft through the two-level planet mechanism of the speed reducer, and transmits power simultaneously to a cutting head planet mechanism and the pinion through the cutting head main shaft to enable the screw hole drill to cut. Simultaneously, the pinion drives the eccentric disc to rotate to enable the reamer to rotate around the center of the cutting head main shaft and be in reciprocating motion along the radial direction. Therefore, an outline similar to an oval is cut out. The structure is simple and compact in entire mechanism, a user can lead the cut cross section to be in a shape similar to an oval, simultaneously lump coal rate is led to increase, energy consumption is lowered, and dust is reduced.

Owner:CHINA UNIV OF MINING & TECH

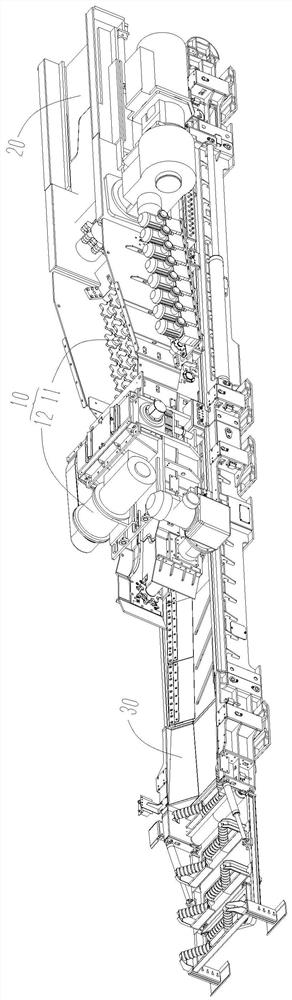

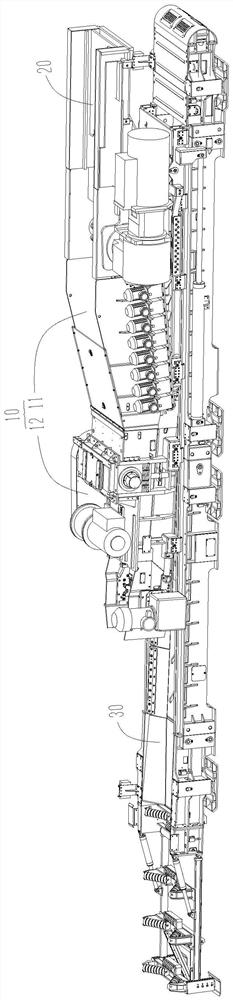

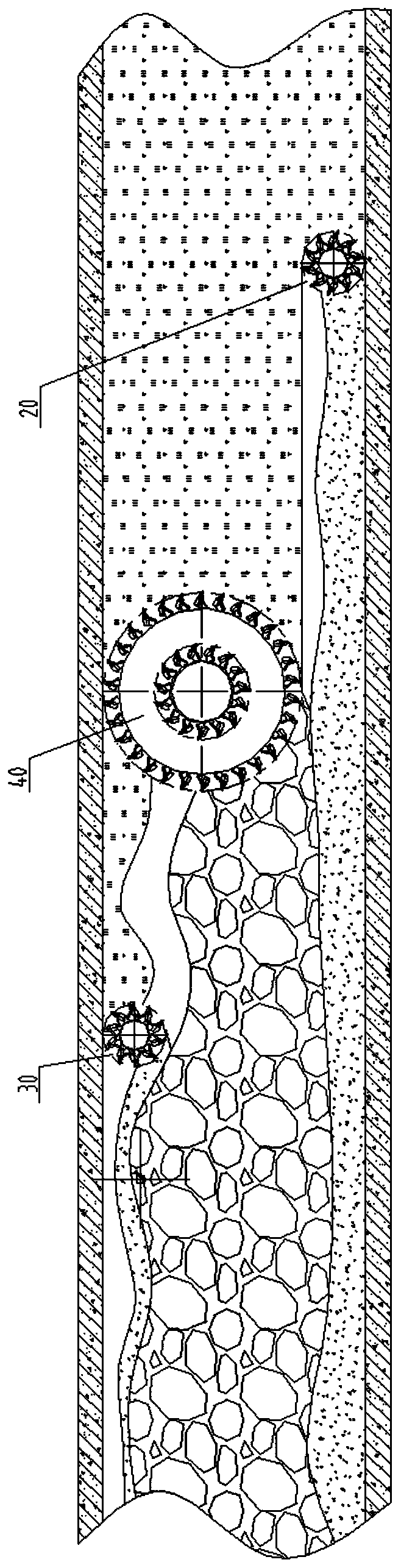

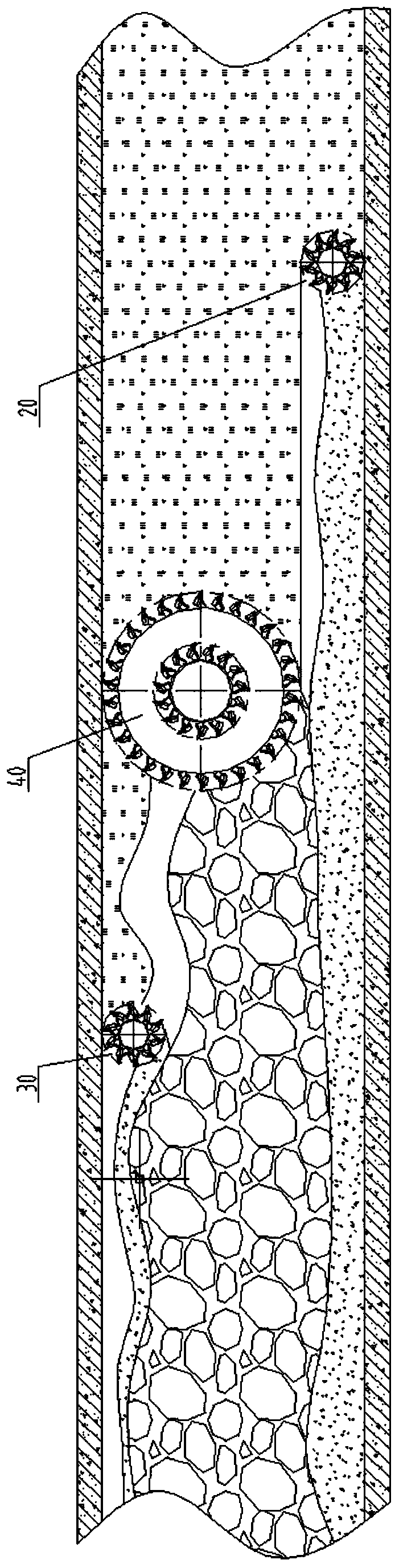

A Coal Mining Method for Increasing Lump Coal Ratio in Trench Cutting Mining

ActiveCN106761734BLarge particle sizeIncrease lump coal rateCutting machinesMining engineeringCoal particle

The invention discloses a coal mining method for improving the lump coal rate by cutting groove mining. The conical roller of the first cutting part cuts along the bottom plate to form a coal seam bottom groove, and the inverted cone and outward expansion type end plate of the third cutting part The pick cuts the groove behind the coal seam, and the coal block rises and falls through the wedging and cutting impact force of the inverted cone outwardly expanding end plate, and the fluctuating coal block is pushed and scraped under the action of the cone outwardly expanding end plate Trigger, the pick on the cylindrical bladeless drum cuts off unfluctuated coal and cleans the coal to ensure that the entire rear groove cutting drum passes through the coal wall smoothly; the conical drum of the second cutting part is used to clean the top plate nearby coal seams. The invention can realize full-height two-way coal mining at one time, cut the coal seam first, and then cut the coal seam and then drop the coal in layers. The walking speed is relatively fast, which can effectively improve the lump coal particle size, lump coal rate and coal mining efficiency, and reduce power consumption. , pick damage and dust generation, and can realize low-power mining of hard coal seams.

Owner:JIANGSU ZHONGJI MINE EQUIP

A lump coal mining method

ActiveCN103939101BThe method steps are simpleReasonable design and simple operationDisloding machinesUnderground miningMining engineeringCoal mining

The invention discloses a lump coal mining method comprising the following steps: 1, advanced pre-splitting of a coal bed, namely carrying out the advanced pre-splitting on a work surface of a to-be-mined coal bed from near to far along the advancing direction of a coal bed working surface; 2, mining of pre-splitting coal bed, namely mining the coal bed after the advanced pre-splitting from near to far, synchronously adjusting supporting force of a hydraulic bracket in the mining process, wherein the synchronous mining and supporting force adjusting process includes the following processes: 201, mining the coal bed, mining a current coal surface by adopting a coal cutter, wherein the adopted coal cutting mode in the mining process is a one-way coal cutting mode; 202, adjusting support and work resistance of the hydraulic bracket; 203, carrying out the next cycle of coal bed mining according to the steps 201 to 202; and 204, repeating the step 203 a plurality of times until all mining processes of a to-be-mined coal bed are finished. The method disclosed by the invention is simple in step, reasonable in design, simple, feasible, and good in using effect, and the lump coal rate and the recovery rate of the fully mechanized coal surface can be effectively increased.

Owner:XIAN UNIV OF SCI & TECH

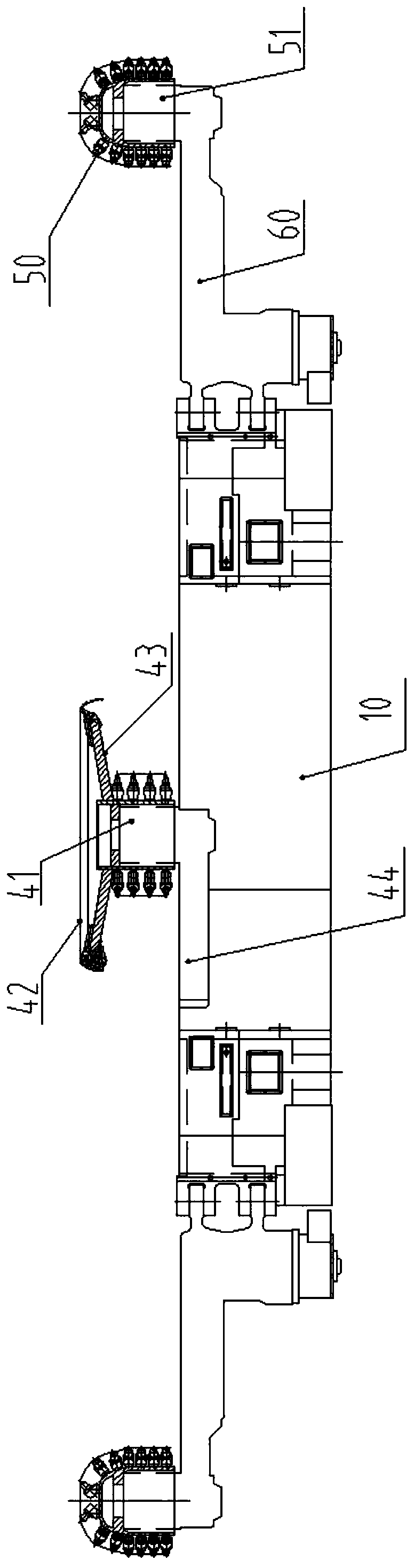

Coal mining machine and coal seam mining method for lump coal mining

ActiveCN103953339BReasonable structural designLow input costDisloding machinesUnderground miningHelical bladeEngineering

The invention discloses a coal mining machine for lump coal mining and a coal mining method. The coal mining machine comprises a body and a cutting part arranged on the body, wherein the number n of helical blades arranged on a drum of the cutting part is more than D / P, the helical angles of the helical blades are 5-30 degrees, and D and P refer to the width and pitch of the helical blades, respectively; the number m of cutting picks arranged on each helical blade is determined by the hardness coefficient f of a mined coal seam; when the hardness coefficient f of the mined coal seam is 2.5-3.5, m is equal to 7-10; when the hardness coefficient f of the mined coal seam is more than 3.5, m is equal to 9-17; the mining method comprises the following steps of 1, setting mining process parameters, namely setting the rotating speed of the drum, traction speed, cutting thickness, the rotating direction of the drum and cutting depth; and 2, mining the coal seam in a unidirectional coal cutting manner. The coal mining machine disclosed by the invention is reasonable in structural design, the method is simple, convenient in implementation and good in using effect, and the lump coal yield of a fully mechanized mining face can be effectively improved.

Owner:XIAN UNIV OF SCI & TECH

Drilling and plowing type coal winning machine plow head

The invention provides a drilling and plowing type coal winning machine plow head which comprises a coal plowing device; the coal plowing device is composed of a plane cutter, cutter seats, a planing body which has an asymmetric structure and a coal drilling device; the cutter seats on the left and right sides are arranged in a staggering manner; the coal drilling device is composed of four explosion-proof motors and four conical drills; the explosion-proof motors are arranged in the planing body; the output ends of the explosion-proof motors are directly connected with the conical drills respectively; and the conical drills are arranged on the left and right sides of the planing body in the staggering manner. The drilling and plowing type coal winning machine plow head can effectively lower the coal plowing difficulty, greatly improves the coal plowing efficiency, can effectively solve the problem of mining thin coal seams with large hardness and no joint development, greatly improves the mining efficiency of the thin coal seams and is wide in application range.

Owner:CHINA UNIV OF MINING & TECH

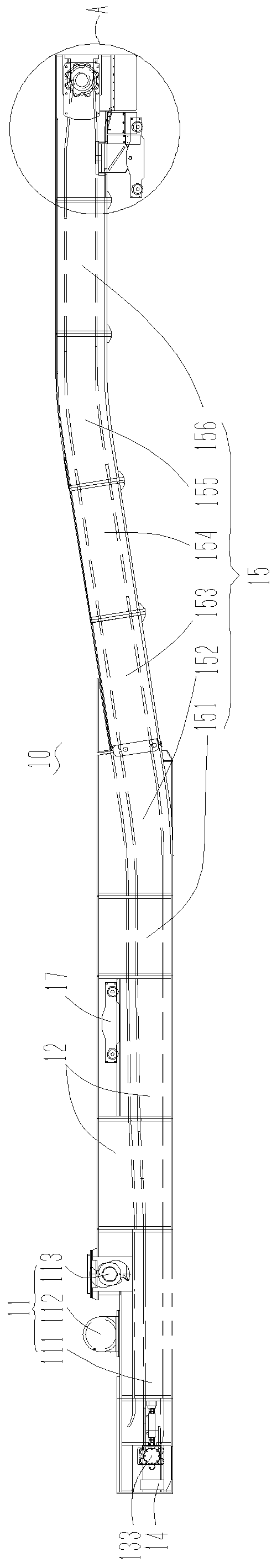

A kind of slot cutting mining lump coal machine

ActiveCN106593435BLarge particle sizeIncrease lump coal rateSlitting machinesCutting machinesEngineeringCoal particle

The invention discloses a lump coal cutting mining machine. A first cutting part and a second cutting part are symmetrically arranged at the two ends of a machine body which is further provided with a third cutting part. Conical drums of the first cutting part and the second cutting part are driven by connecting rocker arms to conduct lifting height adjustment. A rear slot cutting drum of the third cutting part is connected to the middle of the machine body through a speed reduction arm, a cylindrical blade-free drum body of the rear slot cutting drum is spirally provided with cutting teeth, an inverted cone external expansion type end plate is arranged at the front end of the cylindrical blade-free drum body, and cutting teeth are arranged on the periphery of the inverted cone external expansion type end plate. According to the lump coal cutting mining machine, bidirectional full-seam mining can be achieved, coal seams are subjected to cutting at first and then subjected to coal dropping layer by layer in a fluctuation mode, the traveling speed is relatively high, the lump coal particle size, the lump coal rate and the mining efficiency can be effectively improved, power consumption, the damage quantity of the cutting teeth and the dust generating quantity are reduced, and low-power-consumption mining of hard coal seams can be achieved.

Owner:JIANGSU ZHONGJI MINE EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com