Coal mining machine and coal seam mining method for lump coal mining

A technology for shearer and coal seam, applied in cutting machinery, discharge machinery, ground mining and other directions, can solve the problems of poor operability, poor lump coal rate and other problems, and achieve simple processing, economic and social benefits Significant, actionable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

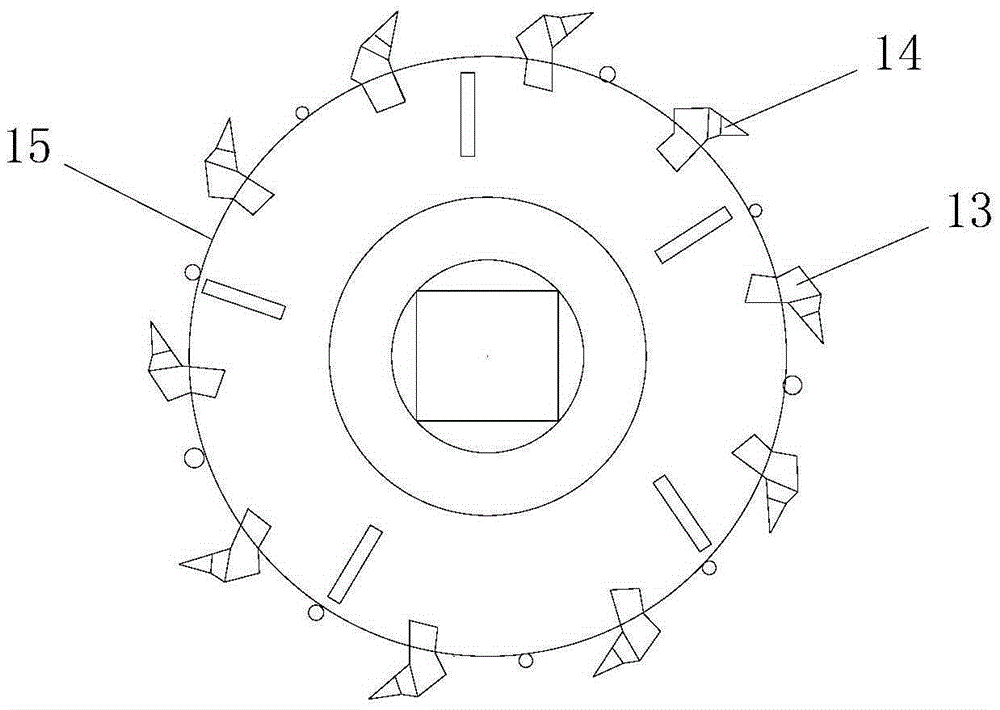

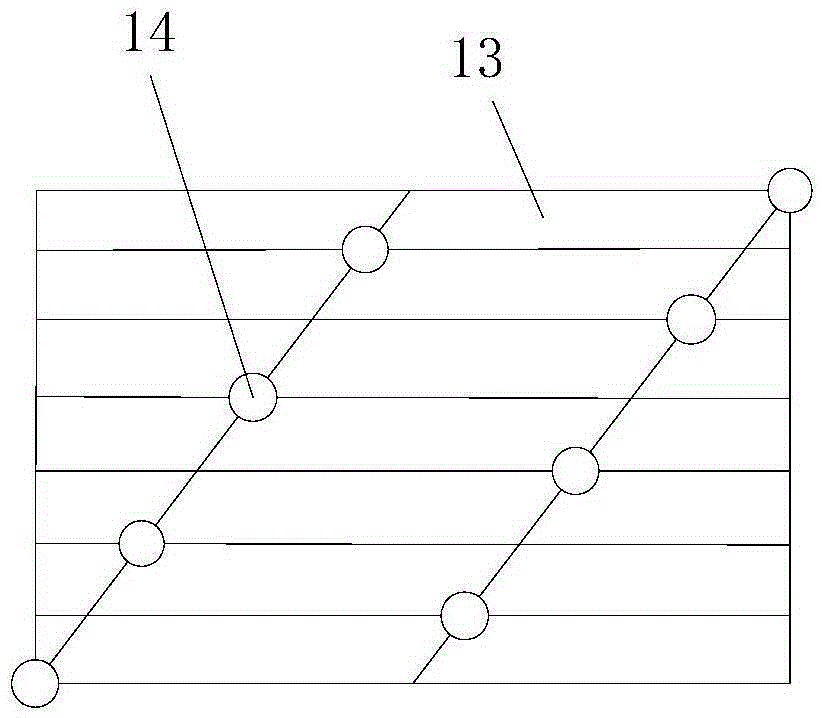

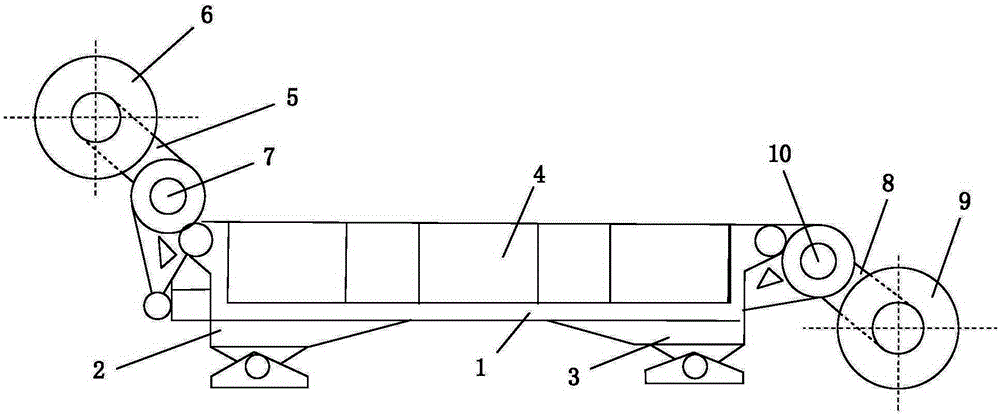

[0052] Such as figure 1 , figure 2 , image 3 and Figure 4 The shown coal mining machine for lump coal mining includes a fuselage 1 and a cutting part installed on the fuselage 1. The cutting part includes a rocker hinged on the fuselage 1, and is installed at the front end of the rocker The drum and the cutting motor that drives the drum, the cutting motor and the drum drive shaft 16 of the drum are connected through a transmission mechanism; the drum is provided with a plurality of helical blades 13, and the helical Number of blades 13 Wherein, D is the width of the helical blade 13, P is the pitch of the helical blade 13; the helix angle of the helical blade 13 is 5°-30°.

[0053] The number of picks 14 set on each of the spiral blades 13 is m; wherein the value of m is determined by the hardness coefficient f of the mined coal seam: when the hardness coefficient f of the mined coal seam is 2.5 to 3.5, m=7 ~10; when the hardness coefficient f of the mined coal seam ...

Embodiment 2

[0144] Such as Figure 7 As shown, in this embodiment, the coal shearer used is different from that of Embodiment 1 in that: the groove cutting member is a spiral cutting device 12 installed on the drum of the coal shearer.

[0145] In this embodiment, the helical cutting device 12 is driven forward and backward by the push drive mechanism, and the helical cutting device 12 is connected to the push drive mechanism through transmission.

[0146] In this embodiment, the helical cutting device 12 is a helical drill bit.

[0147] In actual use, the diameter of the auger bit is 80mm-120mm and its length is 700mm-900mm, and the groove width and groove depth of the micro-groove cut by the helical cutting device 12 are 80mm-120mm and 700mm-900mm respectively.

[0148] In this embodiment, the diameter of the helical drill is 100 mm and the length is 800 mm, and the width and depth of the micro-grooves cut by the helical cutting device 12 are 100 mm and 800 mm, respectively. During ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com