A kind of slot cutting mining lump coal machine

A technology of coal machine and groove cutting, which is applied in the direction of cutting machinery, slitting machinery, earthwork drilling and mining, etc. It can solve the problems of failure to effectively improve the coal mining lump coal rate and lump coal particle size, the increase of roof safety maintenance work, Reduce the working efficiency of the shearer and other problems, achieve the effect of reducing cutting power consumption, realizing low power consumption mining, and improving coal mining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

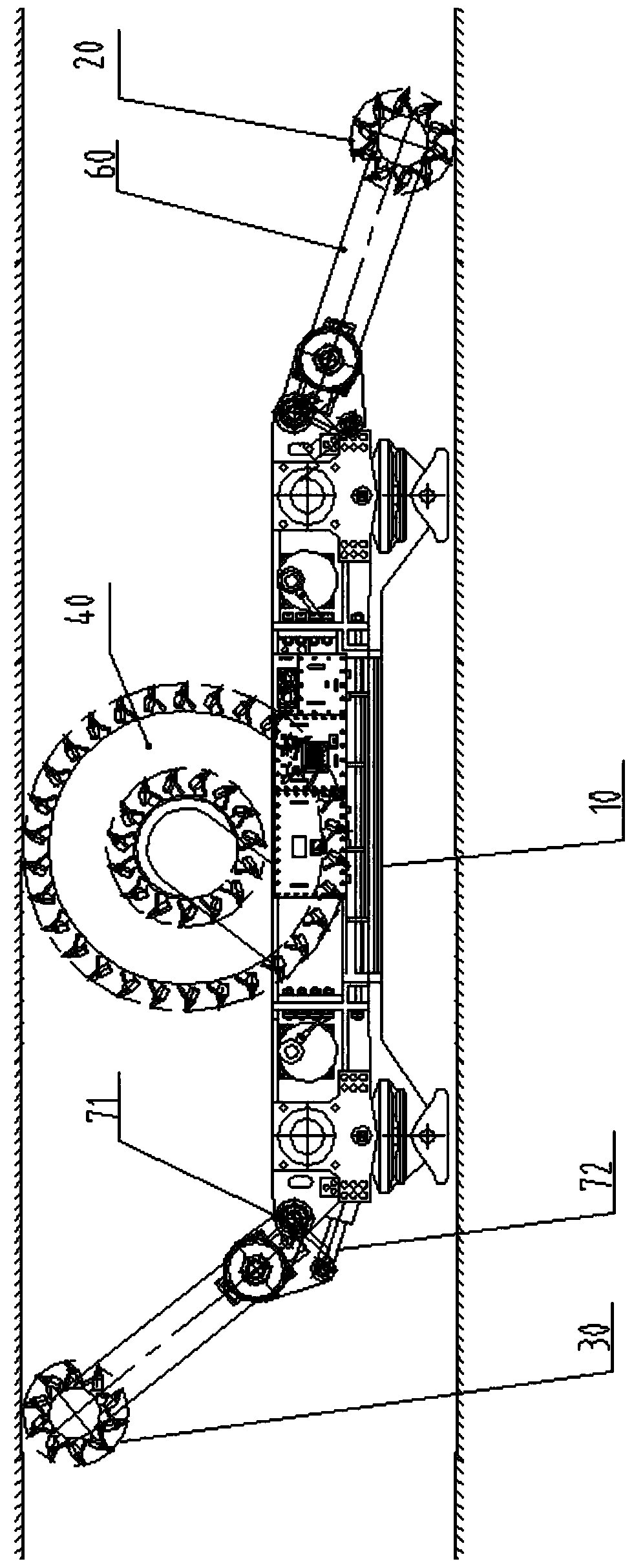

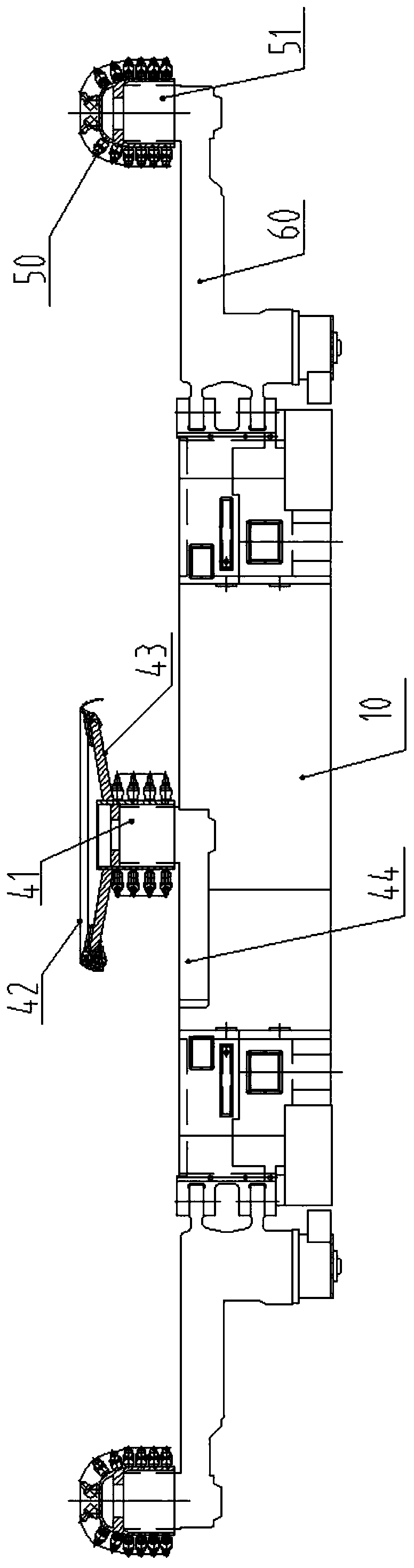

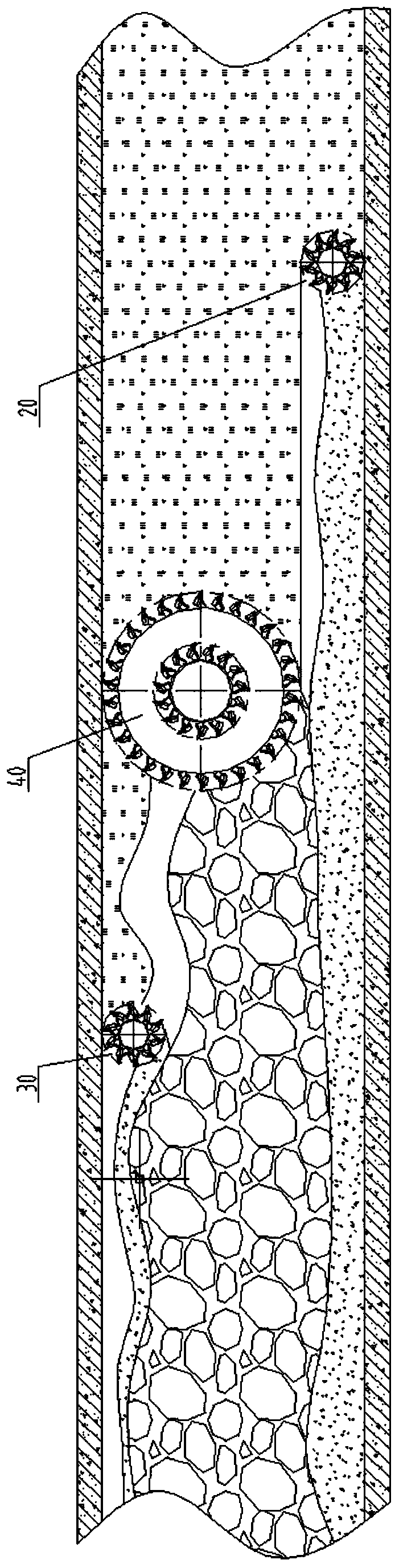

[0021] As shown in the figure, a cutting groove mining lump coal machine includes a first cutting part 20 and a second cutting part 30, and the first cutting part 20 and the second cutting part 30 are respectively arranged on the shearer Both ends of the fuselage body 10 also include a third cutting portion 40, the first cutting portion 20 includes a connected conical roller 50 and a connecting rocker arm 60, and the conical roller 50 includes a conical bladeless cylinder 51, the surface of the cone-shaped bladeless cylinder 51 is provided with picks in a spiral arrangement, and the connecting rocker arm 60 is connected to one end of the fuselage body 10 through the fuselage hinge ear 71 and the fuselage oil cylinder 72; the second cutting The structure of the first cutting part 30 and the first cutting part 20 is symmetrical, and it is arranged on the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com