Duplex pickaxe type cutting tooth holder of drum shearer

A combination pick type and pick technology, applied in the field of tool parts, can solve the problems of increased contact surface rolling and friction, large unit energy consumption, small unit area, etc., to achieve reduced rolling and friction, unit The effect of large area and increased lump coal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

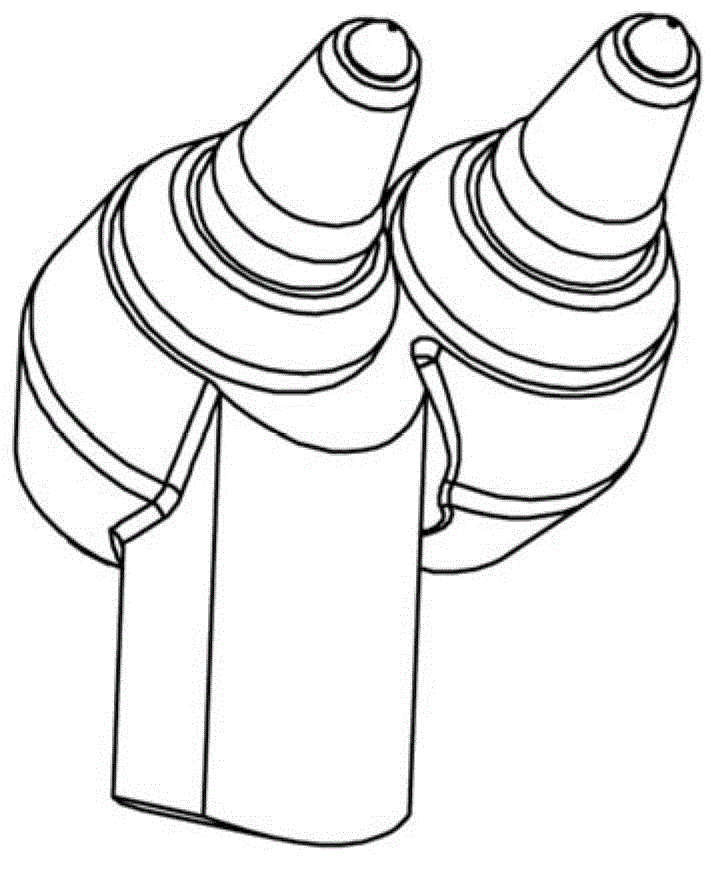

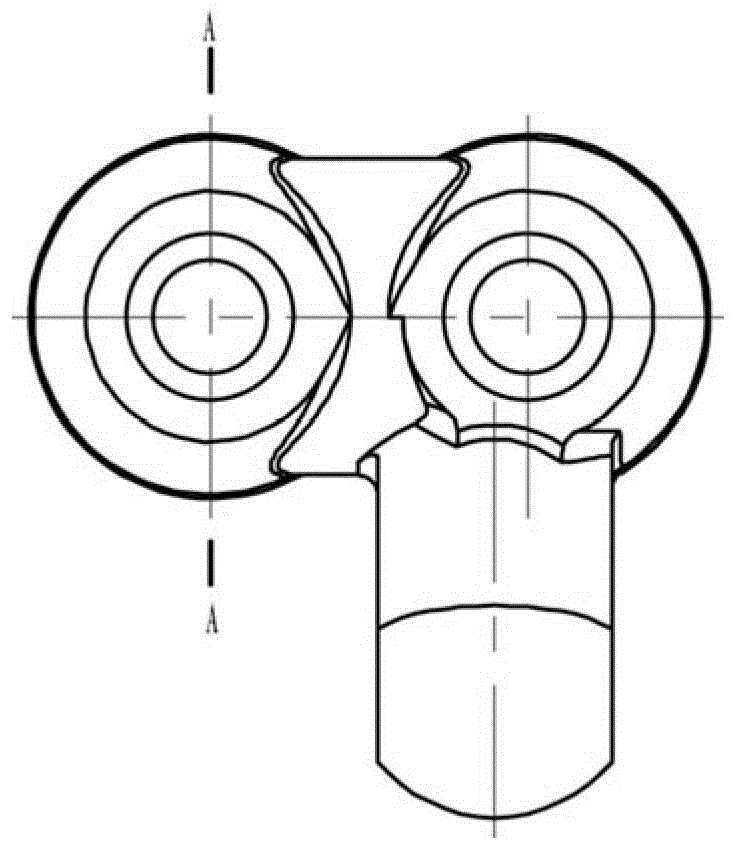

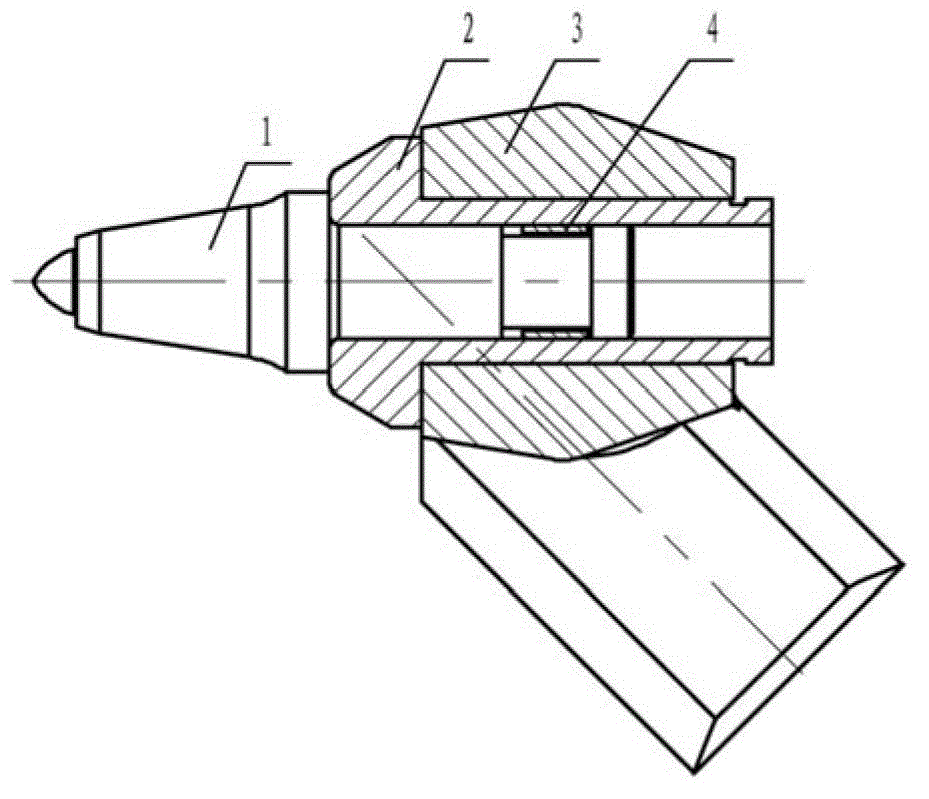

[0009] The pick pick unit 1 is installed in the inner hole of the pick sleeve 2, and fixed axially by the elastic sleeve 4, and then installed on the double pick pick holder 3, and fixed by a retaining ring to prevent falling off. Finally, the tail shank of the double pick type pick seat is directly welded on the blade of the spiral drum according to certain rules. During work, the double pick-shaped pick tooth seat used for installing two pick-shaped picks of the present invention is assembled on the circumference of the working mechanism, so that the pick-shaped pick can realize rotation and feed movement when other power mechanisms drive the working mechanism , to achieve cutting coal and rock and other minerals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com