Wavy helical blade roller

A helical blade and wave-shaped technology, which is applied in the field of wave-shaped helical blade drums, can solve the problems of less lump coal, high cutting specific energy consumption, and large optimization space, so as to improve the lump coal rate, facilitate installation and operation, and avoid stress concentrated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] An implementation of the present invention will be further described below in conjunction with accompanying drawing:

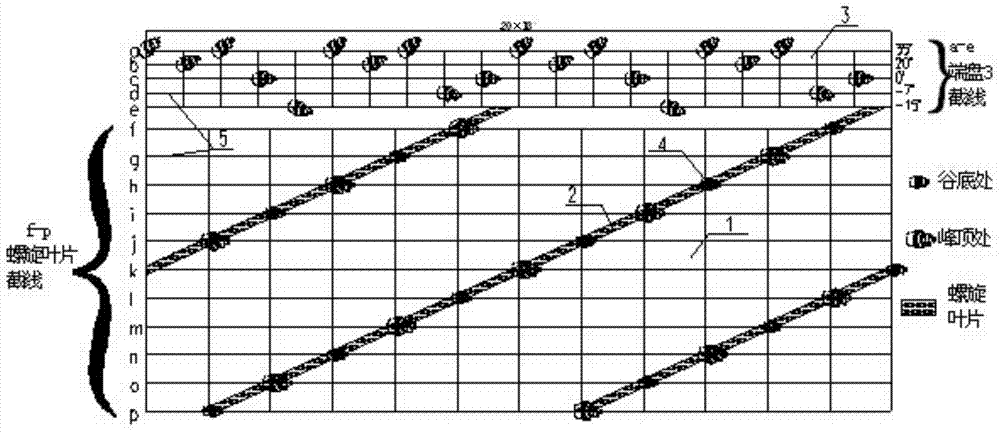

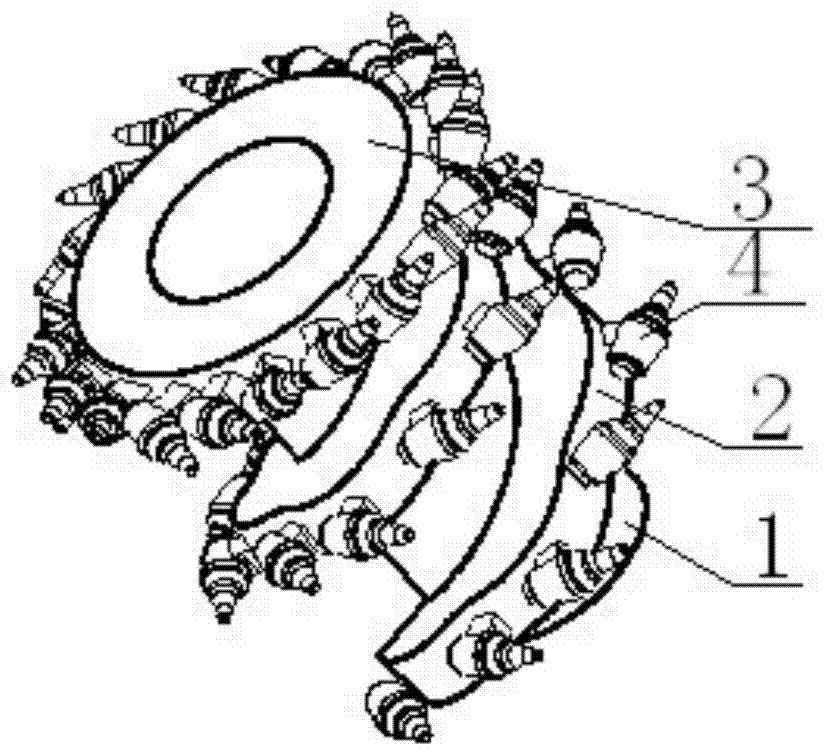

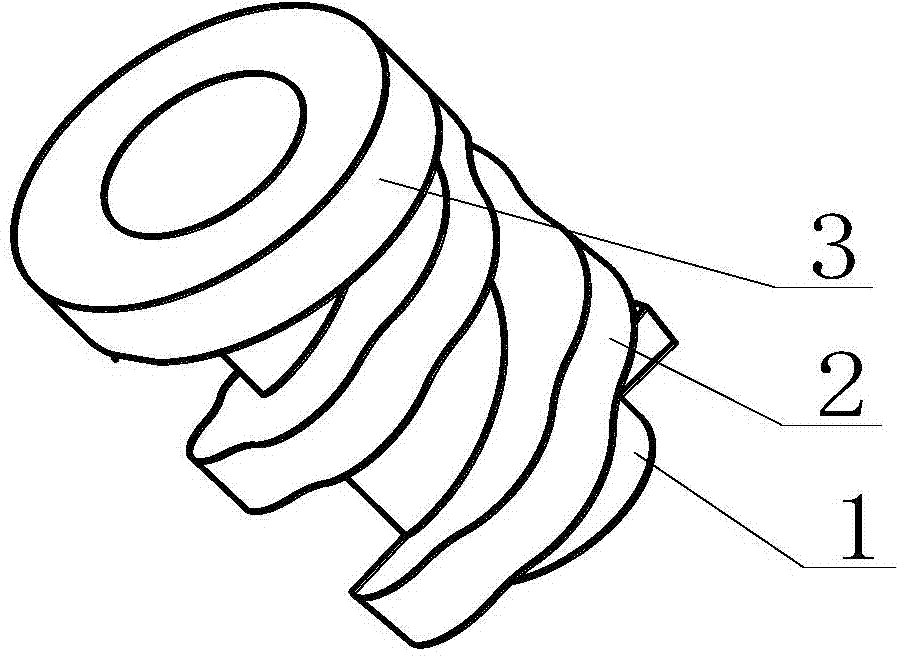

[0012] Such as figure 1 As shown, the corrugated helical blade drum of the present invention is mainly composed of a cylinder hub 1, a corrugated helical blade 2, an end plate 3 and a pick pick 4. The cylinder hub 1 is cylindrical, and the head of the cylinder hub 1 is welded with an end plate 3, and pick-shaped picks 4 with different inclination angles are installed on the end plate 3, and there are a, b, c, d on the end plate 3 and e 5 helical blade section lines 5, the intercept is 20mm, and the inclination angles of the pick picks 4 installed on each section of a, b, c, d and e are 35°, 20°, 0° respectively , -7°, -15°; two helical blades 2 with wavy outer edges are welded on the cylinder hub 1, and the pick-shaped picks 4 on each helical blade 2 are arranged at intervals, and the two helical blades 2 There are a total of f-P11 helical blade secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com