Rapid Coal Mining Technology in Fully Mechanized Mining Face with Large Mining Height

A technology of fully mechanized mining face and large mining height, which is applied in the direction of earthwork drilling, cutting machinery, etc. The chain has a large influence and other problems, so as to achieve the effect of improving the coal loading effect, wide practicability, and eliminating the danger.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Implementation of the present invention will be further described below in conjunction with accompanying drawing:

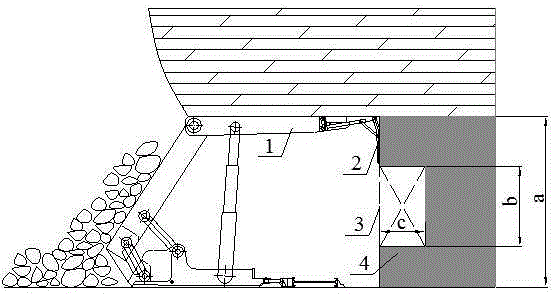

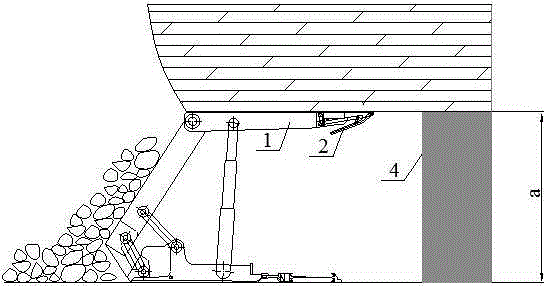

[0016] In the rapid coal mining process of the large mining height fully mechanized mining face of the present invention, the first choice is to use the front and rear drums 3 of the coal mining machine to cut the coal in the middle part of the coal wall 4 along the working face inclination in the fully mechanized mining face, and the height of the coal cutting is b Taking the sideline of the hydraulic support side panel 2 close to the coal wall as the top boundary, the height b of the coal cutting is greater than half of the total height a of the coal seam of the working face, and the depth c of the coal cutting is the cutting depth of the shearer drum, as shown in figure 1 As shown; after the coal cutting of the middle part is completed from one end to the other end through the front and rear drums 3 of the coal mining machine, the side guard plate 2 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com